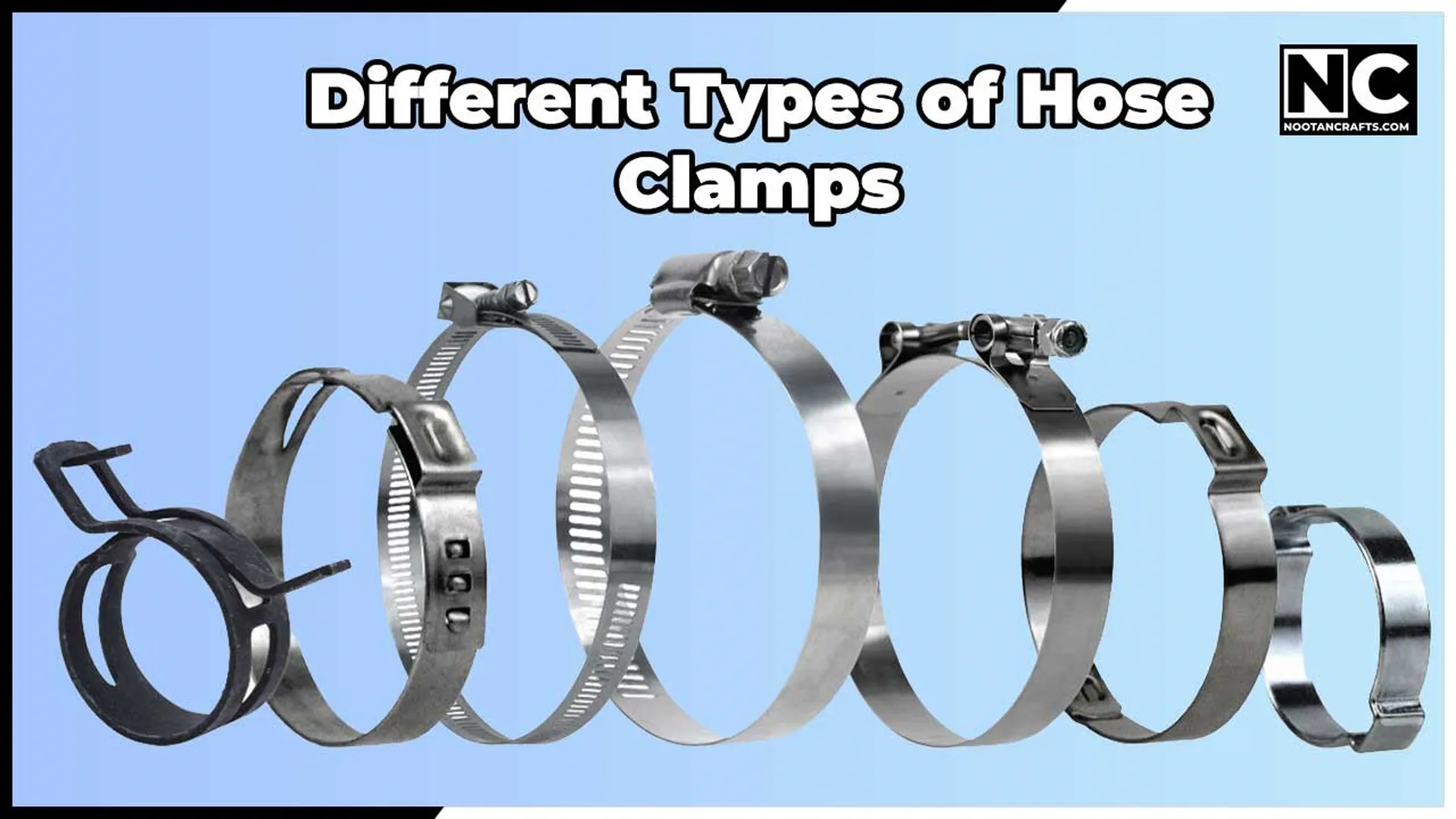

Is Your Different Types Of Hose Clamps Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for different types of hose clamps

