How to Source Push-Push Button Switch Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for push-push button switch

In the fast-evolving landscape of industrial automation and electrical components, sourcing the right push-push button switch can be a daunting task for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With a myriad of options available, each boasting unique functionalities and specifications, making an informed decision is critical to optimizing operational efficiency and ensuring product reliability. This comprehensive guide addresses the complexities of navigating the global market for push-push button switches, offering insights into various types, applications, and essential considerations for supplier vetting.

From understanding the nuances of SPST and DPST configurations to exploring the latest advancements in illuminated and sealed designs, this guide equips international B2B buyers with the knowledge needed to assess their options effectively. Additionally, we delve into critical factors such as pricing, quality standards, and the importance of aligning supplier capabilities with specific project requirements. By providing actionable insights and expert recommendations, this guide empowers buyers to make confident purchasing decisions, ultimately enhancing their operational workflows and product offerings. Whether you’re sourcing for a high-tech manufacturing facility or a specialized electrical project, our resource serves as a vital tool in your procurement arsenal, ensuring you secure the best solutions for your business needs.

Understanding push-push button switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Momentary Pushbutton Switch | Activates while pressed, returns to default state | Consumer electronics, industrial controls | Pros: Simple operation, compact design. Cons: Not suitable for applications needing a maintained state. |

| Latching Pushbutton Switch | Maintains state after being pressed | Machinery, lighting controls | Pros: Reliable for on/off applications. Cons: Can lead to accidental activation if not designed carefully. |

| Illuminated Pushbutton Switch | Features built-in LED for visibility | Control panels, public installations | Pros: Enhanced visibility in low-light environments. Cons: More complex circuitry can increase failure rates. |

| Sealed Pushbutton Switch | IP-rated for dust and moisture resistance | Outdoor equipment, automotive | Pros: Durable in harsh environments. Cons: Higher cost due to additional sealing. |

| Subminiature Pushbutton Switch | Compact size for space-constrained applications | Medical devices, portable electronics | Pros: Ideal for tight spaces. Cons: Limited current capacity may restrict applications. |

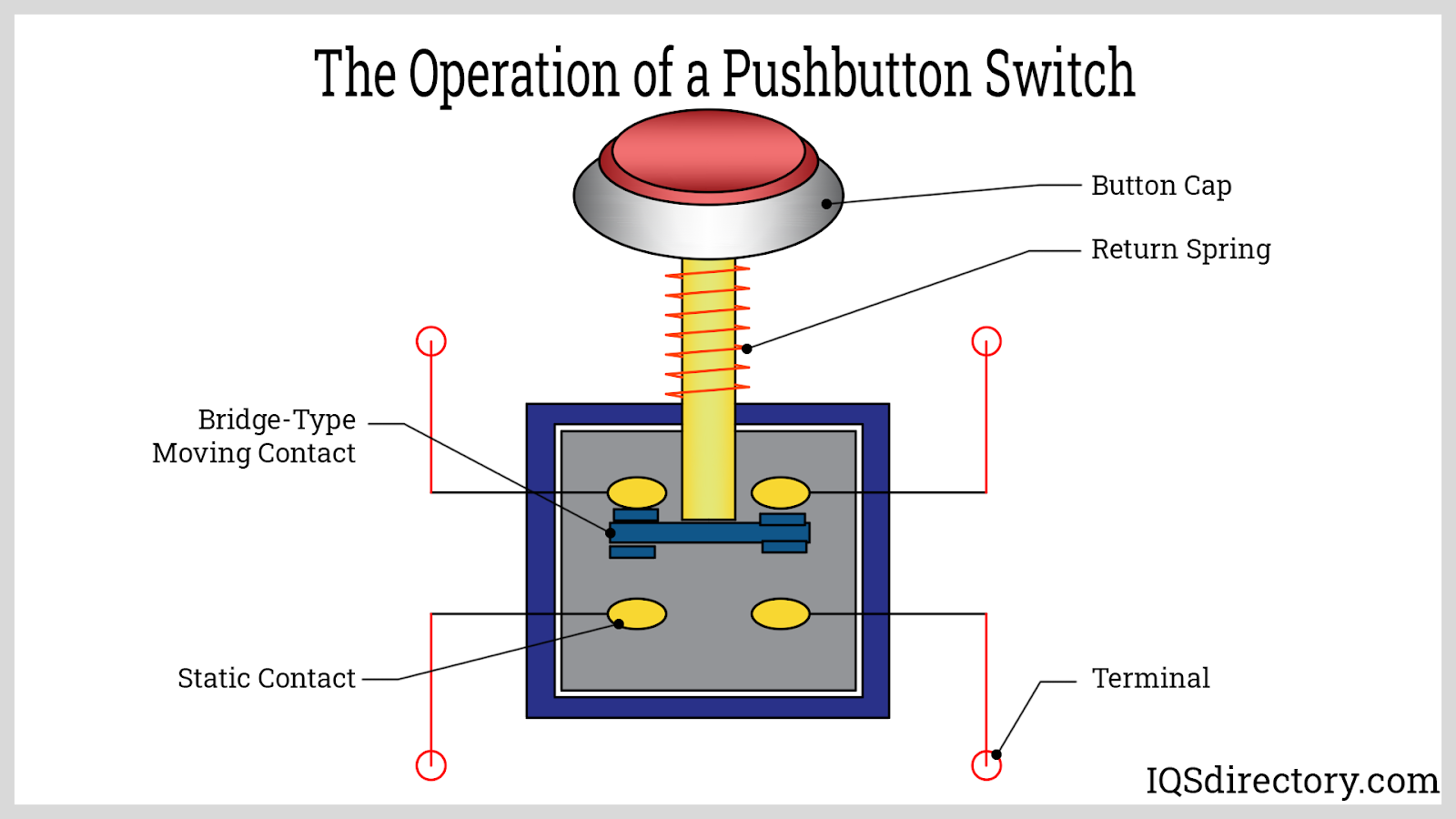

What Are the Key Characteristics of Momentary Pushbutton Switches?

Momentary pushbutton switches are designed to complete an electrical circuit only while being pressed. They automatically return to their default state once released, making them ideal for applications requiring temporary activation, such as in consumer electronics and industrial control panels. When purchasing, consider the switch’s size, actuation force, and electrical ratings to ensure compatibility with your specific application needs.

How Do Latching Pushbutton Switches Operate?

