Unlocking Value: A Strategic Analysis of the Power Supply C Market

Introduction: Navigating the Global Market for power supply c

In today’s interconnected world, sourcing reliable and efficient power supply solutions is a critical challenge for businesses across various sectors. For B2B buyers specifically seeking power supply c options, the task extends beyond mere procurement; it involves navigating a complex landscape filled with diverse products, specifications, and supplier capabilities. This guide aims to demystify the global market for power supply c, providing valuable insights into types, applications, and supplier vetting processes.

With an emphasis on compatibility, cost efficiency, and technological advancements, our comprehensive resource equips international buyers—especially those from Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany—with the knowledge needed to make informed purchasing decisions. We delve into the nuances of power supply standards, highlight key features such as USB-C integration and Power Delivery specifications, and discuss best practices for evaluating potential suppliers.

By the end of this guide, readers will be empowered to navigate the intricate web of options available in the power supply market, ensuring they select solutions that meet their operational needs while maximizing value. Whether you’re looking to enhance your product offerings or streamline your supply chain, understanding the global market dynamics of power supply c is essential for sustaining competitive advantage in today’s fast-paced business environment.

Understanding power supply c Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| USB-C Power Delivery | Supports multiple voltage profiles (5V-20V), compact design | Charging laptops, tablets, and smartphones | Pros: Universal compatibility, fast charging; Cons: Limited to devices supporting USB-C PD. |

| AC-DC Power Supplies | Converts alternating current (AC) to direct current (DC), often modular | Industrial equipment, telecommunications | Pros: High efficiency, customizable; Cons: Complexity in installation, may require specialized knowledge. |

| Flush-Mounted Power Supply | Designed for in-wall installation, often includes USB ports | Residential and commercial spaces | Pros: Space-saving, aesthetic appeal; Cons: Installation can be labor-intensive. |

| High-Power Supplies | Delivering 100W+ power, often used for demanding applications | Data centers, gaming, and high-performance computing | Pros: Supports demanding workloads; Cons: Higher costs, requires robust infrastructure. |

| Multi-Output Power Supplies | Multiple outputs for different devices, adjustable voltage settings | Laboratories, medical equipment | Pros: Versatility, can power various devices; Cons: Bulkier, may have a higher initial cost. |

What Are the Key Characteristics of USB-C Power Delivery?

USB-C Power Delivery (PD) chargers are characterized by their ability to negotiate power levels, providing a flexible charging solution for a wide range of devices. Supporting multiple voltage profiles, such as 5V, 9V, 12V, 15V, and 20V, they are ideal for charging laptops, tablets, and smartphones. For B2B buyers, the main consideration is compatibility; ensuring that the devices in use support USB-C PD is crucial for maximizing the benefits of this technology.

How Do AC-DC Power Supplies Function in Industrial Settings?

AC-DC power supplies convert alternating current into direct current, making them essential for powering various industrial and telecommunications equipment. Their modular designs allow for customization based on specific operational needs. B2B buyers should assess the efficiency ratings and output stability, as these factors can significantly impact operational costs and equipment longevity.

Why Choose a Flush-Mounted Power Supply for Commercial Spaces?

Flush-mounted power supplies are designed for in-wall installation, providing a clean and unobtrusive charging solution. They often include USB ports, making them convenient for modern devices. These units are particularly suitable for commercial and residential applications where aesthetics and space-saving are priorities. However, buyers should consider the installation complexity and potential need for professional assistance.

What Are the Benefits of High-Power Supplies in Data Centers?

High-power supplies, delivering over 100W, are essential in data centers and environments requiring high-performance computing. They support demanding workloads and can power multiple high-end devices simultaneously. B2B buyers need to factor in the infrastructure requirements and higher costs associated with these power supplies, ensuring they align with their operational capabilities and budget.

How Do Multi-Output Power Supplies Enhance Laboratory Operations?

Multi-output power supplies provide adjustable voltage settings and multiple outputs, making them versatile tools for laboratories and medical equipment. They can power various devices, from sensors to testing equipment, enhancing workflow efficiency. However, buyers should be aware of the bulkier designs and potentially higher initial costs, balancing these factors against the operational benefits.

Key Industrial Applications of power supply c

| Industry/Sector | Specific Application of power supply c | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Charging stations for smartphones and tablets | Increases customer satisfaction with fast charging | Ensure compatibility with various device brands and models |

| Automotive | Powering onboard electronics in electric vehicles | Enhances vehicle functionality and user experience | Look for high-efficiency and safety certifications |

| Industrial Automation | Power supply for robotics and control systems | Improves operational efficiency and reliability | Focus on robustness and adaptability to different environments |

| Telecommunications | Base stations for mobile networks | Supports reliable communication in remote areas | Consider local regulations and supply chain logistics |

| Healthcare | Medical device charging stations | Ensures continuous operation of critical devices | Compliance with healthcare standards and certifications |

How is Power Supply C Used in Consumer Electronics Charging Stations?

In the consumer electronics sector, power supply c is essential for charging stations designed for smartphones and tablets. With the proliferation of USB-C devices, businesses can enhance customer satisfaction by providing fast and efficient charging options. This application addresses the common problem of long wait times for device charging, making it crucial for retailers and service providers. International buyers should ensure that the power supply is compatible with multiple brands and models to cater to diverse customer needs.

What Role Does Power Supply C Play in the Automotive Industry?

In the automotive industry, power supply c is increasingly utilized to power onboard electronics in electric vehicles (EVs). This technology enhances vehicle functionality, allowing for advanced features such as infotainment systems, navigation, and battery management. As the demand for EVs rises, manufacturers must focus on sourcing power supplies that offer high efficiency and safety certifications to ensure reliability and performance. Buyers should also consider the integration of these power supplies into existing vehicle architectures.

