A B2B Buyer’s Guide to Party Food Warm: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for party food warm

In the bustling world of event planning and catering, one of the most pressing challenges that B2B buyers face is sourcing reliable solutions for maintaining the quality of party food warm. Ensuring that food remains at optimal serving temperatures not only enhances the dining experience but also complies with food safety standards. This comprehensive guide delves into the diverse landscape of food warming solutions available globally, addressing the unique needs of buyers from Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany.

Within this guide, you will find an in-depth exploration of various types of food warmers, including countertop units, commercial steam tables, and insulated holding cabinets. We will discuss their applications across different sectors, from catering events to large-scale food service operations. Additionally, this resource provides essential insights into supplier vetting processes, helping you identify reputable manufacturers and distributors that align with your business needs. Understanding the cost implications and return on investment for these solutions will empower you to make informed purchasing decisions.

By equipping yourself with the knowledge and tools presented in this guide, you can confidently navigate the global market for party food warm solutions, ensuring that your clients receive the highest quality service while maintaining food safety and satisfaction.

Understanding party food warm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chafing Dishes | Portable, often with a water bath to maintain temperature | Catering, buffets, events | Pros: Keeps food warm for hours; Cons: Requires fuel or electricity. |

| Commercial Food Warmers | Various models (e.g., countertop, holding cabinets) | Restaurants, hotels, catering | Pros: Versatile; Cons: Initial investment can be high. |

| Electric Steam Tables | Uses steam to keep food warm, often with multiple wells | Cafeterias, large-scale events | Pros: Efficient for high volumes; Cons: Requires water supply and maintenance. |

| Slow Cookers/Instant Pots | Multi-functional with a “keep warm” setting | Catering, home events, food trucks | Pros: Easy to use; Cons: Limited capacity for large events. |

| Heated Banquet Carts | Mobile units designed to hold and transport food | Banquets, large gatherings | Pros: Convenient for serving; Cons: Can be bulky and expensive. |

What Are Chafing Dishes and Their Role in Catering?

Chafing dishes are a staple in catering and buffet settings due to their ability to keep food warm for extended periods. They typically consist of a metal pan that sits over a water bath, which helps maintain a consistent temperature. Ideal for events ranging from weddings to corporate functions, these dishes come in both disposable and reusable options. When considering a purchase, buyers should evaluate the size, material, and whether they need disposable or durable models based on their event frequency and budget.

How Do Commercial Food Warmers Enhance Restaurant Operations?

Commercial food warmers encompass a range of equipment, including countertop models, holding cabinets, and warming drawers. These units are designed to maintain safe food temperatures, crucial for both quality and compliance with health regulations. They are particularly beneficial in fast-paced environments like restaurants and hotels, where efficiency is key. Buyers should consider the capacity, power source, and specific features like adjustable temperature settings to meet their operational needs.

Why Choose Electric Steam Tables for High-Volume Events?

Electric steam tables are designed for high-volume food service, utilizing steam to keep multiple dishes at optimal serving temperatures. Commonly found in cafeterias and large events, they offer the advantage of easy temperature control across several wells. While they are efficient, buyers must ensure they have access to a water supply and consider the maintenance required for steam generation, which can influence long-term operational costs.

What Advantages Do Slow Cookers and Instant Pots Offer for Event Catering?

Slow cookers and Instant Pots are increasingly popular in catering due to their versatility and ease of use. Many models feature a “keep warm” setting, allowing for a seamless transition from cooking to serving. They are particularly suitable for smaller events or food trucks where space is limited. Buyers should assess the capacity and functionality, as larger gatherings may require multiple units to meet demand.

How Do Heated Banquet Carts Facilitate Food Service?

Heated banquet carts are specifically designed to transport and serve food at the correct temperature, making them ideal for banquets and large gatherings. These mobile units can hold multiple trays and often include features like adjustable temperature controls. While they enhance service efficiency, buyers should consider their size and weight, as well as the cost, to ensure they fit within their operational logistics and budget constraints.

Key Industrial Applications of party food warm

| Industry/Sector | Specific Application of party food warm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Catering and Events | Use of chafing dishes and warmers for buffets | Ensures food remains at optimal serving temperatures, enhancing guest satisfaction and minimizing waste. | Look for durable, easy-to-clean options with sufficient capacity for high-volume events. |

| Hospitality | Heated banquet carts for meal service | Streamlines food service during large events, improving efficiency and maintaining food quality. | Consider energy efficiency and mobility features for ease of use across various venues. |

| Food Service Operations | Countertop food warmers in restaurants | Keeps dishes warm during peak hours, ensuring quick service and maintaining food quality. | Assess size, power requirements, and compatibility with existing kitchen setups. |

| Healthcare Facilities | Commercial food warmers for patient meals | Maintains appropriate food temperatures, crucial for patient safety and satisfaction. | Evaluate compliance with health regulations and ease of cleaning for sanitation purposes. |

| Retail Food Merchandising | Display warmers for prepared meals | Attracts customers to grab-and-go options, boosting impulse purchases and sales. | Focus on visibility, design, and energy consumption to optimize merchandising strategies. |

How Can Catering and Events Benefit from Party Food Warm Solutions?

In the catering and events sector, maintaining the right food temperature is critical for guest satisfaction. Chafing dishes and food warmers are commonly used to keep buffet items hot and appealing. These solutions help reduce food waste by ensuring that dishes are served at optimal temperatures throughout an event. International buyers should prioritize sourcing durable, easy-to-clean equipment that can handle high-volume service, especially in regions where large gatherings are common.

What Advantages Do Hospitality Venues Gain from Heated Banquet Carts?

