14Mm Heat Resistant Tubing: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 14mm heat resistant tubing

In the quest for reliable 14mm heat resistant tubing, international B2B buyers often face the challenge of navigating a diverse and complex market landscape. This guide is designed to illuminate the essential aspects of sourcing high-quality tubing that meets the rigorous demands of various industries, from food and beverage to automotive and medical applications. Understanding the specifications, certifications, and potential suppliers is critical for making informed purchasing decisions, especially when considering the unique requirements of different regions, such as Africa, South America, the Middle East, and Europe.

Throughout this guide, we will explore the various types of 14mm heat resistant tubing available, including silicone and reinforced options, while detailing their specific applications and performance characteristics. We will also provide insights into effective supplier vetting processes, cost considerations, and market trends that can influence procurement strategies. By equipping buyers with this comprehensive knowledge, we empower them to confidently select tubing solutions that align with their operational needs and compliance standards.

Ultimately, this guide serves as a valuable resource for B2B buyers seeking to optimize their sourcing strategies, mitigate risks, and enhance their supply chain efficiency in a competitive global market. Whether you are based in Nigeria, Vietnam, or elsewhere, understanding the nuances of 14mm heat resistant tubing can significantly impact your business’s success.

Understanding 14mm heat resistant tubing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Transparent Silicone Tube | FDA approved, flexible, temperature range -50°C to +180°C | Food, cosmetics, laboratories | Pros: Easy fluid monitoring; non-toxic; versatile. Cons: Limited chemical resistance to oils and greases. |

| High-Temperature Reinforced Silicone Heater Hose | Heavy wall design, withstands extreme pressure, -65°F to +350°F | Marine, industrial, automotive | Pros: Excellent tensile strength; durable; high performance. Cons: Not suitable for fuel or oil applications. |

| Extreme High Heat Resistant Silicone Tube | Operating temperature up to +315°C, UV and ozone resistant | Food, medical, beverage industries | Pros: High heat tolerance; FDA certified; flexible. Cons: May not be ideal for all chemical applications. |

| Silicone Vacuum Tubing | Designed for vacuum applications, flexible and durable | HVAC systems, laboratory setups | Pros: High flexibility; good for low-pressure applications. Cons: Limited temperature range compared to others. |

| Clear Braided Silicone Hose | Reinforced with a braided design, transparent for visibility | Industrial fluid transfer, food processing | Pros: Enhanced durability; visibility for monitoring. Cons: May have higher cost due to reinforced design. |

What are the Characteristics of Transparent Silicone Tubes?

Transparent silicone tubes are notable for their FDA approval, making them suitable for food and cosmetic applications. They can handle temperatures ranging from -50°C to +180°C, providing versatility across various industries. Their flexibility allows for easy installation in tight spaces, while their transparency enables users to monitor fluid flow visually. However, they have limited resistance to oils and greases, which may restrict their use in certain environments.

How Does High-Temperature Reinforced Silicone Heater Hose Stand Out?

This type of tubing is engineered to meet high-performance standards, suitable for heavy-duty applications in marine, industrial, and automotive sectors. With a temperature range of -65°F to +350°F, it is designed to withstand extreme pressures and conditions. The heavy wall design ensures durability, making it ideal for applications requiring high tensile strength. However, it is not compatible with fuel or oil, which is a consideration for buyers in certain industries.

What Makes Extreme High Heat Resistant Silicone Tubes Ideal for Specific Applications?

Extreme high heat resistant silicone tubes are capable of operating at temperatures up to +315°C, making them suitable for demanding environments such as food and medical industries. Their resistance to UV and ozone ensures longevity in outdoor applications. This tubing is also FDA certified, which is crucial for compliance in food and beverage sectors. However, buyers should consider that these tubes may not be suitable for all chemical applications, limiting their versatility.

Why Choose Silicone Vacuum Tubing for HVAC Systems?

Silicone vacuum tubing is specifically designed for low-pressure applications, making it ideal for HVAC systems and laboratory setups. Its flexibility allows for easy routing and installation, while its durability ensures long-term performance. However, its temperature range is narrower compared to other types of heat-resistant tubing, which may limit its applications in extreme environments. Buyers should assess their specific needs against these limitations.

What Advantages Do Clear Braided Silicone Hoses Offer?

Clear braided silicone hoses are reinforced with a braided design, providing enhanced durability and making them suitable for industrial fluid transfer and food processing. Their transparent nature allows for easy visibility of the contents, which is crucial for monitoring processes. While they may come at a higher cost due to their reinforced structure, their ability to withstand various pressures makes them a valuable investment for industries requiring reliable fluid handling solutions.

Key Industrial Applications of 14mm heat resistant tubing

| Industry/Sector | Specific Application of 14mm heat resistant tubing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting hot liquids and steam in food processing plants | Ensures safety and compliance with FDA regulations | FDA certification, temperature range, flexibility, and durability |

| Automotive | Coolant systems in vehicles | Enhances vehicle performance and longevity | High-temperature resistance, pressure ratings, and compatibility |

| Chemical Processing | Transfer of chemicals in manufacturing | Reduces risk of leaks and contamination | Chemical resistance, temperature tolerance, and safety certifications |

| Medical Equipment | Fluid transport in medical devices | Guarantees sterility and reliability in critical applications | Biocompatibility, FDA approval, and resistance to high temperatures |

| HVAC Systems | Heat exchange systems | Improves energy efficiency and system reliability | Thermal resistance, flexibility for installation, and pressure ratings |

How is 14mm Heat Resistant Tubing Used in the Food and Beverage Industry?