How is Power Supply C Applied in Industrial Automation?

Power supply c finds significant application in industrial automation, particularly in powering robotics and control systems. This technology is vital for improving operational efficiency and reliability in manufacturing processes. By leveraging power supply c, businesses can ensure that their automation systems run smoothly, minimizing downtime. Buyers in this sector should prioritize sourcing power supplies that are robust and adaptable to various operational environments, including extreme temperatures and dust.

What is the Importance of Power Supply C in Telecommunications?

In telecommunications, power supply c is used to energize base stations for mobile networks, ensuring reliable communication in remote and underserved areas. This application is critical for maintaining connectivity and supporting the growing demand for mobile data. Businesses should consider local regulations when sourcing power supplies, as compliance is essential for operational success. Additionally, understanding supply chain logistics is crucial to ensure timely delivery and installation.

How Does Power Supply C Benefit the Healthcare Sector?

In the healthcare sector, power supply c is crucial for charging stations used for medical devices. Ensuring the continuous operation of critical medical equipment is vital for patient care and safety. This application addresses the pressing need for reliable power sources in hospitals and clinics. Buyers must focus on compliance with healthcare standards and certifications to guarantee the safety and efficacy of the power supplies they procure.

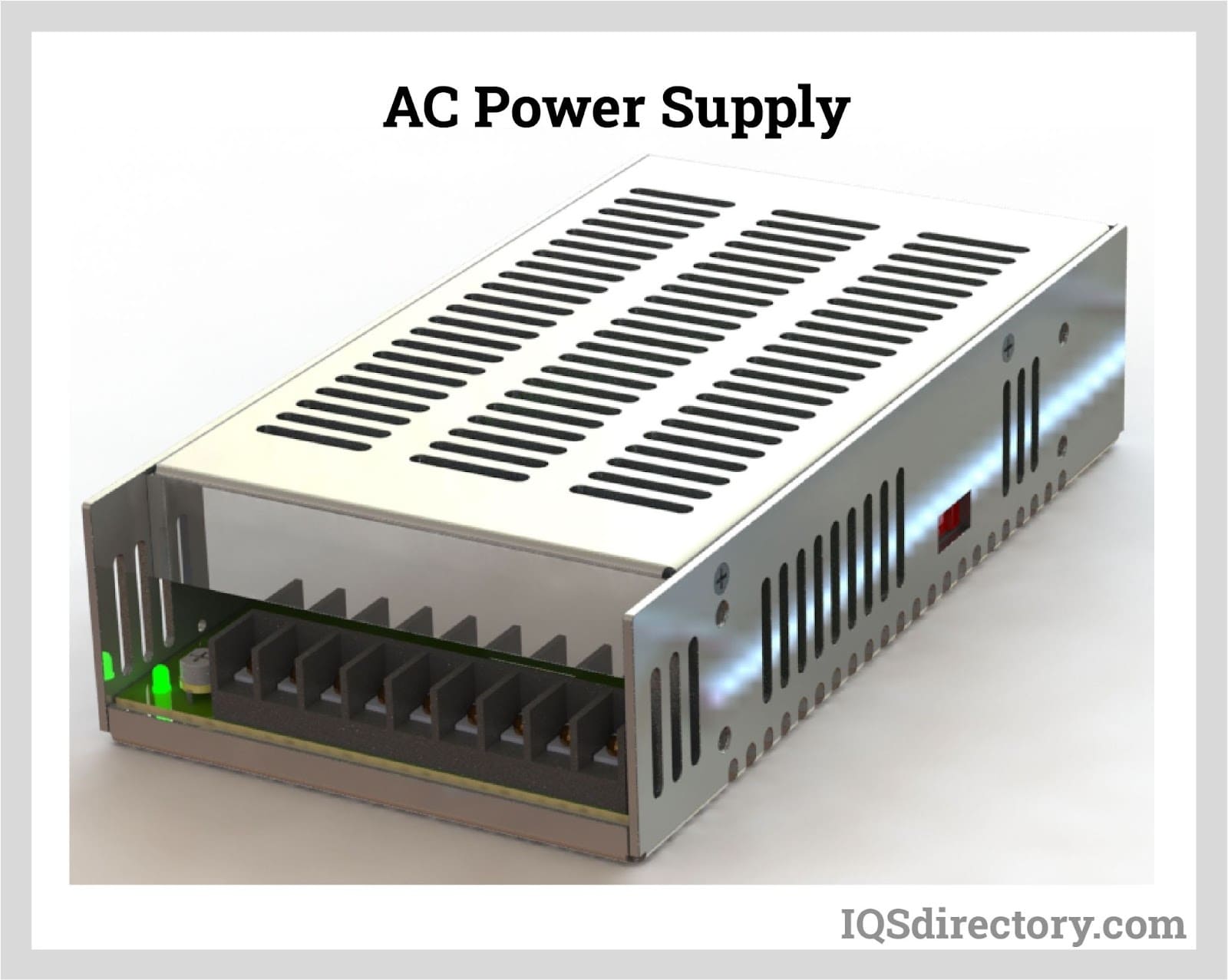

Illustrative image related to power supply c

3 Common User Pain Points for ‘power supply c’ & Their Solutions

Scenario 1: Compatibility Challenges with Diverse Devices

The Problem: One of the primary challenges B2B buyers face when sourcing power supply units is ensuring compatibility across a variety of devices. Many organizations utilize a mix of laptops, tablets, and smartphones from different manufacturers, each with unique power requirements. For instance, devices from Apple, Dell, and Lenovo may require different voltage levels and connectors, leading to confusion and inefficiencies in procurement and inventory management. This can cause delays in operations when devices are rendered unusable due to incompatible chargers.