Latching pushbutton switches differ from momentary types by maintaining their state after being pressed. This feature makes them suitable for applications where a consistent on/off state is required, such as in machinery and lighting controls. Buyers should evaluate the switch’s mechanical design and potential for accidental activation, as well as its electrical specifications to ensure it meets operational requirements.

Why Choose Illuminated Pushbutton Switches?

Illuminated pushbutton switches come equipped with built-in LED lights, enhancing visibility in low-light conditions. This feature is crucial for control panels in public or industrial settings where operators need clear feedback on the switch status. When selecting illuminated switches, consider the type of illumination (e.g., color, brightness) and its impact on the circuit design, as more complex circuitry can lead to higher failure rates.

What Benefits Do Sealed Pushbutton Switches Offer?

Sealed pushbutton switches are designed with IP ratings to resist dust and moisture, making them ideal for outdoor equipment and automotive applications. Their robust construction ensures longevity in harsh environments, but this durability often comes at a higher price point. Buyers should assess the environmental conditions in which the switch will be used and balance the need for protection with budget constraints.

How Do Subminiature Pushbutton Switches Fit into Applications?

Subminiature pushbutton switches are compact, making them ideal for applications where space is limited, such as in medical devices and portable electronics. Despite their small size, they can be surprisingly versatile. However, buyers must be mindful of the limited current capacity, which may restrict their use in certain high-power applications. Evaluating the switch’s specifications against application requirements is essential for optimal performance.

Key Industrial Applications of push-push button switch

| Industry/Sector | Specific Application of push-push button switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Control panels for machinery operation | Enhances operational efficiency and safety | Durability, voltage ratings, and responsiveness |

| Automotive | Interior controls for vehicle functions | Improves user experience and operational reliability | Size, sealing options, and compliance with automotive standards |

| Telecommunications | Signal control in communication devices | Ensures reliable communication and quick response times | Compact design, low power consumption, and high reliability |

| Consumer Electronics | User interfaces for appliances and devices | Boosts user engagement and product usability | Aesthetic design options, tactile feedback, and longevity |

| Healthcare | Medical device controls | Increases patient safety and operational precision | Compliance with medical standards, easy cleaning, and reliability |

How Are Push-Push Button Switches Used in Manufacturing?

In the manufacturing sector, push-push button switches are integral to control panels that operate machinery. These switches allow operators to start or stop machines quickly, enhancing operational efficiency and safety. The ability to customize the switch’s voltage ratings and durability ensures they can withstand harsh industrial environments. International buyers, particularly from regions like Africa and South America, should prioritize sourcing switches that meet specific operational standards and have a proven track record of reliability.

