The Definitive Guide to Valve Ball Pvc: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for valve ball pvc

In today’s rapidly evolving global market, sourcing high-quality valve ball PVC can present significant challenges for international B2B buyers. With the increasing demand for reliable and efficient solutions across various industries—from agriculture and water management to construction and chemical processing—understanding the nuances of PVC ball valves is crucial. This guide aims to equip you with the essential knowledge and strategies needed to navigate the complexities of sourcing valve ball PVC effectively.

We delve into various types of PVC ball valves, their diverse applications, and the key factors to consider when vetting suppliers. Whether you are operating in Africa, South America, the Middle East, or Europe, the insights provided here will empower you to make informed purchasing decisions. You’ll learn about pricing dynamics, quality standards, and best practices for ensuring that your chosen products meet regulatory requirements and operational needs.

By leveraging this comprehensive resource, you will be better positioned to optimize your supply chain, reduce costs, and enhance the reliability of your operations. With actionable insights tailored to your regional context, this guide serves as a valuable tool for building successful partnerships and driving growth in your business.

Understanding valve ball pvc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Ball Valve | Simple design with a rotating ball for flow control | Plumbing, irrigation, chemical processing | Pros: Cost-effective, easy to install; Cons: Limited temperature resistance. |

| True Union Ball Valve | Features removable end connections for easy maintenance | Water treatment, industrial applications | Pros: Easy to service, versatile; Cons: Higher initial cost. |

| Compact PVC Ball Valve | Smaller size, lightweight design | Space-constrained applications, residential use | Pros: Space-saving, lightweight; Cons: May have lower pressure ratings. |

| Clear True Union Valve | Transparent material allows for flow visibility | Laboratories, aquariums, food processing | Pros: Visual flow monitoring; Cons: More expensive, less durable than opaque options. |

| Labcock Valve | Specially designed for laboratory environments | Chemical labs, pharmaceuticals | Pros: High precision, designed for chemicals; Cons: Limited to specific applications. |