The Solution: To overcome compatibility issues, buyers should prioritize sourcing power supplies that adhere to universal charging standards, such as USB-C Power Delivery (PD). When selecting power supply units, look for models that explicitly list compatibility with a wide range of devices. For example, choosing a power supply that supports multiple voltage profiles (5V, 9V, 12V, 15V, and 20V) and current ratings up to 3A ensures versatility. Additionally, consider investing in power supply units with detachable cables to accommodate various device connectors. It’s beneficial to maintain a centralized inventory of chargers that cover the most commonly used devices in your organization, reducing the risk of downtime.

Scenario 2: Inconsistent Power Delivery Leading to Device Damage

The Problem: Another significant concern for B2B buyers is the risk of inconsistent power delivery, which can lead to device overheating or even permanent damage. Organizations may rely on subpar or counterfeit chargers that do not meet safety standards, resulting in unpredictable charging behavior. This not only jeopardizes the lifespan of expensive equipment but can also compromise data integrity and lead to operational disruptions.

The Solution: To mitigate the risks associated with power delivery inconsistencies, buyers should seek certified power supply units that comply with safety standards such as UL, CE, or FCC. It’s essential to partner with reputable suppliers known for their quality assurance processes. Additionally, implementing a regular maintenance schedule to inspect and replace aging power supplies can help prevent unexpected failures. Educating staff about the importance of using only certified chargers will also contribute to a culture of safety and reliability within the organization.

Illustrative image related to power supply c

Scenario 3: Limited Availability of Local Support and Warranty Issues

The Problem: B2B buyers often encounter difficulties with local support and warranty claims when sourcing power supplies from international suppliers. In regions such as Africa or South America, where access to reliable customer service may be limited, issues such as defective units or questions about product specifications can lead to prolonged downtime. Additionally, understanding warranty terms and navigating international shipping for replacements can be cumbersome.

The Solution: To address these concerns, buyers should opt for power supply manufacturers that offer localized support and clear warranty terms. Before making a purchase, inquire about the availability of technical support and whether the supplier has a presence in your region. Look for suppliers that provide a robust warranty policy, ideally with a two-year coverage or longer, and ensure that they offer hassle-free returns and replacements. This can significantly reduce the time and effort involved in resolving issues. Establishing a relationship with suppliers who have a proven track record in your region can also facilitate smoother transactions and better support when needed.

By focusing on these key pain points, B2B buyers can make informed decisions that enhance operational efficiency, ensure device safety, and foster reliable supplier relationships.

Strategic Material Selection Guide for power supply c

What Are the Key Materials Used in Power Supply C Manufacturing?

When selecting materials for power supply c, it’s crucial to consider their properties, advantages, and limitations. The choice of materials significantly impacts performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of power supply c, focusing on their suitability for B2B applications in diverse global markets.

Illustrative image related to power supply c

How Does Copper Contribute to Power Supply C Performance?

Copper is widely recognized for its excellent electrical conductivity, making it a primary choice for wiring and connectors in power supply c. Key properties include a high melting point (1,984°F or 1,085°C) and good corrosion resistance, particularly when coated.

Pros: Copper’s high conductivity ensures minimal energy loss, enhancing efficiency. It is also relatively easy to manufacture and shape, allowing for versatile designs.

Cons: However, copper can be more expensive than alternatives like aluminum and is susceptible to oxidation if not properly coated, which can affect performance over time.

Impact on Application: Copper is compatible with various media, including high-voltage applications, but care must be taken to prevent corrosion in humid or corrosive environments.

International Considerations: Buyers should ensure compliance with standards such as ASTM B170 (for copper wire) and consider the availability of copper in their region, as supply chains can vary significantly.

Illustrative image related to power supply c

What Role Does Aluminum Play in Power Supply C Design?

Aluminum is another common material, often chosen for its lightweight properties and cost-effectiveness. It has a lower melting point (1,221°F or 660°C) compared to copper but offers decent conductivity.

Pros: The primary advantage of aluminum is its lower cost and weight, making it suitable for portable power supply c designs. Additionally, it is resistant to corrosion, especially when anodized.

Cons: Aluminum’s conductivity is about 61% that of copper, which may require larger conductor sizes to achieve equivalent performance. This can complicate manufacturing and design.

Illustrative image related to power supply c

Impact on Application: Aluminum is suitable for lower voltage applications and environments where weight is a critical factor, such as in mobile devices.

International Considerations: Compliance with JIS H 3100 (Japanese Industrial Standards) and other regional standards is vital, especially in markets like Japan and Europe.

How Does Plastic Insulation Enhance Power Supply C Safety?

Plastic materials, particularly thermoplastics like polycarbonate and PVC, are essential for insulation in power supply c applications. They offer good dielectric properties and can withstand a range of temperatures.

Pros: Plastics are lightweight, cost-effective, and provide excellent insulation, reducing the risk of electrical shorts. They can also be molded into complex shapes, enhancing design flexibility.

Cons: However, plastics can degrade over time under UV exposure or high temperatures, which may limit their lifespan in certain applications.

Impact on Application: Plastic insulation is crucial for ensuring safety in consumer electronics and industrial applications, where electrical safety is paramount.

International Considerations: Compliance with IEC 60730 (for electrical devices) and other safety standards is essential, particularly in Europe and the Middle East, where regulatory scrutiny is high.

Illustrative image related to power supply c

What Advantages Does Steel Offer in Power Supply C Structures?

Steel, particularly stainless steel, is often used in the structural components of power supply c units. Its key properties include high tensile strength and excellent durability.

