Is Your Radiant Heat Vs Forced Air Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for radiant heat vs forced air

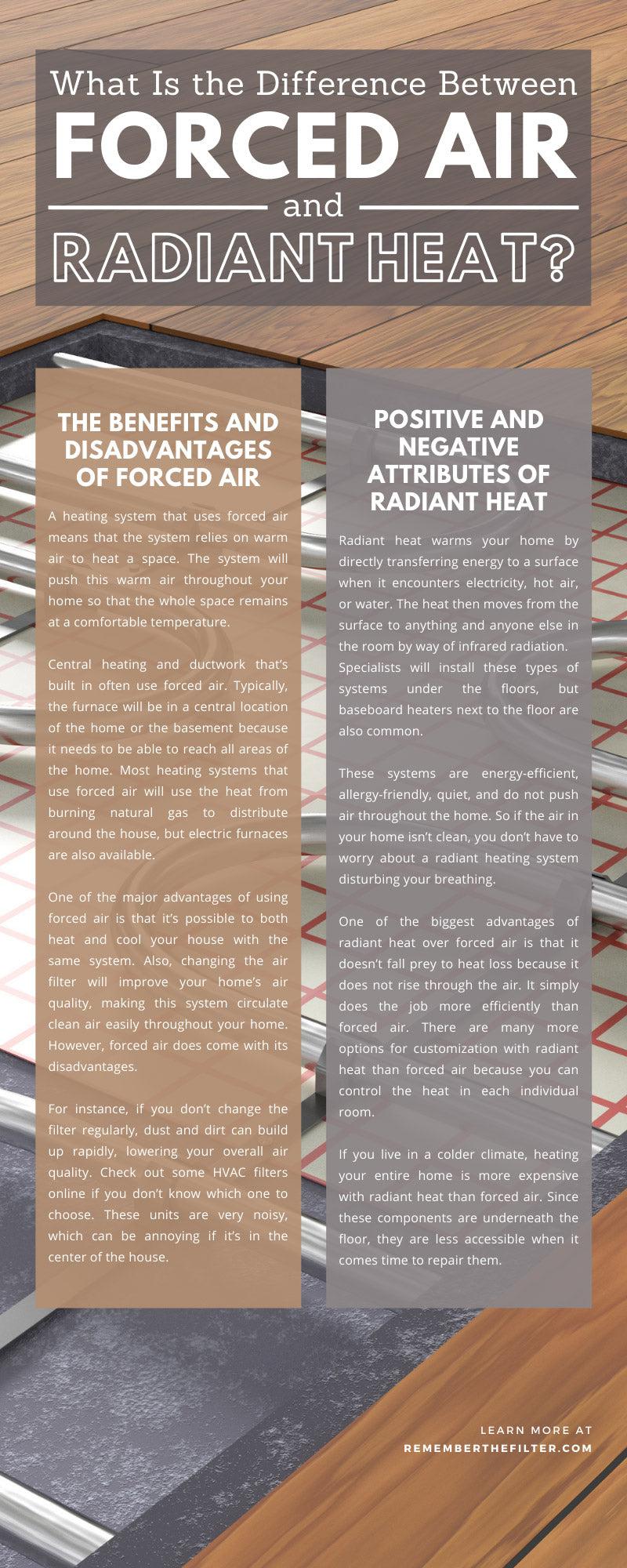

In today’s competitive landscape, selecting the right heating system—radiant heat or forced air—poses a significant challenge for international B2B buyers. These systems not only impact operational costs but also influence comfort levels, air quality, and energy efficiency within commercial spaces. This guide offers a comprehensive exploration of both heating options, detailing their types, applications, supplier vetting processes, and cost implications, empowering decision-makers to navigate the complexities of the global market.

