A B2B Buyer’s Guide to Cleated Belt Conveyor Systems: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cleated belt conveyor systems

In today’s competitive landscape, sourcing cleated belt conveyor systems presents a significant challenge for international B2B buyers. As businesses strive for operational efficiency and cost-effectiveness, the right conveyor solutions can drastically enhance productivity, especially when managing diverse product types across various industries. This comprehensive guide delves into the multifaceted world of cleated belt conveyors, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

By equipping decision-makers from regions like Africa, South America, the Middle East, and Europe—specifically in markets like Saudi Arabia and Germany—with actionable insights, this guide aims to empower informed purchasing decisions. Understanding the nuances of cleated conveyors, from their engineered solutions to food safety standards, enables buyers to select systems that not only meet their operational needs but also align with regulatory requirements.

Whether you are looking to optimize vertical space, enhance product security during transport, or ensure sanitary conditions in food handling, this guide will serve as a vital resource. By navigating the complexities of the global market for cleated belt conveyor systems, B2B buyers can streamline their procurement processes and foster greater operational success.

Understanding cleated belt conveyor systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Cleated Belt Conveyors | Lightweight, low maintenance, customizable cleat sizes | Parts handling, accumulation, precision movement | Pros: Durable, versatile; Cons: Higher initial cost. |

| LPZ Z-Frame Cleated Conveyors | Elevation capabilities, modular design, various cleat options | Food processing, packaging, material handling | Pros: Space-efficient, flexible; Cons: Installation complexity. |

| Sanitary Cleated Belt Conveyors | Food-safe design, seamless cleat attachment | Food handling, pharmaceuticals | Pros: High hygiene standards; Cons: May require specific maintenance protocols. |

| Modular Cleated Belt Conveyors | Interlocking segments, easy to repair, versatile materials | Sanitary applications, general material handling | Pros: Easy maintenance; Cons: Limited load capacity. |

| Incline Cleated Belt Conveyors | Steeper incline angles, enhanced product stability | Elevating bulk materials, packaging lines | Pros: Maximizes vertical space; Cons: Requires careful angle design. |

What are Aluminum Cleated Belt Conveyors and Their B2B Suitability?

Aluminum cleated belt conveyors are known for their lightweight structure and low maintenance requirements. These conveyors can be customized with various cleat sizes to accommodate different product types, making them ideal for applications such as parts handling and precision movement. When considering this option, buyers should evaluate their specific operational needs, as the initial investment may be higher compared to standard conveyors, but the long-term durability and versatility often justify the cost.

How Do LPZ Z-Frame Cleated Conveyors Enhance Operational Efficiency?

The LPZ Z-Frame cleated conveyor is designed for elevation, allowing businesses to utilize vertical space effectively. Its modular design accommodates various cleat configurations, making it suitable for industries such as food processing and packaging. While this conveyor offers significant advantages in space efficiency, buyers should consider the potential complexity of installation and whether their facility can support such systems.

Why Choose Sanitary Cleated Belt Conveyors for Food and Pharmaceutical Applications?

Sanitary cleated belt conveyors are specifically designed to meet food safety standards, featuring seamless cleat attachment methods to minimize contamination risks. These conveyors are ideal for food handling and pharmaceutical applications, where hygiene is paramount. Buyers must consider the specific maintenance protocols required for these systems, as adherence to hygiene standards is critical for compliance and safety.

What Are the Benefits of Modular Cleated Belt Conveyors?

Modular cleated belt conveyors consist of interlocking segments that can be easily replaced, making them an excellent choice for industries requiring frequent maintenance, such as food processing. Their versatility allows them to be used in various applications, although buyers should be aware of their limited load capacity compared to traditional belt conveyors. This feature can be a deciding factor for businesses with heavy product loads.

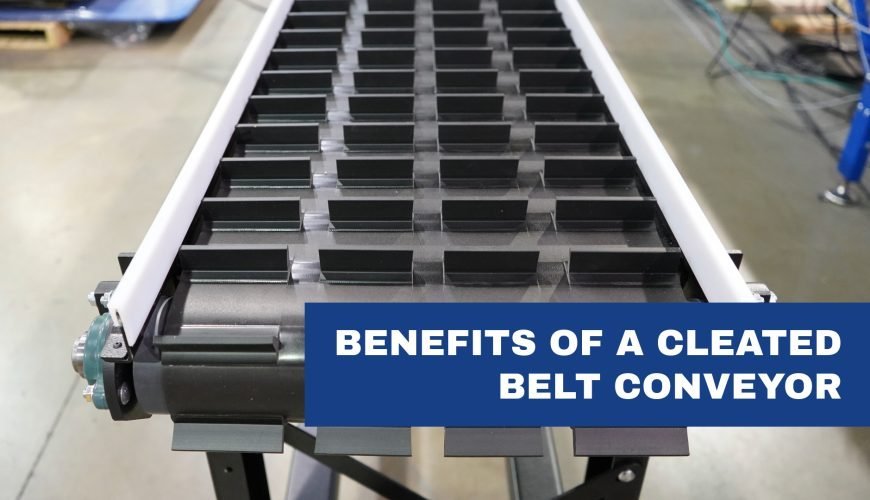

How Do Incline Cleated Belt Conveyors Optimize Space Utilization?

