Is Your Canopy Materials Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for canopy materials

The global market for canopy materials presents a unique challenge for international B2B buyers, particularly when sourcing durable, versatile, and cost-effective solutions that can withstand diverse environmental conditions. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the intricacies of canopy materials—from fabric types to their various applications—can significantly impact your purchasing decisions. This guide aims to demystify the complexities of sourcing canopy materials, offering insights into different fabric options, their performance characteristics, and suitability for specific uses such as outdoor events, commercial installations, or residential enhancements.

As you navigate this extensive market, you will find detailed information on the types of canopy materials available, including waterproof, UV-resistant, and flame-retardant fabrics. Additionally, we provide guidance on supplier vetting processes, helping you identify reputable manufacturers and wholesalers that align with your business needs. Cost considerations, shipping logistics, and quality assurance are also covered, ensuring that you can make informed choices that optimize your budget and project outcomes.

By empowering international B2B buyers with actionable insights and practical solutions, this guide positions you to confidently select the right canopy materials, ultimately enhancing your product offerings and meeting your customers’ demands with excellence.

Understanding canopy materials Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Canvas | Durable, heavy-duty fabric, water-resistant | Tents, awnings, outdoor structures | Pros: Strong, versatile, and long-lasting. Cons: Heavier and may require more maintenance. |

| Polyester | Lightweight, UV resistant, easy to clean | Event canopies, trade show tents | Pros: Cost-effective and available in various colors. Cons: Less durable than canvas under extreme conditions. |

| PVC | Waterproof, tear-resistant, and easy to print | Industrial canopies, temporary shelters | Pros: Excellent weather resistance and durability. Cons: Can be heavier and less breathable. |

| Acrylic | Fade-resistant, lightweight, and versatile | Shade structures, decorative canopies | Pros: Retains color and is easy to handle. Cons: May not be as strong as other materials in high winds. |

| Mesh | Breathable, lightweight, and UV resistant | Bug nets, outdoor shades | Pros: Allows airflow while providing shade. Cons: Limited protection from rain and wind. |

What Are the Characteristics of Canvas Canopy Materials?

Canvas is a traditional choice for canopies, known for its durability and heavy-duty nature. It is often treated to enhance its water resistance, making it suitable for outdoor applications such as tents and awnings. B2B buyers should consider the weight of canvas, as it can be heavier than other materials, requiring robust support structures. Additionally, while canvas is long-lasting, it may need regular maintenance, particularly in harsh weather conditions.

Why Choose Polyester for Canopies?

Polyester canopies are favored for their lightweight properties and UV resistance, making them ideal for temporary structures like event tents and trade show displays. They are typically available in a wide array of colors and patterns, which can be an advantage for branding purposes. However, B2B buyers should note that while polyester is cost-effective, it may not hold up as well as canvas in extreme weather, necessitating careful consideration of the intended use.

Illustrative image related to canopy materials

What Are the Advantages of PVC Canopy Materials?

PVC is recognized for its waterproof and tear-resistant qualities, making it an excellent choice for industrial applications and temporary shelters. It is easy to print on, allowing for branding opportunities. Buyers should be aware that PVC can be heavier and less breathable than other materials, which might affect its use in certain climates. Understanding the environmental conditions where the canopy will be used is crucial for effective purchasing decisions.

How Does Acrylic Compare in Canopy Fabric Options?

Acrylic canopies are lightweight and fade-resistant, making them suitable for decorative applications and shade structures. They retain their color well over time and are easy to work with, which is beneficial for custom projects. However, B2B buyers should consider that acrylic may not provide the same level of strength as canvas or PVC, particularly in high winds. Therefore, assessing the local weather conditions is essential when selecting acrylic for canopy projects.

What Are the Benefits of Using Mesh for Canopies?

Mesh canopies offer a breathable option that allows airflow while providing UV protection, making them ideal for outdoor shade solutions and bug nets. They are lightweight and easy to set up, which can be advantageous for temporary installations. However, B2B buyers should keep in mind that mesh materials provide limited protection against rain and wind, making them less suitable for inclement weather conditions. Understanding the specific needs of the application will guide buyers in choosing the right mesh options.

Key Industrial Applications of canopy materials

| Industry/Sector | Specific Application of canopy materials | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Event Management | Temporary event structures (tents, marquees) | Quick setup and teardown, weather protection | Durability, size options, ease of transport, fire resistance |

| Hospitality | Outdoor dining canopies | Enhanced guest experience, protection from elements | UV resistance, aesthetic appeal, customization options |

| Agriculture | Shade structures for crops | Improved crop yield, protection from sun damage | Material longevity, weather resistance, local availability |

| Retail | Promotional canopies for outdoor sales | Increased visibility, brand promotion | Branding options, portability, weatherproofing |

| Construction | Safety canopies for site protection | Worker safety, equipment protection | Compliance with safety regulations, material strength |