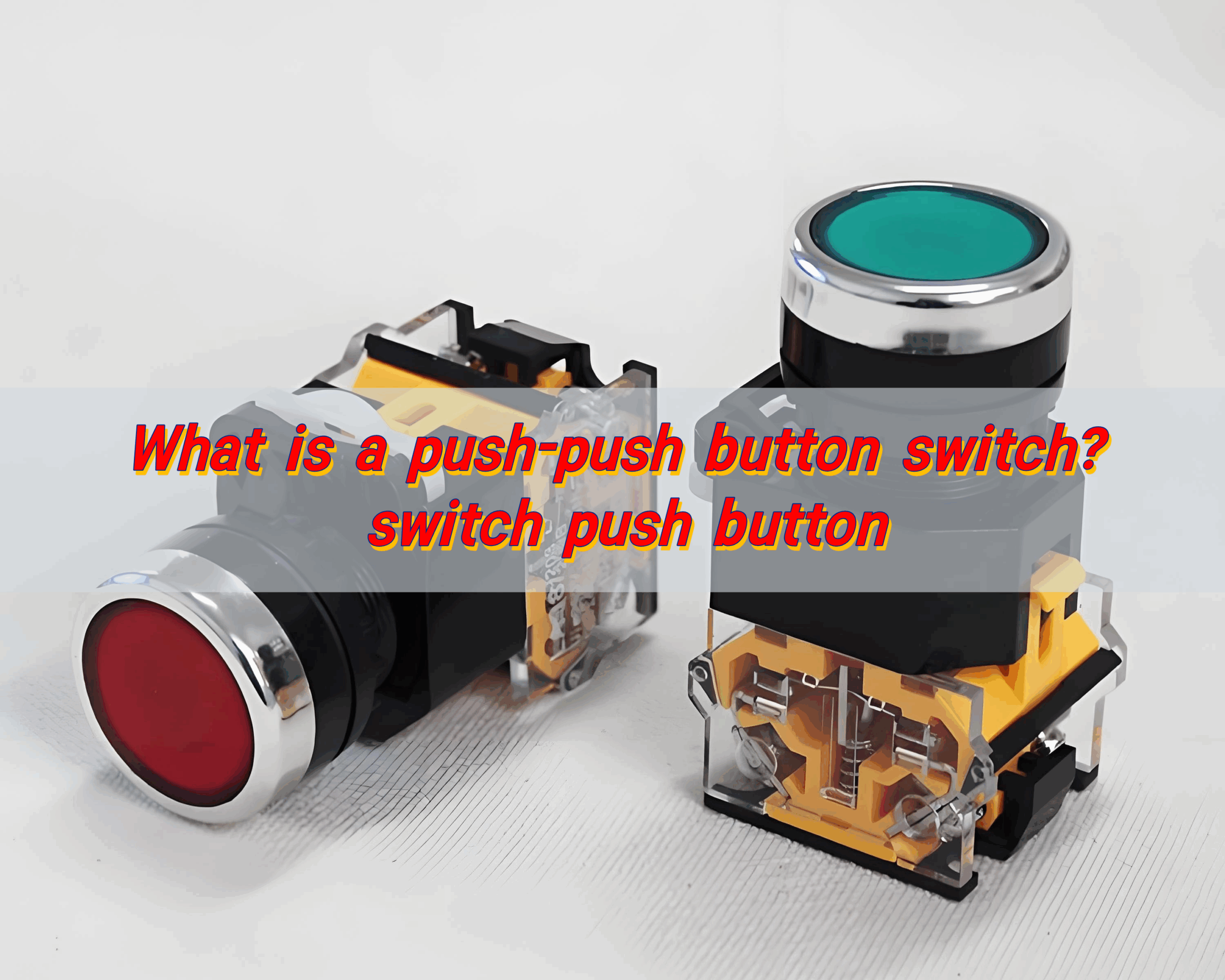

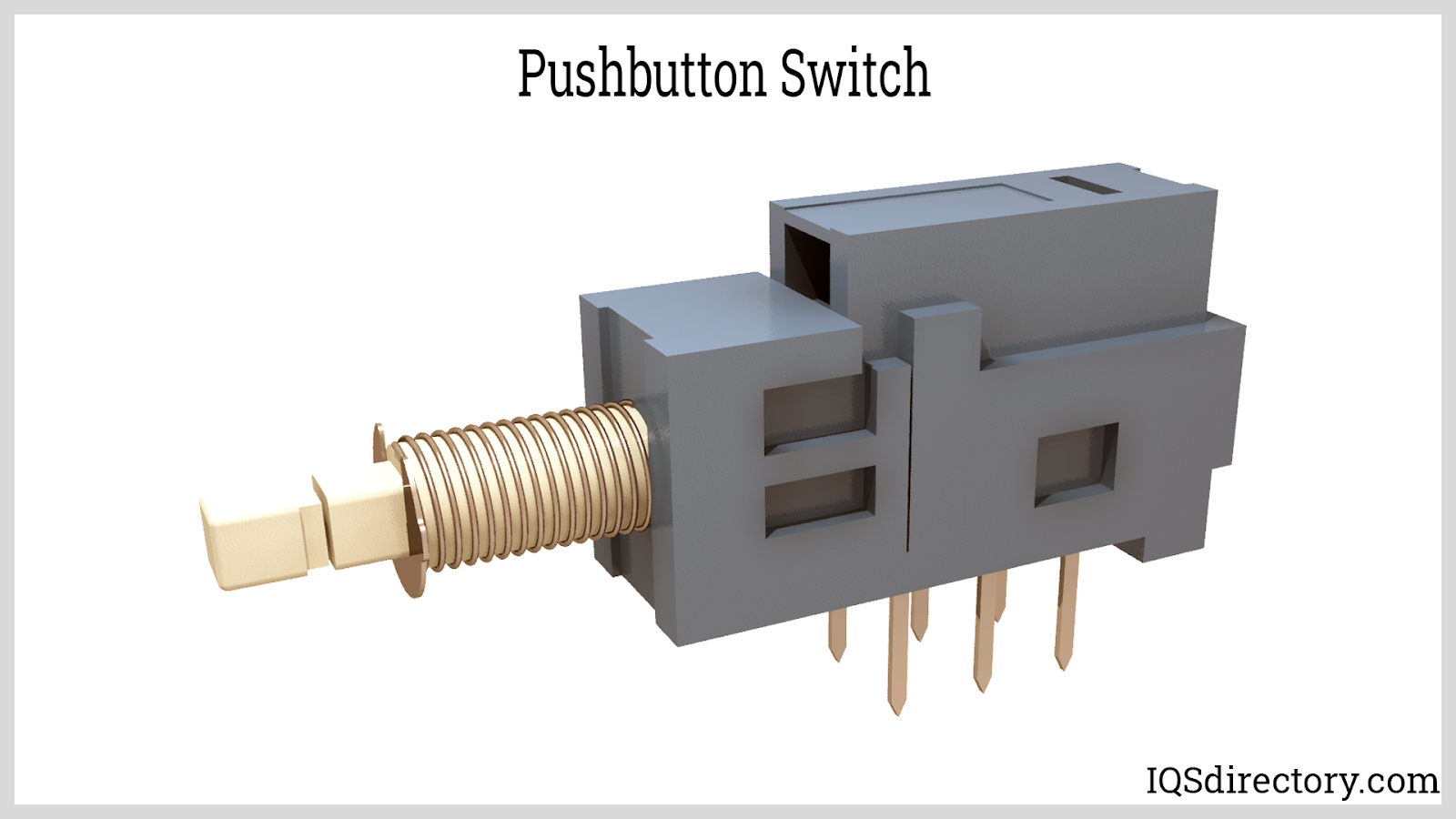

Illustrative image related to push-push button switch

What Role Do Push-Push Button Switches Play in the Automotive Industry?

In the automotive industry, push-push button switches are commonly used for interior controls, such as ignition systems, window operations, and infotainment systems. These switches improve user experience by providing a tactile interface that enhances operational reliability. For buyers in the Middle East and Europe, it is essential to consider the size and sealing options of these switches to ensure they meet stringent automotive standards and can withstand varying environmental conditions.

How Are Push-Push Button Switches Applied in Telecommunications?

Telecommunications rely heavily on push-push button switches for signal control in devices such as routers and communication panels. These switches help ensure reliable communication and quick response times, which are crucial for maintaining service quality. When sourcing for this sector, buyers should focus on compact designs and low power consumption to optimize space and efficiency in their products, especially in competitive markets like Brazil and Saudi Arabia.

What Benefits Do Push-Push Button Switches Offer in Consumer Electronics?

In consumer electronics, push-push button switches serve as user interfaces for a variety of appliances and devices, from kitchen gadgets to gaming consoles. These switches enhance user engagement and product usability by providing a simple and intuitive interface. Buyers from Europe and South America should consider the aesthetic design options and tactile feedback features, as these factors significantly influence consumer satisfaction and product appeal.

How Are Push-Push Button Switches Utilized in Healthcare Applications?

Healthcare applications utilize push-push button switches in medical devices, where precision and reliability are paramount. These switches can control critical functions, ensuring patient safety and operational precision. Buyers in the healthcare sector must prioritize compliance with medical standards, easy cleaning features, and long-term reliability to ensure the devices function correctly and safely in high-stakes environments.

3 Common User Pain Points for ‘push-push button switch’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Push-Push Button Switches

The Problem: B2B buyers often face challenges in sourcing push-push button switches that meet specific quality and performance standards. In regions like Africa and South America, where electrical components may not always adhere to international standards, ensuring product reliability is crucial. Buyers worry about the risk of receiving subpar products that can lead to equipment failures, safety hazards, and potential damage to their brand reputation. Moreover, the lack of clear specifications and certifications from suppliers can complicate the purchasing process, leaving buyers uncertain about the quality of the switches they are sourcing.

