The Definitive Guide to Latch Drawer: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for latch drawer

In the fast-evolving global market for latch drawers, sourcing reliable safety solutions can be a daunting task for B2B buyers. The challenge lies in selecting the right products that not only meet safety standards but also cater to diverse customer needs across regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide on latch drawers is designed to equip international buyers with critical insights into various types, applications, and industry standards, ensuring informed purchasing decisions.

Throughout this guide, you will discover the different categories of latch drawers, including spring-loaded and multi-functional options, suitable for both residential and commercial environments. We delve into the importance of supplier vetting, exploring key factors such as product quality, pricing structures, and compliance with regional safety regulations. Additionally, we address cost considerations and potential return on investment, enabling buyers to make financially sound decisions.

By empowering B2B buyers with actionable insights and best practices, this guide serves as an essential resource for navigating the complexities of sourcing latch drawers. Whether you are based in Nigeria, Vietnam, or any other global market, understanding the nuances of latch drawer products will enhance your procurement strategy and ultimately contribute to your business’s success.

Understanding latch drawer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring-Loaded Latches | Easy-grip surface, spring action for quick access | Child safety products, home furnishings | Pros: Easy installation, reliable security; Cons: May wear over time with heavy use. |

| Tab Latches | Discreet installation, multi-functional use | Childproofing, cabinetry solutions | Pros: Low visibility, self-locking feature; Cons: Requires careful alignment for optimal performance. |

| Corner Drawer Locks | Designed for corner drawers, enhanced child safety | Furniture manufacturing, childcare facilities | Pros: Effective for corner spaces, robust design; Cons: Limited to specific drawer types. |

| Sliding Cabinet Locks | Locks for sliding doors, simple mechanism | Kitchen and bathroom cabinetry | Pros: User-friendly, versatile for various applications; Cons: May not fit all cabinet styles. |

| Universal Flexi Locks | Adjustable fit for various cabinet styles | Retail environments, home safety products | Pros: Flexible installation, accommodates many designs; Cons: May require additional tools for installation. |

What Are Spring-Loaded Latches and Their Suitability for B2B Buyers?

Spring-loaded latches are designed for easy use, featuring a wide, easy-grip surface that allows quick access for parents while keeping curious children at bay. They are ideal for child safety products, commonly used in homes, childcare facilities, and even retail environments where safety is paramount. When considering these latches, B2B buyers should evaluate the durability and ease of installation, as these factors influence long-term usability and customer satisfaction.

How Do Tab Latches Function and What Are Their Key Benefits?

Tab latches are characterized by their discreet installation, which helps maintain the aesthetics of furniture while providing security. These latches can be installed on either the top or side of drawers and cabinets, making them versatile for various applications, including childproofing and cabinetry solutions. B2B buyers should consider the ease of installation and the self-locking feature, which enhances security without compromising accessibility for adults.

What Are the Unique Features of Corner Drawer Locks?

Corner drawer locks are specifically designed for corner cabinets, enhancing child safety in areas that are often overlooked. Their robust design ensures that even the most curious toddlers cannot access potentially dangerous items. These locks are particularly relevant for furniture manufacturers and childcare facilities. Buyers should assess the lock’s compatibility with existing furniture designs and the installation process, as these factors can affect overall safety effectiveness.

Why Choose Sliding Cabinet Locks for Kitchen and Bathroom Applications?

Sliding cabinet locks are tailored for cabinets with sliding doors, providing a straightforward locking mechanism that is both user-friendly and effective. These locks are frequently used in kitchen and bathroom cabinetry, where safety is crucial. B2B buyers should focus on the versatility of these locks to fit various cabinet styles and the ease of installation, as these aspects directly impact customer satisfaction and product reliability.

What Makes Universal Flexi Locks a Flexible Solution for Different Cabinet Styles?

Universal flexi locks offer adjustable fittings that cater to a wide range of cabinet styles, making them a versatile choice for various retail environments and home safety products. Their flexible design allows for easy installation in spaces where traditional locks may not fit. When purchasing, B2B buyers should consider the adaptability of these locks to different cabinet configurations and the potential need for additional tools during installation, which can affect project timelines and costs.

Key Industrial Applications of latch drawer

| Industry/Sector | Specific Application of Latch Drawer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Child Safety Products | Childproofing cabinets and drawers in homes | Enhances child safety, reduces liability for manufacturers | Compliance with safety regulations, eco-friendly materials |

| Furniture Manufacturing | Secure storage solutions in cabinets and drawers | Improves product functionality and customer satisfaction | Material durability, ease of installation, aesthetic design |

| Retail and Hospitality | Locking mechanisms for display cases and storage units | Protects valuable merchandise, enhances customer trust | Theft prevention features, compatibility with various surfaces |

| Automotive Industry | Secure storage in vehicles for tools and equipment | Increases safety and organization within vehicles | Resistance to environmental factors, ease of access for users |

| Home Improvement Retail | Safety locks for DIY home projects | Expands product offerings, attracts safety-conscious consumers | Versatile application, affordability, bulk purchasing options |

How is ‘Latch Drawer’ Used in Child Safety Products?

In the child safety sector, latch drawers are primarily used to secure cabinets and drawers, preventing children from accessing potentially dangerous items. These latches are designed to be easily installed inside cabinets, remaining hidden from view while providing a robust locking mechanism. For international buyers, particularly from regions like Africa and South America, sourcing latches that meet local safety standards is crucial. Eco-friendly materials are also a growing requirement, aligning with global sustainability trends.

What Role Does ‘Latch Drawer’ Play in Furniture Manufacturing?

