A B2B Buyer’s Guide to Double End Threaded Stud Screw Bolt: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for double end threaded stud screw bolt

In the ever-evolving landscape of global commerce, sourcing double end threaded stud screw bolts poses unique challenges for B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe—including key markets like Germany and Vietnam—understanding the nuances of this essential fastener is critical to maintaining operational efficiency. This guide comprehensively addresses the complexities associated with double end threaded stud screw bolts, including their various types, applications, and the importance of supplier vetting.

Buyers will gain insights into the specific thread sizes and materials available, from stainless steel to black oxide finishes, ensuring they can select the right products for their unique needs. Additionally, we will explore cost considerations, helping businesses budget effectively while maximizing value. By equipping international B2B buyers with this knowledge, the guide empowers informed purchasing decisions that can significantly impact project timelines and overall success.

Navigating the global market for double end threaded stud screw bolts can be daunting, but with the right information and strategies, buyers can confidently secure the fasteners that meet their specifications. This guide serves as a valuable resource, demystifying the procurement process and enabling organizations to enhance their supply chains in today’s competitive environment.

Understanding double end threaded stud screw bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Double Ended Stud | Equal length threads on both ends; various sizes | Construction, automotive, machinery | Pros: Versatile, widely available. Cons: Limited load capacity compared to other types. |

| Wrench Flat Double Ended Stud | Flat sections for wrench use; typically heavier duty | Heavy machinery, structural applications | Pros: Enhanced torque application. Cons: May require specialized tools for installation. |

| Metric Double Ended Stud | Metric thread sizes; often used in European markets | Automotive, electronics, industrial equipment | Pros: Meets international standards. Cons: Sizing can be confusing for non-metric systems. |

| Stainless Steel Double Ended Stud | Corrosion-resistant; ideal for outdoor applications | Marine, chemical processing | Pros: High durability, weather resistance. Cons: Generally higher cost than steel options. |

| Custom Length Double Ended Stud | Made to specific lengths; tailored to project needs | Specialized machinery, custom builds | Pros: Perfect fit for unique applications. Cons: Longer lead times and potential for higher costs. |

What Are the Characteristics of Standard Double Ended Studs?

Standard double ended studs feature equal-length threads on both ends, allowing for versatile applications across various industries. They are commonly found in construction, automotive, and machinery sectors. When purchasing, buyers should consider the thread size and overall length to ensure compatibility with existing components. These studs are readily available and typically cost-effective, making them a popular choice for bulk orders. However, they may have limitations in load capacity, which should be assessed based on the specific application.

How Do Wrench Flat Double Ended Studs Enhance Performance?

Wrench flat double ended studs are designed with flat sections that enable the use of wrenches for installation, providing a secure grip during tightening. These are often utilized in heavy machinery and structural applications where greater torque is required. Buyers should evaluate the stud’s material and grade to match the strength needs of their projects. While these studs offer enhanced performance, they may necessitate specialized tools, which could add to the overall project cost.

Why Are Metric Double Ended Studs Important for International Markets?

Metric double ended studs are essential for industries operating in regions that adhere to metric standards, particularly in Europe and parts of Asia. They come in various metric thread sizes and are crucial for automotive and electronic applications. Buyers must ensure they are familiar with metric specifications to avoid compatibility issues. While these studs meet international standards, their sizing can be a challenge for those accustomed to imperial measurements, necessitating careful attention during the purchasing process.

What Advantages Do Stainless Steel Double Ended Studs Offer?

Stainless steel double ended studs are known for their corrosion resistance, making them ideal for outdoor and marine applications. They are widely used in chemical processing industries where exposure to harsh conditions is common. Buyers should consider the grade of stainless steel to ensure it meets the specific environmental demands of their application. Although these studs come at a premium price compared to standard steel options, their longevity and durability can justify the investment, especially in corrosive environments.

How Do Custom Length Double Ended Studs Cater to Unique Needs?

Custom length double ended studs are tailored to meet specific project requirements, providing a perfect fit for specialized machinery or custom builds. These studs can significantly enhance the efficiency of assembly processes by eliminating the need for additional cutting or adjustments. Buyers should anticipate longer lead times when ordering custom lengths, which can affect project timelines. While they may incur higher costs, the benefits of precision and reduced labor can outweigh these factors in specialized applications.

Key Industrial Applications of double end threaded stud screw bolt

| Industry/Sector | Specific Application of double end threaded stud screw bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Used for securing structural components in buildings | Provides enhanced strength and stability to structures | Ensure compliance with local building codes and standards. |

| Automotive | Fastening components in vehicle assembly | Improves assembly efficiency and vehicle durability | Consider material specifications for corrosion resistance. |

| Oil and Gas | Connecting pipes and equipment in drilling operations | Ensures leak-proof connections under high pressure | Verify compatibility with high-pressure and temperature applications. |

| Manufacturing | Assembling machinery and equipment | Facilitates quick assembly and maintenance | Focus on thread specifications and lengths for specific machinery. |

| Aerospace and Defense | Securing components in aircraft and military vehicles | Critical for safety and performance under extreme conditions | Source high-grade materials to meet stringent safety regulations. |

How Are Double End Threaded Stud Screw Bolts Used in the Construction Industry?

