Rear Side Window Cover Trim Panel 2006 Hummer H3: The Ultimate B2B Sourcing Guide for…

Introduction: Navigating the Global Market for rear side window cover trim panel 2006 hummer h3

In the ever-evolving global automotive parts market, sourcing high-quality rear side window cover trim panels for the 2006 Hummer H3 can pose significant challenges for B2B buyers. The need for durable, aesthetically pleasing, and well-fitting accessories is paramount, especially as businesses strive to enhance vehicle performance and appearance while ensuring customer satisfaction. This comprehensive guide addresses these challenges by exploring various types of rear side window cover trim panels, their applications, and the critical aspects of supplier vetting that international buyers must consider.

Within this resource, B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—will find actionable insights into assessing product quality, understanding market pricing, and identifying reliable suppliers. We delve into the materials and features that distinguish premium trim panels, such as those made from high-quality aluminum alloy, which provide effective protection against scratches and environmental wear.

Additionally, this guide offers a thorough analysis of the installation processes and maintenance requirements, ensuring that buyers are well-equipped to make informed decisions. By providing a clear framework for evaluating options and suppliers, this guide empowers businesses to streamline their purchasing processes, enhance their product offerings, and ultimately drive customer loyalty in a competitive marketplace.

Understanding rear side window cover trim panel 2006 hummer h3 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Alloy Honeycomb Panel | Made from durable aluminum alloy; honeycomb design for aesthetics | Automotive accessory retailers, car customizers | Pros: Lightweight, stylish, easy installation. Cons: Higher price point compared to plastic alternatives. |

| UV-Resistant Vinyl Cover | Vinyl material with UV protection; available in multiple colors | Automotive aftermarket suppliers | Pros: Affordable, effective UV protection. Cons: May not be as durable as metal options. |

| Custom-Fit Fabric Cover | Tailored fabric options; often includes insulation properties | Upholstery shops, vehicle customization firms | Pros: Customizable, provides insulation. Cons: Can be harder to clean and maintain. |

| Self-Adhesive Plastic Trim | Easy-to-apply adhesive backing; lightweight plastic material | Car accessory distributors, online retailers | Pros: Quick installation, low cost. Cons: Less durable than metal or high-quality vinyl. |

| OEM Replacement Trim Panel | Original Equipment Manufacturer (OEM) quality; exact fit | Dealerships, OEM parts suppliers | Pros: Guaranteed compatibility, high quality. Cons: Typically more expensive than aftermarket options. |

What Are the Characteristics of the Aluminum Alloy Honeycomb Panel?

The Aluminum Alloy Honeycomb Panel is specifically designed for the Hummer H3, providing a modern aesthetic and robust protection. Its honeycomb structure not only enhances its visual appeal but also contributes to its lightweight nature, making it an ideal choice for automotive accessory retailers and car customizers looking to offer stylish yet functional products. B2B buyers should consider the installation ease and durability, despite the higher price point compared to plastic alternatives.

How Does the UV-Resistant Vinyl Cover Benefit Buyers?

This type of cover is composed of vinyl that offers UV protection, making it suitable for regions with high sun exposure. Available in a range of colors, it allows businesses to cater to diverse customer preferences. Automotive aftermarket suppliers benefit from the affordability and effective sun protection this product provides. However, buyers should note that while it is cost-effective, it may not match the durability of metal options over time.

What Makes the Custom-Fit Fabric Cover Unique?

The Custom-Fit Fabric Cover stands out due to its tailored design and insulation properties, making it an excellent choice for upholstery shops and vehicle customization firms. This option allows for a high degree of customization, appealing to consumers looking for personalized solutions. However, B2B buyers must consider the maintenance challenges, as fabric can be more difficult to clean compared to other materials.

Why Choose the Self-Adhesive Plastic Trim?

Self-Adhesive Plastic Trim is designed for quick and hassle-free installation, making it a popular choice among car accessory distributors and online retailers. Its lightweight nature and low cost make it an attractive option for budget-conscious consumers. However, B2B buyers should be aware that this type may not offer the same level of durability as metal or high-quality vinyl, potentially leading to more frequent replacements.

What Are the Advantages of OEM Replacement Trim Panels?

OEM Replacement Trim Panels ensure a perfect fit and high quality, making them the go-to choice for dealerships and OEM parts suppliers. They provide peace of mind to buyers, knowing they are purchasing a product designed specifically for their vehicle model. While the reliability and compatibility are significant advantages, buyers should be prepared for a higher price point compared to aftermarket options, which can be a critical consideration for budget-sensitive businesses.

Key Industrial Applications of rear side window cover trim panel 2006 hummer h3

| Industry/Sector | Specific Application of rear side window cover trim panel 2006 hummer h3 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Customization and aesthetic enhancement of Hummer H3 vehicles | Enhances vehicle appeal, potentially increasing sales | Quality materials, compatibility with various models, pricing |

| Fleet Management | Replacement for damaged or worn-out window trim panels | Reduces maintenance costs and improves vehicle longevity | Bulk purchasing options, quick delivery times, warranty terms |

| Vehicle Restoration | Retrofits for classic Hummer H3 restorations | Preserves vehicle value and authenticity | Sourcing from reputable suppliers, ensuring fitment accuracy |

| Export and Trade | Shipping of trim panels for international markets | Expands product offerings and meets diverse market needs | Compliance with international shipping regulations, tariffs |

| Automotive Accessories Retail | Retailing as part of aftermarket accessories for Hummer enthusiasts | Increases revenue through accessory sales | Marketing strategies targeting specific demographics, inventory management |

How is the Rear Side Window Cover Trim Panel Used in Automotive Manufacturing?

