How to Source Drawing Tube Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for drawing tube

In the dynamic landscape of international trade, sourcing the right drawing tube can present unique challenges for B2B buyers. Whether you are in the architectural, artistic, or educational sectors, finding a durable and versatile storage solution that meets your specific needs is crucial. This comprehensive guide delves into the diverse types of drawing tubes available in the market, their various applications, and essential factors to consider when sourcing them. From understanding the materials and sizes to evaluating suppliers and pricing strategies, this resource is designed to empower buyers in Africa, South America, the Middle East, and Europe—particularly in regions like Brazil and Saudi Arabia.

Navigating the global market requires a keen understanding of local preferences and international standards. This guide not only outlines the key features and benefits of different drawing tubes but also provides actionable insights on supplier vetting processes and cost considerations. By leveraging this information, B2B buyers can make informed purchasing decisions that enhance operational efficiency and safeguard valuable documents and artworks. Ultimately, our aim is to equip you with the knowledge necessary to navigate the complexities of sourcing drawing tubes, ensuring you select the most suitable options for your business needs.

Understanding drawing tube Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Storage Tube | Rigid construction, moisture-proof, removable cap | Art storage, blueprint transport | Pros: Affordable, lightweight. Cons: Limited size options. |

| Telescoping Drawing Tube | Adjustable length, larger diameter, durable plastic | Professional presentations, shipping art | Pros: Versatile sizing, robust design. Cons: Bulkier than standard tubes. |

| Multi-Purpose Art Tube | Water-resistant, secure locking cap, portable with shoulder strap | Transporting various materials | Pros: Excellent protection, multi-functional. Cons: May be pricier due to features. |

| Heavy-Duty Drafting Tube | Extra-thick walls, reinforced ends, designed for heavy loads | Construction site documents, large artwork | Pros: Superior durability, ideal for heavy items. Cons: Heavier and less portable. |

| Specialty Art Transport Tube | Custom sizes, specific designs for unique art pieces | Exhibition displays, high-value artwork | Pros: Tailored solutions, enhanced protection. Cons: Higher cost, longer lead time for custom orders. |

What Are the Characteristics of a Standard Storage Tube?

Standard storage tubes are typically made from rigid materials that ensure durability and moisture resistance. They come with a removable cap, making access to contents easy while protecting items from dust and damage. Ideal for art storage and blueprint transport, these tubes are lightweight and cost-effective, making them a popular choice for businesses needing basic storage solutions. However, they often come in limited size options, which may not meet all specific project needs.

How Does a Telescoping Drawing Tube Stand Out?

Telescoping drawing tubes feature an adjustable length, allowing users to modify the size according to their requirements. With a larger diameter and made from durable plastic, these tubes are well-suited for transporting professional artwork and blueprints. Their robust construction ensures that contents are well protected during transit. While they offer versatility, their bulkier design may pose challenges for those looking for lightweight options.

What Makes a Multi-Purpose Art Tube Ideal for Various Uses?

Multi-purpose art tubes are designed to accommodate a range of materials, featuring water-resistant properties and a secure locking cap. They often include a shoulder strap for easy portability, making them suitable for transporting items like posters, documents, or art pieces. This flexibility makes them appealing to businesses that require a reliable transport solution. However, their additional features can result in a higher price point compared to standard options.

Why Choose a Heavy-Duty Drafting Tube?

Heavy-duty drafting tubes are built with extra-thick walls and reinforced ends, making them ideal for transporting heavy documents or large artwork. They are particularly useful in construction and architectural contexts, where durability is paramount. While they provide superior protection, their weight and bulkiness may limit portability, making them less suitable for frequent travel.

Illustrative image related to drawing tube

What Are the Benefits of Specialty Art Transport Tubes?

Specialty art transport tubes are often custom-made to fit unique art pieces, providing tailored protection for high-value items. These tubes are ideal for exhibition displays and transporting delicate artwork. While they offer excellent protection and customization options, the higher costs and longer lead times associated with custom orders can be significant considerations for B2B buyers.

Key Industrial Applications of drawing tube

| Industry/Sector | Specific Application of drawing tube | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architecture | Storage and transport of blueprints and architectural plans | Ensures protection against physical damage and environmental conditions | Durability, size options, moisture resistance, and portability |

| Art and Design | Safe storage and transport of artwork and large prints | Preserves the quality of art, preventing creases and damage during transit | Material quality, locking mechanisms, and size versatility |

| Education | Use in schools for transporting projects and presentations | Facilitates organization and protection of student work during transport | Lightweight design, ease of use, and capacity for large items |

| Engineering | Protection of technical drawings and engineering documents | Maintains the integrity of crucial documents, reducing the risk of loss or damage | Size specifications, robustness, and secure closures |

| Event Management | Carrying promotional materials and banners to events | Enhances presentation by keeping materials organized and undamaged | Portability, aesthetic design, and compatibility with various item sizes |

How is the Drawing Tube Used in Architecture and What Problems Does It Solve?

In the architecture sector, drawing tubes are essential for storing and transporting blueprints and architectural plans. These documents are often large and vulnerable to damage from bending, creasing, or exposure to moisture. Drawing tubes provide a rugged, protective casing that ensures these critical documents arrive at their destination intact. International buyers should consider durability and moisture resistance, especially in regions with high humidity or variable climates, to ensure long-term use.