The Solution: To mitigate sourcing challenges, buyers should prioritize suppliers who provide comprehensive product documentation, including certifications such as ISO and UL standards. Engaging with reputable distributors who specialize in electronic components can ensure access to a range of high-quality push-push button switches. Furthermore, buyers can conduct due diligence by requesting samples for testing before making bulk purchases. It’s also advisable to participate in industry trade shows or online platforms that facilitate direct communication with manufacturers. Establishing strong relationships with suppliers can lead to better insight into product quality and reliability, ensuring that the switches sourced are capable of meeting operational demands.

Scenario 2: Compatibility Issues with Existing Systems

The Problem: Another common pain point arises when B2B buyers discover that the push-push button switches they intend to integrate are incompatible with their existing systems. This often occurs due to variations in voltage ratings, current capacities, or physical dimensions. For example, a manufacturer in the Middle East may find that the switches sourced for a new assembly line do not fit the pre-existing panel configurations, resulting in project delays and increased costs. Such compatibility issues can disrupt operations and necessitate additional modifications that were not budgeted for.

The Solution: To avoid compatibility issues, buyers should conduct thorough compatibility assessments before finalizing their switch selection. This includes reviewing the electrical specifications of their current systems and ensuring that the new switches align with these requirements. Buyers should engage with suppliers who offer customization options, allowing them to specify dimensions and electrical ratings that match their needs. Creating a detailed product specification sheet can help communicate requirements clearly to suppliers. Additionally, leveraging simulation software can assist in visualizing how the new switches will fit within existing systems, thereby minimizing the risk of incompatibility.

Scenario 3: Limited Understanding of Technical Specifications

The Problem: Many B2B buyers encounter difficulties due to a lack of understanding of the technical specifications associated with push-push button switches. Terms like SPST, DPDT, current ratings, and IP ratings can be confusing, particularly for those not well-versed in electrical components. This knowledge gap can lead to incorrect product choices, ultimately affecting system performance and increasing the likelihood of operational failures. Buyers may also struggle to communicate their needs effectively with suppliers, resulting in misaligned expectations and unsatisfactory products.

The Solution: To bridge this knowledge gap, buyers should invest time in educating themselves about the various technical specifications relevant to push-push button switches. Participating in workshops, webinars, or online courses focusing on electrical components can enhance understanding and build confidence in making informed purchasing decisions. Additionally, buyers should utilize resources provided by manufacturers and distributors, such as product manuals and specification guides. When in doubt, seeking the assistance of an experienced engineer or technical consultant can provide valuable insights into product selection. Building a collaborative relationship with suppliers can also facilitate better communication about technical needs, ensuring that the correct specifications are met for optimal performance.

Strategic Material Selection Guide for push-push button switch

What Are the Key Materials Used in Push-Push Button Switches?

When selecting materials for push-push button switches, it is essential to consider properties that impact performance, durability, and application suitability. Here, we analyze four common materials: plastic, metal, rubber, and silicone.

How Does Plastic Perform in Push-Push Button Switches?

Plastic is widely used in the manufacturing of push-push button switches due to its lightweight and versatile nature. Key properties include good electrical insulation, resistance to corrosion, and a temperature rating typically ranging from -20°C to 85°C.

Pros: Plastic is cost-effective and easy to mold into various shapes, making it suitable for custom designs. It is also lightweight, which can reduce shipping costs and ease installation.

Cons: However, plastic can be less durable compared to metals, particularly in high-temperature or high-stress environments. It may also degrade over time when exposed to UV light or certain chemicals.

Impact on Application: Plastic is generally compatible with various media but may not be suitable for applications involving harsh chemicals or extreme temperatures.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, particularly regarding flammability and chemical resistance.

What Advantages Do Metals Offer in Push-Push Button Switches?

Metals, such as stainless steel and aluminum, are often chosen for their strength and durability. They typically have high corrosion resistance and can withstand extreme temperatures, with ratings often exceeding 200°C.

Pros: The robust nature of metals ensures longevity and reliability, especially in industrial applications. They also provide excellent conductivity, which is crucial for electrical components.

Cons: The primary drawback is the higher cost compared to plastics, along with increased manufacturing complexity. Additionally, metal components can be heavier, impacting installation and shipping.

Impact on Application: Metals are suitable for applications requiring high mechanical strength and exposure to harsh environments, such as outdoor or industrial settings.

Illustrative image related to push-push button switch

Considerations for International Buyers: Compliance with standards for electrical conductivity and corrosion resistance is critical, especially in regions with high humidity or saline environments, like coastal areas in Brazil or the Middle East.

Why Choose Rubber for Push-Push Button Switches?

Rubber is often utilized in push-push button switches, particularly for seals and gaskets. Key properties include excellent flexibility, a temperature range from -30°C to 100°C, and good resistance to wear and tear.

Pros: Rubber provides excellent sealing capabilities, preventing dust and moisture ingress, which is vital for outdoor applications. It is also relatively inexpensive and easy to work with.

Cons: However, rubber can degrade over time when exposed to certain chemicals or UV light. Its mechanical properties may also diminish in extreme temperatures.

Impact on Application: Rubber is ideal for applications requiring a degree of flexibility and sealing but may not be suitable for high-temperature environments.

Considerations for International Buyers: Buyers should verify that the rubber used complies with international standards for environmental resistance, especially in regions with extreme weather conditions.

What Role Does Silicone Play in Push-Push Button Switches?

Silicone is increasingly popular in push-push button switches due to its excellent thermal stability and flexibility. It can operate in a temperature range from -60°C to 200°C and offers good resistance to UV light and ozone.

Pros: Silicone’s durability and flexibility make it ideal for applications requiring a long lifespan and resistance to environmental factors. It is also non-toxic and safe for various applications.

Cons: The main limitation of silicone is its higher cost compared to rubber and plastic. Additionally, its manufacturing process can be more complex.

Illustrative image related to push-push button switch

Impact on Application: Silicone is particularly suited for applications in extreme environments, such as aerospace or automotive industries, where temperature fluctuations are common.

Considerations for International Buyers: Buyers should ensure that silicone products meet relevant international certifications, particularly in sectors where safety is paramount.