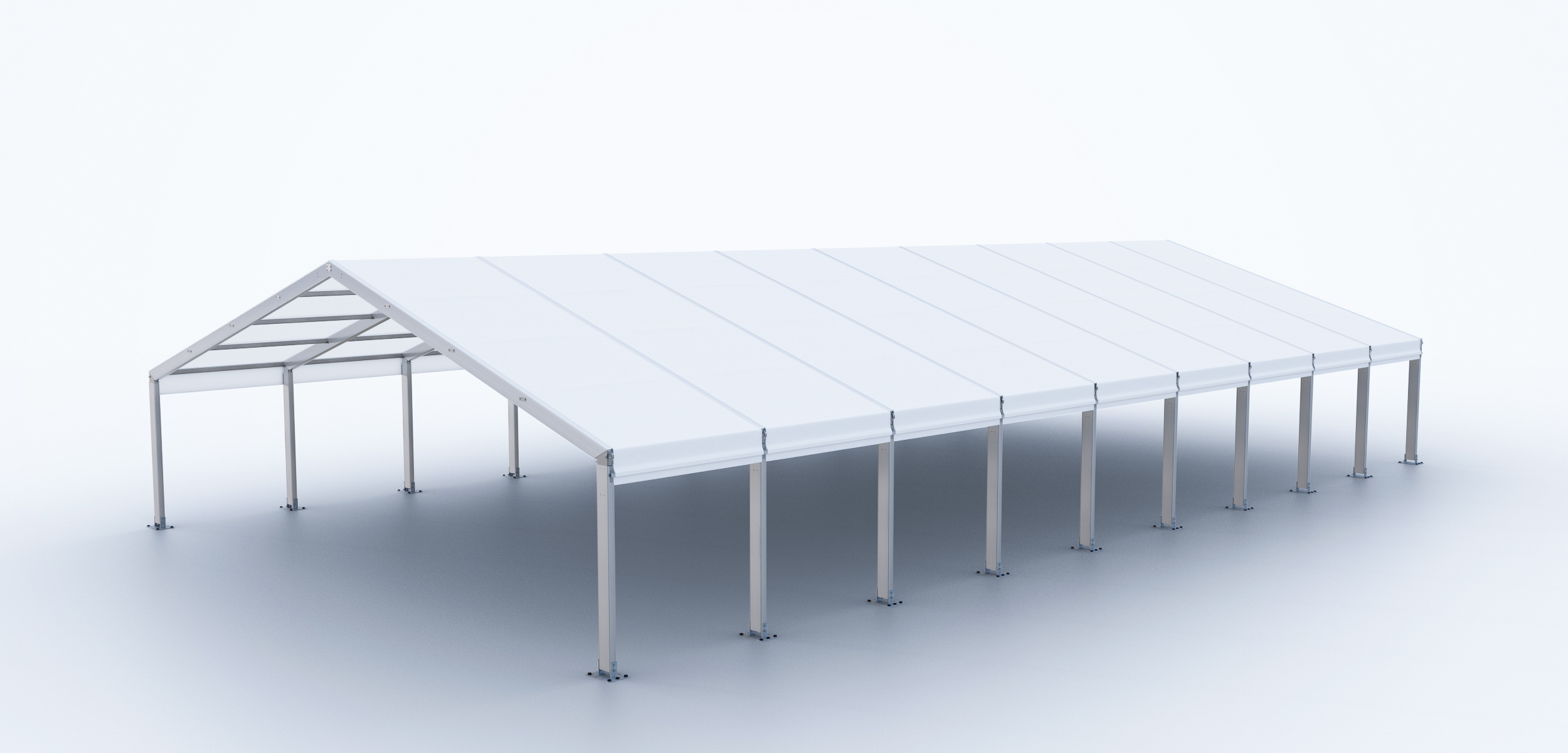

How Are Canopy Materials Used in Event Management?

In the event management sector, canopy materials are crucial for creating temporary structures like tents and marquees. These canopies provide protection against adverse weather conditions, ensuring that events can proceed smoothly regardless of rain or sun. Buyers in this sector need materials that are durable yet lightweight for easy transport and setup. Additionally, fire-resistant fabrics are often mandated by regulations, making compliance a key consideration for international buyers looking to source materials that meet local safety standards.

Illustrative image related to canopy materials

What Role Do Canopy Materials Play in the Hospitality Industry?

In the hospitality industry, outdoor dining canopies enhance the guest experience by providing a comfortable and sheltered environment. These canopies protect patrons from harsh weather while allowing them to enjoy outdoor settings. Buyers should prioritize materials that offer UV resistance and aesthetic appeal, as these factors significantly influence customer satisfaction. Customization options are also important, allowing establishments to align the canopy design with their branding and decor, especially in competitive markets across Africa, South America, and Europe.

How Are Canopy Materials Beneficial in Agriculture?

Canopy materials serve a vital role in agriculture by providing shade structures for crops, which can mitigate sun damage and enhance growth. By reducing heat stress, these canopies can lead to improved crop yields and better quality produce. Buyers in this sector should consider the longevity and weather resistance of the materials, as agricultural applications often require robust solutions that can withstand environmental challenges. Local sourcing options may also be a factor, especially in regions where transportation can impact costs.

Why Are Canopy Materials Important for Retail Promotions?

In retail, promotional canopies are effective tools for outdoor sales events and product displays. They increase visibility and attract customers while providing a sheltered shopping experience. For businesses looking to maximize their impact, sourcing canopies that are lightweight and portable is essential for ease of transport to various locations. Additionally, options for branding and customization can enhance marketing efforts, making these canopies not just functional but also a vital part of the promotional strategy.

How Do Canopy Materials Enhance Safety in Construction?

In construction, safety canopies are essential for protecting workers and equipment from the elements. These structures help maintain a safe work environment, reducing the risk of accidents due to weather-related issues. Buyers must ensure that the materials sourced comply with safety regulations and are strong enough to withstand environmental stresses. Furthermore, the ability to quickly set up and dismantle these canopies is crucial for maintaining project timelines, making sourcing efficiency a key consideration for international buyers in the construction sector.

Illustrative image related to canopy materials

3 Common User Pain Points for ‘canopy materials’ & Their Solutions

Scenario 1: Sourcing High-Quality Canopy Materials for Extreme Weather Conditions

The Problem: For B2B buyers in regions prone to extreme weather—such as heavy rainfall or intense sun—finding canopy materials that can withstand harsh conditions is a significant challenge. Many businesses purchase materials that claim to be durable but fail to perform under real-world stress, leading to costly replacements and lost revenue during peak operational times. This issue is particularly pressing in sectors like outdoor events, hospitality, and construction, where reliability is critical.

The Solution: To ensure the canopy materials you source can endure extreme weather, it’s essential to focus on specific characteristics, such as UV resistance, waterproofing, and tear resistance. When evaluating potential suppliers, request certifications that confirm these properties, such as ASTM ratings or similar industry standards. Additionally, consider sourcing from manufacturers that offer a range of fabric types, including solution-dyed acrylics or heavy-duty polyester, as these tend to provide superior performance. Conducting sample tests in controlled environments can also help validate the material’s durability before making a bulk purchase.

Scenario 2: Overcoming Color Fading Issues with Canopy Fabrics

The Problem: A common concern among B2B buyers is the fading of canopy fabrics due to prolonged exposure to sunlight. This not only affects the aesthetic appeal of outdoor structures but can also damage brand reputation, especially for businesses that rely heavily on visual marketing. For instance, event planners often face the dilemma of providing attractive, vibrant canopies that maintain their color over time, which is crucial for branding during events.

The Solution: To combat color fading, prioritize sourcing fabrics that feature UV-stabilized dyes and solution-dyed fibers, as these materials are specifically designed to resist fading from sun exposure. When selecting canopies, also inquire about the manufacturer’s warranty regarding color retention; a reputable supplier will often provide assurances on the longevity of their product’s colors. Moreover, consider investing in additional treatments or coatings that can enhance UV resistance and protect against fading, thereby prolonging the life and vibrancy of your canopies.

Illustrative image related to canopy materials

Scenario 3: Navigating Compliance and Safety Standards for Canopy Fabrics

The Problem: For B2B buyers in industries such as hospitality, events, and construction, compliance with safety and fire-retardant regulations is non-negotiable. Many buyers struggle to find canopy materials that not only meet aesthetic needs but also adhere to local and international safety standards. Failure to comply can lead to legal repercussions, financial losses, and damage to reputation.

The Solution: Begin by identifying the specific regulations that apply to your industry and location, such as NFPA (National Fire Protection Association) standards for fire retardancy. When sourcing canopy materials, work with suppliers who are knowledgeable about these standards and can provide documentation or certifications that confirm compliance. It’s beneficial to develop a checklist of essential features, such as flame retardancy, mold resistance, and other safety certifications. Additionally, establishing a relationship with a trusted supplier who can guide you through the compliance landscape can streamline your procurement process and ensure you’re always meeting safety requirements.