In the food and beverage sector, 14mm heat resistant tubing is primarily utilized for transporting hot liquids and steam in processing plants. This application is critical for ensuring compliance with stringent food safety regulations, such as those established by the FDA. The tubing’s ability to withstand high temperatures while maintaining flexibility allows for efficient and safe transport, reducing the risk of leaks or contamination. Buyers in this sector should prioritize tubes that are FDA certified and capable of enduring temperatures ranging from -50°C to +180°C.

What Role Does 14mm Heat Resistant Tubing Play in Automotive Systems?

In the automotive industry, 14mm heat resistant tubing serves a vital function in coolant systems, facilitating the transfer of coolant to and from the engine. This application is essential for maintaining optimal engine temperatures, thereby enhancing vehicle performance and longevity. Buyers should look for tubing that meets industry standards for high-temperature resistance and pressure ratings, ensuring reliability under demanding conditions. Compatibility with various coolants, including antifreeze, is also a crucial consideration for sourcing.

How is 14mm Heat Resistant Tubing Applied in Chemical Processing?

Within the chemical processing sector, 14mm heat resistant tubing is employed for the transfer of various chemicals during manufacturing processes. This application helps minimize the risk of leaks and contamination, which can have severe safety and financial implications. Buyers in this industry must focus on sourcing tubing that offers robust chemical resistance and can handle high temperatures, ensuring safe and efficient operations. Additionally, certifications that verify the tubing’s safety for chemical handling should be prioritized.

Why is 14mm Heat Resistant Tubing Essential for Medical Equipment?

In the medical field, 14mm heat resistant tubing is crucial for the reliable transport of fluids in medical devices, such as IV systems and surgical equipment. Its ability to maintain sterility and withstand high temperatures is paramount in critical applications where patient safety is at stake. Buyers should ensure that the tubing is biocompatible and FDA-approved, meeting stringent healthcare regulations. The tubing’s flexibility also aids in the design and installation of various medical devices, making it a preferred choice for manufacturers.

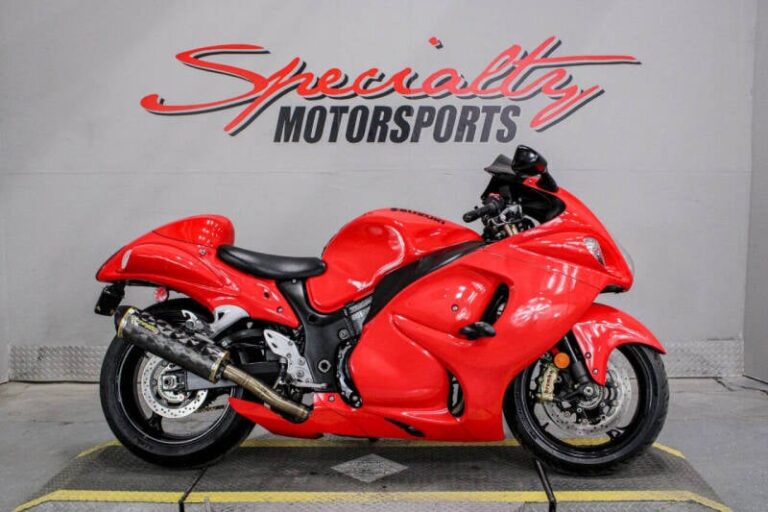

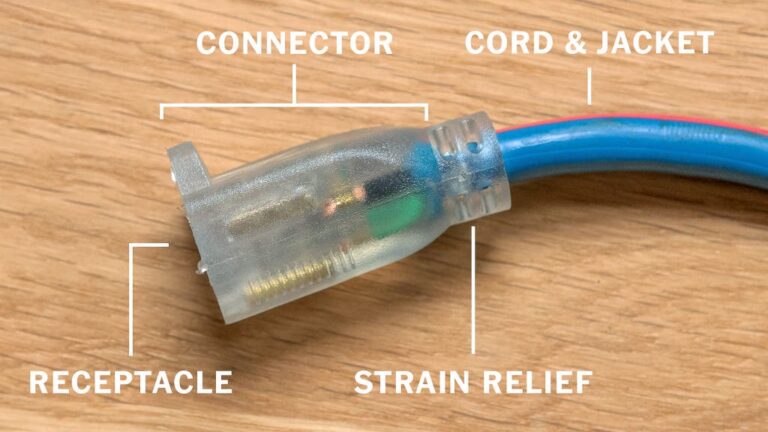

Illustrative image related to 14mm heat resistant tubing

How Does 14mm Heat Resistant Tubing Enhance HVAC Systems?