In furniture manufacturing, latch drawers serve as secure storage solutions that enhance the functionality of cabinets and drawers. These latches are vital in ensuring that drawers remain closed during transport and use, preventing accidental spills and damage. Buyers in Europe and the Middle East should consider the durability of the materials used, as well as the ease of installation, to meet consumer expectations for high-quality furniture. Additionally, aesthetic compatibility with various furniture designs is essential for marketability.

How Do Retail and Hospitality Industries Benefit from ‘Latch Drawer’?

In the retail and hospitality sectors, latch drawers are utilized for securing display cases and storage units. This application is crucial for protecting valuable merchandise and ensuring customer trust in the safety of displayed items. B2B buyers in these industries should prioritize latches that offer robust theft prevention features and compatibility with different surfaces, as this will enhance the overall security of their establishments. The ability to customize latches for various display setups can also be a significant advantage.

What is the Importance of ‘Latch Drawer’ in the Automotive Industry?

In the automotive industry, latch drawers are essential for securing tools and equipment within vehicles. These latches help maintain organization and safety during transit, reducing the risk of items shifting and causing accidents. Buyers from regions with varying climates, such as the Middle East and Africa, should seek latches that are resistant to environmental factors like humidity and temperature changes. Ease of access for users is another critical requirement, ensuring that tools can be retrieved quickly when needed.

How Can Home Improvement Retailers Leverage ‘Latch Drawer’ Products?

Home improvement retailers can capitalize on latch drawers by offering safety locks for DIY home projects. This application not only expands product offerings but also attracts safety-conscious consumers looking to childproof their homes. Sourcing versatile and affordable latch solutions will enable retailers to cater to a wide audience, including international buyers who may have different needs based on local safety regulations. Bulk purchasing options can also enhance profitability while meeting consumer demand efficiently.

3 Common User Pain Points for ‘latch drawer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Child Safety in Commercial Spaces

The Problem: B2B buyers in the childcare and educational sectors face a pressing challenge: ensuring the safety of children in environments where curious toddlers are present. Standard drawer and cabinet locks may not adequately prevent access to potentially dangerous items, posing a significant risk. This concern is compounded by the need for latches that are not only effective but also aesthetically pleasing and easy for adults to operate without hassle. In many cases, companies find themselves compromising safety for usability, leading to potential liabilities and safety violations.

The Solution: To address these safety concerns, buyers should consider sourcing multi-functional latch drawers specifically designed for high-traffic environments. Products such as the Toddleroo by North States Drawer & Cabinet Tab Latches offer a spring-action design that is intuitive for adults while remaining childproof. These latches can be installed discreetly inside drawers or cabinets, ensuring that they do not detract from the overall design of the space. When selecting latches, prioritize those made from non-toxic, eco-friendly materials that adhere securely to surfaces using high-quality adhesive or mounting hardware. Ensure that the latches automatically self-lock to provide continuous protection without requiring constant monitoring. By investing in high-quality, reliable latches, B2B buyers can create safer environments for children while reducing the risk of accidents and associated liabilities.

Scenario 2: Challenges in Installation and Maintenance of Latch Drawers

The Problem: Many B2B buyers, particularly those in facility management or property maintenance, encounter challenges related to the installation and ongoing maintenance of latch drawers. The complexity of installation can lead to additional labor costs and time delays, especially in settings where multiple units need to be secured. Furthermore, once installed, the effectiveness of these latches can diminish over time due to wear and tear, requiring frequent replacements or adjustments, which can disrupt operations.

The Solution: To streamline installation and maintenance, buyers should seek latch drawer solutions that prioritize ease of use and durability. Products like the Safety 1st Spring-Loaded Cabinet & Drawer Latch are designed for straightforward installation, often requiring no special tools or extensive labor. Buyers should consider purchasing latch systems that come with comprehensive installation guides and customer support resources. Opting for durable materials and designs that withstand frequent use will minimize maintenance concerns. Furthermore, establishing a regular inspection routine can help catch any issues early, ensuring that latches continue to function effectively. By choosing user-friendly latch systems, buyers can reduce installation times and maintenance efforts, leading to smoother operations and lower overall costs.

