Is Your Gears And Drives Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for gears and drives

In today’s competitive landscape, sourcing high-quality gears and drives poses a significant challenge for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. The complexity of selecting the right mechanical power transmission components—ranging from spur gears to helical gearboxes—demands not only technical knowledge but also an understanding of market dynamics and supplier reliability. This guide serves as a comprehensive resource, equipping you with vital insights into the various types of gears, their applications, and critical considerations for effective supplier vetting.

Navigating the global market requires a strategic approach to procurement. This guide delves into essential topics, including the different types of gears and drives, their specific applications across industries, cost factors influencing procurement, and best practices for evaluating suppliers. By consolidating this information, we empower B2B buyers to make informed purchasing decisions that enhance operational efficiency and drive business growth. Whether you’re based in bustling cities like Lagos or Frankfurt, understanding these elements will enable you to mitigate risks and capitalize on opportunities in the gears and drives sector. Embrace this journey into the intricacies of gear sourcing, and transform your procurement strategy into a powerful asset for your business.

Understanding gears and drives Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spur Gears | Straight teeth, parallel shafts, high efficiency | Manufacturing, automotive, conveyors | Pros: Simple design, high load capacity. Cons: Noisy at high speeds, limited torque transmission. |

| Helical Gears | Angled teeth, smooth operation, axial thrust | Robotics, aerospace, machinery | Pros: Quieter, higher load capacity. Cons: Requires thrust bearings, more complex to manufacture. |

| Worm Gears | Non-intersecting shafts, high reduction ratios | Lifting equipment, conveyors, robotics | Pros: Compact design, excellent speed reduction. Cons: Lower efficiency, potential for overheating. |

| Bevel Gears | Cone-shaped, used for intersecting shafts | Automotive differentials, machine tools | Pros: Change direction of power transmission. Cons: More complex design, can be less efficient than spur gears. |

| Planetary Gears | Multiple gears orbiting a central gear | Automotive transmissions, robotics | Pros: High torque density, compact design. Cons: Complex assembly, higher manufacturing costs. |

What are Spur Gears and Their Key Applications?

Spur gears are characterized by their straight teeth and parallel shafts, making them one of the most widely used gear types. They are ideal for applications requiring high efficiency, such as in manufacturing and automotive sectors. Buyers should consider their simplicity and high load capacity, but be aware of their noise levels at high speeds and limited torque transmission capabilities.

How Do Helical Gears Differ in Performance?

Helical gears feature angled teeth that provide a smoother operation compared to spur gears, making them suitable for high-speed applications like robotics and aerospace. Their design allows for higher load capacities and quieter operation, which is essential for precision machinery. However, buyers must account for the need for thrust bearings and the complexity involved in their manufacturing process.

What Advantages Do Worm Gears Offer?

Worm gears are unique in that they allow for high reduction ratios between non-intersecting shafts, making them particularly useful in lifting equipment and conveyor systems. Their compact design is advantageous for applications with space constraints. However, potential buyers should consider the lower efficiency and risk of overheating, which can impact performance in demanding applications.

Why Choose Bevel Gears for Directional Changes?

Bevel gears are designed to transmit power between intersecting shafts, making them essential in applications like automotive differentials and machine tools. Their cone-shaped design allows for effective direction changes in power transmission. While they provide versatility, the complexity of their design can lead to inefficiencies compared to simpler gear types, which buyers should weigh when making purchasing decisions.

What Makes Planetary Gears a Preferred Choice?

Planetary gears consist of multiple gears orbiting around a central sun gear, offering a high torque density in a compact design. They are commonly used in automotive transmissions and robotics, where space and efficiency are critical. However, the complexity of their assembly and higher manufacturing costs may be considerations for buyers looking for cost-effective solutions.

Key Industrial Applications of gears and drives

| Industry/Sector | Specific Application of gears and drives | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmission Systems | Enhanced power transfer and fuel efficiency | Quality standards, compatibility with existing systems, delivery timelines |

| Manufacturing | Conveyor Systems | Efficient material handling and reduced downtime | Load capacity, durability, maintenance requirements |

| Renewable Energy | Wind Turbines | Improved energy conversion efficiency | Resistance to environmental factors, certifications for safety |

| Mining | Equipment Drive Systems | Reliable operation under heavy loads | Customization options, sourcing of robust materials, after-sales support |

| Agriculture | Tractors and Harvesters | Increased productivity and reduced operational costs | Performance specifications, adaptability to various terrains, warranty terms |

How Are Gears and Drives Used in the Automotive Sector?

In the automotive industry, gears and drives are integral to transmission systems, which convert engine power into vehicle motion. By optimizing torque and speed, these systems enhance fuel efficiency and vehicle performance. International buyers, particularly from regions like Germany and Nigeria, must consider compatibility with existing vehicle designs, adherence to quality standards, and timely delivery for assembly line integration. The ability to source high-quality, durable components can significantly impact production efficiency and reliability.

What Role Do Gears and Drives Play in Manufacturing?

Manufacturing relies heavily on gears and drives for conveyor systems that facilitate the movement of materials through production lines. These systems minimize downtime and improve operational efficiency by ensuring smooth transitions between processes. Buyers in South America and Africa should prioritize sourcing gears that meet load capacity requirements and are built for longevity. Additionally, understanding maintenance needs and availability of replacement parts is crucial for minimizing operational disruptions.