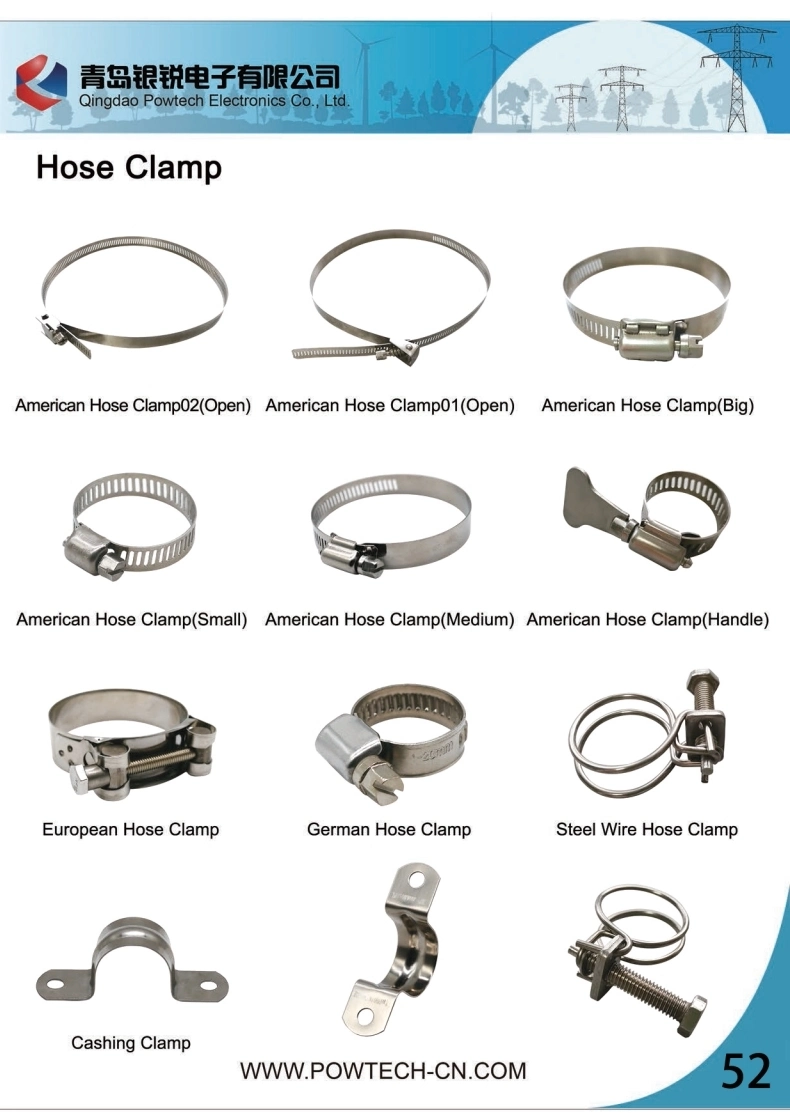

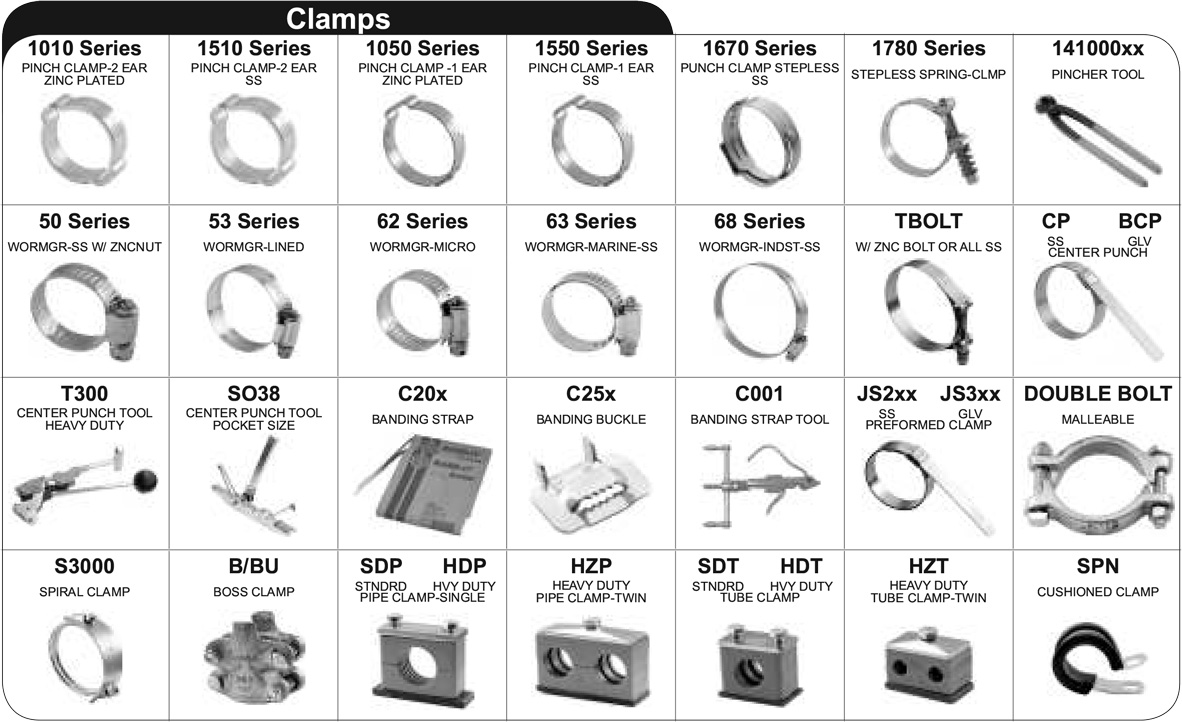

In the ever-evolving landscape of industrial procurement, sourcing the right hose clamps can pose significant challenges for B2B buyers globally. Whether you’re in Africa, South America, the Middle East, or Europe, the need for reliable and effective hose clamps to ensure secure connections in various applications is paramount. This comprehensive guide delves into the diverse types of hose clamps available in the market, from worm-drive to spring clamps, and examines their specific applications across industries such as automotive, plumbing, and manufacturing.

Understanding the nuances of each type of hose clamp, including their materials, strengths, and installation techniques, is crucial for making informed purchasing decisions. Additionally, this guide offers insights into supplier vetting processes, cost considerations, and emerging trends in materials—such as the rise of graphene-based clamps—that could shape future procurement strategies.

By equipping international B2B buyers with actionable knowledge and best practices, this guide aims to enhance your sourcing strategies and ensure you select the right hose clamps for your unique operational needs. With the right information at your fingertips, you can confidently navigate the complexities of the global market and forge partnerships that drive efficiency and innovation in your projects.

Understanding different types of hose clamps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Worm-Drive Hose Clamps | Adjustable band tightened by a screw; corrosion-resistant materials | Automotive, plumbing, HVAC | Pros: Versatile, easy to install, strong hold. Cons: Can be over-tightened if not careful. |

| Ear Clamps | Band with ear-shaped ends crimped for tight fitting | Automotive, industrial piping | Pros: Excellent for flexible hoses, secure connection. Cons: Requires special tools for installation. |

| Spring Clamps | Spring-loaded design for quick application | General repairs, light-duty applications | Pros: Fast and easy to use, lightweight. Cons: Limited holding power for heavy-duty tasks. |

| T-Bolt Band Clamps | T-bolt design for high-pressure applications | Heavy machinery, construction equipment | Pros: High strength, reliable under pressure. Cons: Bulkier design may require more space. |

| Heavy-Duty Hose Clamps | Reinforced materials for robust applications | Industrial, marine, and agricultural uses | Pros: Exceptional durability, withstands harsh environments. Cons: Higher cost compared to standard clamps. |

What Are Worm-Drive Hose Clamps and Their Key Characteristics?

Worm-drive hose clamps are recognized for their adjustable band that tightens around hoses using a screw mechanism. This design allows for a precise fit, making them ideal for applications that require secure connections, such as automotive and plumbing systems. When sourcing worm-drive clamps, buyers should consider the material—typically stainless steel for corrosion resistance—and the size range to ensure compatibility with existing fittings.

Why Choose Ear Clamps for Specific Applications?

Ear clamps feature a unique design with ear-shaped ends that are crimped to provide a secure hold on hoses. They are particularly beneficial in automotive and industrial piping applications where movement is prevalent. Buyers should note that while ear clamps offer strong connections, they require specialized tools for installation and removal, which may impact labor costs in large projects.

How Do Spring Clamps Serve General Repair Needs?

Spring clamps are favored for their simplicity and ease of use, featuring a spring-loaded mechanism that allows for quick attachment and release. They are suitable for light-duty applications, such as home repairs and DIY projects. However, while they are lightweight and convenient, buyers should be aware of their limitations in holding power for more demanding tasks.