Incline cleated belt conveyors are designed to handle steeper angles, allowing for the efficient movement of bulk materials in limited spaces. This design enhances product stability during transportation, making it suitable for packaging lines and other applications. Buyers should carefully evaluate the required incline angles to ensure optimal performance, as improper design can lead to product loss or damage.

Key Industrial Applications of cleated belt conveyor systems

| Industry/Sector | Specific Application of cleated belt conveyor systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Elevating bulk food products to volumetric feeders | Ensures safe and efficient handling of food items, reducing contamination risks. | Need for sanitary designs that comply with food safety regulations. |

| Pharmaceutical | Precision conveying for pill compression and packaging | Increases accuracy and reduces product loss during high-speed operations. | Must meet stringent hygiene and operational standards. |

| Meat & Poultry | Transporting raw meat through processing lines | Enhances safety and efficiency, minimizing contamination during transport. | Compliance with USDA standards and robust material selection. |

| Packaging | Automated sorting and grouping of packaged goods | Improves operational efficiency and speeds up the packaging process. | Consideration for space optimization and modular designs. |

| Material Handling | General transport of materials in warehouses | Streamlines operations and maximizes space utilization. | Flexibility in design and ability to handle various product sizes. |

How Are Cleated Belt Conveyor Systems Used in Food Processing?

In food processing, cleated belt conveyor systems are essential for elevating bulk food items to volumetric feeders. These conveyors are designed to maintain the integrity of food products, preventing spillage and contamination during transit. Buyers in this sector must prioritize sanitary designs that comply with local and international food safety regulations. For instance, in markets such as Germany and Saudi Arabia, adherence to strict hygiene standards is crucial, necessitating the use of materials that are easy to clean and resistant to wear.

What Role Do Cleated Conveyors Play in the Pharmaceutical Industry?

In the pharmaceutical sector, cleated belt conveyors facilitate precision conveying for applications like pill compression and packaging. These systems are engineered to minimize product loss and ensure accurate placement during high-speed operations, which is critical in maintaining production efficiency. International buyers should consider suppliers that provide systems meeting stringent hygiene standards, as the pharmaceutical industry is heavily regulated. Additionally, the ability to customize conveyor specifications to fit unique production lines is a significant advantage.

How Do Cleated Conveyors Enhance Safety in Meat and Poultry Processing?

Cleated belt conveyor systems are vital in transporting raw meat through processing lines, enhancing safety and efficiency. These systems help minimize contamination risks by securely holding meat products during transit, which is particularly important in regions with strict food safety regulations like the EU and the Middle East. Buyers should focus on sourcing conveyors that comply with USDA standards and are constructed from robust materials that can withstand the rigors of meat processing environments.

In What Ways Are Cleated Conveyors Used in Packaging?

In packaging operations, cleated belt conveyors are employed for automated sorting and grouping of packaged goods. This application significantly boosts operational efficiency by streamlining the packaging process and reducing manual handling. For businesses in South America and Africa, where rapid growth in the packaging industry is evident, sourcing flexible and modular conveyor designs can lead to substantial cost savings and improved productivity.

How Do Cleated Belt Conveyors Benefit General Material Handling?

Cleated belt conveyor systems are also widely used for general material handling in warehouses and distribution centers. They facilitate the efficient transport of various materials, optimizing space utilization and streamlining operations. International buyers should look for solutions that offer flexibility in design to accommodate different product sizes and weights, ensuring that the system can adapt to changing operational needs and maximize throughput.

3 Common User Pain Points for ‘cleated belt conveyor systems’ & Their Solutions

Scenario 1: Inefficiency Due to Product Misalignment During Transport

The Problem: Many businesses face significant challenges with product misalignment on cleated belt conveyor systems, especially when handling irregularly shaped or varying sizes of products. This misalignment can lead to increased downtime, as operators must frequently intervene to reposition items, causing delays in the production line. Moreover, the risk of product damage escalates, resulting in additional costs and potential loss of revenue.

The Solution: To tackle this issue, B2B buyers should consider investing in custom cleated belt conveyors that offer adjustable cleat heights and spacing tailored to the specific products being transported. By collaborating closely with manufacturers to specify the optimal cleat design based on product dimensions, weight, and handling requirements, businesses can enhance alignment and stability. Additionally, incorporating sensors and automated controls can provide real-time monitoring and adjustments, ensuring precise positioning and reducing manual intervention. Regular maintenance checks and adjustments will further optimize performance, keeping the production line running smoothly.

Scenario 2: Contamination Risks in Food Processing Environments

The Problem: In industries such as food processing, the integrity of the product is paramount, and contamination risks pose a serious challenge. Cleated belt conveyors that come into contact with food must maintain strict hygiene standards to prevent any potential contamination. Cracks, poor bonds, or improper materials can lead to safety violations, product recalls, and loss of consumer trust.

The Solution: To mitigate contamination risks, it is essential for buyers to source cleated belt conveyor systems made from food-grade materials that comply with industry standards, such as those set by the FDA or USDA. Buyers should prioritize suppliers who offer in-house cleating processes, as this ensures a seamless bond between the cleats and the conveyor belt, minimizing crevices where contaminants could accumulate. Furthermore, selecting conveyors designed for easy cleaning, such as those with smooth surfaces and sealed edges, will facilitate maintenance and uphold sanitation protocols. Implementing a routine cleaning schedule and regular inspections will help maintain hygiene and ensure compliance with safety regulations.