In HVAC systems, 14mm heat resistant tubing is used in heat exchange applications, where it facilitates the transfer of heated or cooled fluids. This application is vital for improving energy efficiency and ensuring the reliability of heating and cooling systems. Buyers should consider the tubing’s thermal resistance and flexibility for easier installation in tight spaces. Additionally, pressure ratings must be assessed to ensure the tubing can withstand the operational demands of the HVAC system, contributing to its overall performance and longevity.

3 Common User Pain Points for ’14mm heat resistant tubing’ & Their Solutions

Scenario 1: Ensuring Compliance with Industry Standards

The Problem: Many B2B buyers in industries such as food processing or pharmaceuticals struggle to find heat-resistant tubing that meets stringent regulatory standards. For instance, if the tubing does not comply with FDA regulations or other local safety standards, it can lead to costly product recalls, fines, and damage to brand reputation. Buyers often find themselves facing uncertainty about the certifications of various tubing options, especially when sourcing from international suppliers.

The Solution: To ensure compliance, B2B buyers should prioritize sourcing from manufacturers that provide clear documentation of regulatory certifications for their 14mm heat-resistant tubing. When negotiating with suppliers, ask for detailed specifications and certifications, such as FDA approval or compliance with European Union regulations. Additionally, conducting due diligence by requesting product samples and third-party test results can help verify claims. Establishing a relationship with suppliers who have a solid track record of compliance can also mitigate risks and enhance supply chain reliability.

Scenario 2: Managing Temperature Variability in Applications

The Problem: A common challenge faced by B2B buyers is the variability in temperature conditions where the 14mm heat-resistant tubing will be used. Industries such as automotive and manufacturing often require tubing that can withstand extreme temperature fluctuations. If the tubing fails to perform under these conditions, it can lead to system failures, increased downtime, and costly repairs.

The Solution: Buyers should carefully assess the temperature range of the applications for which the tubing is intended. It is critical to select 14mm heat-resistant tubing that not only meets but exceeds the maximum expected temperature to provide a safety margin. For instance, if a system operates between -50°C and 180°C, opting for tubing rated for higher temperatures, such as up to 315°C, can enhance performance and longevity. Additionally, consulting with engineers or product specialists to understand the specific heat and pressure requirements of the application can lead to better-informed purchasing decisions.

Scenario 3: Difficulty in Sourcing Durable and Flexible Tubing

The Problem: Many B2B buyers encounter challenges in sourcing tubing that balances flexibility and durability. In applications like HVAC systems or medical devices, the tubing must be able to withstand harsh environments while maintaining the ability to bend and fit into tight spaces. Buyers often find themselves frustrated when the tubing they select becomes brittle or loses flexibility over time, leading to leaks and system inefficiencies.

The Solution: To address this issue, buyers should focus on the material properties of the 14mm heat-resistant tubing. Selecting silicone tubing with high tensile strength and elongation properties will provide the needed flexibility without compromising durability. It’s advisable to inquire about the wall thickness and reinforcement of the tubing, as these factors contribute significantly to its performance under pressure and during bending. Additionally, conducting a thorough supplier evaluation based on product reviews and testimonials can help identify reputable manufacturers known for producing high-quality, flexible tubing. Building long-term relationships with trusted suppliers can also ensure consistent product quality and support for future projects.

Strategic Material Selection Guide for 14mm heat resistant tubing

When selecting materials for 14mm heat resistant tubing, it is crucial to consider several common options that cater to various industrial applications. Each material offers distinct properties, advantages, and limitations that can significantly impact performance and suitability in different environments.

What are the Key Properties of Silicone Tubing for Heat Resistance?

Silicone is a widely used material for heat resistant tubing due to its exceptional thermal stability. It can withstand temperatures ranging from -50°C to +180°C, with some variants rated up to +315°C. Silicone tubing is also flexible and resistant to UV light, ozone, and various chemicals, making it ideal for applications in the food, pharmaceutical, and automotive industries. Its FDA approval for food contact enhances its appeal in sectors requiring stringent compliance.

Pros and Cons: The primary advantage of silicone tubing is its flexibility and ability to maintain performance under extreme conditions. However, it can be more expensive than alternatives like rubber or PVC, and its compatibility with certain oils and fuels is limited.

How Does EPDM Rubber Compare in Terms of Performance?

EPDM (Ethylene Propylene Diene Monomer) rubber is another popular choice for heat resistant tubing. It offers excellent resistance to heat, ozone, and weathering, with a temperature range of -40°C to +120°C. EPDM is particularly suited for outdoor applications due to its durability against environmental factors.

Pros and Cons: EPDM is relatively cost-effective and has good tensile strength. However, it is not as flexible as silicone and can be less effective in high-temperature applications above 120°C. Additionally, EPDM may not be suitable for applications involving petroleum-based products.

What are the Benefits of Using PTFE Tubing?

PTFE (Polytetrafluoroethylene) tubing is renowned for its chemical resistance and high-temperature capabilities, functioning effectively in temperatures up to +260°C. Its non-stick properties make it ideal for applications where contamination must be avoided, such as in pharmaceutical manufacturing.

Pros and Cons: The main advantage of PTFE tubing is its superior chemical resistance and thermal stability. However, it tends to be more expensive and can be less flexible than silicone or rubber options, which may complicate installation in tight spaces.

