Bracket For Aircon Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for bracket for aircon

In today’s competitive landscape, sourcing reliable brackets for air conditioning units presents a significant challenge for international B2B buyers. The selection of the right mounting solution is critical not only for ensuring optimal performance and safety of air conditioning systems but also for adhering to regional regulations and standards. This comprehensive guide delves into the multifaceted world of air conditioning brackets, exploring various types, applications, and their essential roles in installation processes.

Buyers will find detailed insights on materials, weight capacities, and installation methods tailored to diverse climates and building structures across regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Nigeria. Additionally, the guide will outline effective strategies for vetting suppliers, understanding pricing structures, and navigating logistics, enabling businesses to make informed decisions that align with their operational needs and budget constraints.

By equipping stakeholders with actionable knowledge, this guide empowers them to confidently select the most suitable air conditioning brackets, ensuring efficient installations that enhance the longevity and functionality of their HVAC systems. The insights provided here will facilitate a smoother procurement process, ultimately leading to greater customer satisfaction and operational excellence.

Understanding bracket for aircon Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| L Mounting Bracket | Steel construction, supports up to 185 lbs, all-weather | Ductless mini-split systems | Pros: Durable, weather-resistant; Cons: Limited to specific units. |

| Universal AC Wall Bracket | Powder-coated, rubber vibration eliminators, 450 lb capacity | Wall-mounted AC units | Pros: Versatile, high weight capacity; Cons: Higher price point. |

| Adjustable Window Support Bracket | Adjustable design for various window sizes, easy installation | Window-mounted AC units | Pros: Flexible sizing; Cons: May require additional tools for setup. |

| Heavy-Duty Wall Bracket | Extra-strength steel, rust-resistant coating | Commercial and industrial AC installations | Pros: Extremely durable; Cons: Bulkier, may need more space. |

| Ceiling-Mounted Bracket | Designed for overhead installation, can support multiple units | Large commercial spaces | Pros: Space-saving, efficient; Cons: Complex installation process. |

What Are the Key Characteristics of L Mounting Brackets?

L mounting brackets are specifically designed for ductless mini-split air conditioning systems. Constructed from steel, these brackets can support weights of up to 185 lbs, making them ideal for outdoor units that need to withstand various weather conditions. B2B buyers should consider factors such as installation ease and the specific weight requirements of their units, as these brackets are tailored to particular AC models, limiting their versatility.

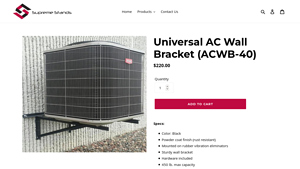

How Do Universal AC Wall Brackets Stand Out?

Universal AC wall brackets offer a robust solution for wall-mounted air conditioning units. With a powder-coated finish for rust resistance and a weight capacity of 450 lbs, these brackets are suitable for a wide range of AC units. They are particularly beneficial for businesses that need flexibility in their installations. Buyers should weigh the initial investment against the long-term benefits of durability and adaptability, as these brackets can accommodate various models.

Why Choose Adjustable Window Support Brackets?

Adjustable window support brackets are designed to fit a range of window sizes, making them an excellent choice for businesses with varying installation requirements. Their easy installation process is a significant advantage for B2B buyers who prefer a straightforward setup. However, buyers should ensure they have the necessary tools for installation, as some models may require additional components. This flexibility can lead to significant time savings during installation.

What Are the Advantages of Heavy-Duty Wall Brackets?

Heavy-duty wall brackets are built for commercial and industrial air conditioning installations, featuring extra-strength steel and rust-resistant coatings. These brackets can handle significant weight and are ideal for larger units commonly found in commercial settings. Buyers should consider the space requirements, as these brackets can be bulkier and may require more room for installation. Their durability makes them a worthwhile investment for long-term use.

When to Consider Ceiling-Mounted Brackets?

Ceiling-mounted brackets are designed for overhead installations, often used in large commercial spaces where floor space is at a premium. They can support multiple units, making them efficient for extensive cooling needs. However, the installation process can be more complex compared to wall-mounted options, which may deter some buyers. Businesses should assess their spatial constraints and cooling requirements when considering this type of bracket.

Key Industrial Applications of bracket for aircon

| Industry/Sector | Specific Application of bracket for aircon | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial HVAC | Supporting rooftop and wall-mounted air conditioning units | Ensures stability and efficiency of cooling systems | Heavy-duty materials, weather resistance, load capacity |

| Residential Construction | Mounting mini-split systems in residential buildings | Maximizes space and enhances energy efficiency | Compliance with local building codes, aesthetic design |

| Retail and Hospitality | Installing air conditioning units in storefronts and hotels | Improves customer comfort and experience | Versatility for various unit types, ease of installation |

| Industrial Facilities | Securing large outdoor AC units in factories | Reduces maintenance costs and prevents equipment damage | High weight capacity, corrosion resistance |

| Telecommunications | Mounting cooling units for data centers | Ensures optimal operation of critical infrastructure | Vibration dampening features, compatibility with various systems |

How Are Brackets for Air Conditioning Used in Commercial HVAC?