Heated banquet carts are essential in the hospitality industry for efficiently serving meals during large events. They help maintain food quality and temperature from kitchen to table, enhancing the dining experience for guests. Buyers in this sector should consider energy-efficient models with mobility features to facilitate service in various settings, ensuring that food safety standards are met while maximizing operational efficiency.

Why Are Countertop Food Warmers Important for Food Service Operations?

In restaurants, countertop food warmers are invaluable for keeping dishes warm during peak hours. This equipment ensures quick service without sacrificing food quality, which is crucial for maintaining customer satisfaction. B2B buyers should assess the size and power requirements of these warmers, ensuring compatibility with existing kitchen setups to optimize workflow and service efficiency.

How Do Commercial Food Warmers Enhance Patient Meal Services in Healthcare?

Healthcare facilities rely on commercial food warmers to maintain appropriate temperatures for patient meals. This is vital not only for food safety but also for ensuring that patients receive nutritious meals that enhance their recovery. Buyers must evaluate equipment compliance with health regulations and ease of cleaning, as sanitation is paramount in healthcare environments.

What Role Do Display Warmers Play in Retail Food Merchandising?

In retail environments, display warmers for prepared meals serve as an effective merchandising tool. They keep food items warm, attracting customers and boosting impulse purchases. When sourcing these solutions, businesses should focus on visibility and design, alongside energy consumption, to align with their merchandising strategies and enhance overall sales performance.

3 Common User Pain Points for ‘party food warm’ & Their Solutions

Scenario 1: Ensuring Consistent Food Temperatures During Events

The Problem: B2B buyers, especially in the catering and hospitality sectors, often face the challenge of maintaining consistent food temperatures over extended periods. Events like weddings or corporate gatherings can last for hours, and food quality diminishes when left at improper temperatures. Cold appetizers or lukewarm main courses can lead to guest dissatisfaction and tarnish a business’s reputation. This issue is particularly pronounced in regions with variable climate conditions, where maintaining heat can be even more challenging.

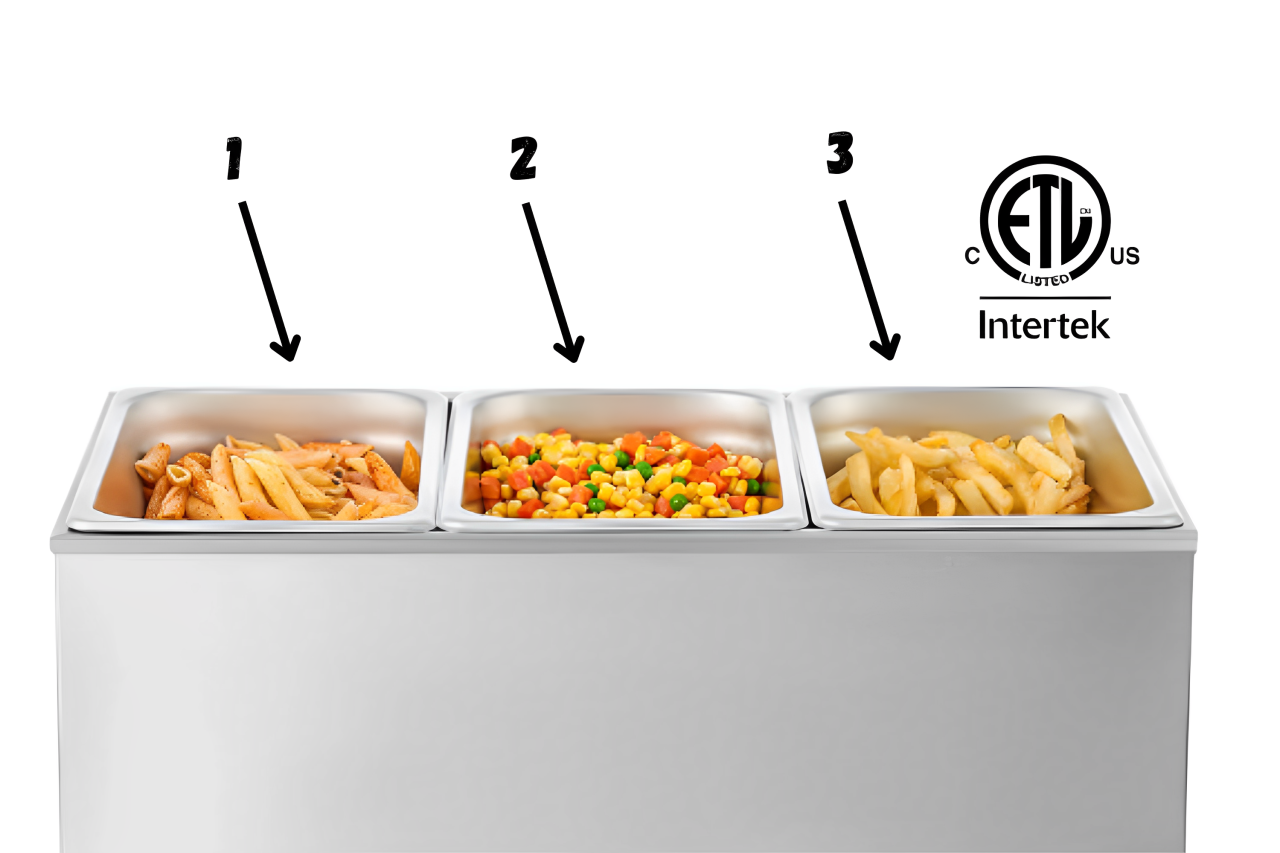

Illustrative image related to party food warm

The Solution: To tackle this issue, businesses should invest in high-quality commercial food warmers tailored to their specific needs. Utilizing equipment such as electric steam tables or heated holding cabinets can help maintain food at safe serving temperatures without overcooking or drying out the dishes. When sourcing these products, buyers should look for models with adjustable temperature controls and good insulation properties to ensure efficiency. Additionally, implementing a regular monitoring system with temperature logs will help ensure food safety and quality throughout the event.