In the automotive manufacturing sector, the rear side window cover trim panel for the 2006 Hummer H3 serves as a crucial component for customization and aesthetic enhancement. Manufacturers can utilize these panels to elevate the visual appeal of vehicles, making them more attractive to consumers. This is particularly valuable in markets like Europe and South America, where vehicle aesthetics play a significant role in purchase decisions. Buyers in this sector must consider the quality of materials and compatibility with various models to ensure a seamless integration into their production lines.

What Role Does the Rear Side Window Cover Trim Panel Play in Fleet Management?

For fleet management companies, the rear side window cover trim panel is vital for replacing damaged or worn-out components in Hummer H3 vehicles. By ensuring that all vehicles in a fleet maintain a consistent appearance and functionality, companies can reduce maintenance costs and enhance the longevity of their assets. International buyers must focus on bulk purchasing options and quick delivery times, as fleet operations often require swift turnaround to minimize downtime.

How is the Rear Side Window Cover Trim Panel Essential for Vehicle Restoration?

In the vehicle restoration industry, especially for classic models like the Hummer H3, the rear side window cover trim panel is essential for retrofitting and preserving the vehicle’s original charm. This application not only maintains the aesthetic integrity of the vehicle but also contributes to its overall value. Buyers in this sector should prioritize sourcing from reputable suppliers who can guarantee fitment accuracy and high-quality materials to ensure the restoration meets industry standards.

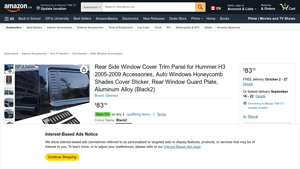

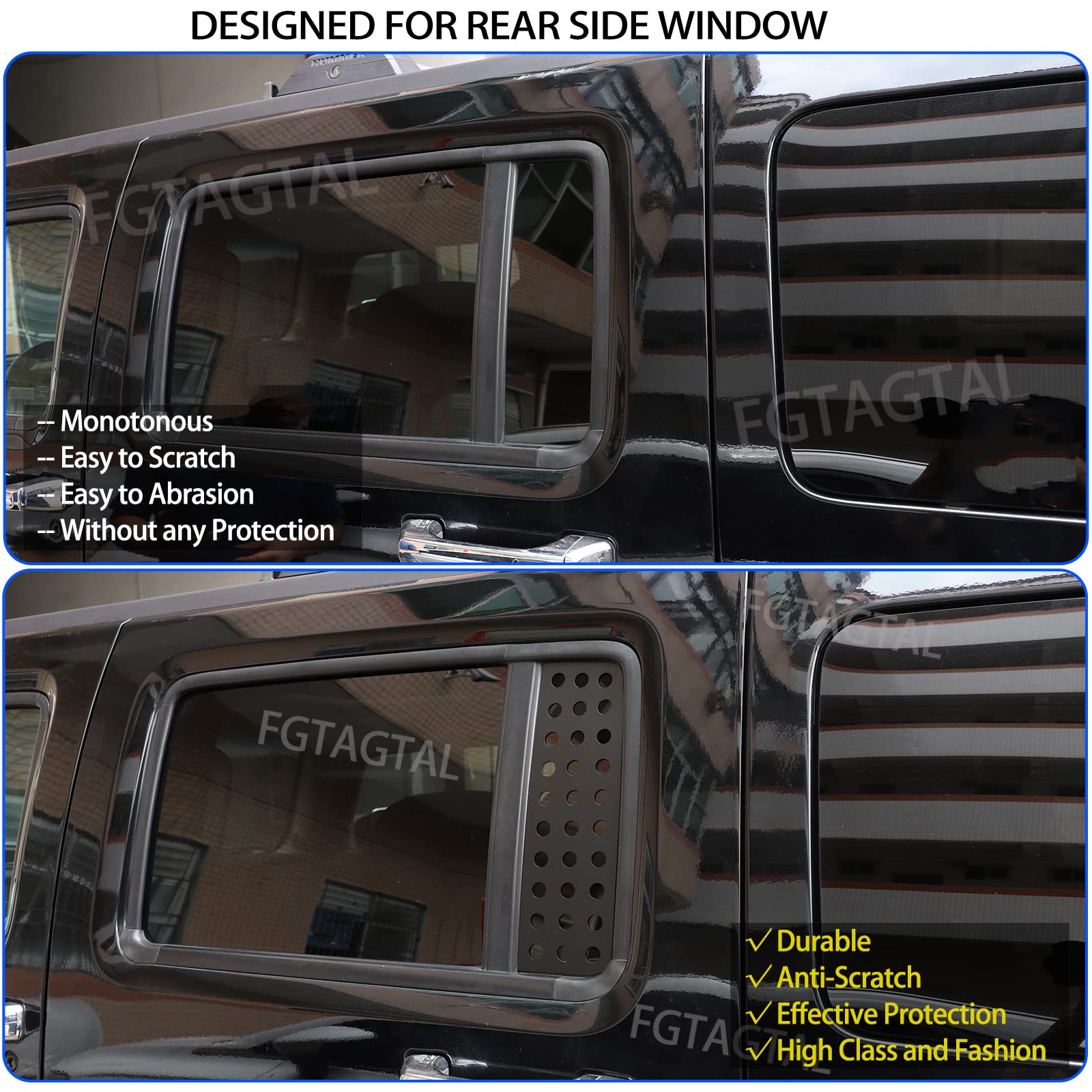

Illustrative image related to rear side window cover trim panel 2006 hummer h3

Why is the Rear Side Window Cover Trim Panel Important for Export and Trade?