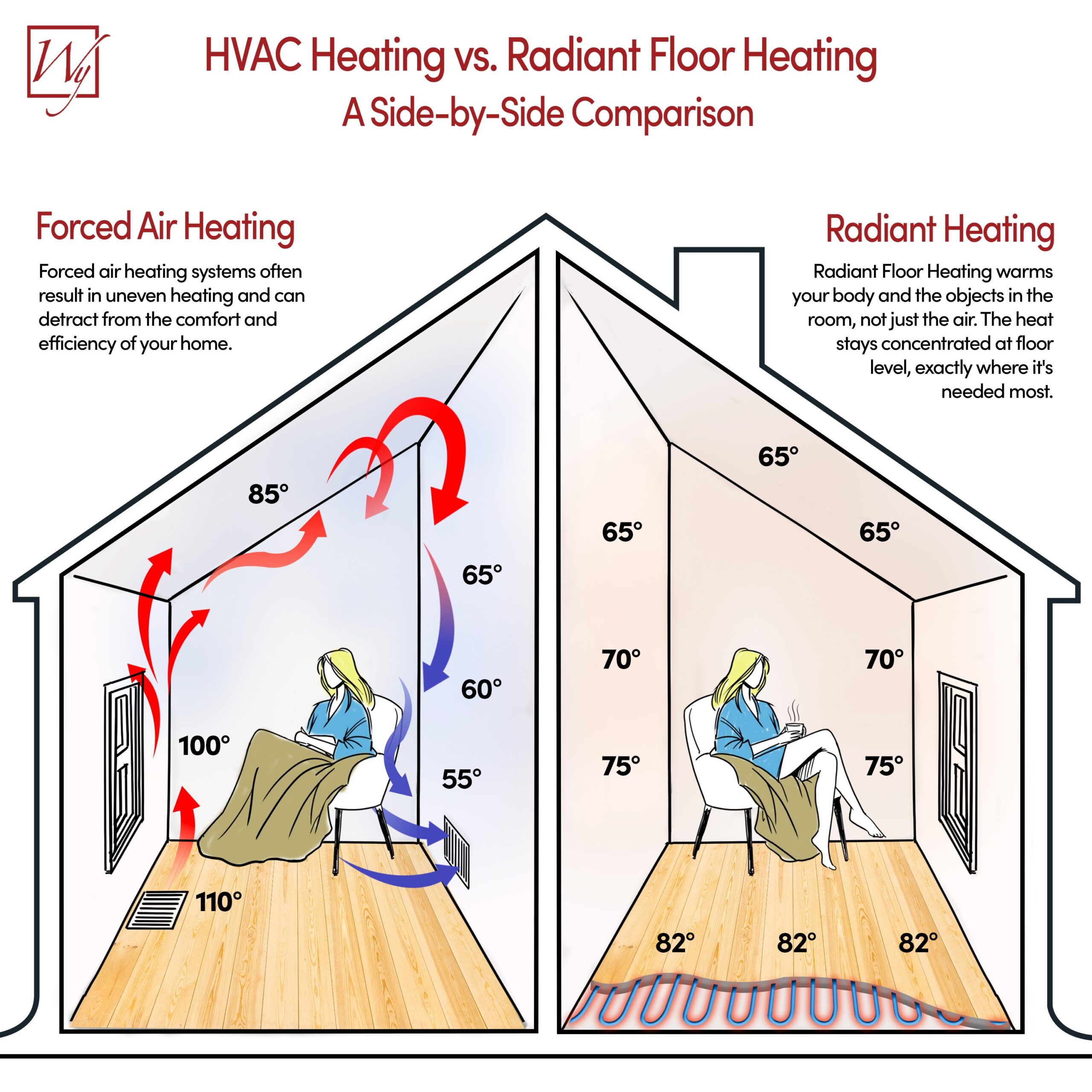

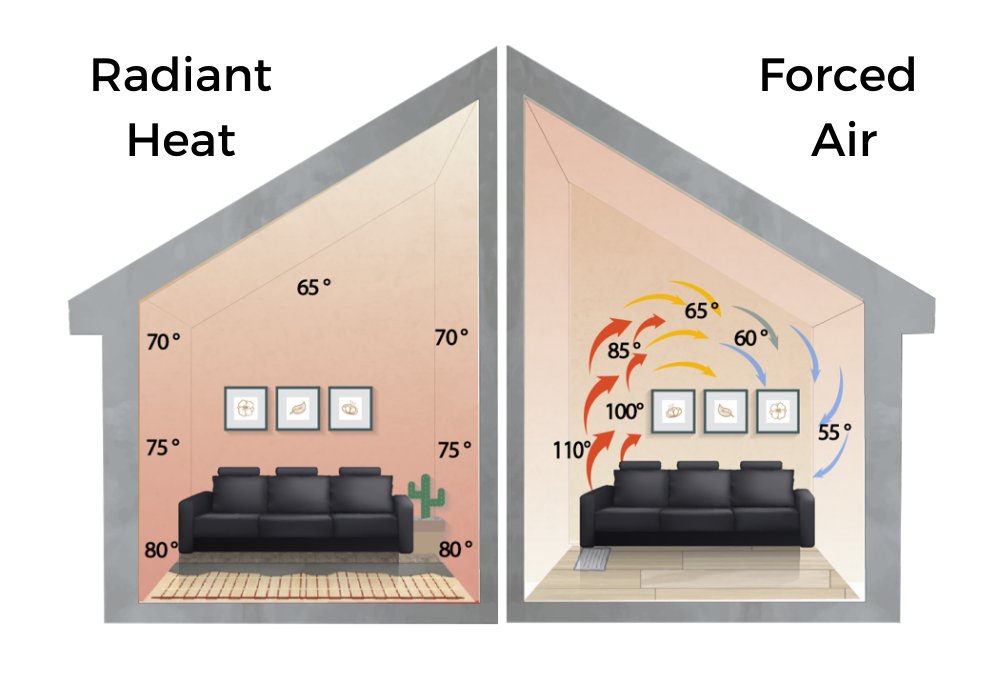

As businesses in Africa, South America, the Middle East, and Europe, including regions like Germany and Vietnam, strive for sustainability and efficiency, understanding the nuances of radiant heat versus forced air becomes paramount. Radiant heating systems deliver consistent warmth and superior air quality, making them increasingly appealing in environments sensitive to allergens and energy waste. In contrast, forced air systems, while prevalent, can present challenges such as temperature fluctuations and maintenance concerns.

By delving into the strengths and weaknesses of each system, this guide equips B2B buyers with actionable insights, enabling them to make informed purchasing decisions that align with their unique operational needs. The goal is to foster an understanding that not only enhances comfort and efficiency but also supports long-term cost savings and sustainability in heating solutions.

Understanding radiant heat vs forced air Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydronic Radiant Heat | Uses hot water circulated through pipes under floors or walls. | Commercial buildings, residential | Pros: Energy efficient, even heating. Cons: Higher installation costs, complex repairs. |

| Electric Radiant Heat | Utilizes electric cables or mats installed beneath flooring. | Residential, small commercial | Pros: Easy installation, low maintenance. Cons: Higher operating costs, limited heating area. |

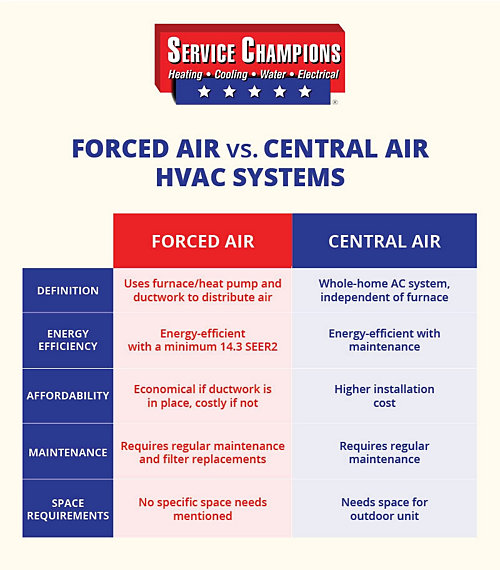

| Forced Air Heating | Relies on ducts and a furnace to distribute heated air. | Industrial facilities, large homes | Pros: Quick heating, dual function (heating & cooling). Cons: Air quality issues, energy loss through ducts. |

| Ductless Mini-Split | Combines heat pump technology with individual room units. | Multi-family units, offices | Pros: Flexible installation, room-specific control. Cons: Higher upfront cost, requires professional installation. |

| Baseboard Radiant Heat | Uses electric or hot water baseboards along walls for heating. | Small offices, residential | Pros: Space-saving, easy to install. Cons: Limited heating capacity, potential for uneven heat distribution. |

What Are the Key Characteristics of Hydronic Radiant Heat?

Hydronic radiant heat systems circulate hot water through pipes installed under floors or within walls, providing a consistent and comfortable heat distribution. This system is particularly suitable for larger commercial buildings and residential spaces where energy efficiency is a priority. For B2B buyers, considerations include installation costs and the complexity of repairs, as well as the long-term energy savings that may offset initial expenses.

How Does Electric Radiant Heat Function in Commercial Settings?

Electric radiant heat systems utilize electric cables or mats placed beneath flooring materials, generating warmth directly from the surface. They are ideal for residential applications and small commercial spaces due to their straightforward installation and low maintenance requirements. However, B2B buyers should weigh the higher operational costs against the benefits of ease of use and minimal upkeep, especially in environments where heating demand is lower.

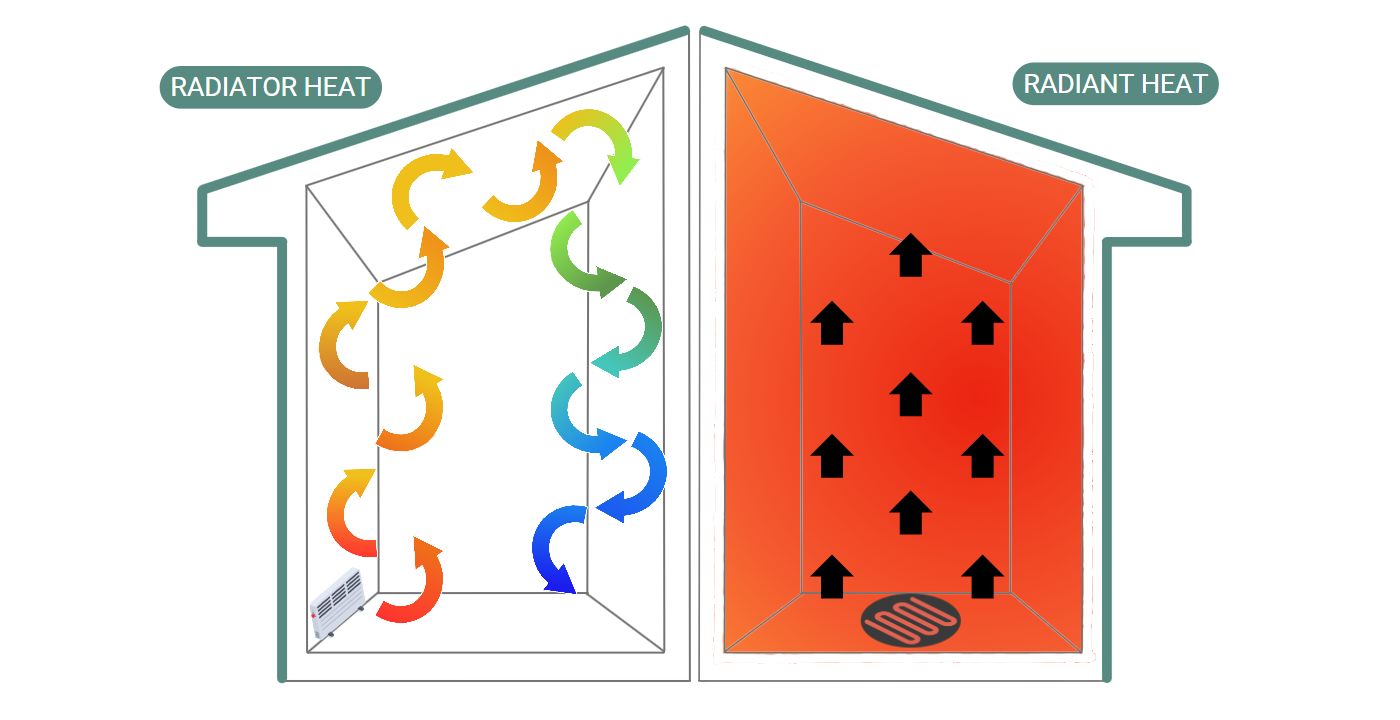

What Are the Advantages of Forced Air Heating in Industrial Facilities?

Forced air heating systems employ ductwork and a furnace to distribute heated air throughout a space. This method is commonly used in industrial facilities and larger homes due to its ability to heat spaces quickly and the dual functionality of providing both heating and cooling. However, B2B buyers must be mindful of potential air quality issues and energy losses through ducts, which can affect overall efficiency and operational costs.

Why Choose Ductless Mini-Split Systems for Multi-Family Units?

Ductless mini-split systems combine heat pump technology with individual room units, allowing for targeted heating and cooling in multi-family units and office environments. Their flexible installation options and room-specific control are significant advantages. However, B2B buyers should consider the higher upfront costs and the need for professional installation, which may impact budgetary constraints.

What Are the Benefits and Limitations of Baseboard Radiant Heat?

