Door Latch Parts Terminology: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for door latch parts terminology

In the dynamic landscape of global commerce, understanding door latch parts terminology is essential for B2B buyers seeking reliable and high-quality components. One of the key challenges faced by international buyers—especially from regions like Africa, South America, the Middle East, and Europe—is the diverse range of products and specifications available in the market. This guide serves as a comprehensive resource, breaking down the intricate world of door latch parts, including various types, applications, and the standards that govern them.

From deadbolts to latches, this guide provides an in-depth look at the essential components, ensuring that buyers are well-equipped to make informed decisions. Additionally, we delve into the crucial aspects of supplier vetting, pricing strategies, and best practices for sourcing door latch parts that meet both functional and regulatory requirements.

By leveraging this guide, B2B buyers can navigate the complexities of the global market with confidence. They will gain insights that empower them to select the right products, mitigate risks associated with sourcing, and ultimately enhance their operational efficiency. Whether you are a procurement manager in Germany or a contractor in Saudi Arabia, understanding door latch parts terminology will be a cornerstone of your successful purchasing strategy.

Understanding door latch parts terminology Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tubular Latch | Spring-loaded mechanism, typically cylindrical design | Commercial doors, residential entryways | Pros: Easy installation; versatile. Cons: May require specific door prep. |

| Deadbolt | Solid steel bolt for added security, available in single/double cylinder | Exterior doors, high-security applications | Pros: High security; durable. Cons: More complex installation; can be expensive. |

| Ball Catch | Spring-loaded ball mechanism, typically used in closets | Closet doors, interior sliding doors | Pros: Discreet; simple operation. Cons: Limited to specific applications. |

| Flush Bolt | Installed flush with the door edge, often used in French doors | Double doors, French doors | Pros: Hidden mechanism; secure locking. Cons: Requires precise installation. |

| Dummy Knob/Lever | Non-functional, decorative, mounts directly to the door | Interior doors, non-privacy applications | Pros: Aesthetic appeal; easy to install. Cons: No locking mechanism; limited function. |

What Are the Characteristics and Suitability of a Tubular Latch?

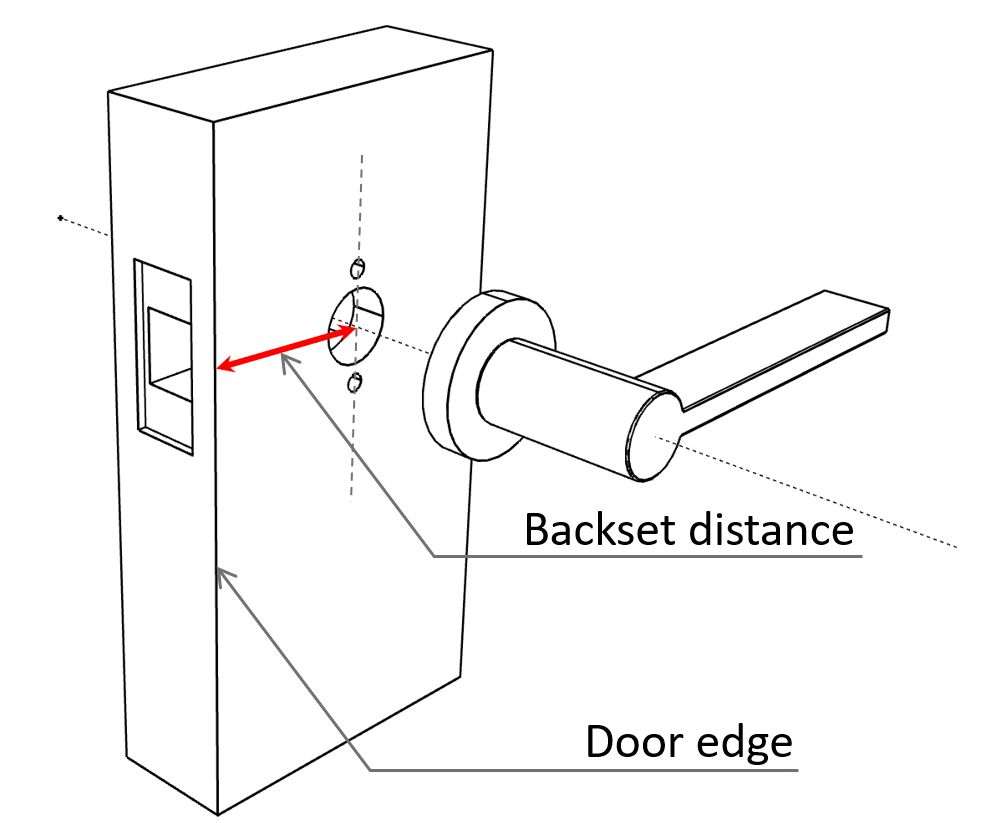

A tubular latch is a widely used door latch mechanism that features a spring-loaded design, allowing for smooth operation when opening and closing doors. This type of latch is typically cylindrical and installed within a bore hole in the door. Tubular latches are suitable for various applications, including commercial and residential entryways, as they are compatible with standard door preparations. When purchasing, consider the backset measurement and ensure that the latch fits the specific door configuration to avoid installation issues.

How Does a Deadbolt Enhance Security in B2B Applications?

Deadbolts are robust locking mechanisms that provide enhanced security for exterior doors. They feature a solid steel bolt that extends deep into the door frame when locked, making forced entry significantly more difficult. Available in single and double cylinder options, deadbolts are ideal for high-security applications in commercial settings, such as offices and warehouses. Buyers should consider the level of security required, the door type, and the complexity of installation when selecting a deadbolt, as some may require professional installation.

What Are the Key Benefits of a Ball Catch in Interior Applications?

Ball catches are unique latch mechanisms designed primarily for interior applications, such as closet doors. They consist of a spring-loaded ball that fits into an indentation on a strike plate, allowing the door to close securely without the need for a traditional latch. Their discreet design makes them ideal for applications where aesthetics are important. When considering a ball catch, buyers should evaluate the specific door type and ensure compatibility, as they are not suitable for all door configurations.

Why Are Flush Bolts Ideal for French Doors?

Flush bolts are often used in conjunction with French doors, providing a secure locking mechanism that is mounted flush with the edge of the door. This design allows one door to remain fixed while the other operates normally, enhancing security without compromising aesthetics. When selecting flush bolts, buyers should focus on the precision of installation, as improper alignment can lead to functionality issues. These bolts are particularly useful in high-traffic areas where both security and ease of use are priorities.

What Role Do Dummy Knobs or Levers Play in Door Hardware?