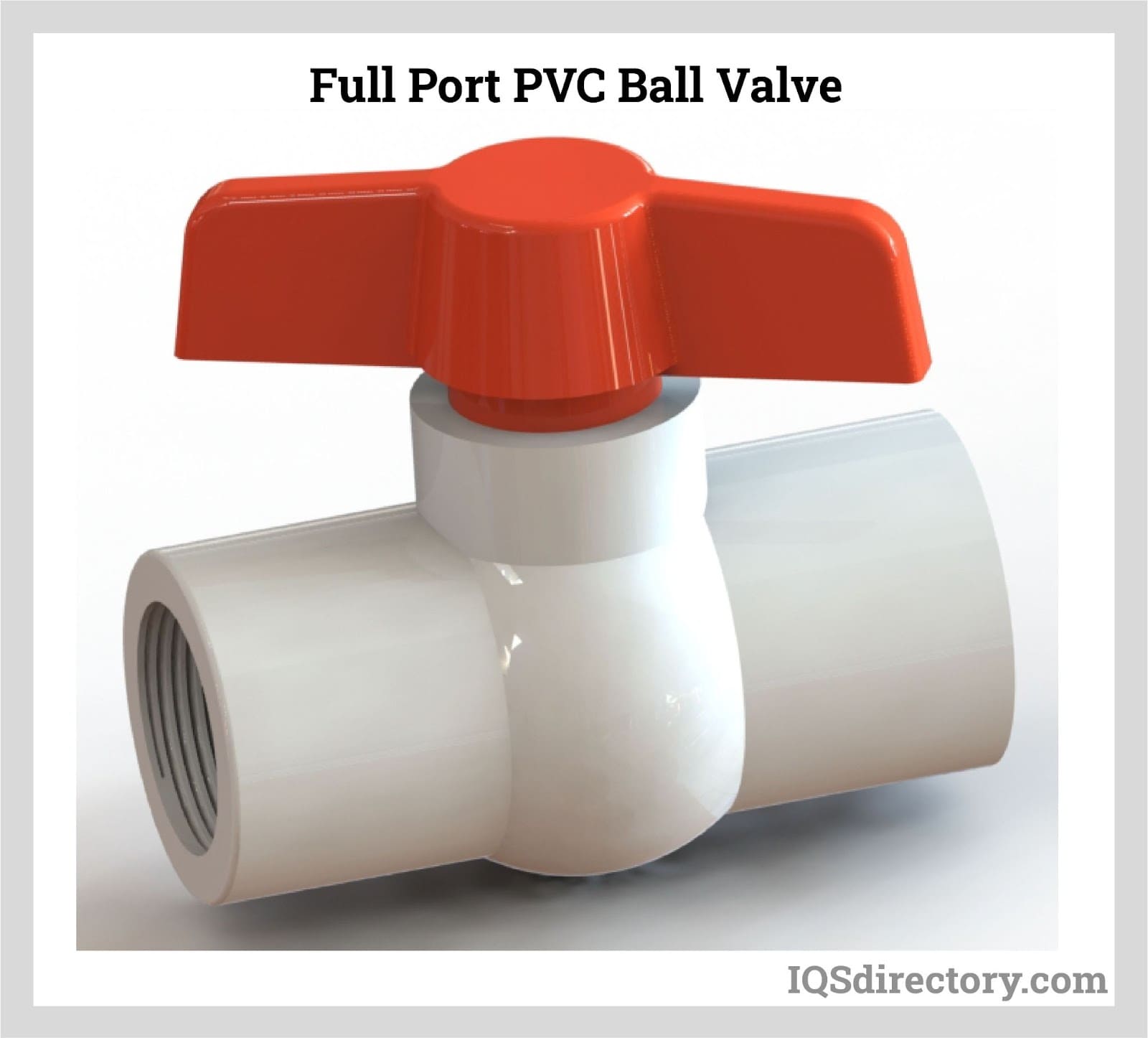

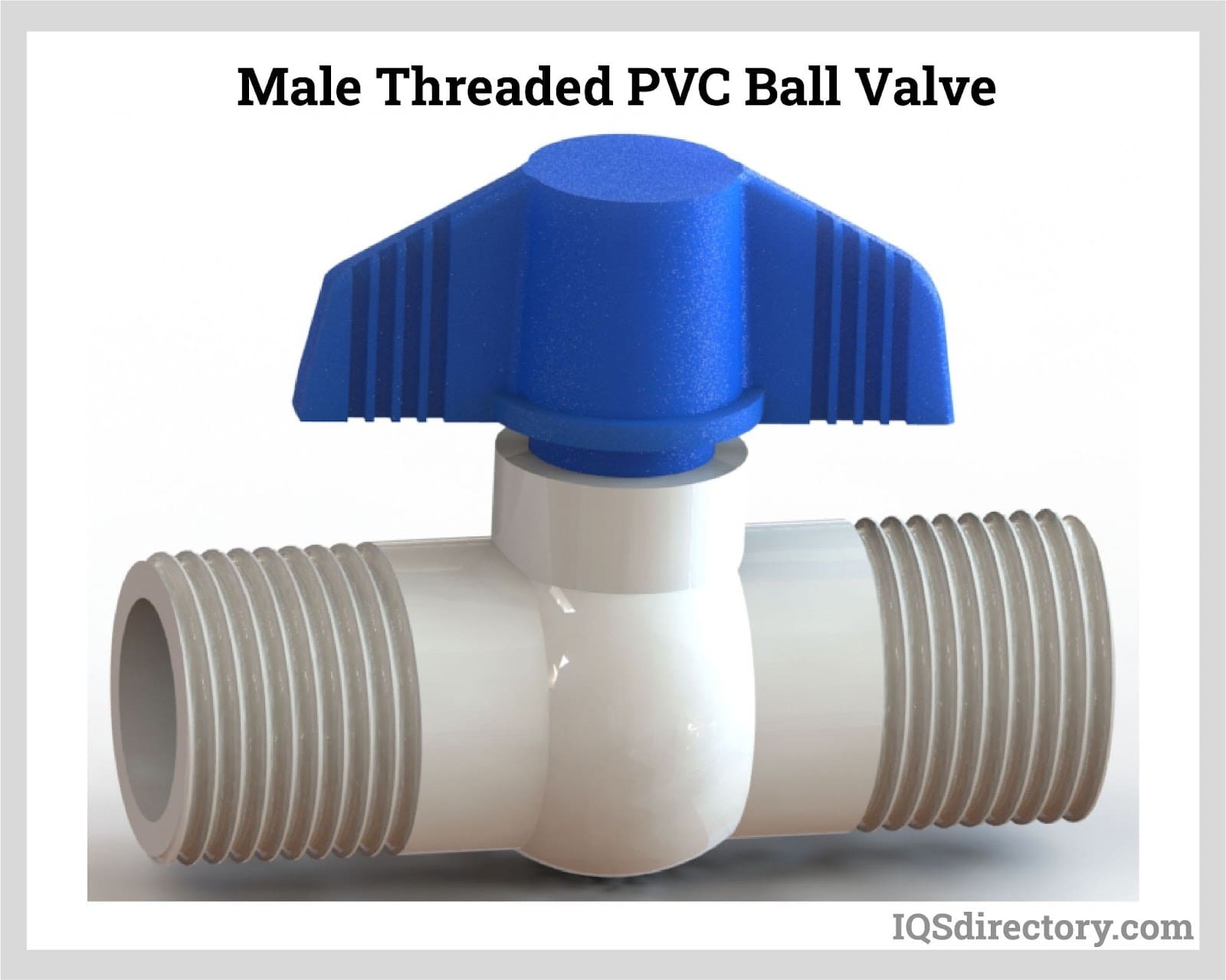

What Are the Characteristics and Suitability of Standard PVC Ball Valves?

Standard PVC ball valves are characterized by their straightforward design, featuring a spherical ball that rotates to control the flow of liquids. They are primarily used in plumbing, irrigation, and chemical processing applications due to their cost-effectiveness and ease of installation. However, buyers should consider their limitations in temperature resistance, as they may not perform well in extreme conditions.

How Do True Union Ball Valves Enhance Maintenance and Versatility?

True union ball valves are distinguished by their removable end connections, allowing for easy maintenance and replacement without disrupting the entire piping system. This feature makes them ideal for water treatment and various industrial applications. While they offer enhanced serviceability and versatility, their higher initial cost may be a consideration for budget-conscious buyers.

Why Choose Compact PVC Ball Valves for Space-Constrained Applications?

Compact PVC ball valves are designed to be lightweight and occupy less space, making them suitable for installations where space is limited, such as in residential settings or smaller industrial facilities. They provide a practical solution for those needing a reliable flow control mechanism in tight environments. However, buyers should note that these valves may come with lower pressure ratings compared to larger models.

What Are the Advantages of Clear True Union Valves in Monitoring Flow?

Clear true union valves are made from transparent materials that allow users to visually monitor the flow of liquids, making them particularly valuable in laboratory settings, aquariums, and food processing industries. Their ability to provide real-time visual feedback is a significant advantage; however, they tend to be more expensive and less durable than traditional opaque options, which may deter some buyers.

In What Scenarios Are Labcock Valves Most Effective?

Labcock valves are specifically designed for laboratory environments, offering high precision and compatibility with various chemicals. These valves are essential in chemical labs and pharmaceutical applications where accurate flow control is crucial. While they excel in specialized settings, their limited application scope may not justify the investment for buyers outside of laboratory contexts.

Key Industrial Applications of valve ball pvc

| Industry/Sector | Specific Application of valve ball pvc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Flow control in filtration and purification systems | Ensures efficient water management and quality | Look for UV resistance and compatibility with chemicals used |

| Agriculture | Irrigation systems and hydroponics | Promotes optimal water usage and crop health | Consider pressure ratings and size compatibility |

| Chemical Processing | Handling corrosive liquids | Provides safe and reliable control of hazardous materials | Ensure chemical compatibility and pressure ratings |

| Food and Beverage | Process control in beverage production | Maintains hygiene and product integrity | Verify FDA compliance and material certifications |

| HVAC Systems | Airflow regulation in heating and cooling systems | Improves energy efficiency and system performance | Assess temperature and pressure ratings |

How is Valve Ball PVC Used in Water Treatment Applications?

In the water treatment industry, valve ball PVC is crucial for controlling the flow of water through filtration and purification systems. These valves provide a reliable means to manage water flow, ensuring that treatment processes operate efficiently. Buyers should prioritize valves with UV resistance and compatibility with various chemicals to meet the specific needs of their treatment systems. International buyers must also consider local regulations and standards regarding water quality to ensure compliance.

