15 Gallon Barrel: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for 15 gallon barrel

In today’s global marketplace, sourcing a 15-gallon barrel can present significant challenges for B2B buyers, particularly those in emerging markets like Africa, South America, the Middle East, and Europe. With varying quality standards, diverse applications, and an abundance of suppliers, navigating this landscape requires a strategic approach. This comprehensive guide delves into the various types of 15-gallon barrels, from traditional wooden options used in distilling and brewing to versatile plastic drums ideal for chemical storage and food-grade applications.

Understanding the nuances of each type is crucial for making informed purchasing decisions that align with your specific operational needs. Additionally, the guide covers essential aspects such as supplier vetting processes, cost considerations, and compliance with international regulations. By equipping international buyers with actionable insights and best practices, this resource aims to empower you to make confident choices that enhance your business operations and product offerings.

Whether you are in Vietnam seeking barrels for craft distillation or in Saudi Arabia looking for reliable storage solutions, this guide serves as a valuable tool. It not only clarifies the complexities of the 15-gallon barrel market but also positions you to negotiate better deals and establish long-lasting supplier relationships. Let us navigate this global market together, ensuring your sourcing decisions are both strategic and successful.

Understanding 15 gallon barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Freshly Emptied Whiskey Barrel | Previously used for whiskey aging; enhances flavor profiles | Distilleries, craft breweries, experimental batches | Pros: Unique flavor infusion; quick turnaround. Cons: Limited availability; may require additional cleaning. |

| Closed Head Poly Drum | Made from high-density polyethylene; single top opening | Chemical storage, food-grade applications | Pros: Lightweight and durable; FDA compliant. Cons: Limited exposure to air; not suitable for aging processes. |

| Mixing Barrel | Designed for mixing applications; includes a lid for containment | Construction, food preparation, mixing chemicals | Pros: Easy to transport; strong yet lightweight. Cons: Not ideal for long-term storage; limited to mixing tasks. |

| Specialty Barrel | Customizable for specific aging processes; various wood types | Distilleries, wineries, gourmet food producers | Pros: Tailored flavor profiles; unique aesthetics. Cons: Higher cost; longer lead times for customization. |

| Decorative Barrel | Primarily for aesthetic purposes; often used in event decor | Event planning, home decor, promotional displays | Pros: Eye-catching design; versatile use. Cons: Limited functionality; not suitable for storage or aging. |

What are the characteristics of Freshly Emptied Whiskey Barrels?

Freshly emptied whiskey barrels are typically sourced from distilleries where they have been used to age spirits. These barrels are prized for their ability to impart complex flavors to new batches of whiskey or other spirits. The high surface area relative to volume accelerates the aging process, making them suitable for small-batch distilling or experimental brewing. B2B buyers should consider the flavor profile they wish to achieve and ensure that the barrels are sourced from reputable distilleries to guarantee quality.

How do Closed Head Poly Drums serve various industries?

Closed head poly drums are constructed from high-density polyethylene, making them ideal for the safe storage of chemicals and food-grade products. Their single top opening and lightweight design facilitate easy handling and transport. These drums are particularly advantageous for industries requiring compliance with FDA standards. When purchasing, buyers should verify the barrel’s suitability for their specific application, especially regarding chemical compatibility and durability.

What are the key features of Mixing Barrels?

Mixing barrels are designed for specific applications, primarily in construction and food preparation. These barrels often come with lids to prevent spillage and contamination during mixing processes. Their lightweight yet robust construction allows for easy maneuverability, making them a practical choice for contractors and food service businesses. Buyers should assess the barrel’s capacity and material to ensure it meets their mixing requirements.

Why choose Specialty Barrels for aging?

Specialty barrels are customizable options that cater to specific aging processes, often made from various types of wood to enhance flavor profiles. These barrels are commonly used by distilleries and wineries to create unique products. While they offer the potential for tailored flavors, buyers should be prepared for higher costs and longer lead times due to the customization involved. Understanding the aging characteristics of different wood types can significantly impact the final product.

What role do Decorative Barrels play in B2B applications?

Decorative barrels are primarily used for aesthetic purposes, often found in event decor or as promotional displays. While they do not serve functional storage or aging roles, their unique designs can enhance the visual appeal of any setting. B2B buyers should consider how these barrels can fit into their branding or event themes, balancing aesthetics with the lack of practical functionality.

Key Industrial Applications of 15 gallon barrel

| Industry/Sector | Specific Application of 15 Gallon Barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beverage Production | Aging and storing spirits, wines, or craft beers | Enhances flavor profile through controlled aging | Quality of wood, previous contents, and barrel condition |

| Chemical Manufacturing | Storage of chemicals and hazardous materials | Ensures safe containment and compliance with regulations | Material compatibility, leakage prevention, and certification |

| Agriculture | Rainwater collection and irrigation | Sustainable water management and resource conservation | Durability, UV resistance, and ease of transport |

| Food Industry | Transporting and storing food-grade products | Maintains product integrity and safety | Food-grade certification, cleanliness, and seal integrity |

| Construction and DIY | Mixing and transporting concrete or other materials | Facilitates efficient handling and mixing processes | Strength, ease of handling, and availability of lids |

How is the 15 Gallon Barrel Used in Beverage Production?