Dummy knobs and levers serve a primarily decorative purpose, offering an attractive finish to doors that do not require a locking mechanism. They are commonly used on interior doors, such as closets or as a pull on non-functional doors. While easy to install, buyers should be aware that dummy knobs do not provide any locking capabilities, making them unsuitable for applications requiring security. When selecting dummy hardware, consider the design and finish to ensure it complements the overall aesthetic of the space.

Key Industrial Applications of door latch parts terminology

| Industry/Sector | Specific Application of door latch parts terminology | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Installation of commercial doors and access points | Enhances security and accessibility in commercial spaces | Compliance with local building codes and standards |

| Hospitality | Door hardware for hotel rooms and facilities | Provides safety and convenience for guests | Durability and aesthetic appeal to match hotel branding |

| Residential Development | Latch systems for residential homes | Ensures safety and privacy for homeowners | Variety of styles and finishes to cater to diverse markets |

| Automotive | Door latches in vehicles | Critical for vehicle security and user experience | Compatibility with various vehicle models and standards |

| Industrial Manufacturing | Secure access to manufacturing facilities | Protects equipment and sensitive areas | Robustness and reliability under high-use conditions |

How is Door Latch Parts Terminology Used in the Construction Industry?

In the construction sector, door latch parts terminology is crucial for the installation of commercial doors and access points. Proper understanding of terms like backset, bore hole, and latch mechanisms ensures that doors are fitted correctly for optimal security and usability. For international buyers, particularly those in Africa and South America, compliance with local building codes and standards is vital. This guarantees that the door hardware not only meets safety requirements but also functions effectively in diverse environmental conditions.

What Role Does Door Latch Parts Terminology Play in the Hospitality Sector?

In the hospitality industry, door latch parts terminology is essential for designing and installing door hardware in hotel rooms and facilities. Understanding the nuances of privacy locks, keyed entry systems, and passage knobs helps ensure that guests have a secure and comfortable experience. For buyers in regions like the Middle East and Europe, sourcing durable and aesthetically pleasing hardware is key to enhancing the overall guest experience while aligning with the hotel’s branding.

How is Door Latch Parts Terminology Relevant to Residential Development?

For residential development, door latch parts terminology is vital in ensuring that latch systems provide safety and privacy for homeowners. Terms such as mortise locks and privacy locks directly relate to the security features that buyers seek in residential properties. International buyers, especially in Europe and Africa, often require a variety of styles and finishes to accommodate different architectural designs and cultural preferences, emphasizing the importance of aesthetic appeal alongside functionality.

Why is Door Latch Parts Terminology Important in the Automotive Industry?

In the automotive industry, door latches are critical components that enhance vehicle security and user experience. Understanding the terminology related to latches, including key cylinders and deadbolts, allows manufacturers to design systems that meet safety regulations and consumer expectations. For international buyers, compatibility with various vehicle models and adherence to industry standards are essential considerations when sourcing these components.

How Does Door Latch Parts Terminology Impact Industrial Manufacturing?

In industrial manufacturing, door latch parts terminology is crucial for securing access to sensitive areas and equipment. Knowledge of latch mechanisms and their installation can significantly impact the security and efficiency of manufacturing operations. Buyers in this sector must prioritize sourcing robust and reliable latch systems that can withstand high-use conditions, ensuring long-term functionality and safety in their facilities.

3 Common User Pain Points for ‘door latch parts terminology’ & Their Solutions

Scenario 1: Navigating Inconsistent Terminology Across Suppliers

The Problem: B2B buyers often face confusion due to inconsistent terminology used by different suppliers regarding door latch parts. For example, a buyer in South America may refer to a “tubular latch,” while a supplier in Europe might label it as a “latch mechanism.” This discrepancy can lead to miscommunication, incorrect orders, and ultimately delays in project timelines. Such misunderstandings become particularly problematic when working with multiple suppliers, as buyers must familiarize themselves with various terms, which can be time-consuming and frustrating.