The export and trade sector benefits significantly from the availability of rear side window cover trim panels, as they can be shipped to various international markets. This expands product offerings and meets the diverse needs of customers across regions such as Africa and the Middle East. Buyers must be aware of compliance with international shipping regulations and tariffs to ensure a smooth transaction and delivery process.

How Does the Rear Side Window Cover Trim Panel Enhance Automotive Accessories Retail?

In the automotive accessories retail space, the rear side window cover trim panel is a popular item among Hummer enthusiasts looking to personalize their vehicles. Retailers can increase revenue through accessory sales by offering these trim panels as part of a broader product range. Marketing strategies targeting specific demographics, along with effective inventory management, are crucial for retailers aiming to capitalize on this niche market.

3 Common User Pain Points for ‘rear side window cover trim panel 2006 hummer h3’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Sourcing Rear Side Window Cover Trim Panels

The Problem:

B2B buyers often face the challenge of ensuring that the rear side window cover trim panels for the 2006 Hummer H3 meet high-quality standards. This is especially critical for international buyers who need to navigate different manufacturing regulations and quality assurance practices across regions such as Africa, South America, and Europe. A poor-quality product can lead to increased return rates, customer dissatisfaction, and potential damage to the brand’s reputation. Buyers may find it difficult to assess the quality of materials, such as aluminum alloy, and the craftsmanship from suppliers who may not provide sufficient product specifications or guarantees.

The Solution:

To mitigate quality assurance challenges, B2B buyers should prioritize sourcing from reputable manufacturers that provide comprehensive product specifications, material certifications, and quality control measures. Conducting background checks on potential suppliers, including reviewing their manufacturing processes and past customer feedback, can also be beneficial. Requesting samples before committing to bulk orders allows buyers to physically inspect the product quality and ensure it meets the necessary standards. Additionally, utilizing third-party quality assurance services to perform audits or inspections can further enhance confidence in the sourcing process. Buyers should also leverage technology, such as digital platforms that aggregate supplier ratings and reviews, to make informed decisions.

Scenario 2: Installation Complications with Rear Side Window Cover Trim Panels

The Problem:

Another common pain point for B2B buyers is the complexity of installing the rear side window cover trim panels. Buyers may encounter issues with the self-adhesive backing not adhering properly to the window surface, leading to misalignment or premature peeling. This can be especially problematic for businesses that rely on quick turnaround times for vehicle modifications or repairs. Inadequate installation can result in additional labor costs and delays in completing customer orders, impacting overall operational efficiency.

The Solution:

To address installation complications, buyers should invest in detailed installation guides and resources provided by manufacturers. These guides should include step-by-step instructions, visual aids, and troubleshooting tips to ensure proper application. Training sessions or workshops for staff on best practices for installation can also be highly effective. Buyers should ensure that the installation area is clean and dry, following the manufacturer’s recommendations for surface preparation before applying the trim panel. Additionally, using high-quality adhesive products that are compatible with the rear side window cover trim can enhance durability and effectiveness. Implementing a standardized installation process can streamline operations and reduce errors.

Scenario 3: Limited Availability of Customization Options for Trim Panels

The Problem:

B2B buyers often struggle with limited options when it comes to customizing rear side window cover trim panels. Customization is crucial for businesses looking to offer unique vehicle enhancements that stand out in a competitive market. Buyers may find it challenging to locate suppliers that provide a variety of styles, colors, and finishes to match their specific branding or customer preferences. This lack of options can hinder the ability to meet diverse customer demands, resulting in lost sales opportunities.

The Solution:

To overcome limited customization options, buyers should actively seek out suppliers known for their flexibility and willingness to accommodate custom orders. Engaging in direct communication with manufacturers to discuss specific needs can lead to personalized solutions, such as custom colors or unique designs. Buyers may also explore partnerships with manufacturers that specialize in bespoke automotive accessories. Attending trade shows or industry events can help buyers network with innovative suppliers who can offer tailored products. Furthermore, leveraging digital design tools to visualize potential customizations before placing orders can enhance the decision-making process, ensuring that the final product aligns with buyer expectations and market trends.

Strategic Material Selection Guide for rear side window cover trim panel 2006 hummer h3

What are the Key Materials for the Rear Side Window Cover Trim Panel of the 2006 Hummer H3?

When selecting materials for the rear side window cover trim panel of the 2006 Hummer H3, several options are commonly considered. Each material offers distinct properties, advantages, and disadvantages that can influence the final product’s performance and suitability for international markets.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

How Does Aluminum Alloy Perform as a Material Choice?

Aluminum alloy is a popular choice for automotive trim panels due to its lightweight nature and excellent corrosion resistance. It typically exhibits good temperature stability, making it suitable for environments with varying climates. The primary advantages of aluminum alloy include its durability and aesthetic appeal, which enhances the vehicle’s overall appearance. However, it can be more expensive than some alternatives and may require specialized manufacturing techniques, increasing production complexity.

From a B2B perspective, international buyers should consider compliance with standards such as ASTM for material specifications. In regions like Europe and Germany, where automotive regulations are stringent, ensuring that aluminum components meet these standards is crucial for market entry.

What Role Does ABS Plastic Play in Trim Panel Manufacturing?