What Role Does Valve Ball PVC Play in Agriculture?

In agriculture, valve ball PVC is widely used in irrigation systems and hydroponics setups, allowing for precise control over water distribution. This application is vital for optimizing water usage and enhancing crop health, particularly in regions facing water scarcity. Buyers should look for valves with appropriate pressure ratings and sizes that fit their specific irrigation designs. Understanding the local climate and crop requirements can further guide sourcing decisions.

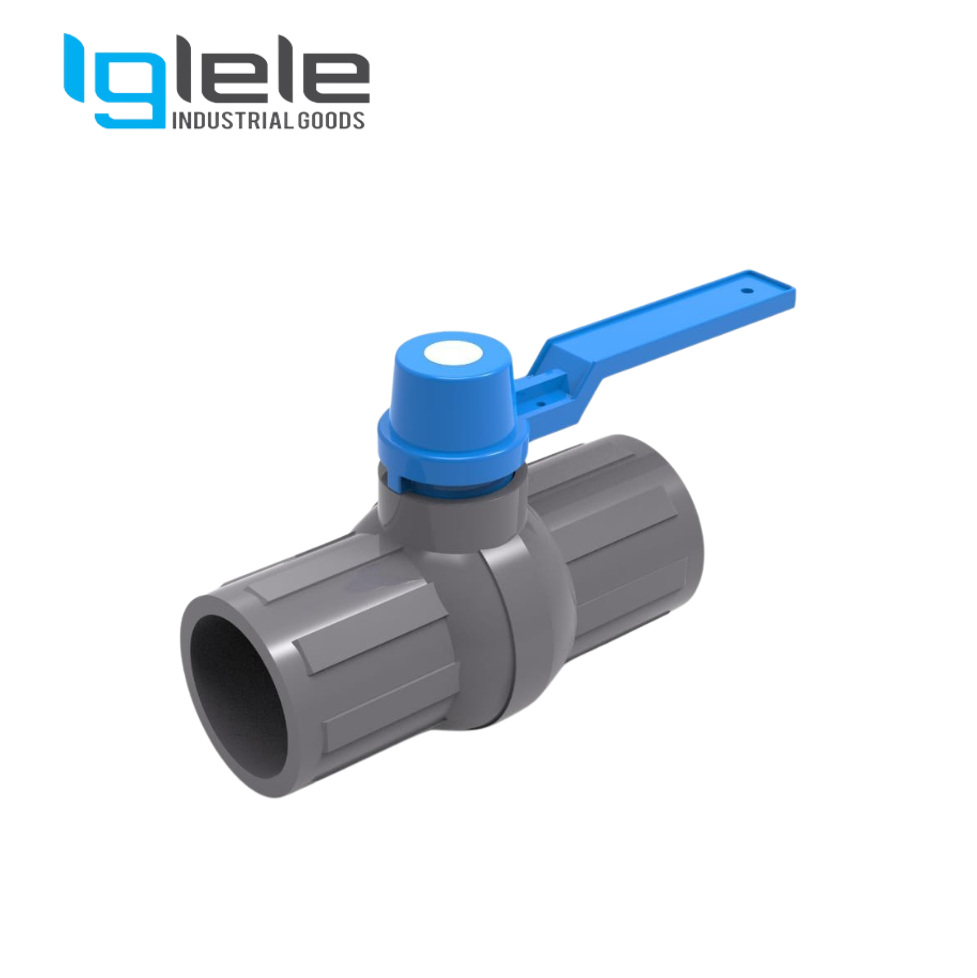

Illustrative image related to valve ball pvc

How is Valve Ball PVC Essential in Chemical Processing?

In chemical processing, valve ball PVC is essential for safely handling corrosive liquids. These valves provide a secure method for controlling the flow of hazardous materials, thereby reducing the risk of spills and contamination. When sourcing for this application, businesses must ensure that the valves are compatible with the specific chemicals being processed and that they meet the necessary pressure ratings for operational safety. Buyers should conduct thorough assessments of chemical compatibility to mitigate risks.

Why is Valve Ball PVC Important in the Food and Beverage Industry?

In the food and beverage sector, valve ball PVC is used for process control during production, ensuring that hygiene and product integrity are maintained throughout the manufacturing process. The valves help regulate the flow of liquids and gases, which is crucial for maintaining consistent quality. Buyers should verify that the valves comply with FDA regulations and possess necessary certifications to ensure safety in food handling. Understanding local food safety standards is also important for international buyers.

How Does Valve Ball PVC Enhance HVAC Systems?

Within HVAC systems, valve ball PVC is employed to regulate airflow in heating and cooling applications. This regulation is key to improving energy efficiency and overall system performance. When sourcing these valves, businesses should assess their temperature and pressure ratings to ensure they meet the specific demands of their HVAC systems. Additionally, international buyers should consider local climate conditions and system designs to select the most suitable valve options.

3 Common User Pain Points for ‘valve ball pvc’ & Their Solutions

Scenario 1: Quality Assurance in PVC Ball Valves

The Problem: Many B2B buyers, particularly in regions like Africa and South America, face challenges in ensuring the quality and reliability of PVC ball valves. With varying standards across manufacturers, a buyer may receive products that fail to meet expected performance, leading to leaks, breakdowns, or even hazardous situations in industrial applications. This not only affects operational efficiency but can also lead to costly repairs and reputational damage.

The Solution: To mitigate quality assurance issues, it is crucial for buyers to source PVC ball valves from reputable suppliers who adhere to international standards, such as ISO or ASTM certifications. Conducting thorough supplier audits can help verify their manufacturing processes and quality control measures. Additionally, buyers should request detailed product specifications and performance data, such as pressure ratings and temperature tolerances, to ensure compatibility with their applications. Establishing long-term relationships with trusted manufacturers can also facilitate better communication and responsiveness regarding product quality.

Scenario 2: Compatibility with Existing Systems

The Problem: A common pain point for B2B buyers is the compatibility of PVC ball valves with existing piping systems. Buyers may find themselves in situations where the valve dimensions, connection types, or pressure ratings do not align with their current infrastructure, leading to installation delays and increased costs. This is particularly problematic in industries like water treatment and chemical processing, where precise specifications are critical.