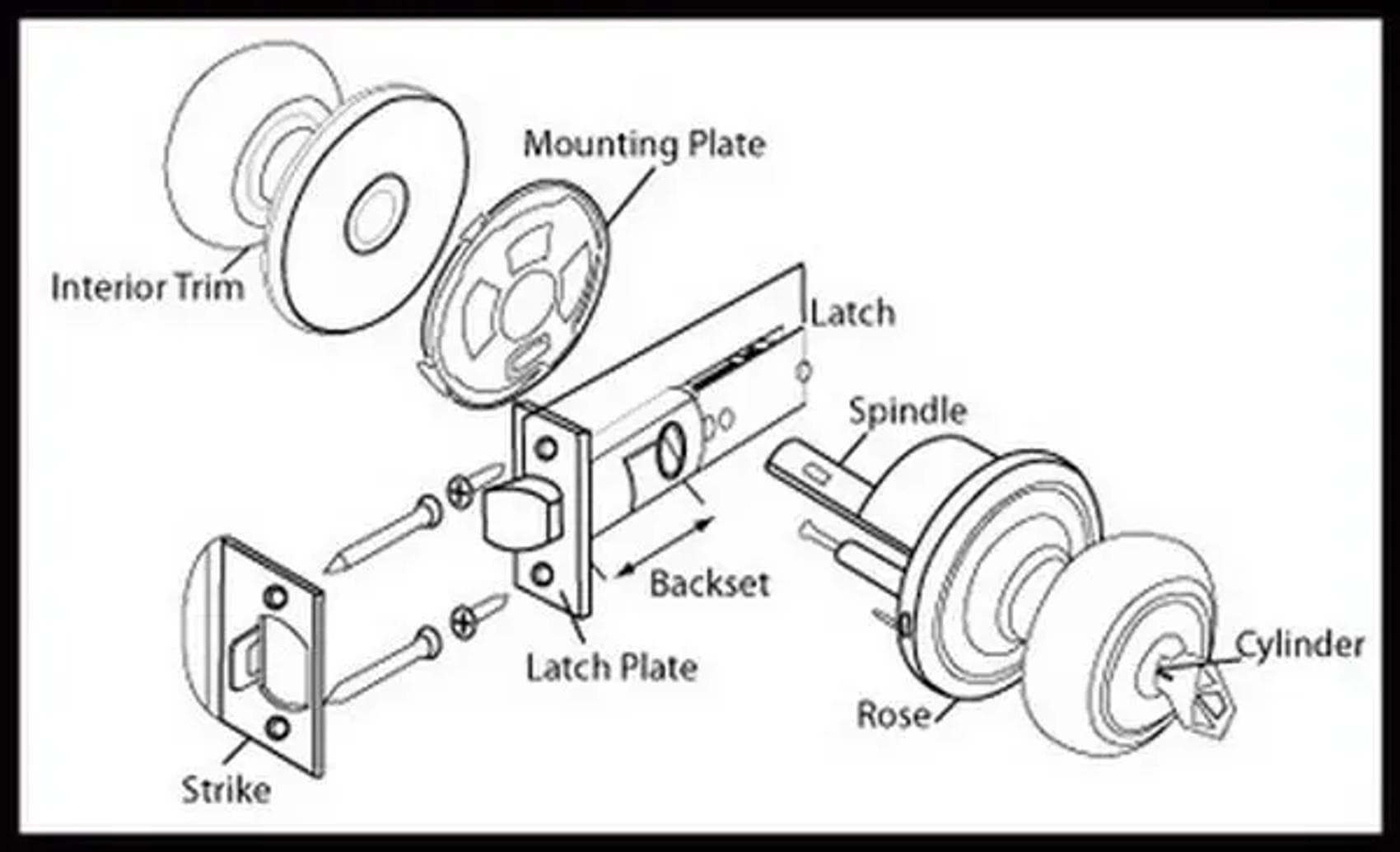

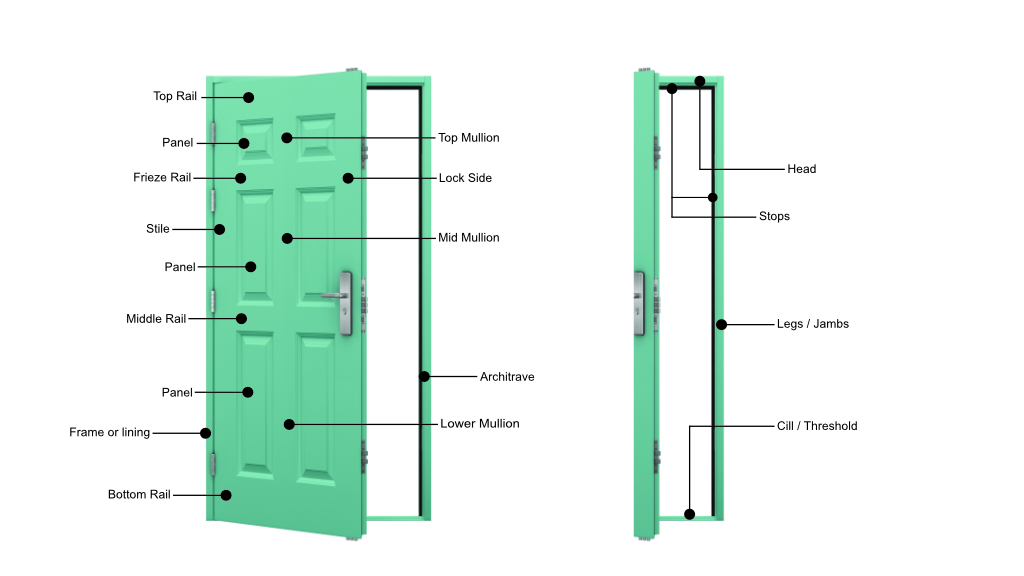

Illustrative image related to door latch parts terminology

The Solution: To mitigate this issue, B2B buyers should establish a standardized glossary of door latch parts terminology that aligns with their suppliers. This can be achieved by reaching out to suppliers to request their specific definitions and terms. Additionally, creating a visual reference guide that includes diagrams and labeled parts can help ensure that everyone involved in the procurement process is on the same page. Utilizing collaborative platforms or shared documents can facilitate real-time updates and ensure that all team members are informed of the standardized terms. By doing this, buyers can streamline their procurement processes, reduce errors, and foster better relationships with suppliers.

Scenario 2: Understanding Compatibility of Door Latch Parts

The Problem: Compatibility issues frequently arise when B2B buyers attempt to source door latch parts for different door types or styles. For instance, a buyer may purchase a latch that does not fit the specific backset measurement of their doors, leading to wasted time and resources. This challenge is exacerbated when buyers are dealing with custom or non-standard door specifications, which may require specialized parts that are not readily available.

The Solution: To address compatibility concerns, buyers should first conduct a comprehensive assessment of their door specifications, including measurements such as bore hole diameter and backset depth. When sourcing door latch parts, buyers should prioritize suppliers that provide detailed product specifications and compatibility information. Utilizing adjustable latches that accommodate multiple backset measurements can also be a practical solution. Furthermore, buyers can consult with technical representatives from suppliers to ensure they are selecting the correct components for their specific applications. Keeping a detailed inventory of existing door hardware and their specifications will enable buyers to make informed decisions and avoid costly mistakes.

Scenario 3: Ensuring Compliance with Regional Standards

The Problem: B2B buyers often struggle with ensuring that door latch parts comply with local building codes and safety standards, which can vary significantly across regions like Africa, the Middle East, and Europe. For example, a buyer in Germany may need to adhere to strict fire safety regulations that dictate the use of specific latch mechanisms, while a buyer in Saudi Arabia might prioritize security features that align with local standards. Failing to comply with these regulations can result in project delays, legal complications, and additional costs.

The Solution: To ensure compliance, buyers should conduct thorough research on the relevant building codes and safety standards in their target markets. Collaborating with local experts or regulatory bodies can provide valuable insights into necessary requirements for door latch parts. Additionally, buyers should work closely with suppliers who are knowledgeable about regional compliance issues and can offer products that meet these standards. Investing in training for procurement teams on local regulations can further enhance understanding and ensure that all specifications are met. By proactively addressing compliance concerns, buyers can streamline the approval process and enhance their project’s success rate.

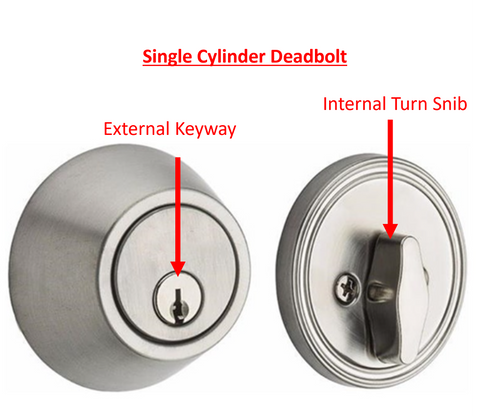

Illustrative image related to door latch parts terminology

Strategic Material Selection Guide for door latch parts terminology

What Are the Key Properties of Common Materials Used in Door Latch Parts?

When selecting materials for door latch components, understanding the properties of various materials is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in door latch parts: stainless steel, brass, zinc die-cast, and plastic.

How Does Stainless Steel Perform in Door Latch Applications?

Stainless steel is renowned for its excellent corrosion resistance and durability, making it a popular choice for door latch parts, especially in environments prone to moisture or extreme temperatures. Key properties include high tensile strength and resistance to rust, which ensures that the latch functions effectively over time.