Baseboard radiant heat systems can operate using either electric or hot water, installed along walls to provide heating. They are suitable for small offices and residential spaces due to their space-saving design and ease of installation. However, B2B buyers should be aware of the limited heating capacity and the potential for uneven heat distribution, which can affect comfort levels in larger areas.

Key Industrial Applications of radiant heat vs forced air

| Industry/Sector | Specific Application of Radiant Heat vs Forced Air | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Heating large warehouses and production floors | Improved energy efficiency and consistent temperature control | Evaluate energy source availability and cost-effectiveness |

| Agriculture | Greenhouse heating systems | Enhanced crop growth and reduced heating costs | Assess local climate impacts and system scalability |

| Hospitality | Hotel room heating and spa facilities | Increased guest comfort and satisfaction | Consider installation and maintenance costs |

| Healthcare | Patient care areas and surgical suites | Enhanced infection control and patient comfort | Ensure compliance with health regulations |

| Automotive | Paint booths and assembly lines | Faster drying times and improved product quality | Investigate temperature consistency and energy savings |

How is Radiant Heat Used in Manufacturing for Temperature Control?

In the manufacturing sector, radiant heat systems are increasingly utilized to maintain consistent temperatures in large warehouses and production floors. This method minimizes temperature fluctuations, which can adversely affect product quality and worker comfort. By offering targeted heating solutions, businesses can reduce energy consumption and lower operational costs. Buyers should consider the energy source available in their region and the potential for long-term savings on energy bills when sourcing these systems.

Illustrative image related to radiant heat vs forced air

What Role Does Radiant Heat Play in Agriculture for Enhancing Crop Growth?

In agriculture, radiant heating systems are crucial for greenhouse environments, providing an efficient means of regulating temperature and humidity levels. This technology promotes optimal growing conditions, leading to enhanced crop yields and reduced heating costs during colder months. For international buyers, especially in regions with extreme climates, it’s essential to evaluate the local climate’s impact on system performance and consider the scalability of the heating solution to accommodate various greenhouse sizes.

How Does Radiant Heat Improve Comfort in the Hospitality Sector?

The hospitality industry benefits significantly from radiant heating systems, particularly in hotel rooms and spa facilities, where guest comfort is paramount. These systems provide a silent, even heat, enhancing the overall guest experience by eliminating drafts and temperature fluctuations. When sourcing these systems, businesses should factor in installation and maintenance costs, as well as the potential for energy savings to improve their bottom line.

Why is Radiant Heating Important in Healthcare Settings?

In healthcare, maintaining a stable and hygienic environment is critical. Radiant heating systems are ideal for patient care areas and surgical suites, as they not only provide consistent warmth but also limit the circulation of dust and allergens. This is essential for infection control and patient comfort. Buyers in this sector must ensure that their heating solutions comply with health regulations and consider the long-term operational efficiency of the systems.

How is Radiant Heat Used in Automotive Applications for Quality Control?

In the automotive industry, radiant heating is often employed in paint booths and assembly lines to ensure that surfaces dry quickly and uniformly. This results in improved product quality and reduced production times. When sourcing radiant heating systems for automotive applications, businesses should investigate the consistency of temperature control and the energy savings that can be achieved, which are crucial for maintaining competitive pricing and operational efficiency.

3 Common User Pain Points for ‘radiant heat vs forced air’ & Their Solutions

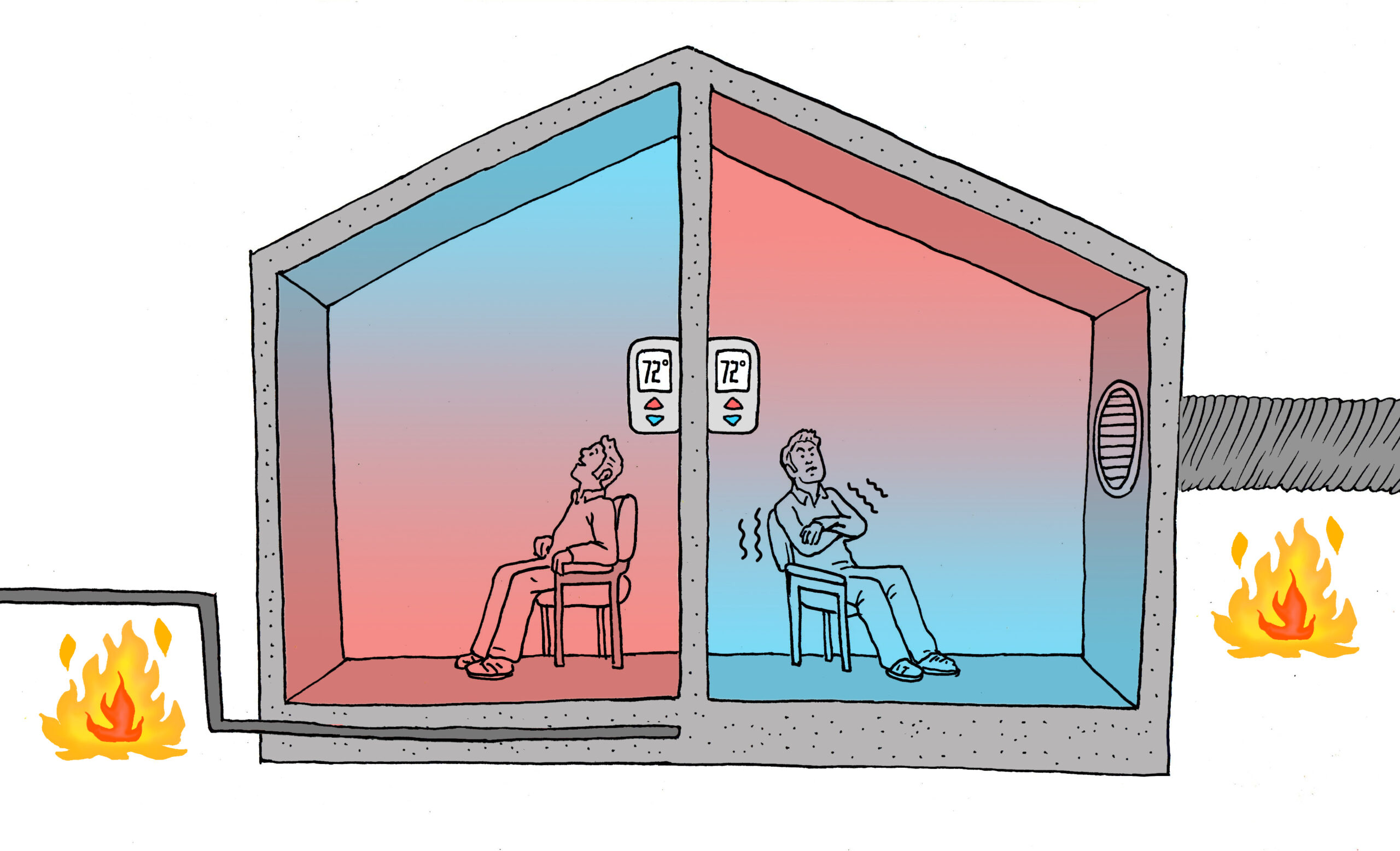

Scenario 1: Inconsistent Heating Across Large Spaces

The Problem: A facility manager overseeing a large commercial building faces the challenge of uneven heating. Employees frequently complain about cold spots in certain areas, while others feel overheated. This inconsistency not only affects comfort but can also lead to decreased productivity and increased complaints. The traditional forced air system struggles to distribute heat evenly due to its reliance on ducts that may leak or become obstructed over time.

