The Definitive Guide to Pricking Iron 3.38 3.85: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for pricking iron 3.38 3.85

In the increasingly competitive landscape of leathercraft, sourcing high-quality pricking iron 3.38 and 3.85 can pose significant challenges for B2B buyers. With varying styles and specifications, businesses must navigate a complex array of options to find tools that not only enhance their stitching quality but also align with their production needs and budget. This comprehensive guide addresses these challenges head-on, providing insights into the diverse types of pricking irons available, their applications in various leatherworking projects, and crucial supplier vetting criteria.

As we delve deeper into the world of pricking irons, readers will discover essential information on cost considerations, including shipping and customs duties, which are particularly relevant for international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Germany. By equipping buyers with knowledge about the specifications, craftsmanship, and performance of pricking irons, this guide empowers them to make informed purchasing decisions that can significantly impact their operational efficiency and product quality.

Whether you’re looking to enhance your craftsmanship with superior tools or seeking reliable suppliers to support your business growth, understanding the global market for pricking iron 3.38 and 3.85 will ensure you stay ahead in the leathercraft industry.

Understanding pricking iron 3.38 3.85 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| French Style Pricking Iron 3.38 | Thinner tooth width (1.8 mm), ideal for fine stitching | Leather goods, accessories | Pros: Produces clean holes; enhances stitching quality. Cons: Requires careful handling to avoid bending. |

| French Style Pricking Iron 3.85 | Slightly wider tooth (1.8 mm), suitable for thicker leather | Footwear, bags, belts | Pros: Versatile for various leather types; durable. Cons: May be less effective on very thin materials. |

| Round Dent Pricking Iron 3.38 | Rounded teeth design, tapered for easy piercing | Custom leatherwork, craft production | Pros: Creates rounded holes; easy to use. Cons: Limited to specific applications where round holes are needed. |

| Round Dent Pricking Iron 3.85 | Similar to 3.38 but for thicker materials | Upholstery, heavy-duty leather | Pros: Good for thicker leather; less chance of tearing. Cons: Not ideal for delicate projects. |

| Premium Steel Pricking Iron 3.38 & 3.85 | High-quality steel, polished for smooth use | High-end leather crafting | Pros: Exceptional durability and performance; consistent quality. Cons: Higher price point may deter budget-conscious buyers. |

What Are the Key Characteristics of French Style Pricking Irons 3.38 and 3.85?

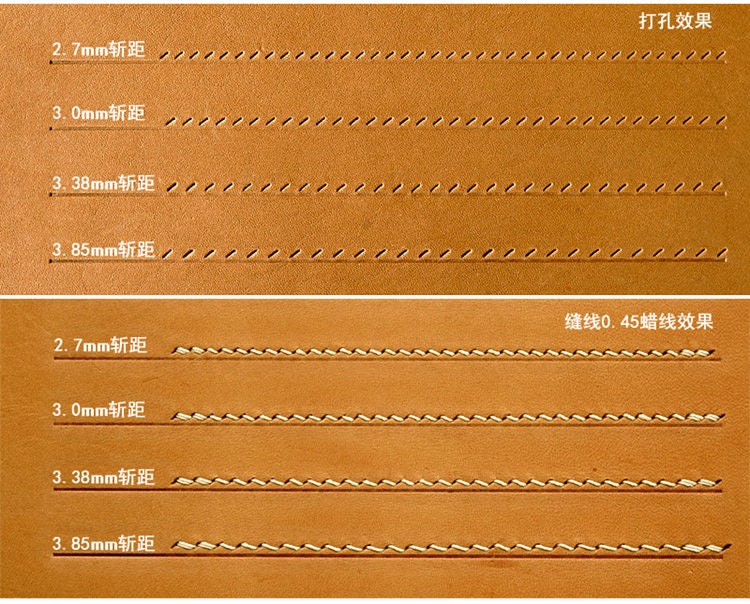

French Style Pricking Irons in the 3.38 mm and 3.85 mm sizes are distinguished by their thinner tooth widths and precise spacing, making them ideal for producing clean, consistent holes in leather. The 3.38 mm variant is particularly suited for fine stitching applications, enhancing the aesthetic quality of leather goods such as wallets and watch straps. Conversely, the 3.85 mm version caters to thicker leather, making it a versatile choice for crafting bags and belts. Buyers should consider the specific leather thickness and the desired stitch quality when selecting these tools.

How Do Round Dent Pricking Irons Differ in Functionality?

Round Dent Pricking Irons, available in both 3.38 mm and 3.85 mm, feature a tapered tooth design that creates rounded holes, which are particularly beneficial in custom leatherwork and craft production. The 3.38 mm version is well-suited for lightweight leather, while the 3.85 mm variant is designed for heavier materials. These tools excel in applications where rounded holes are necessary, such as decorative stitching. However, buyers should note that their specialized design may limit their use in projects requiring standard hole shapes.

What Makes Premium Steel Pricking Irons a Worthwhile Investment?

Premium Steel Pricking Irons in sizes 3.38 mm and 3.85 mm are crafted from high-quality steel and feature polished finishes that enhance their ease of use. These tools are designed for high-end leather crafting, ensuring durability and consistent performance, making them an excellent choice for businesses focused on quality. While they come at a higher price point, the investment is justified by their longevity and the superior stitching quality they provide. Buyers should evaluate their budget against the expected return on investment in terms of craftsmanship quality.

Key Industrial Applications of pricking iron 3.38 3.85

| Industry/Sector | Specific Application of pricking iron 3.38 3.85 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Leather Goods Manufacturing | Precision stitching for high-end leather products | Enhances product quality and durability | Ensure availability of various prong configurations and sizes for different leather types. |

| Footwear Production | Creating consistent stitch patterns on shoes | Improves aesthetic appeal and structural integrity | Look for tools that can handle various thicknesses of leather and are easy to clean. |

| Automotive Upholstery | Crafting custom leather interiors for vehicles | Increases customer satisfaction through quality finishes | Source pricking irons that are durable and can withstand high-volume usage. |

| Craft and Hobby Industries | DIY leather crafting for artisans and hobbyists | Facilitates creativity and personalization of products | Consider lightweight options for ease of use and variety in tooth spacing for diverse projects. |

| Fashion Accessories | Stitching leather bags, belts, and wallets | Adds value through high-quality craftsmanship | Ensure tools are compatible with different thread sizes and leather types for versatility. |

How Does Pricking Iron 3.38 3.85 Enhance Leather Goods Manufacturing?