The Solution: To address compatibility issues, buyers should conduct a comprehensive assessment of their existing systems before purchasing PVC ball valves. This includes measuring the diameter of current pipes, identifying the connection types (e.g., slip, threaded), and understanding the operating pressures and temperatures of the system. When selecting valves, buyers should prioritize those that offer flexible connection options or true union designs, allowing for easier integration. Collaborating with suppliers who provide custom solutions or technical support can further ensure that the chosen valves fit seamlessly into the existing setup.

Illustrative image related to valve ball pvc

Scenario 3: Understanding Applications and Regulations

The Problem: B2B buyers often struggle with identifying the right PVC ball valve for specific applications, especially in regulated industries like food and beverage or pharmaceuticals. Misunderstanding the applications can lead to selecting valves that are either unsuitable or non-compliant with industry standards, resulting in potential product recalls and legal liabilities.

The Solution: To navigate application-specific challenges, buyers should invest time in understanding the unique requirements of their industry. This involves familiarizing themselves with relevant regulations, such as FDA compliance for food-grade applications or environmental standards for chemical processing. Buyers can benefit from consulting with industry experts or utilizing resources such as technical datasheets and application guides provided by manufacturers. Additionally, attending industry seminars or workshops can enhance their knowledge of emerging technologies and best practices in valve selection. By aligning their choices with regulatory requirements and application needs, buyers can avoid costly mistakes and ensure safety and compliance.

Strategic Material Selection Guide for valve ball pvc

What Are the Key Materials Used in PVC Valve Balls?

When selecting valve balls made from PVC, understanding the materials involved is crucial for ensuring optimal performance and compliance with industry standards. Here, we analyze four common materials utilized in the manufacturing of valve balls, focusing on their properties, advantages, disadvantages, and suitability for various applications.

How Does PVC Perform in Valve Applications?

PVC (Polyvinyl Chloride) is the most common material for valve balls. It is lightweight, cost-effective, and resistant to corrosion, making it suitable for a variety of applications, including water treatment and chemical processing. PVC valve balls typically have a maximum working temperature of around 140°F (60°C) and can handle pressures up to 150 PSI.

Illustrative image related to valve ball pvc

Pros: PVC is affordable and easy to manufacture, which translates to lower costs for B2B buyers. Its chemical resistance makes it suitable for a wide range of media, including water, acids, and alkalis.

Cons: However, PVC is less durable than some alternatives, particularly at higher temperatures. It may also become brittle over time when exposed to UV light, which is a consideration for outdoor applications.

What Are the Benefits of CPVC in Valve Balls?

CPVC (Chlorinated Polyvinyl Chloride) is a modified version of PVC that offers improved temperature and pressure ratings. CPVC can handle temperatures up to 200°F (93°C) and pressures up to 200 PSI, making it suitable for hot water applications and more aggressive chemicals.

Pros: The enhanced thermal resistance of CPVC allows for greater versatility in applications, including industrial settings where higher temperatures are common. It also maintains a similar cost profile to PVC, making it an attractive option for buyers.

Cons: The manufacturing process for CPVC can be slightly more complex, potentially leading to higher costs in some regions. Additionally, CPVC may not be compatible with certain solvents, requiring careful consideration of the media being transported.

How Does PVDF Compare for High-Performance Needs?

PVDF (Polyvinylidene Fluoride) is a high-performance plastic known for its exceptional chemical resistance and stability at high temperatures. PVDF valve balls can operate at temperatures up to 300°F (149°C) and pressures exceeding 300 PSI.

Pros: PVDF is ideal for demanding applications, including pharmaceuticals and food processing, due to its purity and resistance to harsh chemicals. Its durability ensures a longer lifespan, reducing the need for frequent replacements.

Cons: The primary drawback of PVDF is its cost, which is significantly higher than PVC and CPVC. This can be a limiting factor for budget-conscious buyers or projects with tight financial constraints.

Illustrative image related to valve ball pvc

What Role Does Stainless Steel Play in Valve Ball Applications?

Stainless Steel is another material option, particularly for valve balls that require enhanced strength and durability. Stainless steel valve balls can handle extreme temperatures and pressures, making them suitable for high-stress applications in industries such as oil and gas.

Pros: Stainless steel offers excellent corrosion resistance and mechanical strength, making it suitable for a wide range of aggressive environments. Its longevity and reliability can justify the higher initial investment.

Cons: The primary disadvantage is the cost, which is generally higher than that of plastic alternatives. Additionally, stainless steel may not be compatible with all media, particularly those that can cause galvanic corrosion when in contact with other metals.

Summary of Material Selection for Valve Balls

| Material | Typical Use Case for valve ball pvc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Water treatment, chemical processing | Cost-effective, lightweight | Less durable at high temperatures | Low |

| CPVC | Hot water applications | Higher temperature resistance | Slightly more complex to manufacture | Medium |

| PVDF | Pharmaceuticals, food processing | Exceptional chemical resistance | High cost | High |

| Stainless Steel | Oil and gas applications | High strength and durability | Higher cost, potential compatibility issues | High |

This strategic material selection guide empowers international B2B buyers to make informed decisions based on the specific requirements of their applications, ensuring compliance with standards and maximizing operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for valve ball pvc

What Are the Key Manufacturing Processes for PVC Valve Balls?

The manufacturing of PVC valve balls involves several critical stages that ensure the final product meets the high standards required by various industries. Understanding these processes is essential for B2B buyers looking to source high-quality valve balls.

Illustrative image related to valve ball pvc

What Are the Main Stages of Manufacturing PVC Valve Balls?

-

Material Preparation: The process begins with the selection of high-quality PVC resin, which is essential for durability and performance. The resin may be blended with additives to enhance properties such as UV resistance or impact strength. Proper storage and handling are crucial to prevent contamination or degradation of the material.

-

Forming: The next stage involves shaping the PVC resin into the desired form. This is typically achieved through processes such as injection molding or extrusion. Injection molding is the most common method, where the PVC is heated until it becomes pliable and then injected into a mold to form the valve ball. The precision of this process is vital for ensuring a perfect fit and function.

-

Assembly: After forming, the components of the valve, including the valve ball and housing, are assembled. This stage may include the installation of seals or gaskets to ensure a watertight closure. The assembly process must be performed under controlled conditions to maintain quality and prevent contamination.