Strategic Material Selection Guide for canopy materials

What Are the Key Properties of Common Canopy Materials?

When selecting materials for canopies, understanding the properties of each option is crucial for performance and longevity. Here, we analyze four common materials used in the production of canopies: Polyester, Vinyl, Canvas, and Acrylic. Each material offers unique benefits and drawbacks that can influence the decision-making process for B2B buyers.

How Does Polyester Perform as a Canopy Material?

Polyester is a synthetic fabric known for its lightweight and durable characteristics. It typically boasts a temperature resistance of up to 150°F (65°C) and is often treated to be UV resistant, which is essential for outdoor applications.

Pros: Polyester is cost-effective and easy to clean, making it a popular choice for temporary structures like pop-up tents. It also has good water resistance when treated, which is beneficial in regions experiencing rain.

Illustrative image related to canopy materials

Cons: However, polyester can be less durable than other materials, especially in extreme weather conditions. Prolonged exposure to UV rays can lead to fading and degradation over time.

Impact on Application: Polyester is suitable for various applications, including outdoor events and festivals. However, it may not be ideal for permanent installations in harsh climates.

Considerations for International Buyers: Buyers should ensure that the polyester fabric meets local standards for UV resistance and flammability, such as ASTM or DIN regulations, particularly in regions like Europe and the Middle East.

What Are the Advantages of Vinyl for Canopy Construction?

Vinyl is a robust material known for its excellent waterproofing and durability. It can withstand temperatures ranging from -20°F to 180°F (-29°C to 82°C) and is resistant to mold and mildew.

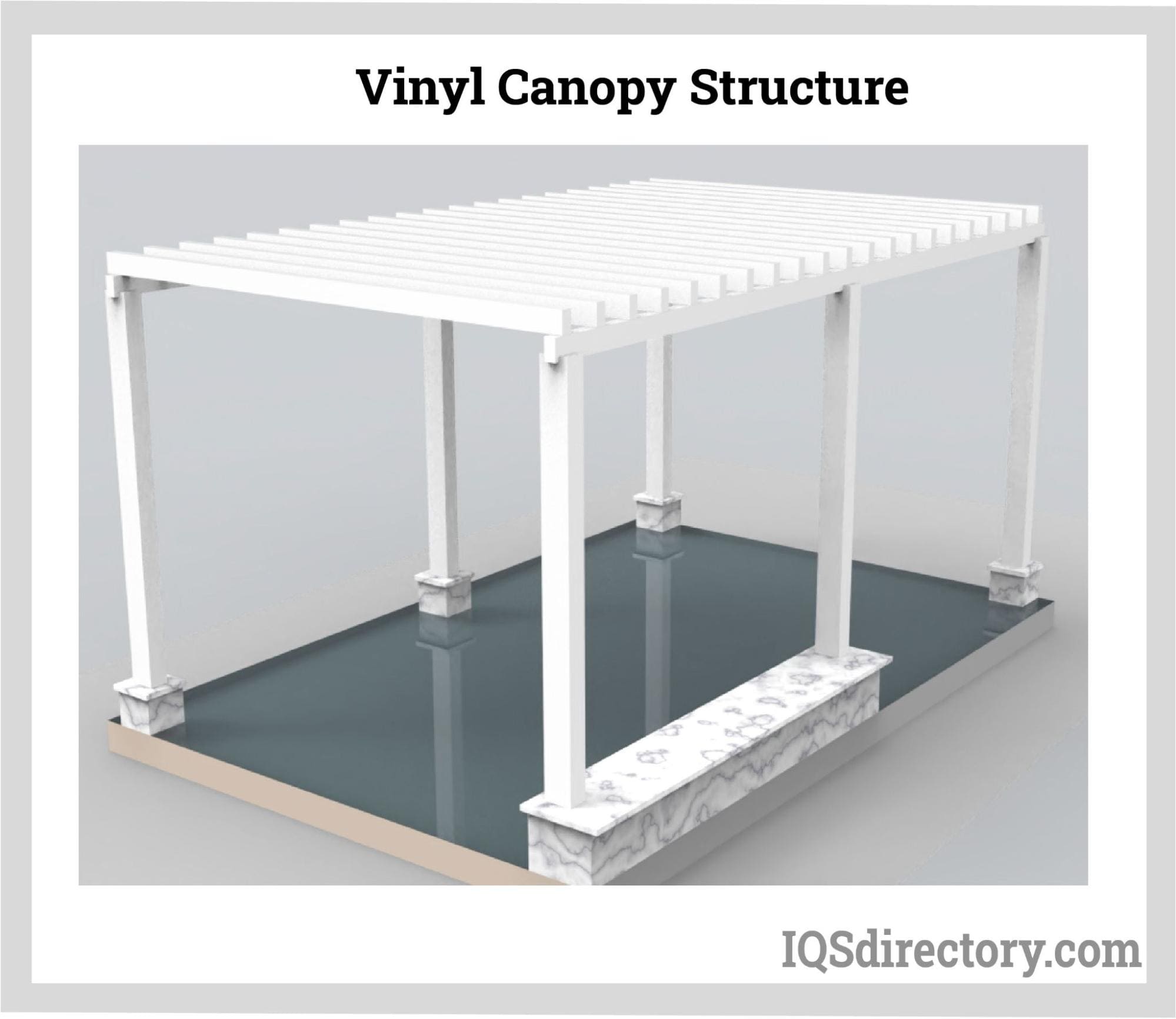

Illustrative image related to canopy materials

Pros: Vinyl’s waterproof nature makes it an excellent choice for canopies in rainy climates. It is also easy to clean and maintain, which is appealing for commercial applications.

Cons: On the downside, vinyl can be more expensive than polyester and may require more complex manufacturing processes. Additionally, it can be less breathable, leading to condensation issues.

Impact on Application: Vinyl is ideal for applications requiring high durability and waterproofing, such as outdoor events, food markets, and industrial uses.

Illustrative image related to canopy materials

Considerations for International Buyers: Compliance with local standards for fire resistance and environmental impact is crucial, especially in regions with strict regulations like Germany.

Why Choose Canvas for Canopy Materials?

Canvas is a traditional fabric made from cotton or a cotton-polyester blend, known for its strength and breathability. It is capable of handling temperatures up to 200°F (93°C) and offers good resistance to wear and tear.

Pros: Canvas is highly durable and provides excellent protection against the elements, making it suitable for long-term installations. It can also be treated for water resistance and UV protection.

Cons: However, canvas tends to be heavier and may require more structural support. It can also be more expensive than synthetic options like polyester.

Impact on Application: Canvas is often used in applications such as permanent outdoor structures, tents, and awnings, where durability is paramount.