Acrylonitrile Butadiene Styrene (ABS) plastic is another common material for trim panels. It is favored for its impact resistance and ease of manufacturing, making it a cost-effective option. ABS can withstand moderate temperatures and is less prone to deformation compared to other plastics. The primary drawback is its lower resistance to UV radiation, which can lead to discoloration over time.

For international buyers, ABS plastic must meet specific compliance requirements, particularly in markets with strict environmental regulations. Buyers in Africa and South America may find ABS to be a more economical option, but they should also consider the long-term durability of the product in harsh climates.

Why Consider Composite Materials for the Trim Panel?

Composite materials, often a blend of plastics and other materials, offer unique advantages such as enhanced strength-to-weight ratios and improved thermal stability. These materials can be engineered to meet specific performance criteria, including resistance to chemicals and UV light. However, the manufacturing process can be complex and may lead to higher costs.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

International buyers should be aware of the varying standards for composites across different regions. For instance, compliance with JIS standards in Japan or DIN standards in Germany can impact marketability. Buyers should ensure that the composites used are suitable for their specific climate conditions, especially in regions with extreme weather.

How Does Polypropylene Compare for Automotive Applications?

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and lightweight properties. It is often used in automotive applications due to its durability and low cost. Polypropylene can withstand higher temperatures compared to other plastics, making it suitable for various automotive environments. However, it may not provide the same level of aesthetic appeal as aluminum or composites.

For B2B buyers, polypropylene’s affordability makes it an attractive option, particularly in emerging markets. However, they should consider its compatibility with the vehicle’s overall design and the potential need for additional treatments to enhance its UV resistance.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

Summary Table of Material Options

| Material | Typical Use Case for rear side window cover trim panel 2006 Hummer H3 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Rear side window cover trim panel | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | High |

| ABS Plastic | Interior trim and decorative elements | Cost-effective and easy to manufacture | Lower UV resistance leading to potential discoloration | Low |

| Composite Materials | High-performance trim applications | Enhanced strength and thermal stability | Complex manufacturing and higher costs | Medium |

| Polypropylene | General trim applications and interior components | Excellent chemical resistance and low cost | Less aesthetic appeal and potential UV limitations | Low |

In conclusion, selecting the right material for the rear side window cover trim panel of the 2006 Hummer H3 involves careful consideration of performance characteristics, manufacturing complexity, and compliance with international standards. By understanding the advantages and limitations of each material, B2B buyers can make informed decisions that align with their market needs and customer expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for rear side window cover trim panel 2006 hummer h3

What Are the Key Stages in the Manufacturing Process for the Rear Side Window Cover Trim Panel of the 2006 Hummer H3?

The manufacturing process of the rear side window cover trim panel for the 2006 Hummer H3 involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets the high standards expected in the automotive industry.

-

Material Preparation

The primary material used in the production of the rear side window cover trim panel is high-quality aluminum alloy. This material is chosen for its strength, durability, and resistance to corrosion. During the material preparation stage, raw aluminum sheets are sourced, inspected for quality, and cut to specific dimensions required for the trim panel. Suppliers often provide certification for the materials, confirming they meet industry standards. -

Forming Techniques

Forming is a crucial step where the cut aluminum sheets are shaped into the desired profile. Techniques such as stamping and bending are commonly used. Stamping involves pressing the aluminum sheets into molds to create precise shapes, while bending is used to form edges and contours. Advanced machinery equipped with CNC (Computer Numerical Control) technology ensures high accuracy and repeatability in forming processes. -

Assembly Process

After forming, the individual components of the trim panel are assembled. This may involve the integration of additional elements such as adhesive layers for easy installation and protective coatings. The assembly is typically done using automated systems or skilled labor to ensure consistency and quality. The use of self-adhesive 3M double-sided adhesive is a common practice, allowing for easy installation without damaging the vehicle’s original components. -

Finishing Touches

The finishing stage enhances the aesthetic appeal and functionality of the trim panel. This may include surface treatments like anodizing or powder coating, which provide additional protection and improve the visual quality of the product. Finishing processes are vital for ensuring that the trim panel can withstand environmental factors such as UV exposure, moisture, and temperature fluctuations.

How Is Quality Assurance Implemented in the Manufacturing of Rear Side Window Cover Trim Panels?

Quality assurance (QA) is critical in automotive manufacturing, where safety and performance are paramount. The QA process for the rear side window cover trim panel adheres to international standards like ISO 9001 and industry-specific regulations such as CE marking.

-

International Standards Compliance

ISO 9001 sets the framework for quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements. Compliance with such standards is often a prerequisite for B2B buyers, especially in regions like Europe, where stringent regulations govern automotive components. -

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each stage meets predefined standards. Key checkpoints include:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected to verify their quality before they enter the production line.

– In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to identify any deviations from specifications, allowing for immediate corrective actions.

– Final Quality Control (FQC): Once the assembly and finishing are complete, a final inspection ensures that the product meets all quality standards before shipping. -

Common Testing Methods Employed

Various testing methods are employed to ensure the durability and functionality of the trim panels. These may include:

– Dimensional Inspection: Ensures that the trim panel fits the vehicle specifications precisely.

– Adhesive Strength Tests: Evaluates the effectiveness of the adhesive used for installation.