In the leather goods manufacturing sector, pricking irons with a spacing of 3.38 mm and 3.85 mm are invaluable for precision stitching. These tools create consistent and clean holes, allowing for uniform stitching that enhances the durability and aesthetic appeal of high-end leather products. Manufacturers in Africa and Europe, for instance, require tools that can handle various leather thicknesses, ensuring that the final products meet luxury standards. Buyers should prioritize sourcing from suppliers that offer a range of prong configurations to accommodate different stitching needs.

What Role Do Pricking Irons Play in Footwear Production?

In footwear production, pricking irons are essential for achieving consistent stitch patterns. The 3.38 mm and 3.85 mm options are particularly useful for crafting shoes, as they create precise holes that facilitate high-quality stitching. This not only enhances the aesthetic appeal of the footwear but also contributes to its structural integrity. For businesses in South America and the Middle East, sourcing durable and easy-to-clean pricking irons is crucial to maintaining efficiency in high-volume production environments.

How Are Pricking Irons Used in Automotive Upholstery?

Automotive upholstery relies heavily on tools like pricking irons to craft custom leather interiors. The 3.38 mm and 3.85 mm pricking irons help create clean, consistent holes that allow for professional-grade stitching, which is essential for customer satisfaction. For buyers in the automotive industry, especially in regions like Europe, sourcing high-quality, durable tools that can withstand rigorous use is paramount. Additionally, businesses should look for pricking irons that can accommodate various leather types and thicknesses.

Why Are Pricking Irons Important for Craft and Hobby Industries?

In the craft and hobby industries, pricking irons are essential for DIY leather crafting. The 3.38 mm and 3.85 mm tools facilitate creativity by allowing artisans to create personalized products with precision. For hobbyists, especially in Africa and South America, lightweight and versatile pricking irons are preferable, as they enable ease of use across various projects. When sourcing these tools, it’s important to consider options that offer different tooth spacings to cater to diverse crafting needs.

How Do Pricking Irons Benefit Fashion Accessories Production?

For the production of fashion accessories such as bags, belts, and wallets, pricking irons are crucial for achieving high-quality craftsmanship. The 3.38 mm and 3.85 mm tools enable artisans to create clean, consistent holes that enhance the overall value of the products. Buyers in Europe and the Middle East should prioritize sourcing pricking irons that are compatible with different thread sizes and leather types to ensure versatility in their production processes. This adaptability can significantly improve the quality and appeal of finished accessories.

3 Common User Pain Points for ‘pricking iron 3.38 3.85’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Stitch Spacing

The Problem: B2B buyers in the leather crafting industry often struggle with maintaining consistent stitch spacing when using pricking irons, particularly with models like the 3.38 and 3.85. Inconsistent spacing can lead to uneven stitching patterns, affecting the overall quality of leather goods. This inconsistency not only impacts the aesthetic appeal but can also compromise the structural integrity of the finished product, resulting in customer dissatisfaction and potential returns.

The Solution: To overcome this challenge, buyers should prioritize sourcing high-quality pricking irons that feature well-defined prong spacing and sharp, polished teeth. It’s advisable to opt for models that provide clear markings for spacing and have a heavier base for stability during use. When using the 3.38 or 3.85 pricking irons, it’s essential to practice consistent pressure and positioning. Buyers can also implement a guide or template to ensure that the pricking iron is aligned correctly before striking. This combination of quality tools and careful technique will enhance stitching consistency, leading to improved product quality and customer satisfaction.

Scenario 2: Tool Durability and Maintenance Concerns

The Problem: Another common pain point for B2B buyers is the durability of pricking irons, especially when frequently used in high-volume production environments. Tools that dull quickly or break under pressure lead to increased costs due to replacements and repairs, not to mention the time lost during production. Buyers may find themselves caught in a cycle of purchasing subpar tools that do not meet their longevity expectations.

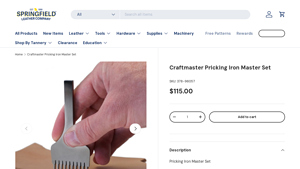

Illustrative image related to pricking iron 3.38 3.85

The Solution: To ensure durability, buyers should select pricking irons made from high-quality materials, such as solid brass or high-carbon steel, which are less prone to rust and wear. It’s crucial to verify the manufacturer’s reputation for quality and to read user reviews for insights on durability. Additionally, proper maintenance is key; buyers should regularly clean their pricking irons to remove leather residue and oil them to prevent rust. Investing in a replacement kit for prongs can also save costs in the long run, allowing users to replace only the damaged parts rather than the entire tool.

Scenario 3: Sourcing Challenges in International Markets

The Problem: Many B2B buyers face significant challenges when sourcing specialized tools like pricking irons from international suppliers. Issues such as high shipping costs, long lead times, customs duties, and potential quality inconsistencies can complicate the purchasing process. Buyers in regions like Africa, South America, and the Middle East may find it particularly difficult to navigate these complexities while ensuring they receive tools that meet their specific requirements.

The Solution: To address these sourcing challenges, buyers should establish relationships with reputable suppliers who offer transparent shipping policies and clear timelines. It is beneficial to seek out suppliers who provide comprehensive product information, including specifications and user guides, to ensure the tools meet their needs. Joining industry networks or forums can also help buyers connect with other professionals who may have recommendations for reliable suppliers. Additionally, considering local manufacturers or distributors can reduce shipping costs and lead times, enabling a more streamlined procurement process.

Strategic Material Selection Guide for pricking iron 3.38 3.85

When selecting materials for pricking irons, particularly the 3.38 mm and 3.85 mm variants, it is essential to consider the properties, advantages, and limitations of each material. This analysis will focus on four common materials used in the manufacturing of pricking irons: high-carbon steel, stainless steel, brass, and aluminum alloy. Each material has unique characteristics that can influence the performance and suitability of pricking irons for various applications.

Illustrative image related to pricking iron 3.38 3.85

What Are the Key Properties of High-Carbon Steel for Pricking Irons?

High-carbon steel is a popular choice for pricking irons due to its high hardness and excellent edge retention. Typically, high-carbon steel can withstand significant pressure and is known for its ability to maintain a sharp edge even after extensive use. However, it is susceptible to corrosion if not properly maintained, requiring regular oiling to prevent rust.

Pros: High-carbon steel offers superior durability and a sharp cutting edge, making it ideal for detailed leatherwork. Its ability to be heat-treated enhances its performance, allowing for precise stitching.

Cons: The main drawback is its vulnerability to corrosion, which can be a significant concern for international buyers in humid climates. Additionally, the manufacturing process can be complex, requiring skilled labor to achieve the desired hardness and sharpness.

How Does Stainless Steel Compare for Pricking Irons?