Scenario 2: Balancing Hot and Cold Menu Items for Diverse Palates

The Problem: Catering companies often struggle to create a balanced menu that accommodates both hot and cold food items, particularly for buffet-style service. A lack of appropriate warming solutions can lead to some dishes being served cold, which can detract from the overall dining experience. This scenario is especially relevant in multicultural settings where guests may have varying preferences for food temperature, necessitating a thoughtful approach to menu planning.

The Solution: To effectively manage this challenge, caterers should consider incorporating both hot food display cases and insulated containers for cold items. By strategically using chafing dishes for hot foods and refrigerated units for cold items, businesses can ensure that all offerings are served at their optimal temperatures. Additionally, investing in portable warming solutions, such as heated banquet carts, allows for flexibility during service. When planning the menu, it’s beneficial to include a mix of dishes that can be enjoyed at room temperature, reducing reliance on warming solutions for every item.

Scenario 3: Managing High Volume Service Without Compromising Quality

The Problem: In high-volume service scenarios, such as buffets or large corporate events, maintaining the quality and temperature of a vast array of dishes can be daunting. Catering companies face the risk of food being underheated or overcooked, resulting in wasted resources and dissatisfied customers. This challenge is particularly prevalent in busy environments where staff may be overwhelmed and unable to monitor food temperatures consistently.

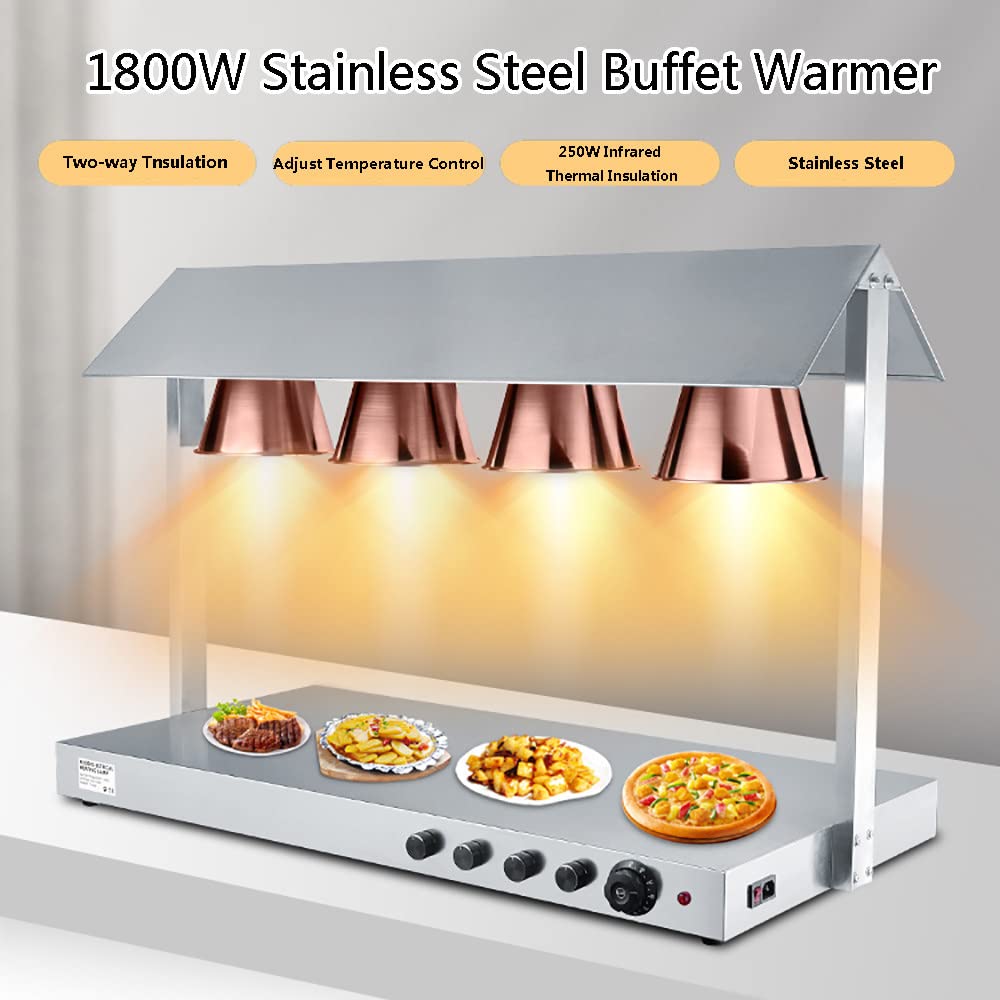

Illustrative image related to party food warm

The Solution: To streamline operations, businesses should invest in robust food warming equipment designed for high capacity. Options like mobile steam tables and countertop food warmers provide the necessary infrastructure to keep multiple dishes at the correct temperature simultaneously. It is crucial for buyers to select warmers that are energy-efficient and easy to clean, as this will save time and costs in the long run. Training staff on the proper use and maintenance of these warmers will also ensure that they can quickly adjust settings as needed during service, thus preserving food quality and enhancing the overall guest experience.

Strategic Material Selection Guide for party food warm

What Are the Key Materials for Party Food Warmers?