Considerations for International Buyers: Buyers should check for compliance with local fire safety standards and ensure that the canvas is treated for mold and mildew resistance, especially in humid climates.

What Makes Acrylic a Preferred Choice for Canopies?

Acrylic is a synthetic material known for its vibrant colors and UV resistance. It can withstand temperatures from -40°F to 180°F (-40°C to 82°C) and is often used in combination with other materials for enhanced performance.

Pros: Acrylic is lightweight and offers excellent color retention, making it visually appealing for canopies. Its UV resistance helps prevent fading and degradation.

Cons: However, acrylic can be more expensive and may not be as durable under extreme weather conditions compared to vinyl or canvas.

Illustrative image related to canopy materials

Impact on Application: Acrylic is commonly used in decorative canopies and awnings where aesthetics are essential, such as in commercial settings.

Considerations for International Buyers: It’s important for buyers to ensure that acrylic products meet local environmental regulations, especially regarding recyclability and sustainability.

Summary Table of Canopy Materials

| Material | Typical Use Case for canopy materials | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Temporary outdoor events | Cost-effective and lightweight | Less durable in extreme weather | Low |

| Vinyl | Industrial and commercial canopies | Excellent waterproofing | More expensive and less breathable | High |

| Canvas | Permanent outdoor structures | Highly durable and breathable | Heavier and requires more support | Medium |

| Acrylic | Decorative canopies and awnings | Vibrant colors and UV resistance | More expensive and less durable | High |

This guide provides a comprehensive overview of the key materials used in canopy construction, helping international B2B buyers make informed decisions tailored to their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for canopy materials

What Are the Main Stages in the Manufacturing Process of Canopy Materials?

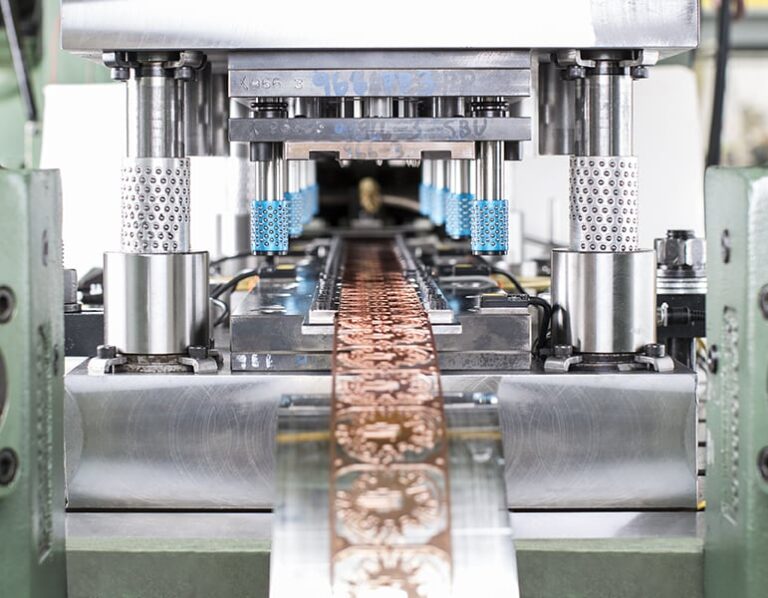

The manufacturing process for canopy materials typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets the required specifications for durability, functionality, and aesthetics.

-

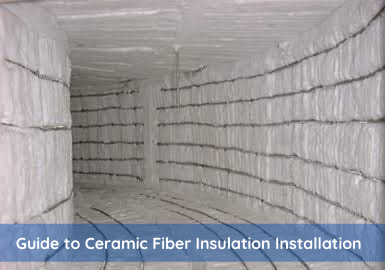

Material Preparation: The first step involves selecting the right fabrics and materials, which can range from polyester and nylon to specialized fabrics like Sunbrella. The chosen materials are then cut to specified dimensions, ensuring minimal waste. Depending on the intended application, additional treatments such as waterproofing, UV resistance, and fire retardancy may be applied at this stage.

-

Forming: This stage involves shaping the fabric into the desired form. Techniques such as heat sealing, welding, or sewing are employed to create seams and joints. The choice of technique often depends on the fabric type and the final use of the canopy. For example, welded seams are commonly used for high-performance canopies to ensure maximum waterproofing and durability.

-

Assembly: Once the fabric components are formed, they are assembled with additional structural elements. This may include the integration of frames, supports, or anchors, which are essential for stability and durability. The assembly process often requires skilled labor to ensure that all components fit together precisely and can withstand environmental stresses.

-

Finishing: The final stage involves quality checks and finishing touches. This may include adding grommets for easy installation, applying coatings for additional protection, or even decorative elements for aesthetic appeal. Proper finishing ensures that the canopy is not only functional but also visually appealing.

How Is Quality Assurance Implemented in Canopy Material Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final products meet international standards and customer expectations. In the canopy materials industry, several relevant standards and practices guide quality assurance.

Illustrative image related to canopy materials

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines a framework for quality management systems. Compliance with this standard indicates that a manufacturer has established processes to ensure consistent quality in their products. Additionally, other industry-specific certifications, such as CE marking for European markets and API standards for specific applications, may also apply.

-

Quality Control Checkpoints: Quality control is typically implemented at multiple stages throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During manufacturing, various checkpoints are established to monitor the production process, ensuring that any deviations from quality standards are promptly addressed.

– Final Quality Control (FQC): Once the canopies are completed, a thorough inspection is conducted to verify that the final product meets all specifications, including durability, appearance, and functionality. -

Common Testing Methods: Various testing methods are employed to validate the performance of canopy materials. These include tensile strength tests, UV resistance tests, waterproofing tests, and fire retardancy assessments. These tests ensure that the materials can withstand environmental conditions specific to their intended use, especially in regions with extreme weather.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, verifying the quality control processes of potential suppliers is crucial for ensuring product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. An on-site visit allows buyers to observe the production environment, check compliance with international standards, and evaluate the use of quality control checkpoints.

-

Requesting Quality Reports: Buyers should request quality assurance documentation from suppliers, including test reports and certificates of compliance. These documents should detail the results of testing conducted on the canopy materials, confirming their durability and performance characteristics.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can conduct thorough inspections and testing, offering buyers confidence in the quality of the materials before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control and standards compliance, particularly when sourcing from different regions.

-

Regional Standards Variability: Different regions may have varying standards for quality and safety. For instance, European buyers may prioritize CE marking, while buyers in the Middle East might focus on local certifications. Understanding these differences is essential for compliance and market acceptance.

-

Cultural and Operational Differences: The approach to quality control can vary significantly across cultures and regions. Buyers should be aware of these differences and consider establishing clear communication channels with suppliers to ensure that quality expectations are understood and met.