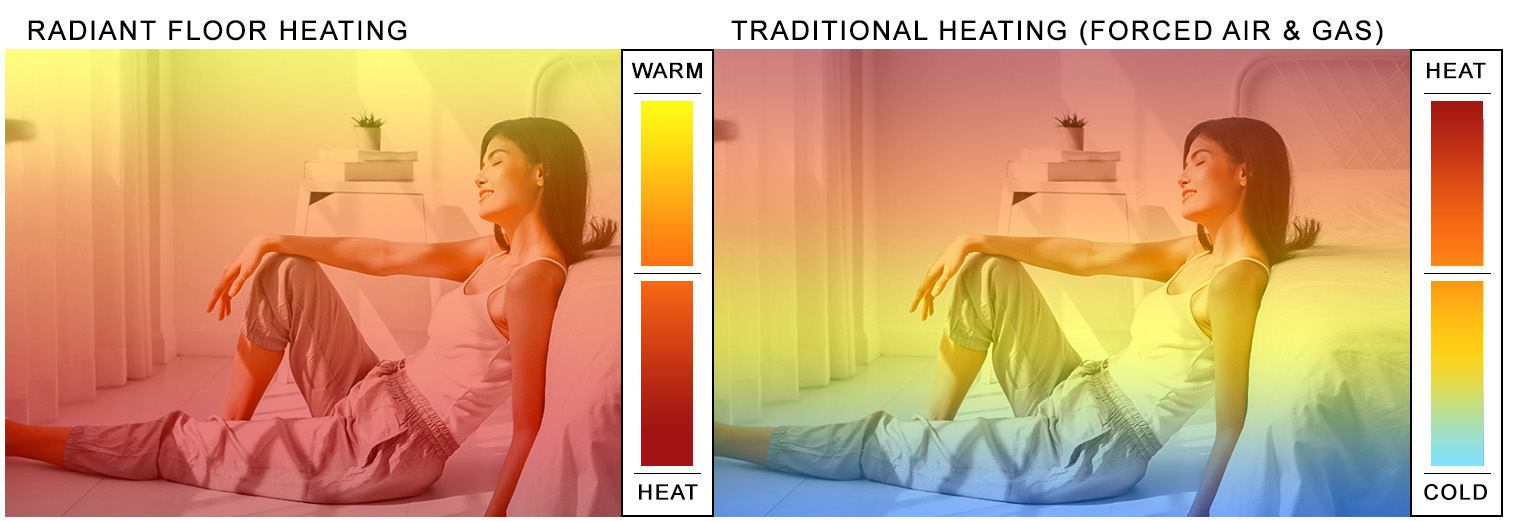

The Solution: To address this issue, consider transitioning to a radiant heating system, which provides consistent, floor-to-ceiling warmth. Radiant heating eliminates drafts and cold spots, delivering heat directly to occupants rather than relying on air movement. When specifying the system, focus on the layout—installing radiant floor heating in areas with the highest foot traffic can enhance comfort. Additionally, combining radiant heating with a smart thermostat allows for room-by-room temperature control, ensuring that heating is tailored to the needs of different spaces. This targeted approach can lead to significant energy savings and improved employee satisfaction.

Scenario 2: High Energy Costs and Inefficiency

The Problem: A B2B buyer for a manufacturing facility is grappling with rising energy costs due to an aging forced air heating system. Frequent repairs and maintenance, coupled with heat loss through ductwork, have made it increasingly difficult to manage the budget. The buyer realizes that the inefficient distribution of heat results in wasted energy, directly impacting the bottom line.

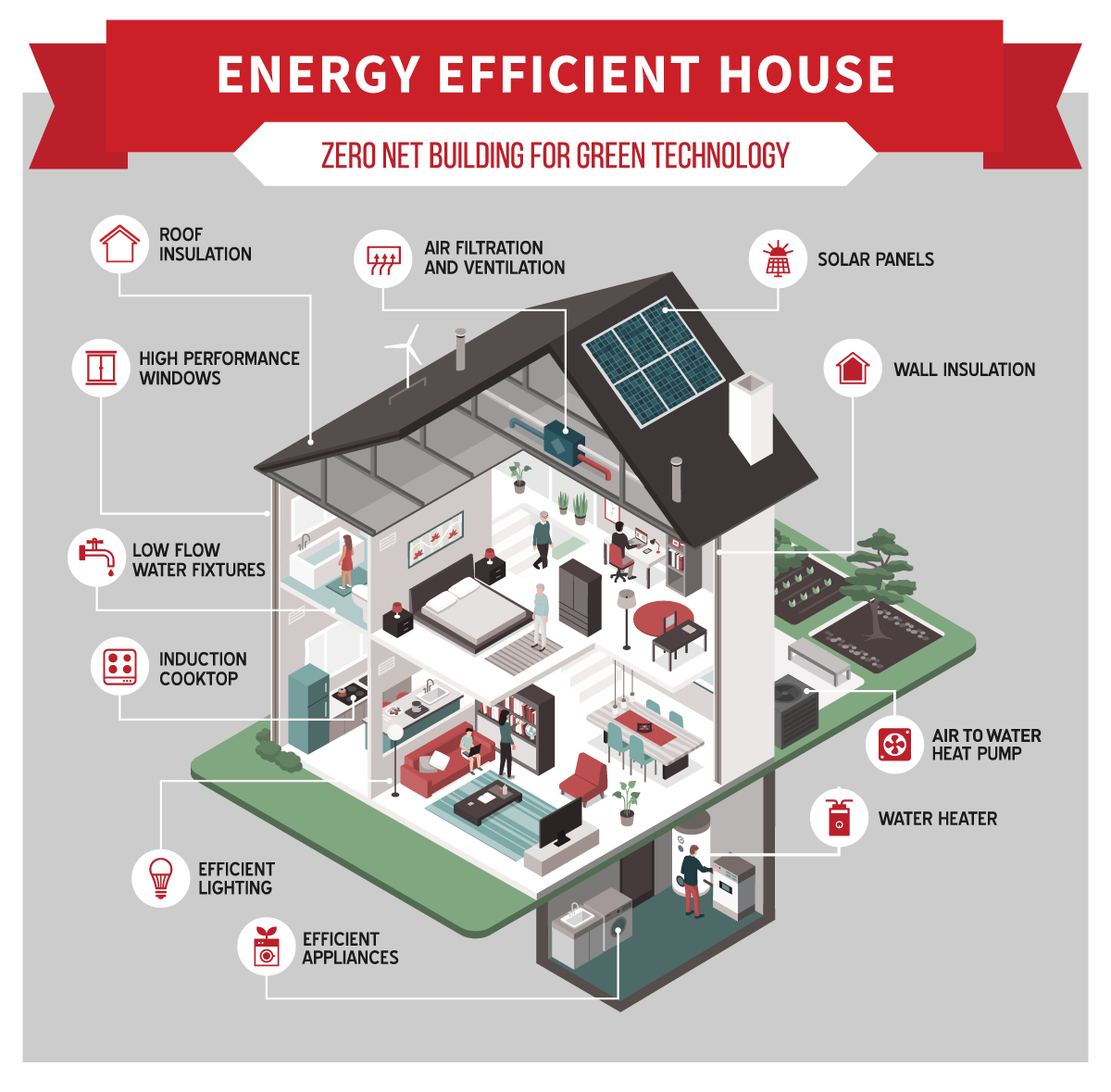

The Solution: Switching to a radiant heating system can provide a long-term solution to this problem. Radiant systems operate with higher energy efficiency, as they eliminate the losses associated with ductwork. When implementing this change, conduct a thorough energy audit to identify the specific heating needs of different areas within the facility. Investing in high-quality, programmable thermostats allows for precise temperature control, ensuring that only occupied areas are heated. Furthermore, consider integrating renewable energy sources, such as solar panels, to power the radiant heating system, further reducing energy costs and environmental impact.

Scenario 3: Concerns About Indoor Air Quality

The Problem: A healthcare facility’s operations manager is increasingly concerned about indoor air quality (IAQ). The existing forced air system circulates dust, allergens, and pathogens throughout the building, posing a risk to patients and staff. The constant cycling of air can aggravate respiratory issues, especially for vulnerable populations, and compliance with health regulations is becoming more challenging.

The Solution: Transitioning to radiant heating can significantly improve IAQ by reducing the circulation of dust and allergens. Since radiant systems do not rely on air movement, they do not stir up particles that can compromise air quality. When specifying the installation, choose a hydronic radiant heating system that utilizes water for heat transfer, as it typically offers better efficiency and comfort. Ensure the system is integrated with advanced air filtration and ventilation systems that can manage fresh air intake without compromising the benefits of radiant heating. Regular maintenance and monitoring of both the heating and air quality systems will further ensure compliance with health standards, creating a safer environment for all occupants.

Strategic Material Selection Guide for radiant heat vs forced air

What Are the Key Materials Used in Radiant Heat and Forced Air Systems?

When considering heating systems, the choice of materials can significantly influence performance, durability, and overall efficiency. Here, we analyze common materials used in radiant heat and forced air systems, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Copper

Key Properties:

Copper is highly conductive, making it an excellent choice for radiant heating systems. It can withstand high temperatures and pressures, with a melting point of approximately 1,984°F (1,085°C). Copper is also resistant to corrosion, particularly in water-based heating systems.

Pros & Cons:

Copper’s durability and thermal efficiency make it a preferred material for both residential and commercial radiant heating applications. However, it is relatively expensive compared to alternatives like PEX (cross-linked polyethylene). The manufacturing complexity is moderate, as it requires specialized tools for installation.

Impact on Application:

Copper is particularly effective in hydronic systems, where hot water circulates through pipes. Its compatibility with various media makes it versatile for different heating applications.

Considerations for International Buyers:

Copper complies with international standards such as ASTM B88 for water tubing. However, its cost may be a barrier in developing regions, necessitating a careful cost-benefit analysis.