What Advantages Do T-Bolt Band Clamps Offer in High-Pressure Scenarios?

T-bolt band clamps are designed for high-pressure applications, featuring a robust T-bolt mechanism that ensures a secure hold. These clamps are commonly used in heavy machinery and construction equipment, where reliability is crucial. When purchasing T-bolt clamps, buyers should consider the clamp’s size and material, as these factors significantly influence performance under pressure.

Why Invest in Heavy-Duty Hose Clamps for Harsh Environments?

Heavy-duty hose clamps are built from reinforced materials to withstand extreme conditions, making them ideal for industrial, marine, and agricultural applications. Their durability ensures long-lasting performance even in challenging environments. Buyers should evaluate the specific requirements of their applications, including temperature ranges and exposure to corrosive substances, to select the appropriate heavy-duty clamp.

Key Industrial Applications of different types of hose clamps

| Industry/Sector | Specific Application of different types of hose clamps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing fuel and coolant hoses | Prevents leaks and enhances safety | Look for high-temperature resistance and corrosion resistance. |

| Agriculture | Connecting irrigation systems | Ensures consistent water supply and prevents leaks | Consider durability against UV exposure and weather conditions. |

| Chemical Processing | Securing hoses in chemical transfer systems | Maintains integrity of hazardous material transport | Sourcing materials that resist chemical corrosion is critical. |

| Construction | Fastening hoses in heavy machinery | Enhances equipment reliability and reduces downtime | Ensure clamps can withstand heavy loads and harsh environments. |

| HVAC | Securing ductwork and tubing | Improves system efficiency and reduces energy loss | Sourcing for compatibility with various duct sizes and materials. |

How Are Different Types of Hose Clamps Utilized in the Automotive Sector?

In the automotive industry, hose clamps are crucial for securing fuel and coolant hoses. Their primary function is to prevent leaks that can lead to engine overheating or fuel-related hazards. Buyers in this sector should prioritize clamps made from high-temperature and corrosion-resistant materials to ensure reliability under extreme conditions. The ability to easily install and remove these clamps can also facilitate maintenance and repairs, making them a vital component for automotive manufacturers and repair shops.

Why Are Hose Clamps Important in Agriculture?

In agriculture, hose clamps are essential for connecting irrigation systems. They ensure that water flows consistently to crops, preventing leaks that can lead to water wastage and reduced crop yields. For international buyers, particularly in regions with extreme weather, sourcing durable clamps that can withstand UV exposure and harsh environmental conditions is crucial. Selecting the right clamp type enhances the longevity of irrigation systems and supports sustainable farming practices.

What Role Do Hose Clamps Play in Chemical Processing?

Hose clamps in the chemical processing industry are used to secure hoses that transport hazardous materials. Their role is to maintain the integrity of these systems, preventing leaks that could pose safety risks or environmental hazards. Buyers must consider sourcing clamps made from materials resistant to chemical corrosion to ensure safety and compliance with industry regulations. This focus on material selection is vital for minimizing risks associated with chemical spills.

Illustrative image related to different types of hose clamps

How Are Hose Clamps Utilized in the Construction Sector?

In the construction sector, hose clamps are used to fasten hoses in heavy machinery, ensuring reliable operation. A secure connection minimizes the risk of hose detachment, which can lead to equipment failure and costly downtime. Buyers should prioritize clamps that can withstand heavy loads and harsh conditions, as construction sites often present challenging environments. The right hose clamp can significantly enhance machinery reliability and operational efficiency.

Why Are Hose Clamps Essential in HVAC Systems?

In HVAC systems, hose clamps are used to secure ductwork and tubing, ensuring efficient airflow and energy conservation. Properly secured ducts prevent air leaks, which can lead to increased energy costs and reduced system performance. For international buyers, it’s important to source clamps that are compatible with various duct sizes and materials, as HVAC systems can vary widely. Selecting high-quality clamps can improve system efficiency and reduce long-term operational costs.

3 Common User Pain Points for ‘different types of hose clamps’ & Their Solutions

Scenario 1: Inconsistent Sealing Leading to Frequent Leaks

The Problem: One of the most common issues B2B buyers face when using hose clamps is inconsistent sealing, which often leads to leaks. This can be particularly problematic in high-pressure environments such as automotive or industrial applications. Buyers may purchase what they believe to be high-quality clamps only to find that they fail to maintain a secure seal over time, resulting in costly downtime and potential damage to machinery. The frustration amplifies when the wrong type of clamp is used for specific applications, causing repeated maintenance and repair costs.

Illustrative image related to different types of hose clamps

The Solution: To address sealing issues, buyers should focus on selecting the appropriate type of hose clamp based on the specific application and materials involved. For example, worm-drive clamps are known for their ability to provide a strong, adjustable grip, making them ideal for flexible hoses connected to rigid fittings. When sourcing clamps, consider those made from corrosion-resistant materials, such as stainless steel, especially for harsh environments. It’s also essential to ensure that the clamp is sized correctly for the hose diameter and application pressure. Regularly inspect and maintain clamps to ensure they are functioning correctly, and replace them at the first sign of wear to prevent leaks.

Scenario 2: Difficulty in Installation and Removal of Hose Clamps

The Problem: Installation and removal of hose clamps can be a daunting task, especially for those working in tight spaces or handling large volumes of clamps. B2B buyers often report struggling with the manual tightening of clamps, leading to inconsistent pressure and potential damage to hoses. In environments where quick repairs are necessary, the inability to efficiently install or remove hose clamps can lead to significant delays and increased labor costs.

The Solution: To streamline the installation and removal process, buyers should consider investing in quick-release or ratchet-style hose clamps. These types of clamps are designed for easy operation, allowing for swift adjustments without the need for specialized tools. Additionally, having a variety of clamps on hand—ranging from standard screw clamps to quick-release options—can prepare teams for different scenarios, reducing downtime. Providing proper training for staff on how to efficiently use these clamps can also enhance productivity. Creating a standard operating procedure (SOP) for clamp installation can help ensure consistency and efficiency across the board.

Scenario 3: Hose Damage from Over-tightening or Incorrect Clamp Type

The Problem: Hose damage is a critical concern for B2B buyers, particularly in industries where hoses are subjected to high pressures or extreme temperatures. Over-tightening clamps can lead to punctures or abrasions in hoses, while using the wrong clamp type can result in inadequate support. This not only shortens the lifespan of the hoses but also poses safety risks and increases replacement costs.