Scenario 3: Limited Space and Inefficient Use of Vertical Capacity

The Problem: Many manufacturing and processing facilities operate within confined spaces, making it challenging to implement effective material handling solutions. Traditional flat belt conveyors often fail to utilize vertical space efficiently, leading to wasted floor area and limiting operational capacity. This inefficiency can hinder productivity and increase operational costs.

The Solution: To address spatial constraints, B2B buyers should consider cleated belt conveyors specifically designed for inclined and vertical transportation. These systems can achieve steep angles of up to 60 degrees, allowing for the efficient use of vertical space. When sourcing these conveyors, it is crucial to assess the load capacity and incline specifications to ensure they meet operational needs. Buyers can also explore modular conveyor systems that allow for customization and adaptability in layout, enabling seamless integration into existing workflows. Investing in advanced cleated belt systems not only optimizes space but also enhances throughput, contributing to overall operational efficiency.

Strategic Material Selection Guide for cleated belt conveyor systems

What Are the Key Materials for Cleated Belt Conveyor Systems?

When selecting materials for cleated belt conveyor systems, it is crucial to consider the specific requirements of your application, including the types of products being transported, environmental conditions, and compliance with industry standards. Below, we analyze four common materials used in cleated belt conveyor systems, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

1. Urethane

Key Properties: Urethane is known for its excellent abrasion resistance and flexibility, making it suitable for a wide range of applications. It typically operates effectively within a temperature range of -30°F to 180°F (-34°C to 82°C) and exhibits good chemical resistance.

Pros & Cons: Urethane cleats are durable and can withstand significant wear, making them ideal for handling heavy or abrasive materials. However, they can be more expensive than other materials and may require complex manufacturing processes to achieve specific cleat designs.

Impact on Application: Urethane is particularly compatible with food handling applications due to its non-toxic nature, making it suitable for the food and pharmaceutical industries.

International Considerations: Buyers in regions like Europe and the Middle East should ensure compliance with food safety standards such as FDA and EU regulations. Urethane’s versatility makes it a preferred choice in these markets.

2. Rubber

Key Properties: Rubber is known for its excellent grip and shock absorption capabilities. It can handle a wide temperature range, typically from -40°F to 200°F (-40°C to 93°C), and is resistant to various chemicals and oils.

Pros & Cons: Rubber cleats provide superior traction, making them ideal for steep inclines. However, they may degrade faster under UV exposure and extreme temperatures, leading to higher replacement costs over time.

Impact on Application: Rubber is commonly used in bulk material handling applications, particularly in mining and construction, where heavy loads and rough handling are typical.

International Considerations: Buyers should consider the specific rubber grades that comply with local standards, such as ASTM in the USA or DIN in Germany. Additionally, the availability of rubber materials may vary by region, influencing procurement strategies.

3. Engineered Plastic

Key Properties: Engineered plastics, such as polypropylene and polyethylene, offer a lightweight alternative with good chemical resistance and durability. They can typically withstand temperatures ranging from -40°F to 180°F (-40°C to 82°C).

Pros & Cons: These materials are often less expensive and easier to manufacture than rubber or urethane. However, they may not provide the same level of traction or durability under heavy loads.

Impact on Application: Engineered plastics are suitable for lighter applications, including packaging and assembly lines, where weight savings are critical.

International Considerations: Buyers should verify compliance with industry standards for engineered plastics, particularly in food applications, to ensure safety and performance. The availability of specific grades may also vary by region.

4. Stainless Steel

Key Properties: Stainless steel is renowned for its strength, corrosion resistance, and ability to withstand high temperatures. It is often used in environments where hygiene is paramount, such as food processing.

Pros & Cons: The durability and longevity of stainless steel make it an excellent choice for demanding applications. However, it is significantly more expensive than other materials and can be heavier, which may impact conveyor design.

Impact on Application: Stainless steel cleated conveyors are ideal for industries requiring high sanitation standards, such as food and pharmaceuticals, where contamination risks must be minimized.

International Considerations: International buyers, especially in the food industry, must ensure compliance with stringent hygiene standards, such as those set by the FDA or EU regulations. The choice of stainless steel grades should also align with local standards.

Illustrative image related to cleated belt conveyor systems

Summary Table of Material Selection

| Material | Typical Use Case for cleated belt conveyor systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Urethane | Food handling, pharmaceuticals | Excellent abrasion resistance | Higher cost and manufacturing complexity | High |

| Rubber | Bulk material handling (mining, construction) | Superior grip and shock absorption | UV degradation and temperature sensitivity | Medium |

| Engineered Plastic | Packaging, assembly lines | Lightweight and cost-effective | Lower traction and durability | Low |

| Stainless Steel | Food processing, pharmaceuticals | High strength and corrosion resistance | High cost and weight | High |

This strategic material selection guide provides international B2B buyers with valuable insights into the performance characteristics and considerations for cleated belt conveyor systems, aiding in informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for cleated belt conveyor systems

What Are the Main Stages of Manufacturing Cleated Belt Conveyor Systems?

The manufacturing of cleated belt conveyor systems involves several critical stages that ensure the final product meets the specific needs of various industries, such as food processing, pharmaceuticals, and material handling. Understanding these stages can help B2B buyers make informed decisions when sourcing these systems.