What Role Does the Drawing Tube Play in the Art and Design Industry?

Artists and designers utilize drawing tubes to safeguard their artwork and large prints during transportation. The tubes prevent physical damage, such as creases or tears, preserving the integrity and value of the art. For B2B buyers, selecting tubes made from high-quality materials that offer secure locking mechanisms is crucial. Additionally, size versatility is important for accommodating various artwork dimensions, especially for international artists who may face different shipping regulations.

How Do Educational Institutions Benefit from Using Drawing Tubes?

In educational settings, drawing tubes are vital for students who need to transport projects and presentations. These tubes help organize and protect student work from damage while fostering a professional appearance. For buyers in the education sector, lightweight designs that are easy to carry are essential, as well as ample capacity to accommodate larger items like posters or projects. Ensuring that the tubes are user-friendly can significantly enhance the student experience.

Why Are Drawing Tubes Important for Engineering Applications?

Engineers rely on drawing tubes to protect technical drawings and engineering documents, which are often critical for project success. These tubes maintain the integrity of the documents, safeguarding them from potential loss or damage during transport. For B2B buyers in engineering, key considerations include robust construction and secure closures, as the documents must withstand various conditions while being moved between job sites or meetings.

How Can Event Management Professionals Leverage Drawing Tubes?

In the event management industry, drawing tubes serve as effective carriers for promotional materials and banners. They ensure that these items remain organized and undamaged, enhancing the overall presentation at events. Buyers in this sector should look for portable designs that are aesthetically pleasing and compatible with various item sizes to meet diverse event requirements. The ability to transport materials securely and stylishly can significantly impact the professional image of event organizers.

3 Common User Pain Points for ‘drawing tube’ & Their Solutions

Scenario 1: Insufficient Protection During Transport

The Problem: B2B buyers often face the challenge of transporting valuable artwork, architectural plans, or important documents without the risk of damage. Many drawing tubes on the market are either too flimsy or not designed to withstand the rigors of shipping and travel. Buyers are concerned that inadequate protection could lead to creases, tears, or even complete loss of their materials, ultimately impacting their business reputation and financial bottom line.

The Solution: To address this issue, buyers should prioritize sourcing drawing tubes made from durable, moisture-resistant materials like rigid PVC or high-density polyethylene. These materials provide superior protection against physical impact and environmental factors. When specifying a drawing tube, consider features such as reinforced ends and secure locking caps that prevent accidental openings during transit. Additionally, opting for telescoping tubes can offer versatility, allowing for the adjustment of length based on the size of the contents, ensuring snug fits that minimize movement. Investing in quality tubes designed specifically for transport can significantly reduce the risk of damage and provide peace of mind during logistics operations.

Scenario 2: Limited Size and Capacity Options

The Problem: Many businesses require drawing tubes in various sizes to accommodate different projects, from small sketches to large blueprints. A common pain point is the lack of options in standard drawing tube sizes, which can lead to inefficiencies or the need for multiple purchases. This can be especially problematic for companies with diverse client needs, as they might struggle to find a single solution that meets all requirements.

The Solution: To overcome this limitation, buyers should seek suppliers that offer a wide range of sizes and customizable options. Look for manufacturers that provide telescoping or expandable drawing tubes that can adjust in length to suit different project dimensions. Additionally, consider vendors that allow for bulk orders or custom sizes tailored to specific needs. By establishing relationships with suppliers who understand the diverse requirements of your business, you can streamline your inventory management and ensure you always have the right tube on hand for any project.

Scenario 3: Difficulty in Accessibility and Portability

The Problem: Professionals in fields such as architecture, design, and art often need to transport their drawings and documents to various locations, whether for client meetings, presentations, or exhibitions. A common frustration arises from the cumbersome nature of many drawing tubes, which can be heavy, awkward to carry, or lack ergonomic features. This can lead to delays and discomfort, impacting productivity and overall efficiency.

The Solution: To enhance portability, buyers should look for lightweight drawing tubes that come with ergonomic features such as adjustable shoulder straps or handles. These design elements make it easier to carry materials over long distances or during busy workdays. Additionally, consider drawing tubes that are collapsible or easy to store when not in use, as this can save space in vehicles or offices. When purchasing, read reviews and seek out products that emphasize user-friendly designs for professionals on the go. By selecting tubes that prioritize portability, businesses can ensure that their teams can focus on their work without the added burden of difficult-to-manage equipment.

Strategic Material Selection Guide for drawing tube

What Are the Key Materials Used in Drawing Tubes?

When selecting materials for drawing tubes, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials used in the production of drawing tubes: PVC, Polyethylene, Aluminum, and Cardboard. Each material has unique characteristics that make it suitable for specific applications, especially for international B2B buyers.

How Does PVC Influence the Performance of Drawing Tubes?

PVC (Polyvinyl Chloride) is a widely used material for drawing tubes due to its durability and resistance to moisture. Key properties include a temperature rating of up to 60°C and excellent corrosion resistance, making it suitable for various environments.

Pros: PVC is relatively inexpensive, lightweight, and offers good impact resistance. Its manufacturing process is straightforward, allowing for large-scale production.