What Role Does PVC Play in Heat Resistant Tubing Applications?

PVC (Polyvinyl Chloride) is often used for heat resistant tubing in applications where cost is a primary concern. While it has a lower temperature tolerance (typically up to +60°C), it is lightweight and offers good chemical resistance.

Pros and Cons: PVC is highly affordable and widely available, making it a common choice for non-critical applications. However, its limited temperature range and flexibility compared to silicone or rubber may restrict its use in high-performance environments.

Summary Table of Material Options for 14mm Heat Resistant Tubing

| Material | Typical Use Case for 14mm heat resistant tubing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Food and pharmaceutical industries, automotive applications | Excellent flexibility and thermal stability | Higher cost, limited oil compatibility | High |

| EPDM | Outdoor applications, automotive hoses | Cost-effective, good weather resistance | Less flexible, limited high-temp performance | Medium |

| PTFE | Pharmaceutical manufacturing, chemical processing | Superior chemical resistance, high-temperature capability | Higher cost, less flexibility | High |

| PVC | General plumbing, low-pressure applications | Affordable and lightweight | Limited temperature range, less flexible | Low |

In conclusion, selecting the appropriate material for 14mm heat resistant tubing requires careful consideration of the specific application, environmental factors, and regulatory compliance. International B2B buyers, especially from diverse markets like Africa, South America, the Middle East, and Europe, should evaluate these factors to ensure optimal performance and cost-effectiveness in their operations.

In-depth Look: Manufacturing Processes and Quality Assurance for 14mm heat resistant tubing

What Are the Key Stages in the Manufacturing Process of 14mm Heat Resistant Tubing?

The manufacturing process of 14mm heat resistant tubing involves several critical stages, ensuring that the final product meets stringent quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-grade silicone materials, often formulated to withstand extreme temperatures and environmental factors. Manufacturers typically use VMQ (Vinyl Methyl Silicone) or FVMQ (Fluorovinyl Methyl Silicone) for their excellent thermal and chemical resistance. The raw materials undergo rigorous quality checks to ensure they meet the necessary specifications.

-

Forming: In this stage, the prepared silicone material is extruded into the desired shape. The extrusion process involves pushing the silicone through a die to create a continuous tube of the required inner and outer diameters. Temperature controls during this stage are crucial, as they influence the material’s properties. For example, maintaining optimal temperatures helps ensure that the tubing remains flexible and durable.

-

Assembly: Depending on the application, additional components may be integrated during the assembly stage. This could include reinforcing layers for enhanced pressure resistance or attaching fittings for specific uses. Manufacturers must ensure that all components are compatible and meet industry standards.

-

Finishing: The final stage involves cutting the tubing to specified lengths and applying any necessary surface treatments. This may include cleaning, labeling, and packaging. The finishing process is essential for ensuring that the product is ready for immediate use and meets all customer specifications.

How Do International Standards Influence Quality Assurance in Manufacturing?

Quality assurance is critical in the manufacturing of 14mm heat resistant tubing, particularly for B2B buyers who require reliable and consistent products. Compliance with international standards such as ISO 9001 is vital, as it provides a framework for quality management systems. This standard emphasizes continuous improvement, customer satisfaction, and process optimization.

What Are the Specific Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials undergo initial inspections to ensure they meet predefined specifications before production begins. This step is crucial, as the quality of the raw materials directly impacts the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor the consistency of the extrusion process, dimensional accuracy, and material properties. This helps identify any deviations from standards early, allowing for corrective actions to be taken promptly.

-

Final Quality Control (FQC): After production, the finished products are subjected to comprehensive testing. This includes assessments of physical properties, dimensional checks, and performance tests to ensure they meet industry standards and customer requirements.

What Common Testing Methods Are Used to Validate the Quality of Heat Resistant Tubing?

Manufacturers employ various testing methods to validate the quality and performance of 14mm heat resistant tubing:

-

Temperature Resistance Testing: Tubing is subjected to extreme temperatures to evaluate its performance under high heat conditions. This ensures that the product can withstand the specified temperature range without degradation.

-

Pressure Testing: The tubing is tested under different pressure conditions to verify its structural integrity. This is particularly important for applications in automotive or industrial settings where high pressure is common.

-

Chemical Resistance Testing: Samples are exposed to various chemicals to assess their resistance and durability. This is essential for applications in the food, medical, and chemical industries.

-

Flexibility and Elongation Testing: The tubing is bent and stretched to determine its flexibility and elongation at break, which are important characteristics for applications requiring bending and movement.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is paramount. Here are effective strategies to ensure supplier reliability:

-

Conducting Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows them to evaluate the manufacturing processes, quality control measures, and overall operational efficiency.

-

Requesting Quality Assurance Reports: Suppliers should be able to provide detailed quality assurance reports, including results from various testing methods and certifications achieved. These documents can serve as proof of compliance with international standards.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an impartial assessment of the supplier’s quality control practices. Inspectors can verify compliance with industry standards and recommend improvements if necessary.

-

Reviewing Certifications: B2B buyers should check for relevant certifications such as CE, API, and FDA compliance, which indicate adherence to specific industry standards. This is especially important for products intended for food, medical, or high-temperature applications.

