Choosing Your Waffle Fry Cutter: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for waffle fry cutter

In the competitive landscape of the food service industry, sourcing the right equipment can be a significant challenge for international buyers. When it comes to producing popular menu items like waffle fries, the importance of a high-quality waffle fry cutter cannot be overstated. This guide serves as a comprehensive resource for B2B buyers seeking to navigate the global market for waffle fry cutters, addressing key considerations such as product types, applications, supplier vetting, and cost analysis.

As the demand for innovative and appealing food presentations rises, understanding the various styles of waffle fry cutters—ranging from manual to electric models—becomes essential. This guide will empower buyers from diverse regions, including Africa, South America, the Middle East, and Europe, by providing actionable insights that facilitate informed purchasing decisions. We will delve into the technical specifications that matter, explore the best suppliers known for quality and reliability, and discuss pricing strategies that fit different budgets.

By equipping B2B buyers with knowledge about the intricacies of waffle fry cutter options, this guide aims to enhance operational efficiency and product offerings. Whether you are a restaurant owner, a food distributor, or a catering service provider, understanding these factors will help you meet customer expectations and stay ahead in a rapidly evolving market.

Understanding waffle fry cutter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Waffle Fry Cutter | Hand-operated, often made of stainless steel | Small restaurants, food trucks | Pros: Cost-effective, easy to use. Cons: Labor-intensive, slower production rate. |

| Electric Waffle Fry Cutter | Automated cutting process, high efficiency | Large-scale food service, catering | Pros: Fast, consistent results. Cons: Higher initial investment, requires power source. |

| Adjustable Mandoline Cutter | Multiple thickness settings for versatility | Cafés, bistros | Pros: Customizable cuts, compact design. Cons: Can be complex to operate, potential for inconsistent cuts. |

| Commercial Waffle Fry Machine | Integrated cutting and frying capabilities | Fast food chains, large kitchens | Pros: Streamlined operations, high volume output. Cons: Expensive, requires significant space. |

| Specialty Waffle Fry Cutter | Unique designs for specific fry shapes | Gourmet restaurants, specialty shops | Pros: Unique offerings, enhances menu appeal. Cons: Limited production volume, niche market. |

What are the Key Characteristics of Manual Waffle Fry Cutters?

Manual waffle fry cutters are typically constructed from durable stainless steel and are designed for hand operation. They are ideal for small restaurants and food trucks where budget constraints are significant. While they are cost-effective and easy to use, the labor-intensive nature of these tools can slow down production, making them less suitable for high-demand environments.

How Do Electric Waffle Fry Cutters Enhance Efficiency?

Electric waffle fry cutters automate the cutting process, significantly increasing efficiency and consistency in output. These machines are particularly beneficial for large-scale food service operations and catering businesses that require a high volume of fries. Although they come with a higher initial investment and necessitate a power source, the speed and reliability they offer can greatly enhance operational productivity.

What Makes Adjustable Mandoline Cutters a Versatile Choice?

Adjustable mandoline cutters allow users to select from multiple thickness settings, making them versatile for different culinary applications. These cutters are popular in cafés and bistros where a variety of fry styles may be required. While they are compact and can produce customized cuts, they may be complex to operate and can lead to inconsistent results if not used correctly.

Why Invest in Commercial Waffle Fry Machines?

Commercial waffle fry machines combine cutting and frying capabilities into one unit, making them ideal for fast food chains and large kitchens. These machines streamline operations, allowing for high-volume output with minimal labor. However, they require a significant financial investment and ample space, which may not be feasible for smaller operations.

What Are the Benefits of Specialty Waffle Fry Cutters?

Specialty waffle fry cutters feature unique designs that create specific fry shapes, appealing to gourmet restaurants and specialty shops looking to differentiate their menu offerings. These tools can enhance the visual appeal and uniqueness of dishes, attracting customers seeking novel dining experiences. However, they may have limited production capabilities and cater to niche markets, which can affect overall profitability.

Key Industrial Applications of waffle fry cutter

| Industry/Sector | Specific Application of Waffle Fry Cutter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Preparation of Waffle Fries for Restaurants | Enhances menu offerings and customer satisfaction with unique fries | Durability, ease of cleaning, and volume capacity are critical. |

| Food Processing | Bulk Production of Frozen Waffle Fries | Streamlines production processes and ensures uniformity in product | Efficiency, machine compatibility, and maintenance support needed. |

| Catering Services | Event Catering with Custom Waffle Fry Options | Differentiates catering offerings, appealing to diverse client needs | Versatility in cutting thickness and portability for off-site events. |

| Snack Food Manufacturing | Creation of Snack Packs with Waffle Fries | Expands product lines and increases market reach | Compliance with food safety standards and packaging requirements. |

| Home Cooking Retail | Retail Sales of Waffle Fry Cutters for Consumers | Taps into the growing home cooking trend and consumer demand | Quality of materials, ease of use, and customer support availability. |

How is the Waffle Fry Cutter Used in the Food Service Industry?