-

Logistics and Shipping Considerations: Quality control does not end with manufacturing. Buyers should also consider the logistics of shipping and storage, which can impact the quality of canopy materials. Proper handling and storage conditions during transit are crucial for maintaining the integrity of the materials.

In conclusion, understanding the manufacturing processes and quality assurance protocols for canopy materials is essential for B2B buyers seeking reliable suppliers. By focusing on key manufacturing stages, quality control measures, and verification methods, buyers can make informed decisions that align with their operational needs and market requirements.

Illustrative image related to canopy materials

Practical Sourcing Guide: A Step-by-Step Checklist for ‘canopy materials’

The procurement of canopy materials requires careful consideration to ensure that you source high-quality products that meet your specific needs. This guide provides a structured checklist for B2B buyers looking to procure canopy materials effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your canopy materials. Consider factors such as size, weight, fabric type (e.g., waterproof, UV resistant), and color. This step is crucial as it sets the baseline for your procurement needs, ensuring that suppliers understand what you are looking for.

Step 2: Identify Suitable Suppliers

Research potential suppliers that specialize in canopy materials. Look for companies with a solid reputation and a proven track record in the industry. Utilize trade directories, industry exhibitions, and online marketplaces to compile a list of candidates. This step is essential to ensure you have a diverse pool of suppliers to evaluate.

Step 3: Evaluate Supplier Credentials

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, certifications, and references from buyers in similar industries or regions. Verify their experience with the specific type of canopy materials you need, as this can significantly impact the quality of the products you receive.

Step 4: Request Samples

Always ask for samples of the canopy materials you are considering. This allows you to assess the quality, durability, and appearance of the fabric firsthand. Pay attention to features such as water resistance, UV protection, and ease of maintenance. Evaluating samples is vital to ensure that the materials will perform as expected in your specific applications.

Step 5: Review Pricing and Terms

Once you have narrowed down your suppliers, request detailed pricing and terms of service. Compare not only the costs but also the payment terms, delivery schedules, and return policies. Understanding the financial aspects and conditions of each supplier will help you make a well-informed decision and avoid unexpected expenses later.

Step 6: Confirm Production Capabilities

Assess the production capabilities of your shortlisted suppliers to ensure they can meet your volume requirements within your desired timeframe. Inquire about their manufacturing processes, lead times, and capacity for customization. This step is critical for aligning supplier capabilities with your business needs, particularly if you have large or specialized orders.

Step 7: Establish Communication Channels

Effective communication is key to a successful procurement process. Establish clear channels for dialogue with your chosen supplier, including points of contact for different issues (e.g., order tracking, quality concerns). Having open lines of communication helps to address any issues promptly and fosters a better working relationship.

Illustrative image related to canopy materials

By following this checklist, B2B buyers can streamline their sourcing process for canopy materials, ensuring they find reliable suppliers and high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for canopy materials Sourcing

What Are the Key Cost Components in Canopy Materials Sourcing?

When sourcing canopy materials, understanding the cost structure is essential for effective budgeting and decision-making. The major cost components include:

-

Materials: The choice of fabric significantly influences cost. Options like polyester, acrylic, and PVC vary in price based on durability, UV resistance, and water repellency. Fabrics treated for fire retardancy or mildew resistance may incur additional costs.

-

Labor: Labor costs encompass the workforce involved in the manufacturing process. This includes cutting, sewing, and finishing the materials. Regions with higher labor costs, such as parts of Europe, may see increased pricing.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory management. Efficient manufacturing processes can help mitigate these costs, thereby impacting the final price.

-

Tooling: Initial costs for molds and cutting dies can be significant, especially for customized or specialized designs. These costs are often spread over larger production runs, making it crucial to consider minimum order quantities.

-

Quality Control (QC): Ensuring that materials meet specified standards requires investment in quality assurance processes. This can involve testing for durability and safety, which adds to the overall cost.

-

Logistics: Shipping and handling costs can vary significantly based on the distance and mode of transport. For international buyers, understanding Incoterms is vital for clarifying responsibilities for shipping and insurance.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Impact Canopy Material Costs?

Several factors can influence the pricing of canopy materials:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize their purchasing strategy.

-

Specifications and Customization: Custom fabrics or specific color patterns can significantly raise costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Premium materials with certifications for UV resistance or environmental standards typically come at a higher price. However, investing in quality can yield long-term savings through durability and reduced replacement costs.

-

Supplier Factors: The reliability and reputation of suppliers can also affect pricing. Established suppliers may charge more for their assurance of quality and service.

-

Incoterms: Understanding the terms of shipment, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), can clarify total costs and responsibilities between buyer and seller.

What Negotiation Tips Should International B2B Buyers Consider?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, negotiating effectively can result in significant savings:

-

Explore Multiple Suppliers: Compare offers from various suppliers to understand the market rate and leverage this information during negotiations.

-

Clarify Total Cost of Ownership: Look beyond the initial price tag. Consider factors like shipping, customs duties, and potential maintenance costs when evaluating offers.

-

Build Long-term Relationships: Establishing a rapport with suppliers can lead to more favorable terms and discounts on future orders.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions. Familiarize yourself with these differences to better navigate negotiations.

What Should Buyers Know About Indicative Prices?

It’s important to approach pricing with the understanding that costs can fluctuate based on market conditions, seasonal demand, and changes in raw material prices. Indicative prices can serve as a guideline, but buyers should expect variations based on their specific requirements and supplier negotiations. Always request detailed quotes that outline all potential costs to ensure transparency and informed decision-making.

Alternatives Analysis: Comparing canopy materials With Other Solutions

Exploring Alternative Solutions to Canopy Materials

In the quest for effective outdoor coverage and shelter solutions, B2B buyers may encounter various alternatives to traditional canopy materials. Understanding the strengths and weaknesses of these options can assist in making informed purchasing decisions. This analysis compares canopy materials against two viable alternatives: awnings and pergolas.

| Comparison Aspect | Canopy Materials | Awnings | Pergolas |

|---|---|---|---|

| Performance | Excellent UV and weather resistance; customizable | Good UV protection; limited rain resistance | Provides shade but minimal weather protection |

| Cost | Generally affordable; varies by fabric type | Mid-range; installation can increase costs | Higher initial investment; more permanent |

| Ease of Implementation | Simple setup; portable options available | Requires professional installation for best results | Complex installation; typically requires a contractor |

| Maintenance | Low maintenance; easy to clean | Moderate; may need fabric replacement | Low; mainly structural upkeep |

| Best Use Case | Temporary or semi-permanent events | Fixed shade for windows and patios | Aesthetic appeal and partial shade in gardens |

What Are the Pros and Cons of Awnings?

Awnings are a popular alternative to canopy materials, particularly for businesses looking to enhance outdoor spaces. They offer good UV protection and can be installed above windows or patios, creating an inviting atmosphere. However, awnings may struggle with heavy rainfall, leading to potential pooling and damage. The cost can also escalate due to installation requirements, especially for motorized models. Despite these drawbacks, awnings can be a stylish and functional addition for long-term shade.