Cons: However, PVC can become brittle over time when exposed to UV light, which may limit its lifespan in outdoor applications. Additionally, it may not be suitable for high-temperature applications beyond its threshold.

For international buyers, especially in regions like Africa and the Middle East, compliance with local environmental regulations regarding PVC usage is crucial, as some countries are moving towards more sustainable materials.

What Benefits Does Polyethylene Offer for Drawing Tubes?

Polyethylene is another popular choice for drawing tubes, particularly in applications requiring flexibility and toughness. It has a temperature rating of approximately -40°C to 80°C and is resistant to chemicals and moisture.

Pros: The primary advantage of polyethylene is its excellent impact resistance and flexibility, making it ideal for transporting delicate materials. It is also recyclable, aligning with sustainability goals.

Cons: On the downside, polyethylene can be more expensive than PVC and may not provide the same level of rigidity, which could be a consideration for buyers needing a more robust solution.

International buyers should note that polyethylene complies with various standards, such as ASTM and ISO, which can facilitate smoother trade and regulatory processes.

Why Choose Aluminum for High-Performance Drawing Tubes?

Aluminum is favored for its lightweight yet sturdy properties, making it an excellent choice for high-performance drawing tubes. It has a temperature rating that can withstand extreme conditions and is highly resistant to corrosion.

Pros: The durability and strength of aluminum make it suitable for heavy-duty applications, such as construction and engineering. Its recyclability also enhances its appeal to environmentally conscious buyers.

Cons: However, aluminum is generally more expensive than plastic alternatives, which may deter budget-sensitive buyers. Additionally, it requires more complex manufacturing processes, which can lead to longer lead times.

For international buyers, particularly in Europe and South America, aluminum’s compliance with industry standards (like DIN and JIS) is a significant advantage, ensuring quality and reliability.

Illustrative image related to drawing tube

How Does Cardboard Compare in Terms of Cost and Functionality?

Cardboard is often used for lightweight applications and temporary storage solutions. It is biodegradable and can be produced from recycled materials, making it an eco-friendly option.

Pros: The primary advantage of cardboard is its low cost and ease of production. It can be customized easily and is suitable for short-term use.

Cons: However, cardboard lacks the durability and moisture resistance of plastic or metal options, making it less suitable for long-term storage or transport of valuable items.

For international B2B buyers, especially in developing regions, the affordability of cardboard can be a significant factor, but they must also consider its limitations in terms of durability and protection.

Summary of Material Selection for Drawing Tubes

| Material | Typical Use Case for drawing tube | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General storage and transport | Cost-effective and lightweight | Becomes brittle with UV exposure | Low |

| Polyethylene | Flexible transport of delicate items | Excellent impact resistance | Higher cost and less rigidity | Medium |

| Aluminum | Heavy-duty applications | Durable and corrosion-resistant | Higher cost and complex mfg | High |

| Cardboard | Temporary storage and lightweight use | Low cost and eco-friendly | Poor durability and moisture resistance | Low |

This guide provides a comprehensive overview of material selection for drawing tubes, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for drawing tube

What Are the Key Stages in the Manufacturing Process of Drawing Tubes?

The manufacturing process of drawing tubes typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages can empower B2B buyers to make informed decisions regarding the quality and reliability of their suppliers.

Material Preparation: Selecting the Right Raw Materials

The first step in manufacturing drawing tubes involves sourcing high-quality raw materials, often plastic or aluminum, depending on the intended use. For plastic tubes, suppliers may use PVC or HDPE, known for their durability and resistance to environmental factors. In contrast, aluminum tubes are chosen for applications requiring lightweight yet robust solutions.

Once the material is selected, it undergoes rigorous testing to ensure it meets specific industry standards. This can include checks for tensile strength, flexibility, and resistance to moisture and UV light. Suppliers often maintain material certifications that outline compliance with international standards, which can be crucial for B2B buyers looking for reliable quality.