In the commercial HVAC sector, brackets are essential for securely supporting rooftop and wall-mounted air conditioning units. These brackets ensure that the units remain stable during operation, which is crucial for maintaining efficient cooling performance. Buyers in this sector must consider the load capacity and weather resistance of the brackets, especially in regions prone to extreme weather conditions. Quality materials are necessary to prevent corrosion and ensure longevity, reducing the frequency of replacements and maintenance costs.

What Role Do Brackets Play in Residential Construction?

In residential construction, air conditioning brackets are often used to mount mini-split systems on walls, optimizing space and enhancing energy efficiency. These brackets allow homeowners to install units high on walls, improving airflow and cooling distribution. Buyers should look for brackets that comply with local building codes and offer an aesthetic finish that matches home designs. The ability to withstand varying temperatures and humidity levels is also a critical consideration for ensuring long-term performance.

Illustrative image related to bracket for aircon

How Do Brackets Enhance Comfort in Retail and Hospitality Settings?

For retail and hospitality industries, air conditioning brackets are vital for installing cooling units in storefronts and hotels. Properly mounted units enhance customer comfort, which is essential for positive experiences and repeat business. The versatility of the brackets to accommodate different types of air conditioning units is a significant factor for buyers in this sector. Additionally, ease of installation and maintenance should be prioritized to minimize disruption to business operations.

Why Are Brackets Important for Industrial Facilities?

In industrial facilities, heavy-duty brackets are used to secure large outdoor air conditioning units, which are critical for maintaining a controlled environment. These brackets help reduce maintenance costs by preventing equipment damage caused by vibrations or shifting. Buyers should focus on sourcing brackets with high weight capacities and resistance to environmental factors, such as corrosion and extreme temperatures, to ensure reliability and safety in demanding industrial settings.

What Are the Specific Needs for Brackets in Telecommunications?

In telecommunications, brackets are crucial for mounting cooling units within data centers, where maintaining optimal temperatures is vital for equipment performance. These brackets must provide stability while minimizing vibrations that could affect sensitive electronic systems. Buyers in this sector should look for features such as vibration dampening and compatibility with various cooling systems. Additionally, sourcing brackets that are easy to install and adjust can significantly enhance operational efficiency in fast-paced environments.

3 Common User Pain Points for ‘bracket for aircon’ & Their Solutions

Scenario 1: Difficulty Ensuring Structural Integrity of Air Conditioning Units

The Problem: B2B buyers often face the challenge of ensuring that air conditioning units are securely mounted, particularly in commercial settings where structural integrity is paramount. In regions with extreme weather conditions, such as heavy winds or rain, the risk of an improperly mounted unit falling or being dislodged increases. This not only poses a safety hazard but can also lead to costly damages and liability issues. Buyers need a solution that guarantees the air conditioning units are firmly anchored, providing peace of mind for both the installation teams and end-users.

The Solution: To address this concern, buyers should invest in high-quality, heavy-duty mounting brackets specifically designed for the weight and dimensions of the air conditioning units being installed. For instance, brackets made from galvanized steel with a rust-resistant finish are ideal for outdoor units, as they withstand environmental wear. Ensure that the brackets have a weight capacity that exceeds the air conditioning unit’s weight by a margin of at least 20%. Additionally, proper installation is crucial; buyers should engage trained professionals who can assess wall structures and utilize appropriate fasteners to anchor the brackets securely. Regular inspections should be scheduled to ensure ongoing safety and stability.

Scenario 2: Inadequate Space Optimization in Commercial Installations

The Problem: Space constraints are a common issue in urban commercial environments where maximizing usable area is crucial. Many businesses struggle with the placement of air conditioning units, which can consume valuable floor space or obstruct pathways. This is particularly problematic in densely populated areas or smaller retail outlets where every square meter counts. Buyers are left needing solutions that allow them to install air conditioning units without sacrificing space or functionality.

The Solution: The ideal approach is to utilize wall-mounted air conditioning brackets. These brackets elevate the units off the ground, freeing up floor space for other uses. Buyers should look for universal mounting brackets that allow for flexible installation options on various wall types. When selecting a bracket, ensure that it includes features such as rubber vibration eliminators, which minimize noise and movement. Additionally, consider brackets that allow for adjustable angles, enabling optimal airflow and cooling efficiency. Consulting with HVAC installation experts can also provide insights into the best practices for maximizing space while ensuring effective cooling.

Scenario 3: Challenges with Compatibility and Sourcing Quality Brackets

The Problem: Sourcing the right brackets for air conditioning units can be a daunting task for B2B buyers, especially when dealing with multiple manufacturers and models. Inconsistent specifications and lack of standardization across different brands can lead to compatibility issues, resulting in increased costs and project delays. Buyers often find themselves navigating a complex landscape of products that may not meet their specific needs, leading to frustration and inefficiency in the procurement process.