Stainless steel is another viable option for pricking irons, known for its excellent corrosion resistance. This material can withstand exposure to moisture and various chemicals, making it suitable for diverse environments, including those found in Africa and South America.

Illustrative image related to pricking iron 3.38 3.85

Pros: The primary advantage of stainless steel is its resistance to rust and staining, which reduces maintenance needs. It also provides a good balance of hardness and toughness, ensuring longevity.

Cons: However, stainless steel can be more expensive than high-carbon steel, impacting overall production costs. Additionally, it may not hold an edge as well as high-carbon steel, requiring more frequent sharpening.

What Are the Benefits of Using Brass for Pricking Irons?

Brass is often used for pricking irons due to its aesthetic appeal and good corrosion resistance. It is a softer metal, which can be beneficial for applications requiring less aggressive punching.

Pros: Brass pricking irons are less likely to damage the leather, making them suitable for delicate work. They are also resistant to corrosion, which is advantageous in various climates.

Cons: The downside of brass is its lower durability compared to steel options. It can wear down more quickly, especially under heavy use, leading to a shorter lifespan for the tool.

Why Consider Aluminum Alloy for Pricking Irons?

Aluminum alloy is a lightweight alternative that can be used for pricking irons, particularly in applications where weight is a concern. This material is known for its good strength-to-weight ratio and resistance to corrosion.

Pros: The primary advantage of aluminum alloy is its lightweight nature, making it easier to handle during prolonged use. It also offers good corrosion resistance, making it suitable for various environments.

Cons: However, aluminum alloys may not provide the same level of durability and edge retention as steel options. They can be more prone to bending and deformation under heavy pressure, which may limit their effectiveness in certain applications.

Illustrative image related to pricking iron 3.38 3.85

Summary Table of Material Selection for Pricking Irons

| Material | Typical Use Case for pricking iron 3.38 3.85 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Carbon Steel | Detailed leatherwork requiring sharp edges | Superior durability and edge retention | Susceptible to corrosion | Medium |

| Stainless Steel | Environments with moisture exposure | Excellent corrosion resistance | Higher cost, edge retention may vary | High |

| Brass | Delicate leather applications | Less damaging to leather, corrosion-resistant | Lower durability, wears down quickly | Medium |

| Aluminum Alloy | Lightweight applications | Lightweight and good corrosion resistance | Less durable, prone to bending | Low |

This guide provides crucial insights for international B2B buyers, helping them make informed decisions based on material properties, performance characteristics, and market considerations. Understanding these factors will enable buyers to select the most suitable pricking iron for their specific applications, ensuring optimal performance and longevity.

In-depth Look: Manufacturing Processes and Quality Assurance for pricking iron 3.38 3.85

What Are the Key Stages in the Manufacturing Process of Pricking Irons 3.38 and 3.85?

The manufacturing of pricking irons, particularly sizes 3.38 mm and 3.85 mm, involves several critical stages that ensure the final product meets high standards of quality and functionality.

Material Preparation: Sourcing and Selection

The first step in manufacturing pricking irons is sourcing high-quality materials. Most reputable manufacturers opt for durable steel or brass, known for their strength and resistance to wear. For instance, high-carbon steel is often chosen for its hardness and edge retention, while brass can provide enhanced corrosion resistance. Suppliers typically engage in stringent material inspections to ensure compliance with international standards, which is crucial for B2B buyers looking for reliability in their purchases.