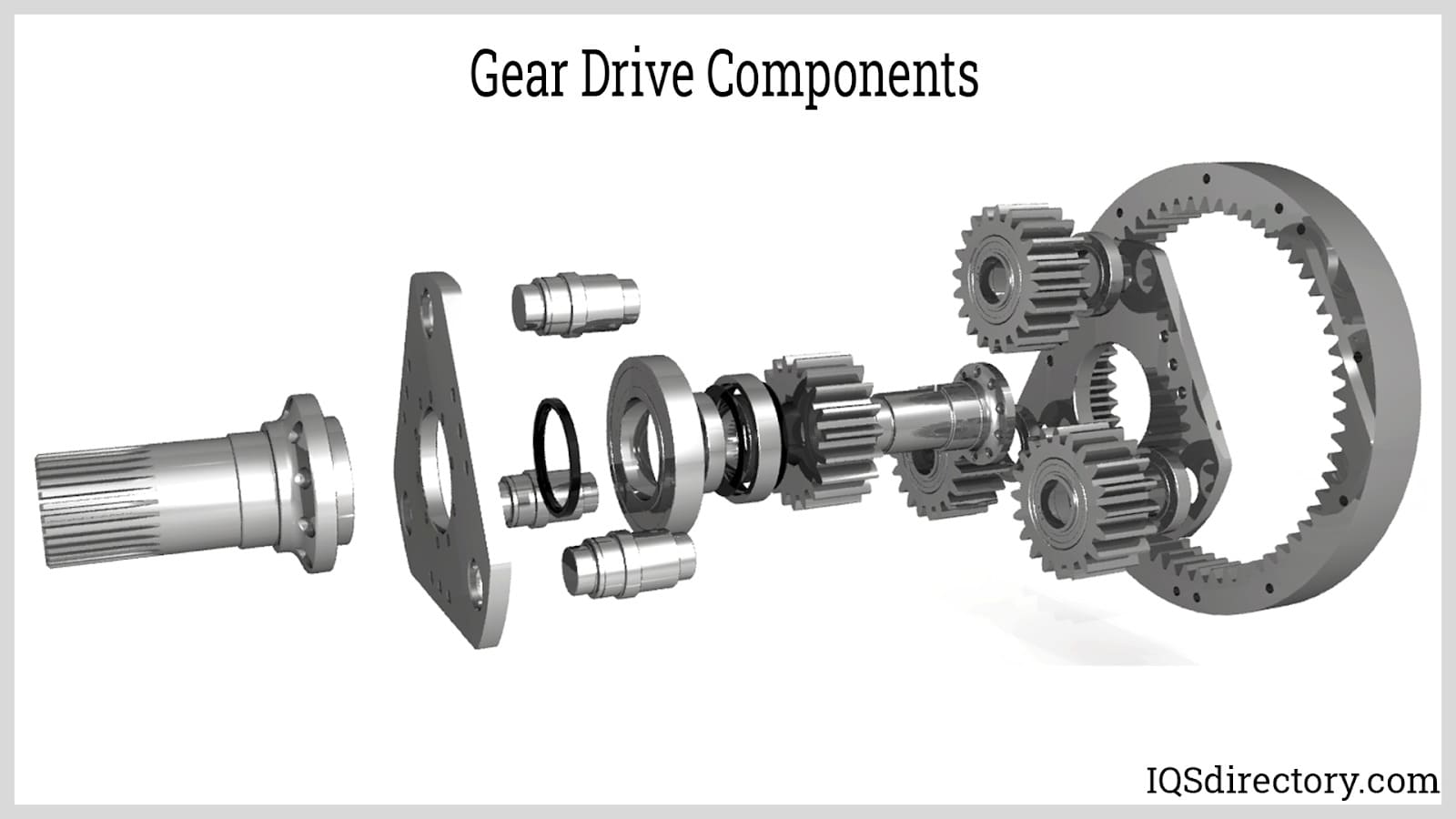

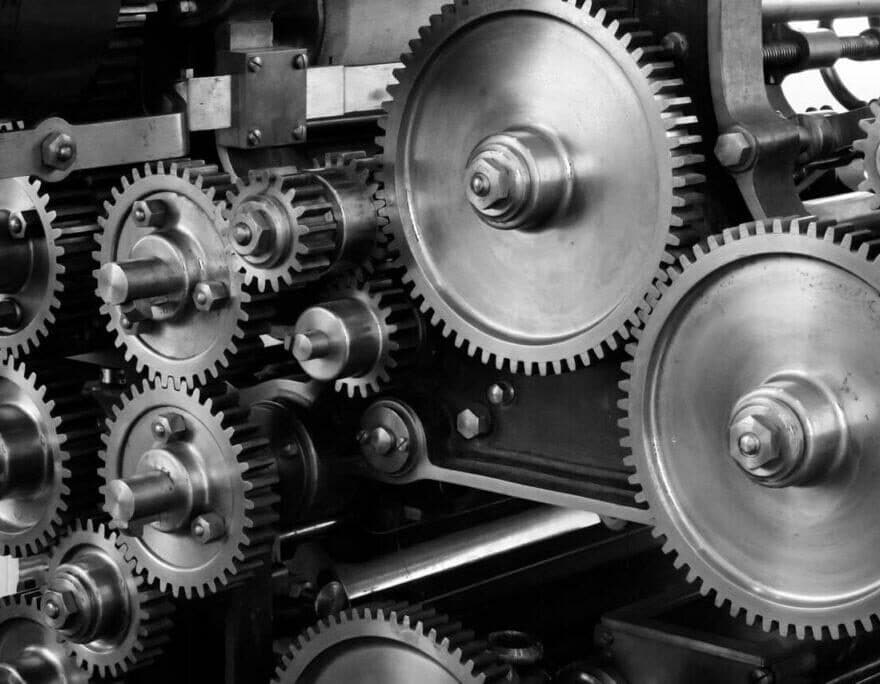

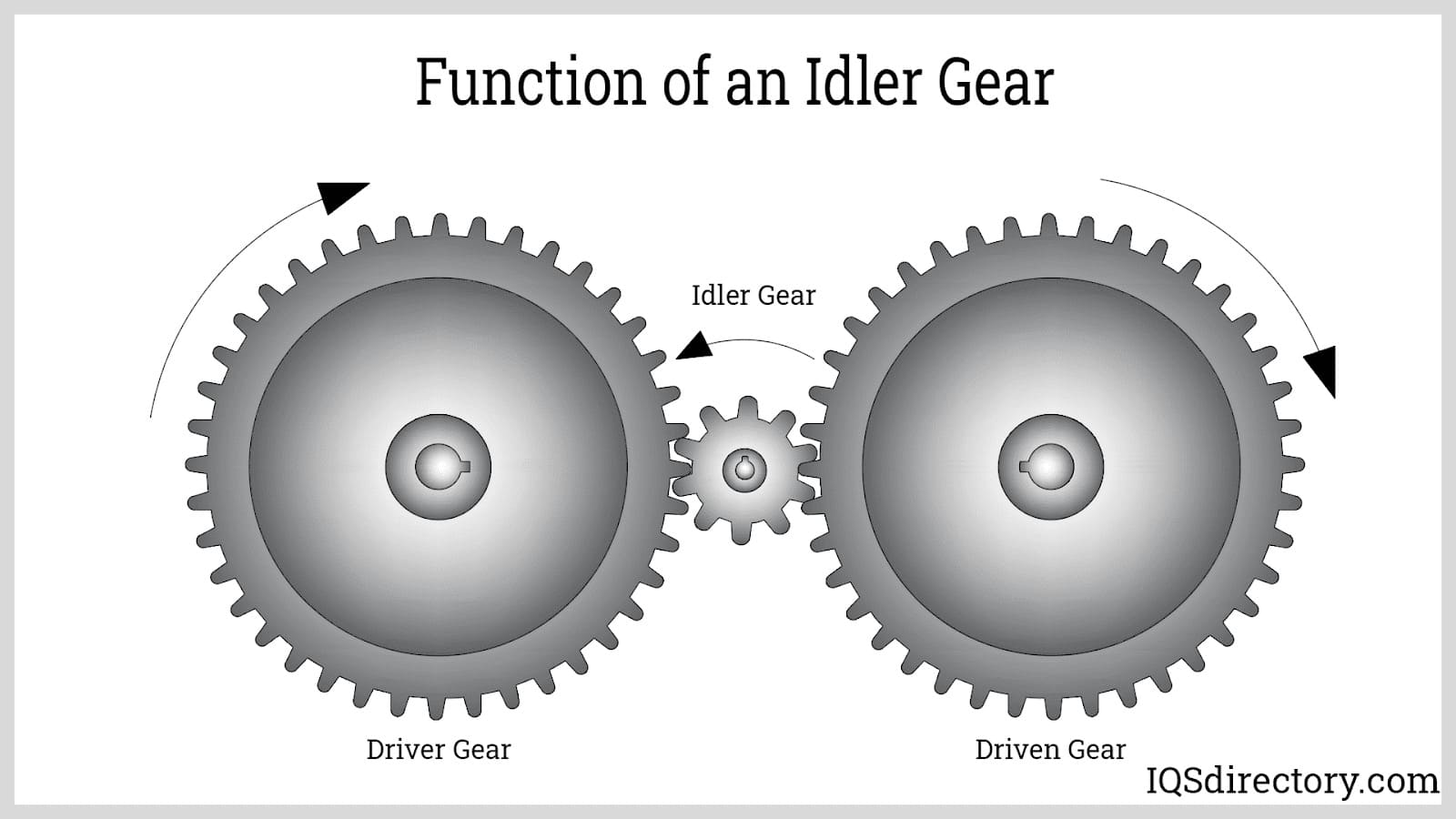

Illustrative image related to gears and drives

How Are Gears and Drives Essential in Renewable Energy?

In renewable energy applications, particularly wind turbines, gears and drives are crucial for converting kinetic energy into electrical energy. They improve the efficiency of energy conversion, enabling better performance in varying wind conditions. Buyers from the Middle East and Europe must consider the environmental resistance of these components, ensuring they meet safety certifications. Sourcing from manufacturers with a proven track record in renewable energy applications can enhance project viability and sustainability.

Why Are Gears and Drives Important in Mining Equipment?

Mining operations depend on robust gear and drive systems to power heavy machinery, ensuring reliable performance under extreme conditions. These systems handle significant loads and are essential for equipment like drills and excavators. For B2B buyers in Africa, sourcing durable and customizable gear solutions is vital for operational success. They should also evaluate after-sales support and the availability of spare parts to ensure ongoing equipment reliability.

How Do Gears and Drives Enhance Agricultural Machinery?

In agriculture, gears and drives are used in tractors and harvesters to facilitate efficient power transfer and enhance productivity. These systems allow for better control of machinery, reducing operational costs and improving yield. Buyers from regions with diverse terrains, such as South America, should look for adaptable gear solutions that can handle varying agricultural conditions. Warranty terms and performance specifications are critical factors to consider when sourcing these components.

3 Common User Pain Points for ‘gears and drives’ & Their Solutions

Scenario 1: Inconsistent Gear Performance in Machinery Operations

The Problem: B2B buyers often encounter inconsistent performance in their machinery due to the use of subpar or incompatible gears and drives. This issue can lead to unexpected downtimes, decreased productivity, and ultimately, increased operational costs. For instance, a manufacturing plant in Nigeria might rely on a specific gear type for an assembly line, but if the gears do not mesh properly or are of low quality, it can cause jamming or excessive wear, leading to costly interruptions in production.