The Solution: To prevent hose damage, buyers must take care to select clamps that are specifically designed for the type of hose material and application pressure. Embossed hose clamps, for instance, are engineered with rounded edges to minimize the risk of damage during tightening. Additionally, buyers should educate their teams on the importance of applying the correct amount of pressure when securing clamps. Utilizing torque wrenches can ensure that clamps are tightened to the manufacturer’s specifications, preventing over-tightening. Regular training and audits of clamp usage can help maintain best practices, ultimately prolonging the life of hoses and reducing the need for replacements.

Strategic Material Selection Guide for different types of hose clamps

When selecting the appropriate hose clamp for a specific application, the choice of material is paramount. Different materials offer varying properties that can significantly impact performance, durability, and cost. Below, we analyze four common materials used in hose clamps: stainless steel, plastic, galvanized steel, and aluminum. Each material presents unique advantages and limitations, making it essential for B2B buyers to understand their implications in various applications.

What Are the Key Properties of Stainless Steel Hose Clamps?

Stainless steel is renowned for its exceptional corrosion resistance and strength. It typically withstands temperatures ranging from -200°F to 1,200°F (-93°C to 649°C) and maintains structural integrity under high pressure. The key properties that make stainless steel a preferred choice include its resistance to rust, oxidation, and chemical exposure.

Pros & Cons:

The durability of stainless steel is a significant advantage, making it suitable for harsh environments, including automotive and industrial applications. However, its higher cost compared to other materials can be a drawback for budget-sensitive projects. Manufacturing complexity is moderate, requiring specialized equipment for cutting and forming.

Impact on Application:

Stainless steel clamps are ideal for applications involving water, oil, and various chemicals, providing a reliable seal that prevents leaks. International buyers should consider compliance with standards such as ASTM A240 for stainless steel grades.

How Do Plastic Hose Clamps Compare for Different Applications?

Plastic hose clamps, often made from nylon or polypropylene, are lightweight and resistant to corrosion. They typically operate effectively within a temperature range of -40°F to 200°F (-40°C to 93°C) and are suitable for low-pressure applications.

Pros & Cons:

The primary advantage of plastic clamps is their low cost and lightweight nature, making them easy to handle and install. However, they lack the strength and durability of metal clamps, which can limit their use in high-pressure or extreme temperature environments. Manufacturing is straightforward, contributing to lower costs.

Impact on Application:

Plastic clamps are well-suited for indoor applications, such as plumbing and HVAC systems, where moisture is minimal. B2B buyers in regions with high humidity should consider the long-term implications of using plastic clamps, as they may degrade faster than metal alternatives.

What Advantages Do Galvanized Steel Hose Clamps Offer?

Galvanized steel clamps are coated with a layer of zinc to enhance corrosion resistance, making them suitable for outdoor applications. They can typically handle temperatures up to 300°F (149°C) and moderate pressure levels.

Pros & Cons:

The galvanization process provides a cost-effective solution for applications requiring moderate strength and corrosion resistance. However, they may not perform well in extreme environments, as the zinc coating can wear off over time, exposing the steel underneath. Manufacturing is relatively simple, making them widely available.

Impact on Application:

These clamps are ideal for agricultural and construction applications, where exposure to moisture is common. Buyers should ensure compliance with local standards, such as ASTM A153 for zinc coatings, to guarantee quality.

Why Choose Aluminum Hose Clamps for Specific Applications?

Aluminum hose clamps are lightweight and resistant to corrosion, with a temperature range of -40°F to 400°F (-40°C to 204°C). They are often used in automotive and aerospace applications due to their strength-to-weight ratio.

Pros & Cons:

The key advantage of aluminum clamps is their lightweight nature, allowing for easy installation and reduced overall weight in applications. However, they can be more expensive than steel options and may not provide the same level of durability under extreme conditions. Manufacturing complexity is moderate, as aluminum requires specific tooling.

Impact on Application:

Aluminum clamps are suitable for applications involving fuel and air systems in vehicles. International buyers should be aware of compliance with standards like SAE J1508, which governs the performance of aluminum clamps.

Illustrative image related to different types of hose clamps

Summary Table of Material Selection for Hose Clamps

| Material | Typical Use Case for different types of hose clamps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Automotive, industrial, chemical applications | Excellent corrosion resistance and durability | Higher cost compared to other materials | High |

| Plastic | Indoor plumbing, HVAC systems | Lightweight and cost-effective | Limited strength and temperature range | Low |

| Galvanized Steel | Agricultural, construction applications | Cost-effective corrosion resistance | Zinc coating may wear off over time | Medium |

| Aluminum | Automotive, aerospace applications | Lightweight with good strength-to-weight ratio | Higher cost and potential durability issues | Medium |

Understanding the properties, advantages, and limitations of each material is crucial for making informed decisions in hose clamp selection. This knowledge empowers international B2B buyers to choose the right product for their specific applications while ensuring compliance with relevant standards.

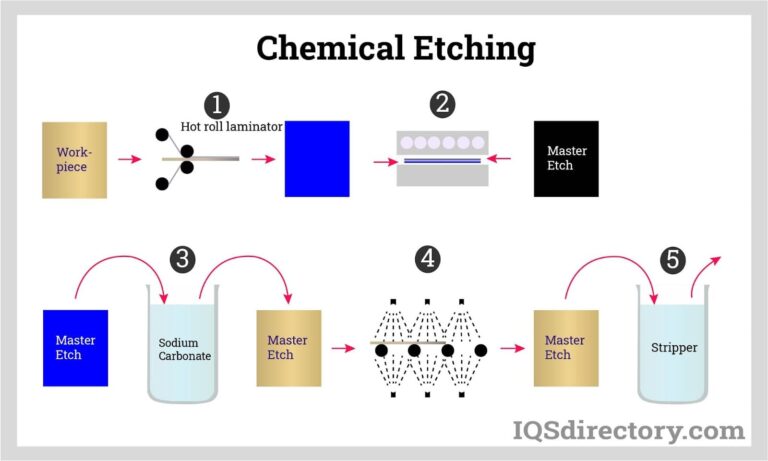

In-depth Look: Manufacturing Processes and Quality Assurance for different types of hose clamps

What Are the Main Stages of the Manufacturing Process for Hose Clamps?