-

Finishing: The finishing process involves trimming excess material and applying any necessary surface treatments, such as polishing or coating. This not only improves the aesthetic appeal of the valve but also enhances its resistance to corrosion and wear. Finishing is crucial for ensuring that the valve can withstand the operational demands of its intended application.

How Is Quality Assurance Implemented in PVC Valve Ball Manufacturing?

Quality assurance is integral to the manufacturing process of PVC valve balls, ensuring that each product meets international standards and customer specifications.

What International Standards Are Relevant for PVC Valve Balls?

B2B buyers should be aware of various international standards that govern the quality of PVC valve balls. Key standards include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides standards specifically for valves used in the oil and gas industry, ensuring safety and reliability in high-pressure environments.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established at various stages of the manufacturing process to maintain high standards:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified requirements before production begins.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the process and identify any deviations from quality standards. This may include checks on dimensions, weight, and material properties.

- Final Quality Control (FQC): Once the valve balls are assembled, a final inspection is conducted. This includes functional testing to ensure that the valve operates correctly and meets pressure and leakage standards.

What Testing Methods Are Commonly Used for PVC Valve Balls?

B2B buyers should understand the various testing methods employed to ensure the quality and reliability of PVC valve balls:

- Pressure Testing: This is a critical test where the valve is subjected to high pressure to verify that it can withstand operational conditions without leaking.

- Temperature Resistance Testing: Valves are tested for performance under extreme temperatures to ensure they can function in various environments.

- Chemical Resistance Testing: Given that PVC valve balls are often used in chemical applications, testing for resistance to different chemicals is essential.

- Durability Testing: This involves subjecting the valve to mechanical stress to evaluate its longevity and performance over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of suppliers is paramount. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits of suppliers can help assess their manufacturing processes and quality assurance practices. This includes reviewing their certifications and quality management systems.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their testing methods, inspection results, and compliance with international standards. These documents should be scrutinized for accuracy and relevance.

-

Utilize Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality control processes. This can include pre-shipment inspections to verify that products meet agreed-upon specifications.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing PVC valve balls from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

- Regulatory Compliance: Different regions have varying regulations regarding product standards. It is crucial to ensure that the supplier complies with local laws and standards in the target market.

- Cultural and Communication Considerations: Understanding cultural differences can facilitate better communication with suppliers, helping to clarify quality expectations and standards.

- Logistics and Supply Chain Reliability: Assessing a supplier’s logistics capabilities is vital, as delays can affect the supply chain. A reliable supplier should have proven logistics and distribution processes in place.

By understanding the manufacturing processes and quality assurance measures for PVC valve balls, B2B buyers can make informed decisions when sourcing these critical components. Ensuring product quality not only enhances operational efficiency but also reduces the risk of costly failures in the field.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘valve ball pvc’

Introduction

Sourcing PVC ball valves effectively requires a strategic approach to ensure quality, reliability, and compatibility with your specific applications. This guide provides a clear checklist to assist B2B buyers in navigating the procurement process, from defining technical requirements to verifying supplier credentials.

1. Define Your Technical Specifications

Start by outlining the precise technical requirements for your PVC ball valves. Consider factors such as size, pressure ratings, and compatibility with other materials in your system.

– Key Specifications to Include:

– Inlet and outlet diameters (e.g., ½”, 1”, 2”).

– Maximum working pressure and temperature ratings.

– Application type (e.g., potable water, chemical handling).

2. Research Market Options

Conduct thorough market research to identify available PVC ball valve products. Utilize online platforms, trade shows, and industry publications to gather information on different brands and types.

– What to Look For:

– Product reviews and ratings from other B2B buyers.

– Popular manufacturers and their product offerings.

– New technologies or innovations in PVC valve design.

3. Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet potential suppliers carefully. Request detailed company profiles, including their history, industry experience, and client testimonials.

– Considerations for Evaluation:

– Check for certifications (e.g., ISO, CE) that indicate quality assurance.

– Assess their ability to meet delivery timelines and customer service responsiveness.

– Ask for references from clients in similar industries or regions.

4. Request Samples

Once you have shortlisted suppliers, request samples of the PVC ball valves you are considering. Testing samples can help you assess quality and suitability for your specific applications.

– Testing Criteria:

– Evaluate the valve’s sealing capabilities and ease of operation.

– Check for any signs of defects or inconsistencies in material.

– Confirm compatibility with your existing systems through practical testing.

5. Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Look beyond just the unit price; consider total cost of ownership, including shipping, tariffs, and potential volume discounts.

– Pricing Factors to Analyze:

– Bulk purchase discounts or loyalty programs.

– Warranty and return policies.

– Shipping costs and delivery schedules.

6. Finalize Your Order and Terms

After selecting a supplier, finalize your order details, including quantities, delivery timelines, and payment terms. Ensure all agreements are documented to avoid any misunderstandings.

– Documentation Essentials:

– Confirm order confirmation and invoice details.

– Review contractual terms for liability and warranty coverage.

– Maintain open lines of communication for any post-order inquiries.

7. Plan for After-Sales Support

After receiving your PVC ball valves, consider the after-sales support offered by the supplier. This can be crucial for troubleshooting and ensuring long-term satisfaction with your purchase.

– Support Aspects to Review:

– Availability of technical support and installation guidance.

– Access to replacement parts and servicing options.

– Supplier’s responsiveness to any issues post-purchase.

By following this checklist, B2B buyers can navigate the complexities of sourcing PVC ball valves with confidence, ensuring they make informed purchasing decisions that meet their operational needs.

Illustrative image related to valve ball pvc

Comprehensive Cost and Pricing Analysis for valve ball pvc Sourcing

What Are the Key Cost Components for Sourcing PVC Ball Valves?

When sourcing PVC ball valves, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

- Materials: The type of PVC used significantly impacts cost. Higher-grade materials may increase initial prices but offer better durability and performance in specific applications.

- Labor: Labor costs can vary based on the manufacturing location. Countries with lower wage rates can offer significant savings, while high-quality craftsmanship may demand higher labor costs.

- Manufacturing Overhead: This encompasses utilities, factory maintenance, and other operational expenses. Efficient manufacturing processes can lower overhead costs, which can be reflected in the pricing of the valves.

- Tooling: Initial tooling costs for custom or specialized valve designs can be substantial. Buyers should consider these costs when evaluating suppliers, especially for low-volume orders.

- Quality Control (QC): Robust QC processes ensure product reliability and compliance with industry standards. Enhanced QC may increase costs but can prevent costly failures in the field.