When selecting materials for party food warmers, it is essential to consider the properties that influence performance, durability, and overall suitability for specific applications. Below, we analyze four common materials used in the manufacturing of food warmers, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Stainless Steel: The Durable Choice for Food Warmers

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and ability to withstand high temperatures. It is also non-reactive, which means it won’t alter the taste of food.

Pros & Cons: The primary advantage of stainless steel is its durability and ease of cleaning, making it a popular choice for commercial applications. However, it can be more expensive than other materials, and its manufacturing process is complex, which may lead to longer lead times.

Illustrative image related to party food warm

Impact on Application: Stainless steel is ideal for environments where hygiene is critical, such as catering and food service. Its compatibility with high-temperature applications ensures food remains hot without compromising safety.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with food safety standards, such as the European Union’s regulations on materials in contact with food. Countries may have specific grades of stainless steel that are preferred, such as 304 or 316.

Aluminum: The Lightweight Contender

Key Properties: Aluminum is lightweight and has excellent thermal conductivity, allowing for rapid heating and cooling. It is also resistant to corrosion, although not as much as stainless steel.

Illustrative image related to party food warm

Pros & Cons: The main advantage of aluminum is its low cost and lightweight nature, making it easy to transport. However, it is less durable than stainless steel and can warp under high heat if not properly designed.

Impact on Application: Aluminum is suitable for short-term food warming applications, such as disposable trays for events. However, its lower durability may limit its use in high-volume settings.

Considerations for International Buyers: Buyers should be aware of local regulations regarding aluminum food contact materials, particularly in regions with stringent safety standards, such as Germany. Additionally, the cost-effectiveness of aluminum can be appealing in developing markets in Africa and South America.

Illustrative image related to party food warm

Polycarbonate: The Versatile Plastic Option

Key Properties: Polycarbonate is a strong, lightweight plastic that can withstand high temperatures. It is also transparent, allowing for visibility of the food inside.

Pros & Cons: The main advantage of polycarbonate is its versatility and lower cost compared to metals. However, it is less heat-resistant than metals and can become discolored over time with exposure to high temperatures.

Impact on Application: Polycarbonate is often used in food warmers where visibility is essential, such as buffet displays. However, its limitations in heat resistance may restrict its use in high-temperature applications.

Considerations for International Buyers: Compliance with food safety standards is crucial, especially for buyers in Europe and the Middle East. It is also essential to consider the environmental impact and recyclability of polycarbonate in regions increasingly focused on sustainability.

Cast Iron: The Traditional Heavyweight

Key Properties: Cast iron is known for its excellent heat retention and distribution properties. It can withstand high temperatures and is highly durable.

Illustrative image related to party food warm

Pros & Cons: The primary advantage of cast iron is its ability to maintain heat for extended periods, making it ideal for serving hot dishes. However, it is heavy and can be costly, and it requires regular maintenance to prevent rust.

Impact on Application: Cast iron is perfect for traditional serving methods, especially in regions where culinary heritage emphasizes heavy cookware. Its heat retention capabilities make it suitable for dishes that need to stay warm for longer periods.

Considerations for International Buyers: Buyers should consider the weight and maintenance requirements of cast iron products. In regions like Africa and South America, where traditional cooking methods prevail, cast iron may be favored, but buyers must also consider shipping costs due to its weight.

Summary Table of Material Selection for Party Food Warmers

| Material | Typical Use Case for Party Food Warm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Catering and commercial food service | Durable and easy to clean | Higher cost and complex mfg | High |

| Aluminum | Disposable trays for events | Lightweight and cost-effective | Less durable and can warp | Low |

| Polycarbonate | Buffet displays | Versatile and transparent | Limited heat resistance | Medium |

| Cast Iron | Traditional serving methods | Excellent heat retention | Heavy and requires maintenance | Medium |

This analysis provides a comprehensive overview of the materials used in party food warmers, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for party food warm

What Are the Key Manufacturing Processes for Food Warmers?

The manufacturing of food warmers involves several critical stages, ensuring that the final products meet high standards of safety, efficiency, and usability. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to party food warm

How Is Material Prepared for Food Warmers?

The first stage in manufacturing food warmers is material preparation, which typically involves sourcing high-quality raw materials such as stainless steel, aluminum, and specialized insulation materials. Suppliers must ensure that these materials comply with international standards, such as ASTM and ISO certifications, to guarantee durability and safety. Additionally, manufacturers often conduct preliminary tests on materials to check for defects or inconsistencies before proceeding to the next stage.

What Techniques Are Used in the Forming Process?

Once the materials are ready, the forming process begins. This involves various techniques, including:

- Sheet Metal Fabrication: This is a common method used for creating the body of food warmers. It includes cutting, bending, and shaping sheets of metal into the desired form.

- Injection Molding: For components such as handles or knobs, injection molding is employed to create precise and uniform parts from plastic or composite materials.

- Welding and Assembly: After forming, parts are assembled through welding, riveting, or bolting. This ensures a strong structural integrity necessary for the performance of the food warmer.

Manufacturers may also utilize advanced technologies like laser cutting and CNC machining to enhance precision and efficiency during the forming stage.

How Does Assembly and Finishing Work in Food Warmers?

The assembly stage involves combining all the individual components into a functional unit. This is often done in a controlled environment to prevent contamination. Key aspects of the assembly process include:

Illustrative image related to party food warm

- Electrical Assembly: For electric food warmers, wiring and electronic components are installed, ensuring compliance with electrical safety standards.

- Insulation Application: Proper insulation is applied to maintain heat retention and energy efficiency, which is crucial for the performance of food warmers.