In the construction sector, double end threaded stud screw bolts are vital for securing structural components such as beams, columns, and frames. Their dual-thread design allows for efficient fastening in tight spaces, providing robust connections that enhance the stability of buildings. For international buyers, especially in regions like Africa and the Middle East, it’s crucial to ensure that these fasteners comply with local building codes and standards, which may vary significantly. Buyers should also consider the environmental conditions, as factors like humidity and temperature can affect material choice.

What Role Do Double End Threaded Stud Screw Bolts Play in the Automotive Sector?

In the automotive industry, double end threaded stud screw bolts are commonly used to fasten various components during vehicle assembly, such as engine parts and chassis. Their ability to provide a secure and reliable connection enhances vehicle durability and performance. For B2B buyers in South America and Europe, sourcing bolts that meet specific material specifications, particularly for corrosion resistance, is essential. This ensures that the fasteners can withstand the rigors of different driving conditions and environmental factors, contributing to vehicle longevity.

How Are Double End Threaded Stud Screw Bolts Applied in the Oil and Gas Industry?

In the oil and gas sector, double end threaded stud screw bolts are crucial for connecting pipes and securing equipment in drilling and production operations. Their robust design ensures leak-proof connections, which is vital in preventing hazardous spills and maintaining safety standards. International buyers, particularly from regions with harsh operational environments, must verify the compatibility of these bolts with high-pressure and temperature applications. This includes assessing material grades and coatings that can withstand corrosive substances commonly found in oil and gas extraction.

What Benefits Do Double End Threaded Stud Screw Bolts Provide in Manufacturing?

Within manufacturing, double end threaded stud screw bolts are used extensively for assembling machinery and equipment. Their design facilitates quick assembly and ease of maintenance, which can significantly reduce downtime in production processes. For B2B buyers, especially those in Europe and Asia, focusing on the specifications of thread sizes and lengths is critical to ensure compatibility with specific machinery requirements. Additionally, understanding the manufacturing processes and quality standards of suppliers can help in sourcing reliable fasteners that enhance operational efficiency.

How Are Double End Threaded Stud Screw Bolts Critical in Aerospace and Defense?

In the aerospace and defense industries, double end threaded stud screw bolts are essential for securing components in aircraft and military vehicles. Their reliability is critical for safety and performance, especially under extreme conditions. For buyers in this sector, sourcing high-grade materials that meet stringent safety regulations is paramount. This includes considerations for weight, strength, and resistance to fatigue, ensuring that the fasteners can perform reliably throughout their lifecycle in demanding environments.

3 Common User Pain Points for ‘double end threaded stud screw bolt’ & Their Solutions

Scenario 1: Sourcing the Right Thread Size for Specific Applications

The Problem: B2B buyers often face difficulties in sourcing double end threaded stud screw bolts that meet specific thread size requirements. This challenge can lead to project delays and increased costs if the wrong sizes are ordered. For instance, a manufacturer in the automotive industry may require M12-1.75 mm threads for their assembly lines. If they mistakenly source a different size, it can halt production and necessitate additional shipping costs to rectify the mistake.

The Solution: To effectively source the correct thread sizes, buyers should invest in a comprehensive understanding of their applications and specifications. It’s advisable to maintain a detailed inventory of the required sizes, including both metric and imperial measurements, as various regions may use different standards. Collaborating closely with suppliers who can provide clear specifications and samples can also minimize errors. Moreover, utilizing digital tools or databases that offer a complete catalog of available sizes can streamline the ordering process. Establishing a reliable supplier relationship can ensure that the buyer has access to a range of options, reducing the chances of misordering.

Scenario 2: Managing Bulk Orders and Inventory Levels

The Problem: For many international B2B buyers, managing inventory levels and bulk orders of double end threaded stud screw bolts can be a logistical nightmare. Companies in construction or manufacturing often require large quantities, and fluctuating demand can lead to overstock or stockouts. This situation not only affects cash flow but can also disrupt project timelines, impacting overall productivity.

The Solution: To effectively manage inventory levels, buyers should implement a robust inventory management system that allows for real-time tracking of stock levels and usage rates. Utilizing software that integrates with existing procurement systems can provide insights into consumption patterns, enabling smarter bulk purchasing decisions. Additionally, establishing a Just-In-Time (JIT) inventory approach can help minimize excess stock while ensuring that necessary items are available when needed. Collaborating with suppliers on forecasting demand can also lead to more favorable terms and streamlined delivery schedules, ensuring that critical components like double end threaded stud screws are always on hand.

Scenario 3: Ensuring Quality and Compliance with International Standards

The Problem: B2B buyers often struggle with ensuring that the double end threaded stud screw bolts they source meet the necessary quality and compliance standards. This issue is particularly relevant for buyers in sectors such as aerospace or automotive, where safety and reliability are paramount. The risk of sourcing substandard products can lead to costly recalls, legal ramifications, and damage to the company’s reputation.