What Are the Quality Control Nuances for International B2B Transactions?

International B2B buyers must be aware of specific quality control nuances when sourcing 14mm heat resistant tubing. These include:

-

Regulatory Compliance: Different regions have varying regulations regarding material safety and quality. Buyers should familiarize themselves with local regulations to ensure that the products they import comply with regional standards.

-

Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother transactions. This includes being aware of communication styles, negotiation practices, and expectations regarding product quality.

-

Logistics and Supply Chain Management: Quality assurance does not end at manufacturing. Buyers should consider the entire supply chain, including transportation and storage conditions, which can impact product integrity.

By understanding the manufacturing processes and quality assurance measures for 14mm heat resistant tubing, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’14mm heat resistant tubing’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure 14mm heat resistant tubing. It will help you navigate the complexities of sourcing this specialized product by outlining essential steps to ensure you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical specifications required for your application. Consider factors such as temperature range, flexibility, and chemical resistance. For instance, some applications may require tubing that can withstand temperatures up to +315°C, while others may only need a range of -50°C to +180°C.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in heat resistant tubing. Look for suppliers with a proven track record in your industry and geographical region. Pay attention to customer reviews and testimonials to gauge their reliability and product quality.

Step 3: Evaluate Material Certifications

Ensure that the materials used in the tubing meet relevant industry standards and certifications. For food and medical applications, look for FDA or food-grade certifications. This ensures that the tubing is safe and compliant with regulations, thereby minimizing risks associated with contamination.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the tubing to evaluate its quality and performance. Testing the samples under actual operating conditions can help you assess their suitability for your specific applications. Pay attention to characteristics such as flexibility, resilience, and resistance to wear.

Step 5: Verify Supplier Certifications

It’s crucial to verify the certifications and quality assurance processes of your chosen supplier. Check for ISO certifications or other relevant industry standards that affirm their commitment to quality. Suppliers with robust quality control measures are more likely to deliver consistent and reliable products.

Step 6: Discuss Lead Times and Delivery Options

Clarify the lead times and delivery options with your suppliers. Understanding their production capacity and shipping logistics is essential to ensure that you receive your order when needed. Discuss bulk order pricing and potential discounts for larger quantities to maximize cost-effectiveness.

Step 7: Establish Payment Terms and Conditions

Finally, establish clear payment terms and conditions with your supplier. Discuss payment methods, credit terms, and any applicable warranties or return policies. Transparent agreements help prevent misunderstandings and ensure a smooth transaction process.

By following this checklist, B2B buyers can effectively navigate the sourcing process for 14mm heat resistant tubing, ensuring that they choose the right products and suppliers to meet their operational requirements.

Comprehensive Cost and Pricing Analysis for 14mm heat resistant tubing Sourcing

What Are the Key Cost Components for Sourcing 14mm Heat Resistant Tubing?

When sourcing 14mm heat resistant tubing, understanding the cost structure is essential for making informed purchasing decisions. Key components of the cost include:

-

Materials: The primary cost driver, the quality and type of silicone used significantly impact pricing. Higher-grade materials that offer superior heat resistance and flexibility typically command a premium. For instance, FDA-approved silicone suitable for food applications may be more expensive than standard options.

-

Labor: Manufacturing processes for silicone tubing often require skilled labor, particularly for high-temperature applications. Labor costs can vary by region, with countries having lower wage standards potentially offering more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Manufacturers that invest in advanced technologies may have higher overhead costs, which can reflect in their pricing.

-

Tooling: The cost of molds and equipment necessary for producing the tubing can be significant, especially for custom sizes or specifications. Suppliers may charge additional fees for tooling when the order volume does not meet minimum requirements.

-

Quality Control (QC): Rigorous quality assurance processes ensure that the tubing meets industry standards. Costs associated with testing and compliance certifications can influence the final price.

-

Logistics: Transportation costs are critical, especially for international shipments. Factors like distance, mode of transport, and local import duties must be considered, as they can significantly affect overall costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on their market position and competition. Understanding the competitive landscape can help buyers gauge reasonable margins.

What Price Influencers Should Buyers Consider When Sourcing?

Several factors can influence the pricing of 14mm heat resistant tubing:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often qualify for discounts, making it advantageous for buyers to consolidate their purchases. Discussing flexible MOQs with suppliers can lead to cost savings.

-

Specifications and Customization: Custom specifications such as length, thickness, and color can increase costs. Buyers should clearly define their needs to avoid unexpected charges.

-

Materials and Quality Certifications: Tubing that meets specific industry standards (like FDA or NSF certifications) may incur higher costs. Buyers should evaluate the necessity of such certifications based on their application.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can influence pricing. Established suppliers with robust quality control may charge more but offer reliability.

-

Incoterms: Understanding shipping terms can affect the total cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping responsibilities and costs.

How Can International Buyers Optimize Costs When Sourcing 14mm Heat Resistant Tubing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage suppliers in negotiations to secure better pricing, especially when purchasing in bulk or forming long-term partnerships. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Total Cost of Ownership (TCO): Consider all costs associated with the product over its lifecycle, including maintenance, disposal, and potential downtime. A lower initial purchase price may not always translate to overall savings.

