Motorcycle Footrest Brake And Shifter Replacement: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for motorcycle footrest brake and shifter replacement

In the ever-evolving landscape of motorcycle maintenance, sourcing high-quality motorcycle footrest brake and shifter replacements presents a significant challenge for international B2B buyers. Companies across Africa, South America, the Middle East, and Europe, such as those in Nigeria and Brazil, face the dual pressures of ensuring product reliability while managing costs. This guide aims to demystify the complexities of the global market for these essential components, offering insights into various types of footrests and shifters, their applications, and the critical factors to consider when selecting suppliers.

As the demand for motorcycle parts grows, understanding the nuances of sourcing from different regions becomes paramount. This comprehensive guide will delve into supplier vetting processes, cost considerations, and the latest trends in motorcycle footrest and shifter technology. By equipping buyers with the knowledge necessary to make informed purchasing decisions, we empower them to navigate the global marketplace effectively.

Whether you’re a distributor looking to expand your product offerings or a repair shop seeking reliable parts for your clientele, this resource is tailored to meet your needs. With actionable insights and expert advice, you will be better prepared to tackle the challenges of sourcing motorcycle footrest brake and shifter replacements, ensuring both quality and value in your procurement process.

Understanding motorcycle footrest brake and shifter replacement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Replacement Pegs | Direct fit for specific motorcycle models | Motorcycle repair shops, OEM dealers | Pros: High compatibility, quality assurance; Cons: Higher cost compared to aftermarket. |

| Aftermarket Adjustable Pegs | Customizable height and angle options | Custom bike shops, aftermarket retailers | Pros: Enhanced comfort, tailored ergonomics; Cons: Potential fitment issues, varying quality. |

| Floorboards | Larger surface area for foot placement | Touring and cruiser bike modifications | Pros: Increased comfort, stability; Cons: May require additional installation efforts. |

| Sportbike Rearsets | Adjustable positioning for performance riding | Performance shops, racing teams | Pros: Improved handling, optimized rider position; Cons: Higher complexity in installation. |

| Universal Pegs | Designed to fit multiple models with adapters | General motorcycle parts suppliers | Pros: Versatile applications, cost-effective; Cons: May lack specific model fitment. |

What Are the Key Characteristics of OEM Replacement Pegs?

OEM (Original Equipment Manufacturer) replacement pegs are designed to match the specifications of the original parts. They are ideal for businesses focused on maintaining the integrity of the motorcycle’s design and performance. Buyers should consider the model compatibility and the warranty offered, as OEM parts typically ensure a perfect fit and reliable performance. However, they often come at a premium price compared to aftermarket options.

How Do Aftermarket Adjustable Pegs Enhance Riding Experience?

Aftermarket adjustable pegs allow for customization of height and angle, catering to individual rider preferences. This type is particularly suited for custom bike shops looking to enhance rider comfort and ergonomics. When purchasing, businesses should evaluate the material quality and adjustability features. While they offer the advantage of personalization, potential fitment issues may arise, necessitating careful selection.

What Advantages Do Floorboards Provide for Touring Motorcycles?

Floorboards offer a larger surface area for foot placement, enhancing comfort during long rides. They are commonly used in touring and cruiser bike modifications, appealing to businesses that cater to long-distance riders. Buyers should consider the ease of installation and compatibility with existing motorcycle models. Although they improve comfort, floorboards may require more complex installation processes, which could affect labor costs.

Why Are Sportbike Rearsets Essential for Performance Riding?

Sportbike rearsets are designed to provide adjustable positioning that optimizes rider ergonomics for performance riding. They are crucial for performance shops and racing teams looking to enhance handling and control. Businesses should assess the adjustability and installation complexity when sourcing these parts. While they significantly improve riding dynamics, they may also require skilled installation, which can increase overall project costs.

What Makes Universal Pegs a Versatile Option for Buyers?

Universal pegs are designed to fit a wide range of motorcycle models, often utilizing adapters for secure fitment. They are ideal for general motorcycle parts suppliers seeking cost-effective solutions for varied customer needs. When considering universal pegs, businesses should evaluate the quality and compatibility with specific models. Although they provide versatility and affordability, they might not offer the precise fit of model-specific options, which could impact performance.