The Solution: To mitigate this issue, buyers should focus on establishing relationships with reputable suppliers who offer a wide range of mounting brackets with detailed specifications. It is advisable to request samples or specifications sheets that clearly outline compatibility with specific air conditioning units. Additionally, leveraging technology such as product comparison tools and online databases can help streamline the sourcing process. Buyers should also consider investing in custom solutions for unique installations, ensuring that the brackets fit seamlessly with the air conditioning units and meet all safety regulations. Regular communication with suppliers can also foster a better understanding of product offerings and lead times, enhancing the overall procurement experience.

Strategic Material Selection Guide for bracket for aircon

What Are the Key Materials for Air Conditioning Brackets?

When selecting materials for air conditioning brackets, it is essential to consider properties that affect performance, durability, and cost. Here, we analyze four common materials: steel, aluminum, stainless steel, and plastic composites. Each material presents unique advantages and limitations that can influence the decision-making process for international B2B buyers.

How Does Steel Perform as a Material for Air Conditioning Brackets?

Steel is a widely used material for air conditioning brackets due to its high strength and load-bearing capacity. It typically has a temperature rating that can withstand extreme conditions, making it suitable for outdoor applications. Steel brackets can support heavy units, with some designs capable of holding up to 450 lbs.

Pros: Steel offers excellent durability and is relatively inexpensive compared to other metals. Its manufacturing processes are well-established, ensuring a consistent supply chain.

Cons: Steel is prone to corrosion if not properly treated, which can be a significant drawback in humid or coastal environments. Additionally, its weight can complicate installation.

Impact on Application: Steel brackets are ideal for heavy-duty applications where strength is paramount. However, buyers in regions with high humidity or salt exposure should consider protective coatings or alternative materials.

Why Choose Aluminum for Air Conditioning Brackets?

Aluminum is another popular choice for air conditioning brackets. It is lightweight yet strong, making it easier to handle during installation. Aluminum has a natural resistance to corrosion, which is beneficial for outdoor applications.

Illustrative image related to bracket for aircon

Pros: The lightweight nature of aluminum reduces shipping costs and eases installation. Its corrosion resistance makes it suitable for various climates, including coastal regions.

Cons: While aluminum is strong, it may not support as much weight as steel, which could limit its use for larger air conditioning units. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum brackets are ideal for residential applications where weight and ease of installation are critical. However, they may not be suitable for industrial-scale units requiring heavy support.

What Are the Benefits of Stainless Steel for Air Conditioning Brackets?

Stainless steel combines the strength of steel with enhanced corrosion resistance. It is a preferred choice for environments where moisture and chemicals are prevalent, such as in the Middle East or coastal areas.

Pros: Stainless steel is highly durable and resistant to rust and corrosion, making it suitable for long-term use. It also maintains its structural integrity under high temperatures.

Cons: The primary drawback of stainless steel is its cost, which is significantly higher than that of regular steel and aluminum. Additionally, it can be more challenging to manufacture, leading to longer lead times.

Impact on Application: Buyers in regions with high humidity or exposure to chemicals will find stainless steel brackets advantageous. However, the higher initial investment may be a consideration for budget-conscious buyers.

How Do Plastic Composites Fit Into Air Conditioning Bracket Selection?

Plastic composites are increasingly being used for air conditioning brackets, especially in residential settings. They offer a lightweight alternative that is resistant to corrosion and UV degradation.

Pros: Plastic composites are typically less expensive than metals and are easy to install. They also do not rust, making them ideal for outdoor use.

Cons: The primary limitation is their load-bearing capacity, which may not be sufficient for larger air conditioning units. They can also be less durable in extreme temperatures compared to metals.

Impact on Application: Plastic composites are suitable for smaller, residential air conditioning units where weight and ease of installation are priorities. However, they may not be suitable for commercial applications requiring robust support.

Summary Table of Material Selection for Air Conditioning Brackets

| Material | Typical Use Case for bracket for aircon | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty outdoor units | High strength and load capacity | Prone to corrosion | Medium |

| Aluminum | Residential air conditioning units | Lightweight and corrosion resistant | Lower load capacity than steel | Medium |

| Stainless Steel | Humid or chemical-prone environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic Composites | Smaller residential units | Cost-effective and easy to install | Limited load capacity | Low |

This strategic material selection guide provides a comprehensive overview of the key materials used for air conditioning brackets, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

Illustrative image related to bracket for aircon

In-depth Look: Manufacturing Processes and Quality Assurance for bracket for aircon

What Are the Main Stages of Manufacturing Brackets for Air Conditioners?