How is Material Prepared for Cleated Belt Conveyors?

The first step in the manufacturing process is material preparation. This involves selecting high-quality materials that meet industry standards for durability and safety. Common materials include urethane, rubber, and engineered plastics, which are chosen based on the specific application of the conveyor system.

Once the materials are selected, they undergo a rigorous inspection to ensure they meet specifications. This may include checking for material integrity, compliance with safety standards, and any certifications needed for specific industries. For food-grade applications, materials must also adhere to FDA regulations to avoid contamination.

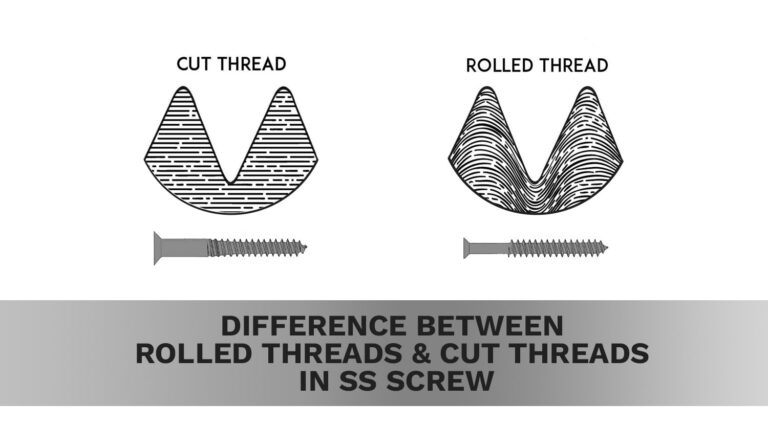

What Techniques Are Used in Forming Cleated Conveyor Components?

The forming stage involves shaping the prepared materials into the various components of the conveyor system. This can include cutting, molding, or extruding the base belt and cleats. For instance, cleats are often formed using techniques like injection molding or extrusion, which allows for precise control over dimensions and characteristics.

Illustrative image related to cleated belt conveyor systems

Advanced technologies, such as radio-frequency welding, are commonly employed to bond cleats to the conveyor belt. This method ensures a seamless bond that minimizes the risk of detachment and enhances the overall durability of the conveyor system. In-house cleating processes, as offered by leading manufacturers, allow for customization in cleat height, spacing, and pattern according to client specifications.

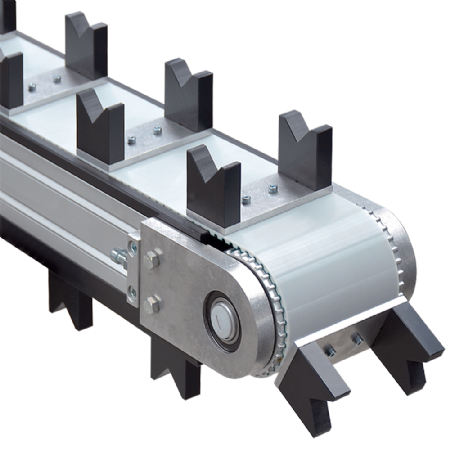

What Does the Assembly Process Entail for Cleated Belt Conveyors?

Following the forming stage, the assembly process brings together the various components of the conveyor system. This includes attaching the cleated belts to the frame, integrating drive systems, and ensuring all parts are securely fastened. Precision in assembly is crucial, as even minor misalignments can lead to operational inefficiencies.

During assembly, manufacturers often conduct initial quality checks to ensure that all components fit together correctly and function as intended. This includes checking for proper belt tension, alignment, and the operation of any automated features, particularly in systems designed for high-speed applications.

What Are the Finishing Processes for Cleated Belt Conveyor Systems?

The finishing stage involves applying protective coatings, conducting final inspections, and preparing the system for shipment. Surface treatments may include powder coating or anodizing, which enhances corrosion resistance and improves aesthetics.

Final inspections ensure that the conveyor systems meet all required standards and specifications. This may involve operational testing, where the conveyor is run to confirm it operates smoothly under load. Any necessary adjustments are made before the system is packaged for delivery.

Illustrative image related to cleated belt conveyor systems

What Quality Assurance Standards Are Relevant for Cleated Belt Conveyor Systems?

Quality assurance is a critical component of the manufacturing process for cleated belt conveyor systems. Buyers must be aware of international standards and industry-specific regulations that ensure product quality and safety.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their commitment to quality and continuous improvement, which is essential for building trust with international B2B buyers.

Additionally, CE marking is crucial for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. For food-grade applications, certifications such as NSF and FDA compliance are essential, as they ensure that materials used in the conveyor systems are safe for contact with food products.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted at various stages to identify any defects or deviations from standards.

-

Final Quality Control (FQC): A comprehensive inspection occurs after assembly and before shipment, where the complete system is tested for functionality and compliance with specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence when evaluating potential suppliers of cleated belt conveyor systems. Understanding how to verify QC practices can help mitigate risks associated with product quality.

Illustrative image related to cleated belt conveyor systems

What Methods Can Buyers Use to Assess Supplier QC?

-

Supplier Audits: Conducting audits of manufacturing facilities can provide insight into the supplier’s quality management processes, including adherence to international standards and the effectiveness of their QC checkpoints.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance history, including any issues identified during the manufacturing process and how they were addressed.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process, ensuring that products meet required standards before they are shipped.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must be aware of the specific quality control nuances that may affect their procurement process.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying regulatory requirements and industry standards. For example, buyers in Europe may prioritize CE marking, while those in the Middle East may focus on compliance with local safety standards. Understanding these nuances is essential for ensuring that the purchased systems are compliant with local regulations.