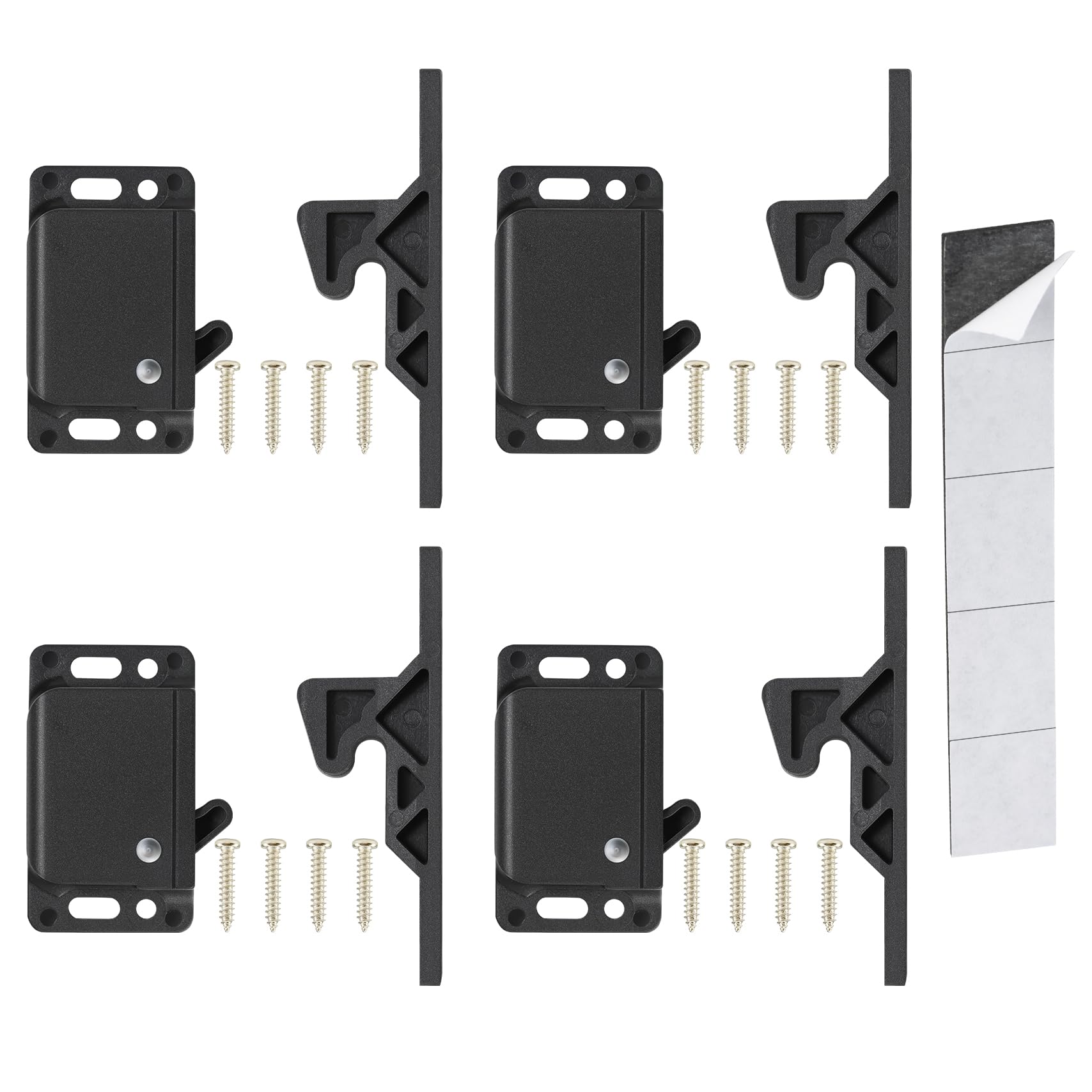

Illustrative image related to latch drawer

Scenario 3: Cost Management in Sourcing Childproof Solutions

The Problem: B2B buyers often grapple with budget constraints while trying to procure high-quality childproof solutions like latch drawers. The market is flooded with various options, but not all offer the same level of quality or effectiveness. Buyers must navigate the fine line between affordability and safety, as cheaper alternatives may compromise on essential safety features, potentially leading to greater costs down the line due to accidents or injuries.

The Solution: To manage costs effectively while ensuring safety, B2B buyers should adopt a strategic sourcing approach. Begin by conducting a thorough market analysis to identify reputable manufacturers known for high-quality latch systems, like Toddleroo or Safety 1st. Request samples and conduct performance tests to assess the effectiveness of different products. Consider bulk purchasing options to leverage discounts and negotiate pricing with suppliers. Additionally, investing in durable, high-performance latches may lead to long-term savings by reducing replacement frequency and liability risks. Buyers should also evaluate the total cost of ownership, factoring in installation and maintenance costs, to make informed purchasing decisions. By prioritizing quality and negotiating effectively, buyers can ensure they are investing in solutions that provide both safety and cost efficiency.

Strategic Material Selection Guide for latch drawer

What Are the Key Properties of Common Materials Used in Latch Drawers?

When selecting materials for latch drawers, it is crucial to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials: plastic, stainless steel, aluminum, and brass.

What Are the Key Properties of Plastic for Latch Drawers?

Plastic, particularly high-density polyethylene (HDPE) and acrylonitrile butadiene styrene (ABS), is widely used in latch drawer applications. These materials are lightweight, resistant to corrosion, and can withstand a range of temperatures. They typically have a temperature rating of -40°C to 80°C, making them suitable for various environments.

Pros: Plastic is cost-effective and easy to mold, allowing for complex designs. It is also non-conductive and offers good insulation properties.

Cons: While durable, plastic can become brittle over time, especially under UV exposure. It may not perform well under high-pressure conditions compared to metals.

Impact on Application: Plastic latches are ideal for residential use, particularly in childproofing applications, as they are less likely to cause injury.

Considerations for International Buyers: Compliance with safety standards such as ASTM and EN is essential. Buyers in regions like Africa and South America may prefer eco-friendly materials, which can influence sourcing decisions.

How Does Stainless Steel Perform in Latch Drawer Applications?

Stainless steel is a popular choice for latch drawers due to its exceptional strength and corrosion resistance. It can withstand high temperatures and pressures, typically rated for use in environments up to 300°C.

Pros: Stainless steel is highly durable and offers a sleek, modern aesthetic. It is resistant to rust and tarnishing, making it suitable for both indoor and outdoor applications.

Cons: The cost of stainless steel is higher than plastic or aluminum, which can impact budget considerations. Additionally, it may require more complex manufacturing processes.

Impact on Application: Stainless steel latches are ideal for commercial applications, particularly in kitchens and laboratories where hygiene and durability are paramount.