The manufacturing process for hose clamps involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess the quality and reliability of the products they are sourcing.

Material Preparation: What Materials Are Used and How Are They Processed?

The primary materials used in hose clamp production include stainless steel, plastic, and increasingly innovative materials like graphene. Each material requires specific preparation processes. For instance, stainless steel is often sourced in rolls, which are then cut into strips of appropriate lengths. Plastic clamps are typically produced from high-density polyethylene (HDPE) or polypropylene, which are extruded or molded into desired shapes.

Illustrative image related to different types of hose clamps

In preparation, suppliers conduct rigorous checks for material integrity, ensuring that the materials meet relevant international standards. This includes verifying the chemical composition, tensile strength, and resistance to corrosion, especially for clamps intended for harsh environments.

How Are Hose Clamps Formed: What Techniques Are Employed?

The forming stage involves shaping the prepared materials into hose clamps using various techniques. Common methods include:

-

Stamping: This technique is frequently used for metal clamps where strips of material are fed into a stamping machine that shapes them into the desired form. This method is efficient and allows for high-volume production.

-

Injection Molding: For plastic clamps, injection molding is prevalent. The raw plastic is heated until molten and then injected into a mold to create the clamp shape. This method ensures precise dimensions and can accommodate complex designs.

-

Bending and Welding: For certain heavy-duty clamps, metal strips may be bent into shape and then welded at joints to ensure strength and durability.

Each technique requires specific machinery and expertise, which can vary by manufacturer. Buyers should inquire about the technologies used by suppliers to ensure they meet production quality standards.

What Does the Assembly Process Involve for Hose Clamps?

After forming, the assembly stage is crucial for ensuring that each clamp functions correctly. This stage can include several steps, such as:

-

Adding Fasteners: Many hose clamps require screws, nuts, or other fastening mechanisms. The assembly process may involve automated machines that insert these components or manual assembly for more complex designs.

-

Quality Checks: At this stage, manufacturers often conduct initial quality control checks to verify that all components are correctly assembled and functioning as intended. This may include ensuring that screws can be tightened appropriately without stripping.

-

Packaging: Once assembled, clamps are typically packaged for shipment. Proper packaging protects against damage during transport and is essential for maintaining product integrity.

What Finishing Processes Enhance the Quality of Hose Clamps?

The finishing stage improves the appearance and durability of hose clamps. Common finishing processes include:

-

Surface Treatment: Techniques such as galvanization, anodizing, or powder coating are often applied to metal clamps to enhance corrosion resistance. Plastic clamps may undergo UV stabilization to prevent degradation from sunlight exposure.

-

Polishing: For aesthetic purposes, especially in applications where the clamp may be visible, polishing is applied to improve the surface finish.

-

Inspection: Final inspections are critical to ensure that each product meets the required specifications. This can include visual inspections as well as measurements for dimensional accuracy.

What International Quality Standards Apply to Hose Clamp Manufacturing?

B2B buyers should be aware of international quality standards that govern the manufacturing processes of hose clamps. Key standards include:

-

ISO 9001: This standard focuses on quality management systems and is applicable across industries. Manufacturers adhering to ISO 9001 demonstrate a commitment to quality and continuous improvement.

-

CE Marking: Particularly relevant for products sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. Buyers should look for this marking on hose clamps intended for European markets.

-

API Standards: For hose clamps used in the oil and gas industry, compliance with American Petroleum Institute (API) standards ensures that products can withstand harsh conditions encountered in these applications.

What Are Common Quality Control Checkpoints in Hose Clamp Manufacturing?

Quality control (QC) is integral to the manufacturing process. Key checkpoints typically include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards before entering the production process.

-

In-Process Quality Control (IPQC): During manufacturing, checks are performed to monitor processes and ensure adherence to quality specifications. This might include measuring dimensions and assessing the integrity of welds or fasteners.

-

Final Quality Control (FQC): After assembly and finishing, a final inspection verifies that the product meets all quality standards before packaging and shipping.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should adopt a systematic approach to verify supplier quality control practices:

-

Supplier Audits: Conducting on-site audits of suppliers allows buyers to assess the manufacturing processes and QC measures firsthand. This helps ensure that suppliers adhere to required standards and practices.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation that outlines their quality control processes, including results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of supplier quality. These organizations can evaluate compliance with international standards and provide detailed reports.

What QC and Certification Nuances Should International Buyers Consider?

When dealing with international suppliers, B2B buyers must navigate various certification nuances:

-

Cultural and Regional Standards: Different regions may have specific regulations governing manufacturing and quality assurance. Understanding these local standards is crucial for compliance and successful procurement.

-

Language Barriers: Documentation and communication may present challenges. Buyers should ensure they have access to clear translations of quality reports and certifications.

-

Traceability and Documentation: Buyers should prioritize suppliers that maintain comprehensive records of their manufacturing processes and quality checks. This traceability is essential for accountability and addressing potential issues in the supply chain.

By understanding these aspects of manufacturing processes and quality assurance for hose clamps, B2B buyers can make informed decisions, ensuring they procure reliable and high-quality products tailored to their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different types of hose clamps’

To assist B2B buyers in effectively sourcing different types of hose clamps, this guide provides a structured checklist that ensures you cover all critical aspects of procurement. By following these steps, you can make informed decisions that meet your operational requirements.

Step 1: Define Your Technical Specifications

Before beginning your sourcing process, it is essential to establish clear technical specifications for the hose clamps you need. Consider factors such as the diameter of the hoses, the materials being clamped, and the environmental conditions they will face. This clarity will help you narrow down your options and ensure that the clamps you procure are fit for purpose.

Step 2: Identify the Types of Hose Clamps Required

Understanding the different types of hose clamps available is crucial. Each type, whether it be worm-drive, screw clamps, or ear clamps, has specific applications and advantages. Familiarize yourself with these types to ensure that you choose the right clamp for your specific use case, especially if you are dealing with diverse projects across different industries.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with proven experience in providing the specific types of hose clamps you need, as this will ensure reliability and quality.

Illustrative image related to different types of hose clamps

- Consider supplier certifications: Verify if they hold relevant industry certifications, which can be a testament to their quality standards and manufacturing processes.