Additionally, cultural differences in business practices may affect communication regarding quality expectations. Establishing clear channels for communication and documentation can help bridge these gaps and foster trust between buyers and suppliers.

Illustrative image related to cleated belt conveyor systems

By understanding the manufacturing processes and quality assurance protocols associated with cleated belt conveyor systems, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cleated belt conveyor systems’

Introduction

When sourcing cleated belt conveyor systems, it’s essential to have a systematic approach to ensure you select the right solution for your operational needs. This guide provides a step-by-step checklist to help international B2B buyers navigate the complexities of procurement, from defining specifications to evaluating suppliers. By following these steps, you can make informed decisions that enhance productivity and efficiency in your operations.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of successful procurement. Consider factors such as the materials being transported, the required incline angles, and the environmental conditions (e.g., temperature, humidity) that the conveyor will operate in.

- Product Type: Identify the dimensions, weight, and fragility of the products to ensure the cleats are appropriately designed.

- Application Needs: Determine if the conveyor will be used for food handling, pharmaceuticals, or general material transport, as this will influence the materials and design.

Step 2: Assess Customization Options

Different applications may require unique cleat designs and configurations. Evaluate the level of customization offered by potential suppliers to meet your specific needs.

- Cleat Height and Material: Look for suppliers that provide a variety of cleat heights and materials such as urethane or rubber, which can impact grip and durability.

- In-House Modifications: Suppliers that offer in-house cleating can ensure better quality control and tailored solutions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is crucial to ensure reliability and capability. Request detailed company profiles, case studies, and references from clients in similar industries or regions.

- Experience and Expertise: Choose suppliers with a proven track record in your specific industry, such as food processing or pharmaceuticals.

- Customer Support: Assess the supplier’s customer service capabilities, including installation support and after-sales service.

Step 4: Verify Compliance and Certifications

Regulatory compliance is vital, especially in industries like food and pharmaceuticals. Ensure that the conveyor systems meet relevant safety and quality standards.

- Industry Certifications: Check for certifications such as ISO, HACCP, or FDA compliance, which indicate adherence to industry best practices.

- Material Safety: Confirm that materials used in the conveyor construction are safe for the intended application, especially when handling food products.

Step 5: Analyze Cost vs. Value

While budget considerations are important, focus on the overall value rather than just the initial purchase price.

- Total Cost of Ownership: Factor in maintenance costs, energy consumption, and potential downtime when evaluating the overall cost.

- Return on Investment (ROI): Assess how the conveyor system will improve efficiency, reduce waste, or enhance product handling to justify the investment.

Step 6: Request Samples or Demonstrations

Whenever possible, request samples or live demonstrations of the conveyor systems to evaluate their performance in real-world scenarios.

- Functionality Testing: Observe how the conveyor handles your specific products, including speed, stability, and incline performance.

- User Experience: Gather feedback from operators on the ease of use and efficiency of the system in practice.

Step 7: Finalize Terms and Conditions

Once you’ve selected a supplier, carefully review and negotiate the terms of the contract to ensure clarity and protection.

- Warranty and Support: Ensure that the warranty covers parts and service, and clarify the extent of customer support provided post-purchase.

- Delivery and Installation: Confirm timelines for delivery and installation, as well as any additional costs associated with setup.

By following this checklist, you can streamline the sourcing process for cleated belt conveyor systems, ensuring that you choose a solution that meets your operational requirements while maximizing efficiency and safety.

Comprehensive Cost and Pricing Analysis for cleated belt conveyor systems Sourcing

What Are the Key Cost Components in Cleated Belt Conveyor Systems?

When evaluating the cost structure of cleated belt conveyor systems, several components play a significant role:

Illustrative image related to cleated belt conveyor systems

-

Materials: The choice of materials for cleated belts significantly impacts costs. Common materials include urethane, rubber, and engineered plastic. Each material has its own price point, influenced by durability, application, and compliance with industry standards (e.g., food safety regulations).

-

Labor: Labor costs encompass the expenses related to manufacturing and assembly. This includes skilled labor for in-house cleating processes, which can enhance quality and flexibility. Companies that invest in skilled labor often see a better return in terms of product performance and longevity.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead and thus lower the overall cost of conveyor systems.

-

Tooling: Customization often requires specific tooling, which can add to initial costs. However, efficient tooling can lead to reduced production times and costs over the product’s lifecycle.

-

Quality Control (QC): QC processes are essential, especially in industries like food and pharmaceuticals. Implementing rigorous QC measures may increase upfront costs but ensures compliance with safety standards, reducing potential liabilities.

-

Logistics: Shipping and handling costs vary based on the geographical location of the supplier and buyer. Import duties, shipping methods, and packaging also play a role in the overall logistics expenses.

-

Margin: Suppliers typically add a margin to cover their operating costs and profit. This margin can fluctuate based on market conditions, competition, and the specific supplier’s value proposition.

How Do Price Influencers Affect Cleated Belt Conveyor Systems?

Several factors influence the pricing of cleated belt conveyor systems, which international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can significantly reduce unit costs. Suppliers often offer discounts for larger orders, making it advantageous for businesses with high volume needs.