In the beverage industry, 15-gallon barrels are primarily utilized for aging spirits, wines, and craft beers. The smaller size allows for increased surface area contact, resulting in faster and more pronounced flavor development. This is particularly beneficial for distillers and brewers looking to experiment with unique flavor profiles or to produce small batches. For international buyers, sourcing barrels that have been previously used for specific spirits can add distinct characteristics to the new product, making it essential to verify the barrel’s history and condition.

What Role Does the 15 Gallon Barrel Play in Chemical Manufacturing?

In chemical manufacturing, 15-gallon barrels serve as reliable storage solutions for various chemicals and hazardous materials. Their robust construction ensures safe containment, which is crucial for compliance with international safety regulations. Buyers must consider the material compatibility of the barrels, ensuring they are suitable for the specific chemicals being stored. Additionally, features such as leakage prevention and appropriate certifications are vital for maintaining safety and regulatory standards in this sector.

How Can Agriculture Benefit from 15 Gallon Barrels?

In agriculture, 15-gallon barrels are increasingly used for rainwater collection and irrigation purposes. Their manageable size makes them ideal for farmers looking to implement sustainable water management practices. By capturing rainwater, agricultural businesses can conserve resources and reduce dependence on municipal water supplies. When sourcing barrels for this application, buyers should prioritize durability and UV resistance to ensure long-term outdoor use, as well as ease of transport for relocation between fields.

Why are 15 Gallon Barrels Important in the Food Industry?

The food industry employs 15-gallon barrels for transporting and storing food-grade products, including syrups, sauces, and other liquids. These barrels help maintain product integrity and safety, which is essential for compliance with food safety standards. Buyers must ensure that the barrels are certified food-grade, thoroughly cleaned, and possess airtight seals to prevent contamination. This is particularly important for international buyers who need to adhere to varying regulations across different markets.

How Do Construction and DIY Projects Utilize 15 Gallon Barrels?

In construction and DIY projects, 15-gallon barrels are frequently used for mixing and transporting concrete or other materials. Their lightweight yet strong design allows for easy handling and efficient mixing processes, making them a popular choice among contractors and DIY enthusiasts. When sourcing these barrels, considerations such as strength, ease of handling, and the availability of lids are crucial for ensuring a smooth operational workflow. This practicality appeals to businesses looking for cost-effective solutions in construction projects.

3 Common User Pain Points for ’15 gallon barrel’ & Their Solutions

Scenario 1: Sourcing Quality Barrels for Distilling and Brewing

The Problem: B2B buyers in the distilling and brewing industries often face challenges in sourcing high-quality 15-gallon barrels that meet their specific production needs. Many suppliers offer barrels that have been poorly maintained or are not suitable for aging spirits or beer. This can lead to issues such as off-flavors, contamination, and inconsistent aging results, ultimately affecting the product quality and brand reputation.

The Solution: To overcome this issue, buyers should prioritize sourcing from reputable suppliers who specialize in freshly emptied or once-used barrels. These barrels often provide better flavor profiles and are more reliable for aging due to their proper maintenance. When assessing suppliers, request detailed information about the barrel’s history, including what it previously contained and how it was cleaned. Additionally, consider investing in barrels that are specifically designed for your product type, whether it be bourbon, wine, or specialty spirits. This targeted approach ensures that the barrels will enhance the flavor and quality of the final product, aligning with your brand’s standards and expectations.

Scenario 2: Logistics and Shipping Challenges for International Orders

The Problem: International B2B buyers frequently encounter logistical hurdles when importing 15-gallon barrels, such as high shipping costs, customs delays, and damage during transit. These challenges can lead to increased lead times and unsatisfactory supply chain performance, jeopardizing production schedules and customer commitments.

The Solution: To mitigate these logistics issues, buyers should work with suppliers who have experience in international shipping and can provide tailored solutions. It is essential to discuss shipping options upfront and choose a supplier who offers multiple freight methods, as this can significantly affect costs and delivery times. Additionally, using barrels that are lightweight and stackable can reduce shipping expenses and minimize the risk of damage. Collaborating with a freight forwarder who understands the specific regulations of your target market can also streamline the customs process, ensuring that your barrels arrive safely and on time.

Illustrative image related to 15 gallon barrel

Scenario 3: Ensuring Compliance with Food Safety Standards

The Problem: Buyers in industries that require food-grade barrels, such as beverage production or food storage, often struggle to find 15-gallon barrels that comply with stringent food safety regulations. The risk of using non-compliant barrels can lead to serious legal and health issues, including product recalls and damage to brand reputation.

The Solution: To ensure compliance, buyers should look for barrels that are explicitly labeled as food-grade and meet FDA or equivalent international standards. It is advisable to request documentation from the supplier verifying the barrels’ compliance. Additionally, consider barrels made from materials like high-density polyethylene (HDPE) or those that have been triple-rinsed, as these are less likely to leach harmful substances into stored products. Establishing a solid relationship with your supplier and regularly communicating your compliance needs will help ensure that you consistently receive barrels that meet safety regulations, thereby protecting your business and your customers.