2. PEX (Cross-Linked Polyethylene)

Key Properties:

PEX is flexible, lightweight, and resistant to scale and chlorine, making it suitable for radiant heating systems. It can handle temperatures up to 200°F (93°C) and pressures up to 80 psi.

Pros & Cons:

The primary advantage of PEX is its lower cost and ease of installation, as it can be snaked into walls and floors without the need for fittings. However, it is less durable than copper and can be susceptible to UV degradation if exposed.

Impact on Application:

PEX is ideal for both hydronic and forced air systems, especially in areas where flexibility and ease of installation are critical. Its compatibility with various heating media enhances its application scope.

Considerations for International Buyers:

PEX must meet standards such as ASTM F876. Buyers in regions with extreme temperature variations should ensure that the PEX used is rated for such conditions.

3. Steel

Key Properties:

Steel is known for its strength and ability to withstand high pressures. It has a melting point of around 2,500°F (1,370°C) and offers good thermal conductivity.

Pros & Cons:

Steel is durable and can last for decades, making it a reliable choice for both radiant and forced air systems. However, it is heavier and more challenging to install than PEX or copper, and it can be prone to corrosion if not properly treated.

Illustrative image related to radiant heat vs forced air

Impact on Application:

Steel is commonly used in forced air ducting and can also be utilized in radiant heating systems, particularly in commercial applications where high durability is required.

Considerations for International Buyers:

Steel must comply with standards such as ASTM A53 for pipes. Buyers in humid or coastal regions should consider additional corrosion-resistant coatings to ensure longevity.

4. Aluminum

Key Properties:

Aluminum is lightweight and has excellent thermal conductivity, with a melting point of about 1,221°F (660°C). It is also resistant to corrosion, especially when anodized.

Pros & Cons:

Aluminum is cost-effective and easy to work with, making it a suitable option for both radiant and forced air systems. However, it can be less durable than steel and may require additional support in larger installations.

Illustrative image related to radiant heat vs forced air

Impact on Application:

Aluminum is often used in forced air systems for ductwork and in radiant heating panels. Its lightweight nature allows for easier installation and modification.

Considerations for International Buyers:

Aluminum must meet standards such as ASTM B221. Buyers should be aware of local preferences for material use, especially in regions with specific building codes.

Summary Table

| Material | Typical Use Case for radiant heat vs forced air | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Hydronic radiant heating systems | Excellent thermal conductivity | High cost | High |

| PEX | Radiant and forced air systems | Cost-effective and easy to install | Susceptible to UV degradation | Medium |

| Steel | Forced air ducting and commercial radiant systems | Durable and long-lasting | Heavy and challenging to install | Medium |

| Aluminum | Ductwork in forced air systems and radiant panels | Lightweight and easy to work with | Less durable than steel | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in radiant heat and forced air systems, allowing for informed decision-making based on performance, cost, and application suitability.

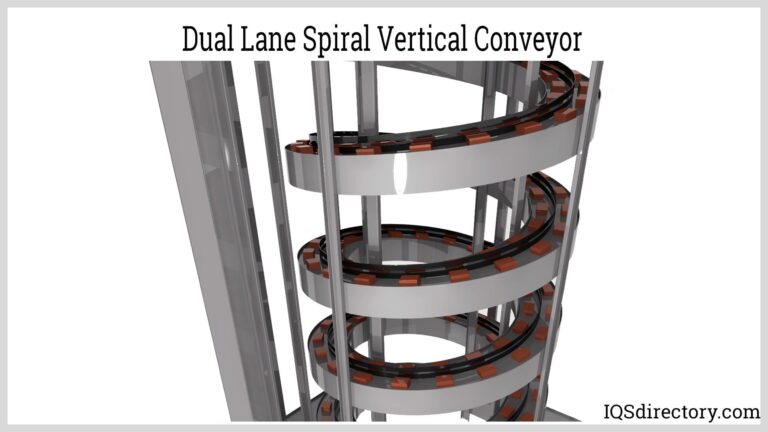

In-depth Look: Manufacturing Processes and Quality Assurance for radiant heat vs forced air

What Are the Key Stages in the Manufacturing Process for Radiant Heat and Forced Air Systems?

The manufacturing processes for radiant heat and forced air systems involve several critical stages, each designed to ensure efficiency, performance, and compliance with international standards. Understanding these stages can help B2B buyers make informed decisions when evaluating suppliers.

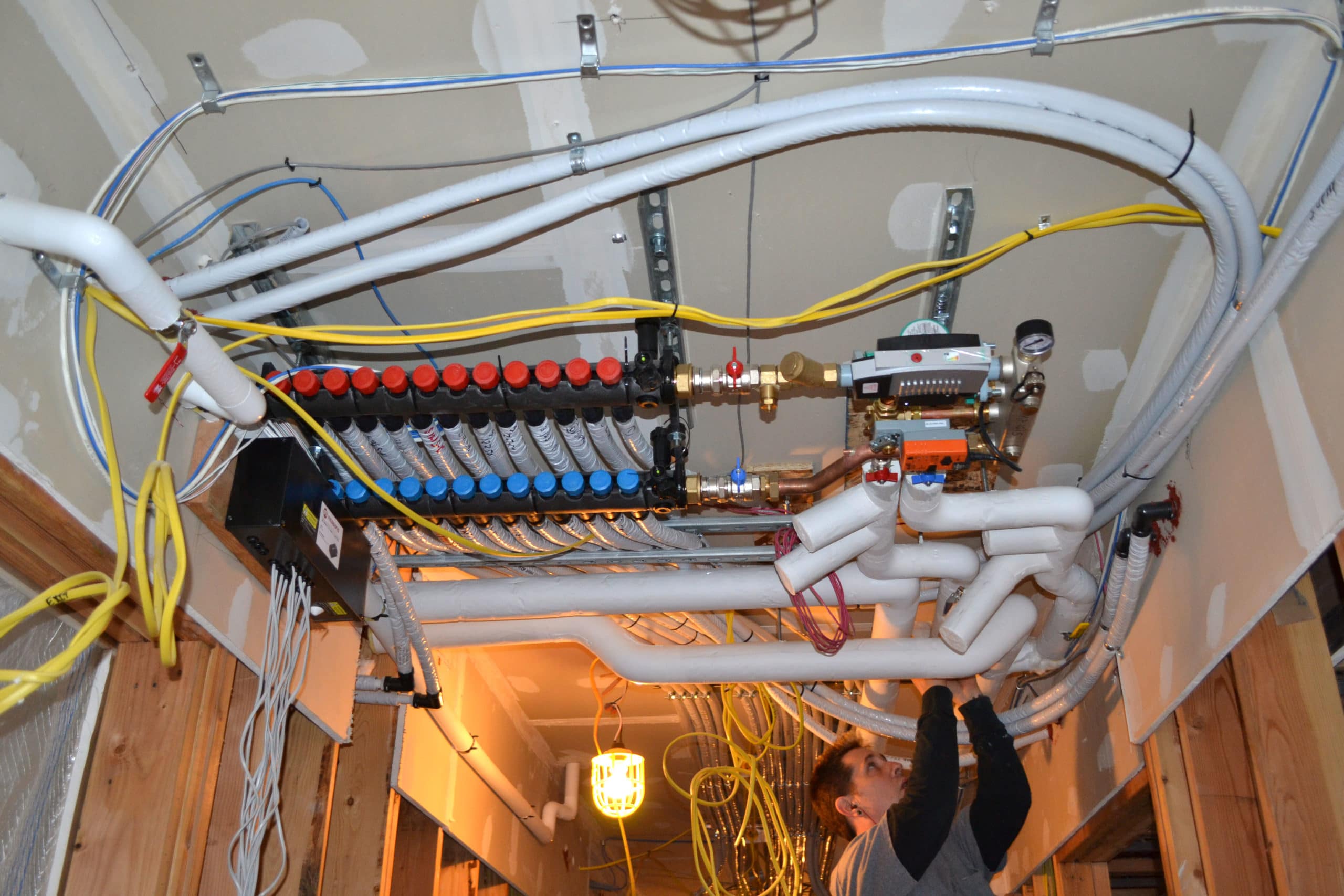

Material Preparation: What Materials Are Used in Each System?

The first stage in manufacturing involves selecting high-quality materials that meet industry standards. For radiant heating systems, materials commonly include:

Illustrative image related to radiant heat vs forced air

- Piping (for hydronic systems): Typically made of durable polyethylene or copper, these materials ensure efficient heat transfer and longevity.

- Electrical components (for electric systems): Copper wires and specialized heating elements designed to withstand high temperatures are essential.

- Insulation materials: To minimize heat loss, manufacturers often use foam or fiberglass insulation.