– Environmental Testing: Simulates conditions such as UV exposure, temperature extremes, and humidity to assess the product’s longevity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability and compliance with local regulations. Here are several strategies to consider:

-

Supplier Audits

Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and adherence to international standards. During these audits, buyers can evaluate documentation, observe production practices, and interview quality assurance personnel. -

Requesting Quality Assurance Documentation

Buyers should request documentation such as quality control plans, inspection reports, and certifications. These documents provide insight into the supplier’s commitment to quality and their operational standards. -

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services can conduct pre-shipment inspections, ensuring that the products meet the agreed specifications before they are sent to the buyer. -

Understanding Regional Compliance Nuances

B2B buyers from diverse regions—such as Africa, South America, the Middle East, and Europe—must be aware of local regulations that may impact quality assurance. For example, compliance with CE marking is essential in Europe, while different standards may apply in other regions. Understanding these nuances helps buyers ensure that they are sourcing compliant products.

Conclusion

The manufacturing and quality assurance processes for the rear side window cover trim panel for the 2006 Hummer H3 are intricate and highly regulated. By understanding the key stages of manufacturing and the importance of quality control, B2B buyers can make informed decisions when sourcing these components. Verifying supplier practices through audits, documentation, and third-party inspections ensures that buyers receive high-quality products that meet their specific needs and comply with international standards. This diligence is particularly crucial for international buyers navigating the complexities of global supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rear side window cover trim panel 2006 hummer h3’

To effectively procure the rear side window cover trim panel for the 2006 Hummer H3, it’s essential to follow a structured approach. This guide provides a clear checklist to ensure that you make informed decisions throughout the sourcing process, maximizing value and ensuring quality.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is vital to ensure that the product meets your requirements. Consider factors such as material type (e.g., aluminum alloy), fit (specific to Hummer H3 models), and design features (like honeycomb texture). These details will guide your supplier discussions and help avoid misunderstandings.

Step 2: Research Market Prices

Conduct thorough market research to understand the typical price range for rear side window cover trim panels. Prices can vary based on material quality and supplier location, so gather quotes from multiple sources. This knowledge will empower you to negotiate effectively and avoid overpaying.

Step 3: Identify Reliable Suppliers

Finding trustworthy suppliers is crucial for a successful procurement process. Look for suppliers with a solid reputation in the automotive parts industry. Evaluate their track record by checking reviews, industry certifications, and their experience with similar products.

- Tip: Use platforms like Alibaba or industry-specific directories to find potential suppliers.

Step 4: Verify Product Quality Standards

Before finalizing any orders, ensure that the suppliers adhere to relevant quality standards. Request product samples or detailed specifications that demonstrate compliance with international quality norms. Understanding how the products are manufactured and tested will give you confidence in their durability and performance.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

Step 5: Check for Warranty and Support

Inquire about warranty terms and after-sales support for the window cover trim panel. A good warranty indicates the supplier’s confidence in their product quality. Additionally, reliable customer support can help resolve any post-purchase issues efficiently.

Step 6: Evaluate Shipping and Delivery Options

Assess the shipping methods offered by your suppliers to ensure they align with your timelines. Understand the logistics involved, including shipping costs, delivery times, and any potential customs duties if you’re importing. This information is crucial for maintaining your supply chain schedule.

Step 7: Establish Payment Terms

Finally, clarify payment terms before placing an order. Determine acceptable payment methods, deposit requirements, and payment schedules. Favorable payment terms can significantly improve your cash flow management and reduce financial risks.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing rear side window cover trim panels for the 2006 Hummer H3 more effectively, ensuring quality products while optimizing costs and supplier relationships.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

Comprehensive Cost and Pricing Analysis for rear side window cover trim panel 2006 hummer h3 Sourcing

What Are the Key Cost Components for Sourcing the Rear Side Window Cover Trim Panel for the 2006 Hummer H3?

When sourcing the rear side window cover trim panel for the 2006 Hummer H3, several cost components contribute to the overall pricing structure. Understanding these components is crucial for B2B buyers to make informed purchasing decisions.

-

Materials: The primary material for this trim panel is typically high-quality aluminum alloy, known for its durability and aesthetic appeal. The choice of materials significantly influences the cost, as premium materials can raise the price due to their enhanced properties, such as resistance to wear and corrosion.

-

Labor: Labor costs encompass the workforce required for manufacturing, which can vary based on the region and the complexity of the production process. For instance, regions with higher labor costs may see increased pricing, while manufacturers in countries with lower labor costs may offer more competitive pricing.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Manufacturers with efficient operations may have lower overheads, allowing them to pass savings onto buyers.

-

Tooling: Tooling costs refer to the investment in specialized equipment and molds required for production. Custom designs or modifications to the standard trim panel can elevate tooling costs, impacting the final pricing.

-

Quality Control (QC): Ensuring that each trim panel meets quality standards involves additional costs for inspection and testing. Buyers should prioritize suppliers with robust QC processes, as this can prevent future costs associated with defects or failures.

-

Logistics: Transportation and shipping costs can vary widely depending on the origin and destination of the product. Factors such as distance, shipping method, and logistics partners play a vital role in determining the final price.

-

Margin: Suppliers will include a profit margin in their pricing structure, which can vary significantly based on market conditions, competition, and the perceived value of the product.

How Do Price Influencers Affect the Cost of the Trim Panel?

Several price influencers can impact the cost of sourcing the rear side window cover trim panel:

-

Volume/MOQ: The minimum order quantity (MOQ) can affect pricing. Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing based on their inventory needs.

-

Specifications/Customization: Custom specifications or features can lead to higher costs. Buyers should clearly outline their requirements to suppliers to avoid unexpected charges.