Pros: Stainless steel is highly durable and can withstand significant wear and tear, making it suitable for high-traffic areas. It also has a sleek appearance, which is aesthetically appealing for modern designs.

Cons: The primary drawback is its cost; stainless steel is generally more expensive than other materials. Additionally, its manufacturing process can be complex, potentially leading to longer lead times.

Impact on Application: Stainless steel latches are ideal for exterior doors or environments with high humidity, as they maintain functionality without rusting.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential. Buyers from regions such as Europe and the Middle East often prefer stainless steel for its longevity and low maintenance, aligning with local building codes.

What Advantages Does Brass Offer for Door Latch Parts?

Brass is another commonly used material for door latch components due to its natural resistance to corrosion and its antimicrobial properties. It is often used in decorative applications because of its warm, golden hue.

Pros: Brass is relatively easy to machine and can be cast into intricate designs, making it suitable for decorative latches. It also offers good durability and resistance to tarnishing.

Cons: Brass can be softer than stainless steel, making it less suitable for high-impact applications. Additionally, it can be more expensive than alternatives like zinc die-cast.

Impact on Application: Brass is ideal for interior doors or low-traffic areas where aesthetics are a priority over heavy-duty performance.

Considerations for International Buyers: Buyers should ensure that brass components meet relevant standards for safety and performance. In regions like Africa and South America, the preference for brass may vary based on cultural aesthetics and local availability.

How Does Zinc Die-Cast Compare for Door Latch Parts?

Zinc die-cast is a cost-effective material often used for producing door latch components. It is lightweight and can be produced in complex shapes, making it a versatile option.

Pros: The primary advantage of zinc die-cast is its affordability and ease of manufacturing, which allows for rapid production of various designs. It also has good corrosion resistance, especially when coated.

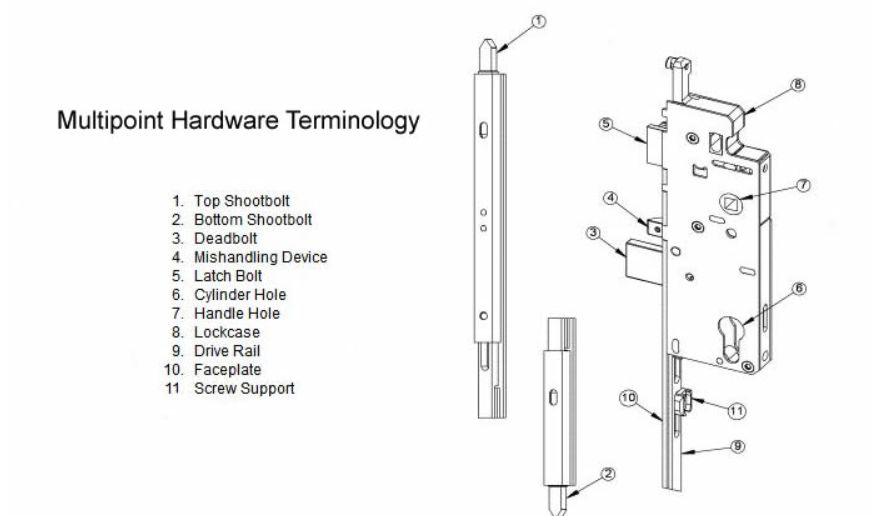

Illustrative image related to door latch parts terminology

Cons: However, zinc die-cast is less durable than stainless steel or brass and may not withstand heavy use or extreme conditions. It can also be prone to cracking under stress.

Impact on Application: Zinc die-cast latches are suitable for interior applications or as secondary latches where high strength is not critical.

Considerations for International Buyers: Buyers should be aware of the quality of zinc die-cast products, as lower-grade materials may not meet international standards. Compliance with regional regulations is also vital.

What Role Does Plastic Play in Door Latch Components?

Plastic is increasingly being used for door latch parts due to its lightweight nature and resistance to corrosion. It is often employed in applications where weight savings are essential.

Pros: The main advantages of plastic include its low cost and versatility in design. It can be molded into various shapes and colors, making it ideal for custom applications.

Cons: However, plastic lacks the strength and durability of metal options and may not perform well under extreme temperatures or heavy loads.

Impact on Application: Plastic latches are best suited for lightweight doors or as temporary solutions in low-traffic areas.

Considerations for International Buyers: Buyers should consider the environmental impact of plastic, as well as its compliance with local regulations. In regions with stringent environmental laws, the use of recyclable materials may be preferred.

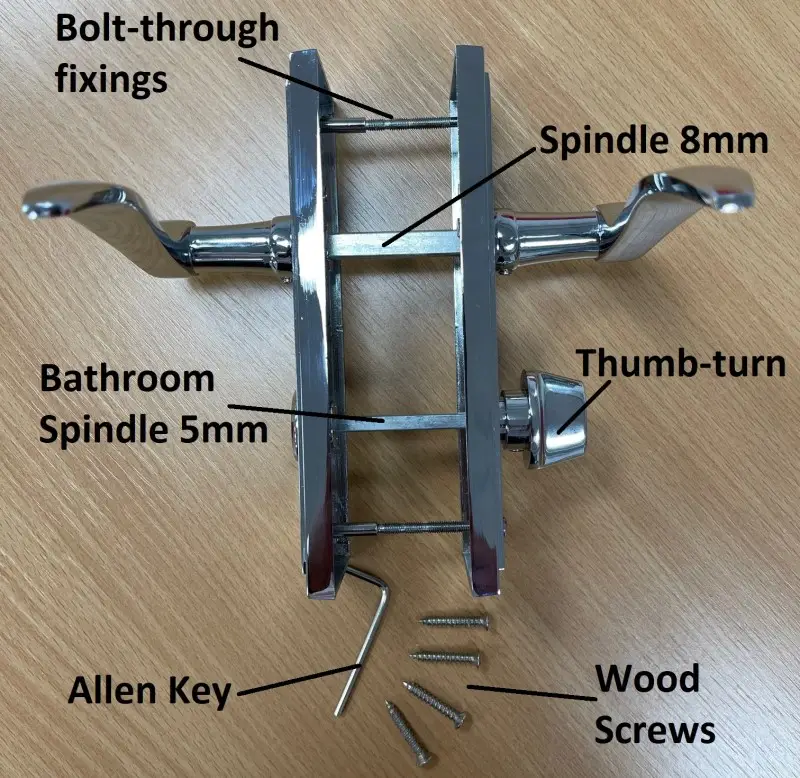

Illustrative image related to door latch parts terminology

Summary of Material Selection for Door Latch Parts

| Material | Typical Use Case for door latch parts terminology | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Exterior doors, high-traffic areas | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Interior doors, decorative applications | Aesthetically pleasing, durable | Softer than stainless steel | Med |

| Zinc Die-Cast | Interior applications, secondary latches | Cost-effective and easy to manufacture | Less durable, prone to cracking | Low |

| Plastic | Lightweight doors, low-traffic areas | Lightweight, versatile design | Lacks strength and durability | Low |

This guide provides B2B buyers with critical insights into material properties and considerations, aiding in informed decision-making for door latch components across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for door latch parts terminology

What Are the Main Stages of Manufacturing Door Latch Parts?