Forming: Shaping the Tool

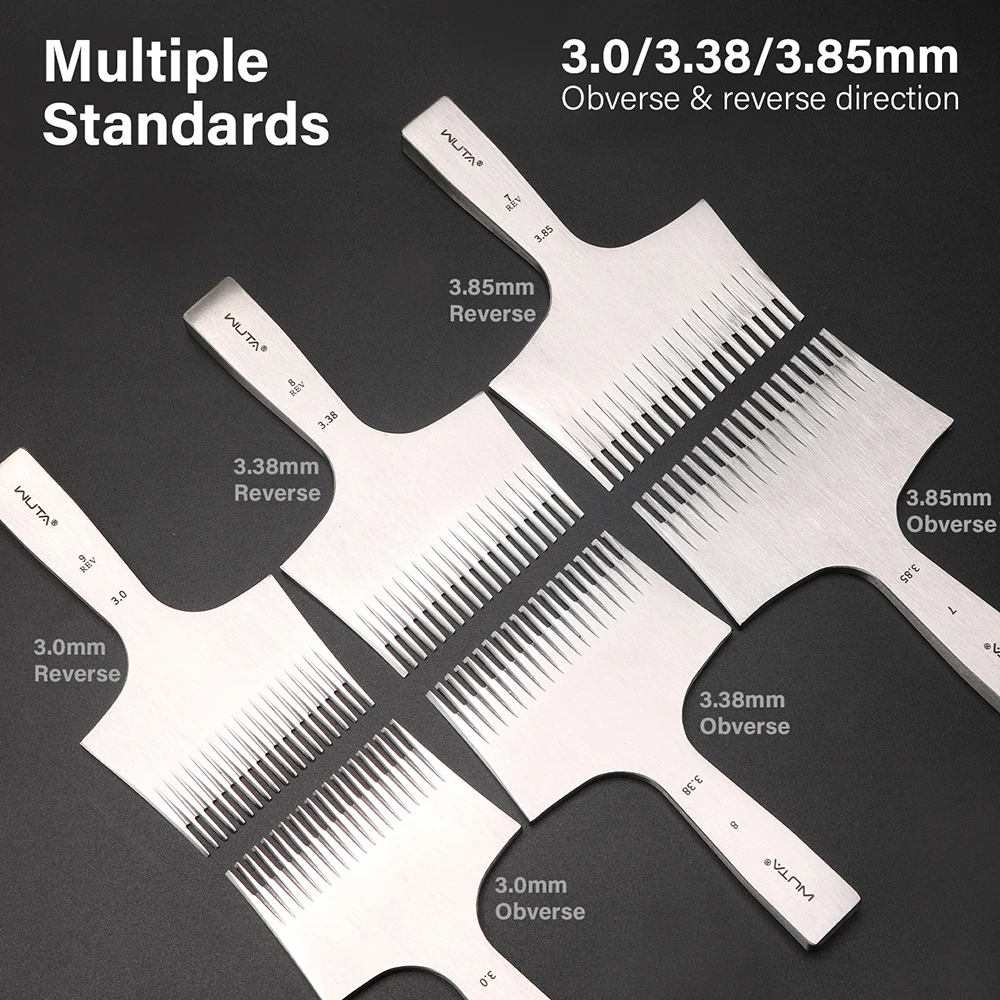

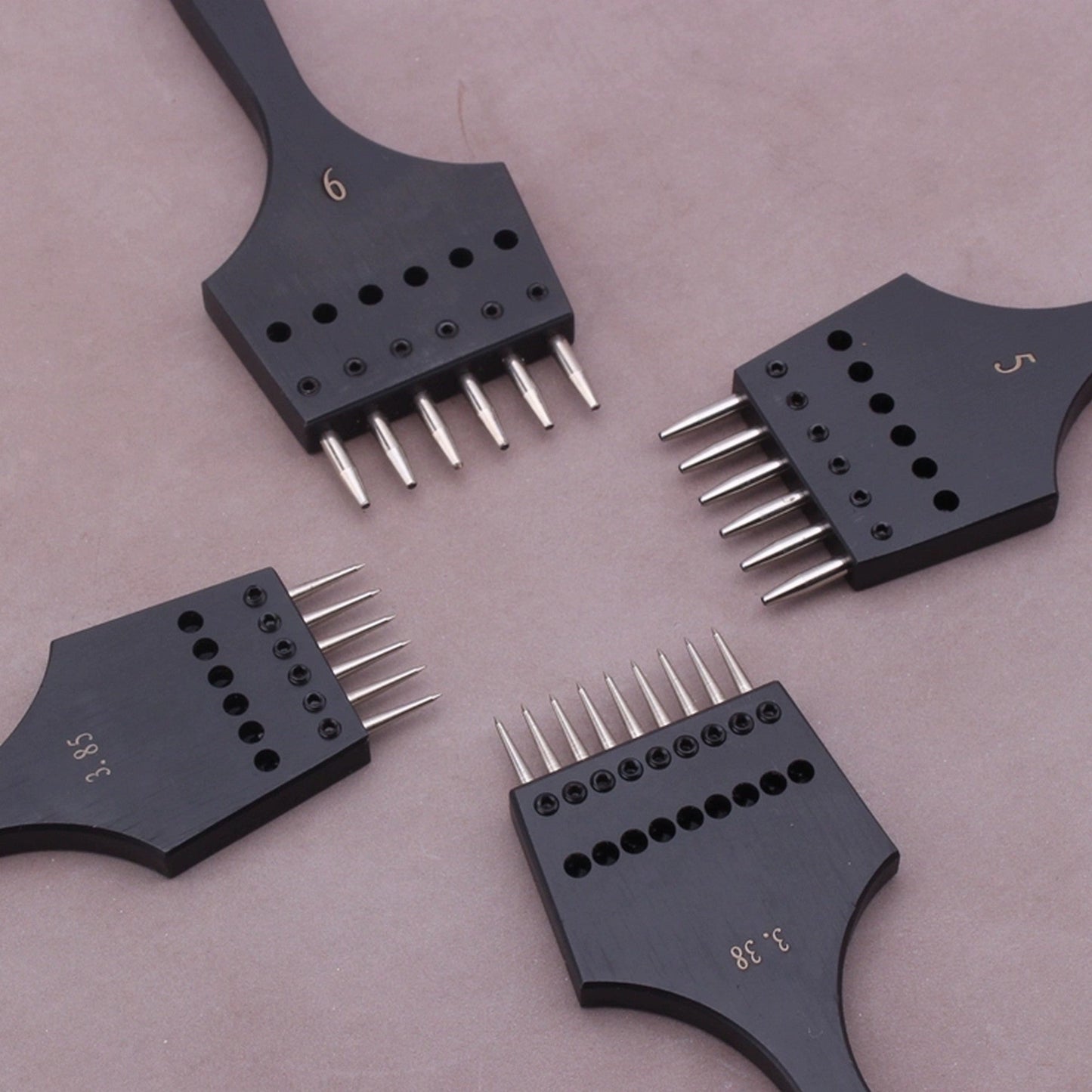

Once the materials are selected, the next phase is forming. This process usually involves cutting the metal into specific shapes, followed by heat treatment to enhance durability. The forming stage may utilize techniques such as forging or machining to achieve the desired tooth width and spacing, which are essential for the pricking irons’ performance. Precision in this stage is critical, as even slight deviations can affect stitching quality and ease of use.

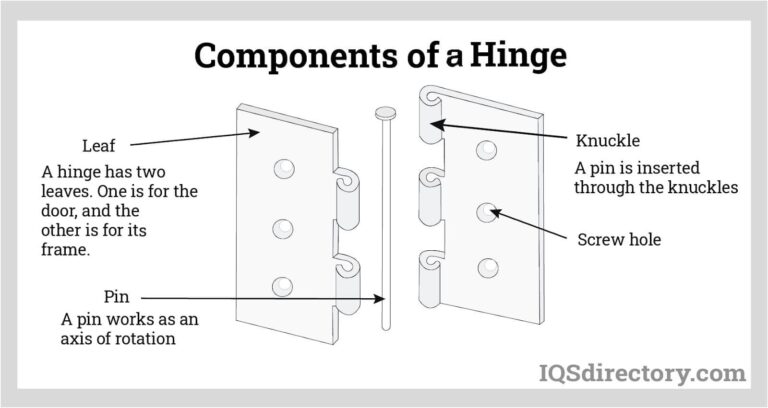

Assembly: Joining Components

In the assembly stage, various components of the pricking iron are brought together. For pricking irons with multiple prongs, this may involve attaching the prongs to a handle, ensuring that each prong is aligned correctly for consistent spacing. Quality manufacturers will use jigs and fixtures to maintain accuracy during this process. The assembly phase is pivotal for ensuring that the tool is not only functional but also ergonomically designed for user comfort.

Finishing: Surface Treatment and Quality Checks

The finishing stage involves several processes aimed at enhancing the aesthetic and functional qualities of the pricking iron. This may include polishing the teeth to ensure they pierce leather smoothly and applying protective coatings to prevent rust and wear. The finishing touches can significantly impact the usability of the tool, making it a vital step in the manufacturing process.

How is Quality Assurance Implemented in Pricking Iron Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing pricking irons, ensuring that each product meets established standards and customer expectations.

What International Standards Are Relevant for Quality Assurance?

For manufacturers, adhering to international standards such as ISO 9001 is essential. This standard focuses on quality management systems and helps organizations ensure they consistently meet customer and regulatory requirements. Additionally, industry-specific certifications like CE mark may be applicable, particularly for companies exporting to Europe, indicating compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Effective quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage inspects raw materials upon arrival. It ensures that all materials used in pricking irons meet specified quality standards.

- In-Process Quality Control (IPQC): During production, manufacturers conduct regular inspections to monitor the manufacturing process. This includes checking dimensions, weight, and alignment of prongs.