Finishing processes, such as powder coating or polishing, are then performed to enhance the aesthetic appeal and protect the product from corrosion. This stage is vital for creating food warmers that are not only functional but also visually appealing for commercial settings.

What Quality Assurance Practices Are Essential for Food Warmers?

Quality assurance (QA) is a fundamental aspect of manufacturing food warmers, ensuring that products are safe and effective for end users. B2B buyers should pay close attention to the QA practices employed by suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

International standards play a significant role in the quality assurance of food warmers. Key certifications include:

- ISO 9001: This standard emphasizes quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: For buyers in Europe, CE marking signifies that the product meets European health, safety, and environmental protection standards.

- UL Certification: In North America, UL certification indicates that the food warmer has been tested for safety and compliance with specific electrical standards.

These certifications provide assurance to B2B buyers regarding the reliability and safety of the products they are purchasing.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage ensures that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and identify any deviations from quality standards.

- Final Quality Control (FQC): After assembly, a comprehensive inspection of the finished product is performed to ensure it meets all quality criteria before shipping.

Implementing these checkpoints allows manufacturers to catch defects early and reduce the likelihood of issues arising post-production.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure they are investing in reliable products. Here are several methods to assess supplier QC:

What Methods Can Be Used for Supplier Audits?

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control practices, and overall operational effectiveness of potential suppliers.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their QC processes, including any certifications, testing results, and historical performance data.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality practices, helping to identify any potential risks before placing large orders.

What Are the Challenges Faced by International B2B Buyers in Ensuring Quality?

B2B buyers from diverse regions, particularly Africa, South America, the Middle East, and Europe, may face unique challenges when sourcing food warmers. Understanding these challenges can help buyers navigate the international landscape more effectively.

How Do Regulatory Differences Impact Sourcing Decisions?

Different countries have varying regulatory requirements for food safety and electrical appliances. Buyers must ensure that the products they are sourcing comply with local regulations in their respective markets. This often requires thorough research and communication with suppliers to confirm that all necessary certifications are in place.

What Are the Cultural Considerations in Supplier Relationships?

Cultural differences can also impact supplier relationships and communication. Understanding regional business practices, negotiation styles, and relationship-building approaches can be crucial for establishing successful partnerships with manufacturers. B2B buyers should invest time in building rapport and trust with suppliers to facilitate smoother transactions and foster long-term collaborations.

Conclusion

The manufacturing processes and quality assurance practices for food warmers are vital components that B2B buyers must consider when sourcing products. By understanding the manufacturing stages, recognizing international standards, and implementing robust quality control measures, buyers can ensure they are selecting reliable suppliers. Navigating the complexities of international sourcing requires diligence, but with the right approach, businesses can successfully procure high-quality food warmers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘party food warm’

Introduction

In the competitive landscape of B2B food service, ensuring that your party food remains warm and appealing is essential for customer satisfaction and operational efficiency. This guide provides a step-by-step checklist for procuring the right equipment and supplies to keep your food warm, helping you make informed decisions that meet your business needs.

Step 1: Assess Your Food Serving Needs

Understanding your specific requirements is the first step in sourcing appropriate warming solutions. Consider factors such as the volume of food, type of dishes, and duration of service. This will inform what types of equipment—like chafing dishes or countertop warmers—are necessary for your operations.

- Key considerations:

- Number of guests expected.

- Types of food to be served (e.g., soups, casseroles).

- Duration of the event.

Step 2: Define Your Technical Specifications

Detail the technical specifications that your warming equipment must meet. This includes temperature range, capacity, and energy source (electric or gas). Having clear specifications will streamline the sourcing process and ensure compatibility with your existing kitchen setup.

Illustrative image related to party food warm

- Important factors:

- Maximum and minimum temperature settings.

- Dimensions and storage capacity.

- Power requirements and efficiency ratings.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, customer testimonials, and case studies to gauge their reliability and quality of service. This step minimizes risks and ensures that you partner with a reputable provider.

- What to look for:

- Experience in your industry or region.

- Quality assurance certifications.

- Availability of customer support.

Step 4: Request Product Samples

Whenever possible, request samples of the warming equipment you are considering. Testing the equipment in real-world conditions will help you assess its performance and suitability for your specific needs.

- Testing criteria:

- Effectiveness in maintaining temperature.

- Ease of use and cleaning.

- Durability and construction quality.

Step 5: Compare Costs and Value

Conduct a comprehensive cost analysis by comparing prices from different suppliers. However, focus not just on the initial cost but also on the long-term value, including warranty, maintenance, and energy efficiency. A slightly higher initial investment may lead to significant savings over time.

Illustrative image related to party food warm

- Cost considerations:

- Upfront purchase price.

- Maintenance costs and warranties.

- Energy consumption and operational costs.

Step 6: Check Compliance with Safety Standards

Ensure that any food warming equipment complies with local and international safety standards. This is crucial for protecting your business from legal liabilities and ensuring the safety of your customers.

- Safety standards to verify:

- Certification from relevant authorities (e.g., CE, NSF).

- Compliance with health regulations.

- User safety features like automatic shut-off.

Step 7: Plan for Installation and Training

Finally, consider the installation and training needs associated with your new equipment. Proper installation and staff training are vital to maximizing the functionality and efficiency of your food warmers.

- Installation details:

- Professional installation services offered by the supplier.

- Availability of training programs for staff.

- User manuals and support resources.

By following this checklist, B2B buyers can make informed decisions that ensure their party food remains warm and appealing, enhancing the overall experience for their customers.