-

Pricing Nuances: Be aware of fluctuations in material costs and currency exchange rates, which can affect pricing. Establishing contracts with fixed pricing can mitigate risks related to price volatility.

-

Local Regulations: Understand import duties and taxes in your region that may apply to silicone tubing. Compliance with local regulations can prevent unexpected costs and delays.

In summary, a comprehensive understanding of cost components and pricing influences, combined with strategic procurement practices, can lead to more informed and cost-effective sourcing decisions for 14mm heat resistant tubing. Always consider indicative prices as a starting point, as actual costs may vary based on the factors discussed.

Illustrative image related to 14mm heat resistant tubing

Alternatives Analysis: Comparing 14mm heat resistant tubing With Other Solutions

Understanding Alternatives to 14mm Heat Resistant Tubing

In the industrial landscape, selecting the right tubing for high-temperature applications is critical. While 14mm heat resistant tubing made from silicone is a popular choice due to its flexibility and high-temperature resilience, it’s essential to explore alternative solutions that may offer different advantages or suit specific applications better. This analysis compares 14mm heat resistant tubing with two viable alternatives: reinforced rubber hoses and PTFE (Polytetrafluoroethylene) tubing.

Comparison Table

| Comparison Aspect | 14mm Heat Resistant Tubing | Reinforced Rubber Hose | PTFE Tubing |

|---|---|---|---|

| Performance | Excellent temperature range (-50°C to +180°C) | Good temperature range (-40°C to +120°C) | Superior chemical resistance and high-temperature tolerance (-200°C to +260°C) |

| Cost | Moderate | Generally lower | Higher due to specialized manufacturing |

| Ease of Implementation | Flexible and easy to install | Requires fittings and clamps | Can be rigid, may require specialized fittings |

| Maintenance | Low maintenance | Moderate maintenance | Very low maintenance |

| Best Use Case | Food processing, HVAC systems | General plumbing, automotive | Chemical handling, food processing, and pharmaceuticals |

What Are the Pros and Cons of Reinforced Rubber Hoses?

Reinforced rubber hoses are a common alternative, particularly in applications where flexibility and affordability are key considerations. They offer a good balance between performance and cost, making them suitable for general plumbing and automotive systems. However, their temperature tolerance is lower than that of silicone tubing, which limits their use in high-heat applications. Additionally, while they provide a reasonable lifespan with moderate maintenance, they may degrade more quickly in environments exposed to extreme temperatures or chemicals.

Why Consider PTFE Tubing Over Silicone?

PTFE tubing stands out for its exceptional chemical resistance and ability to withstand extreme temperatures. It is an excellent choice for industries dealing with harsh chemicals or when a non-stick surface is required. However, PTFE is generally more expensive than silicone tubing and can be less flexible, which may complicate installation in tight spaces. Despite these drawbacks, its longevity and low maintenance requirements make it a compelling option for specialized applications in pharmaceuticals and food processing.

Making the Right Choice for Your Application

When selecting between 14mm heat resistant tubing, reinforced rubber hoses, and PTFE tubing, B2B buyers should consider the specific requirements of their applications. Factors such as temperature range, chemical exposure, installation environment, and budget constraints play a crucial role in this decision-making process. Evaluating these alternatives against the operational needs will ensure that the chosen solution delivers optimal performance and longevity, ultimately enhancing operational efficiency and cost-effectiveness.

In summary, each tubing option has unique advantages and limitations, and understanding these will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for 14mm heat resistant tubing

What Are the Key Technical Properties of 14mm Heat Resistant Tubing?

When selecting 14mm heat resistant tubing for industrial applications, understanding its technical properties is crucial for ensuring compatibility and performance. Here are several critical specifications that buyers should consider:

-

Material Grade

– Commonly, 14mm heat resistant tubing is manufactured from high-quality silicone or other elastomers, such as VMQ silicone. The material grade affects the tubing’s durability, flexibility, and heat resistance. For example, silicone can withstand temperatures ranging from -50°C to +180°C, making it suitable for various applications, including food processing and automotive systems. -

Temperature Range

– The temperature range indicates the maximum and minimum temperatures the tubing can endure without losing its structural integrity. Tubes rated for extreme temperatures, such as -70°C to +315°C, are essential for industries where high heat and cold conditions are prevalent, such as chemical processing or refrigeration. -

Wall Thickness

– The wall thickness of the tubing can influence its pressure handling capabilities and overall flexibility. A thicker wall (e.g., 3mm to 4mm) typically enhances durability and resistance to punctures, making it ideal for high-pressure applications, while a thinner wall may offer greater flexibility for easier installation in tight spaces. -

Hardness (Shore A)

– The hardness of silicone tubing is measured in Shore A durometer, with common values ranging from 60 to 70. A higher Shore A rating indicates a stiffer material, which may be necessary for certain applications requiring structural support, while a lower rating provides greater flexibility, beneficial in applications where bending is required. -

Chemical Resistance

– The ability of tubing to resist various chemicals is vital for applications in industries like pharmaceuticals and food processing. Tubing that is resistant to mild acids, bases, and other chemicals ensures longevity and reduces the risk of contamination or failure in critical systems. -

Certifications

– Certifications such as FDA approval for food-grade materials are essential for industries where health and safety are paramount. Such certifications ensure that the materials used do not leach harmful substances and are safe for contact with food and beverages.