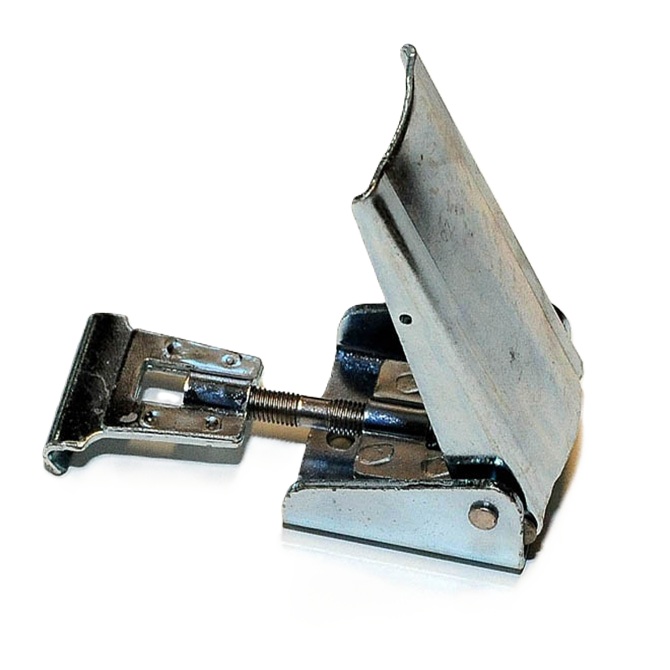

Illustrative image related to latch drawer

Considerations for International Buyers: Compliance with international standards like ISO and ASTM is crucial. Buyers in the Middle East may favor stainless steel for its durability in high-temperature environments.

What Are the Benefits of Using Aluminum for Latch Drawers?

Aluminum is another viable material for latch drawers, known for its lightweight and corrosion-resistant properties. It typically has a temperature rating of -50°C to 150°C, making it versatile for various applications.

Pros: Aluminum is easy to fabricate and offers good strength-to-weight ratios. It is also recyclable, appealing to environmentally conscious buyers.

Cons: While durable, aluminum can be prone to scratching and denting, which may affect its aesthetic appeal over time. It is also less robust than stainless steel.

Impact on Application: Aluminum latches are suitable for lightweight applications, such as in mobile storage solutions or in environments where weight is a concern.

Considerations for International Buyers: Buyers in Europe may look for aluminum products that meet EU regulations for recyclability and sustainability.

Why Choose Brass for Latch Drawer Applications?

Brass is often used for decorative latch drawer applications due to its attractive appearance and corrosion resistance. It typically performs well in temperatures ranging from -20°C to 120°C.

Pros: Brass has a classic look and is highly durable. It also has antimicrobial properties, making it suitable for applications in healthcare settings.

Cons: The cost of brass is generally higher than plastic and aluminum, and it can tarnish over time, requiring maintenance to retain its appearance.

Impact on Application: Brass latches are ideal for high-end residential or commercial applications where aesthetics are important.

Considerations for International Buyers: Compliance with local standards is necessary, and buyers may need to consider the sourcing of brass to ensure it meets environmental regulations.

Summary Table of Material Selection for Latch Drawers

| Material | Typical Use Case for latch drawer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Childproofing in residential settings | Cost-effective and lightweight | Can become brittle over time | Low |

| Stainless Steel | Commercial kitchens and laboratories | Highly durable and corrosion-resistant | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight applications | Good strength-to-weight ratio | Prone to scratching and denting | Medium |

| Brass | Decorative and high-end applications | Attractive appearance and durable | Higher cost and requires maintenance | High |

This analysis provides B2B buyers with essential insights into material selection for latch drawers, considering performance, cost, and compliance with international standards. Understanding these factors can help in making informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for latch drawer

What Are the Key Stages in the Manufacturing Process for Latch Drawers?

The manufacturing of latch drawers involves several critical stages, each designed to ensure the final product meets the required safety, functionality, and aesthetic standards.

-

Material Preparation: The process begins with selecting the right materials. Common materials for latch drawers include non-toxic, eco-friendly plastics like ABS (Acrylonitrile Butadiene Styrene) and metals for enhanced durability. Suppliers often source these materials from certified vendors to guarantee quality. The raw materials undergo thorough testing for compliance with international safety standards before they are used in production.

-

Forming: In this stage, the prepared materials are shaped into the desired components of the latch drawer. Techniques such as injection molding are commonly used for plastic parts, while metal components may be formed through stamping or machining. This stage is crucial for achieving precise dimensions and ensuring that the latch mechanisms function correctly.

-

Assembly: After forming, individual components are assembled. This may involve mechanical fastening, adhesive bonding, or both. Automated assembly lines are often employed to enhance efficiency and consistency. During this stage, latches are tested for their locking mechanisms to ensure they provide the necessary safety features.

-

Finishing: The final stage involves surface treatments and coatings to improve the product’s aesthetic appeal and resistance to wear and tear. This may include painting, plating, or applying protective coatings. Quality control checks during finishing ensure that all products meet the visual and functional standards required.

How Is Quality Assurance Implemented in Latch Drawer Production?

Quality assurance is paramount in the production of latch drawers, particularly given their role in child safety. Manufacturers adhere to various international and industry-specific standards to ensure product reliability and safety.

-

International Standards Compliance: Many manufacturers comply with ISO 9001, a quality management standard that outlines requirements for an effective quality management system. Additionally, CE marking may be required for products sold in Europe, indicating that they meet safety, health, and environmental protection standards.

-

Industry-Specific Standards: Depending on the target market, latch drawers may need to comply with other standards, such as ASTM (American Society for Testing and Materials) for safety and performance. For products aimed at children, additional regulations may apply, such as the Consumer Product Safety Improvement Act (CPSIA) in the United States.

What Are the Key Quality Control Checkpoints in Manufacturing Latch Drawers?