-

Specifications and Customization: Custom features such as cleat height, spacing, and material can increase costs. Buyers should clearly communicate their requirements to suppliers to receive accurate quotes.

-

Material Selection: Higher quality or specialized materials (e.g., FDA-approved for food handling) can lead to higher prices. Buyers must balance material costs with performance needs.

-

Quality and Certifications: Products that meet specific industry certifications (such as BISSC for food processing) may command higher prices due to the additional costs associated with compliance.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can influence pricing. Established suppliers with proven track records may charge more but often provide better quality and service.

-

Incoterms: Understanding the terms of sale (Incoterms) is critical for international buyers. They dictate responsibilities for shipping, insurance, and tariffs, which can affect the overall cost.

What Negotiation and Cost-Efficiency Tips Should Buyers Consider?

International buyers seeking cleated belt conveyor systems should employ strategic negotiation and cost-efficiency practices:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also maintenance, operation, and potential downtime costs. A cheaper conveyor may result in higher TCO due to frequent repairs or inefficiencies.

-

Leverage Competitive Quotes: Obtain quotes from multiple suppliers to gauge market rates. Use this information as leverage in negotiations to secure better pricing or terms.

-

Discuss Long-Term Partnerships: Building a long-term relationship with suppliers can lead to better pricing, preferential treatment, and more favorable payment terms.

-

Inquire About Value-Added Services: Some suppliers offer installation, maintenance, or training services. Understanding these offerings can provide additional value and reduce future operational costs.

-

Be Aware of Pricing Nuances in International Markets: Different regions may have varying pricing structures due to local economic conditions, currency fluctuations, and import regulations. Buyers should conduct thorough market research to inform their purchasing decisions.

Disclaimer on Indicative Prices

It is essential to note that prices for cleated belt conveyor systems can vary widely based on the factors discussed. Buyers should seek detailed quotes tailored to their specific needs and requirements to ensure accurate budgeting.

Alternatives Analysis: Comparing cleated belt conveyor systems With Other Solutions

Understanding Alternatives to Cleated Belt Conveyor Systems

In the realm of material handling, selecting the right conveyor system is crucial for optimizing operations. While cleated belt conveyor systems offer unique advantages such as enhanced stability and the ability to handle inclines, several alternative solutions may also meet specific operational needs. This section explores viable alternatives, comparing them to cleated belt conveyors across key aspects.

| Comparison Aspect | Cleated Belt Conveyor Systems | Modular Belt Conveyors | Screw Conveyors |

|---|---|---|---|

| Performance | Excellent for inclines and precise product placement | Good for horizontal and vertical transport; modular design allows for flexibility | Effective for bulk materials; continuous flow capability |

| Cost | Moderate initial investment; can be cost-effective for high-volume operations | Higher upfront cost due to modular components; lower maintenance costs | Generally lower initial cost; ongoing maintenance can be higher |

| Ease of Implementation | Requires careful planning for custom cleat design and layout | Easier to implement with standard modules; customizable | Simple installation; requires adequate space for horizontal runs |

| Maintenance | Low maintenance; cleats are durable but may require periodic checks | Low maintenance; easy to replace individual modules | Moderate maintenance; potential for wear and tear on screws |

| Best Use Case | Ideal for food processing, pharmaceuticals, and precise assembly | Suitable for diverse applications including food, packaging, and general material handling | Best for bulk materials like grains, powders, and granules |

Detailed Breakdown of Alternatives

Modular Belt Conveyors

Modular belt conveyors consist of interlocking plastic segments that can be easily replaced when damaged. This design allows for flexibility in layout and application, making them suitable for various industries, including food processing and packaging. The main advantage of modular systems is their ease of maintenance and repair. However, the initial investment can be higher compared to cleated belt conveyors, which may be a consideration for budget-conscious buyers.

Illustrative image related to cleated belt conveyor systems

Screw Conveyors

Screw conveyors utilize a rotating helical screw blade to move bulk materials along a trough or tube. They are particularly effective for transporting powders, grains, and other bulk materials in a continuous flow. Their simplicity in design allows for easy installation, making them a popular choice in agricultural and industrial applications. However, they may not be suitable for items that require careful handling or precise placement, as they can generate significant movement and may lead to product degradation.

Conclusion: How to Choose the Right Conveyor System

When selecting a conveyor system, B2B buyers should assess their specific operational requirements, including the type of material being handled, space constraints, and budget. Cleated belt conveyors excel in applications requiring precise placement and the ability to navigate inclines, making them ideal for food and pharmaceutical industries. Modular belt conveyors offer flexibility and ease of maintenance, while screw conveyors are best suited for bulk material transport. By carefully evaluating these alternatives, businesses can make informed decisions that enhance efficiency and productivity in their operations.

Essential Technical Properties and Trade Terminology for cleated belt conveyor systems

What Are the Essential Technical Properties of Cleated Belt Conveyor Systems?

When considering cleated belt conveyor systems for your operations, understanding their technical properties is crucial for optimizing performance and ensuring suitability for your specific applications. Here are key specifications that significantly impact functionality and efficiency.