In contrast, forced air systems primarily utilize:

- Sheet metal: For ductwork, often galvanized steel or aluminum, which provides durability and resistance to corrosion.

- Furnace components: Typically include cast iron or stainless steel for heat exchangers, ensuring efficient heat transfer and structural integrity.

- Blowers and motors: These are usually made from high-grade metal and plastic composites designed for optimal airflow and energy efficiency.

How Are Radiant Heat and Forced Air Systems Formed and Assembled?

The forming and assembly processes differ significantly between radiant heating and forced air systems.

-

Radiant Heating Systems: The manufacturing process may involve molding or extruding the heating elements for electric systems. For hydronic systems, the pipes are formed and connected to create a network that will be embedded in flooring. This requires precision to ensure that the heating elements are evenly distributed to prevent hot or cold spots.

-

Forced Air Systems: Sheet metal is cut and shaped into ductwork using techniques such as stamping and bending. The assembly involves connecting the furnace, ducts, blowers, and thermostats into a cohesive unit. The focus here is on ensuring airtight connections to prevent energy loss.

What Finishing Techniques Are Applied to Ensure Quality?

Finishing processes enhance durability and performance. In radiant heating systems, elements may undergo:

- Coating: To prevent corrosion, especially for hydronic systems that use water.

- Testing for thermal efficiency: Ensuring that the system operates within specified heat output ranges.

For forced air systems, finishing techniques include:

- Sealing: Ducts are often sealed with mastic or foil tape to prevent air leaks.

- Surface treatments: Applied to furnace components to improve heat transfer and reduce wear over time.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that products meet both regulatory and customer expectations. B2B buyers must be aware of the QA measures taken by suppliers.

What International Standards Guide Quality Assurance in Manufacturing?

Manufacturers of both radiant heat and forced air systems often adhere to international standards like ISO 9001, which outlines requirements for a quality management system. Compliance with specific industry standards, such as:

- CE Marking: For products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Relevant for manufacturers of heating systems that may interact with petrochemical processes.

These certifications not only enhance product credibility but also ensure that the manufacturing processes are consistent and reliable.

Which Quality Control Checkpoints Are Critical in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is essential. This includes checking the alignment of ductwork, testing heating elements for functionality, and ensuring that assembly processes adhere to specifications.

-

Final Quality Control (FQC): Before products are shipped, they undergo a final inspection to verify that they meet all performance and safety standards. This may involve operational testing of the heating systems and checking for any defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, must have a strategy for verifying supplier quality control practices.

What Methods Can Buyers Use to Assess Supplier Quality?

-

Audits: Conducting on-site audits of the manufacturing facilities allows buyers to evaluate quality control processes firsthand. This can include reviewing documentation, assessing manufacturing equipment, and observing the QA practices in action.

-

Quality Reports: Requesting detailed quality reports that outline the results of IQC, IPQC, and FQC processes can provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services to evaluate the manufacturing process and final products can add an additional layer of assurance. These inspections can verify compliance with international standards and assess the quality of materials used.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers must navigate various nuances when sourcing heating systems.

-

Regulatory Compliance: Different regions may have specific regulations governing heating systems. Buyers should ensure that suppliers comply with local laws and standards.

-

Cultural Expectations: Understanding the cultural context regarding quality and reliability can influence supplier selection. For instance, some regions may prioritize energy efficiency more than others.

-

Supply Chain Stability: Buyers should consider the supplier’s ability to maintain consistent quality amid global supply chain challenges, which may affect raw material availability and pricing.

By understanding the manufacturing processes and quality assurance measures for radiant heat and forced air systems, B2B buyers can make informed decisions that align with their operational needs and regional requirements. This knowledge not only enhances procurement strategies but also supports long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘radiant heat vs forced air’

Introduction

This guide serves as a practical sourcing checklist for B2B buyers evaluating radiant heat and forced air heating systems. By following these steps, decision-makers can ensure they make informed choices that align with their operational needs, budget constraints, and sustainability goals.

Step 1: Define Your Technical Specifications

Establish the technical specifications for your heating requirements based on the size and layout of your facility. Consider factors such as insulation quality, room dimensions, and intended use of each space. This clarity will help you determine whether radiant heat or forced air is more suitable for your needs.

Step 2: Assess Energy Efficiency and Cost Implications

Evaluate the energy efficiency ratings of both systems, as this will significantly impact long-term operational costs. Look for systems with high Energy Efficiency Ratios (EER) and Seasonal Energy Efficiency Ratios (SEER) for forced air, and consider the thermal efficiency of radiant heating systems. Understanding these metrics helps you forecast energy expenses and make cost-effective decisions.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality standards. Request detailed company profiles, case studies, and references from other businesses in your sector or region. A reputable supplier should be able to demonstrate successful installations and provide evidence of their systems’ performance and reliability.

Step 4: Examine Installation and Maintenance Requirements

Consider the installation complexity and maintenance needs of each heating system. Radiant heating systems, while efficient, may require more intricate installation and can be challenging to access for repairs. Conversely, forced air systems might need regular duct cleaning and filter replacements. Understanding these requirements will help you allocate resources effectively and minimize downtime.

Step 5: Review Compatibility with Existing Infrastructure

Assess how each heating option aligns with your current building infrastructure. If ductwork is already in place, forced air may be more feasible and cost-effective. However, if you are starting from scratch or undergoing renovations, radiant heating can offer enhanced comfort and efficiency. Evaluate the adaptability of both systems to your existing setup.

Step 6: Consider Environmental Impact and Sustainability

Investigate the environmental impact of each heating system. Radiant heating tends to be more energy-efficient and can utilize renewable energy sources, which may align better with sustainability goals. Forced air systems, while effective, can lead to energy waste through duct losses. This assessment will help you choose a system that supports your corporate responsibility initiatives.

Step 7: Gather Feedback from Stakeholders

Finally, involve key stakeholders in the decision-making process. Gather input from facilities management, finance, and operations teams to understand their perspectives on comfort, budget, and maintenance. This collaborative approach ensures that the chosen heating system meets the diverse needs of your organization.

By following this checklist, B2B buyers can make well-rounded decisions when sourcing between radiant heat and forced air systems, leading to improved operational efficiency and comfort in their facilities.

Comprehensive Cost and Pricing Analysis for radiant heat vs forced air Sourcing

What Are the Key Cost Components for Radiant Heat and Forced Air Systems?

When evaluating the costs associated with radiant heat and forced air systems, several key components must be considered. For both heating solutions, the primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: Radiant heating systems typically require specialized materials such as heating cables, mats, and insulation. Conversely, forced air systems rely on furnaces, ductwork, and air filters. The quality and type of materials significantly influence the overall cost. High-quality, energy-efficient materials may incur higher upfront costs but can lead to long-term savings.

-

Labor: Installation costs vary widely based on system complexity. Radiant heating installations often demand skilled labor, particularly for floor systems, which can increase labor costs. Forced air systems, while generally easier to install, can also require significant labor if ductwork needs to be added or retrofitted.

-

Manufacturing Overhead: This encompasses all costs associated with production, including utilities, rent, and equipment maintenance. Both systems will have unique overhead costs depending on the manufacturing processes and technologies employed.

-

Tooling: Custom tooling may be required for specialized components, particularly in radiant systems that involve precise measurements and installations. Forced air systems typically have more standardized components, potentially reducing tooling costs.

-

Quality Control (QC): Ensuring product quality can add to the overall price. Radiant heating systems often undergo rigorous testing to meet safety and efficiency standards, which can increase manufacturing costs.

-

Logistics: Shipping costs can be substantial, especially for bulky forced air components like furnaces and duct systems. International shipping may introduce additional complexities, including customs duties and tariffs.

-

Margin: Supplier margins will vary based on market conditions, competition, and the perceived value of the heating solutions. Suppliers may offer varying margins based on their positioning in the market.

How Do Price Influencers Affect Radiant Heat and Forced Air Systems?

Several price influencers affect the cost of radiant heat and forced air systems, including volume or minimum order quantity (MOQ), specifications or customization, materials quality and certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Buyers should negotiate MOQs that align with their project needs to optimize costs.

-

Specifications/Customization: Custom solutions often come at a premium. Buyers should assess whether standard models meet their requirements, as opting for custom solutions can escalate costs.

-

Materials Quality/Certifications: Higher-quality materials may cost more but can result in lower energy costs and improved longevity. Certifications for energy efficiency or safety can also influence pricing.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer warranties and superior customer service, justifying higher costs.

-

Incoterms: Understanding shipping terms is crucial for international buyers. The choice of Incoterms can affect overall costs, including shipping liability and customs fees.