Quality control checkpoints are essential throughout the manufacturing process to ensure that products meet the necessary standards before they reach the market.

Illustrative image related to latch drawer

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials as they arrive at the manufacturing facility. Tests may include checking for material composition, physical properties, and compliance with relevant standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor production activities. This includes verifying dimensions, functionality, and appearance at various stages of production. Statistical process control (SPC) methods may be employed to analyze data and maintain product consistency.

-

Final Quality Control (FQC): Before packaging and shipping, a final inspection is performed. This includes functional testing of the latch mechanisms, visual inspections for defects, and ensuring that packaging meets shipping standards. Products that do not meet specifications are either reworked or discarded.

What Common Testing Methods Are Used to Ensure Latch Drawer Quality?

To validate the performance and safety of latch drawers, manufacturers utilize several testing methods:

-

Mechanical Pull Force Testing: This method simulates the force a child might exert on the latch. By using specialized equipment, manufacturers can determine if the latch withstands significant pulling without failing.

-

Durability Testing: Latch drawers undergo repeated use simulations to assess their longevity. This helps identify potential points of failure over time.

-

Safety Testing: Specific tests may be conducted to ensure that latch mechanisms cannot be easily manipulated by children. This includes evaluating the design for any sharp edges or small parts that could pose a choking hazard.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital for ensuring product reliability. Here are some effective methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s quality management systems and manufacturing processes directly. This can provide insights into their commitment to quality and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports, including results from IQC, IPQC, and FQC, can help buyers evaluate the supplier’s performance over time. These reports should detail any non-conformities and corrective actions taken.

-

Third-Party Inspections: Engaging third-party quality assurance firms can provide an unbiased evaluation of the supplier’s processes and products. These inspections often include comprehensive testing and compliance assessments.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific challenges regarding quality control, including:

-

Understanding Local Standards: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local safety standards and ensure that their suppliers comply.

-

Logistical Considerations: Importing products may involve additional regulatory checks, which can affect timelines and costs. It’s essential to work with suppliers who understand the import regulations in the buyer’s country.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary across regions. Buyers should communicate their expectations clearly and establish common ground with suppliers to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance protocols for latch drawers, B2B buyers can make informed decisions that ensure the safety and satisfaction of their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch drawer’

In the quest to source high-quality latch drawers, this practical guide aims to provide B2B buyers with a systematic approach to ensure the selection of reliable products that meet safety standards and functional requirements. By following these steps, you can make informed decisions that align with your business needs and customer expectations.

1. Identify Your Product Requirements

Begin by clearly defining the specifications for the latch drawer you need. Consider factors such as size, material (e.g., eco-friendly options), and functionality (e.g., child-proof features). This step is crucial as it sets the foundation for your procurement process and helps to ensure that the products you source will meet your operational needs.

Illustrative image related to latch drawer

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in latch drawers. Utilize online directories, industry forums, and trade shows to compile a list of manufacturers and distributors. Focus on suppliers with a solid reputation in your target markets, such as Africa, South America, the Middle East, and Europe, as they will be more familiar with regional compliance and customer preferences.

3. Verify Supplier Certifications

Ensure that the suppliers you consider are certified and comply with relevant safety and quality standards. Look for certifications such as ISO 9001 for quality management and any local safety certifications applicable to your region. This verification process is essential to mitigate risks associated with product safety and legal compliance.

4. Request Samples for Testing

Before making a bulk purchase, request samples of the latch drawers from shortlisted suppliers. Testing these samples allows you to evaluate their durability, ease of installation, and effectiveness in securing drawers. Pay attention to user feedback, especially concerning the latch’s functionality and ease of use for adults versus children.

5. Assess Pricing and Terms of Sale

Compare pricing structures among different suppliers, considering not just the unit price but also bulk order discounts, shipping costs, and payment terms. Understanding the total cost of ownership is critical for making a financially sound decision. Additionally, clarify return policies and warranty terms to safeguard your investment.

6. Evaluate Customer Support and After-Sales Service

Customer service can significantly impact your experience with a supplier. Investigate the level of support offered, including responsiveness to inquiries, availability of technical assistance, and after-sales service. A supplier that prioritizes customer support can help address any issues that arise post-purchase, ensuring a smoother operational flow.

7. Finalize Your Order with Clear Communication

Once you have selected a supplier, finalize your order with clear communication regarding specifications, quantities, delivery timelines, and payment methods. Establishing a written agreement can help prevent misunderstandings and ensure that both parties are aligned on expectations. This step is vital for maintaining a professional relationship and ensuring satisfaction with the procurement process.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for latch drawers, ensuring they select products that meet safety standards and enhance the functionality of their offerings.

Comprehensive Cost and Pricing Analysis for latch drawer Sourcing

When considering sourcing latch drawers, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Latch Drawer Manufacturing?

The primary cost components involved in latch drawer production include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include non-toxic ABS plastic, metals, and eco-friendly options. High-quality materials may incur higher upfront costs but can lead to greater durability and customer satisfaction.

-

Labor: Labor costs vary by region. In countries with lower wage rates, such as Vietnam or certain African nations, labor costs can be more manageable, potentially leading to lower overall production costs.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Factories with efficient operational practices can help minimize overhead, influencing the final product price.

-

Tooling: The cost of molds and specialized tools for production can be substantial. This is particularly true for customized designs. Buyers should inquire about tooling costs if they require unique specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to manufacturing costs. Suppliers with certifications, such as ISO standards, may charge a premium, reflecting their commitment to quality.