Pros: Steel provides robust support and protection for internal components, enhancing overall durability. It is also highly resistant to mechanical stress and can withstand harsh environmental conditions.

Cons: The primary disadvantage is its weight, which can complicate installation and portability. Additionally, steel can be prone to corrosion if not adequately treated.

Impact on Application: Steel is ideal for industrial applications where durability is critical, but its weight may limit its use in portable devices.

International Considerations: Buyers should consider compliance with DIN 1.4301 (German standard for stainless steel) and ensure that the material meets local regulations regarding safety and environmental impact.

Illustrative image related to power supply c

Summary Table of Material Selection for Power Supply C

| Material | Typical Use Case for power supply c | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and connectors | Excellent electrical conductivity | Higher cost, oxidation risk | High |

| Aluminum | Lightweight applications | Cost-effective, lightweight | Lower conductivity than copper | Medium |

| Plastic | Insulation for wires and components | Lightweight, excellent insulation | Degrades under UV/high temps | Low |

| Steel | Structural components | High durability and strength | Heavy, potential corrosion | Medium |

This analysis provides a comprehensive overview of material selection for power supply c, offering valuable insights for international B2B buyers. Understanding the properties, advantages, and limitations of each material can guide informed purchasing decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for power supply c

What Are the Key Stages in the Manufacturing Process of Power Supply Units?

The manufacturing process for power supply units (PSUs) involves several critical stages, ensuring that the final product meets the necessary specifications and quality standards. These stages are generally categorized into material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first stage in manufacturing PSUs involves sourcing and preparing materials. This typically includes high-quality components such as transformers, capacitors, resistors, and circuit boards. Manufacturers often prioritize materials that comply with international standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals).

Once sourced, materials undergo inspection to ensure they meet specified quality criteria. This is known as Incoming Quality Control (IQC), where materials are checked for defects, dimensions, and compliance with standards. This step is crucial for preventing issues in later stages of production.

How Are Power Supply Units Formed and Assembled?

The forming stage includes processes like stamping and molding components into their desired shapes. For example, metal casings are often stamped from sheets of metal, while plastic parts may be injection-molded. This stage requires precision machinery to maintain quality and consistency.

Illustrative image related to power supply c

Following forming, the assembly process begins. This typically involves soldering components onto printed circuit boards (PCBs), integrating transformers, and assembling the external casing. Automated assembly lines are commonly used to enhance efficiency and precision. Additionally, skilled technicians may perform manual assembly for more complex or sensitive components.

What Finishing Techniques Are Commonly Used in Power Supply Manufacturing?

The finishing stage involves several steps, including testing, painting, and labeling. Final testing is essential to ensure that the power supply functions correctly under various conditions. Manufacturers often conduct Functional Quality Control (FQC) tests to simulate real-world scenarios.

Once the units pass testing, they may undergo surface treatments or coatings to enhance durability and aesthetics. Finally, labeling with necessary certifications and compliance information is completed, allowing B2B buyers to verify the product’s quality and standards.

What Quality Assurance Standards Are Relevant for Power Supply Manufacturing?

Quality assurance is a critical aspect of manufacturing power supplies. International standards, such as ISO 9001, provide a framework for maintaining high-quality production processes. Compliance with ISO standards ensures that manufacturers adopt a systematic approach to quality management, focusing on continuous improvement and customer satisfaction.

In addition to general quality management standards, industry-specific certifications like CE (Conformité Européenne) for European markets and UL (Underwriters Laboratories) for North America are vital. These certifications indicate that the product meets safety and performance criteria established by regulatory bodies.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control is typically integrated at various checkpoints throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This stage involves the inspection of raw materials and components upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to identify defects early. This may involve monitoring soldering quality, component placement, and assembly accuracy.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes comprehensive testing to ensure it meets all specifications and performance criteria.

Each of these checkpoints plays a vital role in maintaining the integrity of the manufacturing process and ensuring that the final product is reliable and safe for end-users.

Illustrative image related to power supply c

What Testing Methods Are Commonly Used to Ensure Power Supply Quality?

Testing methods for power supplies vary depending on the specifications but commonly include:

- Electrical Testing: Checks for voltage output, current ratings, and efficiency under load conditions.

- Thermal Testing: Evaluates how the power supply performs under extreme temperature conditions to ensure it remains operational without overheating.

- Safety Testing: Ensures compliance with safety standards, including insulation resistance and dielectric strength tests.

- EMI/EMC Testing: Verifies that the power supply does not emit excessive electromagnetic interference and complies with electromagnetic compatibility standards.

These tests are often documented in detailed reports, which B2B buyers can request to verify product compliance and quality.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers looking to ensure the quality of their power supply suppliers should consider several verification methods:

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing practices, quality control measures, and adherence to international standards.

-

Quality Assurance Reports: Request detailed quality assurance reports, including IQC, IPQC, and FQC results. These documents should outline testing methods and results, demonstrating the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control measures and product reliability.

-

Certifications: Verify that the supplier holds relevant certifications (ISO, CE, UL) and that these certifications are up-to-date.

What Are the Challenges for International B2B Buyers in Ensuring Quality Control?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, may face unique challenges in verifying quality control. These challenges can include:

-

Regulatory Differences: Varying regulatory requirements across regions can complicate compliance verification. Buyers must ensure that suppliers meet both local and international standards.

-

Cultural Barriers: Communication difficulties may arise due to language differences or varying business practices. Establishing clear channels of communication is essential.