The manufacturing process for door latch parts involves several key stages, each critical to ensuring the functionality and reliability of the final product. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Door Latch Manufacturing?

Material preparation is the foundational step in the manufacturing process. Typically, door latch components are made from various metals, including brass, stainless steel, and zinc die-cast materials. The selection of raw materials is crucial, as it directly impacts durability, corrosion resistance, and overall performance.

During this stage, materials are sourced from certified suppliers who comply with international standards. Material checks, including hardness tests and chemical composition analysis, are performed to ensure they meet specifications. This is particularly important for international buyers, who may have varying standards depending on their regional regulations.

What Forming Techniques Are Used in Door Latch Production?

Once the materials are prepared, the next step involves forming them into specific shapes required for door latch components. Common forming techniques include:

-

Stamping: This process uses a die to cut and shape metal sheets into desired profiles. It is efficient for producing large volumes of parts, such as latch plates and bodies.

-

Casting: In cases where complex shapes are needed, casting techniques may be employed. This involves pouring molten metal into molds to create intricate components like lock mechanisms.

-

Machining: Precision machining is often utilized to achieve tight tolerances and fine details, especially for moving parts like latches and bolts. This includes processes such as milling and turning.

Each technique has its advantages and is chosen based on the specific requirements of the latch design.

How Are Door Latch Parts Assembled?

After forming, the various components are brought together in the assembly stage. This involves:

-

Fitting: Components such as latches, bolts, and faceplates are fitted together. This step may involve manual assembly or automated processes, depending on the production scale.

-

Fastening: Parts are secured using screws, rivets, or welding techniques to ensure durability. The method of fastening can vary based on the design and intended use of the latch.

-

Functional Testing: As the assembly progresses, components undergo functional tests to ensure they work as intended. This includes checking the smooth operation of latches and locks.

What Finishing Processes Are Applied to Door Latch Parts?

The finishing stage focuses on enhancing the aesthetic and functional qualities of door latch parts. Common finishing processes include:

-

Plating: Many door latch components are plated with materials such as chrome or nickel to improve corrosion resistance and provide an attractive finish.

-

Powder Coating: This process involves applying a dry powder that is cured under heat to create a durable finish. It is often used for parts requiring color coding or additional protection.

-

Quality Inspection: Final quality inspections are conducted to ensure that the parts meet the required specifications and standards.

What Quality Control Measures Are Essential for Door Latch Manufacturing?

Quality assurance is a critical aspect of the manufacturing process for door latch parts. International buyers should be particularly aware of relevant quality control measures and standards.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards ensures that manufacturers consistently meet customer and regulatory requirements. Other industry-specific certifications may include:

-

CE Marking: Indicates that the product meets European safety, health, and environmental protection standards.

-

API Certification: Relevant for manufacturers producing latches used in the oil and gas industry, ensuring adherence to specific performance standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon receipt to verify that they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to identify any deviations from the required specifications.

-

Final Quality Control (FQC): The finished products undergo comprehensive testing and inspection before they are packaged and shipped. This may include functional tests, dimensional checks, and surface quality inspections.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that their suppliers maintain rigorous quality control processes:

-

Supplier Audits: Conducting regular audits of suppliers can help verify their adherence to quality standards and manufacturing processes. This is particularly important for international transactions where standards may vary.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including test results and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and final products, ensuring they meet the buyer’s quality expectations.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers must navigate various challenges related to quality control. These may include differing regulatory requirements across regions, language barriers, and cultural differences in business practices. It is essential for buyers to:

-

Understand Local Standards: Familiarize themselves with the standards applicable in their regions, especially if they are importing from countries with different regulations.

-

Establish Clear Communication: Maintaining open lines of communication with suppliers can help address any quality concerns promptly and effectively.

-

Build Strong Relationships: Developing long-term partnerships with reliable suppliers can enhance trust and facilitate smoother quality assurance processes.

By understanding the manufacturing processes and quality assurance standards associated with door latch parts, B2B buyers can make informed decisions, ensuring they procure high-quality components that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door latch parts terminology’

To facilitate effective procurement of door latch parts, this guide provides a structured checklist designed specifically for B2B buyers. Understanding door latch terminology is essential for ensuring compatibility, quality, and security in your purchasing decisions. Follow these steps to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is crucial for ensuring that the door latch parts you select meet your operational needs. Consider factors such as backset measurements, bore hole sizes, and whether you require adjustable or fixed latches. This clarity helps avoid costly errors and ensures compatibility with existing hardware.

- Backset Measurement: Standard backsets are typically 2 3/8″ or 2 3/4″. If your doors have different measurements, be prepared to explore specialized options.

- Bore Hole and Crossbore Sizes: Ensure that the dimensions match standard or custom specifications for seamless installation.

Step 2: Research and Understand Key Terminology

Familiarize yourself with essential terminology related to door latch parts. This understanding will empower you to communicate effectively with suppliers and make informed decisions. Key terms include:

- Latch Mechanism: Understand the difference between tubular latches and mortise locks, as this impacts security and installation methods.

- Privacy vs. Keyed Entry: Know the distinctions between privacy locks and keyed entry systems to select the right product for your application.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. This includes reviewing company profiles and requesting references from previous clients. A well-established supplier with a track record in your region can be invaluable.

- Request Case Studies: Understanding how a supplier has addressed similar needs in the past can provide insights into their capabilities.

- Supplier Certifications: Verify that the suppliers hold necessary quality certifications, which can indicate adherence to industry standards.

Step 4: Assess Quality and Compliance Standards

Quality assurance is non-negotiable in door latch parts procurement. Ensure that the products you consider meet relevant safety and compliance standards applicable to your market.

- Material Specifications: Inquire about the materials used in the latch construction, as this directly affects durability and performance.

- Testing Procedures: Ask suppliers about their quality control processes and whether the products undergo rigorous testing.

Step 5: Request Samples for Evaluation

Before finalizing your order, request samples of the door latch parts. Evaluating physical samples allows you to assess quality, fit, and functionality firsthand.

- Test for Compatibility: Ensure that the samples fit your existing door hardware and meet your specifications.

- Functional Testing: Assess the ease of operation and security features to confirm they meet your expectations.