- Final Quality Control (FQC): Once production is complete, a final inspection is performed. This includes functional testing to ensure that pricking irons perform as expected, particularly regarding the precision of holes made in leather.

Which Testing Methods Are Commonly Used in Quality Assurance for Pricking Irons?

Quality assurance for pricking irons may involve several testing methods:

- Dimensional Inspection: Ensures that the pricking irons meet specified measurements for spacing and tooth width.

- Functional Testing: Involves using the pricking irons on various leather types to assess performance and ease of use.

- Durability Tests: These tests evaluate how well the pricking irons withstand repeated use, focusing on the integrity of the prongs and the handle.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial to ensure product reliability.

What Steps Can Buyers Take to Ensure Quality?

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can help buyers assess the quality control processes in place. This can include reviewing documentation related to material sourcing, production techniques, and quality checks.

-

Request Quality Control Reports: Suppliers should be able to provide documentation of their quality control measures and outcomes. This includes inspection reports, test results, and certifications.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturer’s processes and products. This is particularly important for buyers who are unable to visit the manufacturing site.

What Are the Quality Control Nuances for International Buyers?

B2B buyers must be aware of specific nuances related to quality control when dealing with international suppliers.

- Understanding Local Standards: Different regions may have varying standards and regulations. Buyers should familiarize themselves with these to ensure compliance.

- Cultural Differences: Understanding the cultural context of the supplier’s operations can help buyers navigate potential communication barriers and operational differences.

- Logistics and Shipping Considerations: Quality control doesn’t end at the factory. Buyers should ensure that the shipping process maintains product integrity, requiring additional checks before final delivery.

By understanding the manufacturing processes and quality assurance practices involved in the production of pricking irons, B2B buyers can make informed decisions that enhance their purchasing strategy and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pricking iron 3.38 3.85’

In the competitive landscape of leather crafting, procuring the right pricking irons—specifically the 3.38 mm and 3.85 mm models—is crucial for enhancing stitching quality and efficiency. This guide serves as a practical checklist for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, ensuring a streamlined sourcing process.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications of the pricking irons you need. Consider factors such as spacing (3.38 mm or 3.85 mm), prong count (e.g., 2, 5, or 10 prongs), and tooth width (typically around 1.7-2.0 mm). These details will help you identify suitable products that meet your craftsmanship requirements.

Illustrative image related to pricking iron 3.38 3.85

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers with a proven track record in manufacturing pricking irons. Look for companies that specialize in leather crafting tools and have positive reviews from other B2B buyers. Supplier reliability can be gauged by examining their website, customer testimonials, and industry reputation.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential to ensure product quality and compliance with international standards. Check if the supplier has relevant certifications such as ISO, CE, or others that pertain to manufacturing and product safety. This step minimizes risks associated with substandard tools and ensures you receive high-quality pricking irons.

Step 4: Request Product Samples

Before placing a bulk order, request samples of the pricking irons you are interested in. Testing the tools will allow you to assess their performance, weight, and finish. Evaluate how well they punch through leather and create clean, consistent holes, which is vital for achieving high-quality stitching.

Step 5: Negotiate Pricing and Terms

Once you have selected potential suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Aim for competitive pricing while ensuring that the quality of the product is not compromised. Discuss bulk order discounts and shipping costs, especially considering international shipping fees.

Illustrative image related to pricking iron 3.38 3.85

Step 6: Confirm Shipping and Handling Procedures

Understanding the shipping logistics is crucial for timely delivery. Confirm the shipping methods, estimated delivery times, and any customs duties involved. Ensure that the supplier can provide tracking information to monitor your order’s progress, especially if you are importing goods from overseas.

Step 7: Establish a Relationship for Future Orders

After a successful initial order, aim to establish a long-term relationship with your chosen supplier. This can lead to better pricing, priority in fulfilling orders, and tailored services in the future. Maintaining open communication will help address any concerns and improve collaboration.

By following this checklist, B2B buyers can effectively navigate the procurement process for pricking irons, ensuring they select high-quality tools that enhance their leather crafting capabilities.

Comprehensive Cost and Pricing Analysis for pricking iron 3.38 3.85 Sourcing

What Are the Key Cost Components in Sourcing Pricking Iron 3.38 and 3.85?

When evaluating the cost structure for pricking irons, specifically the 3.38 mm and 3.85 mm models, several key components must be considered. These include:

-

Materials: The primary materials used in manufacturing pricking irons include high-carbon steel and brass. The choice of material significantly impacts both durability and cost. For instance, high-quality steel ensures longevity and better performance but may come at a higher price point compared to lower-grade alternatives.

-

Labor: Skilled labor is essential in the production of pricking irons, especially those that require precision and craftsmanship. Labor costs can vary depending on the region and the skill level of the workforce. In countries with higher labor costs, such as Germany, buyers may find that prices reflect this expense.

-

Manufacturing Overhead: This encompasses costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower overhead costs, which can be reflected in the final pricing of the product.

-

Tooling: The initial investment in specialized tools and dies for pricking iron production can be substantial. These costs are often amortized over production runs, influencing the pricing for smaller orders.

-

Quality Control (QC): Implementing stringent QC processes ensures that each pricking iron meets quality standards, which is vital for maintaining brand reputation. However, rigorous QC can add to overall costs.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors such as shipping method, distance, and customs duties can significantly affect the final price.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market conditions, competition, and the supplier’s positioning.

How Do Price Influencers Affect Sourcing Decisions for Pricking Irons?

Several factors influence the pricing of pricking irons, which buyers should consider when sourcing:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for businesses to consolidate their purchases.

-

Specifications and Customization: Custom specifications, such as unique tooth widths or finishes, can lead to increased costs. Buyers should balance the need for customization with the associated price increases.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO standards) can enhance durability and performance but will increase costs. Buyers should assess whether these certifications add value to their specific applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products, justified by their track record of quality and service.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can significantly affect the total landed cost of the product.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Pricking Irons?

To optimize sourcing costs for pricking irons, international buyers should consider the following strategies:

Illustrative image related to pricking iron 3.38 3.85

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Establishing a good relationship can lead to better terms and potential discounts.

-

Total Cost of Ownership (TCO): Assess the long-term costs associated with the product, including maintenance, replacement, and potential downtime. A lower upfront price may not always equate to better value in the long run.

-

Pricing Nuances for International Buyers: Be aware of additional costs such as tariffs, taxes, and shipping fees when importing pricking irons. These can vary significantly by region, impacting overall cost.