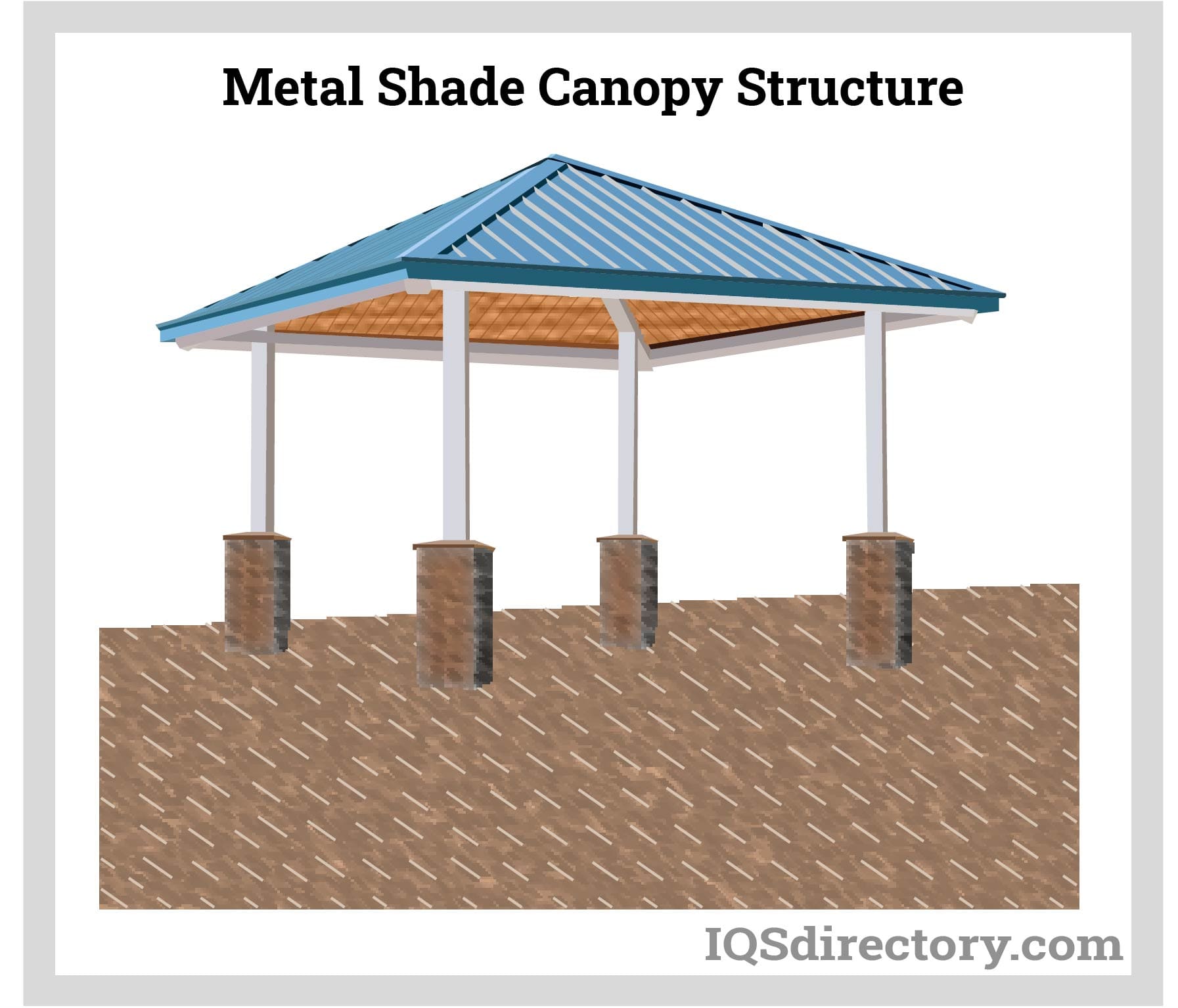

How Do Pergolas Compare in Terms of Functionality?

Pergolas provide an aesthetically pleasing structure that can enhance the landscape of any outdoor area. While they are excellent for creating a shaded environment, they offer minimal protection against rain and wind. The initial investment in a pergola can be higher than other options, as they often require professional installation. However, their durability and the ability to attach climbing plants can add significant visual value and charm to gardens or commercial spaces. For businesses aiming to create a unique outdoor ambiance, pergolas can be an ideal solution.

Illustrative image related to canopy materials

How to Choose the Right Solution for Your Needs?

When selecting the right outdoor coverage solution, B2B buyers should evaluate their specific needs, including the intended use, budget constraints, and desired aesthetics. Canopy materials are versatile and cost-effective for temporary or event-based setups. Awnings are suitable for businesses seeking to enhance customer experience with fixed shade options, while pergolas are ideal for those looking to invest in a permanent, decorative structure. By weighing the pros and cons of each alternative, buyers can make strategic decisions that align with their operational goals and enhance their outdoor environments.

Essential Technical Properties and Trade Terminology for canopy materials

What Are the Key Technical Properties of Canopy Materials?

When selecting canopy materials, understanding the technical properties is crucial for ensuring durability, functionality, and compliance with industry standards. Here are some essential specifications to consider:

-

Material Grade

The material grade indicates the quality and durability of the fabric used in canopies. Common materials include polyester, nylon, and acrylic, each with varying degrees of strength and resistance to environmental factors. For B2B buyers, selecting the appropriate material grade affects the longevity and performance of the canopy, impacting overall customer satisfaction and reducing replacement costs. -

Water Resistance

Canopy fabrics often undergo treatments to enhance water resistance, which is vital for preventing leaks and maintaining structural integrity during rain. Fabrics can be rated based on their water column measurement (in mm), indicating how much water pressure they can withstand before leaking. This property is essential for businesses operating in regions with unpredictable weather, ensuring that their investment remains functional in adverse conditions. -

UV Resistance

UV resistance is a critical property for outdoor canopies, as prolonged exposure to sunlight can degrade the fabric, leading to fading and weakening. Fabrics treated with UV inhibitors can extend the lifespan of the canopy, making this a key specification for buyers focused on long-term use. Understanding UV ratings allows businesses to choose materials that can withstand their local climate, reducing the frequency of replacements. -

Flame Retardancy

Flame retardant canopies are essential in commercial settings where safety regulations are stringent, such as events or outdoor dining. Fabrics can be treated to meet specific fire safety standards, which is crucial for compliance and risk management. B2B buyers must assess the safety needs of their applications to ensure they are selecting appropriate materials that adhere to local regulations. -

Tear Strength

Tear strength measures the fabric’s resistance to being pulled apart, which is particularly important for canopies subjected to high winds or heavy use. This property is typically measured in Newtons (N) and indicates how much force the material can withstand before tearing. For businesses, investing in materials with high tear strength can minimize maintenance costs and extend the lifespan of their canopies.