The Solution: To mitigate these risks, buyers should establish stringent quality control protocols that include sourcing from reputable suppliers who adhere to international standards such as ISO or ASTM. Requesting certifications and conducting audits on suppliers can ensure that products meet the required specifications. Additionally, implementing a testing protocol for incoming inventory can help identify any defects before the components are put into use. Collaborating with industry associations or quality assurance experts can provide valuable insights into best practices for compliance, helping to maintain high standards across the supply chain. By prioritizing quality assurance, companies can protect their operations and maintain trust with their customers.

Strategic Material Selection Guide for double end threaded stud screw bolt

What Are the Key Materials for Double End Threaded Stud Screw Bolts?

When selecting materials for double end threaded stud screw bolts, understanding the properties, advantages, and limitations of each option is crucial for ensuring optimal performance in various applications. Below, we analyze four common materials used in the manufacturing of these fasteners: carbon steel, stainless steel, alloy steel, and aluminum.

How Does Carbon Steel Perform in Double End Threaded Stud Screw Bolts?

Key Properties: Carbon steel is known for its high tensile strength and excellent hardness, making it suitable for applications that require durability. It typically has a temperature rating of up to 400°F (204°C) and can withstand moderate pressures.

Pros & Cons: Carbon steel is relatively inexpensive and widely available, which makes it a popular choice. However, it is susceptible to corrosion unless treated with a protective coating. This can limit its use in environments exposed to moisture or corrosive substances.

Impact on Application: Carbon steel bolts are commonly used in construction and automotive applications where strength is prioritized over corrosion resistance. Buyers should consider the environmental conditions of their applications to avoid premature failure.

Considerations for International Buyers: Compliance with standards such as ASTM A307 is essential when sourcing carbon steel bolts. Buyers in regions like Africa and South America should ensure that suppliers can provide certifications that meet local and international standards.

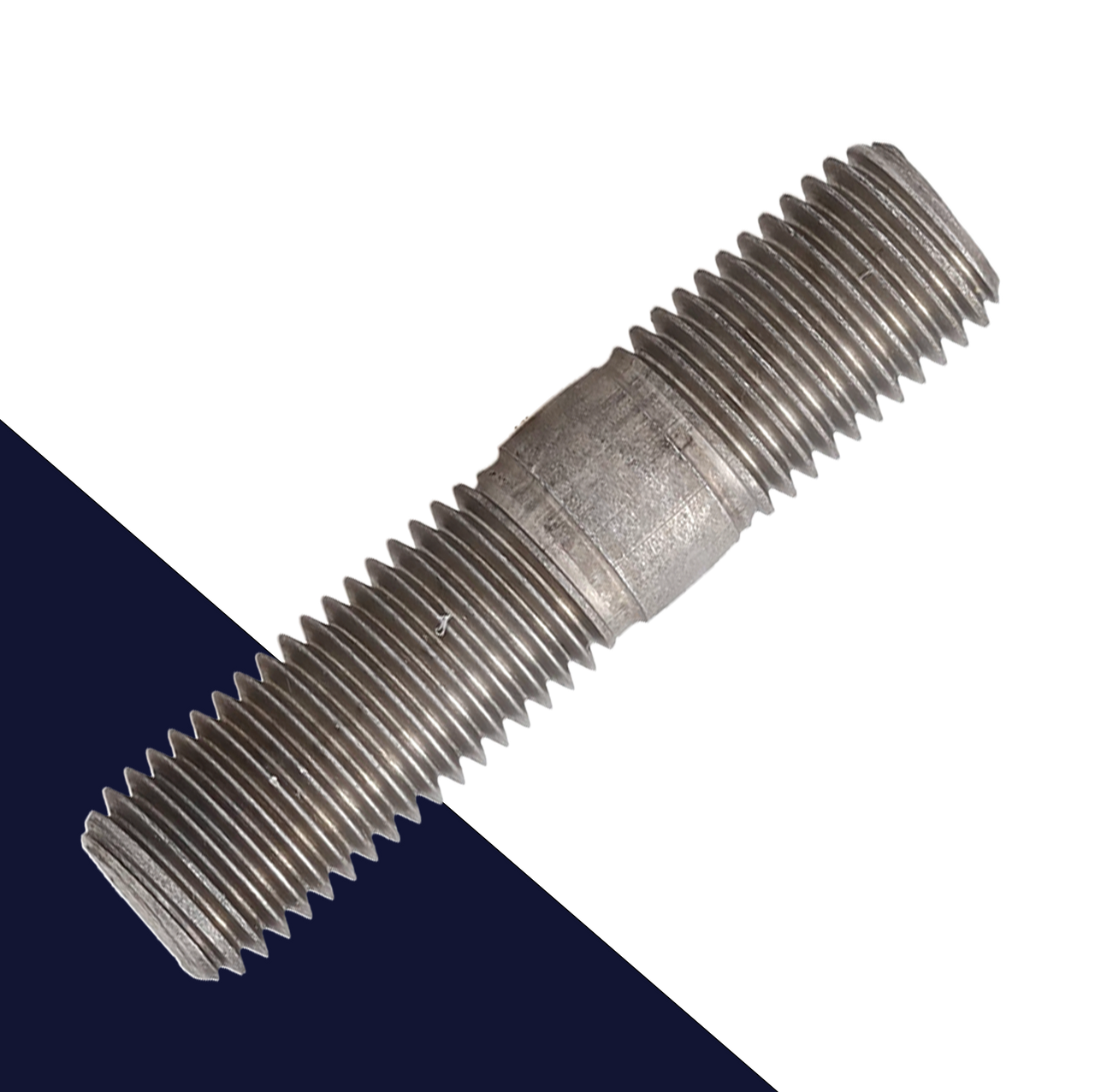

Illustrative image related to double end threaded stud screw bolt

What Are the Advantages of Stainless Steel for Double End Threaded Stud Screw Bolts?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand higher temperatures, typically up to 1500°F (815°C). Its durability makes it ideal for harsh environments.