-

Supplier Diversification: Consider sourcing from multiple suppliers to mitigate risks and leverage competitive pricing. This can also provide access to different materials and innovations in the market.

Conclusion

The cost and pricing landscape for pricking irons, particularly the 3.38 mm and 3.85 mm options, is influenced by a variety of factors ranging from material choice to logistics. By understanding these components and price influencers, international B2B buyers can make informed decisions that enhance their sourcing strategies and ultimately improve their bottom line.

Alternatives Analysis: Comparing pricking iron 3.38 3.85 With Other Solutions

Exploring Alternatives to Pricking Iron 3.38 and 3.85

In the realm of leather crafting, the choice of tools significantly impacts the quality and efficiency of the work. While the pricking iron 3.38 and 3.85 are popular choices for creating precise stitching holes, several alternative solutions may suit different requirements or preferences. This analysis will compare pricking irons with other methods, helping B2B buyers make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Pricking Iron 3.38 3.85 | Leather Stitching Chisels | Rotary Punch Tool |

|---|---|---|---|

| Performance | Excellent for clean holes; great for detailed work | Good for wider spacing; versatile | Effective for various hole sizes; may create larger openings |

| Cost | $29.99 – $45.00 | $20.00 – $50.00 | $15.00 – $40.00 |

| Ease of Implementation | Requires skill; manual use | Moderate skill; manual use | Easy; less skill needed |

| Maintenance | Low; occasional sharpening | Moderate; needs regular maintenance | Low; minimal maintenance required |

| Best Use Case | Fine leatherwork, detailed stitching | General leather projects requiring varied hole sizes | Quick hole punching in thicker materials |

Detailed Breakdown of Alternatives

Leather Stitching Chisels

Leather stitching chisels are a viable alternative to pricking irons, especially for users who need versatility in hole spacing. These chisels allow for wider spacing and can accommodate various prong configurations, making them suitable for a range of leather projects. The primary advantage is their adaptability; however, they may not achieve the same level of precision as pricking irons. Users may find that achieving clean, consistent holes requires more skill and practice, potentially impacting the learning curve for new crafters.

Rotary Punch Tool

The rotary punch tool is another alternative that offers ease of use, especially for those who may not have extensive experience with leatherworking. This tool is effective for creating holes of various sizes quickly, making it ideal for bulk projects or thicker leather materials. The main benefit is its simplicity and speed, allowing for efficient production. However, it may create larger openings than desired for fine stitching, which could compromise the aesthetic quality of detailed work. Additionally, it may lack the finesse required for high-end leather goods.

Illustrative image related to pricking iron 3.38 3.85

Conclusion

When considering the best tool for leatherwork, B2B buyers should evaluate their specific needs, such as the type of leather, the desired precision, and the volume of work. The pricking iron 3.38 and 3.85 excel in delivering clean, detailed stitches, making them ideal for high-quality craftsmanship. However, if versatility or ease of use is a priority, leather stitching chisels or rotary punch tools may offer more suitable options. Ultimately, the right choice hinges on balancing performance, cost, and the skill level of the user, ensuring that the selected tool aligns with the business’s operational goals and product quality standards.

Essential Technical Properties and Trade Terminology for pricking iron 3.38 3.85

What Are the Key Technical Properties of Pricking Iron 3.38 and 3.85?

When considering the purchase of pricking irons, particularly the 3.38 mm and 3.85 mm models, it is essential to understand the technical specifications that define their quality and performance. Here are some critical properties:

-

Material Composition

Pricking irons are typically made from high-quality steel, such as 4Cr13 or similar grades. Steel with a higher carbon content enhances durability and sharpness, making it easier to penetrate leather. The choice of material is vital for B2B buyers as it directly impacts the longevity and effectiveness of the tools, especially in high-volume production environments. -

Tooth Width and Spacing

The tooth width for the 3.38 mm and 3.85 mm pricking irons generally ranges from 1.7 mm to 2.0 mm. The spacing between the teeth also varies, allowing for different stitching densities. For businesses, understanding tooth width and spacing is crucial for ensuring compatibility with various thread sizes and leather thicknesses, which can affect the overall quality of the finished product. -

Prong Count

These pricking irons come with various prong counts, typically ranging from 2 to 10 prongs. The number of prongs affects the number of holes created simultaneously, which can significantly increase efficiency in production. A higher prong count is advantageous for businesses looking to streamline their stitching processes and improve output. -

Weight and Ergonomics

The weight of a pricking iron influences its ease of use and precision. Heavier irons tend to offer more stability during use, minimizing the risk of misalignment. Ergonomics also play a role; tools designed with a comfortable grip can reduce operator fatigue. For B2B buyers, selecting ergonomically designed tools can enhance productivity and reduce the risk of workplace injuries. -

Finishing and Polishing

The finish of pricking irons, including hand-polished teeth, ensures smooth operation and clean hole creation. A well-finished tool reduces friction and enhances the overall user experience. For manufacturers, investing in high-quality finishes can lead to superior stitching results, thereby improving customer satisfaction.

What Are Common Trade Terms Related to Pricking Irons?

Understanding industry terminology is essential for effective communication and negotiation in the B2B sector. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of pricking irons, an OEM may supply the tools to brands that sell them under their own name. This is crucial for buyers looking to establish partnerships with reliable suppliers. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for businesses to manage inventory and budget constraints effectively. Buyers should negotiate MOQs that align with their production needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to request pricing and terms from suppliers. This is a critical step in the procurement process, allowing businesses to compare offers from multiple suppliers to secure the best deal. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps B2B buyers navigate shipping logistics, costs, and risk management. -

Lead Time

This refers to the time taken from placing an order to its delivery. Lead time is a critical consideration for B2B buyers, as longer lead times can impact production schedules and customer fulfillment.

By comprehensively understanding the technical properties and trade terminology associated with pricking irons 3.38 mm and 3.85 mm, B2B buyers can make informed decisions that enhance their operational efficiency and product quality.

Illustrative image related to pricking iron 3.38 3.85

Navigating Market Dynamics and Sourcing Trends in the pricking iron 3.38 3.85 Sector

What Are the Key Market Trends Affecting the Pricking Iron 3.38 3.85 Sector?

The global market for pricking irons, particularly the 3.38 mm and 3.85 mm models, is witnessing significant growth driven by the rising demand for high-quality leather goods. Factors such as the resurgence of artisanal craftsmanship and a growing preference for handmade products over mass-produced alternatives are shaping this sector. In regions like Africa, South America, the Middle East, and Europe, there is a strong inclination towards tools that enhance stitching quality, thereby improving the overall aesthetics and durability of leather products.