The Solution: To mitigate these performance inconsistencies, it is essential to prioritize sourcing high-quality gears that meet precise specifications. Buyers should collaborate closely with reputable manufacturers who provide detailed product documentation, including material specifications, tolerances, and compatibility information. Conducting a thorough assessment of the operational environment—such as load requirements, speed, and temperature conditions—will enable buyers to select the most suitable gear type, whether it be spur, helical, or bevel gears. Additionally, implementing a preventive maintenance schedule that includes regular inspections and lubrication can significantly enhance gear performance and lifespan.

Scenario 2: High Energy Consumption and Inefficiency in Power Transmission

The Problem: Many businesses experience elevated energy costs due to inefficient power transmission systems involving gears and drives. For example, a mining operation in South America may rely on a gear reducer to lower motor speed, but if the gear train is not optimized, it can lead to wasted energy, increased heat generation, and diminished overall system efficiency. This not only affects the bottom line but also raises concerns about sustainability and environmental impact.

Illustrative image related to gears and drives

The Solution: To address this issue, companies should consider upgrading to more efficient gear designs, such as planetary gears or worm gears with a higher gear ratio. These designs can provide better torque output while minimizing energy losses. Moreover, conducting a comprehensive energy audit of the existing systems can help identify specific inefficiencies. Once identified, buyers can work with gear manufacturers to customize solutions that include advanced materials and coatings that reduce friction and improve energy transfer. Additionally, implementing modern control systems that monitor and adjust the operation based on real-time data can further enhance efficiency.

Scenario 3: Difficulty in Sourcing Custom Gear Solutions for Unique Applications

The Problem: B2B buyers often struggle to find gears and drives that meet their unique application needs, especially in specialized industries like aerospace or robotics. For instance, a company in the Middle East may require custom gears for a new prototype that cannot be satisfied with off-the-shelf products. This challenge can lead to delays in project timelines, increased costs, and missed market opportunities.