Step 4: Assess Material Quality and Durability

Given that hose clamps may be exposed to various environmental factors, assessing the materials used in their construction is vital. Look for options made from stainless steel for corrosion resistance or specialized plastics for lightweight applications. Ensure that the materials align with the operational conditions they will be subjected to, including temperature variations and exposure to chemicals.

Step 5: Request Samples for Testing

Before making a bulk purchase, always request samples of the hose clamps. Testing samples in real-world conditions will help you evaluate their performance, durability, and ease of installation. This step is particularly important to ensure that the clamps meet your specifications and perform as expected in your unique applications.

Step 6: Negotiate Terms and Pricing

Once you have identified a reliable supplier and tested their products, it’s time to negotiate terms and pricing. Discuss bulk purchase discounts, payment terms, and delivery schedules to align with your operational needs. Effective negotiation can lead to significant cost savings and better service agreements.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your chosen supplier can lead to better pricing, priority support, and access to new products. Regularly communicate your needs and provide feedback on their products and services. A strong partnership can enhance your supply chain efficiency and ensure you have a reliable source for future projects.

By following this checklist, B2B buyers can streamline the procurement process for hose clamps, ensuring that they select the right products from reputable suppliers while optimizing costs and performance.

Illustrative image related to different types of hose clamps

Comprehensive Cost and Pricing Analysis for different types of hose clamps Sourcing

What Are the Key Cost Components Influencing Hose Clamp Pricing?

When sourcing hose clamps, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Stainless steel, plastic, and specialized materials like graphene are commonly used. Stainless steel clamps are generally more expensive due to their durability and corrosion resistance, while plastic clamps are more affordable but may not offer the same longevity.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs may provide more competitive pricing, but this can sometimes compromise quality. In contrast, manufacturers in developed regions may charge higher labor costs but often provide superior quality assurance.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and other indirect expenses. Efficient manufacturing processes can help mitigate these costs, leading to more competitive pricing.

-

Tooling: The initial setup for manufacturing specific types of clamps can require significant investment. Custom tooling for specialized designs or sizes can increase costs, impacting the final price.

-

Quality Control (QC): Ensuring that products meet quality standards is vital. Robust QC processes may incur additional costs, but they are essential for maintaining reliability, especially for applications in demanding environments.

-

Logistics: Shipping and handling costs can vary widely, especially for international buyers. Factors such as distance, shipping method, and local tariffs can affect the total cost.

-

Margin: Manufacturers typically mark up their costs to achieve a profit margin. Understanding the typical margin in the hose clamp market can help buyers gauge fair pricing.

What Price Influencers Should Buyers Consider When Sourcing Hose Clamps?

Several factors can influence the price of hose clamps, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Negotiating minimum order quantities (MOQs) can yield better pricing.

-

Specifications and Customization: Custom clamps tailored to specific applications can incur higher costs. Be clear about your requirements to avoid unexpected pricing.

-

Material Selection: Different materials have varying costs. For instance, opting for corrosion-resistant materials may increase the price but can lead to long-term savings by reducing replacement frequency.

-

Quality Certifications: Clamps that meet international quality standards or certifications may carry a premium. However, they often ensure reliability and compliance, particularly in regulated industries.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is essential for calculating total landed costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly impact pricing and logistics.

What Tips Can Help Buyers Negotiate Cost-Efficient Hose Clamp Purchases?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiation Strategies: Engage suppliers in discussions about pricing flexibility, especially for bulk purchases. Highlight long-term business potential to negotiate better terms.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the TCO, which includes installation, maintenance, and replacement costs. Higher upfront costs for quality clamps can lead to lower TCO.

-

Understand Pricing Nuances: Be aware that pricing may fluctuate based on market demand, raw material costs, and geopolitical factors. Regularly review market trends to make timely purchasing decisions.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide leverage during negotiations. It also allows you to compare quality and service levels.

-

Local Regulations and Tariffs: Understand any local regulations or tariffs that may apply to imported clamps. This knowledge can help in budgeting and avoiding unexpected costs.

Disclaimer on Indicative Prices

Prices for hose clamps can vary widely based on the factors discussed. It is advisable to conduct thorough market research and obtain multiple quotes to ensure fair pricing. Keep in mind that the information provided here is indicative and may change based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing different types of hose clamps With Other Solutions

When considering solutions for securing hoses and pipes, various alternatives to traditional hose clamps can offer distinct advantages. Understanding these options is essential for B2B buyers who seek to optimize performance, cost-effectiveness, and ease of use in their applications. This analysis compares different types of hose clamps with two notable alternatives: adhesive bonding and crimp fittings.

Illustrative image related to different types of hose clamps

Comparison Table

| Comparison Aspect | Different Types Of Hose Clamps | Adhesive Bonding | Crimp Fittings |

|---|---|---|---|

| Performance | Reliable, adjustable sealing | Strong bond, may be permanent | Provides a secure connection |

| Cost | Moderate initial cost | Low to moderate | Moderate to high |

| Ease of Implementation | Simple installation with tools | Requires surface preparation | Requires special tools |

| Maintenance | Low, easy to inspect | Difficult to inspect, permanent | Low, once installed |

| Best Use Case | Temporary or adjustable needs | Permanent assemblies | Permanent, high-pressure applications |

What Are the Pros and Cons of Adhesive Bonding as an Alternative?

Adhesive bonding presents a compelling alternative for securing hoses and pipes, especially in situations where a permanent bond is required. The primary advantage of adhesive bonding lies in its ability to create a seamless, leak-proof connection. This method can be cost-effective, particularly for large-scale projects where labor costs are a concern. However, it requires meticulous surface preparation to ensure proper adhesion, and once set, the bond is difficult to inspect or repair without cutting the hose. Adhesive bonding is best suited for applications where flexibility and future adjustments are not necessary.

How Do Crimp Fittings Compare to Hose Clamps?

Crimp fittings offer another robust solution for hose connections, particularly in high-pressure environments. This method involves compressing a fitting around the hose to create a permanent seal. The primary advantage of crimp fittings is their reliability and strength, making them ideal for critical applications in industries such as automotive and aerospace. However, the installation requires specialized tools and training, which can increase upfront costs. Additionally, once crimped, these fittings cannot be easily adjusted or removed, making them less versatile than traditional hose clamps. Crimp fittings are best used in scenarios where a permanent connection is crucial.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right solution for securing hoses and pipes, B2B buyers should carefully consider their specific application requirements. Different types of hose clamps offer flexibility and ease of maintenance, making them suitable for temporary or adjustable connections. In contrast, adhesive bonding may be ideal for permanent installations that prioritize a leak-proof seal, while crimp fittings are best for high-pressure applications that demand robust reliability.