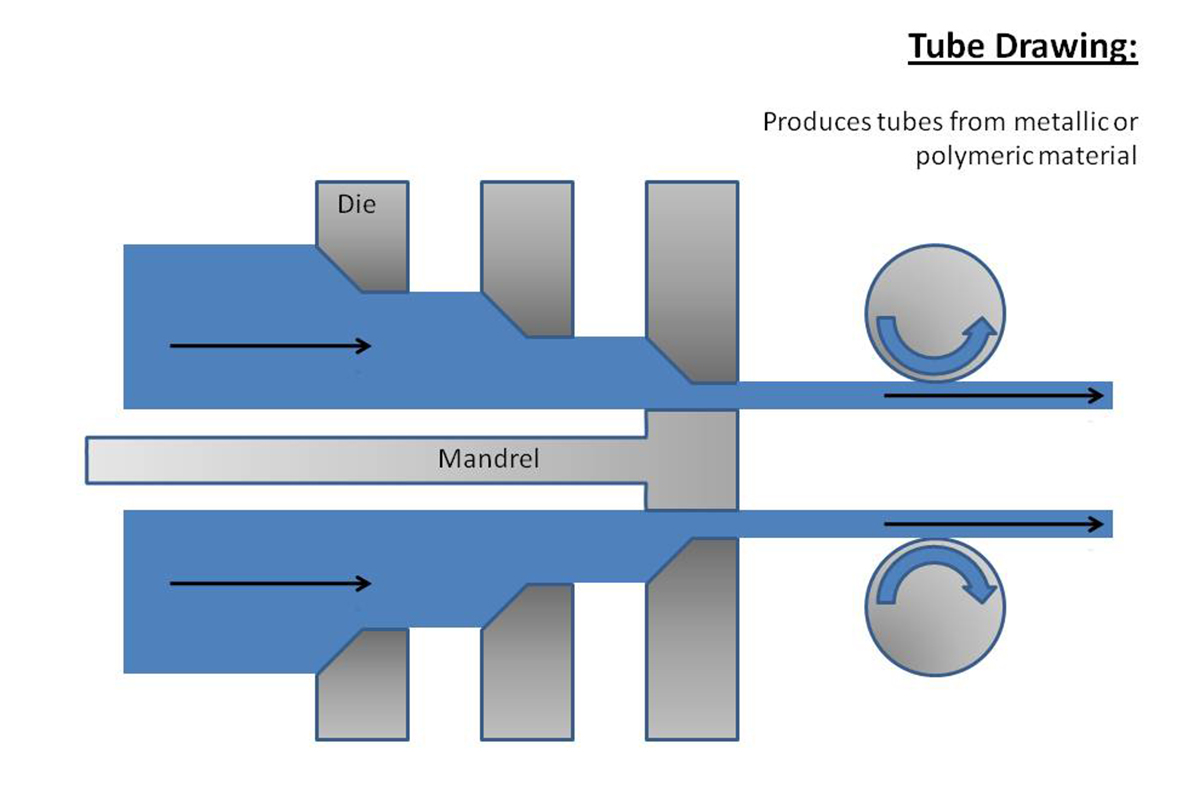

How Are Drawing Tubes Formed?

The forming stage utilizes various techniques such as extrusion or injection molding to shape the raw materials into tubes.

-

Extrusion involves forcing the material through a die, creating a continuous tube that can be cut to desired lengths. This method is efficient for producing uniform tubes at scale.

-

Injection Molding is used for more complex designs, allowing for the incorporation of features like locking caps or handles directly into the tube. This method ensures precision and can reduce the need for additional assembly steps later.

After forming, the tubes are typically cooled and cut to the required specifications. This stage is critical, as any dimensional inaccuracies can affect the tube’s performance in its intended application.

What Assembly and Finishing Techniques Are Commonly Used?

Assembly involves adding any additional components, such as end caps or adjustable straps, to enhance the functionality of the drawing tubes. The assembly process can be manual or automated, depending on the volume and complexity of the product line.

Finishing processes may include surface treatment to improve aesthetics and functionality. For instance, tubes might be coated to enhance resistance to scratches or UV light. Printing or labeling is often performed at this stage to ensure branding and product information is clearly visible.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a critical aspect of the drawing tube manufacturing process. International standards such as ISO 9001 provide a framework for maintaining quality throughout production. Compliance with these standards indicates that a manufacturer has established effective quality management systems.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for oil and gas applications may be relevant. These certifications are essential for ensuring that products meet specific safety and performance criteria.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure each batch of drawing tubes meets established specifications. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet quality standards before manufacturing begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to monitor dimensions and material properties. This ensures that any deviations from specifications are caught early.

-

Final Quality Control (FQC): Once the products are complete, they undergo a final inspection to verify that they meet all quality and performance criteria before shipping.

What Testing Methods Are Commonly Used in Quality Assurance?

B2B buyers should be aware of common testing methods used to verify the integrity and performance of drawing tubes. These may include:

- Dimensional Testing: Ensuring the tubes meet specified lengths and diameters.

- Pressure Testing: For tubes intended to hold liquids or gases, pressure testing is essential to confirm they can withstand operational pressures without failure.

- Environmental Testing: This assesses how well the tubes perform under various environmental conditions, such as exposure to moisture, UV light, or extreme temperatures.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

To ensure the reliability of their suppliers, B2B buyers can take several steps to verify quality assurance processes:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing practices and adherence to quality standards. This includes reviewing their quality management systems and processes.

-

Requesting Quality Reports: Buyers should ask for documented quality reports, including results from IQC, IPQC, and FQC stages. These reports can offer transparency into the supplier’s quality control measures.

-

Third-Party Inspections: Engaging third-party inspection services can provide unbiased verification of a supplier’s quality practices. This is particularly beneficial for international buyers who may not have the capacity to conduct on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, and the Middle East, should be aware of specific quality control nuances. Variations in local regulations, import/export standards, and certifications can affect the compliance of drawing tubes with regional requirements.

Buyers should also consider the logistical aspects of transporting goods across borders, ensuring that quality is maintained throughout the supply chain. This may involve working with suppliers who have experience navigating international shipping and customs regulations.

Conclusion: Ensuring Quality in Your Drawing Tube Supply Chain

Understanding the manufacturing processes and quality assurance practices associated with drawing tubes is essential for B2B buyers looking to ensure they receive high-quality products. By focusing on material selection, manufacturing techniques, and quality control measures, buyers can mitigate risks and foster successful partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drawing tube’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure drawing tubes. Drawing tubes are essential for the protection and transport of valuable documents, artwork, and blueprints, making the selection of a reliable supplier critical. The following steps will help you navigate the procurement process effectively, ensuring that your investment meets your specific needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the specifications required for the drawing tubes. This includes dimensions, material type, and intended use.