-

Logistics and Supply Chain Issues: International shipping can lead to delays and complications in receiving products. Buyers should have contingency plans to address potential supply chain disruptions.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing power supply units, ensuring that they receive products that meet their specifications and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power supply c’

This guide aims to equip international B2B buyers with a practical checklist for sourcing power supply units, specifically focusing on USB-C models. By following these steps, you can ensure that you select a reliable supplier and product that meets your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline the technical requirements for the power supply units you need. Consider factors such as voltage, current output, and compatibility with existing devices. For instance, a USB-C power supply might need to deliver varying voltage levels (5V, 9V, 12V, etc.) depending on the devices being charged.

- Voltage Requirements: Ensure the supply can handle the voltage your devices require.

- Power Delivery Standards: Look for compliance with USB Power Delivery (PD) specifications for optimal performance.

Step 2: Identify Your Target Market Regulations

Understanding the regulations and standards applicable in your target market is critical. Different regions may have specific certifications for electrical equipment, which could affect product availability and compliance.

- CE and UL Certifications: Verify that the power supply units have necessary certifications like CE for Europe or UL for North America to ensure safety and compliance.

- Voltage Compatibility: Make sure the power supply is suitable for the voltage used in your target market, especially if you are sourcing from different regions.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, product specifications, and references from existing clients, particularly those in similar industries or regions.

Illustrative image related to power supply c

- Supplier Reputation: Research online reviews and testimonials to gauge the supplier’s reliability.

- Case Studies: Ask for examples of previous projects or clients to assess their experience in your sector.

Step 4: Request Samples for Testing

Before placing a bulk order, always request product samples to evaluate their quality and performance. This step is crucial to ensure that the power supply units meet your specified requirements.

- Testing Compatibility: Check the samples with your devices to confirm they function correctly under expected load conditions.

- Assess Build Quality: Inspect the physical quality of the power supplies, including durability and design.

Step 5: Understand Pricing and Payment Terms

Discuss pricing and payment terms upfront to avoid surprises later in the process. Understanding the total cost of ownership, including shipping and potential tariffs, is vital for budgeting.

- Bulk Order Discounts: Inquire about discounts for larger orders to maximize your budget.

- Payment Flexibility: Look for suppliers offering flexible payment terms that suit your cash flow.

Step 6: Evaluate Customer Support and Warranty

Ensure the supplier provides robust customer support and a reasonable warranty for their products. This can be a significant factor in your long-term satisfaction with the purchase.

- Technical Support: Check if the supplier offers lifetime technical support to assist with any issues that arise post-purchase.

- Warranty Terms: Look for products that come with at least a two-year warranty to safeguard your investment.

Step 7: Confirm Logistics and Delivery Times

Finally, clarify the logistics involved in the procurement process. Understanding lead times, shipping methods, and any potential delays can help you plan your operations effectively.

Illustrative image related to power supply c

- Shipping Options: Discuss various shipping methods to find the most cost-effective and timely solutions.

- Delivery Tracking: Ensure the supplier provides tracking capabilities for shipments to monitor delivery progress.

By following this checklist, you will be better positioned to make informed purchasing decisions, ensuring that the power supply units you procure meet your operational needs and comply with relevant regulations.

Comprehensive Cost and Pricing Analysis for power supply c Sourcing

What Are the Key Cost Components of Power Supply C Sourcing?

In the realm of power supply sourcing, various cost components contribute to the final pricing structure. Understanding these elements can help B2B buyers make informed decisions.

-

Materials: The cost of raw materials, such as electronic components and housing materials, significantly influences the total cost. High-quality materials that ensure durability and compliance with international standards may increase initial costs but can lead to better performance and longevity.

-

Labor: Labor costs encompass wages for skilled technicians and assembly line workers involved in manufacturing. In regions with higher labor costs, such as parts of Europe, the total expense may be greater than in developing regions like Africa or South America.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and factory management. Efficient production processes can help minimize overhead, allowing for competitive pricing.

-

Tooling: Investment in specialized tools and machinery for production can be a significant upfront cost. However, these expenses can be amortized over larger production runs, reducing per-unit costs for bulk orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures that power supplies meet safety and performance standards. While this adds to the cost, it can prevent losses from returns or warranty claims.

-

Logistics: Shipping and handling costs vary based on the supplier’s location and the buyer’s destination. Efficient logistics strategies can minimize these costs and reduce lead times.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. The margin can vary based on the competitive landscape, perceived value, and customer relationship dynamics.

How Do Price Influencers Impact Power Supply C Sourcing?

Several factors influence pricing, which B2B buyers should consider when sourcing power supplies.

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing tiers. Larger orders usually attract discounts, enabling buyers to lower their per-unit costs.

-

Specifications and Customization: Tailored specifications may increase costs due to additional engineering and production processes. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: Suppliers that adhere to quality certifications (e.g., ISO, CE) may charge higher prices due to the assurance of reliability and safety. Buyers should evaluate whether these certifications are necessary for their market.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can all impact pricing. Established suppliers with a proven track record may command higher prices due to perceived value.

-

Incoterms: The terms of shipment (Incoterms) can significantly affect total costs. For instance, choosing FOB (Free on Board) may reduce initial costs but increase overall expenses if buyers are responsible for shipping and insurance.

What Are the Best Buyer Tips for Cost-Efficiency in Power Supply C Sourcing?

To maximize cost-efficiency in sourcing power supplies, buyers should adopt several strategies:

-

Negotiate Pricing: Don’t hesitate to negotiate prices, especially for larger orders. Building long-term relationships with suppliers can lead to better terms and discounts over time.

-

Consider Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, maintenance, and operational costs. A slightly higher initial investment may lead to lower TCO if the product is more reliable and efficient.

-

Be Aware of Pricing Nuances for International Sourcing: International buyers, particularly from regions like Africa or South America, should factor in currency fluctuations, tariffs, and potential delays in customs. Establishing relationships with local distributors can mitigate some of these challenges.