In the food service sector, waffle fry cutters are crucial for restaurants looking to offer a unique dining experience. By utilizing these cutters, establishments can prepare perfectly shaped waffle fries that enhance their menu. This not only attracts customers but also addresses the need for consistent quality. Buyers in this sector should prioritize durable materials and ease of cleaning, as high-volume usage is common.

What Role Does the Waffle Fry Cutter Play in Food Processing?

For food processing companies, the waffle fry cutter is essential in the bulk production of frozen waffle fries. These machines help ensure uniformity in size and shape, which is critical for cooking consistency and customer satisfaction. When sourcing, businesses should focus on efficiency and compatibility with existing production lines, as well as reliable maintenance support to minimize downtime.

How Can Catering Services Benefit from Waffle Fry Cutters?

Catering services can leverage waffle fry cutters to provide customized options for events, appealing to diverse client preferences. By offering unique waffle fries, caterers can differentiate their services and enhance customer satisfaction. Buyers in this industry should consider the versatility of the cutter and its portability, ensuring it can be easily transported and used in various settings.

What Advantages Do Snack Food Manufacturers Gain from Waffle Fry Cutters?

Snack food manufacturers can utilize waffle fry cutters to create innovative snack packs featuring waffle fries. This not only expands their product lines but also caters to consumer demand for unique snack options. Compliance with food safety standards and the ability to package products efficiently are key considerations for buyers in this sector.

Why Should Retailers Invest in Waffle Fry Cutters for Home Cooking?

Retailers targeting the home cooking market can benefit from offering waffle fry cutters to consumers interested in preparing restaurant-quality fries at home. This taps into the growing trend of home cooking and enhances customer engagement. When sourcing, retailers should focus on the quality of materials and ease of use, along with robust customer support to assist consumers post-purchase.

3 Common User Pain Points for ‘waffle fry cutter’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Cuts for Waffle Fries

The Problem: B2B buyers, particularly those in the foodservice industry, often struggle with achieving uniform cuts when using waffle fry cutters. Inconsistent fry sizes can lead to uneven cooking, resulting in some fries being overcooked while others remain undercooked. This not only affects the quality of the food but can also impact customer satisfaction and repeat business. Moreover, buyers may find that cheaper models of waffle fry cutters do not provide the precision needed, causing frustration among kitchen staff.

The Solution: To tackle this issue, B2B buyers should invest in high-quality waffle fry cutters that offer adjustable settings for cut thickness. Products like the Broner Wave-Waffle Cutter XXL Powerline, which has garnered positive reviews for its cutting precision, can be a valuable addition to a commercial kitchen. Additionally, ensuring that the cutter is made from durable materials, such as stainless steel, will maintain sharpness and performance over time. Regular maintenance, such as sharpening blades and cleaning the cutter after use, will also enhance the consistency of cuts. Training staff on the proper technique for using the cutter can further improve outcomes, ensuring that every fry meets the desired quality.

Scenario 2: Managing Supply Chain Issues for Waffle Fry Cutters

The Problem: International B2B buyers often face challenges related to supply chain disruptions, particularly when sourcing specialized equipment like waffle fry cutters. Delays in shipping, customs clearance issues, or even product shortages can hinder restaurant operations, leading to potential revenue loss. This is especially concerning for businesses that plan to introduce new menu items featuring waffle fries, as they rely on timely access to equipment.

The Solution: To mitigate these supply chain risks, buyers should establish relationships with multiple suppliers to ensure a steady flow of products. Diversifying sources can help in times of scarcity or delays. Additionally, buyers can explore local manufacturers or distributors within their region, which may reduce shipping times and costs. It is also wise to maintain an inventory of essential kitchen equipment, including waffle fry cutters, to buffer against unexpected shortages. Engaging in proactive communication with suppliers about lead times and availability can further enhance operational efficiency.

Scenario 3: Safety Concerns and Injuries in the Kitchen

The Problem: The kitchen environment can be hazardous, and using waffle fry cutters is no exception. B2B buyers must contend with the risk of injuries among staff while using these tools, especially if they are not designed with safety features. Cuts and accidents can lead to increased liability, worker’s compensation claims, and a decrease in staff morale.

The Solution: To enhance safety in the kitchen, B2B buyers should prioritize purchasing waffle fry cutters that come equipped with safety features such as non-slip bases and protective guards. Investing in ergonomic designs can also reduce strain on staff, making the cutting process more comfortable and safer. Providing comprehensive training on the safe operation of these cutters is crucial; this should include proper handling techniques and the importance of using personal protective equipment (PPE). Regular safety drills and refreshers on kitchen safety protocols can foster a culture of safety, helping to minimize the likelihood of accidents and injuries.