Manufacturing brackets for air conditioners involves several critical stages, each essential for ensuring the final product’s strength, durability, and functionality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with selecting high-quality raw materials, typically steel or stainless steel, known for their strength and resistance to corrosion. The chosen materials are cut to size using precision cutting tools, ensuring uniformity and adherence to design specifications. This stage may also involve pre-treating the materials to enhance their surface properties, such as applying anti-corrosive coatings. -

Forming Techniques

After preparation, the materials undergo forming processes, which may include bending, stamping, and welding. Techniques like CNC (Computer Numerical Control) machining are often employed for precise shaping and to create complex geometries. This ensures that the brackets can support the necessary weight while fitting seamlessly with various air conditioning units. -

Assembly Process

Once the individual components are formed, they are assembled into the final bracket structure. This may involve welding parts together, using bolts or rivets, and attaching additional elements such as rubber vibration eliminators to reduce noise and enhance stability. Automated assembly lines may be used to increase efficiency and consistency. -

Finishing Procedures

The finishing stage typically involves surface treatments such as powder coating or galvanizing, which not only improve aesthetics but also protect against environmental factors like moisture and UV radiation. This step is crucial for enhancing the longevity of the brackets, especially in outdoor settings where exposure to the elements is a concern.

What Are the Key Quality Control Measures for Air Conditioning Brackets?

Quality assurance is paramount in the manufacturing of air conditioning brackets, given their critical role in securing heavy units. Adhering to international standards and implementing rigorous quality control (QC) measures helps ensure product reliability and safety.

-

International and Industry-Specific Standards

Manufacturers often adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) may be applicable, depending on the use case. These certifications assure buyers that the products meet safety, health, and environmental protection standards. -

Quality Control Checkpoints

Effective QC processes include several checkpoints throughout the manufacturing cycle:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to identify any defects or deviations from specifications.

- Final Quality Control (FQC): Once production is complete, a thorough inspection is carried out to verify that the finished brackets meet all design and performance criteria.

- Common Testing Methods

Various testing methods are employed to validate the strength and durability of the brackets. These may include tensile strength tests, fatigue tests, and corrosion resistance tests. Additionally, visual inspections ensure that there are no visible defects, such as cracks or improper finishes.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, must take proactive steps to verify the quality control processes of their suppliers.

-

Supplier Audits

Conducting audits of potential suppliers is a critical step in ensuring their manufacturing processes align with quality standards. Buyers should look for suppliers that are willing to provide transparency regarding their QC procedures, including documentation of their certifications and compliance with international standards. -

Reviewing Quality Reports

Requesting detailed quality reports from suppliers can provide insights into their QC performance. These reports should include information on testing results, defect rates, and corrective actions taken in response to quality issues. -

Third-Party Inspections

Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s manufacturing and quality assurance processes. These agencies can conduct inspections at various stages of production, providing buyers with additional assurance regarding product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific quality control nuances when sourcing air conditioning brackets from global suppliers. Understanding these nuances can help mitigate risks and ensure the procurement of high-quality products.

Illustrative image related to bracket for aircon

-

Cultural and Regulatory Differences

Different countries may have varying regulatory requirements and quality standards. Buyers should familiarize themselves with the specific standards applicable in their region, as well as those in the supplier’s country. This knowledge is crucial for ensuring compliance and avoiding potential legal issues. -

Communication Barriers

Effective communication is vital for establishing clear quality expectations. B2B buyers should ensure that there is a mutual understanding of quality standards and specifications. Utilizing detailed contracts and specifications can help bridge any gaps in communication. -

Logistical Considerations

Shipping and handling can impact product quality, especially for sensitive items like air conditioning brackets. Buyers should discuss packaging and transportation methods with suppliers to minimize the risk of damage during transit. Additionally, understanding the lead times for international shipments is essential for planning and inventory management.

Conclusion

In-depth knowledge of manufacturing processes and quality assurance for air conditioning brackets is essential for B2B buyers. By understanding the stages of manufacturing, implementing robust quality control measures, and verifying supplier capabilities, businesses can secure reliable and durable products. As the demand for efficient air conditioning solutions continues to grow, particularly in regions with extreme climates, ensuring the quality of support brackets will play a critical role in the overall performance of HVAC systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bracket for aircon’

This guide serves as a practical checklist for B2B buyers seeking to procure air conditioning brackets. By following these steps, you can ensure that you make informed decisions that align with your technical requirements and business objectives.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your air conditioning brackets is crucial. This includes the weight capacity, material (such as stainless steel for durability), and compatibility with different air conditioning units. Clearly defining these specifications helps narrow down options and ensures that the selected brackets meet safety and performance standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of air conditioning brackets. Utilize online resources, industry directories, and trade shows to gather a list of potential vendors. Pay attention to their market presence, customer reviews, and product range, as these factors can indicate reliability and quality.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with international standards. Look for ISO certifications, CE markings, or other relevant quality certifications that ensure the brackets meet safety and performance criteria. This step mitigates risks associated with product failures and liabilities.