Pros & Cons: The primary advantage of stainless steel is its resistance to rust and corrosion, making it suitable for marine and chemical applications. However, it is more expensive than carbon steel and may not be necessary for applications where corrosion is not a concern.

Impact on Application: Stainless steel bolts are ideal for applications in the food processing, pharmaceutical, and chemical industries due to their hygienic properties and resistance to chemicals.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM A193 and DIN 1.4401. In Europe, the preference for stainless steel is often driven by stricter environmental regulations.

How Does Alloy Steel Compare for Double End Threaded Stud Screw Bolts?

Key Properties: Alloy steel combines carbon steel with other elements like chromium, molybdenum, and nickel to enhance strength and toughness. It typically performs well under high-stress conditions and can handle elevated temperatures.

Illustrative image related to double end threaded stud screw bolt

Pros & Cons: Alloy steel is highly durable and can be heat-treated for additional strength, making it suitable for heavy-duty applications. However, it is generally more expensive than carbon steel and may require specialized manufacturing processes.

Impact on Application: Alloy steel bolts are commonly used in the automotive and aerospace industries, where high performance is critical.

Considerations for International Buyers: Compliance with standards such as ASTM A354 is important. Buyers should also consider the availability of alloy steel in their region, as it may not be as widely stocked as carbon or stainless steel.

What Role Does Aluminum Play in Double End Threaded Stud Screw Bolts?

Key Properties: Aluminum is lightweight and has good corrosion resistance. It typically performs well at temperatures up to 400°F (204°C) and is non-magnetic.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, making it ideal for applications where weight reduction is critical. However, it has lower tensile strength compared to steel, which may limit its use in high-load applications.

Impact on Application: Aluminum bolts are often used in the aerospace and automotive industries, where weight savings are essential.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B211. In regions like the Middle East, where weight considerations are paramount, aluminum may be preferred for specific applications.

Summary Table of Material Selection for Double End Threaded Stud Screw Bolts

| Material | Typical Use Case for double end threaded stud screw bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, automotive applications | Cost-effective and widely available | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, chemical industries | Excellent corrosion resistance | Higher cost than carbon steel | High |

| Alloy Steel | Automotive, aerospace industries | High strength and durability | More expensive and complex to manufacture | Med |

| Aluminum | Aerospace, lightweight applications | Lightweight and good corrosion resistance | Lower tensile strength than steel | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, allowing them to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for double end threaded stud screw bolt

What Are the Key Stages in the Manufacturing Process of Double End Threaded Stud Screw Bolts?

The manufacturing of double end threaded stud screw bolts involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards.

Material Preparation

The process begins with the selection of appropriate raw materials. Typically, high-strength steel or stainless steel is chosen for its durability and resistance to corrosion. Suppliers often source materials that meet specific international standards, such as ASTM or ISO. After procurement, the materials undergo inspection to verify their chemical and mechanical properties, ensuring they align with the specifications required for double end threaded studs.

Forming Techniques

Once the materials are prepared, the next stage involves forming the studs. This can be achieved through various methods, including:

- Cold Heading: This is the most common method where the material is shaped at room temperature, allowing for precise control over dimensions and improved mechanical properties.

- Machining: For some applications, machining may be used to create threads and other features. CNC (Computer Numerical Control) machines ensure high precision and repeatability.

- Forging: In cases where higher strength is required, forging can be employed, which alters the grain structure of the metal, enhancing its mechanical properties.

Assembly and Finishing

After forming, the studs may require assembly, particularly if they are part of a larger fastener system. However, in most cases, the double end threaded studs are a standalone product. The finishing stage includes processes such as:

Illustrative image related to double end threaded stud screw bolt

- Surface Treatment: This may involve processes like plating, coating (e.g., black oxide, phosphate), or passivation to enhance corrosion resistance and aesthetic appeal.

- Heat Treatment: This is often applied to improve hardness and tensile strength, particularly for heavy-duty applications.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of double end threaded stud screws, ensuring that the final products meet both customer expectations and regulatory standards.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards indicates that the manufacturer has established processes to ensure consistent quality. Additionally, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications may also be relevant.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step ensures that raw materials meet specifications before production begins. Tests may include chemical composition analysis and mechanical property testing.

- In-Process Quality Control (IPQC): During manufacturing, real-time inspections and measurements are conducted to ensure conformity to specifications. This includes checking dimensions, thread quality, and surface finish.

- Final Quality Control (FQC): After production, finished products undergo rigorous testing. This may involve destructive tests, such as tensile strength testing, as well as non-destructive tests like ultrasonic or magnetic particle inspection.