By addressing these common pain points with tailored solutions, B2B buyers can enhance their purchasing experience, improve product quality, and streamline operations related to 15-gallon barrels.

Strategic Material Selection Guide for 15 gallon barrel

What Are the Common Materials Used for 15 Gallon Barrels?

When selecting a 15-gallon barrel, the choice of material is crucial for ensuring optimal performance, compliance with industry standards, and suitability for specific applications. Below, we analyze four common materials used in the construction of 15-gallon barrels: wood, high-density polyethylene (HDPE), stainless steel, and fiberglass.

How Does Wood Influence the Performance of 15 Gallon Barrels?

Wood barrels, particularly those made from oak, are traditionally used for aging spirits and wines. The key properties of wood include its natural porosity, which allows for oxygen exchange, and its ability to impart flavors to the contents. Wood barrels can withstand moderate pressure and temperature variations, making them suitable for many applications.

Pros: Wood barrels are renowned for enhancing the flavor profile of beverages, making them ideal for distillers and brewers. They also have a classic aesthetic appeal, which can be a selling point for premium products.

Cons: Wood barrels require more maintenance and are susceptible to leaks and rot if not properly cared for. They can also be relatively expensive due to the cost of raw materials and craftsmanship involved in their production.

Impact on Application: Wood barrels are best suited for aging alcoholic beverages, as the wood interacts with the liquid to create complex flavors. However, they may not be suitable for all liquids, particularly those that are acidic or corrosive.

Considerations for International Buyers: Compliance with food safety standards is critical, particularly in regions like Europe and the Middle East, where regulations may differ. Buyers should ensure that the wood is sourced sustainably and treated to prevent contamination.

What Role Does High-Density Polyethylene (HDPE) Play in Barrel Selection?

HDPE barrels are lightweight, durable, and resistant to chemicals, making them a popular choice for various industrial applications. They are often used for storing food-grade materials and chemicals due to their corrosion resistance and impermeability.

Pros: HDPE barrels are cost-effective, easy to handle, and can be manufactured in large quantities. They are also resistant to UV light and do not rust, making them suitable for outdoor storage.

Cons: While HDPE barrels are durable, they may not withstand extreme temperatures as well as metal barrels. Additionally, they do not impart any flavors to the contents, which can be a disadvantage for applications requiring flavor enhancement.

Impact on Application: HDPE barrels are ideal for storing liquids such as oils, chemicals, and water. They are also suitable for food-grade applications, provided they meet FDA regulations.

Considerations for International Buyers: Buyers should confirm that the barrels comply with local regulations regarding food safety and chemical storage. Different regions may have specific standards, such as ASTM in the U.S. or DIN in Europe.

Why Choose Stainless Steel for 15 Gallon Barrels?

Stainless steel barrels are known for their strength, durability, and resistance to corrosion. They are commonly used in the food and beverage industry due to their hygienic properties and ability to withstand high pressures and temperatures.

Pros: Stainless steel barrels are easy to clean and maintain, making them ideal for repeated use. They are also non-reactive, ensuring that the contents remain pure and untainted.

Cons: The initial cost of stainless steel barrels is typically higher than that of wood or plastic options. They can also be heavier, which may pose challenges in handling and transportation.

Impact on Application: Stainless steel barrels are suitable for a wide range of applications, including fermentation, storage of beverages, and chemical processing. Their versatility makes them a preferred choice for many industries.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international standards for food safety and corrosion resistance. Certifications may vary by region, and understanding local compliance is essential.

How Does Fiberglass Compare as a Material for 15 Gallon Barrels?

Fiberglass barrels are lightweight and resistant to corrosion, making them suitable for various applications, including chemical storage and food processing. They are often used in environments where traditional materials may fail.

Pros: Fiberglass barrels are durable and can withstand harsh chemicals and environmental conditions. They are also non-reactive, ensuring that the contents remain uncontaminated.

Cons: While fiberglass is resistant to corrosion, it can be more expensive than plastic options. Additionally, the manufacturing process can be complex, leading to higher production costs.

Impact on Application: Fiberglass barrels are ideal for storing aggressive chemicals and can also be used in food processing applications. Their resistance to corrosion makes them suitable for outdoor storage.

Considerations for International Buyers: Buyers should verify that fiberglass barrels comply with local regulations for chemical and food storage. Understanding the specific requirements in regions like Africa and South America is essential for compliance.

Summary Table of Material Selection for 15 Gallon Barrels

| Material | Typical Use Case for 15 Gallon Barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Aging spirits and wines | Enhances flavor profile | Susceptible to leaks and rot | High |

| High-Density Polyethylene (HDPE) | Storing chemicals and food-grade materials | Cost-effective and lightweight | Limited temperature resistance | Low |

| Stainless Steel | Fermentation and chemical processing | Hygienic and easy to clean | Higher initial cost | High |

| Fiberglass | Storing aggressive chemicals | Corrosion resistant | More expensive than plastic | Medium |

This guide provides a comprehensive overview of the materials used in 15-gallon barrels, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 15 gallon barrel

What Are the Main Stages of the Manufacturing Process for a 15 Gallon Barrel?