Step 4: Request Samples for Testing

Always request samples of the brackets before making bulk purchases. This allows you to evaluate the quality, durability, and compatibility with your air conditioning units. Testing samples can prevent costly mistakes and ensures that the product meets your operational needs.

Step 5: Assess Pricing and Payment Terms

Comparing prices from multiple suppliers can help you secure the best deal. However, don’t focus solely on the lowest price; consider the total cost of ownership, including shipping, taxes, and potential import duties. Additionally, review payment terms to ensure they align with your cash flow and budgeting requirements.

Step 6: Check for Warranty and Support Services

Inquire about the warranty offered on the air conditioning brackets and any after-sales support services. A robust warranty indicates the manufacturer’s confidence in their product, while good customer support ensures you can resolve any issues quickly. This is particularly important for international transactions where communication may be challenging.

Step 7: Finalize the Order and Confirm Logistics

Once you’ve selected a supplier, finalize your order by confirming all details, including quantities, specifications, and delivery timelines. Discuss logistics to ensure timely delivery, especially if you are operating in regions with complex shipping regulations. Clear communication at this stage can prevent misunderstandings and delays.

By following this checklist, B2B buyers can streamline the sourcing process for air conditioning brackets, ensuring they select high-quality products that meet their specific needs while maintaining compliance and efficiency.

Comprehensive Cost and Pricing Analysis for bracket for aircon Sourcing

What Are the Key Cost Components for Air Conditioning Bracket Sourcing?

When sourcing brackets for air conditioning units, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common options include steel, which is durable and weather-resistant, and aluminum, which is lighter but may not provide the same strength. Coatings like powder coating for rust resistance also add to material costs.

-

Labor: Labor costs vary depending on the region and the complexity of manufacturing. Skilled labor is required for processes like welding and assembly, especially for high-quality brackets that meet safety standards.

-

Manufacturing Overhead: This includes expenses related to the factory operations, such as utilities, rent, and maintenance. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Custom brackets may require specific tools or molds, contributing to higher upfront costs. For standard designs, tooling costs can be amortized over larger production runs.

-

Quality Control (QC): Investing in quality control systems ensures that the brackets meet industry standards. This can include testing for weight capacity and resistance to environmental factors.

-

Logistics: Transportation costs depend on the distance from the manufacturer to the buyer, as well as shipping methods. Import duties and tariffs can also affect the final cost, especially for international buyers.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the typical margin in your industry can help in negotiations.

How Do Price Influencers Affect Air Conditioning Bracket Costs?

Several factors can influence the price of air conditioning brackets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Establishing a relationship with suppliers for consistent orders can also secure better pricing.

-

Specifications and Customization: Customized brackets tailored to specific air conditioning units may incur additional costs. Clearly defining specifications upfront can minimize unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but also enhance product reliability and safety, which are critical for B2B buyers.

-

Supplier Factors: The reputation and reliability of suppliers can significantly affect pricing. Established suppliers may offer better quality assurance but at a premium.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can impact total costs.

What Are Essential Buyer Tips for Cost-Efficient Sourcing?

When sourcing air conditioning brackets, international B2B buyers should consider the following tips for cost-efficiency:

-

Negotiation: Always negotiate prices, especially when placing large orders. Suppliers may have flexibility in pricing that can lead to significant savings.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including installation, maintenance, and potential replacement. A higher upfront cost may result in lower lifetime costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, shipping delays, and potential tariffs when sourcing from different regions. Building relationships with local suppliers can mitigate some risks associated with international sourcing.

-

Research and Compare: Take the time to compare multiple suppliers and products. This research can uncover better pricing options and variations in product quality.

-

Stay Informed About Market Trends: Understanding market dynamics, such as material shortages or demand fluctuations, can provide leverage in negotiations and sourcing decisions.

Disclaimer on Indicative Prices

Prices for air conditioning brackets can vary widely based on the factors discussed. The costs provided by suppliers are indicative and subject to change based on market conditions, order specifics, and regional economic factors. Always request updated quotes and consider all influencing elements before finalizing a purchase.

Alternatives Analysis: Comparing bracket for aircon With Other Solutions

Understanding Alternatives to Brackets for Air Conditioning Units

When considering the installation of air conditioning systems, selecting the right support mechanism is crucial. While brackets for air conditioners are a popular choice, several alternative solutions exist that can achieve similar goals. This analysis will compare air conditioning brackets with two viable alternatives: ground mounts and adjustable window supports.