What Testing Methods Are Commonly Used?

Several testing methods are employed to ensure the integrity and performance of double end threaded stud screw bolts:

- Tensile Testing: Measures the maximum load a material can withstand while being stretched before breaking.

- Hardness Testing: Determines the material’s resistance to deformation and wear.

- Thread Inspection: Ensures that the threads are cut accurately and meet the specified tolerances, which is crucial for proper fit and performance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers, especially when sourcing from different regions such as Africa, South America, the Middle East, and Europe.

What Steps Should Buyers Take?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards firsthand.

- Requesting Quality Reports: Suppliers should provide documentation of quality control measures, including test results and certifications. This transparency is essential for building trust.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can verify that the products meet specified standards before shipment.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must be aware of the nuances in quality control that can vary by region. For instance:

- Regulatory Compliance: Different regions may have specific regulations governing the use of fasteners in construction and industrial applications. Understanding these regulations helps ensure compliance and avoid potential legal issues.

- Cultural Factors: Variations in manufacturing practices and quality expectations can exist across different cultures. Buyers should be prepared to adapt their quality assurance processes to align with local practices while maintaining their standards.

Conclusion

The manufacturing processes and quality assurance practices for double end threaded stud screw bolts are critical components that directly affect product performance and reliability. B2B buyers must engage thoroughly with suppliers to ensure that their products meet the highest standards. By understanding the manufacturing stages, quality control checkpoints, and testing methods, buyers can make informed decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘double end threaded stud screw bolt’

In this practical sourcing guide, B2B buyers looking to procure double end threaded stud screw bolts will find a structured checklist to streamline their procurement process. This guide emphasizes critical steps to ensure quality and reliability while sourcing fasteners for diverse applications.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before initiating the procurement process. Consider the required thread size, length, material (e.g., stainless steel vs. carbon steel), and finish (e.g., black oxide, plain). This clarity helps in narrowing down options and ensures compatibility with your existing applications.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for double end threaded stud screw bolts will aid in making informed purchasing decisions. Conduct market analysis to identify average costs, seasonal pricing fluctuations, and emerging suppliers. This knowledge empowers you to negotiate better terms and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Look for suppliers with a proven track record in delivering high-quality fasteners. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; also consider their manufacturing capabilities and production standards.

- Key Considerations:

- Supplier certifications (ISO, ASTM)

- Reviews and testimonials from past clients

Step 4: Request Samples for Quality Assessment

Always request samples of the double end threaded stud screw bolts before placing a bulk order. This step allows you to assess the quality, dimensional accuracy, and finish of the product. Conduct tests to ensure that the samples meet your specifications and industry standards.

- Testing Methods:

- Visual inspection for defects

- Dimensional checks using calipers

- Mechanical property tests if applicable

Step 5: Verify Compliance with International Standards

Ensure that the products comply with relevant international standards, especially if you are sourcing from different regions. Compliance with standards such as ISO or DIN can significantly impact the product’s performance and safety. This step is particularly important for industries like construction or automotive, where regulations are stringent.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, negotiate the terms of the contract. Discuss pricing, payment terms, delivery schedules, and return policies. It’s important to have these terms clearly outlined to avoid potential disputes later on.

- Focus Areas:

- Bulk order discounts

- Warranty and after-sales support

- Lead times and shipping arrangements

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your supplier can lead to better pricing, priority service, and improved communication. Regularly review supplier performance and provide feedback to foster collaboration. This partnership approach can enhance your supply chain efficiency over time.

By following this checklist, B2B buyers can streamline their procurement process for double end threaded stud screw bolts, ensuring they select reliable suppliers and receive high-quality products that meet their specific needs.

Illustrative image related to double end threaded stud screw bolt

Comprehensive Cost and Pricing Analysis for double end threaded stud screw bolt Sourcing

Understanding the cost structure and pricing analysis for double end threaded stud screw bolts is essential for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis will delve into the various cost components, price influencers, and provide actionable buyer tips to optimize sourcing strategies.

What Are the Key Cost Components in Sourcing Double End Threaded Stud Screw Bolts?

Materials: The primary cost driver in manufacturing double end threaded stud screws is the raw materials used, typically steel or stainless steel. Prices fluctuate based on market conditions, with stainless steel being significantly more expensive than standard steel due to its corrosion-resistant properties.

Labor: Labor costs vary significantly by region and supplier. Countries with higher labor costs, such as Germany, may impact the final pricing, while regions in Africa or South America may offer lower labor costs, potentially benefiting international buyers.

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and facility rent. Efficient manufacturing processes can reduce these overheads, allowing suppliers to offer more competitive pricing.

Tooling: Specialized tooling for production can represent a significant upfront investment. Buyers should consider suppliers that have invested in modern tooling technologies, as this can lead to better quality and lower production costs over time.

Quality Control (QC): Ensuring that products meet specified standards incurs additional costs. Suppliers with robust QC processes may charge more, but this can lead to savings in the long run by reducing returns and defects.

Logistics: Shipping and handling costs are critical, especially for international shipments. The choice of Incoterms can significantly influence these costs, impacting the total price paid by the buyer.