The manufacturing of a 15-gallon barrel involves several key stages, each crucial for ensuring the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers appreciate the complexity and quality that goes into each barrel.

How Is Material Prepared for 15 Gallon Barrels?

The first step in the manufacturing process is material preparation. For wooden barrels, high-quality oak is often selected due to its favorable properties for aging liquids. The wood is typically air-dried or kiln-dried to reduce moisture content and prevent warping. For plastic barrels, high-density polyethylene (HDPE) is the material of choice, known for its durability and resistance to corrosion. The HDPE is sourced from reputable suppliers to ensure it meets food-grade standards, especially if the barrels are used for beverages or food storage.

What Techniques Are Used in Forming 15 Gallon Barrels?

Once the materials are prepared, the next stage is forming. For wooden barrels, staves are cut to specific dimensions and shaped to create a tight fit. The bending of the staves is usually achieved through steam treatment, which makes the wood pliable. The staves are then assembled into a circular shape, secured with metal hoops, and toasted or charred to enhance flavor profiles, particularly in the case of whiskey and wine barrels.

In the case of plastic barrels, the HDPE is heated and molded into the desired shape using blow-molding or injection-molding techniques. This process ensures a seamless, leak-proof construction, making them suitable for various applications, including chemical storage and food processing.

What Finishing Techniques Are Applied to 15 Gallon Barrels?

Finishing involves several processes to enhance the barrel’s appearance and functionality. For wooden barrels, this may include sanding and applying a finish to protect the wood from external elements. The barrels may also undergo a final inspection to check for any defects before being labeled and packaged.

Plastic barrels are typically subjected to quality checks after molding. They are cleaned and may have additional features like bungs or lids added, ensuring they are ready for immediate use. The finishing process for both types often includes branding or labeling, which is crucial for B2B buyers needing to maintain traceability and compliance with regulations.

Illustrative image related to 15 gallon barrel

What Quality Assurance Standards Are Relevant for 15 Gallon Barrels?

Quality assurance is a critical aspect of the manufacturing process for 15-gallon barrels. To ensure that the barrels meet international and industry-specific standards, manufacturers often adhere to various quality management systems and certifications.

Which International Standards Apply to 15 Gallon Barrel Manufacturing?

ISO 9001 is one of the most widely recognized international standards for quality management systems. It emphasizes a process approach to enhance customer satisfaction by meeting customer requirements consistently. Manufacturers of 15-gallon barrels may seek ISO 9001 certification to demonstrate their commitment to quality.

In addition to ISO standards, specific industries may require compliance with regulations like CE marking for products sold in Europe, and API standards for barrels used in the oil and gas sector. Understanding these certifications can help B2B buyers ensure they are purchasing from reputable suppliers.

What Are the Key Quality Control Checkpoints in Barrel Manufacturing?

Quality control (QC) is integrated into the manufacturing process through various checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, various parameters are monitored, such as dimensions, weight, and structural integrity.

- Final Quality Control (FQC): Before shipping, finished barrels undergo a thorough inspection for defects and compliance with specifications.

These checkpoints help identify and rectify issues early in the production process, reducing the risk of delivering subpar products.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability.

What Steps Can Be Taken to Verify Supplier QC?

-

Request Certification and Documentation: B2B buyers should ask for copies of quality management certifications, inspection reports, and testing results. This documentation provides insight into the supplier’s commitment to quality.

-

Conduct Supplier Audits: Regular audits can help buyers assess the manufacturing processes and QC measures firsthand. This can include on-site visits to the manufacturing facility to observe processes and meet the quality assurance team.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the barrels being produced. These inspectors can verify compliance with international standards and provide detailed reports to buyers.

What Are the QC and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification can be particularly important for B2B buyers from different regions. For instance, buyers in Europe may have stringent requirements regarding CE marking, while those in the Middle East might prioritize compliance with local regulations.

How Do Regional Standards Impact Barrel Quality?

Buyers should be aware that different regions may have varying standards for materials and manufacturing processes. For instance, barrels used for food storage in Europe must meet EU regulations, while those in the Middle East may need to comply with GCC standards. This can affect the choice of materials, manufacturing techniques, and overall barrel design.

In summary, the manufacturing processes and quality assurance measures for 15-gallon barrels are integral to delivering high-quality products to B2B buyers. By understanding these processes, buyers can make informed decisions and ensure they source barrels that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’15 gallon barrel’

In today’s competitive market, sourcing the right 15-gallon barrel can significantly impact your business operations, whether you are in distilling, brewing, or storage. This practical checklist serves as a comprehensive guide for international B2B buyers to ensure that they make informed decisions when procuring 15-gallon barrels.

Step 1: Define Your Technical Specifications

Before starting your search, clarify the specific requirements for your barrels. Consider the intended use—whether for aging spirits, storing food-grade products, or chemical applications. Additionally, identify the materials (e.g., wood, polyethylene) and design (e.g., closed head, open head) that best suit your needs. This step is crucial as it will help you filter potential suppliers effectively.