Comparison Table

| Comparison Aspect | Bracket For Aircon | Ground Mounts | Adjustable Window Supports |

|---|---|---|---|

| Performance | High load capacity, stable installation | Excellent stability for larger units | Suitable for smaller, window units |

| Cost | $54 – $220 (varies by model) | $100 – $300 depending on materials | $70 – $80 |

| Ease of Implementation | Requires wall drilling and fastening | Typically requires concrete or stable ground | Simple installation, less invasive |

| Maintenance | Low maintenance, durable materials | May require periodic checks for stability | Minimal maintenance, easy adjustments |

| Best Use Case | Ideal for wall-mounted mini-splits | Best for heavy, standalone units | Suitable for window-mounted air conditioners |

Pros and Cons of Alternatives

Ground Mounts

Ground mounts offer a robust solution for supporting larger air conditioning units, particularly those that are standalone or part of a central cooling system. These mounts provide excellent stability and can accommodate heavier units. However, they often require significant installation effort, including pouring concrete or ensuring a stable ground surface. Additionally, they may not be suitable for all environments, particularly where space is limited or in urban settings where ground mounting is impractical.

Adjustable Window Supports

Adjustable window supports are designed for air conditioning units that fit within window frames. They are generally easier to install than brackets or ground mounts, requiring minimal drilling and often utilizing existing window structures. This makes them a less invasive option for users looking to maintain the aesthetic of their buildings. However, adjustable window supports may not provide the same level of stability for larger units, which can lead to potential safety concerns if the air conditioning unit exceeds the support’s weight limit.

Making the Right Choice for Air Conditioning Support

For B2B buyers, the decision on which support solution to choose depends heavily on the specific requirements of the air conditioning installation. If stability and load-bearing capacity are paramount, especially for larger or heavier units, ground mounts may be the best option despite their higher cost and installation complexity. Conversely, if the installation is for smaller window-mounted units and ease of installation is a priority, adjustable window supports present a practical solution.

Ultimately, understanding the unique needs of each installation, including weight, space constraints, and installation environment, will guide buyers in selecting the most appropriate air conditioning support system. Each solution has its strengths and weaknesses, and making an informed choice will ensure the longevity and efficiency of the air conditioning unit.

Essential Technical Properties and Trade Terminology for bracket for aircon

What Are the Essential Technical Properties of Brackets for Air Conditioning Units?

When sourcing brackets for air conditioning units, understanding their technical properties is crucial for ensuring durability, safety, and compatibility with various AC models. Here are some key specifications to consider:

1. Material Grade

The most common materials for air conditioning brackets are steel and aluminum. Steel brackets, often galvanized or powder-coated, offer high strength and corrosion resistance, making them suitable for outdoor installations. Aluminum brackets are lighter and resistant to rust, ideal for indoor applications. Selecting the right material impacts the lifespan and performance of the bracket, especially in harsh environments.

2. Load Capacity

This specification indicates the maximum weight the bracket can safely support. For instance, brackets with a load capacity of 185 lbs or more are typical for mini-split systems. It is essential to choose a bracket that exceeds the weight of the air conditioning unit to ensure stability and prevent accidents. A proper load capacity also affects installation flexibility in various settings, such as residential or commercial buildings.

3. Finish and Coating

Brackets may have different finishes, such as powder coating or galvanization. A powder-coated finish enhances corrosion resistance and adds aesthetic value, while galvanization provides a robust protective layer against rust. The finish is particularly important for outdoor units exposed to moisture and varying weather conditions.

4. Vibration Dampening Features

Some brackets come equipped with rubber vibration eliminators to reduce noise and vibrations transmitted to the wall or window. This feature is crucial for maintaining a comfortable indoor environment, particularly in residential settings. It also protects the integrity of the installation, as excessive vibrations can lead to wear and tear over time.

5. Installation Hardware Included

The inclusion of mounting hardware is an essential consideration when purchasing air conditioning brackets. Comprehensive kits typically include screws, anchors, and installation instructions, which can streamline the installation process. Ensuring that the hardware meets quality standards is vital for a secure and lasting installation.

What Are Common Trade Terms Related to Air Conditioning Brackets?

Understanding industry jargon can significantly enhance communication and negotiations with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are then sold under another company’s brand. In the context of air conditioning brackets, an OEM may provide brackets designed specifically for certain AC units, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory effectively and minimize costs. Suppliers often set MOQs to ensure that production runs are economically viable.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price bids for specific products or services. In the case of air conditioning brackets, issuing an RFQ can help buyers compare prices, terms, and delivery timelines from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, insurance, and risks associated with transporting air conditioning brackets from suppliers, especially when dealing with international markets.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. Understanding lead times is vital for B2B buyers to plan installations and manage project timelines efficiently. Delays in lead time can impact project schedules, particularly in construction and renovation projects.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing brackets for air conditioning units, leading to safer installations and better overall performance.

Navigating Market Dynamics and Sourcing Trends in the bracket for aircon Sector

What Are the Current Market Dynamics and Key Trends in the Bracket for Aircon Sector?

The global air conditioning market is experiencing significant growth, driven by increasing temperatures, urbanization, and rising disposable incomes, particularly in regions like Africa, South America, the Middle East, and Europe. For international B2B buyers, understanding these dynamics is crucial for sourcing brackets for air conditioning units. One key trend is the shift towards mini-split systems, which require specialized brackets for installation. These systems are favored for their energy efficiency and ability to cool individual rooms, creating demand for sturdy, reliable mounting solutions.