Illustrative image related to party food warm

Comprehensive Cost and Pricing Analysis for party food warm Sourcing

What Are the Key Cost Components for Sourcing Party Food Warm Equipment?

When evaluating the cost structure for sourcing party food warm equipment, several critical components must be considered. The primary cost components include:

-

Materials: The choice of materials directly influences both the quality and cost of food warmers. Stainless steel, for instance, is often favored for its durability and heat retention, but it may come at a higher price compared to less robust materials.

-

Labor: Labor costs encompass both direct labor involved in manufacturing and indirect labor related to administration and management. Understanding the labor market in the supplier’s region can provide insight into potential cost variations.

-

Manufacturing Overhead: This includes costs associated with the production facility, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce these overhead costs, impacting overall pricing.

-

Tooling: Customization often requires specialized tooling, which can add to the initial investment. It’s essential to gauge whether the tooling costs will be absorbed into the unit price or charged separately.

-

Quality Control (QC): Robust QC processes ensure product reliability and safety, but they also incur additional costs. Buyers should inquire about the supplier’s QC practices to understand how these costs may influence pricing.

-

Logistics: Transportation and handling costs are significant, especially for international shipments. Factors such as distance, mode of transport, and customs duties can greatly affect the final pricing.

-

Margin: Suppliers typically include a margin to cover their risks and profit expectations. Understanding the competitive landscape can help buyers negotiate better pricing.

How Do Price Influencers Impact the Cost of Party Food Warm Equipment?

Several factors can influence the pricing of party food warm equipment, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes often leads to significant discounts. Buyers should negotiate MOQs to maximize cost savings.

-

Specifications and Customization: Custom designs or advanced features can increase costs. It’s crucial to assess whether the additional features justify the price increase for your specific needs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like CE or ISO) often come with a premium. However, they may also provide long-term savings through durability and efficiency.

-

Supplier Factors: The supplier’s reputation, reliability, and location can significantly impact pricing. Established suppliers may charge more due to their experience and trustworthiness.

-

Incoterms: Understanding the agreed Incoterms (like FOB or CIF) is vital, as they dictate who is responsible for shipping costs and risks at various points in the transportation process. This clarity can help avoid unexpected expenses.

What Are the Best Negotiation Strategies for International Buyers in Party Food Warm Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation is key to achieving favorable pricing. Here are some tips:

-

Understand Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes shipping, installation, and maintenance costs. This broader perspective can lead to better purchasing decisions.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can provide leverage during negotiations. Regular communication and trust can lead to better terms and discounts.

-

Be Informed About Pricing Nuances: Each market has its pricing dynamics influenced by local economic conditions, demand-supply scenarios, and currency fluctuations. Stay informed to negotiate effectively.

-

Request Transparent Pricing: Ask suppliers for a detailed breakdown of costs. This transparency can help identify areas for negotiation, such as materials or logistics.

-

Consider Long-term Partnerships: Proposing long-term contracts may incentivize suppliers to offer better pricing. Suppliers often value stability and consistent orders.

Conclusion: What Should B2B Buyers Keep in Mind?

In conclusion, sourcing party food warm equipment involves navigating a complex landscape of costs and pricing influences. By understanding the key cost components, recognizing price influencers, and employing strategic negotiation tactics, international B2B buyers can make informed decisions that align with their budgetary constraints and operational needs. Always remember that prices can fluctuate based on market conditions, so remaining adaptable and proactive in your sourcing strategy is essential.

Alternatives Analysis: Comparing party food warm With Other Solutions

Exploring Alternative Solutions to Keep Party Food Warm

In the realm of event catering and hospitality, maintaining food at optimal temperatures is crucial for both safety and guest satisfaction. While ‘party food warm’ solutions are widely utilized, there are several alternative methods that can effectively keep food warm during events. This section provides a comparative analysis of these options to aid international B2B buyers in making informed decisions tailored to their unique operational needs.

| Comparison Aspect | Party Food Warm | Slow Cookers & Instant Pots | Chafing Dishes |

|---|---|---|---|

| Performance | Excellent at maintaining warmth | Good; warm function can vary | Very good; retains heat for hours |

| Cost | Moderate to high, depending on model | Low to moderate | Moderate to high |

| Ease of Implementation | Simple to set up and operate | Requires some knowledge of settings | Easy to use; requires setup time |

| Maintenance | Requires regular cleaning | Low; generally easy to clean | Moderate; depends on type (disposable vs. reusable) |

| Best Use Case | Ideal for large gatherings | Great for smaller, informal events | Perfect for buffets and catered events |

What Are the Pros and Cons of Using Slow Cookers and Instant Pots?

Slow cookers and Instant Pots are versatile kitchen appliances that can be used for a variety of cooking tasks, including keeping food warm. The main advantage of these devices is their affordability and ease of use. They come with preset functions that allow for seamless operation. However, their performance in maintaining food temperature can vary based on the model and settings used. They are best suited for smaller gatherings where a variety of dishes can be prepared in advance. On the downside, they may not be the best fit for high-volume events or formal settings where presentation is key.

Illustrative image related to party food warm

How Do Chafing Dishes Compare in Effectiveness for Keeping Food Warm?

Chafing dishes are a staple in the catering industry and are designed specifically for keeping food warm. They excel in retaining heat for extended periods, making them ideal for buffets and large gatherings. Available in both disposable and reusable options, chafing dishes cater to various budgets and preferences. The downside is that they require a bit more setup time and can involve additional costs if using fuel or sternos for heating. However, for events that prioritize presentation and longevity of food warmth, chafing dishes are often the preferred choice.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate food warming solution, B2B buyers should consider several factors, including the scale of the event, budget constraints, and the type of food being served. For large events where visual appeal and food safety are paramount, investing in chafing dishes may be the best option. Alternatively, for smaller gatherings or more casual settings, slow cookers or Instant Pots could provide a cost-effective and efficient solution. Ultimately, the right choice will depend on the specific operational requirements and customer expectations that each business must meet.