– Dimensions: Consider the sizes you need based on the type of documents or artwork you will be storing or transporting.

– Material: Choose between options such as PVC or rigid plastic, which offer durability and protection against environmental factors.

Step 2: Research Potential Suppliers

Invest time in researching potential suppliers who specialize in drawing tubes.

– Industry Reputation: Look for suppliers with a strong presence in your region, particularly in markets such as Africa, South America, the Middle East, and Europe.

– Product Range: Ensure the suppliers offer a variety of products that meet your specifications, including adjustable or telescoping options.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that suppliers possess the necessary certifications and quality standards.

– ISO Certifications: Check for ISO 9001 or similar quality management certifications that indicate adherence to industry standards.

– Environmental Compliance: Ensure that the materials used comply with environmental regulations, which can be particularly important in certain markets.

Step 4: Request Samples for Testing

Always request samples before finalizing your order. This step is vital to assess the quality and suitability of the drawing tubes for your specific needs.

– Durability Tests: Evaluate the strength of the materials and their ability to withstand transport conditions.

– Usability: Check features such as cap security and portability options like shoulder straps to ensure they meet your operational requirements.

Step 5: Review Pricing and Terms

Compare pricing among shortlisted suppliers, but don’t focus solely on the lowest price.

– Total Cost of Ownership: Consider factors like shipping costs, potential duties, and warranty terms.

– Bulk Order Discounts: Inquire about discounts for larger orders, which can be particularly beneficial for businesses that require frequent supplies.

Step 6: Check Customer Reviews and Testimonials

Look for feedback from previous customers to gauge supplier reliability and product performance.

– Industry-Specific Reviews: Seek testimonials from buyers in similar sectors to understand how the products perform under comparable conditions.

– Response to Issues: Assess how suppliers handle complaints or product issues, as this reflects their customer service quality.

Step 7: Finalize Your Order and Establish a Relationship

Once satisfied with your chosen supplier, finalize your order and consider establishing a long-term relationship.

– Negotiation: Discuss terms for future purchases to secure better pricing or service.

– Communication: Maintain open lines of communication for any future needs or adjustments, ensuring a smooth procurement process moving forward.

By following these steps, B2B buyers can effectively source drawing tubes that meet their specifications and operational requirements, ultimately enhancing their business’s efficiency and professionalism.

Comprehensive Cost and Pricing Analysis for drawing tube Sourcing

What Are the Key Cost Components in Drawing Tube Manufacturing?

When sourcing drawing tubes, it’s crucial to understand the various components that contribute to the overall cost structure. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of material significantly influences the cost. For instance, PVC plastic is commonly used for its durability and moisture resistance, while higher-quality materials may be utilized for specialized applications, affecting pricing accordingly.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor might be necessary for custom designs or quality checks, which can increase costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: The initial investment in tooling and machinery can be substantial, particularly for custom or specialized drawing tubes. This cost is usually amortized over the production volume.

-

Quality Control: Ensuring that products meet specific standards is vital, particularly for international markets. QC processes add to manufacturing costs but are essential for maintaining product integrity.

-

Logistics: Transportation and shipping costs can vary widely, especially for international buyers. Factors such as distance, mode of transport, and fuel prices play a significant role.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can fluctuate based on the competitive landscape and market demand.

How Do Price Influencers Impact Drawing Tube Sourcing?

Several factors can influence the pricing of drawing tubes, particularly for international B2B buyers. Understanding these can lead to more favorable procurement outcomes.

-

Volume/MOQ: Minimum order quantities (MOQs) and bulk purchasing often lead to discounts. Buyers should assess their needs against supplier MOQs to optimize costs.

-

Specifications and Customization: Custom specifications or unique designs can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-grade materials and quality certifications can elevate prices but may be necessary for certain applications. Buyers should weigh the benefits against their budget.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers may command higher prices due to their reliability and quality assurance.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, impacting overall costs.

What Buyer Tips Can Help in Negotiating Better Prices?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can employ various strategies to enhance their procurement efficiency.

-

Negotiate Effectively: Establishing strong relationships with suppliers can lead to better negotiation outcomes. Open communication about needs and expectations fosters trust and may yield cost savings.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and potential resale value, especially for high-quality tubes.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to labor costs, material availability, and market demand. Buyers should conduct market research to understand these nuances.

-

Leverage Local Expertise: Engaging local intermediaries or sourcing agents can provide valuable insights into local market conditions and supplier capabilities, potentially leading to better deals.

Conclusion: Navigating the Complexities of Drawing Tube Sourcing

Understanding the cost components, price influencers, and negotiation strategies is crucial for international B2B buyers looking to source drawing tubes effectively. By being well-informed and strategic, companies can optimize their procurement processes and achieve favorable pricing outcomes. Keep in mind that prices can fluctuate due to market conditions, and it is advisable to consult multiple suppliers for the best deals.