-

Logistics: Shipping costs can vary based on the mode of transportation (air, sea, land) and the distance to the destination. Understanding Incoterms is essential, as they define the responsibilities of buyers and sellers concerning logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can fluctuate based on competition, market demand, and the supplier’s operational efficiency.

What Influences Pricing for Latch Drawers?

Pricing for latch drawers is influenced by several factors:

-

Volume/MOQ: Bulk orders often lead to discounts, as suppliers benefit from economies of scale. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should weigh the benefits of customization against the potential price hike.

-

Quality and Certifications: Products with higher quality standards or certifications may come at a premium. However, they often provide better long-term value through reliability and fewer replacement needs.

-

Supplier Factors: The supplier’s reputation, reliability, and previous performance can impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Familiarizing oneself with Incoterms can help buyers understand shipping responsibilities and costs, impacting the overall price.

What Are Essential Buyer Tips for Cost Efficiency?

To navigate the complexities of sourcing latch drawers effectively, buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers about pricing, especially for large orders. Highlighting potential long-term partnerships can strengthen negotiation positions.

-

Total Cost of Ownership (TCO): Look beyond the purchase price. Consider logistics, potential warranty claims, and maintenance costs. A lower upfront cost may not always translate to savings in the long run.

-

Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and local regulations can affect pricing. Buyers should factor in these elements when budgeting for purchases.

-

Supplier Diversity: Explore multiple suppliers to compare prices and quality. This can lead to better deals and more reliable supply chains.

In conclusion, understanding the cost structure and pricing dynamics of latch drawer sourcing is vital for international B2B buyers. By considering the outlined cost components, pricing influencers, and practical tips, businesses can make informed decisions that optimize their sourcing strategies. Keep in mind that indicative prices may vary, and it’s essential to conduct thorough due diligence when engaging suppliers.

Alternatives Analysis: Comparing latch drawer With Other Solutions

Understanding Alternative Solutions to Latch Drawers

When considering safety and functionality in various industries, latch drawers are often a go-to solution for securing cabinets and drawers. However, several alternative methods can also achieve similar goals, each with distinct advantages and disadvantages. This section compares latch drawers with two prominent alternatives: spring-loaded cabinet latches and magnetic safety locks. By analyzing these options, B2B buyers can make informed decisions based on their specific needs.

| Comparison Aspect | Latch Drawer | Spring-Loaded Cabinet Latch | Magnetic Safety Lock |

|---|---|---|---|

| Performance | Reliable for child safety; easy to use for adults | Strong pull-force tested; effective against toddlers | High security with tamper-proof design |

| Cost | Moderate, typically around $12.99 for a pack of 10 | Budget-friendly, approximately $5.49 for a pack of 10 | Higher initial investment, around $15-$20 per lock |

| Ease of Implementation | Simple installation with adhesive or screws | Quick setup with adhesive backing | Requires careful alignment; may need additional tools |

| Maintenance | Low; requires occasional checks for functionality | Minimal; check adhesive strength periodically | Low; batteries may need replacement over time |

| Best Use Case | Ideal for residential settings, particularly for childproofing | Effective in family homes with active toddlers | Suitable for both residential and commercial environments requiring higher security |

In-Depth Look at Alternative Solutions

Spring-Loaded Cabinet Latch

Spring-loaded cabinet latches are designed for quick and easy access while ensuring safety from curious toddlers. These latches are installed inside cabinets, making them invisible to children and guests. Their performance has been validated through rigorous testing, showing they can withstand significant pull force. Additionally, their budget-friendly price point makes them an attractive option for families looking to childproof their homes without breaking the bank. However, while they are effective, they may not offer the same level of security as other options, particularly in environments where older children or determined pets are present.

Magnetic Safety Lock

Magnetic safety locks provide a higher level of security, making them ideal for both residential and commercial applications. These locks use a magnetic mechanism to keep drawers and cabinets securely closed, only accessible with a specific key or magnet. Their tamper-proof design adds an extra layer of safety, especially in environments where valuable or hazardous materials are stored. The installation may require more precision and sometimes additional tools, which could be a drawback for some users. Additionally, while the upfront cost is higher, the long-term benefits of enhanced security can justify the investment.

Making the Right Choice for Your Needs

When selecting between latch drawers and alternative solutions, B2B buyers should consider specific operational requirements and safety standards. If cost-effectiveness and ease of installation are priorities, spring-loaded cabinet latches may be the best fit. However, for environments demanding higher security, magnetic safety locks offer superior protection. Ultimately, understanding the unique challenges and needs of your business or residential environment will guide you toward the most effective safety solution.

Essential Technical Properties and Trade Terminology for latch drawer

What Are the Key Technical Properties of Latch Drawers?

When evaluating latch drawers for procurement, several critical specifications should be considered to ensure quality and suitability for your needs. Here are some essential technical properties:

-

Material Grade

The material used in latch drawers significantly affects durability and safety. Common materials include ABS (Acrylonitrile Butadiene Styrene), which is known for its strength and impact resistance. Eco-friendly options are increasingly available, appealing to environmentally-conscious buyers. Selecting the right material can enhance product lifespan and reduce replacement costs. -

Load Capacity

This specification refers to the maximum weight a latch drawer can securely hold. It is crucial for businesses that deal with varying drawer contents, such as tools or kitchenware. Understanding load capacity helps prevent drawer failures, ensuring safety and functionality in high-usage environments. -

Installation Method

Latch drawers may offer various installation methods, including adhesive backing or screw mounting. Adhesive options, like those that use 3M® technology, provide ease of installation without damaging surfaces, while screw mounting may offer more robust support. Choosing the right installation method is essential for ensuring that the latch operates effectively over time. -

Self-Locking Mechanism

Many latch drawers feature a self-locking design, which automatically secures the drawer when closed. This feature is vital for safety, particularly in homes with children or in environments where access to potentially hazardous materials must be restricted. Understanding the locking mechanism can help in assessing the security level required for your application. -

Compliance Standards

Compliance with international safety standards (like ASTM or EN standards) is crucial for latch drawers, especially in markets where safety regulations are stringent. Products that meet these standards are more likely to be trusted by consumers, thereby enhancing marketability. Ensuring compliance can mitigate liability risks and enhance brand reputation.