-

Quality and Certifications: Suppliers that provide certified products (e.g., ISO, CE) may charge more due to the assurance of quality. However, investing in certified products can lead to lower Total Cost of Ownership (TCO) over time.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may have higher prices due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is essential for international buyers, as they define the responsibilities of buyers and sellers in shipping. Choosing favorable terms can lead to significant cost savings.

What Tips Can Help Buyers Optimize Costs When Sourcing This Product?

-

Negotiate Terms: Engage in negotiations with suppliers to achieve better pricing or terms, especially when ordering larger quantities. Highlighting potential long-term partnerships can incentivize suppliers to offer discounts.

-

Focus on Total Cost of Ownership (TCO): Assess the total cost, including initial purchase price, shipping, and potential maintenance costs. A lower initial price may not always equate to better value.

-

Leverage Local Knowledge: Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage local market knowledge and relationships to find competitive suppliers.

-

Consider Alternative Materials: If budget constraints are a concern, explore alternatives to aluminum that still meet quality standards but may offer cost savings.

-

Stay Informed About Market Trends: Regularly monitoring market trends can help buyers anticipate price fluctuations and adjust their purchasing strategies accordingly.

Conclusion

Sourcing the rear side window cover trim panel for the 2006 Hummer H3 involves a detailed understanding of the cost structure and pricing dynamics. By analyzing the various components and influencers, international B2B buyers can make strategic decisions that enhance their purchasing power while ensuring product quality.

Alternatives Analysis: Comparing rear side window cover trim panel 2006 hummer h3 With Other Solutions

Introduction: Why Consider Alternatives for Rear Side Window Cover Trim Panels?

When it comes to enhancing the aesthetics and functionality of a vehicle’s interior, particularly for the Hummer H3, the rear side window cover trim panel serves as a crucial component. However, buyers should evaluate alternative solutions that can offer similar benefits in terms of protection, style, and ease of use. This analysis compares the rear side window cover trim panel for the 2006 Hummer H3 against two viable alternatives: custom window tinting and removable window shades. Each option has distinct advantages and drawbacks that can significantly impact the decision-making process for B2B buyers.

Comparison Table

| Comparison Aspect | Rear Side Window Cover Trim Panel 2006 Hummer H3 | Custom Window Tinting | Removable Window Shades |

|---|---|---|---|

| Performance | High-quality aluminum for durability | Excellent UV protection | Moderate UV protection |

| Cost | Approximately $83.78 | $100 – $300 (varies by service) | $20 – $60 per set |

| Ease of Implementation | Easy installation with self-adhesive backing | Requires professional installation | Simple DIY installation |

| Maintenance | Low maintenance; wipe clean | Requires occasional cleaning | Washable and reusable |

| Best Use Case | Permanent, stylish upgrade for Hummer H3 | Long-term UV protection and privacy | Flexible use for privacy and sun protection |

Detailed Breakdown of Alternatives

Custom Window Tinting

Custom window tinting involves applying a film to the windows of the vehicle, providing excellent UV protection and heat rejection. This solution is ideal for buyers looking for a more permanent solution that enhances privacy and minimizes sun exposure. However, the installation requires professional expertise, which can increase initial costs significantly, ranging from $100 to $300 depending on the complexity and quality of the film used. While the maintenance is minimal, the film may require occasional cleaning and can be susceptible to peeling over time.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

Removable Window Shades

Removable window shades present a cost-effective and flexible alternative for vehicle owners. Priced between $20 to $60 per set, these shades can be easily installed and removed as needed, offering versatility for varying conditions. They provide moderate UV protection and can enhance privacy temporarily. However, they may not offer the same level of durability and aesthetic appeal as the rear side window cover trim panel. Additionally, while they are washable and reusable, their effectiveness can diminish with frequent use, leading to potential replacement needs.

Conclusion: How to Choose the Right Solution for Your Needs

Choosing the right solution for enhancing the rear side window of a Hummer H3 involves assessing specific needs and preferences. For B2B buyers, the rear side window cover trim panel is a robust option that provides durability and style, making it suitable for long-term use. In contrast, custom window tinting offers superior UV protection but at a higher cost and with more complex installation. Removable window shades are a budget-friendly option that provides flexibility but may lack longevity. Ultimately, buyers should consider factors such as performance requirements, budget constraints, and the desired permanence of the solution to make an informed decision.

Essential Technical Properties and Trade Terminology for rear side window cover trim panel 2006 hummer h3

What Are the Key Technical Properties of the Rear Side Window Cover Trim Panel for the 2006 Hummer H3?

When sourcing the rear side window cover trim panel for the 2006 Hummer H3, understanding its technical specifications is essential for making informed purchasing decisions. Here are some critical properties to consider:

-

Material Composition

The rear side window cover trim panel is primarily constructed from high-quality aluminum alloy. This material is favored for its durability, lightweight nature, and resistance to corrosion, making it ideal for automotive applications. Buyers should prioritize panels made from aluminum alloy to ensure longevity and performance under various environmental conditions. -

Fit Type

A vehicle-specific fit is crucial for optimal installation and functionality. The trim panel for the Hummer H3 is designed to match the original factory specifications, ensuring that it integrates seamlessly with the vehicle’s design. A precise fit minimizes installation time and reduces the risk of damage to the vehicle during the application. -

Surface Finish

The surface finish of the trim panel, often presented in a matte or glossy black, not only enhances aesthetic appeal but also provides additional protection against scratches and UV damage. The right finish can help maintain the vehicle’s appearance and resale value, making it an important consideration for B2B buyers. -

Adhesive Type

Many rear side window cover trim panels come with self-adhesive backing, typically utilizing high-strength 3M double-sided tape. This feature simplifies installation, allowing for a clean application without the need for tools or professional assistance. The choice of adhesive is critical for ensuring that the panel remains securely attached over time, especially in varied climates. -

Weight

The weight of the trim panel, usually around 220 grams, is a factor that influences shipping costs and handling. Lighter panels can reduce overall shipping expenses, an important consideration for international buyers looking to optimize logistics.