Strategic Material Selection Guide for waffle fry cutter

What Materials Are Best for Waffle Fry Cutters?

When selecting materials for waffle fry cutters, it is essential to consider properties such as durability, corrosion resistance, and manufacturing complexity. Below is an analysis of four common materials used in waffle fry cutter production.

Stainless Steel: The Industry Standard

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength, making it suitable for food processing environments. It typically withstands temperatures up to 500°F (260°C) without losing its structural integrity.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and staining, which is crucial for maintaining hygiene in food preparation. However, it can be more expensive than other materials, and its manufacturing process may require more complex machining, which can increase production costs.

Impact on Application: Stainless steel is compatible with various food products and is often preferred in commercial kitchens due to its ease of cleaning and long lifespan.

Considerations for International Buyers: Buyers in regions such as Africa and South America should ensure compliance with local food safety standards, which often align with international norms like ASTM. Additionally, the availability of stainless steel may vary, affecting lead times and costs.

Plastic: Lightweight and Cost-Effective

Key Properties: High-density polyethylene (HDPE) and polypropylene are common plastics used in waffle fry cutters. They are lightweight, resistant to impact, and can handle temperatures up to 230°F (110°C).

Pros & Cons: Plastics are generally less expensive than metals and can be molded into complex shapes, making them suitable for intricate designs. However, their lower temperature resistance and potential for wear over time can limit their durability compared to metals.

Impact on Application: Plastic waffle fry cutters are ideal for small-scale operations or home kitchens where high-volume production is not a concern.

Considerations for International Buyers: Buyers should verify that the plastics used are food-grade and compliant with regulations such as FDA or EU standards. In regions with high humidity, like parts of the Middle East, the longevity of plastic materials may be a concern.

Aluminum: A Lightweight Alternative

Key Properties: Aluminum is lightweight and offers good corrosion resistance, especially when anodized. It can withstand temperatures up to 400°F (204°C).

Pros & Cons: The advantages of aluminum include its lightweight nature and cost-effectiveness. However, it may not be as durable as stainless steel and can be prone to scratches and dents, affecting the quality of the cut over time.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable or handheld waffle fry cutters.

Considerations for International Buyers: Buyers should consider the availability of aluminum and its compliance with local standards. In Europe, for instance, aluminum products must meet specific regulations regarding food safety.

Cast Iron: The Heavy-Duty Choice

Key Properties: Cast iron is highly durable and can withstand high temperatures, making it suitable for heavy-duty applications. It typically has a temperature rating of up to 600°F (316°C).

Pros & Cons: The primary advantage of cast iron is its robustness and longevity. However, it is heavy and can be more challenging to handle, and it requires regular maintenance to prevent rusting.

Impact on Application: Cast iron is ideal for commercial kitchens that require heavy-duty equipment capable of withstanding rigorous use.

Considerations for International Buyers: Buyers should be aware of the maintenance needs of cast iron and ensure that they have the infrastructure to support its use, especially in regions with high humidity where rust can be an issue.

Summary Table

| Material | Typical Use Case for waffle fry cutter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Commercial kitchens | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Home kitchens or small-scale operations | Lightweight and cost-effective | Lower durability and temperature resistance | Low |

| Aluminum | Portable or handheld cutters | Lightweight and cost-effective | Prone to scratches and dents | Medium |

| Cast Iron | Heavy-duty commercial kitchens | Extremely durable | Heavy and requires maintenance | Medium |

This material selection guide provides essential insights for B2B buyers in various international markets. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for waffle fry cutter

What Are the Main Stages of Manufacturing a Waffle Fry Cutter?

The manufacturing process for waffle fry cutters involves several critical stages, ensuring that the final product meets both functionality and quality standards. These stages typically include:

-

Material Preparation: The primary materials used for waffle fry cutters are high-grade stainless steel and durable plastics. Stainless steel is preferred for its resistance to corrosion and ease of cleaning, which are essential for kitchen equipment. The materials are sourced from reputable suppliers and undergo initial quality checks to ensure they meet specified standards.

-

Forming: This stage involves shaping the prepared materials into the desired cutter components. Techniques such as stamping and laser cutting are commonly used for metal parts to achieve precision in design. For plastic components, injection molding is frequently employed, allowing for complex shapes and efficient mass production.

-

Assembly: After forming, the individual components are assembled into the final product. This process may involve both automated machinery and manual labor. Attention to detail is crucial during assembly to ensure that all parts fit together correctly, contributing to the cutter’s overall performance and durability.

-

Finishing: The finishing stage includes polishing, coating, and packaging. Polishing enhances the aesthetic appeal and provides a smooth surface that is easy to clean. Coating may be applied to enhance durability and resistance to wear. Finally, the products are packaged securely to prevent damage during transportation.