-

Stay Informed About Market Trends: Understanding market trends and technological advancements can provide leverage in negotiations and help identify opportunities for cost savings.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing power supply c With Other Solutions

When evaluating power supply solutions, it is crucial for B2B buyers to consider various alternatives that may better meet their operational needs. This section provides a comparative analysis of ‘Power Supply C’ against two viable alternatives—Displine’s 20W Flush Mount Power Supply and Plugable’s 60W USB-C Power Delivery Charger. Each option offers unique features and benefits that may appeal to different market segments.

| Comparison Aspect | Power Supply C | Displine 20W Flush Mount Power Supply | Plugable 60W USB-C Power Delivery Charger |

|---|---|---|---|

| Performance | 60W output capability | 20W output, supports USB PD | 60W output, supports multiple profiles |

| Cost | Competitive pricing | $72 | $49.95 |

| Ease of Implementation | Moderate complexity | Easy installation with flush mount | Simple plug-and-play design |

| Maintenance | Low maintenance | Low maintenance | Low maintenance |

| Best Use Case | Laptops, tablets | Home and office installations | Portable charging for laptops and devices |

What are the Pros and Cons of Displine’s 20W Flush Mount Power Supply?

Displine’s 20W Flush Mount Power Supply is an elegant solution for environments where aesthetics matter, such as homes or offices. Its flush-mounted design allows for a neat installation, effectively hiding cables and providing a clean look. However, with a maximum output of 20W, it may not be suitable for high-demand devices or multiple simultaneous charges, limiting its versatility. This product is ideal for charging devices like iPads and Samsung tablets but may fall short for users needing to power laptops or multiple devices simultaneously.

Illustrative image related to power supply c

How Does Plugable’s 60W USB-C Power Delivery Charger Compare?

Plugable’s 60W USB-C Power Delivery Charger is a robust alternative that offers flexibility and high compatibility with a range of devices, including laptops and smartphones. With a compact design and detachable cables, it caters well to mobile professionals who require a reliable charging solution on the go. The major advantage of this charger is its ability to negotiate power delivery across various voltage profiles (5V, 9V, 12V, 15V, and 20V), making it versatile for different devices. However, its performance may vary with certain devices, particularly Apple products, which could charge slowly when using specific adapters.

How to Choose the Right Power Supply Solution for Your Needs?

When selecting the appropriate power supply solution, B2B buyers should assess their specific requirements, such as the type of devices being charged, the volume of simultaneous charges needed, and whether aesthetic considerations are important. For those operating in environments where design is key, Displine’s offering may provide the perfect balance of form and function. Conversely, for businesses requiring a high-output solution that can accommodate a variety of devices, Plugable’s charger would be a more suitable option. By carefully evaluating these aspects, buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for power supply c

What Are the Key Technical Properties of Power Supply Units?

When sourcing power supply units (PSUs), understanding their technical specifications is essential for ensuring compatibility and performance. Below are critical properties that buyers should consider:

Illustrative image related to power supply c

1. Input Voltage Range

The input voltage range indicates the acceptable voltage levels for the power supply to operate efficiently. For example, many PSUs operate within a range of 110V to 240V AC. This specification is crucial for international buyers to ensure that the PSU can function in different regions without requiring additional converters.

2. Output Power Rating

The output power rating, typically measured in watts (W), indicates the maximum power the PSU can deliver to connected devices. For instance, a power supply rated at 60W can handle devices that require up to 60 watts of power. Understanding this rating helps businesses select a PSU that meets their device needs without risking overload or device damage.

3. Power Delivery (PD) Standard

Power Delivery is a charging protocol that allows devices to negotiate power requirements for efficient charging. For example, a PSU compliant with USB PD can adjust its output to deliver 5V, 9V, 12V, 15V, or 20V, depending on the device’s needs. This flexibility is important for companies that use various devices, as it promotes compatibility and faster charging times.

4. Compatibility and Certifications

Compatibility refers to the range of devices that a PSU can power, which is often specified in product descriptions. Certifications such as UL, CE, and FCC ensure that the power supply meets safety and quality standards. Buyers should prioritize products with these certifications to minimize risks and ensure compliance with international safety regulations.

5. Form Factor and Design

The form factor describes the physical size and shape of the PSU, which affects installation and compatibility with various setups. For example, compact designs are advantageous for mobile applications, while larger units may be better suited for stationary setups. Understanding the form factor helps businesses choose PSUs that fit their operational needs.

6. Temperature Range and Tolerance

The operational temperature range specifies the environmental conditions under which the PSU can function effectively. Additionally, tolerance levels indicate the acceptable variations in output voltage and current. These specifications are vital for businesses operating in extreme environments or requiring precise power delivery.

What Are Common Trade Terms Related to Power Supply Units?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps businesses identify trusted suppliers for their power supply needs.

Illustrative image related to power supply c

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of goods a supplier is willing to sell. This term is essential for budget planning and inventory management, especially for companies looking to establish long-term partnerships with manufacturers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products or services. This is a critical step in the procurement process, enabling businesses to compare offers and select the best supplier for their power supply needs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps businesses understand their obligations and avoid unexpected costs.

5. Lead Time

Lead time refers to the time between placing an order and receiving the goods. Understanding lead times is crucial for inventory management and planning, especially for businesses with tight schedules.

6. Warranty Period

The warranty period is the duration during which a supplier is responsible for repairing or replacing defective products. A longer warranty can indicate a supplier’s confidence in their product quality, which is essential for B2B buyers looking to minimize risks.

Illustrative image related to power supply c

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing power supply units, ultimately leading to better procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the power supply c Sector

What Are the Global Drivers and Key Trends in the Power Supply Sector?