Ultimately, the decision should weigh the nature of the application, installation capabilities, and long-term maintenance considerations. By thoroughly evaluating these aspects, buyers can make informed choices that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for different types of hose clamps

What Are the Key Technical Properties of Hose Clamps?

Understanding the essential technical properties of hose clamps is crucial for B2B buyers, especially when sourcing materials that meet specific industry standards. Here are some critical specifications:

-

Material Grade

Hose clamps can be constructed from various materials such as stainless steel, galvanized steel, plastic, and even advanced materials like graphene. Stainless steel is favored for its corrosion resistance and durability, making it suitable for outdoor and industrial applications. The choice of material directly impacts the clamp’s lifespan and performance in different environments, which is vital for reducing replacement costs. -

Clamp Size and Range

The size of a hose clamp is defined by the diameter it can accommodate. This range is crucial for ensuring a proper fit on hoses and preventing leaks. B2B buyers should consider the specific requirements of their applications, as the wrong size can lead to inefficiencies and increased maintenance costs. -

Tensile Strength

This refers to the maximum load that a clamp can withstand before failing. High tensile strength is essential for applications involving high pressure or vibration, such as in automotive or industrial settings. Understanding tensile strength helps buyers select clamps that will maintain integrity under operational stresses. -

Torque Specification

Torque specification indicates the amount of force required to tighten the clamp effectively. This is important to prevent over-tightening, which can damage hoses, or under-tightening, which can lead to leaks. B2B buyers should ensure that their teams are trained to apply the correct torque to maximize performance and safety. -

Corrosion Resistance

This property determines how well a clamp can withstand environmental factors like moisture and chemicals without degrading. Clamps made from materials with high corrosion resistance are essential for applications in humid or chemically aggressive environments, ensuring longevity and reliability. -

Temperature Range

Different applications expose hose clamps to varying temperature conditions. Knowing the operational temperature range is crucial for selecting a clamp that will not warp, degrade, or lose its grip over time. This is particularly significant in automotive or industrial applications where temperature fluctuations are common.

What Are Common Trade Terms Related to Hose Clamps?

Familiarity with industry-specific jargon can significantly enhance the procurement process. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is important for B2B buyers to ensure compatibility and quality when sourcing hose clamps. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory effectively and negotiate better pricing based on their purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. This is a critical step in the purchasing process, allowing buyers to compare options and make informed decisions. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms can prevent misunderstandings regarding shipping costs, delivery, and risk transfer. -

Lead Time

Lead time refers to the time between placing an order and receiving the product. It is essential for B2B buyers to understand lead times to manage their project timelines effectively and avoid delays. -

Certification Standards

These refer to industry standards that a product must meet to ensure quality and safety, such as ISO or ASTM certifications. Knowing these standards helps buyers ensure that the hose clamps they purchase meet regulatory requirements and performance expectations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they select the right hose clamps for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the different types of hose clamps Sector

What Are the Key Trends Shaping the Hose Clamps Market?

The global hose clamps market is witnessing significant growth driven by several factors. Increasing industrialization and urbanization in regions like Africa, South America, the Middle East, and Europe are propelling demand for efficient plumbing, automotive, and manufacturing solutions. With the rise of e-commerce and digital marketplaces, international B2B buyers now have easier access to a broader range of products, including specialized hose clamps. Technological advancements are also playing a crucial role, with manufacturers increasingly adopting innovative materials such as stainless steel and plastics to enhance durability and corrosion resistance.

Illustrative image related to different types of hose clamps

Emerging trends include the use of smart technology in hose clamps, where sensors can monitor pressure and detect leaks, providing added value for end-users in sectors such as automotive and construction. Moreover, the shift towards lightweight materials, including graphene, is expected to revolutionize the market, offering superior strength without added weight. International buyers are advised to stay abreast of these trends, as they can significantly impact sourcing decisions and long-term supply chain strategies.

How Is Sustainability Influencing Sourcing Decisions in the Hose Clamps Sector?

Sustainability has become a pivotal factor in the sourcing of hose clamps, affecting both environmental impact and ethical supply chains. Manufacturers are increasingly aware of their carbon footprints and are seeking materials that minimize ecological damage. For instance, stainless steel and recyclable plastics are gaining popularity due to their durability and lower environmental impact compared to traditional metal clamps.

Additionally, certifications such as ISO 14001 for environmental management systems and materials with ‘green’ labels are becoming essential for B2B buyers. These certifications ensure that suppliers adhere to sustainable practices, which can enhance a company’s reputation in the market. Buyers in Africa, South America, the Middle East, and Europe are encouraged to prioritize suppliers who are committed to ethical sourcing, as this aligns with global efforts towards environmental conservation and responsible business practices. Incorporating sustainable sourcing strategies not only mitigates environmental risks but can also lead to cost savings in the long run through improved efficiency and waste reduction.

Illustrative image related to different types of hose clamps

What Is the Historical Context of Hose Clamps and Their Evolution?

The history of hose clamps dates back to the early 20th century when they were primarily made from metal, which often led to issues such as rust and corrosion. Over the decades, advancements in manufacturing processes and materials have transformed hose clamps into more durable and efficient tools. The introduction of stainless steel and high-quality plastics has significantly improved their lifespan and resistance to environmental factors.