What Are the Best Buyer Tips for Cost-Efficiency in Heating Systems?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency when sourcing heating systems.

Illustrative image related to radiant heat vs forced air

-

Negotiate Wisely: Engage in negotiations with suppliers to secure better pricing, especially for larger orders. Leverage competition among suppliers to obtain favorable terms.

-

Consider Total Cost of Ownership (TCO): Beyond initial costs, evaluate the TCO, which includes installation, maintenance, and energy consumption over the system’s lifespan. Radiant heating may have a higher upfront cost but can offer lower operational costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local market conditions. This knowledge can help in negotiations and in understanding the pricing landscape.

-

Conduct Market Research: Stay informed about market trends and pricing benchmarks in the heating industry. This information can empower buyers to make informed decisions.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on specific project requirements, supplier negotiations, and market conditions. Always consult with suppliers for precise quotations tailored to your unique needs.

Alternatives Analysis: Comparing radiant heat vs forced air With Other Solutions

When evaluating heating solutions for commercial or industrial applications, it is crucial to explore various options beyond the commonly used radiant heat and forced air systems. Understanding alternative heating technologies can help B2B buyers make informed decisions that align with their specific operational needs, budget constraints, and environmental considerations.

Comparison Table

| Comparison Aspect | Radiant Heat Vs Forced Air | Electric Baseboard Heating | Hydronic Heating Systems |

|---|---|---|---|

| Performance | Even warmth; no drafts | Quick heat; localized | Efficient; consistent |

| Cost | Higher installation cost | Lower initial cost | Moderate to high cost |

| Ease of Implementation | Complex installation under flooring | Easy to install; plug-in options available | Requires plumbing installation |

| Maintenance | Low maintenance | Minimal maintenance | Moderate; regular checks needed |

| Best Use Case | Large, open spaces; new constructions | Small rooms; supplemental heat | Large areas; consistent heating |

Detailed Breakdown of Alternatives

Electric Baseboard Heating

Electric baseboard heating is a popular option for its simplicity and effectiveness in small spaces. These systems provide direct, localized heat through convection, making them ideal for individual rooms or as supplemental heating. Their installation is straightforward, often requiring only electrical connections, which can be appealing for retrofitting. However, they can lead to higher electricity bills if used extensively, and their reliance on electric power may not be viable in regions with inconsistent electricity supply.

Hydronic Heating Systems

Hydronic heating systems use hot water circulated through pipes to heat spaces. This method is known for its efficiency and ability to maintain consistent temperatures, making it suitable for larger facilities. Hydronic systems can be integrated with renewable energy sources, enhancing their sustainability profile. However, installation can be complex and costly, requiring professional plumbing expertise. Regular maintenance is essential to ensure optimal performance, particularly in preventing leaks and maintaining water quality.

Conclusion

When selecting the right heating solution, B2B buyers should consider their specific operational requirements, including the size of the space, budget constraints, and maintenance capacity. Radiant heat provides a comfortable and efficient option for large, open areas, while forced air systems may be better suited for environments that require both heating and cooling. Alternatives like electric baseboard and hydronic heating offer unique advantages, especially in smaller or specialized applications. Evaluating the pros and cons of each system will empower buyers to make strategic decisions that maximize comfort, efficiency, and cost-effectiveness in their heating solutions.

Essential Technical Properties and Trade Terminology for radiant heat vs forced air

What Are the Key Technical Properties for Radiant Heat and Forced Air Systems?

Understanding the technical properties of heating systems is crucial for B2B buyers when evaluating options for commercial or residential projects. Here are some essential specifications to consider:

-

Heating Efficiency Rating (AFUE for Forced Air, and R-value for Radiant)

– Definition: The Annual Fuel Utilization Efficiency (AFUE) measures the efficiency of forced air systems, indicating how much fuel is converted into heat. In contrast, the R-value measures thermal resistance for radiant systems, indicating how well a material insulates.

– B2B Importance: Higher efficiency ratings translate to lower operating costs and reduced energy consumption, which is critical for businesses looking to minimize expenses and meet sustainability goals. -

Heat Output Capacity (BTU/hr)

– Definition: British Thermal Units (BTUs) measure the heat output capacity of a heating system per hour. This specification is crucial for understanding the system’s ability to warm a given space effectively.

– B2B Importance: Buyers need to match the BTU output with the specific heating requirements of their facilities to ensure optimal performance, preventing both under-heating and excessive energy costs. -

Material Composition and Durability

– Definition: The materials used in heating systems, such as copper, aluminum, or polymer for radiant systems, and the metal grades for ductwork in forced air systems, significantly impact durability and performance.

– B2B Importance: Selecting high-grade materials ensures longevity and reduces maintenance costs, which is a critical consideration for procurement managers when evaluating long-term investments. -

Installation Requirements

– Definition: This includes the complexity of installation and the need for additional infrastructure, such as ductwork for forced air systems or floor retrofitting for radiant systems.

– B2B Importance: Understanding installation requirements helps businesses budget for initial setup costs and avoid unexpected expenses or delays. -

Noise Levels (Decibels)

– Definition: The sound produced by heating systems, particularly forced air systems, which can range from moderate to loud.

– B2B Importance: For businesses in noise-sensitive environments, such as hospitals or schools, lower noise levels can significantly enhance comfort and productivity.

What Trade Terminology Should B2B Buyers Know When Considering Heating Systems?

Familiarity with industry terminology can streamline the purchasing process and facilitate better communication with suppliers. Here are some common terms:

Illustrative image related to radiant heat vs forced air

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Knowing whether a system is sourced from an OEM can help buyers ensure they are purchasing high-quality, reliable products. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ can help businesses manage inventory levels and budget constraints effectively. -

RFQ (Request for Quotation)

– Definition: A standard business process where a buyer requests pricing and other details from suppliers for specific products or services.

– Importance: Submitting an RFQ can help buyers obtain competitive pricing and terms from multiple suppliers, leading to better procurement decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms can help businesses understand shipping responsibilities, costs, and risks associated with importing heating systems. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Importance: Knowing the lead time is essential for project planning, ensuring that heating systems are available when needed to avoid delays in construction or operational readiness. -

Warranty Period

– Definition: The duration for which a manufacturer guarantees their product against defects or failures.

– Importance: A longer warranty period can indicate manufacturer confidence in product quality and can significantly impact long-term operational costs.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and financial goals.

Navigating Market Dynamics and Sourcing Trends in the radiant heat vs forced air Sector

What Are the Global Drivers Influencing Radiant Heat and Forced Air Markets?

The heating sector is experiencing notable transformation driven by various global factors, including energy efficiency mandates, rising energy costs, and shifting consumer preferences towards sustainable solutions. International B2B buyers are increasingly looking for systems that not only provide comfort but also align with energy regulations in their regions. For instance, Europe is pushing for stringent energy efficiency standards, leading to a surge in the adoption of radiant heating systems that offer superior efficiency compared to traditional forced air systems.

Emerging markets, particularly in Africa and South America, are witnessing a growing demand for affordable and efficient heating solutions, driven by urbanization and increasing disposable incomes. In these regions, the forced air system remains popular due to its lower initial installation costs; however, the long-term operating costs often favor radiant heating options. Technological advancements, such as smart thermostats and integration with renewable energy sources, are also shaping sourcing trends. These innovations enhance the efficiency of both systems, making them more appealing to buyers who prioritize long-term sustainability.

How Are Sustainability and Ethical Sourcing Shaping the Heating Industry?

Sustainability is no longer a mere trend; it has become a core principle for B2B buyers in the heating sector. The environmental impact of heating systems is significant, with traditional forced air systems often contributing to higher energy consumption and greenhouse gas emissions due to duct losses and inefficiencies. In contrast, radiant heating systems are inherently more efficient, reducing overall energy usage and the carbon footprint associated with heating a space.

Moreover, the importance of ethical supply chains is gaining traction. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using eco-friendly materials and ensuring fair labor practices in their manufacturing processes. Certifications like Energy Star or LEED for radiant heating systems signal a commitment to sustainability and can enhance a supplier’s marketability. By prioritizing ‘green’ certifications and materials, businesses can not only meet regulatory requirements but also appeal to environmentally conscious consumers, thus enhancing their brand reputation and market position.

What Is the Historical Context of Heating Solutions for B2B Buyers?

The evolution of heating solutions has shifted dramatically over the past century, primarily influenced by technological advancements and changing energy landscapes. Initially, forced air systems dominated the market due to their relatively low installation costs and ease of use. However, as energy costs rose and environmental concerns became more pronounced, the limitations of forced air systems—such as heat loss through ducts and air quality issues—came to the forefront.