The Solution: To overcome sourcing difficulties, buyers should establish strong relationships with gear manufacturers who offer custom engineering services. Engaging in open dialogue about specific requirements, including dimensions, load capacity, and operational conditions, allows for the development of tailored solutions. It is also advisable to request prototypes or samples to test compatibility before committing to larger orders. Leveraging advanced manufacturing technologies such as 3D printing for prototyping can expedite the development process. Furthermore, buyers should consider manufacturers that provide comprehensive support services, including design assistance and ongoing technical support, to ensure that the custom solutions will perform optimally in their intended applications.

Strategic Material Selection Guide for gears and drives

What Are the Key Properties of Common Materials Used for Gears and Drives?

In the selection of materials for gears and drives, several factors come into play, including mechanical properties, environmental resistance, and manufacturing considerations. Here, we analyze four common materials: steel, aluminum, plastic, and bronze, focusing on their suitability for various applications and the implications for international B2B buyers.

How Does Steel Perform as a Material for Gears and Drives?

Key Properties: Steel is renowned for its high tensile strength, durability, and ability to withstand high temperatures and pressures. It offers excellent wear resistance, making it suitable for high-load applications.

Pros & Cons: The primary advantage of steel is its strength and durability, which leads to a longer lifespan for gears and drives. However, steel can be heavy and prone to corrosion unless treated, which may increase manufacturing complexity and costs.

Impact on Application: Steel gears are ideal for heavy machinery and automotive applications where high torque and reliability are crucial. However, they may not be suitable for environments with high corrosion potential unless adequately protected.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN. The availability of treated steel options can also be a deciding factor in regions with high humidity or saline environments.

What Are the Benefits of Aluminum in Gear and Drive Applications?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It performs well in moderate temperature applications and is often used in environments where weight savings are critical.

Pros & Cons: The main advantage of aluminum is its weight, which can significantly reduce the overall mass of machinery. However, aluminum is less strong than steel and may not withstand high torque applications without deformation.

Impact on Application: Aluminum gears are commonly used in aerospace and automotive applications where weight reduction is essential. They are also suitable for applications requiring good corrosion resistance, such as marine environments.

Considerations for International Buyers: Buyers should be aware of specific aluminum grades and their compliance with international standards. For example, certain grades may be preferred in Europe (e.g., EN standards) for aerospace applications.

How Do Plastics Compare as a Material for Gears and Drives?

Key Properties: Engineering plastics, such as nylon and acetal, offer good wear resistance and low friction properties. They are lightweight and can operate effectively in a range of temperatures.

Pros & Cons: The advantages of plastic gears include their low weight and resistance to corrosion and chemicals. However, they typically have lower load-bearing capacities compared to metals, which limits their use in high-torque applications.

Impact on Application: Plastic gears are ideal for applications in consumer electronics, automotive interiors, and light machinery. They are particularly effective in environments where noise reduction is important.

Considerations for International Buyers: Buyers should consider the specific chemical compatibility of plastics with the intended media. Compliance with standards such as ISO for plastics can also influence material selection.

What Role Does Bronze Play in Gear and Drive Manufacturing?

Key Properties: Bronze is known for its excellent wear resistance, low friction, and good corrosion resistance, especially in marine environments. It has a high fatigue strength, making it suitable for high-load applications.

Pros & Cons: The main advantage of bronze is its durability and resistance to corrosion, which makes it ideal for applications exposed to harsh environments. However, bronze can be more expensive than steel and aluminum, which may impact overall project budgets.

Impact on Application: Bronze gears are often used in marine applications, automotive components, and heavy machinery where durability is paramount. Their resistance to wear makes them suitable for high-friction applications.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM Bronze specifications. The cost implications of using bronze in regions with budget constraints, such as parts of Africa and South America, should also be carefully evaluated.

Summary of Material Selection for Gears and Drives

| Material | Typical Use Case for gears and drives | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive applications | High strength and durability | Heavy, prone to corrosion | High |

| Aluminum | Aerospace, automotive, marine applications | Lightweight, corrosion-resistant | Lower strength than steel | Medium |

| Plastic | Consumer electronics, automotive interiors | Low weight, low friction | Limited load capacity | Low |

| Bronze | Marine applications, heavy machinery | Excellent wear resistance | Higher cost than steel | High |

This material selection guide is designed to aid international B2B buyers in making informed decisions based on the specific requirements of their applications, regional standards, and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for gears and drives

What Are the Key Stages in the Manufacturing Process for Gears and Drives?

The manufacturing of gears and drives involves several critical stages that ensure the final product meets the required specifications for performance and durability. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing process begins with the selection of appropriate raw materials. Common materials include carbon steel, alloy steel, and, in some cases, engineering plastics for lighter applications. These materials are chosen based on their mechanical properties, such as tensile strength and hardness, which are crucial for the gear’s performance under load.

Once selected, the raw materials undergo treatment processes like heat treatment to enhance their properties. This can include processes like quenching, tempering, or annealing, which modify the material’s structure to improve hardness and ductility. Buyers should look for suppliers who provide documentation on material certifications, ensuring compliance with international standards.

What Forming Techniques Are Used in Gear Manufacturing?

Forming is the next stage, where raw materials are shaped into gear forms. Several techniques are employed:

Illustrative image related to gears and drives

-

Machining: This is the most common method for producing high-precision gears. It involves processes like turning, milling, and grinding to achieve the desired shape and dimensions. CNC (Computer Numerical Control) machines are often used for their accuracy and repeatability.

-

Forming Processes: Techniques such as forging or stamping can be used for bulk production of gears, especially for larger sizes. These processes can improve material strength through work hardening.

-

Casting: For complex shapes, casting processes may be used. This involves pouring molten metal into molds, which is then cooled to form the gear. This method is often more cost-effective for lower volumes or intricate designs.

Each of these techniques has its advantages and is chosen based on factors like production volume, cost, and required precision. B2B buyers should inquire about the specific methods used by suppliers and their implications for quality.

How Are Gears Assembled and Finished for Optimal Performance?