What Are Common Trade Terms Related to 14mm Heat Resistant Tubing?

Familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of heat resistant tubing, an OEM may provide specialized tubing designed for specific machinery or applications. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it impacts inventory management and cost-effectiveness. Buyers should negotiate MOQs to align with their project needs and budgets. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers of 14mm heat resistant tubing, issuing an RFQ can help compare prices and terms from multiple suppliers, ensuring they receive the best deal. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps clarify shipping, risk, and insurance responsibilities, which is crucial for international B2B transactions involving heat resistant tubing. -

Lead Time

– Lead time is the amount of time it takes from placing an order until the product is delivered. Understanding lead time is essential for project planning, especially in industries where timing is critical, such as manufacturing or construction. -

Certification Compliance

– This term refers to the adherence to industry standards and regulations, such as ISO or ASTM. Certification compliance is essential for ensuring that the tubing meets specific safety and quality benchmarks, which can influence purchasing decisions.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing 14mm heat resistant tubing, ultimately enhancing operational efficiency and product reliability.

Illustrative image related to 14mm heat resistant tubing

Navigating Market Dynamics and Sourcing Trends in the 14mm heat resistant tubing Sector

What Are the Current Market Dynamics and Key Trends Influencing the 14mm Heat Resistant Tubing Sector?

The global market for 14mm heat resistant tubing is witnessing significant growth driven by several key factors. The increasing demand from industries such as automotive, food and beverage, pharmaceuticals, and HVAC systems is propelling the need for high-performance tubing solutions. As these sectors expand, the necessity for materials that can withstand extreme temperatures and harsh environmental conditions becomes crucial. Notably, emerging markets in Africa, South America, and the Middle East are showing a growing appetite for advanced silicone tubing, particularly in industrial applications where durability and flexibility are paramount.

Technological advancements are also shaping sourcing trends. The rise of digital platforms enables international B2B buyers to access a broader range of suppliers and products, facilitating more competitive pricing and better quality assurance. Moreover, the integration of Industry 4.0 practices, including smart manufacturing and IoT, is enhancing the production capabilities of manufacturers, allowing for more customized solutions in tubing specifications. Buyers are increasingly looking for suppliers who can offer not just quality products but also rapid prototyping and just-in-time delivery.

How Does Sustainability Impact the Sourcing of 14mm Heat Resistant Tubing?

Sustainability and ethical sourcing are becoming essential considerations for B2B buyers in the 14mm heat resistant tubing market. The environmental impact of manufacturing processes and the materials used is under scrutiny, prompting companies to seek suppliers who prioritize eco-friendly practices. The use of sustainable materials, such as FDA-approved silicone that meets stringent health and safety standards, is gaining traction among buyers who are increasingly concerned about their carbon footprint.

Furthermore, certifications related to sustainability, such as ISO 14001 for environmental management systems and other ‘green’ credentials, are critical in supplier evaluation processes. B2B buyers are not only looking for products that meet their technical specifications but also those that align with their corporate social responsibility objectives. By choosing suppliers who demonstrate a commitment to reducing environmental impact and promoting ethical supply chains, companies can enhance their brand reputation while contributing positively to global sustainability efforts.

Illustrative image related to 14mm heat resistant tubing

What Is the Historical Context of 14mm Heat Resistant Tubing Development?

The evolution of 14mm heat resistant tubing can be traced back to advancements in polymer chemistry and materials science. Initially, rubber was the primary choice for flexible tubing, but it had limitations in terms of temperature resistance and chemical compatibility. The introduction of silicone materials in the late 20th century revolutionized the sector, offering superior performance in extreme conditions.

Over the decades, innovations in silicone formulations and manufacturing techniques have led to the development of specialized tubing that meets the diverse needs of various industries. Today, 14mm heat resistant tubing is characterized by its flexibility, resilience, and ability to withstand temperatures ranging from -70°C to +315°C. This historical progression underscores the importance of continuous research and development in meeting the ever-evolving demands of international markets, particularly in regions such as Africa and South America, where industrialization is rapidly advancing.

In summary, understanding the market dynamics, the importance of sustainability, and the historical context of 14mm heat resistant tubing can empower B2B buyers to make informed sourcing decisions that align with their operational needs and ethical standards.

Illustrative image related to 14mm heat resistant tubing

Frequently Asked Questions (FAQs) for B2B Buyers of 14mm heat resistant tubing

-

How do I choose the right 14mm heat resistant tubing for my application?

When selecting 14mm heat resistant tubing, consider the specific temperature range and chemical compatibility required for your application. Look for tubing made from high-quality materials such as silicone, which offers flexibility and durability under extreme conditions. Evaluate the tubing’s resistance to UV light, ozone, and environmental factors, especially if used outdoors. Additionally, ensure the tubing meets industry standards relevant to your sector, such as FDA approval for food applications. Consulting with suppliers about your specific needs can help narrow down the best options. -

What are the typical applications of 14mm heat resistant tubing?