1. Material Grade

The material grade of the conveyor belt is fundamental in determining its durability and suitability for various environments. Common materials include urethane, rubber, and engineered plastics. Each material offers different levels of resistance to wear, chemicals, and temperature, which is particularly important in industries such as food processing and pharmaceuticals where hygiene and safety are paramount. Selecting the appropriate material can enhance the lifespan of the conveyor and minimize maintenance costs.

2. Cleat Height and Design

Cleat height can range from a fraction of an inch to several inches, depending on the products being transported. The design of the cleats—such as their spacing and pattern—also plays a critical role in preventing product slippage, especially on inclines. For B2B buyers, understanding the relationship between cleat design and product type is essential for ensuring safe and efficient material handling.

3. Tolerance and Alignment

Tolerance refers to the allowable deviation in the dimensions of the conveyor components. Accurate tolerance levels ensure that the conveyor operates smoothly without issues such as misalignment or excessive wear. For buyers, this specification is vital as it directly affects the reliability and efficiency of the conveyor system, impacting overall productivity.

4. Load Capacity

The load capacity of a cleated belt conveyor indicates the maximum weight it can handle during operation. This specification is crucial for businesses that need to transport heavy or bulky products. Ensuring that the conveyor’s load capacity aligns with operational needs prevents potential overloading and reduces the risk of equipment failure, thereby safeguarding investments.

5. Drive System Type

The type of drive system used in a cleated conveyor system—be it a belt drive, chain drive, or direct drive—affects both performance and maintenance requirements. A well-suited drive system ensures optimal power transmission and can influence the conveyor’s speed and efficiency. For B2B decision-makers, understanding the differences in drive systems can aid in selecting the most effective solution for their specific requirements.

What Are Common Trade Terms Related to Cleated Belt Conveyors?

Understanding industry terminology is essential for effective communication and decision-making in B2B transactions. Here are some common trade terms you might encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of cleated conveyors, working with an OEM can ensure that the parts are made to specific standards and are compatible with existing systems, which is crucial for operational efficiency.

Illustrative image related to cleated belt conveyor systems

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for businesses to manage inventory effectively and negotiate better terms with suppliers, ensuring that they can meet operational demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price bids for specific products or services. Understanding how to prepare and send an RFQ can streamline the procurement process, enabling businesses to receive competitive pricing for cleated belt conveyors and their components.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms helps businesses navigate logistics, ensuring clarity on costs, risks, and responsibilities involved in the procurement of conveyor systems from international suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is crucial for planning production schedules and managing inventory, ensuring that operations run smoothly without interruptions.

By grasping these technical properties and trade terms, businesses can make informed decisions when investing in cleated belt conveyor systems, ultimately enhancing operational efficiency and productivity.

Illustrative image related to cleated belt conveyor systems

Navigating Market Dynamics and Sourcing Trends in the cleated belt conveyor systems Sector

What Are the Current Market Dynamics and Key Trends in Cleated Belt Conveyor Systems?

The global market for cleated belt conveyor systems is witnessing significant growth, driven by the increasing demand for automation and efficiency in material handling across various industries. Key trends include the integration of advanced technologies such as IoT, AI, and robotics, which enhance operational efficiency and enable predictive maintenance. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for customized solutions that cater to specific industry needs, such as food processing, pharmaceuticals, and logistics.

Another notable trend is the shift towards modular designs that allow for easier maintenance and scalability. This flexibility appeals to businesses in dynamic markets, enabling them to adapt to changing production demands without significant capital investments. Additionally, the rise of e-commerce has amplified the need for reliable and efficient conveyor systems to streamline warehousing and distribution processes, particularly in urban areas.

Moreover, regional market dynamics vary significantly. For instance, European markets are increasingly focused on sustainability and energy efficiency, while Middle Eastern and African markets are experiencing rapid industrialization, which is propelling the demand for innovative conveyor solutions. Understanding these regional dynamics can help international buyers tailor their sourcing strategies effectively.

How Are Sustainability and Ethical Sourcing Addressed in the Cleated Belt Conveyor Systems Sector?

As sustainability becomes a focal point for businesses globally, the cleated belt conveyor systems sector is evolving to meet these demands. The environmental impact of manufacturing processes, including the energy consumption and waste generated, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and implementing sustainable practices.

Ethical sourcing is equally critical, with a growing emphasis on transparent supply chains. Buyers are encouraged to seek out manufacturers who use responsibly sourced materials and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential criteria in supplier selection.

Moreover, the use of ‘green’ materials, such as recycled plastics or biodegradable options for cleats, is gaining traction. Suppliers offering these sustainable alternatives not only enhance their brand value but also align with the corporate responsibility goals of their clients. By prioritizing sustainability and ethical sourcing, businesses can strengthen their market position while contributing to global efforts toward a more sustainable future.

What Is the Brief Evolution and History of Cleated Belt Conveyor Systems?

The evolution of cleated belt conveyor systems can be traced back to the early 20th century when the demand for efficient material handling began to rise alongside industrial growth. Originally designed for flat surfaces, these systems quickly adapted to the need for elevation and incline transportation, leading to the integration of cleats. The cleats, strategically placed on the conveyor belts, provided the necessary grip to transport loose or bulk materials up steep angles without risk of spillage.