What Are Common Trade Terms Related to Latch Drawers?

Navigating the procurement process involves familiarizing yourself with industry jargon. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are used in another company’s end product. Understanding OEM relationships can be crucial for ensuring quality and compatibility, particularly when sourcing latch drawers for assembly into larger systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory management. Suppliers with low MOQs may be preferable for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information and terms for specific products. This is vital for procurement teams as it aids in comparing costs and terms across different suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risk management. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. This is particularly important for businesses that rely on just-in-time inventory systems. Knowing the lead time helps in planning and ensuring that production schedules are met without delays.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions regarding latch drawers, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the latch drawer Sector

What Are the Current Market Dynamics and Sourcing Trends in the Latch Drawer Sector?

The latch drawer market is witnessing robust growth driven by increasing safety concerns among parents and the rise in home improvement projects globally. Factors such as urbanization, rising disposable incomes, and a growing emphasis on child safety are propelling demand, particularly in regions like Africa, South America, the Middle East, and Europe. In these markets, the demand for reliable and effective drawer latches is not just a necessity but a growing trend among consumers who prioritize safety and functionality.

Illustrative image related to latch drawer

Emerging technologies, such as smart home integration, are becoming increasingly relevant in the latch drawer sector. B2B buyers are seeking products that can seamlessly integrate with home automation systems, thereby enhancing convenience and security. Additionally, manufacturers are adopting advanced materials and production techniques to create more durable and aesthetically pleasing products. The shift towards e-commerce platforms is also reshaping sourcing strategies, allowing international buyers to access a broader range of products and suppliers more efficiently.

In terms of market dynamics, competition is intensifying, leading to price sensitivity among buyers. Suppliers are focusing on quality differentiation and value-added services, such as customizable solutions and faster delivery times. This competitive landscape encourages B2B buyers to engage in strategic sourcing practices, emphasizing not only cost but also quality, compliance, and supplier reliability.

How Is Sustainability Influencing Sourcing Decisions in the Latch Drawer Industry?

Sustainability is becoming a critical factor in the sourcing decisions of B2B buyers in the latch drawer sector. The environmental impact of manufacturing processes and materials used in products is under increasing scrutiny. Suppliers that prioritize eco-friendly practices, such as using non-toxic and recyclable materials, are gaining favor among businesses looking to enhance their sustainability credentials.

Ethical sourcing is also paramount. Buyers are increasingly demanding transparency in supply chains, ensuring that materials are sourced responsibly and labor practices are fair. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO 14001 for environmental management systems are becoming essential for suppliers aiming to establish credibility in the market.

Moreover, innovative materials like bio-based plastics or sustainably sourced metals are emerging, allowing manufacturers to meet both safety standards and environmental goals. As consumers become more environmentally conscious, B2B buyers who align with these sustainable practices can enhance their brand image and appeal to a growing segment of eco-aware consumers.

What Is the Historical Context of the Latch Drawer Market?

The latch drawer market has evolved significantly over the years, transitioning from basic locking mechanisms to advanced safety solutions. Initially, latch designs focused primarily on functionality, with little emphasis on aesthetics or user-friendliness. However, as consumer awareness of safety, particularly concerning childproofing, has increased, manufacturers have adapted their designs to incorporate both form and function.

The introduction of materials such as ABS plastic and innovative adhesive solutions has further transformed the market. These developments not only enhance product durability but also facilitate easier installation and improved user experience. As the market continues to evolve, the emphasis on technology integration and sustainability will likely shape the future landscape of latch drawer products, catering to the demands of a more discerning international B2B buyer base.

Frequently Asked Questions (FAQs) for B2B Buyers of latch drawer

-

How do I choose the right latch drawer for my business needs?

When selecting a latch drawer, consider the specific application and environment where it will be used. Evaluate factors such as the type of materials (e.g., ABS, metal), the latch mechanism (spring-loaded, press-n-release), and installation requirements. Additionally, assess the safety standards and certifications applicable in your region. It may be beneficial to request samples to test the latches in real-world scenarios before placing a bulk order. -

What are the key features to look for in a latch drawer?

The best latch drawers typically include features such as ease of installation, durability, and child safety mechanisms. Look for latches that are made from non-toxic, eco-friendly materials and offer a strong grip for adults while remaining difficult for children to operate. Additionally, consider options with automatic locking capabilities and discreet installation to enhance aesthetic appeal and functionality. -

What is the minimum order quantity (MOQ) for latch drawers?

MOQs can vary significantly by supplier and region. Typically, manufacturers may set MOQs anywhere from 100 to 1,000 units, depending on the complexity of the latch design and production costs. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are a smaller business or just starting to test the market for latch drawers. -

How can I ensure quality assurance when sourcing latch drawers internationally?

To ensure quality, request product samples before committing to a large order. Additionally, you can ask for certifications that verify compliance with international safety standards. Consider visiting the supplier’s manufacturing facility or hiring a third-party quality inspection service to evaluate the production process. Establishing clear quality control criteria and open communication with the supplier will also help mitigate risks. -

What payment terms should I expect when sourcing latch drawers?