Which Key Techniques Are Used in Waffle Fry Cutter Manufacturing?

The manufacturing of waffle fry cutters incorporates various techniques aimed at enhancing efficiency, precision, and quality. Key techniques include:

-

CNC Machining: Computer Numerical Control (CNC) machining is employed for high precision in cutting and shaping metal parts. This technique allows for intricate designs and consistent quality across batches.

-

Quality Welding: For models that require welded components, quality welding techniques are essential to ensure strength and durability. This includes TIG (Tungsten Inert Gas) welding, which is known for producing clean and precise welds.

-

Surface Treatment: Surface treatments such as electro-polishing or powder coating are applied to improve corrosion resistance and enhance the visual appeal of the cutters.

What Are the Quality Control Standards Relevant to Waffle Fry Cutters?

Quality assurance is a critical aspect of manufacturing waffle fry cutters. Several international and industry-specific standards apply, including:

-

ISO 9001: This standard outlines a framework for effective quality management systems. Manufacturers aiming for ISO 9001 certification demonstrate their commitment to quality and customer satisfaction through systematic processes.

-

CE Marking: For products sold within the European Economic Area (EEA), obtaining CE marking is crucial. It indicates compliance with safety, health, and environmental protection standards.

-

API Standards: For manufacturers targeting specific industries, adherence to American Petroleum Institute (API) standards may be relevant, particularly if the products are used in environments where safety and performance are critical.

What Are the Key Quality Control Checkpoints in Waffle Fry Cutter Manufacturing?

Quality control (QC) checkpoints are integral to ensuring the consistency and reliability of waffle fry cutters. Common QC checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival. This includes checking for defects in materials and verifying that they meet specifications before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to identify and rectify any issues in real-time. This may involve monitoring machine settings and conducting random sampling of products.

-

Final Quality Control (FQC): Once the cutters are assembled, a final inspection is performed. This includes checking for functionality, aesthetic qualities, and compliance with safety standards. Products that pass FQC are then prepared for packaging and shipment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are several methods to effectively assess a supplier’s QC:

-

Conduct Audits: Performing on-site audits allows buyers to observe the manufacturing processes and quality control measures firsthand. This provides insight into the supplier’s commitment to maintaining high standards.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC. Regular reports detailing compliance with international standards can also be requested.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspectors can conduct thorough assessments and report on compliance with established standards.

What Are the QC/Certification Nuances for International Buyers?

When sourcing waffle fry cutters from international manufacturers, buyers should be aware of specific nuances related to quality control and certification:

-

Local Regulations: Different countries have varying regulations regarding food safety and equipment standards. Buyers must ensure that the products comply with local regulations in their respective markets.

-

Cultural and Market Differences: Understanding cultural preferences and market demands is essential. For instance, certain regions may prioritize durability over aesthetics, while others may have specific design preferences.

-

Supply Chain Transparency: Ensuring transparency in the supply chain can help buyers assess risks and make informed decisions. This involves understanding where and how the materials are sourced and processed.

By thoroughly evaluating the manufacturing processes and quality assurance practices of potential suppliers, B2B buyers can make informed purchasing decisions that align with their operational needs and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘waffle fry cutter’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure waffle fry cutters. As demand for unique food offerings increases, ensuring the right equipment is critical for maintaining quality and efficiency in food preparation. This checklist will help you navigate the procurement process and make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clarify your technical requirements for the waffle fry cutter. Consider factors such as size, material, and cutting capacity.

- Size: Determine the volume of fries you plan to produce, which will influence the cutter’s capacity.

- Material: Stainless steel is often preferred for its durability and resistance to corrosion, ensuring longevity in a commercial kitchen.

Step 2: Research Market Options

Conduct thorough research to identify various waffle fry cutter models available in the market. Compare features, pricing, and supplier reviews to gauge the best options for your needs.

- Online Reviews: Look for feedback from other commercial buyers to understand performance and reliability.

- Competitor Analysis: Investigate what models similar businesses are using to ensure you’re selecting a competitive product.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet suppliers meticulously. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Certifications: Ensure suppliers have relevant certifications that demonstrate product quality and compliance with safety standards.

- Response Time: Assess how quickly suppliers respond to inquiries, as this can indicate their level of customer service.

Step 4: Request Samples or Demos

Whenever possible, request samples or demonstrations of the waffle fry cutter. This hands-on experience is invaluable in assessing whether the equipment meets your operational needs.

- Functionality Testing: Evaluate the cutter’s performance in real-world conditions, such as ease of use and the quality of the cuts.

- Durability Assessment: Inspect the build quality and materials to ensure they can withstand the demands of a busy kitchen.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, terms, and after-sales support.

- Bulk Discounts: Inquire about price reductions for larger orders, which can significantly impact your budget.