Summary Table of Material Selection for Push-Push Button Switches

| Material | Typical Use Case for push-push button switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Consumer electronics, light-duty applications | Cost-effective and versatile | Less durable in harsh conditions | Low |

| Metal | Industrial applications, outdoor switches | High strength and durability | Higher cost and weight | High |

| Rubber | Seals and gaskets in switches | Excellent sealing capabilities | Degrades in extreme conditions | Med |

| Silicone | Aerospace and automotive applications | High thermal stability and flexibility | Higher cost and complex manufacturing | High |

By understanding the properties, pros and cons, and application impacts of these materials, international B2B buyers can make informed decisions tailored to their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for push-push button switch

What Are the Key Stages in the Manufacturing Process of Push-Push Button Switches?

The manufacturing process of push-push button switches involves several critical stages to ensure quality and functionality. Understanding these stages is essential for B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe.

Material Preparation: What Materials Are Used and Why?

The first stage in manufacturing push-push button switches involves the selection and preparation of raw materials. Typically, manufacturers use high-grade plastics for the switch housing, ensuring durability and resistance to wear. Metals, such as brass or stainless steel, are commonly used for internal contacts due to their excellent conductivity and corrosion resistance. These materials undergo thorough inspection for quality, ensuring they meet specific requirements before moving to the next stage.

Forming: How Are Components Shaped?

The forming process includes techniques such as injection molding for plastic components and stamping or machining for metal parts. Injection molding is particularly efficient for producing complex shapes and high volumes of plastic housings, while stamping is used to create precise metal contacts. Manufacturers employ computer numerical control (CNC) machines for machining metal parts, ensuring high precision and consistency.

What Assembly Techniques Are Commonly Used in Push-Push Button Switch Manufacturing?

Once individual components are prepared, the assembly stage begins. This process often involves manual assembly and automated techniques to enhance efficiency. Automated assembly lines may use robotic arms for tasks like inserting metal contacts into plastic housings, which reduces the risk of human error and speeds up production.

Quality control during assembly is crucial. Each switch may undergo functional testing to ensure it activates correctly and meets specified operational parameters. This stage often involves using specialized equipment to simulate real-world conditions, ensuring the switches perform reliably under various scenarios.

How Is Finishing Handled in the Manufacturing of Push-Push Button Switches?

The finishing stage is where aesthetic and functional attributes are added to the push-push button switches. This may include surface treatments such as plating to enhance corrosion resistance or applying finishes for improved tactile feedback. Additionally, components may undergo labeling or printing processes to ensure clear user instructions are visible.

Quality assurance checks during this stage often focus on visual inspections and tactile feedback assessments. Manufacturers aim to ensure that the final product not only meets functional specifications but also provides a pleasing user experience.

What Are the International Quality Standards Relevant to Push-Push Button Switches?

Quality assurance is a critical aspect of manufacturing push-push button switches. International standards such as ISO 9001 set the framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Compliance with these standards is vital for suppliers looking to do business globally.

In addition to ISO standards, industry-specific certifications such as CE for the European market or UL for North America are crucial. These certifications indicate that products meet necessary safety and performance requirements, which is particularly relevant for buyers in regulated markets.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are essential to ensure that each stage of manufacturing maintains high standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide certificates of conformity to ensure materials meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is vital. This may include sampling finished components at various stages to ensure they meet quality benchmarks.

-

Final Quality Control (FQC): Before packaging and shipping, a final inspection is conducted to verify that the finished products meet all specifications. This often includes functional testing and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure their suppliers adhere to rigorous quality control processes. Here are some strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. Audits help identify areas for improvement and ensure compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand their quality management practices. These reports should include information on testing methods, defect rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct inspections at various stages of production, ensuring adherence to industry standards.

What Are the Unique Quality Control Challenges for International Buyers?

International buyers, particularly from regions such as Africa and South America, may face unique challenges when it comes to quality control. Variations in regulatory standards, logistical hurdles, and communication barriers can complicate the procurement process.

To navigate these challenges, buyers should:

-

Understand Local Regulations: Familiarizing themselves with local regulations and standards in their respective markets can help buyers make informed decisions about product specifications.

-

Establish Clear Communication: Maintaining open lines of communication with suppliers is essential for addressing quality concerns promptly. Regular updates and feedback can enhance collaboration and improve product quality.

-

Leverage Technology: Utilizing digital tools for tracking and managing quality control processes can streamline operations and enhance transparency. This can be particularly beneficial for international transactions where time zones and distances may pose challenges.

Conclusion: The Importance of Robust Manufacturing and Quality Assurance Processes

For B2B buyers, understanding the manufacturing processes and quality assurance practices for push-push button switches is vital for making informed purchasing decisions. By focusing on material preparation, forming, assembly, finishing, and adhering to international quality standards, manufacturers can produce reliable products. Buyers must also actively engage in verifying supplier quality control practices to ensure they receive high-quality switches that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘push-push button switch’

This guide aims to provide a practical sourcing checklist for B2B buyers looking to procure push-push button switches. By following these steps, you can ensure that your purchasing decisions are informed, efficient, and aligned with your technical requirements and business needs.

Illustrative image related to push-push button switch

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your push-push button switches. Consider factors such as voltage ratings, current capacity, contact configuration (SPST, DPST, etc.), and operational environment (indoor, outdoor, moisture exposure). This will help you narrow down your options and ensure compatibility with your existing systems.

Step 2: Research Market Trends and Standards

Stay updated on the latest trends in pushbutton switch technology and industry standards. Understanding market expectations and compliance standards—such as UL or CE certifications—will help you make informed decisions and avoid potential pitfalls. This knowledge can also guide you in selecting suppliers that adhere to these standards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, including their experience in manufacturing push-push button switches, and ask for references from businesses in similar sectors. Look for suppliers who demonstrate reliability and have a strong track record of customer satisfaction.

Illustrative image related to push-push button switch

- Check for Certifications: Ensure that the suppliers hold relevant certifications that validate their compliance with safety and quality standards.

- Assess Manufacturing Capabilities: Investigate their production processes and technology to ensure they can meet your quality and quantity requirements.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the push-push button switches you are considering. Testing these samples will allow you to evaluate their functionality, durability, and compatibility with your applications. Pay attention to the tactile feedback, switch life expectancy, and any additional features like illumination or sealing.

Step 5: Understand Pricing and Payment Terms

Get a clear understanding of the pricing structure and payment terms from your shortlisted suppliers. Compare quotes while considering factors such as bulk discounts, shipping costs, and any additional fees. Transparent pricing will help you budget effectively and avoid unexpected expenses.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to secure favorable terms and conditions. Discuss lead times, minimum order quantities, warranty provisions, and after-sales support. This step is crucial for establishing a mutually beneficial relationship and ensuring that your needs are prioritized throughout the procurement process.