Step 6: Establish Clear Terms and Conditions

Once you’ve identified a suitable supplier, ensure that all terms and conditions are clearly outlined in a formal agreement. This includes pricing, delivery timelines, and warranty provisions.

- Payment Terms: Negotiate payment terms that align with your budgeting and cash flow needs.

- Delivery and Return Policies: Clarify delivery schedules and procedures for handling defective or incompatible parts.

Step 7: Monitor Supplier Performance

After procurement, continuously monitor the supplier’s performance to ensure ongoing quality and service. Establish a feedback loop to address any issues promptly.

- Regular Check-Ins: Schedule periodic evaluations of product performance and supplier responsiveness.

- Performance Metrics: Define specific metrics for assessing supplier performance, such as delivery timeliness and product quality.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing door latch parts, ensuring that their procurement process is efficient, informed, and aligned with their operational needs.

Comprehensive Cost and Pricing Analysis for door latch parts terminology Sourcing

What Are the Key Cost Components in Door Latch Parts Sourcing?

In the B2B sector, understanding the cost structure of door latch parts is crucial for effective sourcing and budgeting. The main cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for door latch parts include brass, stainless steel, and zinc die-cast, with prices varying based on quality and availability. Premium materials may lead to higher durability but also increase costs.

-

Labor: Labor costs are influenced by the manufacturing location. Regions with lower labor costs can provide competitive pricing, but this may also affect quality. Skilled labor may be required for more complex latch designs, which could increase overall expenses.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead and subsequently lower pricing.

-

Tooling: The initial investment in tooling can be substantial, especially for custom or specialized parts. It’s essential to consider whether the tooling costs will be amortized over a large volume of parts, which can reduce the per-unit cost.

-

Quality Control (QC): Rigorous quality control processes ensure that the final product meets industry standards. This can add to the cost but is vital for maintaining reliability, particularly in international markets where certification requirements may differ.

-

Logistics: Shipping and handling fees can vary based on distance, shipping method, and volume. For international buyers, understanding Incoterms is essential to anticipate additional costs, such as customs duties and taxes.

-

Margin: Suppliers typically apply a profit margin on top of their costs. This margin can vary widely based on market competition, brand reputation, and relationship dynamics between buyers and suppliers.

How Do Price Influencers Affect Door Latch Parts Procurement?

Several factors can influence pricing for door latch parts, particularly in international transactions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Establishing a reliable demand forecast can help negotiate better pricing with suppliers.

-

Specifications and Customization: Custom designs or specifications can significantly increase costs. Suppliers may charge more for bespoke solutions due to additional labor and material requirements.

-

Material Quality and Certifications: Higher quality materials or certified products (e.g., ISO, CE) can raise costs but may also provide long-term savings through reduced maintenance and increased reliability.

-

Supplier Factors: The supplier’s reputation, production capacity, and reliability can impact pricing. Established suppliers with a track record of quality may charge a premium, but they often offer better service and reliability.

-

Incoterms: Understanding the implications of Incoterms is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of goods.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Door Latch Parts?

When sourcing door latch parts, buyers can adopt several strategies to enhance cost-efficiency:

-

Negotiate Wisely: Leverage volume commitments and long-term relationships to negotiate better terms. Suppliers are often willing to provide discounts for bulk orders or repeat business.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with installation, maintenance, and potential replacements. Higher upfront costs may be justified by lower TCO.

-

Understand Pricing Nuances in Different Regions: Pricing strategies can differ significantly across regions. For instance, European suppliers may have different compliance costs compared to those in Africa or South America. It’s crucial to factor these variations into your sourcing strategy.

-

Stay Informed on Market Trends: Keeping abreast of global material prices and manufacturing trends can aid in timing your purchases effectively. This knowledge can provide leverage during negotiations.

-

Consider Local Suppliers: For buyers in Africa and South America, exploring local suppliers can reduce shipping costs and lead times, enhancing overall efficiency.

By understanding these cost components, price influencers, and effective sourcing strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing door latch parts terminology With Other Solutions

Exploring Alternatives to Door Latch Parts Terminology for B2B Buyers

In the door hardware industry, understanding the terminology associated with door latch parts is critical for effective communication and procurement. However, there are alternative solutions and technologies that can fulfill similar functions while potentially offering different benefits. This analysis explores these alternatives, comparing them against traditional door latch parts terminology to help B2B buyers make informed decisions.

Illustrative image related to door latch parts terminology

| Comparison Aspect | Door Latch Parts Terminology | Smart Lock Technology | Keyless Entry Systems |

|---|---|---|---|

| Performance | Reliable mechanical function | High security, programmable access | Moderate security, convenience |

| Cost | Varies by quality and brand | Higher upfront investment | Moderate cost, varies by features |

| Ease of Implementation | Standardized installation | Requires technical setup | Simple installation, user-friendly |

| Maintenance | Low maintenance, durable | Software updates, battery replacements | Low maintenance, but may require software updates |

| Best Use Case | Traditional settings, residential and commercial doors | High-security environments, smart homes | High-traffic areas, convenience-focused applications |

What Are the Advantages and Disadvantages of Smart Lock Technology?

Smart lock technology leverages electronic mechanisms to provide enhanced security features, such as remote access and programmability. One significant advantage is the ability to control access via smartphones or key fobs, making it ideal for high-security environments and smart homes. However, the initial investment can be considerable, as costs may include installation and ongoing maintenance, such as software updates and battery replacements. Additionally, smart locks may be vulnerable to hacking if not properly secured, which is a concern for many users.

How Do Keyless Entry Systems Compare?

Keyless entry systems offer a blend of convenience and moderate security by allowing users to access doors without traditional keys. These systems typically utilize keypad entry, RFID cards, or biometrics, making them suitable for high-traffic areas where quick access is essential. The installation process is generally user-friendly, requiring minimal technical expertise. However, while they provide ease of use, their security level may not match that of more advanced smart locks, making them less suitable for environments requiring higher security measures.

How Can B2B Buyers Choose the Right Solution?

When selecting the right door latch solution, B2B buyers should consider their specific needs, including security requirements, budget constraints, and the intended application environment. For businesses operating in high-security sectors, investing in smart lock technology may offer the best protection and flexibility. Conversely, organizations looking for traditional security may find that a thorough understanding of door latch parts terminology can guide them to suitable mechanical solutions. Ultimately, the choice between these alternatives should align with the organization’s operational demands and long-term security strategy.

Essential Technical Properties and Trade Terminology for door latch parts terminology

What Are the Key Technical Properties of Door Latch Parts?