14mm heat resistant tubing is widely used in various industries, including food and beverage, pharmaceuticals, automotive, and HVAC systems. Its versatility allows it to handle hot fluids, air, and even electrical insulation in high-temperature environments. Common applications include coolant hoses, heater hoses, and connections in heating and cooling systems. The transparent variant is especially useful in monitoring fluid flow in laboratories and food processing, while reinforced tubing is ideal for high-pressure applications. -

What are the standard temperature ranges for 14mm heat resistant tubing?

The temperature range for 14mm heat resistant tubing can vary depending on the material. For silicone tubing, typical ranges are from -50°C to +180°C (-58°F to +356°F), while some specialized variants can withstand temperatures up to +315°C (+599°F). It is crucial to verify the specifications provided by the manufacturer to ensure the tubing meets the thermal demands of your specific application. -

What are the minimum order quantities (MOQ) for sourcing 14mm heat resistant tubing?

Minimum order quantities for 14mm heat resistant tubing can vary significantly by supplier. Some manufacturers may offer flexible ordering options, allowing purchases by the meter, while others may require bulk orders of several hundred meters or more. When sourcing internationally, it’s essential to clarify MOQ with potential suppliers upfront, as this can impact your inventory management and shipping costs. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely depending on the supplier’s policies and the nature of your business relationship. Common terms include advance payment, letters of credit, or payment upon delivery. For larger orders, negotiating favorable terms such as net 30 or net 60 can be beneficial. Always ensure that the payment method you choose is secure and provides adequate protection against potential fraud, especially in international transactions. -

How can I vet suppliers of 14mm heat resistant tubing?

Vetting suppliers is critical to ensure product quality and reliability. Start by checking their certifications, such as ISO or FDA approvals, which indicate adherence to industry standards. Request samples to assess product quality and consistency. Additionally, look for customer reviews or case studies that demonstrate their experience in your industry. Engaging in direct communication and asking about their manufacturing processes can also provide insights into their operational integrity. -

What quality assurance measures should I look for in 14mm heat resistant tubing?

Quality assurance measures for 14mm heat resistant tubing should include stringent testing protocols for temperature resistance, chemical compatibility, and physical durability. Inquire whether the supplier conducts regular inspections and has a quality management system in place. Certifications from recognized organizations can also indicate a commitment to maintaining high standards. Additionally, consider requesting a Certificate of Compliance to verify that the tubing meets specific regulations or standards relevant to your industry. -

What logistics considerations should I keep in mind when sourcing internationally?

When sourcing 14mm heat resistant tubing internationally, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable logistics partner to ensure timely delivery and handle any potential challenges with cross-border shipping. Be aware of import duties and taxes that may apply to your order, as these can significantly affect your total costs. Additionally, ensure that the supplier provides clear shipping documentation to facilitate a smooth customs process.

Top 3 14Mm Heat Resistant Tubing Manufacturers & Suppliers List

1. McMaster – 14mm Hose Selection

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 14mm Hose Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

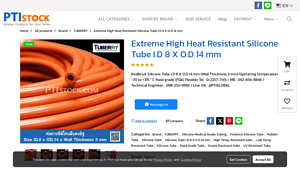

2. PTI Stock – Extreme High Heat Resistant Silicone Tube

Domain: ptistock.com

Registered: 2018 (7 years)

Introduction: {“Product Name”: “Extreme High Heat Resistant Silicone Tube”, “Inner Diameter (I.D)”: “8 mm”, “Outer Diameter (O.D)”: “14 mm”, “Wall Thickness”: “3 mm”, “Operating Temperature”: “-70 to +315 °C”, “Material”: “100% Redbrick Silicone Rubber”, “Color”: “Redbrick”, “Food Grade”: “Yes (FDA certified)”, “Heat Resistance”: “+315ºC”, “Chemical Resistance”: “Resistant to vegetable/animal oils and diluted s…

3. Raleigh Beer Garden – Heat Resistant Silicone Tube

Domain: theraleighbeergarden.com

Registered: 2013 (12 years)

Introduction: This company, Raleigh Beer Garden – Heat Resistant Silicone Tube, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 14mm heat resistant tubing

The demand for 14mm heat resistant tubing continues to grow across various industries, driven by its versatility and performance in high-temperature applications. Strategic sourcing of this product not only ensures access to high-quality materials but also fosters relationships with reliable suppliers who can meet diverse needs. Buyers should prioritize suppliers that provide FDA-approved, flexible silicone options capable of withstanding extreme temperatures and environmental conditions, ensuring compliance with industry standards.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the specific applications and properties of 14mm heat resistant tubing is crucial. This knowledge empowers buyers to make informed decisions that align with their operational requirements and regulatory standards.

As we look to the future, the market for heat resistant tubing is poised for innovation and growth. Engaging with suppliers who are committed to quality and sustainability will be vital. Buyers are encouraged to explore partnerships that not only meet immediate needs but also support long-term strategic goals. Embrace the opportunity to enhance your operations with superior tubing solutions tailored for your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.