Which Trade Terms Are Relevant for Purchasing the Rear Side Window Cover Trim Panel?

Understanding trade terminology is essential for navigating the procurement process effectively. Here are several key terms relevant to the purchase of the rear side window cover trim panel:

-

OEM (Original Equipment Manufacturer)

OEM parts are components made by the vehicle’s original manufacturer. Purchasing OEM trim panels ensures compatibility and quality, which can be critical for maintaining the vehicle’s integrity and performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. B2B buyers should be aware of MOQs, as they can affect inventory management and cash flow. Understanding this term helps in negotiating better deals with suppliers. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. This process is essential for comparing offers and ensuring competitive pricing, especially for bulk orders. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps in clarifying who is responsible for shipping, insurance, and tariffs, thereby minimizing risks associated with international trade. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is received. Awareness of lead times is vital for planning inventory levels and ensuring timely delivery to customers. -

Warranty Period

The warranty period is the duration for which the product is guaranteed against defects. A longer warranty may indicate higher quality and can provide peace of mind for B2B buyers, ensuring that they are covered in case of any manufacturing defects.

By grasping these technical specifications and trade terminologies, B2B buyers can make more informed decisions when sourcing the rear side window cover trim panel for the 2006 Hummer H3, ensuring both quality and value in their purchases.

Navigating Market Dynamics and Sourcing Trends in the rear side window cover trim panel 2006 hummer h3 Sector

What Are the Key Market Dynamics and Trends Influencing the Rear Side Window Cover Trim Panel for the 2006 Hummer H3?

The market for rear side window cover trim panels, particularly for the 2006 Hummer H3, is shaped by several global drivers and emerging trends. The automotive industry is witnessing a shift towards customization and personalization, with buyers increasingly seeking unique accessories that enhance both aesthetics and functionality. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where local buyers are keen on products that reflect their style and cater to specific climatic conditions, like sun protection and UV resistance.

Technological advancements in manufacturing processes, such as the use of high-quality materials like aluminum alloys, have led to improved product durability and performance. Additionally, the rise of e-commerce platforms is transforming sourcing dynamics, allowing international buyers to access a wider array of products and suppliers. This shift is fostering a more competitive market, as businesses strive to differentiate their offerings through superior quality, innovative designs, and robust customer service.

Moreover, the increasing focus on sustainability is compelling manufacturers to adopt eco-friendly practices in production and sourcing. As a result, buyers are now more inclined to partner with suppliers who demonstrate a commitment to ethical sourcing and environmental responsibility, particularly in regions where these values resonate strongly with consumers.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

How Is Sustainability and Ethical Sourcing Impacting the Rear Side Window Cover Trim Panel Market?

Sustainability has become a critical factor in the sourcing strategies of B2B buyers in the automotive accessory market. The environmental impact of production processes is under scrutiny, and companies are increasingly held accountable for their supply chain practices. For the rear side window cover trim panel for the 2006 Hummer H3, this translates into a growing demand for products that utilize sustainable materials and production techniques.

Buyers are now seeking suppliers who provide transparency regarding their sourcing practices, particularly in relation to material origins and manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and the use of recycled or recyclable materials are becoming essential criteria in supplier selection. Suppliers that demonstrate adherence to these standards not only mitigate environmental impact but also appeal to a growing segment of environmentally-conscious consumers.

Furthermore, engaging in ethical sourcing practices can enhance brand reputation and customer loyalty, particularly in markets where consumers prioritize sustainability. This trend is particularly relevant in Europe and parts of the Middle East, where regulatory frameworks and consumer expectations around environmental responsibility are becoming increasingly stringent.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

What Is the Historical Context of the Rear Side Window Cover Trim Panel Market?

The rear side window cover trim panel for vehicles like the 2006 Hummer H3 has evolved significantly over the years. Initially, automotive accessories were primarily functional, focusing on basic protection and durability. However, as consumer preferences shifted towards personalization and enhanced vehicle aesthetics, manufacturers began to innovate.

The introduction of materials such as aluminum alloys marked a turning point, offering superior durability and a modern appearance compared to traditional materials. This evolution coincided with broader trends in the automotive industry, where customization options expanded to meet diverse consumer needs. Today, the market is characterized by a blend of functionality, style, and sustainability, reflecting the changing landscape of consumer expectations and technological advancements.

As B2B buyers navigate this dynamic market, understanding these historical trends is essential for making informed sourcing decisions that align with both current demands and future market directions.