Essential Technical Properties and Trade Terminology for party food warm

What Are the Essential Technical Properties of Party Food Warm Equipment?

Understanding the technical specifications of food warming equipment is crucial for B2B buyers in the hospitality and catering sectors. Here are some critical specifications to consider:

-

Temperature Range

The temperature range indicates the minimum and maximum temperatures the equipment can maintain. For party food warmers, a typical range is between 140°F (60°C) to 200°F (93°C). This specification is vital as it ensures food safety by keeping dishes above the danger zone (below 140°F) where bacteria can thrive. -

Material Grade

Food warmers are commonly made from stainless steel or aluminum. Stainless steel is preferred for its durability, corrosion resistance, and ease of cleaning, while aluminum is lightweight and conducts heat efficiently. The choice of material impacts the longevity of the equipment and its ability to maintain consistent temperatures, which is essential for preserving food quality. -

Power Consumption

Measured in watts, power consumption affects both operational costs and the equipment’s efficiency. High-wattage warmers can heat food quickly but may incur higher electricity bills. Understanding the power requirements helps in selecting equipment that aligns with budget constraints while meeting performance needs. -

Capacity

Capacity refers to the volume of food the warmer can hold, typically measured in liters or the number of pans it can accommodate. This specification is crucial for businesses that cater to large events, as it determines how much food can be kept warm simultaneously, impacting service efficiency. -

Control Features

Many modern food warmers come with digital controls, timers, and programmable settings. These features allow for precise temperature management, enhancing food safety and quality. Understanding these controls is essential for operators to maintain optimal food temperatures throughout events. -

Mobility Options

Some food warmers are designed with wheels for easy transport, while others are stationary. Mobility is important for event caterers who may need to set up and break down at various locations. Assessing mobility needs can significantly influence purchasing decisions.

What Trade Terminology Should B2B Buyers Know About Party Food Warm Equipment?

Familiarity with industry-specific terminology can facilitate better communication and decision-making. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality standards and warranties associated with the equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory planning, especially for businesses looking to minimize costs while ensuring they have enough equipment for their needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. It is a key step in the procurement process, allowing buyers to compare prices and terms from multiple vendors, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping costs, risks, and delivery obligations. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead times is crucial for planning events and ensuring that equipment arrives on schedule, preventing last-minute shortages. -

Warranty Period

The warranty period is the time frame during which a manufacturer guarantees the performance of their equipment. Knowing the warranty details helps buyers assess the risk associated with their investment and the potential costs of future repairs or replacements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and food safety standards in the hospitality sector.

Navigating Market Dynamics and Sourcing Trends in the party food warm Sector

What Are the Current Market Dynamics and Key Trends in the Party Food Warm Sector?

The global party food warm sector is experiencing robust growth, driven by increasing consumer demand for quality catering solutions and the rise of event-based gatherings. Key market drivers include the expanding middle class in emerging economies such as Africa and South America, where social events are becoming more elaborate and frequent. Additionally, the proliferation of online food delivery services is reshaping how food is prepared and served, necessitating efficient food warming solutions that maintain temperature and quality during transit.

Emerging technologies are playing a significant role in sourcing trends within the sector. Innovations such as smart food warmers equipped with IoT capabilities are gaining traction, allowing for real-time temperature monitoring and energy management. B2B buyers are increasingly looking for equipment that not only meets food safety standards but also enhances operational efficiency. This trend is particularly relevant for buyers in regions like Europe and the Middle East, where regulations around food safety are stringent.

Furthermore, sustainability is becoming a critical factor in purchasing decisions. Buyers are favoring suppliers who provide eco-friendly warming solutions, including energy-efficient appliances and products made from recyclable materials. As the market evolves, staying abreast of these trends will be essential for international B2B buyers aiming to remain competitive.

Illustrative image related to party food warm

How Important Is Sustainability and Ethical Sourcing in the Party Food Warm Sector?

The environmental impact of food warming solutions is a growing concern, particularly as the food service industry grapples with sustainability challenges. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability practices. This includes the use of materials that minimize environmental impact and energy-efficient warming technologies that reduce carbon footprints.

Ethical supply chains are not just a trend; they are becoming a fundamental expectation among consumers and businesses alike. Buyers are seeking certifications such as Green Seal or Energy Star that indicate a product’s adherence to eco-friendly standards. These certifications not only enhance a company’s credibility but also align with the values of environmentally-conscious consumers.

Moreover, the push for sustainable practices extends to packaging and waste management. Suppliers offering biodegradable or recyclable packaging solutions are gaining favor, as they contribute to reducing overall waste. By focusing on sustainability, B2B buyers can differentiate themselves in a competitive market while also appealing to a growing demographic that values environmental responsibility.

How Has the Party Food Warm Sector Evolved Over Time?

The evolution of the party food warm sector can be traced back to the increasing demand for catering services in the mid-20th century. Initially, food warmers were simple, mechanical devices that relied on basic heating elements. However, as the catering industry grew, so did the complexity and technology of food warming solutions.

The late 20th century saw significant advancements with the introduction of electric and gas food warmers, which allowed for greater temperature control and efficiency. The advent of digital technology and smart appliances in the 21st century has further transformed the landscape, enabling features such as programmable settings and remote monitoring.