Alternatives Analysis: Comparing drawing tube With Other Solutions

Exploring Alternatives to Drawing Tubes: A Comprehensive Comparison

In the realm of art and document storage, drawing tubes serve as a popular solution for safeguarding valuable materials during transport or storage. However, several alternatives may suit specific needs better, depending on factors such as performance, cost, and convenience. Below, we explore three viable alternatives to drawing tubes: Storage Tubes, Telescoping Poster Tubes, and Rigid Document Cases.

| Comparison Aspect | Drawing Tube | Storage Tube | Telescoping Poster Tube | Rigid Document Case |

|---|---|---|---|---|

| Performance | Excellent protection against creasing and water damage. | Good for general storage; offers decent protection. | Versatile and expandable, ideal for larger items. | Superior protection against impact and bending. |

| Cost | Moderate pricing, typically around $30-$50. | Generally lower cost, around $10-$30. | Mid-range, usually $50-$70. | Higher initial investment, $60-$100. |

| Ease of Implementation | Simple to use, no assembly required. | Straightforward; easy to load items. | Requires adjustment for length, but still user-friendly. | Slightly complex; may require extra organization. |

| Maintenance | Low maintenance; durable materials. | Low; generally maintenance-free. | Low; robust design withstands wear. | Moderate; needs occasional cleaning. |

| Best Use Case | Ideal for artists and architects transporting large formats. | Suitable for casual users needing basic storage. | Best for professionals needing flexibility in size. | Recommended for archival storage or high-value documents. |

In-Depth Analysis of Alternatives

Storage Tubes

Storage tubes are a cost-effective alternative, constructed from rugged materials like PVC. They are suitable for artists and casual users who require basic protection for rolled documents, blueprints, or artwork. However, while they provide decent moisture resistance, they may not offer the same level of durability or protection against physical damage as drawing tubes. Their affordability makes them an attractive option for those on a budget, but they are best suited for less valuable items.

Illustrative image related to drawing tube

Telescoping Poster Tubes

Telescoping poster tubes stand out due to their expandable design, accommodating materials ranging from 32 inches to 52 inches in length. This feature is particularly beneficial for professionals, such as architects or artists, who frequently transport large documents. Made from rigid plastic, these tubes are designed to protect contents from environmental factors, including water and UV damage. However, their price point is typically higher than standard storage tubes, which may deter budget-conscious buyers.

Rigid Document Cases

For buyers who prioritize maximum protection, rigid document cases are an excellent choice. Constructed from high-impact materials, these cases prevent bending and crushing, making them ideal for high-value documents or artwork. While their cost is higher and they may require more organizational effort to use effectively, they provide superior protection. They are particularly advantageous for archival purposes or for businesses that frequently transport sensitive materials.

Making the Right Choice for Your Needs

When deciding among these alternatives, B2B buyers should consider their specific requirements, such as the type of materials being stored, the frequency of transport, and budget constraints. If cost is the primary concern, storage tubes may suffice for basic needs. Conversely, for those needing enhanced protection and flexibility, telescoping poster tubes or rigid document cases will likely deliver greater value in the long run. Understanding the unique strengths and weaknesses of each option will enable buyers to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for drawing tube

What Are the Key Technical Properties of Drawing Tubes?

When selecting drawing tubes for commercial applications, understanding their technical properties is crucial. Below are some essential specifications that B2B buyers should consider:

1. Material Grade

The material grade of a drawing tube significantly influences its durability and functionality. Common materials include high-density polyethylene (HDPE), PVC, and rigid plastic. Each material offers varying levels of strength, flexibility, and resistance to environmental factors such as moisture and UV light. For example, HDPE is known for its robustness, making it suitable for transporting valuable documents and artwork. Understanding the material grade helps buyers ensure they choose a tube that meets their specific storage and transport needs.

2. Diameter and Length

The diameter and length of drawing tubes are critical specifications that dictate the type of content they can accommodate. Tubes may vary in size, typically ranging from 6 inches to over 7 inches in diameter and lengths from 24 inches to 52 inches or more. These dimensions determine the volume of materials that can be stored and transported, making it essential for buyers to select sizes that align with their inventory requirements.

3. Weight Capacity

Weight capacity refers to the maximum load a drawing tube can support without compromising its integrity. This property is particularly important for buyers dealing with heavy or dense materials, such as blueprints or art portfolios. A tube with a robust design can prevent bending, creasing, or damage during transit, ensuring that contents remain intact.

4. Moisture and UV Resistance

Moisture and UV resistance are vital for protecting contents from environmental damage. Tubes designed with these properties safeguard valuable items from water exposure and fading caused by sunlight. For international buyers, especially in regions with high humidity or intense sun exposure, selecting tubes with these protective features is essential to preserve the quality of their materials.

5. Cap and Locking Mechanism

The design of the cap and locking mechanism is another important technical property. A secure locking cap prevents accidental spills or loss of contents during transport. Buyers should look for tubes that offer easy access while ensuring that the contents remain protected from external elements.

What Common Trade Terms Should B2B Buyers Understand Regarding Drawing Tubes?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to drawing tubes:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of drawing tubes, OEM suppliers often provide custom solutions tailored to the specific needs of businesses. Buyers should consider OEM options for specialized requirements or bulk purchasing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses, especially those looking to manage inventory effectively. Buyers should evaluate whether the MOQ aligns with their demand to avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. By submitting an RFQ for drawing tubes, buyers can compare different suppliers’ offerings, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers during shipping and delivery. Understanding Incoterms is essential for B2B transactions involving drawing tubes, as they outline who is responsible for shipping costs, insurance, and risk during transportation.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times for drawing tubes is vital for planning inventory and meeting project deadlines. Buyers should communicate their timelines with suppliers to ensure timely delivery.