Emerging B2B tech trends such as e-commerce platforms and digital supply chain management systems are revolutionizing how international buyers source pricking irons. With advancements in technology, buyers can now access a wider variety of suppliers, compare prices in real-time, and place bulk orders efficiently. Additionally, the increasing emphasis on customization options is allowing manufacturers to cater to specific market needs, such as pricking irons with varied prong configurations and tooth widths.

Moreover, the growing awareness of product quality and craftsmanship among buyers is leading to a preference for brands that emphasize hand-crafted tools, which can significantly enhance stitching precision. In markets like Brazil and Germany, buyers are actively seeking suppliers who can provide detailed information on product specifications, including tooth width and spacing, to ensure they select the right tools for their specific applications.

Illustrative image related to pricking iron 3.38 3.85

How Is Sustainability Impacting the Sourcing of Pricking Irons?

Sustainability is becoming a cornerstone of sourcing strategies in the pricking iron sector. As global awareness of environmental issues grows, international buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices. This includes the use of responsibly sourced materials, such as high-quality steel and brass, which not only reduce environmental impact but also enhance the longevity of the tools.

Buyers are now more inclined to seek out suppliers who offer transparency in their supply chains, ensuring that their products are produced in a manner that respects both workers’ rights and environmental standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainable practices, making them more appealing to conscientious buyers.

Furthermore, the demand for eco-friendly materials is on the rise. Manufacturers that utilize recycled metals or sustainable production processes can differentiate themselves in a competitive market. This shift towards sustainability is not just a trend; it reflects a broader movement within the B2B landscape where buyers are increasingly willing to invest in products that align with their values.

What Is the Historical Context Behind Pricking Irons?

The evolution of pricking irons can be traced back to traditional leatherworking practices, where artisans relied on rudimentary tools to create intricate designs and stitch leather pieces together. Initially made from simple materials, the design and functionality of these tools have significantly improved over centuries. The introduction of high-quality steel and brass has enhanced their durability and performance, while advances in manufacturing techniques have led to more precise tooling options.

Illustrative image related to pricking iron 3.38 3.85

Historically, pricking irons have played a crucial role in the leather goods industry, enabling craftsmen to achieve cleaner, more consistent stitching. Today, the availability of various prong sizes and tooth widths, such as the popular 3.38 mm and 3.85 mm models, reflects the industry’s evolution towards customization and specialization. As the market continues to grow, the rich history of pricking irons remains a testament to the craftsmanship and innovation that define the leatherworking sector.

Frequently Asked Questions (FAQs) for B2B Buyers of pricking iron 3.38 3.85

-

How do I select the right pricking iron size for my leatherwork?

Choosing the right pricking iron size depends on the thickness of the leather and the type of stitching you intend to perform. For 3.38mm and 3.85mm pricking irons, it is advisable to use thread sizes between 0.3mm to 0.5mm. If you’re working with thicker leather, a wider spacing may be beneficial for a more robust stitch. Additionally, consider the number of prongs; more prongs can create more evenly spaced holes, enhancing the overall appearance of your stitching. Always test different sizes on scrap leather to determine the best fit for your specific needs. -

What is the best type of pricking iron for detailed leatherwork?

For detailed leatherwork, the 3.38mm pricking iron is often preferred due to its spacing, which allows for tighter, more precise stitching. This size is ideal for projects such as wallets, watch straps, and small accessories where a clean finish is crucial. The thinner teeth create a less bulky hole, ensuring that the thread fits neatly without compromising the leather’s integrity. Additionally, consider irons with a tapered design for easier piercing and clean hole extraction. -

What are the customization options available for pricking irons?

Many suppliers offer customization options for pricking irons, including bespoke sizes, tooth widths, and prong counts. When sourcing, inquire about the possibility of branding or engraving your company logo on the tools. Some manufacturers may also allow you to specify the material used, such as high-carbon steel for durability or brass for aesthetic appeal. Always confirm minimum order quantities (MOQ) for custom orders, as these may vary by supplier. -

How can I ensure the quality of pricking irons from suppliers?

To ensure the quality of pricking irons, conduct thorough supplier vetting. Request samples to assess the craftsmanship, weight, and finish of the tools. Look for manufacturers with positive reviews and established reputations in the leatherworking community. Certifications or quality assurance processes can also indicate a commitment to producing high-quality tools. Additionally, consider suppliers that offer warranties or satisfaction guarantees, as these often reflect confidence in their product quality. -

What are the payment terms typically offered for bulk purchases of pricking irons?

Payment terms for bulk purchases can vary significantly by supplier and region. Common options include upfront payment, 30% deposit with the balance upon shipment, or net 30-60 days terms for established businesses. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify payment terms before placing an order to avoid misunderstandings and ensure a smooth transaction process. -

What logistics considerations should I keep in mind when importing pricking irons?

When importing pricking irons, consider shipping costs, customs duties, and delivery times. Verify if the supplier includes these charges in their pricing or if they will be billed separately upon arrival. Additionally, ensure you understand the customs regulations of your country regarding importing tools, as these can vary. Choose reliable shipping methods, such as FedEx or DHL, which offer tracking and insurance options, ensuring your tools arrive safely and on time. -

How do I handle potential issues with my order of pricking irons?

If you encounter issues with your pricking iron order, such as defects or incorrect sizes, promptly contact the supplier’s customer service. Most reputable suppliers will have a return policy or replacement process in place. Document any issues with photos and detailed descriptions to expedite the resolution. Additionally, ensure you understand the warranty or guarantee policy offered by the supplier, as this will outline your rights in case of product malfunctions or dissatisfaction. -

What are the recommended care instructions for maintaining pricking irons?

To maintain your pricking irons, clean them after each use to remove any leather residue and prevent rust. Use a soft cloth and mild soap, avoiding abrasive materials that could scratch the surface. For steel irons, apply a light coat of oil to prevent oxidation. Store the tools in a dry place, ideally in a protective case or pouch, to prevent damage. Regular maintenance not only extends the life of your tools but also ensures consistent performance in your leatherworking projects.