The power supply sector is experiencing significant transformation, driven by technological advancements and evolving consumer demands. Key trends include the increasing adoption of USB-C technology, which is becoming the standard for charging devices across various industries. This trend is particularly relevant for international B2B buyers, as USB-C offers compatibility with a wide array of devices, from laptops to smartphones, enhancing operational efficiency and reducing the need for multiple chargers.

Moreover, the shift toward renewable energy sources is reshaping the market dynamics. As countries in Africa, South America, the Middle East, and Europe strive to meet sustainability targets, there is a growing demand for power supplies that can integrate with solar and wind energy systems. This opens up opportunities for suppliers who can provide innovative solutions that support energy independence and reduce carbon footprints.

Emerging markets are also witnessing increased investments in infrastructure, driving the demand for reliable power supply solutions. Buyers from regions like Vietnam and Germany are particularly focused on sourcing high-quality, efficient power supplies that comply with international standards. As the market becomes more competitive, B2B buyers must prioritize partnerships with manufacturers that demonstrate a commitment to quality and innovation.

How Does Sustainability Influence B2B Sourcing Decisions in the Power Supply Sector?

Sustainability has become a pivotal factor in B2B sourcing decisions within the power supply sector. International buyers are increasingly aware of the environmental impact of their procurement choices and are seeking suppliers who prioritize ethical sourcing practices. This includes the responsible management of materials, energy-efficient manufacturing processes, and adherence to environmental regulations.

Buyers are also looking for products that carry green certifications, such as ENERGY STAR or RoHS compliance, which signify adherence to stringent environmental standards. These certifications not only assure buyers of the product’s sustainability but also enhance their brand reputation in an eco-conscious market.

Furthermore, the use of sustainable materials in power supply products, such as recyclable plastics and eco-friendly packaging, is gaining traction. Suppliers that embrace these practices are likely to attract more international buyers who value sustainability as a core business principle. By integrating sustainability into their sourcing strategies, B2B buyers can contribute to a healthier planet while simultaneously meeting their operational needs.

How Has the Power Supply Sector Evolved Over Time?

The evolution of the power supply sector reflects broader technological advancements and shifts in consumer behavior. Initially dominated by proprietary charging solutions, the market has transitioned towards universal standards like USB-C, which facilitate compatibility across a wide range of devices. This shift has simplified the charging process for businesses, enabling them to streamline operations and reduce costs associated with maintaining multiple charging solutions.

Moreover, the increasing reliance on mobile devices and portable technology has propelled the demand for compact and efficient power supplies. As organizations adapt to remote work and mobile-first strategies, the need for versatile power solutions that can cater to various environments has become paramount. The historical move from bulky, less efficient power supplies to sleek, energy-efficient designs underscores the sector’s commitment to innovation and responsiveness to market needs.

In summary, the power supply sector is not only adapting to new technologies and consumer preferences but is also embracing a future that prioritizes sustainability and ethical sourcing. International B2B buyers must remain vigilant about these trends to ensure they are sourcing products that align with both operational goals and ethical standards.

Illustrative image related to power supply c

Frequently Asked Questions (FAQs) for B2B Buyers of power supply c

-

How do I choose the right power supply for my devices?

When selecting a power supply, consider the voltage and current requirements of your devices. Check the compatibility with USB-C standards, as various devices may support different profiles (e.g., 5V, 9V, 20V). It’s also important to evaluate the power delivery capabilities, ensuring the power supply can deliver sufficient wattage for optimal performance. Additionally, factor in the design and form factor to ensure it fits your installation needs, especially if you are using flush-mounted systems. -

What is the best power supply type for international markets?

For international markets, USB-C power supplies that meet the USB Power Delivery (PD) standards are often the best choice. They offer versatility and compatibility with a wide range of devices, including laptops, tablets, and smartphones. Opt for suppliers who provide universal voltage input (e.g., 100-240VAC) to accommodate different electrical systems globally. Moreover, look for products that comply with international safety standards, ensuring reliability and customer satisfaction. -

How can I ensure the quality of power supplies from suppliers?

To ensure quality, conduct thorough supplier vetting by checking certifications and compliance with international standards, such as CE, UL, or RoHS. Request samples to evaluate the product firsthand and assess performance under different conditions. Engage in direct communication with suppliers about their quality assurance processes, including testing methods and warranties. Finally, consider customer reviews and case studies to gauge the supplier’s reputation in the market. -

What are the typical payment terms for B2B purchases of power supplies?

Payment terms can vary widely among suppliers but typically include options like net 30, net 60, or advance payment. Some suppliers may offer discounts for early payments or larger orders. It’s crucial to clarify these terms upfront and ensure they align with your company’s cash flow management. Consider using secure payment methods like letters of credit or escrow services for larger transactions to mitigate risk. -

What should I consider regarding minimum order quantities (MOQs)?

Minimum order quantities (MOQs) can significantly impact your purchasing strategy. Understand the MOQ set by suppliers, as it often correlates with pricing advantages. If the MOQ is too high for your needs, consider negotiating for a lower quantity, especially if you are a new customer. Additionally, evaluate the potential for bulk purchasing in the future to meet MOQs, which may result in cost savings. -

How do I handle logistics and shipping for international orders?

Handling logistics involves understanding the shipping options, costs, and timeframes associated with international orders. Work with suppliers who offer comprehensive shipping solutions, including customs clearance and delivery tracking. It’s advisable to partner with freight forwarders experienced in handling electronic components to navigate potential regulatory hurdles. Always account for lead times and plan orders in advance to ensure timely delivery, especially when sourcing from different continents. -

What customization options should I ask suppliers about?