Step 7: Finalize the Order and Confirm Delivery Logistics

Once you have selected a supplier, finalize your order by confirming all details, including specifications, quantities, and delivery timelines. Ensure that you have a clear logistics plan in place, including shipping methods and tracking capabilities, to avoid delays and ensure timely receipt of your products.

By following this checklist, you will be well-equipped to source push-push button switches that meet your business requirements effectively, ensuring a smooth procurement process and reliable operational performance.

Comprehensive Cost and Pricing Analysis for push-push button switch Sourcing

What Are the Key Cost Components in Push-Push Button Switch Sourcing?

When sourcing push-push button switches, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials can vary significantly based on the switch type and specifications. For instance, switches with gold-plated contacts will generally be more expensive than those with standard brass contacts.

-

Labor: Labor costs are influenced by the location of manufacturing. Regions with lower labor costs, such as parts of Asia, may offer more competitive pricing compared to Europe or North America.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient production processes can help minimize these overheads.

-

Tooling: Custom tooling for specific switch designs can represent a significant upfront cost. However, these costs can be amortized over larger production runs, making them more manageable for high-volume orders.

-

Quality Control: Ensuring that switches meet industry standards and certifications (e.g., UL, CE) can add to the overall cost but is essential for international compliance and customer satisfaction.

-

Logistics: Shipping costs can vary widely depending on the destination and chosen Incoterms. For international buyers, understanding these costs is vital to avoid unexpected expenses.

-

Margin: Suppliers typically apply a markup to cover their costs and generate profit. This margin can vary based on the supplier’s market position and the level of competition.

How Do Price Influencers Affect Push-Push Button Switch Pricing?

Several factors influence the pricing of push-push button switches, making it essential for buyers to consider them during negotiations.

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced per-unit pricing. Suppliers may offer discounts for bulk purchases, which is particularly beneficial for businesses looking to stock up.

-

Specifications and Customization: Custom features, such as illumination options or unique actuator designs, can increase costs. Buyers should balance their need for customization with budget constraints.

-

Materials and Quality Certifications: Premium materials and adherence to quality certifications can elevate costs. Buyers seeking high-quality or specialized switches should be prepared for higher prices.

-

Supplier Factors: The reputation and location of suppliers can impact pricing. Established suppliers with a history of quality may charge more, but the reliability may justify the expense.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is critical for international transactions. They define the responsibilities and costs associated with shipping, insurance, and customs, which can affect the total landed cost.

What Are the Best Negotiation Tips for B2B Buyers of Push-Push Button Switches?

To ensure cost-efficiency and favorable terms, B2B buyers should adopt strategic negotiation tactics.

-

Leverage Volume Discounts: Clearly communicate your expected order quantities. Suppliers may offer better pricing tiers for larger orders.

-

Request Detailed Quotes: Obtain itemized quotes that break down costs into materials, labor, and logistics. This transparency can help identify areas for negotiation.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront cost but also the long-term implications, such as maintenance and replacement costs. A slightly more expensive switch may offer longer durability and lower TCO.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms in future transactions. Regular communication can foster trust and reliability.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Comparing different suppliers can provide leverage in negotiations and ensure competitive pricing.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of unique pricing nuances.

-

Currency Fluctuations: Exchange rates can impact pricing, especially for large orders. Consider negotiating in stable currencies to mitigate risks.

-

Import Duties and Taxes: Be aware of import tariffs and taxes applicable in your region. These can significantly affect the overall cost of sourcing switches from abroad.

-

Cultural Factors: Understanding cultural differences in negotiation styles can enhance communication and lead to more favorable outcomes.

Disclaimer on Indicative Prices

Pricing for push-push button switches can vary widely based on the factors discussed. The prices mentioned in various sources should be considered indicative and subject to change based on market conditions, supplier negotiations, and specific requirements. Always seek updated quotes and comprehensive breakdowns before finalizing any orders.

Alternatives Analysis: Comparing push-push button switch With Other Solutions

Introduction: Exploring Alternatives to Push-Push Button Switches

In the realm of electrical control devices, the push-push button switch is a popular choice for its simplicity and reliability. However, businesses often face the need to evaluate other solutions to ensure they are choosing the most effective technology for their applications. This analysis provides a comparative overview of the push-push button switch against two viable alternatives: toggle switches and capacitive touch switches. Each alternative presents unique advantages and disadvantages that can influence a buyer’s decision based on performance, cost, ease of implementation, maintenance, and best use case scenarios.

| Comparison Aspect | Push-Push Button Switch | Toggle Switch | Capacitive Touch Switch |

|---|---|---|---|

| Performance | Reliable, tactile feedback; suitable for low-voltage applications | High durability; can handle higher voltage and current loads | Fast response time; no mechanical wear; sensitive to touch |

| Cost | Low to moderate cost; affordable for bulk purchases | Generally low cost; varies with complexity | Higher initial cost; installation and integration can add to expenses |

| Ease of Implementation | Simple installation; requires minimal space | Easy to install; may require more space depending on the type | More complex; requires specific mounting and can be sensitive to environmental factors |

| Maintenance | Low maintenance; robust design | Very low maintenance; long lifespan | Minimal maintenance; may require recalibration in harsh environments |

| Best Use Case | Residential lighting, simple appliances | Industrial equipment, machinery | Modern interfaces, consumer electronics, smart devices |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Toggle Switches?

Toggle switches are widely used in various applications due to their robustness and versatility. They are capable of handling higher voltage and current loads, making them suitable for industrial and commercial environments. The primary advantage of toggle switches is their durability; they can withstand harsh conditions and have a long operational lifespan. However, they require more space for installation compared to push-push button switches, which can be a limiting factor in compact designs. Additionally, they provide a less tactile response than push-push buttons, which may affect user experience in applications where feedback is crucial.

How Do Capacitive Touch Switches Compare?

Capacitive touch switches represent a modern alternative that leverages touch-sensitive technology. They offer quick response times and eliminate mechanical wear, leading to potentially longer lifespans. Their sleek design allows for flexible integration into modern electronic devices, making them ideal for user interfaces in consumer electronics. However, the initial cost is typically higher than that of push-push button switches, and installation can be more complex due to the need for specific mounting. Furthermore, capacitive switches may struggle in environments with high humidity or dirt, which could lead to false activations or operational issues.