Illustrative image related to rear side window cover trim panel 2006 hummer h3

Frequently Asked Questions (FAQs) for B2B Buyers of rear side window cover trim panel 2006 hummer h3

-

1. How do I ensure the rear side window cover trim panel fits my Hummer H3?

To guarantee compatibility, always check the vehicle specifications before purchasing. The rear side window cover trim panel for the Hummer H3 is designed specifically for model years 2005-2009. Verify the vehicle’s model and production year against the supplier’s product details. It’s also advisable to request detailed measurements from the supplier to confirm a perfect fit, especially if sourcing internationally. -

2. What materials are typically used for rear side window cover trim panels?

The most common material for rear side window cover trim panels is high-quality aluminum alloy. This material is favored for its durability, resistance to wear and tear, and ability to withstand various environmental conditions. When sourcing, inquire about the material specifications to ensure that it meets your quality standards and provides the necessary protection for the vehicle. -

3. What are the standard payment terms for purchasing automotive accessories internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payment, a deposit followed by balance upon shipping, or net 30/60 terms. Always clarify payment methods accepted (e.g., wire transfer, PayPal) and any additional fees that may apply. Establishing clear payment terms can help mitigate risks and ensure smooth transactions. -

4. How can I vet suppliers for rear side window cover trim panels?

To effectively vet suppliers, research their reputation through online reviews and ratings. Request references from previous clients and verify their business licenses and certifications. Additionally, consider visiting their manufacturing facilities if possible, or request detailed product samples to assess quality. Engaging in direct communication can also provide insights into their reliability and customer service. -

5. What is the minimum order quantity (MOQ) for rear side window cover trim panels?

MOQs can vary significantly based on the supplier and the specific product. Generally, for automotive parts, MOQs can range from 50 to 200 units. Always discuss your needs with the supplier to see if they can accommodate smaller orders, especially if you are testing the market or starting a new product line. -

6. What quality assurance measures should I expect from suppliers?

Reputable suppliers typically implement strict quality assurance (QA) protocols, including material inspections, production monitoring, and final product testing. Inquire about their QA processes and certifications (e.g., ISO standards) to ensure they adhere to industry best practices. Request documentation of testing procedures and results to ensure that the products meet your quality expectations. -

7. How do I handle logistics and shipping for international orders?

When sourcing internationally, consider the shipping method (air, sea, or courier) based on cost, urgency, and the nature of the products. Discuss logistics with the supplier and determine who will handle shipping arrangements, customs clearance, and duties. Utilize freight forwarders or logistics companies experienced in international shipping to streamline the process and mitigate potential issues. -

8. Can I customize the rear side window cover trim panels for my business?

Many suppliers offer customization options, such as branding, specific color finishes, or unique designs. Discuss your requirements with potential suppliers and ask about their capabilities for customization. Be aware that custom orders may have higher MOQs and longer lead times, so plan accordingly to ensure timely delivery for your business needs.

Top 5 Rear Side Window Cover Trim Panel 2006 Hummer H3 Manufacturers & Suppliers List

1. Hummer – Alloy Rear Side Window Glass Cover Trim 2PCS

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Alloy Rear Side Window Glass Cover Trim 2PCS for Hummer H3 2005-09 (Left & Right) – Condition: New – Price: $65.99 each or Best Offer – Free shipping – Estimated delivery: Fri, Sep 12 – Tue, Sep 16 – Bulk savings available for multiple purchases.

2. Hummer – Rear Side Window Cover Trim Panel

Domain: amazon.ca

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Rear Side Window Cover Trim Panel for Hummer H3 2005-2009 Accessories”, “Features”: {“Material”: “Aluminum Alloy”, “Color”: “Black2”, “Fit Type”: “Vehicle Specific Fit”, “Applicable Models”: “Hummer H3 2005, 2006, 2007, 2008, 2009”, “Installation”: “Self-adhesive 3M double-sided adhesive, easy installation without removing original accessories”, “Protection”: “Prevents scratches,…

3. JSJ – Rear Window Glass Panel Cover Decal

Domain: importacionesjsj.com

Registered: 2012 (13 years)

Introduction: Window Glass Panel Cover Decal for Car Rear Window; Trim type: d-1061488; specific design for rear window glass panel; enhances appearance and protection; easy to install; durable material; suitable for various car models.

4. PIUGILH – D-Pillar Trim Cover for Hummer H3

Domain: alshallalchannel.com

Registered: 2021 (4 years)

Introduction: {“product_name”:”PIUGILH D-Pillar Trim Cover”,”fit_for”:”Hummer H3 2005-2009″,”type”:”Rear Window Side D-Pillar Trim Frame Guard Cover Decoration”,”color”:”Piano Black”}

5. Hummer – RH Rear Quarter Panel Trim

Domain: factoryoemparts.com

Registered: 2010 (15 years)

Introduction: This company, Hummer – RH Rear Quarter Panel Trim, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for rear side window cover trim panel 2006 hummer h3

How Can Strategic Sourcing Enhance Your Procurement of Rear Side Window Cover Trim Panels?

In summary, the strategic sourcing of rear side window cover trim panels for the 2006 Hummer H3 can significantly enhance operational efficiency and cost-effectiveness for international buyers. By prioritizing quality materials, such as high-grade aluminum alloy, and ensuring compatibility with specific vehicle models, businesses can mitigate risks associated with inferior products. Additionally, leveraging features like easy installation and aesthetic appeal not only improves customer satisfaction but also opens avenues for upselling and cross-selling.

Understanding market dynamics and supplier capabilities is crucial. Engaging with reliable manufacturers and suppliers ensures access to innovative designs and timely delivery, which are vital in meeting market demands. As the automotive accessory market continues to evolve, staying ahead of trends through strategic sourcing will empower businesses to capture new opportunities across diverse regions including Africa, South America, the Middle East, and Europe.

Looking ahead, international B2B buyers are encouraged to establish partnerships with trusted suppliers who align with their quality standards and logistical needs. By embracing a proactive sourcing strategy, companies can enhance their competitive edge and drive sustainable growth in the automotive accessories market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.