Step 2: Research Available Types of Barrels

Familiarize yourself with the various types of 15-gallon barrels on the market. Options include freshly emptied wooden barrels, plastic drums, and mixing barrels. Each type offers unique benefits:

– Wooden Barrels: Ideal for aging beverages, enhancing flavor through interaction with wood.

– Plastic Drums: Lightweight and resistant to corrosion, suitable for chemical and food storage.

Understanding these differences helps you choose the right type for your application.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough research. Assess their reputation by reviewing customer testimonials and case studies. Request information about their sourcing practices, production processes, and compliance with international regulations. A reliable supplier should have a proven track record of delivering quality products consistently.

Step 4: Verify Certifications and Compliance

Ensure that the barrels meet relevant industry standards and certifications. For food-grade barrels, confirm compliance with FDA regulations and other local standards. Look for certifications that indicate quality assurance, such as ISO or FDA approval. This step is vital to guarantee that the barrels are safe for their intended use and meet regulatory requirements.

Step 5: Request Samples for Quality Assessment

Before finalizing your order, request samples from potential suppliers. Assess the quality, durability, and suitability of the barrels for your specific application. Pay attention to details such as barrel construction, seals, and finishes. Testing samples can prevent costly mistakes and ensure that you receive the best product for your needs.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms. Request quotes from multiple suppliers to compare costs and ensure competitive pricing. Inquire about bulk purchase discounts, shipping costs, and payment options. Transparent communication about costs can help you budget effectively and avoid unexpected expenses.

Step 7: Finalize Logistics and Delivery

Once you have selected a supplier, confirm the logistics for delivery. Discuss shipping methods, lead times, and any potential customs requirements if you are importing barrels internationally. Clear logistics planning is essential to ensure timely delivery and uninterrupted operations.

By following this checklist, B2B buyers can streamline the sourcing process for 15-gallon barrels, ultimately making more informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for 15 gallon barrel Sourcing

What Are the Key Cost Components in Sourcing a 15-Gallon Barrel?

When sourcing 15-gallon barrels, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Illustrative image related to 15 gallon barrel

Materials: The choice of materials significantly affects the cost. For instance, wooden barrels (often used for aging spirits) may range from $129 to $189 based on the source and previous contents. Conversely, high-density polyethylene (HDPE) barrels, suitable for food-grade applications, are generally more economical, priced around $13 for used models.

Labor and Manufacturing Overhead: Labor costs vary by region and the complexity of barrel production. In regions with higher labor costs, such as Europe, the overall price may be elevated. Manufacturing overhead also plays a role, encompassing the cost of utilities, equipment maintenance, and facility operations, which can fluctuate based on local economic conditions.

Tooling and Quality Control: The initial investment in specialized tooling for barrel production can be substantial. This cost is typically amortized over large production runs, making it more economical for bulk orders. Additionally, stringent quality control measures are essential, especially for barrels intended for food or beverage storage, to ensure compliance with international safety standards.

Logistics and Margin: Logistics costs vary based on shipping routes and methods. For international buyers, factors such as customs duties and freight insurance can add to the total cost. Supplier margins also vary; larger manufacturers may offer lower prices due to economies of scale, while smaller suppliers might charge a premium for bespoke services.

How Do Price Influencers Affect the Sourcing of 15-Gallon Barrels?

Several factors influence the pricing of 15-gallon barrels, particularly for international B2B buyers.

Illustrative image related to 15 gallon barrel

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to bulk pricing. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

Specifications and Customization: Custom specifications, such as specific wood types or barrel finishes, can increase costs. Buyers must weigh the benefits of customization against budget constraints.

Material Quality and Certifications: The quality of materials used impacts both pricing and usability. Barrels with certifications (e.g., food-grade standards) may come at a premium but are essential for compliance in many markets.

Supplier Factors: Reliability, reputation, and responsiveness of suppliers can influence costs and long-term partnerships. Establishing a relationship with reputable suppliers can lead to better pricing and terms over time.

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers in shipping, insurance, and tariffs, which can significantly affect total costs.

What Buyer Tips Should Be Considered for Cost-Efficiency in International Sourcing?

B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should consider several strategies for effective sourcing of 15-gallon barrels.

Negotiation: Always approach negotiations with a clear understanding of your budget and requirements. Leverage volume to negotiate better terms and explore options for long-term contracts that may yield additional savings.

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, which includes shipping, storage, and potential disposal costs. A lower initial price might not always result in cost savings over the product’s lifecycle.

Illustrative image related to 15 gallon barrel

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing. Establishing payment terms that mitigate these risks can be beneficial. Additionally, familiarize yourself with local market conditions, as prices can vary significantly across regions.

Research and Due Diligence: Conduct thorough research on potential suppliers, including their production capabilities, delivery timelines, and customer feedback. This diligence can help avoid costly mistakes and ensure a reliable supply chain.