Margin: Suppliers typically add a profit margin to cover their costs and ensure business sustainability. Understanding the standard margin in the industry can help buyers gauge whether a quote is competitive.

Illustrative image related to double end threaded stud screw bolt

What Influences the Pricing of Double End Threaded Stud Screw Bolts?

Volume/MOQ: Minimum Order Quantities (MOQ) can greatly influence pricing. Bulk orders often lead to significant discounts, so buyers should consider consolidating orders to take advantage of lower per-unit costs.

Specifications and Customization: Custom specifications such as thread size, length, and finish can affect pricing. Customized products may have longer lead times and higher costs, so it’s advisable for buyers to standardize requirements where possible.

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can lead to increased costs. Buyers should balance the need for quality with budget constraints, particularly in competitive markets.

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a proven track record may charge a premium, but they often provide better service and quality assurance.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibility and costs between the buyer and supplier, impacting overall pricing.

What Are the Best Tips for Negotiating Prices for International B2B Buyers?

Negotiate Wisely: Always approach negotiations with a clear understanding of the market rates. Leverage quotes from multiple suppliers to negotiate better terms and prices.

Focus on Total Cost of Ownership (TCO): When evaluating offers, consider not just the purchase price but the total cost of ownership, including logistics, potential tariffs, and maintenance costs. This perspective can often reveal that higher upfront costs may lead to lower overall expenses.

Consider Long-Term Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time. Suppliers may offer loyalty discounts or improved service to repeat customers.

Be Aware of Pricing Nuances in Different Markets: International buyers must understand local market conditions, currency fluctuations, and economic factors that may impact pricing. This knowledge can help in making informed purchasing decisions and avoiding unexpected costs.

Disclaimer on Indicative Prices: It’s essential to note that prices can vary based on numerous factors, including market conditions and specific supplier quotes. Always confirm current pricing with suppliers before making purchasing decisions.

Illustrative image related to double end threaded stud screw bolt

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions, optimize their sourcing strategies, and ultimately achieve better value for their investments in double end threaded stud screw bolts.

Alternatives Analysis: Comparing double end threaded stud screw bolt With Other Solutions

Understanding Alternative Solutions to Double End Threaded Stud Screw Bolts

In the fastener industry, choosing the right solution can significantly impact project outcomes. While double end threaded stud screw bolts are widely used for various applications, there are alternative solutions that may better suit specific needs, depending on factors such as performance requirements, cost constraints, and ease of implementation. This section evaluates double end threaded stud screw bolts against two viable alternatives: Hex Bolts and Threaded Rods.

Comparison Table

| Comparison Aspect | Double End Threaded Stud Screw Bolt | Hex Bolts | Threaded Rods |

|---|---|---|---|

| Performance | High tensile strength; versatile | Reliable for high-stress applications | Good for tension applications |

| Cost | Moderate; varies by material type | Generally lower cost | Cost-effective for bulk applications |

| Ease of Implementation | Requires precise alignment | Easy to install; minimal tools needed | Requires additional nuts and washers |

| Maintenance | Low; durable under normal conditions | Low; corrosion-resistant options available | Moderate; can corrode if not properly treated |

| Best Use Case | Structural applications, tensioning | General-purpose fastening | Custom lengths for specific applications |

Detailed Breakdown of Alternatives

Hex Bolts

Hex bolts are one of the most common fasteners used in various industries. They feature a hexagonal head that allows for easy tightening with standard tools. The primary advantage of hex bolts is their ease of installation, making them ideal for applications where speed is essential. They are typically available at a lower cost than double end threaded studs, making them a budget-friendly option for general-purpose fastening needs. However, hex bolts are not as versatile in applications requiring tensioning between two components, which may limit their use in structural applications.

Threaded Rods

Threaded rods provide a flexible fastening solution that can be cut to any length, making them ideal for custom applications. They are often used in conjunction with nuts and washers, which can make installation slightly more complex than using double end threaded studs. Threaded rods are particularly effective in applications requiring high tension, such as in the construction of steel frames. While they can be cost-effective when purchased in bulk, the need for additional components can increase overall costs. Maintenance can also be a concern, as threaded rods can corrode if not properly treated or protected.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between double end threaded stud screw bolts and their alternatives, B2B buyers should consider their specific application requirements. For projects involving structural integrity and tensioning, double end threaded studs may provide the best performance. In contrast, if cost and ease of installation are paramount, hex bolts could be the ideal choice. Meanwhile, threaded rods offer versatility for custom solutions but may require more complexity in assembly. Ultimately, the right choice will depend on the balance of performance, cost, and application needs, ensuring that buyers make informed decisions that align with their project goals.

Illustrative image related to double end threaded stud screw bolt

Essential Technical Properties and Trade Terminology for double end threaded stud screw bolt

What Are the Key Technical Properties of Double End Threaded Stud Screw Bolts?