After forming, gears undergo assembly and finishing processes. Assembly may involve fitting multiple gears together, often requiring precise alignment to ensure smooth operation. Techniques such as press fitting or welding may be used, depending on the design.

Finishing processes are crucial for enhancing the gear’s surface properties. This can include:

- Grinding: To achieve tight tolerances and a smooth surface finish.

- Heat Treatment: To further improve hardness and wear resistance.

- Coating: Application of protective coatings to reduce wear and corrosion.

Buyers should ensure that suppliers have stringent processes for these stages, as they significantly impact the gear’s performance and lifespan.

What Quality Control Measures Are Essential for Gears and Drives?

Quality control (QC) is a vital aspect of the manufacturing process, ensuring that gears and drives meet industry standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards indicates that a supplier has established processes for maintaining quality throughout production. Additionally, industry-specific certifications, such as CE (European Conformity) and API (American Petroleum Institute), may be relevant depending on the application of the gears.

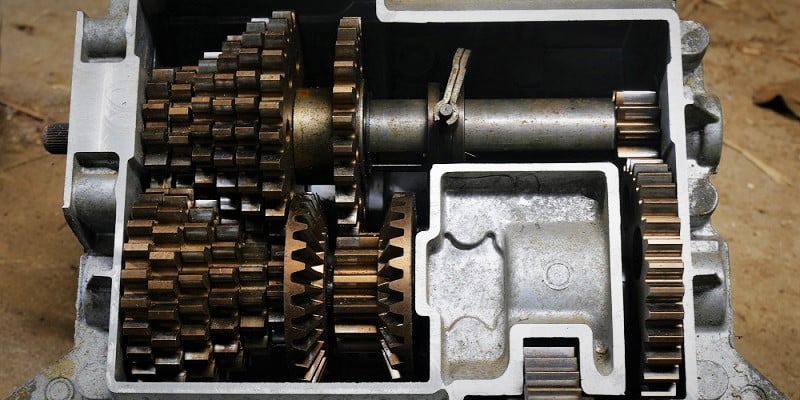

Illustrative image related to gears and drives

B2B buyers should ask suppliers for copies of their quality certifications and any relevant test reports to verify compliance.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are typically categorized into three stages:

-

Incoming Quality Control (IQC): At this stage, incoming materials are inspected for compliance with specifications. This includes testing raw materials for chemical composition and mechanical properties.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to ensure that processes are being followed correctly. This may involve monitoring machining tolerances and dimensional accuracy.

-

Final Quality Control (FQC): Once production is complete, final inspections are performed. This includes functional testing, dimensional checks, and performance assessments to ensure the product meets specified standards.

Each checkpoint serves to catch potential defects early, reducing waste and ensuring quality.

What Testing Methods Are Commonly Used to Ensure Gear Quality?

Common testing methods include:

- Dimensional Inspection: Using tools such as calipers and micrometers to verify that gears meet precise measurements.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or magnetic particle inspection can detect internal defects without damaging the gear.

- Load Testing: Gears may be subjected to load tests to evaluate their performance under operational conditions.

B2B buyers should inquire about the specific testing methods employed by suppliers and request access to test reports.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

Verifying a supplier’s quality assurance practices is crucial for mitigating risks in international trade. Here are actionable steps buyers can take:

-

Supplier Audits: Conducting regular audits of potential suppliers can help buyers assess their quality control processes firsthand. This can include reviewing their manufacturing facilities and quality management systems.

-

Requesting Reports: Buyers should request detailed quality control reports, including results from IQC, IPQC, and FQC, to understand the level of scrutiny applied during production.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality practices. This is especially important for buyers in regions with varying quality standards.

-

Certifications and Compliance: Buyers should ensure that suppliers possess the necessary certifications and comply with local and international regulations, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

Conclusion

Understanding the manufacturing processes and quality assurance measures for gears and drives is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and rigorous quality control, buyers can make informed decisions when selecting suppliers. Furthermore, verifying a supplier’s commitment to quality through audits and certifications will help ensure that the products meet the required standards for performance and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gears and drives’

Introduction

Sourcing gears and drives is a critical process for businesses seeking to enhance their mechanical systems. This guide provides a step-by-step checklist to help B2B buyers navigate the complexities of procuring these essential components, ensuring that they select the right products and suppliers to meet their operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for gears and drives. This includes specifying gear types (e.g., spur, helical, bevel), material preferences, size, load capacity, and performance characteristics.

– Why it matters: Precise specifications help eliminate ambiguity, ensuring that suppliers understand your needs and can provide appropriate solutions.

– What to look for: Consider operational conditions such as speed, torque, and environmental factors (e.g., temperature, humidity) that might affect performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in gears and drives. Use industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors.

– Why it matters: A diverse supplier pool increases your chances of finding a vendor that meets your specific needs in terms of quality, price, and service.

– What to look for: Focus on suppliers with a proven track record in your industry, as well as those who offer customized solutions.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality standards held by potential suppliers. Look for ISO certifications or other relevant industry standards that demonstrate their commitment to quality and reliability.

– Why it matters: Certifications are indicators of a supplier’s ability to produce high-quality products consistently, which is essential for maintaining operational efficiency.

– What to look for: Inquire about their quality assurance processes and whether they conduct regular audits to maintain compliance.

Illustrative image related to gears and drives

Step 4: Request Sample Products

Once you have narrowed down your list of suppliers, request samples of the gears and drives you intend to purchase. Testing these samples will allow you to assess their quality and compatibility with your existing systems.

– Why it matters: Samples provide a tangible way to evaluate the product’s performance and durability before making a bulk purchase.

– What to look for: Pay attention to the material quality, finish, and overall craftsmanship of the samples.

Step 5: Assess Pricing and Payment Terms

Compare pricing structures among shortlisted suppliers while considering the total cost of ownership. Look beyond the initial purchase price to include factors such as shipping, handling, and potential custom duties.

– Why it matters: Understanding the full financial impact of your procurement will help you budget effectively and avoid unexpected costs.

– What to look for: Evaluate payment terms, including discounts for bulk purchases or early payments, which can enhance cash flow.

Step 6: Check Customer References and Reviews

Before finalizing your supplier choice, reach out to previous customers or look for online reviews to gauge their experiences. Positive feedback can provide insights into the supplier’s reliability and customer service.