Illustrative image related to push-push button switch

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate switch for your business needs, consider the specific application and operational environment. If you require a reliable, cost-effective solution for simple control tasks, the push-push button switch remains an excellent choice. For applications demanding higher durability and voltage handling, toggle switches may be more suitable. Conversely, if your project involves modern electronics where aesthetics and quick response times are paramount, capacitive touch switches could be the way to go. Ultimately, understanding the unique benefits and limitations of each alternative will empower B2B buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for push-push button switch

What Are the Key Technical Properties of Push-Push Button Switches?

When selecting push-push button switches for industrial or commercial applications, understanding their technical specifications is crucial. Here are some essential properties:

-

Material Grade

– The materials used in manufacturing push-push button switches can significantly affect their durability and performance. Common materials include plastic for the housing, and copper or gold for contacts. High-grade materials ensure resistance to wear, corrosion, and extreme temperatures, which is essential for longevity in demanding environments. -

Current and Voltage Ratings

– Each switch comes with specific ratings indicating the maximum current and voltage it can handle. For example, a switch rated for 3A at 120VAC is designed to safely control devices drawing up to 3 amps at 120 volts. Understanding these ratings helps buyers ensure the switch can manage the electrical loads of their applications without risk of failure. -

Mounting Type

– Push-push button switches can be panel-mounted, surface-mounted, or through-hole mounted. The choice of mounting type impacts installation ease and the switch’s suitability for specific applications. Buyers should assess their installation environment to select the appropriate type, ensuring compatibility with existing equipment. -

Contact Configuration

– This specification refers to how the internal contacts are arranged, which affects the switch’s functionality. Common configurations include Single Pole Single Throw (SPST) and Double Pole Double Throw (DPDT). Understanding contact configuration is vital for ensuring the switch aligns with the intended circuit design. -

IP Rating (Ingress Protection)

– The IP rating indicates the switch’s resistance to dust and moisture. For instance, an IP67 rating means the switch is dust-tight and can withstand immersion in water up to 1 meter. This is particularly important for outdoor or industrial applications where exposure to harsh elements is likely. -

Actuation Force

– This term refers to the amount of force required to activate the switch. Different applications may require different actuation forces; for example, a soft-touch switch might be ideal for consumer electronics, while a higher force might be necessary for heavy machinery. Understanding actuation force ensures the switch’s usability in its intended context.

What Are Common Trade Terms Related to Push-Push Button Switches?

Familiarity with industry jargon can streamline communication and enhance negotiation processes. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of push-push button switches, working with OEMs can provide access to customized solutions tailored to specific application needs. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to assess if a supplier meets their purchase requirements without overcommitting financially. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting price quotes for specific products. It’s a crucial step in the procurement process, allowing buyers to compare costs and terms from multiple vendors for push-push button switches. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce (ICC) related to international shipping. Knowledge of Incoterms helps buyers understand the responsibilities and risks involved in the transportation of goods, including who bears the cost for shipping and insurance. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for planning and inventory management, especially when integrating push-push button switches into larger systems or projects. -

Certification Standards

– These are guidelines that products must meet to ensure safety and performance. Examples include UL (Underwriters Laboratories) and CE (Conformité Européenne) markings. Familiarity with certification standards helps buyers ensure compliance with regulatory requirements in their respective markets.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing push-push button switches, ensuring compatibility, reliability, and cost-effectiveness in their applications.

Illustrative image related to push-push button switch

Navigating Market Dynamics and Sourcing Trends in the push-push button switch Sector

What Are the Key Market Trends Influencing the Push-Push Button Switch Sector?

The push-push button switch sector is witnessing significant transformation driven by advancements in technology, evolving consumer preferences, and regulatory changes. Globally, the pushbutton switch market is expanding due to the increasing demand for automation and smart technology across various industries, including automotive, industrial machinery, and consumer electronics. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly looking for innovative solutions that enhance operational efficiency and reduce energy consumption.

Emerging trends include the integration of IoT capabilities in pushbutton switches, allowing for remote monitoring and control. This trend is particularly relevant for international buyers who prioritize connectivity and smart technology in their sourcing decisions. Additionally, there is a growing demand for customizable switches that cater to specific industry needs, such as sealed designs for harsh environments or illuminated options for enhanced user interaction.

Market dynamics are also shaped by the competitive landscape, where manufacturers are focusing on reducing lead times and improving supply chain efficiency. This is crucial for B2B buyers, as timely availability of components can significantly impact project timelines and costs. Buyers should stay informed about the latest product innovations and sourcing options to make strategic procurement decisions.

How Is Sustainability Shaping Sourcing Strategies for Push-Push Button Switches?

Sustainability is becoming a central theme in the sourcing strategies for push-push button switches. International buyers are increasingly recognizing the environmental impact of their procurement choices, leading to a heightened demand for sustainable products. The industry is responding by adopting greener manufacturing processes and materials, emphasizing the use of recyclable and eco-friendly components.

Illustrative image related to push-push button switch

Ethical sourcing is gaining traction, with buyers looking for suppliers that adhere to environmentally responsible practices. This includes certifications such as ISO 14001, which demonstrates a commitment to minimizing environmental footprints. B2B buyers are encouraged to prioritize suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly and ethically.

Moreover, innovations in materials science are leading to the development of “green” certifications for pushbutton switches. These certifications can help buyers identify products that meet specific environmental standards, thus aligning with corporate sustainability goals. By prioritizing sustainability, businesses not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Evolution of Push-Push Button Switches and Its Significance for B2B Buyers?

The evolution of push-push button switches has been marked by significant technological advancements since their inception. Originally designed for simple electrical circuits, these switches have transformed into complex devices capable of supporting advanced functionalities. The introduction of miniaturization in electronic components has allowed for the creation of compact pushbutton switches that cater to modern design aesthetics and space constraints.

Illustrative image related to push-push button switch

Additionally, the shift towards digital and automated systems has driven innovation in the pushbutton switch sector. Manufacturers are now producing switches that integrate seamlessly with smart devices, enabling enhanced user experiences. For B2B buyers, understanding this evolution is crucial, as it informs their purchasing decisions and helps them identify products that align with current technological trends.