Disclaimer on Indicative Prices

Prices for 15-gallon barrels can fluctuate based on various factors, including market demand, supplier pricing strategies, and geopolitical influences. The figures provided are indicative and should be verified with suppliers to ensure accuracy and relevance to your specific sourcing needs.

Alternatives Analysis: Comparing 15 gallon barrel With Other Solutions

Introduction: Exploring Alternative Solutions to the 15 Gallon Barrel

When considering storage and transportation solutions for liquids or granular products, the 15-gallon barrel is a popular choice due to its versatility and efficiency. However, various alternatives exist that may better suit specific needs or operational contexts. This section evaluates the 15-gallon barrel against other viable solutions, allowing B2B buyers to make informed decisions based on performance, cost, ease of implementation, and maintenance.

Comparison Table

| Comparison Aspect | 15 Gallon Barrel | 15 Gallon Poly Drum | 15 Gallon Mixing Barrel |

|---|---|---|---|

| Performance | Excellent for aging and flavor infusion; ideal for small batches. | Good for storage; lightweight and durable. | Suitable for mixing materials; strong and lightweight. |

| Cost | Moderate cost, around $130-$190 depending on type. | Low cost, approximately $13.00 per drum. | Moderate cost, around $63.14. |

| Ease of Implementation | Requires manual handling and setup. | Easy to maneuver and stack; minimal setup required. | Simple to use with built-in handles. |

| Maintenance | Requires cleaning and maintenance after use. | Low maintenance; easy to clean due to smooth surface. | Easy to clean; designed for repeated use. |

| Best Use Case | Ideal for distillers and brewers needing flavor development. | Suitable for chemical storage, food-grade applications, and emergency water storage. | Best for mixing construction materials or liquids. |

Detailed Breakdown of Alternatives

1. 15 Gallon Poly Drum

The 15-gallon poly drum is a lightweight and cost-effective alternative to traditional barrels. Made from high-density polyethylene (HDPE), it is resistant to corrosion and denting, making it suitable for various storage needs. Its low price point (around $13) makes it attractive for bulk purchasing, especially for businesses needing to store chemicals or food products. However, its design lacks the flavor infusion capabilities of wooden barrels, limiting its application in industries like brewing and distilling. Furthermore, while easy to clean, it may not provide the same aesthetic appeal for brands focusing on presentation.

2. 15 Gallon Mixing Barrel

The 15-gallon mixing barrel is primarily designed for construction and DIY applications, offering a robust solution for mixing materials. It features a strong, lightweight design with built-in handles for easy transport. Priced around $63, it presents a moderate investment for businesses focused on mixing liquids or concrete. While it excels in mixing applications, it is less suitable for aging beverages or storing products requiring prolonged contact with wood. This barrel type also demands some maintenance but is generally easy to clean and reusable, making it a practical choice for construction companies.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right storage or mixing solution hinges on understanding specific operational requirements and constraints. The 15-gallon barrel is ideal for applications requiring flavor development, such as in the brewing and distilling industries. In contrast, the 15-gallon poly drum serves well for general storage needs, particularly when cost is a primary concern. Meanwhile, the mixing barrel is best suited for construction and DIY projects. B2B buyers should assess their unique needs, considering factors such as product type, desired outcomes, and budget constraints, to make the most informed choice.

Essential Technical Properties and Trade Terminology for 15 gallon barrel

What Are the Key Technical Properties of a 15 Gallon Barrel?

When considering the procurement of 15-gallon barrels, understanding their technical properties is crucial for ensuring the right fit for your business needs. Here are some essential specifications to keep in mind:

-

Material Grade

– Definition: The material grade indicates the type of material used in barrel construction, such as wood (oak, pine) or plastic (HDPE).

– B2B Importance: The choice of material affects the barrel’s durability, flavor impartation (in the case of wooden barrels), and suitability for specific contents (e.g., food-grade plastics for chemicals or beverages). Selecting the right material ensures compliance with safety standards and helps in optimizing the aging or storage process. -

Dimensions and Volume Tolerance

– Definition: Standard dimensions for a 15-gallon barrel typically include a height of about 30 inches and a diameter of approximately 16 inches. Tolerance refers to allowable deviations from these dimensions.

– B2B Importance: Accurate dimensions ensure compatibility with existing storage and transportation systems. Understanding tolerances helps buyers avoid issues related to space constraints or packaging inefficiencies. -

Bung Size and Type

– Definition: The bung is the opening in the barrel for filling and emptying contents, typically available in sizes like 2-inch or 3-inch.

– B2B Importance: The bung size influences ease of access for filling, cleaning, and sampling. Choosing the right bung type ensures compatibility with pumps and other equipment, facilitating smoother operations. -

Weight Capacity

– Definition: This refers to the maximum weight the barrel can safely hold, which varies based on the material and construction.

– B2B Importance: Knowing the weight capacity is vital for logistics and transportation planning. It helps ensure that the barrels can safely carry the intended contents without risk of structural failure. -

Closure Type

– Definition: Closure types can include screw caps, bungs, or lids, depending on the barrel design.

– B2B Importance: The choice of closure affects the barrel’s seal integrity and ease of access. A secure closure prevents leaks and contamination, which is essential for maintaining product quality during storage or transport.