– Why it matters: Real-world experiences from other businesses can reveal potential issues or advantages that may not be apparent during the initial assessment.

– What to look for: Focus on reviews related to product quality, delivery times, and responsiveness to customer inquiries.

Step 7: Finalize Contracts and Terms

Once you have selected a supplier, ensure that all agreements are documented in a formal contract. This should include specifications, pricing, delivery schedules, and warranty information.

– Why it matters: A clear contract protects both parties and minimizes the risk of misunderstandings or disputes.

– What to look for: Ensure that the terms are fair and that you have recourse in case of non-compliance or product issues.

Illustrative image related to gears and drives

By following this checklist, B2B buyers can make informed decisions when sourcing gears and drives, ultimately enhancing their operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for gears and drives Sourcing

What Are the Key Cost Components in Gears and Drives Manufacturing?

Understanding the cost structure of gears and drives is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. Common materials for gears and drives include steel, aluminum, and engineering plastics. Each material has distinct properties affecting durability, weight, and cost. For instance, steel gears are typically more robust and suitable for heavy-duty applications, while plastic gears are lighter and often more cost-effective for lower-load scenarios.

-

Labor: Labor costs vary by region and can impact the overall pricing. Skilled labor is essential for precision manufacturing, especially when dealing with complex gear systems. Countries with higher wage standards may see increased production costs, while regions with a skilled but less expensive workforce can provide a competitive edge.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which is crucial for maintaining competitive pricing.

-

Tooling: The initial investment in tooling and machinery can be substantial, especially for custom gears. Tooling costs are often amortized over production runs, meaning larger orders can significantly reduce the per-unit cost.

-

Quality Control (QC): Ensuring the reliability and performance of gears and drives necessitates rigorous quality control processes. The costs associated with QC, including testing and certification, should be factored into the overall pricing.

-

Logistics: Transportation and handling costs can vary widely based on the supplier’s location and the buyer’s location. International shipping can be particularly costly, influenced by factors such as shipping methods, tariffs, and insurance.

-

Margin: Suppliers typically add a profit margin to the total cost, which can vary based on market conditions, competition, and the perceived value of their products.

How Do Price Influencers Affect Gears and Drives Procurement?

Several factors can influence pricing for gears and drives:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for favorable terms based on anticipated needs.

-

Specifications and Customization: Customized gears, tailored to specific applications, can significantly increase costs due to additional design and manufacturing processes. Clearly defining requirements can help manage expectations and costs.

-

Material Choices: Higher-grade materials will typically incur higher costs. Buyers must balance material selection with performance requirements to optimize cost-effectiveness.

-

Quality and Certifications: Products that meet international standards (e.g., ISO, AGMA) often come at a premium. However, investing in certified products can enhance reliability and reduce long-term operational costs.

-

Supplier Factors: Supplier reputation, reliability, and service levels can all impact pricing. Established suppliers may charge more due to their perceived quality and service assurance.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers in shipping, which can affect overall costs, especially in terms of logistics and insurance.

What Are Essential Buyer Tips for Cost-Efficient Sourcing?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Effective negotiation can lead to favorable terms, especially for larger orders. Establishing a long-term relationship with suppliers can provide leverage for better pricing.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. A lower initial cost may lead to higher long-term expenses if the quality is compromised.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local regulations that can affect pricing. Building a comprehensive understanding of these factors can lead to more informed purchasing decisions.

-

Supplier Diversification: Engaging with multiple suppliers can provide competitive pricing options and reduce risk. This strategy can also ensure a steady supply of critical components.

Disclaimer on Indicative Prices

Prices for gears and drives can fluctuate based on market conditions, material costs, and production methods. It is advisable for buyers to obtain quotes from multiple suppliers to ensure they are receiving competitive pricing tailored to their specific needs.

Illustrative image related to gears and drives

Alternatives Analysis: Comparing gears and drives With Other Solutions

Introduction to Alternative Solutions for Gears and Drives

In the realm of mechanical power transmission, gears and drives are widely recognized for their efficiency in converting and controlling energy. However, various alternative solutions exist that can serve similar purposes, each with unique advantages and limitations. This analysis will compare gears and drives against two viable alternatives: belt and pulley systems, and direct drive systems. Understanding these options allows B2B buyers to make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Gears And Drives | Belt and Pulley Systems | Direct Drive Systems |

|---|---|---|---|

| Performance | High torque transmission, precise control | Moderate torque, speed flexibility | High efficiency, low maintenance |

| Cost | Higher initial investment | Generally lower upfront cost | Moderate, depending on application |

| Ease of Implementation | Requires precise alignment and installation | Easier to install, less precision needed | Simple installation, minimal components |

| Maintenance | Regular maintenance needed for lubrication | Minimal maintenance, occasional belt replacement | Low maintenance, few moving parts |

| Best Use Case | Heavy machinery, automotive applications | Light to medium load applications | High-speed applications, robotics |

Detailed Breakdown of Alternatives

Belt and Pulley Systems

Belt and pulley systems consist of two or more pulleys connected by a belt, allowing for the transmission of power. These systems excel in applications requiring speed variation and flexibility, making them suitable for light to medium load operations. The main advantage of belt systems is their lower initial cost and easier installation compared to gears and drives. However, they can experience slippage and reduced efficiency at higher loads, making them less effective for heavy-duty applications.

Direct Drive Systems

Direct drive systems involve connecting the motor directly to the load without intermediate components, leading to high efficiency and minimal energy loss. These systems are ideal for applications requiring precision and reliability, such as robotics and high-speed machinery. The primary benefits include reduced maintenance needs due to fewer moving parts and lower operational noise. However, they may require specialized motors and can be more expensive depending on the application. Additionally, direct drive systems may not be suitable for all load types, particularly those requiring significant torque reduction.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate power transmission solution, B2B buyers must consider various factors, including performance requirements, budget constraints, ease of implementation, and maintenance capabilities. Gears and drives offer unparalleled torque and control, making them ideal for heavy machinery, while belt and pulley systems provide flexibility and cost-effectiveness for lighter applications. Direct drive systems, on the other hand, excel in high-efficiency environments where precision is critical. By evaluating these alternatives against specific operational needs, buyers can make strategic decisions that enhance productivity and efficiency in their operations.