Top 6 Pricking Iron 3.38 3.85 Manufacturers & Suppliers List

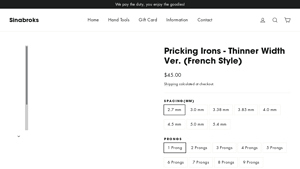

1. Sinabroks – Pricking Irons (Thinner Width Ver.)

Domain: sinabroks.com

Registered: 2018 (7 years)

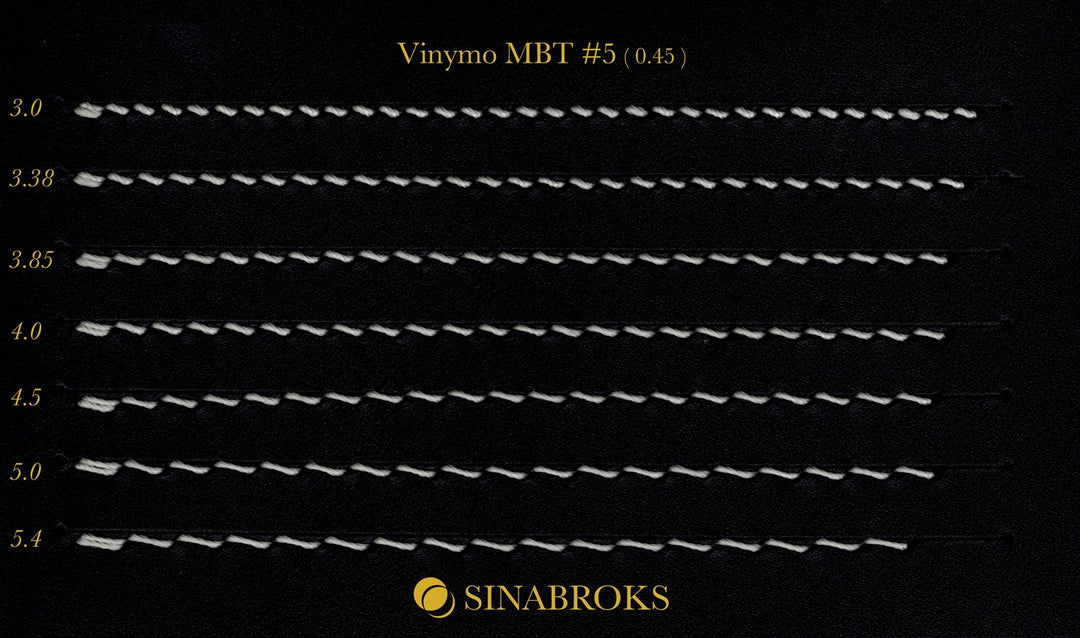

Introduction: {“product_name”: “Pricking Irons – Thinner Width Ver. (French Style)”, “regular_price”: “$45.00”, “spacing_options”: [2.7, 3.0, 3.38, 3.85, 4.0, 4.5, 5.0, 5.4], “prong_options”: [1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 12], “best_selling_sizes”: [3.85, 4.0], “recommended_thread_size”: “0.3 – 0.5 thickness thread”, “tooth_widths”: [1.6, 1.8], “tooth_length”: “13 mm”, “material”: “solid brass”, “rust_prevent…

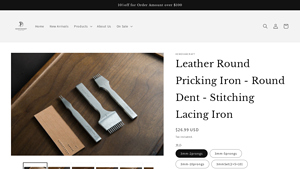

2. Kemovan – Leather Round Pricking Iron

Domain: kemovancraft.com

Registered: 2019 (6 years)

Introduction: {‘name’: ‘Leather Round Pricking Iron – Round Dent – Stitching Lacing Iron’, ‘regular_price’: ‘$26.99 USD’, ‘variants’: [{‘size’: ‘3mm-2prongs’, ‘price’: ‘$26.99’}, {‘size’: ‘3mm-5prongs’, ‘price’: ‘$32.99’}, {‘size’: ‘3mm-10prongs’, ‘price’: ‘$40.99’}, {‘size’: ‘3mmSet(2+5+10)’, ‘price’: ‘$82.99’}, {‘size’: ‘3.38mm-2prongs’, ‘price’: ‘$25.99’}, {‘size’: ‘3.38mm-5prongs’, ‘price’: ‘$31.99’}, {‘siz…

3. Sinabroks – Pricking Iron Sizes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Sinabroks pricking iron sizes available: 3.38mm, 3.85mm, or 4mm. Suitable for making wallets and small handbags. Recommended thread sizes: 0.5 or 0.6mm. 3mm is considered standard for wallets. 3.38mm is noted as a great size for wallets and pattern making. The 3.85mm and 4mm sizes are described as ‘chonky’ and less refined. French style irons are preferred for better results.

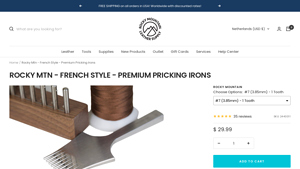

4. Rocky Mountain – Premium Pricking Irons

Domain: rmleathersupply.com

Registered: 2014 (11 years)

Introduction: Rocky Mountain Premium Pricking Irons, French Style, FREE SHIPPING on all orders in USA, Worldwide with discounted rates, Processing Time: 2-4 Business Days.

5. Craftmaster – Pricking Iron Master Set

Domain: springfieldleather.com

Registered: 1999 (26 years)

Introduction: Craftmaster Pricking Iron Master Set includes a variety of pricking irons for leatherworking. The set features multiple sizes for different stitching needs, ensuring precision and consistency in leather projects. Made from high-quality materials, these tools are designed for durability and ease of use. Ideal for both beginners and experienced leather crafters, the set enhances the quality of hand-…

6. Buckleguy – Pricking Irons

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Pricking irons; dual tine irons; sizes: 3.38mm and 3.85mm; brand: Buckleguy; price range: mid-tier; user experience: transitioning from needle in a drill press to pricking irons; recommended for various stitch line lengths; total cost of book cover project: approximately $65 (excluding labor); thread used: .04mm in red from Mandala Crafts; needle: John James 004.

Strategic Sourcing Conclusion and Outlook for pricking iron 3.38 3.85

How Can Strategic Sourcing Enhance Your Procurement of Pricking Irons 3.38 and 3.85?

In summary, the strategic sourcing of pricking irons, specifically the 3.38 mm and 3.85 mm models, offers significant advantages for international B2B buyers. These tools, crafted from high-quality materials such as solid brass and durable steel, provide exceptional performance in leathercraft, enhancing stitching precision and efficiency. By investing in reliable suppliers, businesses can ensure consistent product quality, which is critical for maintaining high standards in craftsmanship.

Moreover, understanding the specific needs of your market—whether in Africa, South America, the Middle East, or Europe—allows for better alignment of product offerings with customer demands. With the increasing global demand for high-quality leather goods, sourcing pricking irons that combine functionality with durability can set your business apart.

As you consider your next procurement move, leverage the insights gained to establish strong relationships with suppliers who prioritize craftsmanship and reliability. Embrace the potential for growth in your leathercraft operations by strategically sourcing tools that will elevate your production capabilities. Start exploring your options today to secure the best pricking irons for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to pricking iron 3.38 3.85