Illustrative image related to drawing tube

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when procuring drawing tubes, ensuring that they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the drawing tube Sector

What Are the Current Market Dynamics and Key Trends in the Drawing Tube Sector?

The drawing tube market has been experiencing notable growth driven by increasing demand from artists, architects, and professionals who require effective storage and transportation solutions for large documents and artwork. Global drivers include the rise of remote working and online education, which has spurred the need for portable and protective storage options for presentations and art projects. Additionally, the growing art and design sectors in emerging markets, particularly in Africa and South America, are contributing to the expansion of this market.

Emerging B2B tech trends include the integration of e-commerce platforms that facilitate direct sourcing, making it easier for international buyers to find and procure drawing tubes that meet specific needs. The use of advanced materials, such as moisture-resistant plastics and lightweight composites, is also on the rise, enhancing product durability and functionality. Additionally, a focus on customization is becoming increasingly important, with suppliers offering various sizes, colors, and features like telescoping designs that cater to diverse customer requirements.

International B2B buyers, particularly from regions such as Brazil and Saudi Arabia, are encouraged to stay updated on the latest innovations and product offerings. Understanding local market preferences and regulatory requirements is crucial for effective sourcing. Building relationships with manufacturers who offer reliable supply chains and are responsive to regional needs can significantly enhance procurement strategies.

How Is Sustainability Shaping Sourcing Trends in the Drawing Tube Sector?

Sustainability is becoming a key consideration in the drawing tube market, with growing awareness of environmental impacts influencing procurement choices. Buyers are increasingly prioritizing products made from recyclable or biodegradable materials, as well as those that follow sustainable manufacturing practices. This shift is particularly evident in regions like Europe, where stringent environmental regulations push companies to adopt greener practices.

Ethical sourcing is also gaining traction, with buyers seeking assurance that their products are manufactured under fair labor conditions and with minimal environmental impact. Certifications such as ISO 14001 for environmental management and other green certifications are becoming critical criteria for B2B procurement. Suppliers that can demonstrate compliance with these standards not only enhance their marketability but also build trust with environmentally conscious buyers.

Moreover, the demand for transparency in supply chains is rising. Companies that can provide detailed information about the sourcing of materials and the environmental footprint of their products are likely to gain a competitive edge. By aligning sourcing strategies with sustainability goals, businesses can not only reduce their ecological impact but also appeal to a growing segment of consumers who prioritize ethical considerations in their purchasing decisions.

Illustrative image related to drawing tube

What Is the Historical Evolution of the Drawing Tube Market?

The drawing tube has evolved significantly from its inception, initially designed for the protection and transport of maps and blueprints. Early models were primarily made from cardboard, which, while lightweight, lacked the durability required for long-term storage and transportation. As the demand for high-quality art materials grew, manufacturers began to innovate, introducing more robust materials such as PVC and other plastics that offer greater protection against moisture, light, and physical damage.

In recent decades, technological advancements have further transformed the industry, leading to the development of telescoping designs and customizable features that cater to specific user needs. This evolution has been closely tied to changes in artistic practices and the increasing globalization of the art market. Today, drawing tubes are not only essential tools for artists and architects but also serve as valuable branding opportunities for manufacturers who can offer distinctive designs and high-quality construction.

As international trade continues to expand, the drawing tube market is poised for further growth, driven by ongoing innovation and a heightened focus on sustainability and ethical sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of drawing tube

-

How do I ensure the quality of drawing tubes from international suppliers?

To ensure the quality of drawing tubes, it’s essential to conduct thorough supplier vetting. Start by requesting samples to evaluate material durability and construction. Look for certifications that demonstrate compliance with international quality standards. Additionally, consider working with suppliers who have established a reputation in the market, and check customer reviews and testimonials. Utilizing third-party quality assurance services can also help verify product quality before bulk orders. -

What are the best materials for drawing tubes to protect my artwork?

The best materials for drawing tubes include durable, moisture-resistant plastics like PVC or high-density polyethylene. These materials protect against creasing, tearing, and water damage, ensuring your artwork remains intact during transport and storage. Additionally, some tubes feature reinforced designs for extra sturdiness. When sourcing, inquire about the specific material specifications to ensure they meet your protection requirements. -

What customization options are available for drawing tubes?

Many suppliers offer customization options for drawing tubes, including size adjustments, color choices, and branding opportunities. You can request tubes in various diameters and lengths to accommodate different types of artwork or documents. Custom printing of logos or designs on the tubes is also common, which can enhance brand visibility. When discussing customization, ensure you communicate your specific needs clearly to the supplier to achieve the desired outcome. -

What is the typical minimum order quantity (MOQ) for drawing tubes?

Minimum order quantities (MOQs) for drawing tubes can vary significantly between suppliers, often ranging from 100 to 1,000 units. Factors influencing MOQ include the supplier’s production capacity and the level of customization required. When negotiating, inquire about the possibility of lower MOQs for first-time orders or samples. Understanding MOQs helps in planning your inventory and ensuring you can meet your project demands without overcommitting financially. -

What payment terms should I expect when sourcing drawing tubes internationally?