What Are Common Trade Terms Related to 15 Gallon Barrels?

Familiarity with industry jargon can enhance communication and negotiation processes. Here are some common terms relevant to purchasing 15-gallon barrels:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is important for buyers seeking custom barrels or specific features, as it influences product availability and warranty conditions. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell in a single order.

– Relevance: Knowing the MOQ helps businesses plan their purchases effectively. It prevents over-commitment and ensures that stock levels meet operational needs without excess. -

RFQ (Request for Quotation)

– Definition: A formal document requesting pricing and terms from suppliers for specific goods or services.

– Relevance: Submitting an RFQ is crucial for comparing prices and terms across different suppliers, enabling better negotiation and cost management. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that delineate responsibilities of buyers and sellers.

– Relevance: Understanding Incoterms helps businesses navigate shipping and logistics, clarifying who bears costs and risks at various stages of transport. -

Lead Time

– Definition: The time it takes from placing an order to receiving the goods.

– Relevance: Knowing the lead time is essential for planning inventory and production schedules, ensuring that operations run smoothly without interruptions.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions regarding their purchase of 15-gallon barrels, ensuring they meet both operational and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the 15 gallon barrel Sector

What are the Key Market Dynamics and Trends Influencing the 15 Gallon Barrel Sector?

The 15-gallon barrel market is currently experiencing significant growth, driven by several global factors. The rise in craft beverage production, particularly in the distilling and brewing sectors, is one of the primary catalysts. As international consumers increasingly seek unique flavors and artisanal products, distillers and brewers are turning to smaller barrels for quicker aging processes and enhanced flavor extraction. This trend is particularly pronounced in regions like Africa and South America, where emerging markets are beginning to adopt craft beverage practices.

Moreover, technological advancements in barrel production and treatment have allowed manufacturers to offer customizable options that cater to specific flavor profiles and storage needs. For instance, innovations in wood sourcing and treatment enable barrels to enhance the characteristics of spirits and wines more effectively. In regions such as the Middle East, where regulatory frameworks for beverage production are evolving, there is a growing demand for compliant and reliable sourcing of barrels that meet local standards.

Illustrative image related to 15 gallon barrel

International B2B buyers are also increasingly focusing on logistics and supply chain efficiency. The ability to source barrels quickly and reliably has become a competitive advantage. With the expansion of e-commerce platforms, buyers from Europe, Vietnam, and Saudi Arabia can easily compare prices, quality, and supplier reputations, fostering a more transparent marketplace. Additionally, fluctuating raw material costs and geopolitical factors can impact sourcing strategies, compelling buyers to adopt more flexible procurement practices.

How is Sustainability Influencing the Sourcing of 15 Gallon Barrels in B2B Transactions?

Sustainability is becoming a key consideration for B2B buyers in the 15-gallon barrel sector. The environmental impact of barrel production, particularly concerning deforestation and waste, has led to a heightened demand for ethically sourced materials. Buyers are increasingly looking for suppliers who can demonstrate sustainable practices, such as using recycled wood or certified sustainably harvested materials.

Moreover, the push for “green” certifications is influencing purchasing decisions. International buyers are interested in suppliers that can provide evidence of environmental stewardship, such as Forest Stewardship Council (FSC) certification or adherence to similar standards. These certifications not only enhance a company’s reputation but also align with the growing consumer preference for environmentally friendly products.

Ethical sourcing extends beyond materials to include the entire supply chain. Buyers are keen to partner with suppliers who prioritize fair labor practices and community engagement in their sourcing strategies. This trend is particularly important in emerging markets, where transparency and ethical considerations can significantly influence brand loyalty and market acceptance.

Illustrative image related to 15 gallon barrel

What is the Historical Context of the 15 Gallon Barrel Market?

The 15-gallon barrel has evolved significantly since its inception, primarily used for the transportation and storage of liquids. Historically, barrels have been a staple in the wine and spirit industries, with larger formats dominating the market. However, the craft beverage movement has spurred interest in smaller barrels, allowing for quicker aging and experimentation with flavors.

In recent years, technological advancements have transformed barrel production, enabling a wider variety of materials and designs. This evolution reflects changing consumer preferences and the growing importance of customization in beverage production. As the market continues to develop, the 15-gallon barrel is poised to play a pivotal role in the future of craft beverages, offering a blend of tradition and innovation that appeals to both producers and consumers alike.

In conclusion, understanding these market dynamics, sustainability imperatives, and historical context can empower B2B buyers in making informed decisions when sourcing 15-gallon barrels. By aligning with suppliers that prioritize quality, sustainability, and ethical practices, businesses can enhance their operational efficiency and brand value in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of 15 gallon barrel

-

How do I determine the right type of 15-gallon barrel for my needs?

When selecting a 15-gallon barrel, consider the intended use—whether for aging spirits, food storage, or chemical containment. For distillers and brewers, freshly emptied barrels offer enhanced flavors due to the residual contents. Alternatively, for non-food applications, HDPE poly barrels may provide durability and resistance to corrosion. It’s crucial to verify the material’s compatibility with your specific contents, as well as FDA or international standards for food-grade storage if applicable. -

What are the standard dimensions of a 15-gallon barrel?