- Warranty and Support: Ensure you understand warranty terms and the availability of replacement parts, as these factors will affect long-term maintenance costs.

Step 6: Check Shipping and Delivery Options

Understand the shipping terms and delivery timelines to ensure the cutter arrives when needed.

- Shipping Costs: Clarify whether shipping costs are included in the price or if they will be billed separately.

- Lead Times: Confirm expected delivery dates to plan your kitchen operations accordingly.

Step 7: Finalize the Purchase and Monitor Performance

After completing all checks and negotiations, finalize the purchase. Post-delivery, monitor the performance of the waffle fry cutter to ensure it meets your expectations.

- Feedback Loop: Create a system for your kitchen staff to provide feedback on the cutter’s performance, which can inform future purchasing decisions.

- Regular Maintenance: Establish a maintenance schedule to keep the equipment in optimal condition, extending its lifespan and ensuring consistent output quality.

By following this detailed checklist, you can confidently navigate the sourcing process and select a waffle fry cutter that meets your business needs, enhancing your food preparation capabilities and customer satisfaction.

Comprehensive Cost and Pricing Analysis for waffle fry cutter Sourcing

What Are the Key Cost Components in Sourcing Waffle Fry Cutters?

When analyzing the cost structure of waffle fry cutters, several components contribute to the final price. The primary costs include:

-

Materials: The choice of materials significantly impacts the cost. Stainless steel, known for its durability and resistance to corrosion, is commonly used. Lower-quality materials may reduce initial costs but can lead to higher long-term expenses due to replacement or repairs.

-

Labor: Labor costs vary based on the manufacturing location and the skill level required for assembly. Regions with lower labor costs, such as parts of Asia or South America, may offer competitive pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. Overhead can vary widely depending on the efficiency of the manufacturing facility and the region in which it operates.

-

Tooling: The initial investment in tooling can be significant, especially for custom designs. High-quality molds and cutting tools are essential for producing precise waffle cuts, affecting both cost and quality.

-

Quality Control (QC): Implementing rigorous QC processes ensures that each cutter meets safety and performance standards, which can add to the cost but is essential for maintaining a good reputation in the market.

-

Logistics: Shipping costs can be substantial, especially for international buyers. Factors such as distance, shipping method, and import duties can significantly affect the overall cost.

-

Margin: Suppliers typically add a profit margin that can vary based on competition and market demand. Understanding this margin is crucial for negotiating better prices.

What Factors Influence Pricing for Waffle Fry Cutters?

Several factors can influence the pricing of waffle fry cutters beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Buyers should consider their needs and potential future orders to leverage better pricing.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: Cutters made from higher-quality materials or those that meet specific industry standards may command a higher price. Certifications can also affect buyer trust and willingness to pay.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established suppliers may charge higher prices due to their proven track record, while new entrants might offer lower prices to attract business.

-

Incoterms: Understanding the terms of delivery can significantly impact total costs. Buyers should clarify responsibilities for shipping, customs clearance, and insurance to avoid hidden charges.

How Can Buyers Negotiate and Achieve Cost Efficiency?

To ensure a cost-effective purchasing process, B2B buyers should consider the following strategies:

-

Negotiate Terms: Always engage suppliers in discussions about pricing, payment terms, and bulk discounts. Building a relationship can lead to better deals in the long run.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price to consider maintenance, durability, and replacement costs. A higher upfront investment in quality may result in lower TCO.

-

Understand Pricing Nuances: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, import duties, and local market conditions, which can affect pricing.

-

Research Competitors: Comparing multiple suppliers and their offerings can provide leverage during negotiations. Knowing the market average helps in assessing whether a price is fair.

-

Consider Long-Term Partnerships: Establishing long-term relationships with suppliers can yield benefits such as reduced pricing, priority service, and improved product quality over time.

Conclusion

While sourcing waffle fry cutters involves various cost components and pricing influencers, buyers can achieve better value through informed negotiations and strategic planning. Understanding the total cost of ownership and maintaining awareness of market conditions will help international buyers make more effective purchasing decisions. Prices can fluctuate based on numerous factors, so always seek multiple quotes and remain adaptable to changing market dynamics.

Alternatives Analysis: Comparing waffle fry cutter With Other Solutions

Introduction: Exploring Alternatives to Waffle Fry Cutters

When considering the best tools for producing waffle fries, it’s essential to evaluate various alternatives that can achieve similar results. While waffle fry cutters are specifically designed for this purpose, other options exist that may be more suitable depending on factors such as production volume, operational costs, and ease of use. This analysis will help B2B buyers make informed decisions by comparing waffle fry cutters with viable alternatives.