Essential Technical Properties and Trade Terminology for gears and drives

What Are the Critical Technical Properties of Gears and Drives?

Understanding the technical properties of gears and drives is essential for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

-

Material Grade

The material grade of gears and drives affects their strength, durability, and performance under load. Common materials include carbon steel, stainless steel, and engineering plastics. Choosing the right material ensures that the components can withstand operational stresses and environmental conditions, thereby reducing the risk of failure and maintenance costs. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In gears, precise tolerances are crucial for ensuring smooth operation and minimizing wear. High tolerance levels lead to better meshing of gears, resulting in higher efficiency and longer service life. In B2B transactions, specifying tolerance can prevent costly production errors and ensure compatibility in assemblies. -

Gear Ratio

The gear ratio indicates the relationship between the input speed and output speed of a gear system. It is vital for determining the torque and speed characteristics of a drive. A well-defined gear ratio allows businesses to optimize performance for specific applications, from heavy machinery to automotive systems, ensuring they meet operational requirements. -

Load Capacity

Load capacity defines the maximum load a gear can handle without failure. It is influenced by factors such as material strength, design, and size. Understanding load capacity helps businesses select the right gears for their applications, ensuring safety and reliability while avoiding over-specification that can lead to unnecessary costs. -

Efficiency

Gear efficiency refers to the ratio of output power to input power in a gear system. High efficiency reduces energy loss and operational costs, making it a critical consideration for manufacturers looking to improve productivity. Buyers should inquire about efficiency ratings to ensure they are investing in products that provide optimal performance. -

Surface Finish

Surface finish affects the wear resistance and noise levels of gears. A smoother finish can reduce friction and wear, extending the lifespan of the gears. Buyers should consider surface finish specifications to ensure that the gears will operate quietly and efficiently in their intended applications.

What Are Common Trade Terms in the Gears and Drives Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B environments. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products or components that are used in another company’s end products. In the gears and drives industry, OEMs often require specific designs and tolerances to fit into their machinery. Understanding OEM requirements helps buyers ensure compatibility and quality in their sourcing. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand, as it can impact inventory levels and cash flow. Negotiating MOQs can help businesses optimize their supply chain while ensuring they have enough stock to meet demand. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. It is a critical step in the procurement process, allowing buyers to compare offers and negotiate favorable terms. A well-structured RFQ can facilitate better communication and more competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for managing shipping, insurance, and customs duties, ultimately ensuring smoother transactions across borders. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This term is crucial for production planning and inventory management. Buyers should consider lead times when placing orders to ensure they can meet their operational schedules without delays. -

Torque

Torque is a measure of the rotational force that a gear can exert. Understanding torque specifications helps buyers select gears that can handle the required load in their applications. It is essential for ensuring that the chosen gears will perform effectively without risk of failure.

By grasping these properties and terms, B2B buyers can navigate the gears and drives market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Illustrative image related to gears and drives

Navigating Market Dynamics and Sourcing Trends in the gears and drives Sector

What Are the Current Market Dynamics and Key Trends in the Gears and Drives Sector?

The gears and drives sector is experiencing significant transformation driven by technological advancements and evolving market demands. Global drivers such as the push for automation, increased energy efficiency, and the integration of IoT technologies are reshaping the landscape. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing.

Emerging trends include the adoption of precision-engineered components that enhance performance and durability. For instance, the rise of smart manufacturing technologies, including predictive maintenance and real-time monitoring, is prompting companies to source advanced gear systems equipped with sensors and connectivity features. Furthermore, the demand for lightweight materials, such as plastics and composites, is on the rise, as they provide significant advantages in reducing energy consumption and enhancing overall system efficiency.

In addition, there is a noticeable shift towards local sourcing to mitigate supply chain disruptions and ensure faster delivery times. This trend is particularly relevant for international buyers in regions like Nigeria and Germany, where logistical challenges can significantly impact production timelines. By establishing relationships with local manufacturers or distributors, companies can enhance their supply chain resilience and responsiveness.

Illustrative image related to gears and drives

How Does Sustainability and Ethical Sourcing Impact the Gears and Drives Sector?

As sustainability becomes a critical concern across industries, the gears and drives sector is not exempt from scrutiny regarding environmental impact and ethical sourcing. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing eco-friendly materials.

The importance of ethical supply chains cannot be overstated, as companies face growing pressure from stakeholders to ensure transparency and responsibility in their sourcing practices. This includes verifying that materials used in gear and drive manufacturing are sourced from environmentally responsible suppliers. Certifications like ISO 14001 for environmental management systems or adherence to standards set by the Global Reporting Initiative (GRI) are becoming essential for suppliers seeking to establish credibility in the market.

Moreover, the use of green materials—such as recycled metals and biodegradable plastics—is gaining traction. Buyers are encouraged to seek out partners who can provide these materials, not only to meet regulatory requirements but also to align with their corporate sustainability goals. By integrating sustainability into their sourcing strategies, B2B buyers can contribute to a more circular economy while enhancing their brand reputation.

What Is the Historical Evolution of the Gears and Drives Sector?

The gears and drives sector has a rich history that traces back to the early days of mechanical engineering. Initially, gears were simple wooden or metal structures used in basic machinery to transmit power and motion. The Industrial Revolution in the 18th and 19th centuries marked a significant turning point, as the demand for more efficient power transmission led to innovations in gear design and manufacturing techniques.

By the 20th century, advancements in metallurgy and precision machining enabled the production of more complex gear systems, including helical and bevel gears. The introduction of computer-aided design (CAD) and manufacturing (CAM) in the late 20th century further revolutionized the sector, allowing for more precise and customizable solutions. Today, the integration of digital technologies, such as IoT and AI, is setting the stage for the next evolution in gears and drives, creating opportunities for enhanced performance, efficiency, and sustainability in industrial applications.

Frequently Asked Questions (FAQs) for B2B Buyers of gears and drives

-

How do I solve issues with gear wear and tear?

To address gear wear and tear, start by evaluating the operational conditions such as load, speed, and lubrication. Regular maintenance schedules can help identify early signs of wear. Implementing high-quality lubrication based on the manufacturer’s recommendations can reduce friction and prolong gear life. Additionally, consider using gears made from harder materials or those with surface treatments that enhance durability. If wear is significant, consulting with a gear specialist for potential redesign or material upgrades may be necessary. -

What is the best type of gear for high torque applications?