What Are Common Trade Terms in the Canopy Materials Industry?

Understanding trade terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms frequently used in the canopy materials industry:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of canopy materials, an OEM can supply customized fabrics or components tailored to specific business needs. B2B buyers benefit from OEM partnerships by obtaining high-quality, specialized products that enhance their offerings. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of product that a supplier is willing to sell. It is a critical consideration for B2B buyers, as it affects inventory management and initial investment costs. Understanding MOQ can help businesses plan their purchasing strategies and negotiate better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products. This process is essential for comparing offers and making informed purchasing decisions. B2B buyers should articulate their requirements clearly in RFQs to ensure they receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers involved in global sourcing, as they define who bears costs and risks at various points in the shipping process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This term is significant for B2B buyers who need to manage their supply chains effectively. Understanding lead times can help businesses plan their production schedules and maintain adequate inventory levels.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and improve their operational efficiency in the canopy materials market.

Illustrative image related to canopy materials

Navigating Market Dynamics and Sourcing Trends in the canopy materials Sector

What Are the Key Trends Driving the Canopy Materials Market?

The global canopy materials market is witnessing significant growth driven by several key factors. One of the primary drivers is the increasing demand for outdoor recreational spaces, particularly in regions such as Africa, South America, and the Middle East. This trend is complemented by the rising popularity of events like festivals, fairs, and exhibitions, which require temporary structures such as tents and canopies. Furthermore, the growing construction and real estate sectors in developing regions are fueling the need for durable and versatile canopy materials.

Technological advancements are also reshaping sourcing strategies in the industry. Innovative materials, such as UV-resistant fabrics and flame-retardant textiles, are becoming standard offerings. Moreover, the rise of e-commerce platforms is simplifying the procurement process for international buyers, allowing them to source materials directly from manufacturers with ease. This shift is particularly notable in Europe, where buyers are increasingly leveraging digital tools to streamline their supply chains.

How Important Is Sustainability and Ethical Sourcing in the Canopy Materials Sector?

Sustainability has emerged as a critical consideration for B2B buyers in the canopy materials sector. The environmental impact of sourcing practices is under scrutiny, prompting companies to adopt more sustainable approaches. This includes using recycled materials, eco-friendly production processes, and reducing waste throughout the supply chain.

Illustrative image related to canopy materials

Ethical sourcing is equally important, as consumers and businesses alike demand transparency in their supply chains. Buyers are increasingly seeking suppliers who can demonstrate responsible practices, such as fair labor conditions and environmentally conscious manufacturing. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are gaining traction, providing assurance that materials are produced sustainably. For international buyers, particularly those in Europe and North America, aligning with suppliers who prioritize sustainability not only meets regulatory requirements but also enhances brand reputation in a competitive marketplace.

How Has the Canopy Materials Market Evolved Over Time?

The canopy materials market has evolved significantly from its origins in basic fabric coverings to a diverse array of high-performance materials. Initially, canopies were primarily made from natural fibers like cotton and linen. However, the introduction of synthetic materials such as polyester and nylon has transformed the market, offering greater durability, water resistance, and UV protection.

In recent years, innovations in textile technology have further expanded the functionality of canopy materials. Today’s fabrics can be engineered to be flame-retardant, mold-resistant, and lightweight, catering to the specific needs of various industries, from hospitality to construction. This evolution reflects a broader trend towards customization and specialization in B2B sourcing, enabling buyers to select materials that best fit their operational requirements.

Overall, the canopy materials market is positioned for continued growth, driven by evolving consumer preferences and technological advancements that enhance product offerings. B2B buyers looking to capitalize on these trends must remain informed and adaptable to effectively navigate this dynamic landscape.

Illustrative image related to canopy materials

Frequently Asked Questions (FAQs) for B2B Buyers of canopy materials

-

How do I choose the right canopy material for my needs?

When selecting canopy materials, consider factors such as the intended use (e.g., outdoor events, permanent structures), local climate conditions, and specific requirements like UV resistance or waterproofing. For temporary applications, lightweight and easily transportable fabrics may suffice, while permanent installations should use durable, weather-resistant materials. Additionally, assess the material’s fire retardant properties, especially for public events. Consulting with suppliers about their recommendations based on your specific needs can lead to more informed choices. -

What are the benefits of using waterproof canopy fabrics?

Waterproof canopy fabrics provide essential protection from rain and moisture, ensuring that events or outdoor structures remain functional and comfortable. These materials are treated to repel water, preventing leaks and water damage. Additionally, waterproof fabrics often possess mold and mildew resistance, extending the lifespan of the canopy. This is particularly beneficial in humid regions, where moisture accumulation can be a significant concern. By investing in waterproof options, businesses can enhance customer satisfaction and reduce maintenance costs. -

What is the minimum order quantity (MOQ) for canopy materials?

Minimum order quantities for canopy materials can vary significantly among suppliers. Typically, MOQs may range from as low as 50 yards to several hundred yards, depending on the type of fabric and the supplier’s production capabilities. It’s important to communicate your specific needs with potential suppliers to understand their policies. Smaller businesses may benefit from sourcing from wholesalers who offer lower MOQs or exploring options for bulk purchasing with shared shipping to meet minimum requirements. -

How can I ensure the quality of canopy materials when sourcing internationally?

To ensure quality when sourcing canopy materials internationally, conduct thorough supplier vetting. Request samples to evaluate fabric quality, durability, and compliance with industry standards. Additionally, consider suppliers with established reputations and positive reviews. Utilizing third-party inspection services can provide an additional layer of quality assurance before shipment. Maintaining clear communication about your specifications and expectations will also help mitigate risks associated with international sourcing. -

What customization options are available for canopy materials?

Many suppliers offer extensive customization options for canopy materials, including color, pattern, and size. Businesses can also request specific treatments, such as UV protection or flame retardancy. Custom branding, such as printed logos or designs, is often available for promotional uses. When inquiring about customization, provide detailed specifications to ensure that the supplier can meet your requirements, and confirm lead times for production to avoid delays in your projects. -

What payment terms should I expect when sourcing canopy materials?

Payment terms for canopy materials can vary widely depending on the supplier and the order size. Typically, suppliers may request a deposit of 30% to 50% upfront, with the balance due before shipping or upon delivery. It’s advisable to discuss payment options such as letters of credit or escrow services for larger transactions to protect both parties. Ensure that you fully understand the terms before committing to a purchase to avoid any misunderstandings later. -

How do logistics and shipping impact my canopy material sourcing?

Logistics and shipping play a crucial role in the timely delivery of canopy materials. Factors such as shipping distance, mode of transport (air vs. sea), and local customs regulations can affect lead times and costs. It is advisable to work closely with suppliers who have experience in international shipping to navigate these complexities. Additionally, consider potential delays related to customs clearance and factor these into your project timelines to ensure smooth operations. -

What certifications should I look for in canopy materials?