Comparison Table

| Comparison Aspect | Waffle Fry Cutter | Mandoline Slicer | Crinkle Cutter |

|---|---|---|---|

| Performance | High; consistently produces thick, uniform cuts | Moderate; can produce thinner cuts, but may vary | Low; requires manual skill and precision |

| Cost | Moderate; typically ranges from $30 to $200 | Affordable; usually between $15 to $50 | Very low; often under $20 |

| Ease of Implementation | Easy; designed specifically for waffle fries | Moderate; requires some technique for best results | Easy; straightforward manual use |

| Maintenance | Low; minimal cleaning required | Moderate; needs regular blade sharpening | Low; easy to clean and maintain |

| Best Use Case | High-volume kitchens needing consistent waffle fries | Versatile; can handle various cuts, not just waffles | Home use or small-scale operations |

Detailed Breakdown of Alternatives

Mandoline Slicer

Mandoline slicers are versatile kitchen tools that can create a variety of cuts, including waffle fries, if designed with the appropriate blade. They can be an economical choice for businesses that also need to slice vegetables and fruits. However, the performance for waffle fries may vary, as many models do not achieve the desired thickness or consistency. Additionally, some users may find the learning curve steep, as achieving the perfect cut requires skill and practice. Regular maintenance, such as sharpening blades, is also necessary to ensure optimal performance.

Crinkle Cutter

A crinkle cutter is a simple, manual tool that can create crinkle cuts and is often utilized for home cooking or small-scale operations. While it is very affordable and easy to use, the crinkle cutter demands a certain level of skill for consistent results. The manual operation can lead to variations in thickness and shape, which may not meet the standards required in a commercial setting. This tool is best suited for businesses with lower production needs or those looking to add a unique touch to their offerings without investing heavily in equipment.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate cutting tool for waffle fries depends significantly on your specific operational requirements. A waffle fry cutter is ideal for high-volume kitchens that demand efficiency and consistency, while mandoline slicers provide versatility for businesses needing varied cuts. Crinkle cutters may be suitable for smaller operations or unique culinary presentations. B2B buyers should weigh the performance, cost, and operational needs of their establishment to determine the best solution tailored to their culinary objectives.

Essential Technical Properties and Trade Terminology for waffle fry cutter

What Are the Key Technical Properties of a Waffle Fry Cutter?

When evaluating waffle fry cutters for B2B procurement, understanding their technical specifications is essential for ensuring product quality and operational efficiency. Here are several critical specifications:

-

Material Grade

– Most waffle fry cutters are made from stainless steel, which offers durability and resistance to corrosion. High-grade stainless steel (like 304 or 316) is preferable as it withstands heavy usage and cleaning without degrading, ensuring long-term performance in commercial settings. -

Cutting Thickness Adjustability

– The ability to adjust the thickness of the cuts is crucial for consistency in food preparation. Many waffle fry cutters feature multiple settings, allowing operators to create fries of various thicknesses to meet customer preferences. This flexibility can enhance menu offerings and improve customer satisfaction. -

Blade Quality and Design

– The design and sharpness of the blades directly affect the cutter’s efficiency. High-quality, well-engineered blades ensure clean cuts and minimize waste. Look for cutters with replaceable blades, as this can reduce long-term maintenance costs and downtime. -

Production Capacity

– This specification refers to the volume of fries that can be processed in a given time. For high-volume food service operations, understanding the cutter’s capacity will help ensure that it can meet demand during peak hours without compromising speed or quality. -

Ease of Cleaning and Maintenance

– Equipment that is easy to disassemble and clean can significantly reduce labor costs and downtime. Consider waffle fry cutters designed with smooth surfaces and fewer crevices, which help to streamline the cleaning process and maintain hygiene standards. -

Safety Features

– Safety is paramount in any food preparation environment. Features such as non-slip handles, safety guards, and ergonomic designs can prevent accidents and injuries, making it essential to evaluate these aspects during the selection process.

What Are Common Trade Terms in the Waffle Fry Cutter Industry?

Familiarity with industry terminology helps streamline communications and negotiations. Here are several important trade terms you should know:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of waffle fry cutters, understanding whether a supplier is an OEM can indicate the quality and reliability of the equipment. -

MOQ (Minimum Order Quantity)

– This term represents the smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, particularly for businesses in regions where import costs can be significant. -

RFQ (Request for Quotation)

– An RFQ is a formal process used to invite suppliers to provide price quotes for specific products or services. For B2B buyers, issuing an RFQ for waffle fry cutters can help in comparing prices and terms from different suppliers, ensuring the best deal. -

Incoterms (International Commercial Terms)

– These are a series of predefined commercial terms published by the International Chamber of Commerce, which outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for understanding shipping costs, risk transfer, and insurance coverage when importing waffle fry cutters. -

Lead Time

– This term refers to the time taken from placing an order to receiving the product. For businesses that rely on waffle fry cutters for daily operations, understanding lead times can help in planning and maintaining adequate inventory levels. -

Warranty Period

– The warranty period is the duration for which a manufacturer guarantees their product against defects. A longer warranty period can indicate confidence in product quality and provide peace of mind for B2B buyers, reducing the risk of unexpected costs associated with repairs or replacements.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when sourcing waffle fry cutters, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the waffle fry cutter Sector

What Are the Key Market Dynamics and Trends Influencing the Waffle Fry Cutter Sector?