For high torque applications, helical gears are often preferred due to their ability to handle higher loads and provide smoother operation compared to spur gears. Their angled teeth allow for gradual engagement, which reduces impact and noise. Additionally, worm gears can also be suitable for applications requiring significant torque reduction, though they may have lower efficiency. Assess the specific requirements of your application, including space constraints and desired speed ratios, to make the most informed choice. -

What factors should I consider when selecting a gear supplier?

When selecting a gear supplier, consider their experience in the industry and their reputation for quality and reliability. Evaluate their certifications, such as ISO standards, which indicate adherence to quality management systems. Additionally, inquire about their production capabilities, lead times, and customization options. It’s also essential to assess their customer support services, including after-sales support and troubleshooting assistance. Finally, check references and customer reviews to gauge their performance and trustworthiness. -

What are the minimum order quantities (MOQ) for gears and drives?

Minimum order quantities (MOQ) for gears and drives can vary significantly based on the supplier and the complexity of the gear type. Typically, standard gears may have lower MOQs, while custom gears could require larger orders to justify production costs. It’s advisable to discuss your specific needs directly with suppliers to understand their policies. In some cases, suppliers may offer flexibility in MOQs for first-time buyers or for establishing long-term partnerships. -

How do I ensure the quality of gears and drives from international suppliers?

To ensure quality from international suppliers, request detailed specifications and certifications that align with international standards. Consider conducting a factory audit or quality inspection prior to placing large orders. Establish clear quality assurance protocols, including testing methods for the gears, before shipment. Utilize third-party inspection services if necessary, and maintain open communication with the supplier regarding quality expectations throughout the production process. -

What payment terms should I negotiate with gear suppliers?

Payment terms can vary widely among gear suppliers, so it is crucial to negotiate terms that protect your cash flow while ensuring the supplier’s security. Common practices include a deposit upfront (typically 30-50%) with the balance due upon delivery or inspection of the goods. Consider discussing options for letter of credit or escrow services for larger orders, which can provide additional security for both parties. Always ensure that payment terms are documented in the purchase agreement. -

What logistics considerations should I keep in mind when sourcing gears internationally?

When sourcing gears internationally, consider the shipping methods, lead times, and customs regulations of both the exporting and importing countries. Factor in the costs of freight, insurance, and potential tariffs or duties. Working with a logistics partner experienced in international trade can streamline the process and help navigate complexities. Additionally, ensure that the supplier is capable of providing necessary documentation for smooth customs clearance to avoid delays. -

How can I customize gears to meet specific application needs?

Customizing gears involves specifying particular dimensions, materials, and performance characteristics that suit your application. Begin by clearly defining your requirements, including load capacity, speed, and environmental conditions. Collaborate closely with your supplier to explore available options and design capabilities. Advanced manufacturing techniques, such as CNC machining and additive manufacturing, can facilitate the production of specialized gears. Always request prototypes or samples to validate the design before finalizing large orders.

Top 6 Gears And Drives Manufacturers & Suppliers List

1. Gears & Gear Drives – Mechanical Power Transmission Components

Domain: gearsngeardrives.com

Registered: 2009 (16 years)

Introduction: Gears & Gear Drives offers a range of mechanical power transmission components including: Spur Gears, Helical Gears, Worm and Worm Wheel, Splines, Bevel Gear, Rack and Pinion, Timing Belt Pulleys, Chain Sprockets, Ratchet, Internal Gear, Screw & Nut Mechanism, Gear Pump Spares, Worm Gearbox, Helical Geared Motor, and Crane Gearbox. The company emphasizes customer satisfaction, timely delivery, and…

2. IQS Directory – Gear Drives

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Gear drives, also known as gear trains or gearboxes, are mechanical systems designed to transfer power from a driving source to a driven machine. They can modify the rotational speed of the output shaft, functioning as speed reducers that increase torque while decreasing speed. Key components include gears (typically made from alloyed steel), shafts, keys, couplings, bearings, housing, and flanges…

3. KHK Gears – Types of Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Types of Gears: Spur Gears, Helical Gears, Gear Rack, Worm Gears, Bevel Gears, Miter Gears, Internal Gears, Screw Gears. Key Characteristics: Spur Gears – cylindrical with straight teeth, no axial load; Helical Gears – winding teeth, better meshing, thrust force; Gear Rack – converts rotational to linear motion; Bevel Gears – cone-shaped for intersecting shafts; Spiral Bevel Gears – curved teeth, …

4. Wiley – Gear Interaction Essentials

Domain: onlinelibrary.wiley.com

Registered: 1994 (31 years)

Introduction: This company, Wiley – Gear Interaction Essentials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Regal Rexnord – Gearbox Solutions

Domain: regalrexnord.com

Registered: 2021 (4 years)

Introduction: The page discusses various types of gears offered by Regal Rexnord, including Inline Gearboxes, Parallel Shaft Gearboxes, Precision Gearboxes, Right Angle Gearboxes, and Shaft Mount Gearboxes. It also mentions custom gearbox solutions and parts and kits for gearboxes.

6. McMaster – Metal and Plastic Gears

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Metal and Plastic Gears, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for gears and drives

In summary, effective strategic sourcing in the gears and drives sector is essential for optimizing supply chain efficiency and enhancing competitive advantage. Buyers must prioritize suppliers that demonstrate a commitment to quality, timely delivery, and robust support services. Understanding the diverse range of gears—such as spur, helical, and bevel gears—along with their specific applications enables businesses to make informed purchasing decisions that align with their operational needs.

For international B2B buyers, particularly from emerging markets in Africa and South America, as well as established industries in Europe and the Middle East, the focus should be on fostering partnerships with manufacturers who embrace innovation and sustainability. This approach not only ensures the procurement of high-performance components but also supports long-term operational resilience.

As the demand for advanced mechanical solutions continues to grow, now is the time to engage with reliable suppliers who can meet your unique requirements. By leveraging strategic sourcing practices, businesses can position themselves for success in an increasingly competitive landscape. Embrace this opportunity to enhance your operations and drive growth in the gears and drives market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.