When sourcing double end threaded stud screw bolts, understanding their critical specifications is essential for ensuring optimal performance and compatibility in various applications. Here are the key properties to consider:

-

Material Grade

The material used in double end threaded studs is crucial for durability and strength. Common materials include carbon steel, stainless steel, and alloy steel, with grades such as Grade 5 and Class 8 denoting their tensile strength and yield. For example, Grade 5 steel is often used in automotive and industrial applications due to its good balance of strength and ductility. Selecting the appropriate material grade helps prevent failures and ensures long-term reliability. -

Thread Size and Type

Thread size is specified in either metric (e.g., M10-1.5) or imperial (e.g., 1/4″-20) formats and affects the compatibility with existing components. The type of thread (e.g., coarse or fine) also influences the load-bearing capacity and installation ease. Understanding thread specifications is critical for ensuring proper fit and function in assembly processes. -

Workable Length

This refers to the total length of the stud available for installation, excluding the threaded portions. It is vital to match the workable length with the application requirements to ensure that the stud fits correctly within the assembly space. Incorrect lengths can lead to structural failures or improper load distribution. -

Thread Length

Thread length is divided into two categories: Thread Length A and Thread Length B, which indicate the lengths of the threaded sections on either end of the stud. This specification is important for determining how much of the stud will engage with the corresponding nuts or components. Insufficient thread length can compromise the integrity of the connection. -

Finish

The finish of double end threaded studs, such as black oxide, plain, or phosphate, affects corrosion resistance and aesthetic appeal. For outdoor or industrial applications where exposure to moisture and chemicals is common, selecting the right finish can prolong the life of the fastener and reduce maintenance costs. -

Package Quantity

This refers to how many units are included in each package, which can range from a single piece to bulk quantities (e.g., 100 pieces). Understanding packaging helps in inventory management and cost-effectiveness, especially for large-scale projects.

What Are Common Trade Terms Related to Double End Threaded Stud Screw Bolts?

Familiarity with industry terminology can streamline the procurement process and facilitate better communication with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can help buyers assess quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity that a supplier is willing to sell. This is crucial for budgeting and inventory management, especially for businesses that may not require large quantities of fasteners at one time. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to request pricing and terms from suppliers. It typically includes specifications such as material, dimensions, and quantities. Using RFQs can help buyers ensure competitive pricing and facilitate clearer communication regarding requirements. -

Incoterms (International Commercial Terms)

These are standard trade terms used in international sales contracts, defining the responsibilities of buyers and sellers for the delivery of goods. Familiarity with Incoterms can aid in understanding shipping costs and risk management in international transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and inventory management, especially in industries with tight schedules. -

Certification

Certification indicates that a product meets specific industry standards or regulations. Common certifications for fasteners include ISO and ASTM standards, which can assure buyers of product quality and compliance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing double end threaded stud screw bolts, ultimately improving operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the double end threaded stud screw bolt Sector

What Are the Current Market Dynamics and Key Trends in the Double End Threaded Stud Screw Bolt Sector?

The double end threaded stud screw bolt market is experiencing significant evolution, driven by various global factors. The rise in infrastructure development across Africa, South America, and the Middle East has led to increased demand for high-quality fasteners in construction and manufacturing sectors. Additionally, advancements in manufacturing technologies, such as automation and precision engineering, are enhancing product quality while reducing production costs. International buyers are increasingly leveraging digital platforms for sourcing, enabling them to compare suppliers and products more efficiently.

Emerging trends in B2B sourcing include a shift towards customized solutions, as companies seek to differentiate themselves through tailored products that meet specific project requirements. Moreover, the integration of data analytics and AI into supply chain management is helping businesses optimize inventory levels and improve order accuracy. As a result, international buyers are better positioned to respond to market fluctuations and customer demands.

How Are Sustainability and Ethical Sourcing Impacting the Double End Threaded Stud Screw Bolt Market?

Sustainability is becoming a key consideration for B2B buyers in the double end threaded stud screw bolt sector. The environmental impact of manufacturing processes, including carbon emissions and resource depletion, has prompted many companies to seek suppliers that prioritize eco-friendly practices. This includes using recycled materials and adopting energy-efficient production methods.

Ethical sourcing is equally crucial, as businesses strive to ensure that their supply chains are transparent and responsible. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can enhance a supplier’s credibility and appeal to conscientious buyers. Companies that embrace sustainable practices not only mitigate risks associated with regulatory compliance but also enhance their brand reputation in an increasingly eco-aware market.

What Is the Historical Context of the Double End Threaded Stud Screw Bolt Market?

The double end threaded stud screw bolt has a rich history that traces back to the industrial revolution, where the need for robust fastening solutions became paramount. Initially crafted from wrought iron, advancements in metallurgy led to the development of high-strength steel and stainless steel variants, which significantly improved durability and resistance to corrosion. Over the decades, innovations in manufacturing techniques, such as cold heading and heat treatment, have optimized the production process and expanded the applications for these fasteners across various industries, including automotive, aerospace, and construction. As global markets continue to evolve, the double end threaded stud screw bolt remains a critical component in modern engineering solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of double end threaded stud screw bolt

-

How do I choose the right double end threaded stud screw bolt for my application?

Selecting the appropriate double end threaded stud screw bolt involves considering several factors, including the material, thread size, length, and load requirements. Stainless steel is ideal for corrosion resistance, while carbon steel is suitable for general applications. Ensure you match the thread size and length with your existing components. If you’re unsure, consulting with a technical expert or the supplier can help clarify which specifications best meet your operational needs. -

What is the best way to source double end threaded stud screw bolts internationally?