The global waffle fry cutter market is experiencing robust growth, fueled by the rising popularity of waffle fries in various culinary sectors, including fast food, casual dining, and home cooking. The increasing consumer demand for unique food presentation and textures is driving restaurants and foodservice providers to invest in quality equipment. Additionally, the advent of technology in food preparation equipment, such as automation and improved cutting precision, is reshaping sourcing strategies. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide innovative and efficient cutting solutions to meet the evolving tastes of their customers.

Emerging trends in the sector include the rise of multifunctional kitchen equipment that combines various cutting techniques, including waffle cuts, into one device. This trend is particularly appealing to small and medium-sized enterprises (SMEs) that may have limited kitchen space. Furthermore, the integration of online platforms for sourcing and procurement is becoming prevalent, allowing buyers to compare products, read reviews, and access bulk purchasing options, especially in markets like Brazil and Vietnam. As global supply chains adapt to fluctuating consumer preferences, companies that can offer flexible, customizable solutions are likely to gain a competitive edge.

How Does Sustainability Impact Sourcing Decisions for Waffle Fry Cutters?

Sustainability is becoming a critical consideration for B2B buyers in the waffle fry cutter sector. As environmental concerns rise globally, buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, such as recycled metals and biodegradable plastics, in manufacturing waffle fry cutters. Additionally, companies are being scrutinized for their production processes, with an emphasis on reducing waste and energy consumption.

Ethical sourcing is also gaining traction, as buyers seek to ensure that their suppliers adhere to fair labor practices and responsible sourcing of raw materials. Certifications like ISO 14001 (Environmental Management) and Fair Trade can enhance a supplier’s appeal by showcasing their commitment to sustainable operations. In regions such as Europe and the Middle East, where consumers are more environmentally conscious, suppliers that align with these values will likely see increased demand from B2B buyers.

What Is the Historical Context of Waffle Fry Cutters and Their Market Evolution?

The waffle fry cutter has evolved significantly from its early iterations, which were primarily manual devices requiring considerable skill to operate. Historically, the demand for waffle fries surged in the 1980s with the rise of fast-food chains that introduced them as a novelty item, appealing to a broader audience seeking unique dining experiences. As culinary trends shifted towards more diverse and creative food options, the waffle fry cutter became a staple in both commercial kitchens and home cooking environments.

Over time, technological advancements have led to the development of more sophisticated cutting tools, including electric fry cutters and multifunctional devices that can produce various cuts. This evolution reflects a broader trend in the foodservice industry toward efficiency and versatility, aligning with the growing expectations of B2B buyers who seek both quality and functionality in their equipment. As the market continues to expand, the waffle fry cutter is positioned to remain a popular choice for those looking to enhance their culinary offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of waffle fry cutter

-

How do I choose the right waffle fry cutter for my business?

Selecting the right waffle fry cutter involves assessing your specific needs, including volume, type of potatoes, and desired fry thickness. Consider whether you need a manual or electric model based on your production capacity. Look for features such as adjustable cutting thickness, ease of cleaning, and durability of materials, especially if you plan to use it frequently. Reading reviews and seeking recommendations from other business owners in your sector can also provide valuable insights into the best options available. -

What is the best material for a waffle fry cutter?

The best waffle fry cutters are typically made from high-quality stainless steel, which offers durability, resistance to corrosion, and ease of maintenance. Plastic components should be BPA-free and designed for heavy-duty use if present. Look for cutters with sharp, replaceable blades to ensure consistent cutting quality. When sourcing from suppliers, inquire about material specifications to ensure they meet health and safety standards relevant to your market. -

What are the typical minimum order quantities (MOQs) for waffle fry cutters?

Minimum order quantities can vary significantly between suppliers, depending on the type of cutter and their production capabilities. Generally, you might expect MOQs to range from 50 to 100 units for standard models. For customized designs or specific features, MOQs may be higher. Always confirm with the supplier before placing an order to ensure you can meet their requirements and align with your inventory needs. -

What payment terms should I expect when purchasing waffle fry cutters internationally?

Payment terms can vary based on the supplier’s policies and your negotiation. Common terms include a deposit (often 30-50%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or other financing options for larger orders. It is crucial to establish clear terms before finalizing your order, including currency, payment method, and any potential fees associated with international transactions. -

How can I ensure the quality of waffle fry cutters before purchase?