Payment terms can vary by supplier but often include options such as 30% upfront and 70% upon delivery, or full payment in advance. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. It’s also important to clarify any potential additional costs, such as shipping and import duties, to avoid unexpected expenses. -

What logistics considerations are important when importing latch drawers?

When importing latch drawers, consider shipping methods (air freight vs. sea freight), transit times, and customs regulations in your country. Ensure that you have a reliable logistics partner who can handle customs clearance and provide accurate shipping documentation. Additionally, assess the overall shipping costs and delivery timelines to align with your inventory needs and customer expectations. -

How do I vet suppliers for latch drawers in international markets?

To vet suppliers, start by checking their business credentials, including registration and certifications. Look for reviews and ratings from previous customers, and consider using platforms that offer supplier verification services. Engaging in direct communication with potential suppliers can provide insights into their reliability and responsiveness. Attending trade shows or industry events can also help you connect with reputable manufacturers. -

Can latch drawers be customized for specific business applications?

Yes, many suppliers offer customization options for latch drawers, including size, color, and material specifications. Discuss your requirements with the supplier to understand the extent of customization they can provide, as well as any associated costs. Custom solutions can help you differentiate your product offerings and meet specific market demands, so be sure to convey your vision clearly during negotiations.

Top 6 Latch Drawer Manufacturers & Suppliers List

1. North States – Toddleroo Drawer & Cabinet Tab Latches

Domain: northstatesind.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Toddleroo by North States Drawer & Cabinet Tab Latches”, “model_number”: “6182”, “UPC”: “”, “MSRP”: “$12.99”, “quantity_in_pack”: “10-pack”, “material”: “non-toxic, eco-friendly ABS”, “features”: [“multi-functional”, “works on top or side of most drawers and cabinets with even surfaces”, “3M adhesive and mounting hardware included”, “spring action design with press-n-release moti…

2. Safety 1st – Spring-Loaded Cabinet & Drawer Latch

Domain: safety1st.com

Registered: 1995 (30 years)

Introduction: Product Name: Safety 1st Spring-Loaded Cabinet & Drawer Latch (10 Pack)\nItem Number: 483920924\nPrice: $5.49\nPack Size: 10 latches\nFeatures: \n- Spring-loaded for easy use\n- Easy-grip surface for quick parental access\n- Simple installation inside cabinets or drawers\n- Proven stronger against leading competitors in mechanical pull force tests and real-life toddler scenarios (as of August 2017…

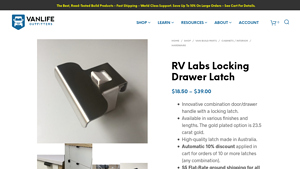

3. RV Labs – Locking Drawer Latch

Domain: vanlifeoutfitters.com

Registered: 2017 (8 years)

Introduction: {“name”: “RV Labs Locking Drawer Latch”, “price_range”: “$18.50 – $39.00”, “description”: “Innovative combination door/drawer handle with a locking latch. Available in various finishes and lengths. The gold plated option is 23.5 carat gold. High-quality latch made in Australia.”, “discount”: “Automatic 10% discount applied in cart for orders of 10 or more latches (any combination).”, “shipping”: “…

4. RV Designer – Cabinet Door and Drawer Push Latch

Domain: blueoxtowbars.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “RV Designer Cabinet Door and Drawer Push Latch”, “brand”: “RV Designer”, “sku”: “48098”, “list_price”: “$39.95”, “in_stock_qty”: “28.13”, “features”: [“Used to hold cabinet doors and drawers closed”, “Push latch with small and large catch”, “5 pound pull”], “shipping_info”: “Product ships FREE on orders over $99”, “contact_info”: “Talk to a specialist- Live chat or call 877-895-1…

5. RV Designer – Roller Catch & Double Barrel Catches

Domain: dyersonline.com

Registered: 2000 (25 years)

Introduction: [{‘name’: ‘RV Designer Roller Catch’, ‘item_number’: ‘H203’, ‘price’: ‘$4.74’, ‘stock’: ‘5+ In Stock’}, {‘name’: ‘RV Designer Double Barrel Catch with Metal Clip’, ‘item_number’: ‘H215’, ‘price’: ‘$7.47’, ‘stock’: ‘5+ In Stock’}, {‘name’: ‘RV Designer Double Barrel Catch with Nylon Clip’, ‘item_number’: ‘H217’, ‘price’: ‘$8.97’, ‘stock’: ‘5+ In Stock’}, {‘name’: ‘RV Designer Roller Catch with Pron…

6. McMaster – Drawer Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Drawer Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for latch drawer

As global demand for latch drawer solutions continues to rise, strategic sourcing has become an essential component for B2B buyers aiming to enhance safety and functionality in diverse environments. By prioritizing high-quality materials and innovative designs, such as those demonstrated by brands like Toddleroo and Safety 1st, businesses can ensure they are equipping their operations with reliable, childproof products that meet international safety standards.

Engaging with reputable suppliers who offer comprehensive product support, including installation guides and customer service, can significantly streamline procurement processes. This approach not only optimizes inventory management but also fosters long-term partnerships that are crucial for sustainable growth in competitive markets.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should actively explore emerging trends in latch drawer solutions. Emphasizing eco-friendly materials and user-friendly designs will resonate with consumers and set brands apart in a crowded marketplace. Now is the time to invest in strategic sourcing initiatives that align with these evolving needs, ensuring your business remains at the forefront of innovation and safety in the latch drawer industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to latch drawer

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.