- Logistics: Shipping costs can vary significantly based on the distance, mode of transport, and chosen Incoterms. Buyers should factor in logistics as part of the total cost.

How Do Price Influencers Affect PVC Ball Valve Costs?

Several factors influence the pricing of PVC ball valves, particularly in the international market:

- Volume and Minimum Order Quantities (MOQ): Suppliers often provide better pricing for larger orders. Understanding the MOQ and potential volume discounts can lead to significant savings.

- Specifications and Customization: Custom specifications or unique features can raise costs. Buyers should weigh the necessity of these customizations against their budget.

- Material Quality and Certifications: Higher quality materials and certifications (like ISO or NSF) typically come at a premium. However, these can enhance the product’s lifespan and safety, reducing long-term costs.

- Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers with a track record of reliability may charge more but offer peace of mind.

- Incoterms: Understanding the implications of different Incoterms (like FOB, CIF, etc.) is crucial. They determine who bears costs and risks at various shipping stages, affecting the overall price.

What Buyer Tips Can Help Negotiate Better Prices for PVC Ball Valves?

International B2B buyers should adopt strategic approaches when sourcing PVC ball valves:

- Negotiate Terms: Don’t hesitate to negotiate pricing and payment terms. Suppliers may offer better rates for prompt payment or larger orders.

- Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, longevity, and operational costs. A more expensive valve may offer better performance and lower TCO over time.

- Understand Pricing Nuances: Be aware of market fluctuations, especially in raw material costs. Timing your purchase can lead to better pricing.

- Explore Multiple Suppliers: Engaging with multiple suppliers can provide leverage in negotiations and help identify the best pricing and quality combination.

- Leverage Local Knowledge: Understanding regional market dynamics in Africa, South America, the Middle East, and Europe can provide insights into pricing strategies and supplier reliability.

Conclusion and Disclaimer on Indicative Prices

When sourcing PVC ball valves, the cost structure is multifaceted, with numerous influencers at play. Prices can vary widely based on the aforementioned factors, and buyers should conduct thorough research and engage in strategic negotiations. The prices mentioned in various sources are indicative and can fluctuate based on market conditions and supplier policies. Always request quotes and verify costs before making procurement decisions.

Alternatives Analysis: Comparing valve ball pvc With Other Solutions

Understanding Alternatives to Valve Ball PVC

In the realm of fluid control, various solutions exist to manage the flow of liquids in industrial applications. While valve ball PVC is a popular choice due to its affordability and versatility, other alternatives may offer specific advantages depending on the application. In this analysis, we will explore two viable alternatives: metal ball valves and butterfly valves, comparing them across key performance metrics.

Comparison of Valve Ball PVC with Alternative Solutions

| Comparison Aspect | Valve Ball PVC | Metal Ball Valves | Butterfly Valves |

|---|---|---|---|

| Performance | Good flow control and sealing | Excellent durability and high pressure tolerance | Efficient for large flow rates |

| Cost | Low to moderate cost | Higher initial investment | Moderate cost |

| Ease of Implementation | Easy installation and lightweight | Requires more skilled labor | Simple installation but needs space |

| Maintenance | Low maintenance; resistant to corrosion | Moderate maintenance; can corrode | Low maintenance; few moving parts |

| Best Use Case | Water treatment, landscaping, pools | Oil and gas, high-pressure systems | HVAC systems, water distribution |

Detailed Breakdown of Alternatives

Metal Ball Valves

Metal ball valves are crafted from materials such as stainless steel or brass, providing superior durability compared to PVC options. They are capable of handling higher pressures and temperatures, making them suitable for applications in the oil and gas industry. However, the initial investment is significantly higher, and installation may require skilled labor due to their weight and complexity. Over time, maintenance can also be a concern, as metal valves may corrode depending on the environmental conditions.

Butterfly Valves

Butterfly valves offer a unique design characterized by a rotating disc that regulates flow. They are especially efficient for large flow rates and are commonly used in HVAC systems and water distribution networks. One of the key advantages of butterfly valves is their compact size, which allows for installation in tight spaces. However, they may not provide the same level of sealing as ball valves, particularly in low-flow situations. Their cost is moderate, making them a feasible option for various industrial applications.

Making the Right Choice for Your Needs

When choosing between valve ball PVC and its alternatives, consider your specific application requirements. If cost and ease of installation are your primary concerns, valve ball PVC is an excellent choice, particularly for lower-pressure environments. Conversely, if your project demands higher durability and pressure tolerance, metal ball valves may be the better option despite the increased initial costs. For scenarios requiring efficient flow management in confined spaces, butterfly valves can provide a balanced solution. Ultimately, understanding the unique advantages and limitations of each option will guide B2B buyers in selecting the best fit for their operational needs.

Essential Technical Properties and Trade Terminology for valve ball pvc

What Are the Key Technical Properties of PVC Ball Valves?

Understanding the technical specifications of PVC ball valves is critical for B2B buyers to ensure they select the right product for their applications. Here are some essential properties to consider:

1. Material Grade

PVC (Polyvinyl Chloride) is the primary material used in these valves, known for its durability and resistance to corrosion. In some cases, chlorinated PVC (CPVC) may be used for higher temperature applications. The material grade affects the valve’s lifespan and suitability for various fluids, making it crucial for buyers to choose valves that align with their specific operational conditions.

2. Pressure Rating

PVC ball valves come with specific pressure ratings, commonly ranging from 100 PSI to 200 PSI. This rating indicates the maximum pressure the valve can withstand without failure. For industrial applications, selecting a valve with a suitable pressure rating is vital to prevent leaks or catastrophic failures, which can lead to costly downtime and repairs.

3. Temperature Tolerance

The maximum working temperature of PVC ball valves typically varies between 73°F to 180°F. Knowing the temperature tolerance is essential for applications involving heated fluids or environments, as exceeding this limit can compromise valve integrity and functionality.

4. Inlet and Outlet Diameter

Inlet and outlet diameters determine the flow capacity of the valve. Common sizes range from ½ inch to 6 inches. Buyers must match the valve size to their piping systems to ensure optimal flow and prevent bottlenecks, which can impact system efficiency.

5. Connection Type

Connection types, such as slip-joint, threaded, or solvent weld, dictate how the valve will integrate with existing piping systems. The choice of connection type is crucial for installation ease and ensuring a secure, leak-free fit, making it a key consideration for procurement professionals.