Today, the sector is characterized by a blend of traditional and innovative solutions, with an emphasis on sustainability and efficiency. As B2B buyers navigate this evolving landscape, understanding its history provides valuable context for making informed purchasing decisions that align with current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of party food warm

-

How do I choose the right food warmer for my business needs?

Selecting the appropriate food warmer depends on several factors, including the type of food you serve, the volume of food, and your operational space. For high-volume settings like buffets or catering events, consider commercial steam tables or chafing dishes that provide even heat distribution. For smaller operations, countertop warmers may suffice. Evaluate features such as temperature controls, capacity, and energy efficiency to ensure you meet health and safety standards while keeping food at optimal serving temperatures. -

What is the best method to keep food warm during events?

The most effective method to keep food warm during events is to utilize specialized equipment like food warmers, chafing dishes, and steam tables. These devices maintain food at safe temperatures, preventing bacterial growth. For short-term solutions, insulated containers or coolers can also keep food warm when covered properly. It’s essential to monitor temperatures regularly to ensure food remains above 140°F (60°C), maintaining both safety and quality throughout the event. -

What are the minimum order quantities (MOQ) for food warmers?

Minimum order quantities can vary significantly by supplier and region. Many manufacturers set MOQs to ensure cost-effectiveness in production and shipping. Generally, you might expect MOQs to range from 10 to 100 units, especially for customized equipment. It’s advisable to discuss specific needs with suppliers to explore options that fit your business scale, including potential for smaller initial orders or bulk discounts. -

How can I vet suppliers for food warmers internationally?

When vetting international suppliers, begin by assessing their reputation through reviews, certifications, and industry experience. Request product samples to evaluate quality and performance. Verify compliance with international standards, such as ISO or CE certifications, which ensure safety and reliability. Additionally, consider their production capacity, lead times, and after-sales support to ensure they can meet your ongoing business needs effectively. -

What payment terms should I expect when sourcing food warmers?

Payment terms for international purchases can vary, but common practices include a deposit upfront (often 30-50%) with the balance due before shipment. Some suppliers may offer letters of credit or other financing options. It’s crucial to clarify terms upfront and ensure they are documented in your purchase agreement to avoid disputes. Understanding the payment process, including currency exchange rates and transaction fees, is also essential for budgeting. -

How do I ensure quality assurance for food warmers?

Quality assurance can be ensured by establishing clear specifications and standards in your purchase agreement with suppliers. Request documentation for quality control processes, including testing procedures and certifications. Regular inspections and audits of manufacturing facilities can also help maintain product quality. Additionally, consider including a warranty or guarantee in your contract to protect against defective products. -

What logistics considerations should I be aware of when importing food warmers?

Logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with international shipping to navigate customs efficiently. Understand the import duties and taxes applicable in your country to accurately forecast total costs. Additionally, plan for potential delays due to customs inspections or shipping disruptions, especially when sourcing from regions with varying infrastructure reliability. -

Can I customize food warmers to suit my brand or specific needs?

Many suppliers offer customization options for food warmers, including branding, size, and functionality adjustments. Discuss your specific requirements with potential suppliers, as some may have minimum order quantities for customized products. Customizing can help align the equipment with your brand identity while ensuring it meets your operational needs. Be prepared to provide detailed specifications and discuss any additional costs associated with customization.

Top 5 Party Food Warm Manufacturers & Suppliers List

1. Reddit – Recipe Planning Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Recipe Planning Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. The Pioneer Woman – Kitchen Essentials

Domain: thepioneerwoman.com

Registered: 2006 (19 years)

Introduction: Aluminum Foil, Slow Cooker, Instant Pot, Air Fryer, Oven, Toaster Oven, Cooler, Chafing Dishes

3. Host Modern – Insulated Serveware & Warming Solutions

Domain: hostmodern.co

Registered: 2023 (2 years)

Introduction: 1. Insulated Serveware: Great for soups, stews, and pasta; portable and easy to use; retains heat for a few hours but may overcook certain foods.

2. Ovens and Warming Drawers: Maintains consistent heat (170-200°F); ideal for large dishes; can dry out food if not monitored.

3. Chafing Dishes: Uses a water pan heated by fuel; provides even heat for extended periods; requires fuel and can be bulky.

4…

4. Facebook – Baked Sauce Trays

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Baked Sauce Trays, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Wilprep – Triple Well Food Warmer

Domain: wilprepkitchen.com

Registered: 2023 (2 years)

Introduction: Wilprep’s Triple Well Food Warmer: 1. Three stainless steel wells with pan covers to trap heat. 2. Efficient heating with a stainless steel U-shaped heating tube for rapid and uniform heating. 3. Large capacity suitable for catering.

Strategic Sourcing Conclusion and Outlook for party food warm

In the evolving landscape of party food warm solutions, strategic sourcing remains pivotal for international B2B buyers. Understanding the diverse range of food warmers—from countertop units to commercial steam tables—enables businesses to select equipment that meets both operational demands and budgetary constraints. Leveraging suppliers who provide high-quality, efficient warming solutions can enhance food safety, improve customer satisfaction, and ultimately drive profitability.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for reliable food warming equipment will only grow. Buyers should prioritize partnerships with manufacturers and distributors who offer innovative, sustainable, and compliant products tailored to local culinary practices and preferences.

Looking ahead, the integration of technology in food warming solutions, such as smart temperature controls and energy-efficient models, will shape the future of this sector. We encourage international buyers to engage with suppliers that not only meet current needs but also anticipate future trends, ensuring a competitive edge in the dynamic food service industry. Embrace strategic sourcing to secure the best options for your business and delight your customers with consistently warm, delicious food at every event.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.