In contrast, radiant heating emerged as a more efficient alternative, gaining traction in both residential and commercial sectors. Its ability to provide consistent warmth without the drawbacks associated with forced air systems has made it increasingly popular in modern construction and renovation projects. As B2B buyers look for sustainable and cost-effective solutions, the historical context underscores a shift towards radiant heating, positioning it as a viable option for those aiming to balance comfort with environmental responsibility.

By understanding these market dynamics, sustainability considerations, and historical context, international B2B buyers can make informed decisions when sourcing heating systems that best meet their needs and align with global trends.

Frequently Asked Questions (FAQs) for B2B Buyers of radiant heat vs forced air

-

How do I choose between radiant heat and forced air for my project?

Choosing between radiant heat and forced air depends on several factors, including your project’s specific needs, budget, and local climate. Radiant heat offers consistent, even warmth and better air quality, making it ideal for spaces prone to allergens. However, it can be more expensive to install for whole-house heating. Forced air systems, while generally cheaper to install and capable of cooling, often suffer from heat loss and can stir up dust. Consider the long-term operational costs and efficiency when making your decision. -

What is the best heating system for large commercial spaces?

For large commercial spaces, the best heating system often depends on the building’s layout and usage. Forced air systems can quickly heat large areas and are easier to install if ductwork is already present. However, radiant heating is increasingly favored for its energy efficiency and comfort, especially in environments where air quality is a concern. Evaluate the specific heating requirements and consult with heating system specialists to determine the most effective solution for your space. -

What are the typical lead times for sourcing radiant heat and forced air systems?

Lead times for sourcing heating systems can vary significantly based on the manufacturer, location, and order size. Generally, forced air systems may have shorter lead times due to their widespread availability and established supply chains. Radiant heating systems, particularly custom installations, might require longer lead times. It’s advisable to plan ahead and communicate with suppliers about their current inventory and expected delivery times to ensure your project remains on schedule. -

What are the minimum order quantities (MOQ) for radiant heat and forced air systems?

Minimum order quantities for heating systems can differ among suppliers and depend on the type of system being purchased. Radiant heat systems often have higher MOQs due to their specialized components and installation requirements. Conversely, forced air systems may have more flexible MOQs, especially for standard models. Always check with potential suppliers to understand their MOQ policies and negotiate terms that align with your project needs. -

How do I vet suppliers for heating systems?

Vetting suppliers for heating systems involves assessing their credibility, experience, and product offerings. Start by researching their industry reputation, checking reviews, and asking for references from previous clients. Ensure they provide warranties and after-sales support for their products. Additionally, consider suppliers that adhere to international quality standards and certifications, especially for projects in regions with strict regulations on heating systems. -

What payment terms are common in international B2B transactions for heating systems?

Payment terms in international B2B transactions can vary widely but typically include options like advance payment, net 30/60/90 days, or letters of credit. It’s important to negotiate terms that protect both parties and allow for smooth cash flow. Consider using escrow services for large transactions to ensure that funds are released only when agreed-upon conditions are met. Always clarify any potential currency conversion fees and ensure compliance with local regulations. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers should have robust quality assurance (QA) processes in place to ensure their heating systems meet industry standards. This includes thorough testing of products before shipment, adherence to international quality certifications, and clear documentation of compliance. Ask potential suppliers about their QA protocols, including testing methods, inspection procedures, and how they handle defective products. A transparent QA process is essential for ensuring reliability and performance in your heating systems. -

What logistics considerations should I be aware of when importing heating systems?

When importing heating systems, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling heating equipment to navigate the complexities of international shipping. Ensure that all documentation, including bills of lading and import permits, is in order to avoid delays. Additionally, factor in lead times for customs clearance and local delivery, as these can impact your project timelines significantly.

Top 8 Radiant Heat Vs Forced Air Manufacturers & Suppliers List

1. Warmly Yours – Radiant Heat vs Forced Air Heating

Domain: warmlyyours.com

Registered: 1998 (27 years)

Introduction: Radiant Heat vs Forced Air heating systems; Radiant heating provides comfort, improved air quality, and efficiency; Forced air heating uses furnaces and ductwork to distribute warm air; Common heating fuels include oil, natural gas, electricity, propane, and wood; Pros of forced air systems: heats and cools, improves air quality with filters, fast heating; Cons of forced air systems: prone to air …

2. Reddit – Radiant Heating Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Radiant heating is noted for its efficiency and ability to maintain consistent temperatures without cold spots. It uses a water heater, with options for tankless units, and can be powered by gas or electricity. Installation costs can be high, but it is praised for lower energy bills compared to forced air systems. Forced air systems are criticized for moving dust and requiring more frequent cleani…

3. GBD Magazine – Forced Air Systems

Domain: gbdmagazine.com

Registered: 2009 (16 years)

Introduction: Forced Air Systems:

– Description: Use ducts to transport and blow heated or cooled air into a space.

– Pros:

– Speed: Heats and distributes air faster than radiant systems.

– Affordable: Lower installation costs compared to radiant systems.

– Easy installation: Compatible with existing ductwork.

– Cons:

– Not as energy-efficient as radiant systems.

– Can contribute to poor air q…

4. Garage Journal – Heating Solutions Comparison

Domain: garagejournal.com

Registered: 2006 (19 years)

Introduction: 1. **Heating Options**: In-floor radiant hydronic heating vs. forced air heating.

2. **Structure Size**: 2,304 sq. ft. interior area; 60’x30′ main structure with 16′ ceilings; additional enclosed areas in lean-to’s.

3. **Cost Considerations**: Initial bid for radiant heating system was $60k, including in-slab heat tubes, gas boiler, controls, venting, gas tubing, under-slab insulation, and wir…

5. Meyer Air – Forced Air Heating and Cooling System

Domain: meyerair.com

Registered: 2012 (13 years)

Introduction: Forced Air: Distributes warm or cool air through ducts, ideal for homes needing both heating and cooling. Operates via a central furnace or heat pump, using a fan to push air through ducts. Pros: Versatile, integrates with air conditioning, includes air filtration, heats quickly, cost-effective installation. Cons: Circulates dust/allergens, noisy operation, can dry out air, temperature stratificat…

6. Today’s Homeowner – Radiant Floor Heating Guide

Domain: todayshomeowner.com

Registered: 1996 (29 years)

Introduction: Radiant Floor Heating: Installation cost ranges from $10-$15 per square foot for electric systems (plus $5-$10 for installation); hydronic systems can cost up to twice as much. Provides even warmth, energy-efficient, silent operation. Types include Electric Mats (easy DIY, not for irregular shapes), Electric Single-Wire (customizable, requires professional installation), and Hydronic Systems (uses…

7. Fine Homebuilding – Radiant Heating Systems

Domain: finehomebuilding.com

Registered: 1997 (28 years)

Introduction: Radiant heating systems using propane boilers in south-central Colorado are reported to have high annual heating costs, with one contractor noting that radiant heated homes can have double the yearly heating costs compared to forced air systems. Radiant heating is noted for its higher upfront costs but questions remain about its annual cost efficiency. In colder regions, radiant heating is preferr…

8. Radiant Heat – Forced Air Comparison

Domain: radiantheat.net

Registered: 1998 (27 years)

Introduction: Forced Air vs. Radiant Heat Comparison: 1. Heat Distribution: Radiant heat warms objects and people directly, improving body circulation and keeping floors warm, while forced air heats the air, leading to hot ceilings and cold spots. 2. Cleanliness: Radiant heat keeps furniture and surfaces clean as it does not blow dust and dirt around, unlike forced air systems which can circulate airborne parti…

Strategic Sourcing Conclusion and Outlook for radiant heat vs forced air

In evaluating the strategic sourcing of heating systems, the choice between radiant heat and forced air is pivotal for international buyers. Radiant heating offers numerous advantages, including enhanced comfort through even temperature distribution, improved air quality, and energy efficiency. This system’s ability to provide targeted heating makes it particularly appealing in regions with varying climate needs, such as Africa and the Middle East, where energy costs are a critical concern. Conversely, forced air systems, while prevalent and capable of heating and cooling, often suffer from inefficiencies related to heat loss and air quality issues.

Illustrative image related to radiant heat vs forced air

For B2B buyers, strategic sourcing should prioritize not only the initial costs but also the long-term operational efficiency and comfort that these systems provide. Understanding local fuel availability, installation challenges, and maintenance requirements is essential for making informed decisions that align with business goals and sustainability initiatives.

As the market continues to evolve, forward-thinking organizations should consider investing in radiant heating solutions that align with modern energy standards and consumer preferences. Embrace the opportunity to enhance your facilities with efficient heating options that foster productivity and comfort, setting your organization apart in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to radiant heat vs forced air

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.