When sourcing door latch parts, understanding the technical specifications is vital for ensuring product compatibility and reliability. Here are several critical specifications to consider:

-

Material Grade

The material grade of door latch components often determines their durability and resistance to wear and corrosion. Common materials include stainless steel, brass, and zinc die-cast. High-grade stainless steel, for instance, is favored for exterior applications due to its resistance to rust and environmental factors. For B2B buyers, selecting the right material grade can directly impact the longevity of the product and reduce maintenance costs. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. For latch parts, maintaining precise tolerances is crucial for ensuring proper fit and function. If a latch does not fit correctly, it can lead to security vulnerabilities or operational failures. Understanding tolerance levels helps buyers ensure that components will work seamlessly with existing hardware. -

Backset Measurement

The backset is the distance from the edge of the door to the center of the latch bore hole, typically measured in inches. Standard backsets are 2 3/8″ or 2 3/4″. Knowing the backset measurement is essential for selecting compatible latches and ensuring ease of installation. This specification can significantly affect project timelines and costs if not accurately assessed. -

Latch Type and Mechanism

Different latch types (e.g., tubular, deadbolt, mortise) serve various purposes and offer different levels of security. Understanding the specific function and mechanism of each type is crucial for B2B buyers aiming to meet specific security requirements. For instance, deadbolts provide enhanced security compared to standard latches, making them ideal for exterior doors. -

Finish and Coating

The finish of door latch parts affects not only aesthetics but also performance. Various finishes like chrome, satin nickel, or oil-rubbed bronze can provide different levels of corrosion resistance and wear. Buyers should consider the environmental conditions where the latch will be installed, as this will influence the choice of finish and, consequently, the product’s lifespan. -

Load Ratings

Load ratings indicate the maximum weight a latch can handle without compromising its function. For heavy-duty applications, such as commercial or industrial settings, it’s essential to select latches with appropriate load ratings. This ensures both safety and functionality in high-traffic areas.

What Are Common Trade Terms in Door Latch Parts Sourcing?

Navigating the B2B landscape for door latch parts requires familiarity with industry-specific jargon. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the assembly of a final product. When sourcing door latch parts, working with OEMs ensures that the components meet original specifications and quality standards, which is crucial for maintaining warranty and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for B2B buyers to manage inventory and cash flow effectively. Some suppliers may have high MOQs, which can impact purchasing decisions, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing, terms, and conditions for specific products or services. For door latch parts, submitting an RFQ helps buyers gather information from multiple suppliers, enabling them to make informed purchasing decisions based on price and quality. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for B2B buyers to ensure clarity on shipping responsibilities, costs, and risks associated with the delivery of door latch parts. -

Lead Time

Lead time is the amount of time it takes from placing an order until the product is delivered. For door latch parts, understanding lead times helps businesses plan their projects more effectively, ensuring that they have the necessary components when needed. -

Certification Standards

Certification standards (like ISO or ANSI) indicate that a product meets specific quality and safety criteria. For buyers, selecting certified door latch parts can enhance credibility and trust in their offerings, as well as ensure compliance with local regulations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance product quality and operational efficiency in their projects.

Navigating Market Dynamics and Sourcing Trends in the door latch parts terminology Sector

What Are the Key Drivers Influencing the Door Latch Parts Market?

The global door latch parts market is significantly influenced by several key drivers, including rising urbanization, increasing construction activities, and heightened security concerns. In regions like Africa and South America, rapid urban growth has led to a surge in residential and commercial building projects, creating a robust demand for reliable door hardware. In Europe, particularly Germany, stringent building regulations and a focus on safety have propelled the need for high-quality latch mechanisms.

Emerging technologies are also reshaping the landscape of the door latch parts sector. Smart locking systems that integrate with IoT devices are gaining traction, offering enhanced security and convenience. This trend is particularly relevant for international B2B buyers looking to differentiate their product offerings. Furthermore, the adoption of e-commerce platforms for sourcing door latch components is becoming increasingly popular, allowing businesses to access a wider range of suppliers and streamline their procurement processes.

How Is Sustainability Shaping the Sourcing of Door Latch Parts?

The environmental impact of manufacturing processes in the door latch parts sector cannot be overlooked. As global awareness of climate change grows, the emphasis on ethical sourcing and sustainable materials is becoming paramount. International B2B buyers are increasingly seeking suppliers who prioritize eco-friendly practices, such as using recycled materials and minimizing waste during production.

Certifications like ISO 14001 for environmental management systems and FSC certification for sustainable wood sourcing are becoming vital for suppliers to demonstrate their commitment to sustainability. Buyers are encouraged to evaluate their suppliers based on these certifications, as they can signify a commitment to environmental responsibility.

Additionally, the trend toward using non-toxic materials in the production of door latch components is gaining momentum. As buyers focus on creating safer environments, the demand for ‘green’ products is likely to grow, presenting opportunities for suppliers who can meet these criteria.

How Have Door Latch Parts Evolved Over Time?

The evolution of door latch parts has been marked by advancements in both design and functionality. Historically, latches were simple mechanical devices made of wood or basic metal. As security concerns increased, the industry responded with more complex locking mechanisms, including mortise locks and deadbolts that provide enhanced safety.

In recent years, the integration of technology into door latch systems has transformed the market. Smart locks, which utilize biometrics or smartphone applications for access, are becoming increasingly popular. This shift reflects a broader trend toward automation and security in the construction and hardware industries, making it essential for B2B buyers to stay informed about the latest innovations in door latch technology.

By understanding these market dynamics and trends, international B2B buyers can make informed decisions when sourcing door latch parts, ensuring they align with current demands and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of door latch parts terminology

-

How do I ensure the quality of door latch parts when sourcing internationally?

To ensure quality when sourcing door latch parts internationally, it is essential to conduct thorough supplier vetting. This includes reviewing the supplier’s certifications, such as ISO standards, and requesting samples to evaluate material quality and craftsmanship. Establishing clear quality assurance (QA) criteria in your purchase agreement can also help maintain standards. Additionally, consider using third-party inspection services to verify that products meet your specifications before shipment, particularly when importing from regions like Asia or Europe. -

What is the best material for door latch parts in humid climates?

For humid climates, stainless steel is often the best choice for door latch parts due to its corrosion resistance and durability. Other suitable materials include brass and zinc-coated components, which also offer good resistance to moisture and rust. When sourcing these materials, ensure that the supplier specifies the grade of stainless steel, as higher grades (like 316) provide superior protection against environmental factors. Always request material certifications to confirm the suitability of the components for your specific climate conditions. -

How can I customize door latch parts to fit my specific needs?

Customization of door latch parts can typically be arranged with manufacturers that offer bespoke services. Start by providing detailed specifications, including dimensions, materials, and design features required. Many suppliers are open to producing custom parts for bulk orders, so it’s advisable to discuss Minimum Order Quantities (MOQs) upfront. Additionally, request prototypes to assess how well the custom parts meet your needs before finalizing the order. -

What are the common payment terms for international suppliers of door latch parts?