A typical 15-gallon barrel usually has a height of approximately 30 inches and a diameter of about 16 inches. These dimensions can vary slightly based on the barrel’s design and manufacturer. When sourcing barrels, confirm the specifications to ensure they fit your storage or transport needs, especially if space constraints are a concern in your facility. -

How can I vet suppliers for 15-gallon barrels internationally?

To effectively vet suppliers, start by researching their reputation through industry reviews and testimonials. Verify their certifications, such as ISO or FDA compliance, to ensure quality standards. Engaging in direct communication can provide insights into their production practices and customer service. Additionally, consider requesting samples or visiting their facilities, if feasible, to assess their operations firsthand. -

What is the minimum order quantity (MOQ) for 15-gallon barrels?

The MOQ for 15-gallon barrels can vary significantly based on the supplier and the type of barrel. Generally, manufacturers may require a minimum order of anywhere from 10 to 100 barrels, particularly for customized or specialty items. Always inquire about potential discounts for bulk orders and check if they offer flexible options for smaller orders to accommodate your immediate needs. -

What payment terms should I expect when purchasing 15-gallon barrels?

Payment terms for purchasing 15-gallon barrels can differ widely among suppliers. Common practices include upfront payment, a deposit followed by the balance upon delivery, or net 30/60 terms for established accounts. It’s essential to clarify payment methods accepted, including bank transfers, letters of credit, or online payment platforms. Ensure that you understand any fees associated with international transactions, such as currency conversion or transfer fees. -

What quality assurance measures should I look for when sourcing barrels?

Quality assurance for barrels involves several checks, including material integrity, proper sealing, and compliance with safety standards. Suppliers should provide certifications that detail the barrel’s suitability for its intended use, especially for food-grade applications. Look for guarantees regarding the barrel’s durability and resistance to leakage. It’s advisable to request a detailed inspection report or have a third-party inspection if sourcing in large quantities. -

How do I handle logistics and shipping for 15-gallon barrels?

When arranging logistics for shipping 15-gallon barrels, consider the weight and volume of your order, as these factors will influence freight costs. Confirm shipping options with your supplier, including delivery timelines and any customs regulations that may apply in your destination country. Partnering with a reliable freight forwarder can streamline the process, ensuring compliance with international shipping standards and minimizing delays. -

Are there customization options available for 15-gallon barrels?

Many suppliers offer customization options for 15-gallon barrels, including branding, color, and specific design features such as bungs or lids. Customization can enhance your product’s marketability and align with your brand identity. However, it’s important to discuss minimum order quantities and lead times for customized barrels, as these may differ from standard offerings. Always request a prototype or mock-up before finalizing your order to ensure it meets your specifications.

Top 1 15 Gallon Barrel Manufacturers & Suppliers List

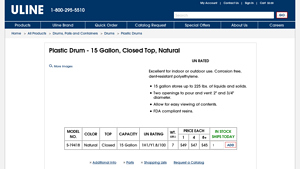

1. Uline – Plastic Drum 15 Gallon

Domain: uline.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Plastic Drum – 15 Gallon, Closed Top, Natural”, “Model Number”: “S-19418”, “Capacity”: “15 Gallon (57 L)”, “Weight”: “7 lbs (3 Kg)”, “Material”: “HDPE (High Density Polyethylene)”, “Color”: “Natural”, “UN Rating”: “1H1/Y1.8/100”, “Dimensions”: {“Height”: “26 1/4 inches”, “Diameter”: “14 inches”}, “Temperature Range”: “0° – 120° F”, “Features”: [“Corrosion free”, “Dent-resistant”,…

Strategic Sourcing Conclusion and Outlook for 15 gallon barrel

What Are the Key Benefits of Strategic Sourcing for 15 Gallon Barrels?

In today’s competitive landscape, strategic sourcing for 15-gallon barrels is essential for businesses looking to optimize their supply chains. Sourcing high-quality barrels, whether for distilling, brewing, or industrial use, allows companies to enhance product quality while managing costs effectively. The diverse options available—from freshly emptied wooden barrels to durable plastic drums—offer flexibility and adaptability for various applications, catering to different market needs across Africa, South America, the Middle East, and Europe.

How Can International Buyers Leverage Global Sourcing Opportunities?

International buyers should focus on establishing relationships with reputable suppliers who understand regional regulations and can provide barrels that meet specific industry standards. Engaging with suppliers who offer customization options can also enhance product differentiation in local markets. By leveraging these global sourcing opportunities, businesses can ensure they remain competitive while minimizing lead times and costs.

What Is the Future Outlook for 15 Gallon Barrel Sourcing?

As demand for sustainable and versatile packaging solutions grows, the market for 15-gallon barrels is expected to expand. Companies that prioritize strategic sourcing will be better positioned to adapt to changing market dynamics and consumer preferences. Now is the time for international B2B buyers to explore these opportunities and invest in quality sourcing strategies to secure their supply chains and drive growth in their respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to 15 gallon barrel

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.