Additionally, advancements in technology are influencing sourcing trends. Smart brackets that offer integrated features, such as vibration dampening and corrosion resistance, are gaining traction. B2B buyers are increasingly looking for suppliers who can offer these innovative solutions, aligning with the growing focus on product performance and longevity. Furthermore, e-commerce platforms are reshaping the procurement landscape, enabling buyers to access a wider range of products and suppliers globally, streamlining their sourcing processes.

In regions like Saudi Arabia and Nigeria, where extreme weather conditions are common, the demand for high-capacity, durable brackets is paramount. Buyers must also navigate varying regulatory environments, which can impact the specifications and certifications required for air conditioning brackets. Staying informed about these market dynamics will empower B2B buyers to make strategic sourcing decisions that align with both current needs and future trends.

How Does Sustainability and Ethical Sourcing Impact the Bracket for Aircon Sector?

Sustainability is becoming a central theme in the sourcing of air conditioning brackets, with environmental impact considerations influencing purchasing decisions. Many B2B buyers are increasingly aware of the carbon footprint associated with manufacturing processes and the materials used in products. Opting for brackets made from recycled or sustainably sourced materials not only mitigates environmental harm but also enhances brand reputation, particularly in markets sensitive to ecological issues.

Illustrative image related to bracket for aircon

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with suppliers who demonstrate transparency in their sourcing practices and adhere to fair labor standards. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the push for “green” materials in manufacturing is reshaping the industry. Brackets that feature environmentally friendly coatings or treatments—such as powder coating that eliminates harmful solvents—are increasingly sought after. This trend not only addresses environmental concerns but also enhances product durability, providing long-term value to buyers.

What Is the Historical Context of the Bracket for Aircon Sector?

The evolution of air conditioning brackets has been closely tied to advancements in air conditioning technology and the growing demand for efficient cooling solutions. Initially, air conditioning units were predominantly bulky, window-mounted systems that required basic support structures. As technology progressed, particularly with the introduction of mini-split systems in the late 20th century, the need for more sophisticated and reliable mounting solutions emerged.

Modern brackets are now designed to support heavier loads and withstand various environmental conditions, reflecting the shift towards more efficient and versatile air conditioning systems. This evolution has prompted manufacturers to innovate continuously, focusing on strength, ease of installation, and compatibility with diverse unit types. As the market continues to grow, the historical context of air conditioning brackets highlights the importance of adaptability and innovation in meeting the changing needs of consumers and B2B buyers alike.

Frequently Asked Questions (FAQs) for B2B Buyers of bracket for aircon

-

How do I solve the issue of air conditioning units falling from their mounts?

To prevent air conditioning units from falling, ensure you select high-quality brackets designed for the specific weight and size of your unit. Look for brackets made from durable materials like stainless steel, which provide the necessary strength and corrosion resistance. Additionally, proper installation is crucial; brackets should be securely fastened to the wall or window frame. Always consult installation guidelines and, if possible, hire professional services to guarantee safety and compliance with local regulations. -

What is the best type of bracket for mounting ductless mini-split air conditioners?

The best type of bracket for ductless mini-split air conditioners is a heavy-duty L-mounting bracket, which can support a significant weight, typically up to 185 lbs. These brackets are designed for all-weather performance and stability. Look for features such as rust-resistant coatings and rubber vibration eliminators to minimize noise and protect the unit. Ensure that the bracket is compatible with the specific model of your air conditioner for optimal performance. -

What are the key considerations when sourcing air conditioning brackets internationally?

When sourcing air conditioning brackets internationally, consider factors such as material quality, load capacity, and compliance with local regulations. It’s important to verify that the supplier adheres to international safety standards and certifications. Additionally, assess the supplier’s production capabilities, lead times, and logistics support to ensure timely delivery. Establishing clear communication regarding pricing, minimum order quantities (MOQ), and payment terms is essential to avoid misunderstandings and delays. -

How can I vet suppliers for air conditioning brackets?

To vet suppliers for air conditioning brackets, conduct thorough research by checking their business credentials, customer reviews, and product certifications. Request references from previous clients and assess their experience in the HVAC industry. Consider visiting their manufacturing facilities, if feasible, or utilizing third-party inspection services to evaluate product quality. Engaging in direct communication to discuss your specific needs and expectations will also help gauge their reliability and responsiveness. -

What are the typical minimum order quantities (MOQs) for air conditioning brackets?

Minimum order quantities (MOQs) for air conditioning brackets can vary significantly based on the supplier and the type of bracket. Generally, MOQs can range from 50 to 500 units. Some manufacturers may offer flexibility for smaller orders, especially for new customers or initial samples. However, larger orders may provide better pricing and reduced shipping costs. Always clarify MOQs with your supplier before finalizing your order to align with your business requirements. -

What payment terms should I expect when sourcing air conditioning brackets?