When sourcing power supplies, inquire about customization options such as branding, specific voltage outputs, or unique form factors to meet your project requirements. Some suppliers may offer tailored solutions for specific applications or markets, which can enhance your product’s competitiveness. Discuss minimum order requirements for custom designs and timelines for prototyping and production to align with your launch schedule. -

What are the common warranty and support options for power supplies?

Most reputable suppliers offer warranties ranging from one to three years, covering defects in materials and workmanship. It’s essential to understand the terms of the warranty, including what is covered and the process for claims. Additionally, inquire about customer support services, such as technical assistance and troubleshooting. A supplier with robust post-purchase support can greatly enhance your overall experience and ensure product reliability.

Top 7 Power Supply C Manufacturers & Suppliers List

1. Displine – 20W Flush Mount Power Supply

Domain: displine.com

Registered: 2017 (8 years)

Introduction: Displine 20W flush mount power supply with USB-C, Sale price: $72.00, Regular price: $72.00, Nominal input: 220 – 250V, 50 – 60Hz, Nominal output: 5V, 3A and 9V, 2.22A, USB PD (Power Delivery Standard), Compatible with 40mm deep flush-mounted boxes and all Displine wall mounts with USB-C, Not suitable for US power circuits (120 V), Compatible with all iPads with USB-C charging port and Samsung Gal…

2. Plugable – USB Type-C Power Delivery 60W Power Supply

Domain: plugable.com

Registered: 2003 (22 years)

Introduction: Plugable USB Type-C Power Delivery 60W Power Supply, designed as a spare or replacement charger for compatible laptops, tablets, and phones. Price: $49.95 USD. SKU: USBC-PS-60W. Features include a portable design, hassle-free 2-year warranty, fast free shipping on orders over $35, lifetime technical support, and a 30-day money-back guarantee. Amazon Rating: 45 reviews.

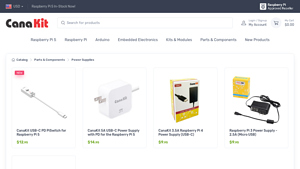

3. CanaKit – Power Supplies for Raspberry Pi

Domain: canakit.com

Registered: 1996 (29 years)

Introduction: Power Supplies: 1. CanaKit USB-C PD PiSwitch for Raspberry Pi 5 – $12.95 2. CanaKit 5A USB-C Power Supply with PD for the Raspberry Pi 5 – $14.95 3. CanaKit 3.5A Raspberry Pi 4 Power Supply (USB-C) – $9.95 4. Raspberry Pi 3 Power Supply – 2.5A (Micro USB) – $9.95 5. 12V DC / 600mA AC / DC Adapter (Regulated) – $17.95

4. Framework – USB-C Power Supply for Framework Laptop 12

Domain: community.frame.work

Registered: 2015 (10 years)

Introduction: USB-C Power Supply for Framework Laptop 12; compatible with any USB-C power supply; lower wattage supplies charge slower; Framework charger includes a ground pin for safety; recommended wattage is 60W or 100W; avoid no-name power supplies; some compatibility issues reported with specific brands like Anker; detachable power cord preferred for better usability; users have successfully used various b…

5. Merriam-Webster – C Power Supply Definition

Domain: merriam-webster.com

Registered: 1999 (26 years)

Introduction: This company, Merriam-Webster – C Power Supply Definition, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Hubitat – C-8 Power Requirements

Domain: community.hubitat.com

Registered: 2014 (11 years)

Introduction: Hubitat C-8 requires the provided power supply and USB-A-to-USB-C power cable to function. Other USB-C power supplies and cables do not power the device. The device can power on with POE-to-USB-C splitters, but this may cause issues with the Z-wave radio. The C-8 is designed to phase out older micro-USB connectors in favor of USB-C, although it does not fully comply with USB-C power negotiation st…

7. Lenco Heaven – Budget Linear Power Supply Options

Domain: lencoheaven.net

Registered: 2009 (16 years)

Introduction: Budget linear power supply for SMSL Su-1 DAC, ideally using USB-C. Suggested options include: 1. Studer 900 power supply board available on eBay, requiring a 12VDC SMPS to power it. 2. Audiophonics LPSU25 linear regulated low-noise power supply (220V to 5V, 2A, 25VA) available for around £75. 3. Various linear PSUs with USB A output available on eBay, starting from around £75. 4. An option from Al…

Strategic Sourcing Conclusion and Outlook for power supply c

What Are the Key Takeaways for Strategic Sourcing in Power Supply C?

In the rapidly evolving landscape of power supply solutions, strategic sourcing is essential for international B2B buyers seeking reliability and compatibility. Prioritizing products that comply with global standards, such as USB-C Power Delivery, ensures that your operations remain efficient and adaptable to various devices. By focusing on suppliers who offer high-quality, versatile power supplies with warranties and technical support, businesses can mitigate risks associated with product failures and compatibility issues.

How Can Buyers Leverage Strategic Sourcing for Competitive Advantage?

Investing in strategic sourcing not only enhances operational efficiency but also fosters long-term partnerships with suppliers. This approach can lead to better pricing, improved service levels, and access to cutting-edge technologies. As markets in Africa, South America, the Middle East, and Europe continue to expand, aligning with manufacturers that emphasize quality and innovation will be pivotal in maintaining a competitive edge.

What Is the Future Outlook for Power Supply C Solutions?

As the demand for sustainable and efficient power solutions grows, the future of power supply C is promising. Buyers are encouraged to stay informed about technological advancements and evolving market trends. Embrace the shift towards universal charging solutions and consider how strategic sourcing can optimize your supply chain. By making informed decisions today, businesses can position themselves for success in the dynamic global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.