Over the decades, advancements in materials and technology have significantly enhanced the design and functionality of cleated conveyors. The introduction of modular components allowed for more versatile configurations, enabling businesses to customize their systems to fit specific operational needs. Today, cleated belt conveyors are integral to various industries, including food processing, pharmaceuticals, and logistics, highlighting their vital role in modern manufacturing and distribution processes. This ongoing evolution reflects the sector’s adaptability to changing market demands and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of cleated belt conveyor systems

-

How do I solve the issue of product misalignment on my conveyor?

To address product misalignment, consider using cleated belt conveyors, which feature raised sections (cleats) that secure items in place during transport. Opt for custom cleat heights and spacing tailored to your specific product dimensions and movement needs. Additionally, ensure that the conveyor is correctly aligned and maintained to prevent slippage or misalignment. Collaborating with a reputable supplier can provide insights into the most effective configurations and materials to enhance stability. -

What is the best cleated belt conveyor for food handling applications?

For food handling, look for cleated belt conveyors made from food-grade materials such as urethane or engineered plastic. Sanitary designs, like those that comply with USDA standards, are essential to prevent contamination. The AquaGard series, for example, offers seamless construction and easy cleaning, making it ideal for the food industry. When selecting, ensure the cleat height and spacing are appropriate for your products to maintain safety and efficiency during transport. -

What are the key factors to consider when customizing a cleated belt conveyor?

When customizing a cleated belt conveyor, focus on the following factors: cleat height and spacing, material compatibility, conveyor length and width, and the specific application environment (e.g., temperature, humidity). Discuss your operational requirements with the manufacturer to ensure the design meets your needs. Additionally, consider the incline angle if applicable, as this will impact the conveyor’s capacity to transport products without compromising stability. -

How can I vet suppliers of cleated belt conveyor systems?

To effectively vet suppliers, conduct thorough research on their experience in the industry, customer reviews, and their portfolio of previous projects. Request references from other businesses that have purchased similar systems. Evaluate their manufacturing capabilities, especially regarding customization and quality assurance processes. Ensure that they comply with international standards relevant to your region and industry, which can impact product reliability and safety. -

What are typical minimum order quantities (MOQs) for cleated belt conveyors?

Minimum order quantities for cleated belt conveyors can vary widely among suppliers, typically ranging from one unit for custom builds to larger quantities for standard models. It’s advisable to clarify this with potential suppliers during the initial inquiry. Some manufacturers may offer flexibility in MOQs for first-time buyers or trial orders, allowing you to assess their products without a significant upfront investment. -

What payment terms should I expect when purchasing conveyor systems internationally?

Payment terms for international purchases often include options like upfront deposits, letters of credit, or payment upon delivery. Many suppliers may request a 30-50% deposit before production, with the balance due upon completion or delivery. Discuss these terms upfront to avoid surprises and ensure they align with your financial processes. It’s also beneficial to confirm the accepted payment methods, including wire transfers or credit terms, particularly for larger transactions. -

How do I ensure quality assurance for my cleated belt conveyor system?

Quality assurance can be ensured by working with suppliers who have robust QA processes in place. Request information on their testing and certification procedures, such as ISO standards or industry-specific certifications. Additionally, you may want to schedule factory visits or request third-party inspections to verify the quality of materials and workmanship. Establishing clear communication about your quality expectations from the outset can help mitigate potential issues. -

What logistics considerations should I keep in mind when importing conveyor systems?

When importing conveyor systems, consider factors such as shipping methods, lead times, customs regulations, and import duties. Work with suppliers who have experience in international shipping to navigate these complexities effectively. Ensure that the supplier provides necessary documentation for customs clearance, including invoices and compliance certificates. It’s also wise to plan for potential delays and have contingency strategies in place to avoid disruptions in your operations.

Top 1 Cleated Belt Conveyor Systems Manufacturers & Suppliers List

1. Accurate Industrial – Conveyor Belt Cleats

Domain: accurateindustrial.com

Registered: 1999 (26 years)

Introduction: Conveyor Belt Cleats: Various types including T-cleat, High Frequency (HF) baseless cleat, Scoop cleat, Beefy cleat, Gusset cleat, Fabric reinforced cleat, and Bolt on cleat (Tatch-A-Cleat®). Cleats are used for moving items on inclines/declines and maintaining consistent spacing. Customization options available based on application requirements. Key dimensions include height, width, cleat indent,…

Strategic Sourcing Conclusion and Outlook for cleated belt conveyor systems

How Can Strategic Sourcing Enhance Your Cleated Belt Conveyor Systems?

In conclusion, the strategic sourcing of cleated belt conveyor systems is essential for optimizing operational efficiency and enhancing product handling across diverse industries. By understanding the unique features and benefits of cleated conveyors—such as improved stability, precision, and sanitary options—international B2B buyers can make informed decisions that align with their specific needs. Collaborating with reputable suppliers ensures that you receive customized solutions tailored to your operational requirements, maximizing both space and productivity.

Illustrative image related to cleated belt conveyor systems

As you evaluate potential partners, consider the long-term advantages of sourcing from manufacturers who prioritize quality control, innovation, and industry compliance. The ability to adapt cleating options based on the product type and operational demands can significantly reduce risks associated with product loss and contamination.

Looking forward, the global market for cleated belt conveyor systems is poised for growth, driven by advancements in automation and increasing demand for efficient material handling solutions. Now is the time for businesses in Africa, South America, the Middle East, and Europe to invest in these technologies. Explore your options and elevate your operations—partner with a leading conveyor system provider today to secure a competitive edge in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.