In recent years, the focus on innovation has led to the development of various types of hose clamps, each designed for specific applications, from automotive to industrial uses. As technology continues to evolve, the future of hose clamps promises even more enhancements, such as smart clamps equipped with sensors for real-time monitoring. This evolution reflects broader trends in manufacturing and sourcing that emphasize efficiency, sustainability, and adaptability to market demands. For international B2B buyers, understanding this historical context can provide valuable insights into the selection of appropriate hose clamps for their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of different types of hose clamps

-

1. How do I choose the right type of hose clamp for my application?

When selecting a hose clamp, consider the material compatibility, pressure requirements, and environmental factors. For high-pressure applications, T-bolt or worm-drive clamps are ideal due to their robust design. If corrosion is a concern, opt for stainless steel or plastic clamps. Additionally, evaluate the hose diameter and whether you need a permanent or adjustable solution. Always consult manufacturer specifications to ensure the clamp meets your operational needs. -

2. What are the key factors to consider when sourcing hose clamps internationally?

When sourcing hose clamps globally, prioritize supplier reliability, product quality, and compliance with international standards. Check for certifications that indicate adherence to quality management systems, such as ISO 9001. It’s also essential to understand trade regulations and tariffs in your region. Conduct thorough due diligence by reviewing supplier references and assessing their manufacturing capabilities. Effective communication regarding specifications and timelines is crucial for successful procurement. -

3. What minimum order quantities (MOQs) should I expect when purchasing hose clamps?

MOQs can vary significantly based on the supplier and the type of hose clamp. Typically, manufacturers may set MOQs ranging from 100 to 1,000 units. For specialized or custom clamps, MOQs might be higher due to production setup costs. Always negotiate MOQs with suppliers to align with your inventory needs and budget constraints. Some suppliers may offer flexibility for first-time orders or bulk purchases. -

4. How can I ensure quality assurance (QA) when sourcing hose clamps?

To ensure quality assurance, request samples before placing large orders. Conduct inspections at various production stages, and consider third-party quality control services to verify compliance with your specifications. Establish clear quality metrics and communicate them with your supplier. Regular audits and performance reviews can also help maintain quality standards over time, ensuring that the products meet your operational requirements. -

5. What payment terms should I negotiate with hose clamp suppliers?

Payment terms can vary widely among suppliers. Common options include partial upfront payment with the balance due upon delivery or net 30/60 days post-delivery. It’s advisable to negotiate terms that align with your cash flow while ensuring supplier confidence. Utilize secure payment methods, such as letters of credit or escrow services, especially for larger transactions. Clearly outline payment terms in the purchase agreement to avoid disputes. -

6. How can I customize hose clamps for specific applications?

Customization options often include size, material, and design alterations to meet specific application requirements. Communicate your needs clearly with the supplier, providing detailed specifications and any relevant standards. Many manufacturers can produce clamps tailored to unique dimensions or functionalities, such as enhanced corrosion resistance or specific pressure ratings. Be prepared for potential lead times associated with custom orders. -

7. What logistics considerations should I keep in mind when importing hose clamps?

When importing hose clamps, factor in shipping costs, lead times, and customs duties. Choose reliable logistics partners familiar with international shipping regulations to ensure smooth delivery. Prepare all necessary documentation, including commercial invoices and packing lists, to facilitate customs clearance. Additionally, consider warehousing options if you require storage before distribution, as this can impact overall supply chain efficiency. -

8. How do I address issues with defective hose clamps received from a supplier?

If you receive defective hose clamps, document the issues with clear photographs and detailed descriptions. Contact the supplier promptly to discuss the problems and request a replacement or refund. Familiarize yourself with the supplier’s return and warranty policies beforehand to streamline the process. Maintain professional communication and provide all necessary documentation to resolve the issue amicably, fostering a positive supplier relationship for future transactions.

Top 5 Different Types Of Hose Clamps Manufacturers & Suppliers List

1. Dixon Valve – Hose Clamps Overview

Domain: blog.dixonvalve.com

Registered: 1996 (29 years)

Introduction: Hose clamps are devices used to attach and seal hoses onto fittings, preventing hoses from slipping off. They are used in various industries including agriculture, automotive, and industrial applications. There are six main types of hose clamps: band, bolt, ear, spiral, T-bolt, and worm gear.

1. **Band Clamps**: Suitable for large-diameter hoses, often used in agricultural and industrial applica…

2. Atag Europe – Hose Clamps

Domain: atag-europe.com

Registered: 2010 (15 years)

Introduction: Hose clamps are manufactured in various types depending on their intended use and the need for different levels of tightening and workload. Key features include: screws, bolts, and eyelets; tilting housing, quick release, and springs; dynamic control of Belleville washers for constant tightening torque; single or double wire options; metal bands of various lengths (commonly 8-9 mm and 12-13 mm); s…

3. Cntopa – Worm Gear Hose Clamps

Domain: cntopa.com

Registered: 2014 (11 years)

Introduction: Types of Hose Clamps: A. Worm Gear Clamps – Description: Metal band with screw mechanism, often stainless steel. Common Uses: Automotive, plumbing, industrial. Advantages: Adjustable size, strong hold, inexpensive. Disadvantages: Can damage hose if over-tightened, corrosion risk, requires screwdriver. B. Spring Clamps – Description: Spring mechanism for constant pressure, made from stainless or sp…

4. Hose Clamps – 1989 454 Motorhome Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hose clamps for replacing hoses on a 1989 454 motorhome; seeking recommendations for preferred and disliked brands.

5. Clips and Fasteners – Automotive Hose & Tubing Clips & Clamps

Domain: clipsandfasteners.com

Registered: 2007 (18 years)

Introduction: Automotive Hose & Tubing Clips & Clamps include various types such as Natural Nylon Tubing Clamps, Constant Tension Band Hose Clamps, and Closed Clamps. Key specifications include: 1/4″ Tube Diameter Natural Nylon Tubing Clamps (Hole Diameter: 3/16″, Width: 3/8″, 25 Per Package, Price: $5.19), 3/8″ Tube Diameter Natural Nylon Tubing Clamps (25 Per Package, Price: $4.85), 1/2″ Tube Diameter Natural…

Strategic Sourcing Conclusion and Outlook for different types of hose clamps

How Can Strategic Sourcing Enhance Your Hose Clamp Procurement?

In conclusion, strategic sourcing plays a pivotal role in optimizing your procurement of hose clamps. Understanding the diverse types available—from worm-drive to embossed clamps—enables international buyers to select the right solutions tailored to specific applications, whether in automotive, plumbing, or industrial settings. Emphasizing materials such as stainless steel and innovative options like graphene can lead to enhanced durability and performance, significantly impacting operational efficiency.

Moreover, assessing suppliers based on quality, reliability, and adaptability will ensure that your sourcing strategy aligns with your business needs. As markets in Africa, South America, the Middle East, and Europe continue to evolve, staying ahead of trends in hose clamp technology will be crucial for maintaining a competitive edge.

As you plan your next procurement cycle, consider the long-term value of strategic partnerships and the importance of leveraging innovative materials. Engaging with trusted suppliers can not only streamline your operations but also enhance product reliability. Begin your journey towards more effective sourcing today—your operational success depends on it.

Illustrative image related to different types of hose clamps

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.