To source double end threaded stud screw bolts internationally, start by identifying reliable manufacturers or suppliers through industry directories, trade shows, or online marketplaces. Check for certifications and customer reviews to assess their credibility. Establish communication to discuss your specific requirements, including material, dimensions, and quantities. It’s beneficial to request samples before making a large order to ensure product quality meets your standards. -

What customization options are available for double end threaded stud screw bolts?

Many suppliers offer customization options for double end threaded stud screw bolts, including variations in thread size, length, and material. Additional customization can involve specific coatings for corrosion resistance or unique packaging requirements for shipping. When engaging with suppliers, clearly outline your needs and inquire about their capabilities to meet those specifications. This will help ensure the final product aligns with your project requirements. -

What are the minimum order quantities (MOQ) for double end threaded stud screw bolts?

Minimum order quantities (MOQ) for double end threaded stud screw bolts vary by supplier and product type. Some manufacturers may have an MOQ as low as 100 pieces, while others might require orders of several thousand units. It’s important to discuss your project needs with suppliers to determine their MOQ and explore options for smaller test orders if necessary. Negotiating terms can sometimes lead to flexibility in MOQs, especially for long-term partnerships. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms for international orders of double end threaded stud screw bolts typically include options like advance payment, letter of credit, or net payment terms (e.g., 30 or 60 days). It’s crucial to establish clear terms before finalizing your order to avoid misunderstandings. Discussing payment methods that offer security for both parties is essential, especially for high-value transactions. Always ensure that your payment terms align with your cash flow management strategies. -

How do I ensure quality assurance when sourcing double end threaded stud screw bolts?

To ensure quality assurance, request certifications from your supplier that verify compliance with international standards, such as ISO or ASTM. Establish a quality control process that may include product inspections during manufacturing and before shipment. Ask for samples or conduct audits of the supplier’s facilities if possible. Building a relationship with your supplier and maintaining open communication can also foster a culture of quality and reliability. -

What are the shipping considerations for double end threaded stud screw bolts?

When arranging shipping for double end threaded stud screw bolts, consider factors such as lead times, shipping methods (air, sea, or land), and customs regulations in your country. It’s advisable to work with freight forwarders who specialize in international shipping to navigate logistics efficiently. Be aware of any potential tariffs or taxes that may apply to your order. Proper packaging is also critical to prevent damage during transit. -

How can I vet suppliers for double end threaded stud screw bolts effectively?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with international standards. Start by checking online reviews and ratings, and ask for references from previous clients. Evaluate their certifications and assess their experience in your specific industry. Additionally, consider visiting their facilities or arranging virtual meetings to discuss their processes and quality control measures. Building a trustworthy relationship with suppliers can lead to better service and product quality.

Top 2 Double End Threaded Stud Screw Bolt Manufacturers & Suppliers List

1. GLFUS – Double End Studs

Domain: glfus.com

Registered: 2010 (15 years)

Introduction: Double End Studs are available in various sizes and materials. Key specifications include:

– Diameter options: 1/4, 5/16, M8, 3/8, 7/16, 1/2, 3/4, 7/8, 1, 1 1/4, 1 1/2, 1 3/4, 2, 3

– Thread Pitch options: 10, 13, 14, 16, 18, 20, 4, 4 1/2, 5, 6, 7, 8

– Length options: Ranging from 3/8 to 108 inches

– Material options: Steel (B-7, Grade 8, Low Carbon) and Stainless Steel (304, 17-4 PH)

– Finish: Pla…

2. Rick and Ann’s – 304 Stainless Steel Double End Threaded Stud

Domain: rickandanns.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “304 Stainless Steel Double End Threaded Stud”, “product_id”: “1203467”, “material”: “304 Stainless Steel”, “type”: “Double End Threaded Stud”}

Strategic Sourcing Conclusion and Outlook for double end threaded stud screw bolt

How Can Strategic Sourcing Enhance Your Procurement of Double End Threaded Stud Screw Bolts?

In today’s competitive landscape, strategic sourcing of double end threaded stud screw bolts is essential for international B2B buyers aiming to optimize their supply chains. By carefully evaluating suppliers based on quality, pricing, and delivery capabilities, organizations can secure the best materials while minimizing costs. The diverse range of options available—including various thread sizes, materials, and finishes—allows buyers to tailor their purchases to specific project requirements, ensuring compatibility and performance.

Moreover, establishing strong relationships with trusted suppliers can lead to better negotiation terms and consistent supply, which is crucial for projects that demand reliability. Buyers in regions such as Africa, South America, the Middle East, and Europe can leverage these partnerships to enhance their operational efficiency and respond swiftly to market demands.

As we look ahead, the importance of sustainability and ethical sourcing will only grow. B2B buyers are encouraged to consider suppliers who prioritize environmentally friendly practices and materials. Embracing strategic sourcing not only strengthens procurement processes but also positions businesses for future growth. Engage with your suppliers today to explore how optimized sourcing can elevate your operations and drive success in an evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.