6. Application Suitability

PVC ball valves are versatile and used across various applications, including water supply, hydroponics, and chemical processing. Understanding the specific application is vital for buyers to ensure compatibility with the fluids being handled and to meet regulatory requirements.

What Common Trade Terms Should B2B Buyers Know About PVC Ball Valves?

Navigating the purchasing process for PVC ball valves involves familiarizing oneself with industry-specific terminology. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end products. For B2B buyers, sourcing from reputable OEMs ensures quality and reliability, as these manufacturers adhere to industry standards and specifications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for procurement planning, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs that align with their operational needs without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, issuing RFQs helps gather competitive quotes, facilitating informed purchasing decisions and potential cost savings.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects such as shipping costs, insurance, and risk transfer. Familiarity with Incoterms is vital for B2B transactions, particularly for international buyers, as it clarifies obligations and helps avoid disputes.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving it. Understanding lead times is crucial for supply chain management and project planning, allowing buyers to anticipate delivery and avoid delays in their operations.

6. Certification Standards

Certification standards, such as NSF or ISO, indicate that a product meets specific safety and quality benchmarks. For B2B buyers, verifying certification ensures compliance with industry regulations and enhances trust in the product’s performance.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing PVC ball valves, ultimately optimizing their operations and ensuring product reliability.

Navigating Market Dynamics and Sourcing Trends in the valve ball pvc Sector

What Are the Key Trends in the Global Valve Ball PVC Market?

The global valve ball PVC market is experiencing significant growth, driven by several factors. First, the increasing demand for lightweight and corrosion-resistant materials in various industries, including plumbing, irrigation, and chemical processing, is propelling the adoption of PVC ball valves. Furthermore, the push for efficient water management systems in regions facing water scarcity, particularly in Africa and the Middle East, is leading to a rise in the installation of PVC valves in irrigation systems and water treatment facilities.

Illustrative image related to valve ball pvc

Emerging technologies, such as the integration of IoT (Internet of Things) in valve management, are reshaping the sourcing landscape. Remote monitoring and control capabilities are becoming standard, allowing for real-time data analysis and proactive maintenance. This trend is particularly relevant for B2B buyers seeking to enhance operational efficiency and reduce downtime in their supply chains. Additionally, suppliers are increasingly leveraging e-commerce platforms to streamline procurement processes, offering a wider range of products with enhanced visibility into pricing and availability.

In Europe, particularly in Germany, stringent regulations around water quality and safety are influencing product specifications and sourcing decisions. Buyers are required to ensure compliance with local standards, which often necessitates sourcing from certified manufacturers. As a result, international buyers must remain agile and informed about regulatory changes to maintain competitiveness in their respective markets.

How Is Sustainability Impacting Sourcing Decisions for Valve Ball PVC Products?

Sustainability is a crucial consideration for B2B buyers in the valve ball PVC sector. The environmental impact of plastic production and waste management has prompted companies to reassess their supply chains. Ethical sourcing has emerged as a priority, with an increasing number of organizations seeking suppliers that adhere to sustainable practices. This includes using recycled materials and reducing the carbon footprint of production processes.

Buyers are also looking for ‘green’ certifications that validate the environmental credentials of their suppliers. Certifications such as ISO 14001 for environmental management systems and certifications from organizations like the Forest Stewardship Council (FSC) indicate a commitment to sustainable practices. Furthermore, the use of alternative materials, such as bioplastics or PVC produced through renewable energy sources, is gaining traction. These materials not only minimize environmental impact but also appeal to end-users who prioritize sustainability.

Illustrative image related to valve ball pvc

In regions like South America and Africa, where regulatory frameworks regarding environmental sustainability are evolving, buyers must be proactive in ensuring their sourcing decisions align with future regulations. This forward-thinking approach can enhance brand reputation and foster long-term partnerships with environmentally-conscious stakeholders.

What Is the Historical Context Behind the Development of Valve Ball PVC Technology?

The evolution of valve ball PVC technology can be traced back to the mid-20th century when PVC (Polyvinyl Chloride) began to gain popularity as a versatile material in plumbing and industrial applications. Initially used for its durability and resistance to corrosion, PVC ball valves quickly became a preferred choice due to their ability to provide a watertight seal and reliable operation.

As industries expanded and the demand for efficient fluid control systems grew, manufacturers innovated designs to improve functionality and performance. The introduction of true union ball valves and compact designs allowed for easier installation and maintenance, catering to the needs of various sectors, including agriculture, chemical processing, and municipal water systems.

In recent years, the focus has shifted towards integrating smart technology into valve systems, enhancing their usability and efficiency. This evolution reflects the ongoing commitment to meeting the diverse needs of international B2B buyers, particularly as global industries seek to optimize operations and embrace sustainable practices.

Illustrative image related to valve ball pvc

Frequently Asked Questions (FAQs) for B2B Buyers of valve ball pvc

-

How do I choose the right PVC ball valve for my application?

When selecting a PVC ball valve, consider the specific requirements of your application, including the type of fluid being transported, pressure ratings, and temperature ranges. PVC ball valves are suitable for various applications such as water supply, chemical processing, and food and beverage industries. Look for valves that offer features like a true union design for easy maintenance and repair, as well as compatibility with your existing piping system. Always consult with suppliers to ensure the valve meets your operational standards. -

What are the advantages of using PVC ball valves over other materials?

PVC ball valves are lightweight, corrosion-resistant, and cost-effective compared to metal valves. They are ideal for chemical handling due to their resistance to a wide range of chemicals. Additionally, PVC valves provide excellent sealing capabilities, ensuring minimal leakage and efficient flow control. Their ease of installation and maintenance also makes them a preferred choice in many industries, including agriculture, water treatment, and manufacturing. -

What customization options are available for PVC ball valves?

Many suppliers offer customization options for PVC ball valves, including size variations, end connections (such as threaded or socket), and special coatings for enhanced durability. Some manufacturers can also provide valves with specific pressure ratings or temperature tolerances tailored to your needs. When sourcing, communicate your requirements clearly to suppliers to ensure they can meet your specifications effectively. -

What is the minimum order quantity (MOQ) for PVC ball valves?