As the market continues to evolve, staying abreast of these changes will empower international buyers to leverage the latest innovations, ensuring that their procurement strategies align with industry standards and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of push-push button switch

-

1. How do I choose the right push-push button switch for my application?

Selecting the right push-push button switch involves considering several factors such as the electrical specifications (current and voltage ratings), mounting type (panel mount, through-hole, etc.), and the function (momentary or latching). Evaluate your application requirements, including environmental conditions, to determine if you need features like IP ratings for water and dust resistance. Additionally, consider the actuator style and any illumination needs. Collaborating with suppliers who offer customization can help ensure you find a switch that meets your specific needs. -

2. What are the common applications for push-push button switches?

Push-push button switches are widely used in various industries, including consumer electronics, automotive, telecommunications, and industrial equipment. They serve functions like controlling lighting systems, machinery operation, and user interfaces for electronic devices. Their versatility allows them to be utilized in both low-power and high-power applications. Understanding the specific requirements of your industry will help in selecting the appropriate switch that aligns with your operational needs. -

3. What customization options are available for push-push button switches?

Many manufacturers offer customization options for push-push button switches, including size, color, actuation force, and functionality. You can also request features like illumination, special markings, or specific materials to enhance durability or aesthetic appeal. When discussing customization with suppliers, ensure that you articulate your exact requirements, as this will help them provide a solution tailored to your specific application. -

4. What are the minimum order quantities (MOQs) for push-push button switches?

Minimum order quantities (MOQs) for push-push button switches can vary significantly between suppliers and depend on factors such as the complexity of customization, production capabilities, and materials used. Typically, MOQs range from 100 to 1,000 units for standard models, while customized switches may have higher MOQs. It’s advisable to communicate your needs with potential suppliers to negotiate terms that fit your purchasing strategy. -

5. How do I vet suppliers for push-push button switches?

When vetting suppliers for push-push button switches, consider their experience, reputation, and certifications. Look for suppliers with a proven track record in your industry and check for quality assurance certifications such as ISO 9001. Request references or case studies to understand their reliability. Additionally, inquire about their manufacturing processes, lead times, and after-sales support to ensure they align with your business needs. -

6. What payment terms should I expect when sourcing push-push button switches?

Payment terms for sourcing push-push button switches can vary based on supplier policies and the scale of your order. Common terms include a percentage upfront (usually 30-50%) with the balance due upon delivery or a net 30 to net 60 payment period after invoice receipt. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify payment terms before finalizing any agreements. -

7. How can I ensure the quality of push-push button switches?

To ensure the quality of push-push button switches, request samples before placing a bulk order and perform thorough testing based on your application requirements. Inquire about the supplier’s quality assurance processes, including any third-party testing or certifications. Establish clear specifications and standards for the switches and ensure that your supplier adheres to these. Regular communication and site visits (if feasible) can also help maintain quality standards throughout production. -

8. What logistics considerations should I keep in mind when importing push-push button switches?

When importing push-push button switches, consider logistics aspects such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with the specific requirements of your destination country. Understand any tariffs or duties that may apply and ensure that all documentation is in order to avoid delays. Lastly, establish a clear timeline for production and shipping to align with your project schedules, allowing buffer time for potential delays.

Top 7 Push-Push Button Switch Manufacturers & Suppliers List

1. Kyle Switch Plates – Push Button Light Switches

Domain: kyleswitchplates.com

Registered: 2012 (13 years)

Introduction: Push Button Light Switches, Push Button Dimmer Switches, Push Button Switch Plates, Regular Push Button Light Switches (single pole), 3-Way Pushbutton Switches, 4-Way Push-Button Switch, Push Button Dimmer Switch (300W and 600W versions), Trimmed Push Button Light Dimmers, Dual Pushbutton Light Switches, Dual Momentary Low Voltage Push Button Switches, Classic Accents brand, Lifetime warranty, Pus…

2. House of Antique Hardware – Antique Push Button Light Switch

Domain: houseofantiquehardware.com

Registered: 1999 (26 years)

Introduction: This company, House of Antique Hardware – Antique Push Button Light Switch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Digi-Key – Pushbutton Switches

Domain: digikey.com

Registered: 1995 (30 years)

Introduction: This company, Digi-Key – Pushbutton Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. C&K – Miniature Pushbutton Switches

Domain: ckswitches.com

Registered: 2016 (9 years)

Introduction: C&K offers a wide range of miniature, subminiature, and ultra-miniature pushbutton switches for various applications including printed circuit board, surface mount, and panel mount. Key features include: momentary and latching versions, SPST, SPDT, DPST, and DPDT functions, illuminated, sealed, and low-profile configurations, and various mounting options (smd, threaded, snap-in). Applications span…

5. TE Connectivity – Push Button Switches

Domain: te.com

Registered: 1992 (33 years)

Introduction: Push Button Switches, Momentary Switches from TE Connectivity.

6. Jameco – Pushbutton Switches

Domain: jameco.com

Registered: 1998 (27 years)

Introduction: Pushbutton switches are essential components in the electronics industry, utilized in applications such as calculators, doorbells, and video game controllers. They come in various sizes, configurations, and colors, with options for momentary, latching, and illuminated contacts. These switches are designed for both momentary and maintained functions, featuring a button that opens or closes a circui…

7. Omron – Pushbutton Switches

Domain: components.omron.com

Registered: 1997 (28 years)

Introduction: This company, Omron – Pushbutton Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for push-push button switch

In the evolving landscape of push-push button switches, strategic sourcing emerges as a critical lever for international B2B buyers. Understanding the diverse applications and specifications of these switches—from miniature variants for compact designs to robust options for industrial use—enables businesses to tailor their procurement strategies effectively. The emphasis on sourcing quality components with appropriate voltage and current ratings ensures operational reliability and safety, particularly in demanding environments.

Illustrative image related to push-push button switch

Buyers should prioritize partnerships with reputable suppliers who can provide not only product diversity but also customization options, such as built-in illumination and sealing for enhanced durability. This strategic approach not only mitigates risks associated with product failure but also fosters innovation by integrating the latest technologies in switch design.

As we look to the future, it is imperative for B2B buyers in regions such as Africa, South America, the Middle East, and Europe to engage proactively with suppliers. By leveraging strategic sourcing, businesses can position themselves competitively in their respective markets. Now is the time to explore sourcing opportunities that align with your operational needs and growth objectives, ensuring your organization remains at the forefront of industry advancements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.