Common payment terms for international suppliers vary, but many will require a deposit of 30% to 50% upfront, with the balance due upon shipment or delivery. Terms may also include Letters of Credit (LC) for larger orders, providing security for both parties. It’s crucial to clarify payment terms in advance to avoid misunderstandings. Be aware of currency fluctuations and choose a stable payment method that minimizes risk, especially when dealing with suppliers from different continents. -

What should I consider regarding logistics when importing door latch parts?

When importing door latch parts, consider shipping methods, lead times, and costs. It’s essential to work with a reliable freight forwarder who understands customs regulations in your country. Additionally, factor in the potential for delays due to customs clearance and ensure all necessary documentation, such as invoices and packing lists, is accurate and complete. Opting for Incoterms like DDP (Delivered Duty Paid) can simplify logistics, as it places the responsibility for shipping and customs clearance on the supplier. -

How do I verify the reliability of a supplier for door latch parts?

Verifying a supplier’s reliability involves researching their business history, customer reviews, and industry reputation. Request references from other businesses that have purchased from them, and check for any certifications that demonstrate quality and compliance with international standards. Utilize platforms such as Alibaba or Global Sources, which often provide supplier ratings and transaction histories. Conducting a factory visit, if feasible, can also provide insights into their operational capabilities. -

What are the common certifications required for door latch parts in Europe and the Middle East?

In Europe, door latch parts often require CE marking, indicating conformity with health, safety, and environmental protection standards. Additionally, certifications such as ISO 9001 for quality management systems can enhance supplier credibility. In the Middle East, look for compliance with local standards, such as the Gulf Cooperation Council (GCC) certification, which ensures products meet regional safety and quality requirements. Always confirm that the supplier can provide the necessary documentation for these certifications. -

What are the implications of different backset measurements for door latch parts?

Backset measurements are crucial for ensuring that door latch parts fit correctly. Standard backsets are typically 2 3/8″ or 2 3/4″, but variations exist. When sourcing, specify the backset measurement to avoid compatibility issues with existing doors. Manufacturers may offer adjustable backsets, but higher-end products usually do not. If your project requires non-standard measurements, be prepared to discuss custom solutions with suppliers, as this may affect lead times and costs.

Top 6 Door Latch Parts Terminology Manufacturers & Suppliers List

1. Direct Door Hardware – Door Knobs & Lever Handles

Domain: directdoorhardware.com

Registered: 2003 (22 years)

Introduction: Door Hardware Terms include various types of products such as Door Knobs (Modern, Crystal, for Thick Doors, with 5″ Backset), Lever Handles (Modern, Rustic, Keyless, for Thick Doors, with 5″ Backset), Deadbolts (Single Cylinder, Double Cylinder, Keyless, Single Sided, Indicator), Handlesets (for Thick Doors, Mortise, Keyless), Door Hinges (3 1/2″, 4″, 4 1/2″, Spring Hinges, Ball Bearing Hinges, Sp…

2. Homestead Hardware – Door Hardware Glossary

Domain: homesteadhardware.com

Registered: 2005 (20 years)

Introduction: Door Hardware Glossary of Terms includes: Door Knobs, Door Levers, Entry Door Handle Sets, Deadbolt Door Locks, Hinges, Door Accessories, Cabinet Hardware, Bathroom Hardware. Key terms defined include: Active Door, Backset, Bore, Center-to-Center Hole Spacing, Custom Keying, Cylinder, Deadbolt, Door Handle Plate, Door Swing, Door Thickness, Double Cylinder, Dummy (pair and single), Edge Bore, Face…

3. Codelocks – Mechanical and Electronic Locks

Domain: codelocks.us

Registered: 2004 (21 years)

Introduction: Codelocks offers a range of mechanical and electronic locks including the CL100, CL200, CL400, CL500, CL600, CL2000, CL4000, CL5000, and specialist products such as panic hardware and fire-rated locks. They also provide solutions for marine applications, key secure locks, and various door types including aluminium and glass. The product line includes KitLock electronic and mechanical locks, NetCod…

4. Level – Smart Locks

Domain: level.co

Registered: 2010 (15 years)

Introduction: {“products”:[{“name”:”Level Lock Pro”,”description”:”The ultimate in performance, design, and technology, with Apple home keys and door status detection.”,”price”:”$349″},{“name”:”Level Lock”,”description”:”The smallest, most beautifully designed smart lock ever made, built to simplify your everyday.”,”price”:”$249″},{“name”:”Level Bolt”,”description”:”Retrofit your lock with Level Bolt to make it…

5. Homebuilders Hardware – Knobs and Handles

Domain: homebuildershardware.com

Registered: 2005 (20 years)

Introduction: Knobs and Handles: Various shapes and sizes, made of brass, bronze, or stainless steel. Rosette: Decorative plate surrounding the knob or handle, available in various styles and materials. Lock Cylinder: Contains the keyway for locking/unlocking, connected to the latch mechanism via a spindle. Spindle: Thin rod connecting the knob/handle to the latch mechanism, available in different lengths and d…

6. Locksmiths – Essential Terms Dictionary

Domain: locksmiths.co.uk

Registered: 1996 (29 years)

Introduction: Locksmith Terminology – Dictionary of Locksmith Terms (Parts of a Lock) includes various terms related to locks such as: Anti-thrust bolt, Anti-thrust plate, Automatic deadlatch, Backplate, Backset, Barrel Bolt, Birmingham Bar, Blank (key), Bolt, Bow (of a key), BS – British Standard Specification, BS3621, Burglar Bars, Cabinet lock, Cam, Cam lock, Cap (of the lock), Casement Door, Casement Window…

Strategic Sourcing Conclusion and Outlook for door latch parts terminology

In the rapidly evolving landscape of door latch parts, understanding the terminology and specifications is critical for international B2B buyers. Key takeaways emphasize the importance of standardized measurements, such as backset and bore hole dimensions, to ensure compatibility across diverse door hardware solutions. Leveraging strategic sourcing practices not only enhances procurement efficiency but also aids in securing high-quality components that meet specific regional standards.

As buyers navigate the global marketplace, particularly in regions like Africa, South America, the Middle East, and Europe, they should prioritize suppliers who offer comprehensive product knowledge and customizable solutions. Establishing strong relationships with manufacturers can facilitate better pricing, improved lead times, and access to innovative designs tailored to local preferences.

Looking ahead, the demand for durable and aesthetically pleasing door latch components will continue to grow. Now is the time for international buyers to act—evaluate your sourcing strategies, invest in robust supplier partnerships, and stay informed about emerging trends in door hardware. By doing so, you can position your business for success in an increasingly competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to door latch parts terminology

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.