Payment terms for sourcing air conditioning brackets vary by supplier and region but commonly include options such as upfront payments, partial deposits, or payment upon delivery. Many suppliers may require a 30% deposit before production, with the remaining balance due prior to shipment. It’s essential to negotiate terms that align with your cash flow and risk tolerance. Consider using secure payment methods such as letters of credit or escrow services to protect your investment. -

How do I ensure quality assurance (QA) for air conditioning brackets?

To ensure quality assurance for air conditioning brackets, request product samples before placing a large order. Establish clear specifications and standards for the brackets, including load capacity and material quality. Work with suppliers that have rigorous QA processes in place, such as ISO certifications or third-party inspections. Implementing a quality control checklist during the production phase can help identify any issues early, ensuring that the final products meet your expectations. -

What logistics considerations should I keep in mind when importing air conditioning brackets?

When importing air conditioning brackets, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose reliable shipping partners that offer tracking and insurance to mitigate risks during transit. Be aware of any import tariffs or taxes that may apply in your country, as these can affect overall costs. Planning for storage and distribution upon arrival will also ensure that you can meet customer demands efficiently.

Top 5 Bracket For Aircon Manufacturers & Suppliers List

1. Supreme – Universal AC Wall Bracket

Domain: shop.supremestands.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Universal AC Wall Bracket (ACWB-40)”, “regular_price”: “$220.00”, “sale_price”: “$220.00”, “color”: “Black”, “finish”: “Powder coat finish (rust resistant)”, “features”: [“Mounted on rubber vibration eliminators”, “Sturdy wall bracket”, “Hardware included”], “max_capacity”: “450 lb.”}

2. Top Shelf – TSB-2438 AC Bracket

Domain: nytimes.com

Registered: 1994 (31 years)

Introduction: This company, Top Shelf – TSB-2438 AC Bracket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Super Air Cool – Air Conditioning Brackets

Domain: superaircool.com

Registered: 2020 (5 years)

Introduction: Air conditioning brackets are steel frames installed on walls or windows to support the weight of air conditioning units. They are essential for window air conditioners, wall-mounted units, and outdoor mini-split systems. Made from heavy metal like stainless steel, these brackets secure the air conditioner in place, allowing for an outward tilt to enable condensation drip outside. They are necessa…

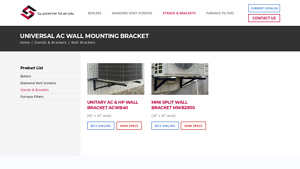

4. Supreme Stands – Adjustable AC Unit Mounts

Domain: supremestands.com

Registered: 2015 (10 years)

Introduction: Adjustable A/C Unit Mount, Air Conditioning Condenser Wall Bracket, Universal AC Wall Mounting Bracket (ACWB40) dimensions: 40″ x 30″ wide, Mini Split Wall Bracket (MWB2830) dimensions: 28″ x 30″ wide. Features include patented reversibility for heat pump stands, sleek and simple designs, quick and easy installation, powder-coated protection, and compatibility with various brands.

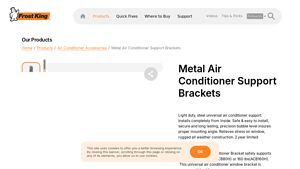

5. Frost King – Metal Air Conditioner Support Brackets

Domain: frostking.com

Registered: 1996 (29 years)

Introduction: Product Name: Metal Air Conditioner Support Brackets

Product SKUs: ACB80H, ACB160H

Weight Capacity: ACB80H holds units up to 80 lbs; ACB160H holds units up to 160 lbs

Material: Light duty steel

Installation: Installs completely from inside

Features: Safe and easy to install, secure and long-lasting, includes precision bubble level for proper mounting angle, relieves stress on window, rugged all-we…

Strategic Sourcing Conclusion and Outlook for bracket for aircon

In today’s competitive landscape, strategic sourcing for air conditioning brackets is essential for international buyers seeking quality and reliability. The key takeaways from this guide highlight the importance of selecting robust, certified brackets that can support the weight of various air conditioning units, particularly in regions with diverse climates such as Africa, South America, the Middle East, and Europe. Prioritizing suppliers who offer durable materials, like stainless steel, and innovative designs can significantly enhance installation safety and efficiency.

Furthermore, understanding the local market dynamics and compliance standards is crucial for successful sourcing. Engaging with suppliers who have a strong track record and can provide tailored solutions will not only optimize your procurement strategy but also ensure that you meet customer demands effectively.

As we look ahead, the demand for air conditioning solutions is set to rise, driven by increasing urbanization and climate change. Now is the time for B2B buyers to leverage strategic sourcing to secure the best products at competitive prices. Explore partnerships with reputable manufacturers and distributors to position your business for success in this growing market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to bracket for aircon

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.