Minimum order quantities (MOQ) for PVC ball valves can vary significantly between suppliers. While some may allow orders as low as 10 units, others might require larger quantities to achieve favorable pricing. It’s essential to discuss MOQs upfront with potential suppliers to align your purchasing needs and budget. Additionally, consider the possibility of consolidating orders with other products to meet MOQ requirements. -

What payment terms should I expect when buying PVC ball valves internationally?

Payment terms for international purchases of PVC ball valves typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers also offer net payment terms, allowing you to pay within a specified period after receiving the goods. It’s crucial to clarify payment conditions before finalizing the order to avoid misunderstandings and ensure smooth transactions. -

How can I vet suppliers of PVC ball valves before making a purchase?

To vet suppliers, start by researching their reputation in the industry, checking customer reviews, and assessing their experience with international trade. Request certifications and compliance documentation to ensure they meet quality and safety standards. Additionally, inquire about their manufacturing processes and quality assurance protocols. Visiting their facilities or requesting samples can also provide insights into their operational capabilities. -

What quality assurance measures should I look for in PVC ball valves?

Quality assurance measures for PVC ball valves should include compliance with international standards such as ISO or ASTM. Suppliers should conduct regular testing for pressure and temperature tolerance, as well as leakage tests. Documentation such as test reports and certificates of conformity should be provided upon request. Establishing a clear quality assurance agreement with your supplier can help ensure consistent product performance. -

What logistics considerations should I keep in mind when sourcing PVC ball valves internationally?

When sourcing PVC ball valves internationally, consider shipping methods, lead times, and customs regulations in your country. Opt for suppliers who can provide reliable shipping options and track your orders throughout the delivery process. Additionally, ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate smooth customs clearance. Discussing logistics upfront can help avoid delays and unexpected costs.

Top 7 Valve Ball Pvc Manufacturers & Suppliers List

1. PVC Fittings Online – PVC Ball Valves

Domain: pvcfittingsonline.com

Registered: 2011 (14 years)

Introduction: PVC ball valves are commonly used in landscaping and allow for quick on/off flow control while creating a watertight seal. They are suitable for applications in pools, laboratories, food and beverage industries, water treatment, life sciences, and chemical applications. The valves feature a ball that rotates on a 90-degree axis, enabling water flow when in the “on” position and stopping flow compl…

2. Asahi – Ball Valves

Domain: asahivalves.com

Registered: 1998 (27 years)

Introduction: 14 products available in the Ball Valves category, including:

1. PVC Type-21 Ball Valve – Sale price from $41.85

2. PVC Type-21 Ball Valve with Vent Hole – Sale price from $91.38

3. PVC Type-21 SST Flow Control Ball Valve – Sale price from $170.00

4. CPVC Type-21 Ball Valve – Sale price from $61.65

5. CPVC Type-21 Ball Valve with Vent Hole – Sale price from $244.79

6. PP Type-21 Ball Valve -…

3. NORMA Group – PVC Ball Valve 1 in. IPS S X S

Domain: ndspro.com

Registered: 1996 (29 years)

Introduction: PVC Ball Valve, 1 in. IPS S X S, White by NORMA Group. SKU: E1310-10. Creates a shut off point in the pipeline. Leak-resistant valve connects two 1 in. Sch. 40 pipes in irrigation or pressurized systems. Prevents backflow of water, costly property damage, and pipe corrosion. Made of durable PVC plastic with Teflon ball seat, EPDM O-ring, and ABS handle. Features an easy to turn, two-sided handle. …

4. Assured Automation – P2 Series PVC Ball Valves

Domain: assuredautomation.com

Registered: 1996 (29 years)

Introduction: P2 Series PVC Ball Valves: Full Port Ball Valves with NPT (1/2″ to 4″) or Glue Socket (1/2″ to 4″) Connections. Features include: Double blocking with true union ends, patented Dual Block® system to prevent back-off, full port for unobstructed flow, double o-ring stem seals, integrated mounting pad for actuators, and support bracketing for anchoring. Valve seats have o-ring backing cushions. NSF /…

5. Reddit – PVC Shutoff Valves vs. Alternatives

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: PVC shutoff valves are commonly used in irrigation systems but face criticism for their reliability under constant pressure. Alternatives mentioned include brass ball valves and higher quality PVC ball valves, specifically SCH 80 (grey) labeled as ‘heavy duty’ or ‘industrial grade’. True union PVC ball valves are also suggested as better options. Concerns arise when PVC shutoff valves are left clo…

6. ProLine – PVC 1/2-in SOLVENT Ball Valve

Domain: bkproducts.com

Registered: 2000 (25 years)

Introduction: {‘name’: ‘PVC 1/2-in SOLVENT x 1/2-in SOLVENT Ball Valve – Non-Potable Gray’, ‘item_number’: ‘107-633-NPG’, ‘list_price’: ‘$3.01’, ‘description’: ‘The ProLine Series PVC Schedule 40 Ball Valves are used for cold water pressure distribution systems in residential, commercial, agricultural and light industrial applications. This NSF-approved valve features TPV seats and EPDM O-rings and is construct…

7. Soval – 400 Series PVC Socket Ball Valves

Domain: soval.com

Registered: 1997 (28 years)

Introduction: This company, Soval – 400 Series PVC Socket Ball Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for valve ball pvc

What Are the Key Takeaways for Strategic Sourcing of PVC Ball Valves?

In the dynamic landscape of valve ball PVC sourcing, understanding market trends, quality standards, and supplier capabilities is paramount. PVC ball valves are indispensable across various industries, including landscaping, water treatment, and chemical processing. Their ability to deliver a reliable watertight seal and quick flow control makes them a preferred choice. Strategic sourcing not only enhances operational efficiency but also ensures cost-effectiveness, especially when targeting international markets.

How Can International Buyers Leverage Strategic Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the key is to establish strong partnerships with reputable suppliers. This approach facilitates access to high-quality products at competitive prices while ensuring compliance with local regulations. Moreover, leveraging digital platforms for procurement can streamline processes and expand sourcing options.

What’s Next for B2B Buyers in the PVC Valve Market?

As the demand for PVC ball valves continues to grow, staying ahead of industry innovations and market shifts will be crucial. Buyers should actively engage with suppliers to explore new materials and designs that enhance performance and sustainability. Embrace this opportunity to refine your sourcing strategy and position your business for future success. Make informed decisions today to secure a competitive edge in the evolving global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.