Payment terms for international transactions typically range from advance payment, partial payments, to net 30 or 60 days after delivery. Many suppliers may require a deposit upfront, especially for custom orders. It’s crucial to discuss and agree upon payment terms before finalizing the contract. Consider using secure payment methods that offer buyer protection, such as letters of credit or escrow services, to minimize risk during the transaction. -

How can I optimize logistics for importing drawing tubes from abroad?

Optimizing logistics involves selecting the right shipping methods, understanding customs regulations, and working closely with reliable freight forwarders. Choose between air or sea freight based on urgency and budget, as air is faster but more expensive. Familiarize yourself with the import regulations in your country to avoid delays. Additionally, negotiate shipping rates and delivery terms with your supplier to ensure cost-effective and timely delivery. -

What are the common issues faced when importing drawing tubes, and how can I avoid them?

Common issues when importing drawing tubes include customs delays, damage during transit, and miscommunication with suppliers. To avoid these, ensure all documentation is complete and accurate, including invoices, packing lists, and certificates of origin. Implement a robust insurance policy to cover potential damages during transport. Establish clear communication channels with your supplier to address any concerns promptly and ensure all parties are on the same page. -

How do I evaluate potential suppliers for drawing tubes?

When evaluating potential suppliers, consider factors such as their manufacturing capabilities, experience in the industry, and customer feedback. Request references and samples to assess product quality. Review their production processes to ensure they adhere to international standards. Additionally, check for certifications that indicate compliance with safety and quality regulations. A reliable supplier should demonstrate transparency and responsiveness throughout your interactions.

Top 6 Drawing Tube Manufacturers & Suppliers List

1. Drafting Supplies Dew – Blueprint & Drawing Carriers

Domain: draftingsuppliesdew.com

Registered: 2002 (23 years)

Introduction: Blueprint and drawing tubes and carriers are essential accessories for architects, engineers, and designers on the move. These containers provide a secure and convenient way to transport and protect large-format documents, such as blueprints, architectural drawings, posters, and maps. With their reliable protection and portability, blueprint tubes are indispensable tools for safeguarding valuable …

2. USA Art Supply – Extra Large Telescoping Drawing & Drafting Tube

Domain: usartsupply.com

Registered: 2008 (17 years)

Introduction: Extra Large Black Telescoping Drawing & Drafting Tube – Item#: USA DT-118 – Adjustable length from 32″ to 52″ – Durable 7-1/4″ outside diameter and 6-5/8″ inside diameter – Weighs 3.8 lb – Made from durable, rigid plastic for protection during travel and storage – Ideal for storing and transporting posters, blueprints, maps, and artwork – Features a secure locking cap to prevent spills – Lightweig…

3. Blick – Storage Tubes

Domain: dickblick.com

Registered: 1995 (30 years)

Introduction: Blick Storage Tubes are constructed of rugged PVC plastic, designed for the storage and protection of valuable artwork, blueprints, charts, and documents. The tubes are moisture-proof, sealed at one end, and feature an easy-to-use, removable cap at the other end. They come with an adjustable shoulder strap for convenience. Available in assorted colors, the tubes are offered in two sizes: Short (26…

4. Engineer Supply – Drawing Tubes

Domain: engineersupply.com

Registered: 1999 (26 years)

Introduction: Drawing tubes are designed for storing large documents such as drawings, maps, artwork, posters, and blueprints. They provide protection from exterior elements, folds, and tears while being portable. Suitable for both students and professionals, these tubes can fit into lockers, cars, or other small spaces.

5. Above Ground – Drafting Tubes

Domain: store.abovegroundartsupplies.com

Registered: 1999 (26 years)

Introduction: This company, Above Ground – Drafting Tubes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. eBay – Waterproof Telescoping Poster Tube

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Drawing Storage Tube options available on eBay include:

– Waterproof Telescoping Poster Tube (Extendable Storage Tube for Artwork and Documents) priced between $15.07 to $79.67, with free delivery and located in Cary, NC.

– Extendable Poster Tube (30″ to 53″ Storage Tube with Strap for Artwork Document Holder) priced at $22.67, with free delivery and located in Cary, NC.

– Telescoping Poster Tube …

Strategic Sourcing Conclusion and Outlook for drawing tube

How Can Strategic Sourcing Enhance Your Procurement of Drawing Tubes?

In conclusion, the strategic sourcing of drawing tubes is pivotal for B2B buyers aiming to optimize their supply chains and ensure quality assurance. By focusing on durable materials, such as rugged PVC and expandable designs, companies can safeguard their valuable documents and artworks during transport and storage. Prioritizing suppliers that offer customizable options and robust customer support will not only meet diverse storage needs but also enhance overall operational efficiency.

International buyers from Africa, South America, the Middle East, and Europe must remain proactive in evaluating suppliers based on product quality, shipping reliability, and cost-effectiveness. As global markets become increasingly interconnected, fostering strong relationships with reputable manufacturers can lead to significant competitive advantages.

Illustrative image related to drawing tube

Looking ahead, now is the time to assess your current sourcing strategies and explore innovative solutions in the drawing tube market. Embrace the opportunity to streamline your procurement processes, enhance your product offerings, and ultimately, drive growth in your business. Engage with trusted suppliers today to secure your supply chain for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to drawing tube