When sourcing canopy materials, look for certifications that indicate quality and safety, such as ISO certifications, fire safety ratings, and compliance with environmental standards. Certifications can provide assurance that the materials meet industry regulations and performance standards. Additionally, inquire if the fabrics are tested for UV resistance, mold resistance, and durability under various conditions. Prioritizing certified materials can enhance your product offerings and ensure compliance with local regulations in your target markets.

Top 10 Canopy Materials Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Canopy Fabric Solutions

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Canopy Fabric Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Sunbrella – Outdoor Shade Solutions

Domain: sunbrella.com

Registered: 1995 (30 years)

Introduction: Awnings, Canopies, and Pergolas featuring Sunbrella fabrics are designed for outdoor living, offering innovative shade solutions. The fabrics are UV protective, fade resistant, and durable, ensuring long-lasting color and performance. The collection includes a wide range of colors and styles, suitable for creating comfortable outdoor retreats. Sunbrella fabrics are recommended by The Skin Cancer F…

3. Decorative Fabrics Direct – Awning & Canopy Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Awning Fabric | Canopy Fabric, Free Shipping Coupon Code: SHIPFREE for Most $199 Orders, Distributor wholesale prices, Variety of colors for retractable and fixed awnings, Top brands including Sunbrella, Mold resistant, Water repellent, UV protection, Suitable for windows, businesses, RVs, campers, homes, Replacement fabric or new installations, Special Order Only (5 Yard Minimum Order), Price ran…

4. Shelter Structures – Key Product Details for Pop-up Canopy Fabrics

Domain: shelter-structures.com

Registered: 2009 (16 years)

Introduction: Key Product Details for Pop-up Canopy Fabrics: 1. PVC Coated Polyester: Water Resistance: 1000-1500mm, UV Stability: Medium, Breathability: Good, Durability: 2-4 years, Weight: Light, Notable Features: Affordable, good rainfall performance. 2. Polyester: Water Resistance: Low, UV Stability: Low, Breathability: Very Good, Durability: 2-3 years, Weight: Very Light, Notable Features: Inexpensive, eas…

5. Duralux Canopies – Aluminum Canopy Solutions

Domain: duraluxcanopies.com

Registered: 2018 (7 years)

Introduction: Canopy Materials: Aluminum, Treated Wood, Glass.

Aluminum:

– Sleek, modern appearance

– Cost-effective and lightweight

– Extremely durable, lasts decades

– Corrosion-resistant

– Can be used alone or with other materials

– Potential noise during inclement weather

– May not fit classic aesthetics

– Custom louvered options available.

Wood:

– Eco-friendly and durable

– Cost-effective

– …

6. EZUP – Custom Printed Canopies

Domain: ezup.com

Registered: 1995 (30 years)

Introduction: Professional Grade Fabric, Custom Printed & Sewn in the USA, Canopy Sizes: 10′ x 10′, 10′ x 20′, 13′ x 13′, 5′ x 5′, 8′ x 12′, Frame Material: Various models including Endeavor™, Eclipse®, Express™, Warranty: 14 items available, Starting Prices: Custom Endeavor® 10′ x 10′ Canopy at $928.20, Endeavor® 13’ x 13’ Canopy at $2,043.00, Speed Shelter® 8′ x 12′ Canopy at $695.00, Endeavor® Vinyl 10′ x 10…

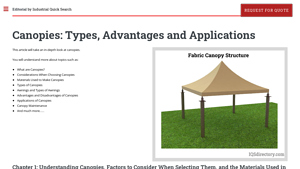

7. IQS Directory – Canopy Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Canopies are protective structures made from fabric or metal, designed to shield against weather conditions like sunlight, rain, hail, and snow. They can be open-sided or fully enclosed, providing varying degrees of privacy and comfort in outdoor spaces. Key considerations for selecting canopies include their purpose (sunshade or structural emphasis), design integration with existing architecture,…

8. MVP Visuals – Canopy Fabric Essentials

Domain: mvpvisuals.com

Registered: 2005 (20 years)

Introduction: Canopy fabric is used to create shelter for shade, rain protection, and brand visibility. Key types of canopy fabric include: 1. Polyester (150D–600D): Most common and versatile; durable, easy to handle, treated for water and UV resistance. 600D polyester is recommended for its balance of strength, weight, and print quality. Best for pop-up tents, event canopies, and branded displays. 2. PVC-Coate…

9. Mitchell Metals – Aluminum Canopies and Walkway Covers

Domain: mitchellmetals.net

Registered: 2005 (20 years)

Introduction: Mitchell Metals offers a variety of aluminum canopies and walkway covers, including: 1. Covered Walkway: – Walkway canopy with beams – Walkway canopy without beams – Architectural canopy – Wall-attached canopy 2. Bus/Parent Drop-Off Canopy: – Bus-Parent drop-off canopy – Bus-Parent drop-off canopy with lineal beams – Bus-Parent drop-off canopy with decking long ways 3. Cantilevered Canopy: – Canti…

10. MakerPipe – Shade Materials Guide

Domain: makerpipe.com

Registered: 2012 (13 years)

Introduction: Types of Shade Materials: 1. Shade Cloth: Lightweight, durable, varying sun protection, easy to install. 2. Canvas: Robust, durable, excellent sun protection, heavier, may require more support. 3. Polyethylene: Durable, UV resistant, affordable, not breathable. 4. Polyester: High durability, water resistant, ideal for rainy climates, may lack UV protection. 5. Sun Shade Sails: Tensioned shades, va…

Strategic Sourcing Conclusion and Outlook for canopy materials

What Are the Key Insights for Strategic Sourcing of Canopy Materials?

As we conclude this guide on canopy materials, it is essential to emphasize the importance of strategic sourcing in optimizing your procurement process. By focusing on durable, versatile fabrics that offer UV resistance, waterproofing, and fire retardancy, international B2B buyers can ensure that their canopy solutions are not only functional but also safe and long-lasting. Understanding the diverse options available—from canvas to synthetic blends—allows for tailored solutions that meet specific regional and application needs.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in quality canopy materials not only enhances the aesthetic appeal of outdoor spaces but also improves operational efficiency and customer satisfaction. As markets in Africa, South America, the Middle East, and Europe continue to evolve, sourcing from reliable suppliers who prioritize sustainability and innovation will be crucial. This proactive approach positions businesses to respond effectively to changing consumer demands and environmental regulations.

What Are the Next Steps for B2B Buyers?

We encourage international buyers to engage with suppliers who offer comprehensive support, including product customization and bulk purchasing options. Now is the time to leverage strategic sourcing to foster partnerships that drive growth and sustainability in your operations. Explore the potential of canopy materials today and secure your competitive advantage for tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.