To ensure quality, request samples or prototypes from suppliers before placing a large order. Conduct thorough research on the supplier’s reputation, including reviews and testimonials from previous customers. Additionally, inquire about their quality assurance processes, certifications, and compliance with international safety standards. If possible, visit their manufacturing facility to observe their production methods and quality control measures firsthand. -

What are common logistics considerations when importing waffle fry cutters?

When importing waffle fry cutters, consider shipping methods, costs, and delivery times. Air freight is faster but more expensive than sea freight, which may be more suitable for bulk orders. Ensure that your supplier can provide necessary shipping documentation and that you understand customs regulations in your country to avoid delays. It’s also wise to have a reliable freight forwarder to help navigate the logistics process effectively. -

Can I customize the design or features of a waffle fry cutter?

Many manufacturers offer customization options for waffle fry cutters, including blade thickness, size, and branding elements. Customization often requires a higher MOQ and may involve additional costs, so it’s essential to discuss your specific needs with potential suppliers early in the negotiation process. Ensure that you clearly communicate your requirements and obtain a detailed quote that outlines the customization capabilities. -

What are the best practices for maintaining waffle fry cutters?

To extend the life of your waffle fry cutter, regularly clean it after each use to prevent food residue buildup, which can lead to corrosion or dull blades. Follow the manufacturer’s recommendations for cleaning and maintenance, which may include oiling moving parts or replacing blades periodically. Store the cutter in a dry place to avoid moisture damage, and conduct routine inspections to ensure all components are functioning correctly before each use.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Waffle Fry Cutter Manufacturers & Suppliers List

1. Waffle Fry Cutter – Heavy-Duty Metal Design

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Waffle fry cutter designed for thick waffle fries, similar to those from Chick-fil-A. The user mentions that most waffle fry cutters have shallow ridges, resulting in more of a waffle chip than a fry. They express a preference for a heavy-duty metal cutter over plastic options, referencing a specific product on Amazon.

2. Target – Waffle Fry Cutters

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Waffle Fry Cutters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Borner – Wave-Waffle Cutter XXL

Domain: smokingmeatforums.com

Registered: 2005 (20 years)

Introduction: Borner Wave-Waffle Cutter XXL Powerline is recommended for making Waffle Fries. It is currently out of stock. Users mention that there are various Mandolines available, but few specifically cater to waffle cuts. One user has a cubing Mandoline from PL8 but notes it does not cut Waffle fries. Another user mentions that the thickness can be adjusted on their Mandoline, with a maximum thickness of ab…

4. Instructables – Waffle Fries Recipe

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Waffle Fries Recipe: Ingredients: 4 large russet potatoes, optional cajun seasoning. Materials: crinkle cutter, pot (or deep fryer), frying basket, food thermometer. Cooking Instructions: 1. Cut potatoes using crinkle cutter. 2. Heat oil to 375 degrees. 3. Fry potatoes for about 5 minutes until golden brown. 4. Cool on paper towels and add seasoning if desired. 5. Serve with ketchup or preferred d…

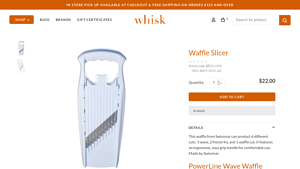

5. Swissmar – Waffle Slicer

Domain: whisknyc.com

Registered: 2008 (17 years)

Introduction: Waffle Slicer by Swissmar

– Article code: BED11393

– SKU: dkb-V-2052

– Price: $22.00

– In stock: Yes

– Features:

– Produces 6 different cuts: 3 wave, 2 French fry, and 1 waffle cut

– Ergonomic, easy-grip handle for comfortable use

– Easy “click” system for changing the position of the insert

– Safety position locks insert and shields the wave blade

– Side rails for using the original Bo…

Strategic Sourcing Conclusion and Outlook for waffle fry cutter

As the demand for waffle fries continues to rise across various global markets, the strategic sourcing of waffle fry cutters becomes increasingly vital for B2B buyers. By prioritizing quality, functionality, and supplier reliability, businesses can ensure they meet customer expectations while optimizing operational efficiency. Key considerations include evaluating the durability of materials, the versatility of cutting options, and the availability of replacement parts, which are essential for maintaining productivity in high-volume settings.

Investing in the right waffle fry cutter not only enhances menu offerings but also supports sustainability by minimizing food waste through precise cutting. Furthermore, fostering strong relationships with suppliers can lead to better pricing and exclusive access to innovative cutting technologies.

Looking ahead, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe should seize the opportunity to enhance their culinary capabilities. By leveraging strategic sourcing practices, businesses can position themselves competitively in the market. Now is the time to explore partnerships with trusted suppliers and invest in equipment that will elevate your offerings and drive growth. Embrace the trend and ensure your business is equipped to meet the growing demands of waffle fry enthusiasts.