Key Industrial Applications of motorcycle footrest brake and shifter replacement

| Industry/Sector | Specific Application of motorcycle footrest brake and shifter replacement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Production of OEM footrest and shifter components | Ensures high-quality, reliable products for end-users | Compliance with international quality standards and certifications |

| Motorcycle Repair Shops | Replacement services for damaged or worn-out components | Increases customer satisfaction and repeat business | Availability of diverse aftermarket parts and quick turnaround time |

| Motorcycle Rental Services | Maintenance of fleet motorcycles to ensure safety and performance | Reduces downtime and enhances customer experience | Cost-effectiveness and bulk purchasing options for parts |

| Custom Motorcycle Builders | Customization of footrests and shifters for unique builds | Attracts niche markets and enhances brand identity | Access to specialty parts and customization options |

| Motorbike Racing Teams | Upgrading performance parts for competitive advantage | Improves bike handling and rider comfort | Availability of high-performance and lightweight materials |

How is Motorcycle Footrest Brake and Shifter Replacement Used in Manufacturing?

In the motorcycle manufacturing sector, the production of OEM (Original Equipment Manufacturer) footrest and shifter components is critical. These parts are essential for the functionality and safety of motorcycles. Manufacturers must ensure that they comply with international quality standards, which is particularly important for B2B buyers in regions like Africa and South America, where safety regulations may vary. Reliable sourcing of these components can lead to reduced production costs and enhanced product reliability.

What Role Do Repair Shops Play in Motorcycle Footrest and Shifter Replacement?

Motorcycle repair shops frequently handle the replacement of footrests and shifters due to damage or wear. This service is vital for maintaining customer satisfaction and loyalty. Buyers in this sector need to consider the availability of diverse aftermarket parts that can cater to different motorcycle models. Quick turnaround times are also crucial, as customers expect timely repairs to get back on the road.

How Do Rental Services Benefit from Footrest and Shifter Maintenance?

Motorcycle rental services must maintain their fleet to ensure safety and performance. Regular replacement of footrests and shifters can significantly reduce the risk of accidents, thereby enhancing customer experience. B2B buyers in this industry should focus on cost-effectiveness and bulk purchasing options for parts to maintain profitability while ensuring high safety standards.

Why is Customization Important for Builders?

Custom motorcycle builders often seek unique footrests and shifters to differentiate their offerings. This customization not only enhances the aesthetic appeal of the motorcycles but also attracts niche markets. Buyers in this sector should prioritize access to specialty parts and customization options, enabling them to create tailored solutions that resonate with their clientele.

How Do Racing Teams Utilize Performance Upgrades?

Motorbike racing teams invest in high-performance footrest and shifter replacements to gain a competitive edge. These upgrades can improve bike handling and rider comfort, which are essential for success in competitive environments. Teams must ensure they have access to lightweight and high-performance materials, emphasizing the importance of sourcing quality components that meet the rigorous demands of racing.

3 Common User Pain Points for ‘motorcycle footrest brake and shifter replacement’ & Their Solutions

Scenario 1: Difficulty Sourcing High-Quality Replacement Parts

The Problem: B2B buyers often encounter challenges in sourcing high-quality motorcycle footrest brake and shifter replacement parts. In regions such as Africa and South America, where supply chains may be less developed, buyers might find themselves inundated with low-quality products that do not meet safety standards or are incompatible with their motorcycles. This not only jeopardizes rider safety but can also lead to costly returns and extended downtime for their fleet of motorcycles.

The Solution: To effectively source high-quality replacement parts, B2B buyers should establish relationships with reputable suppliers who specialize in motorcycle components. This can involve attending industry trade shows, joining motorcycle enthusiast forums, or utilizing platforms like Alibaba or TradeIndia to vet suppliers through reviews and ratings. Additionally, buyers should prioritize suppliers who provide detailed specifications, certifications, and warranty information for their products. Conducting thorough quality checks, such as requiring sample parts for evaluation, can also mitigate the risk of purchasing subpar components.

Scenario 2: Complicated Installation Processes

The Problem: Installing footrests, brake pedals, and shifters can often be a complicated process, especially for businesses that lack specialized mechanical knowledge. B2B buyers may face difficulties in understanding the specific installation requirements for different motorcycle models, leading to improper installations that affect performance and safety. This complexity can result in increased labor costs and time delays in getting motorcycles back on the road.

The Solution: To streamline the installation process, buyers should invest in comprehensive installation guides or manuals tailored to the specific motorcycle models they work with. Partnering with suppliers who offer detailed, model-specific instructions and video tutorials can significantly enhance the installation experience. Additionally, providing training sessions for mechanics can empower staff with the necessary skills and knowledge to perform replacements efficiently. For businesses operating in regions where technical expertise may be limited, establishing a network of certified mechanics or workshops can serve as an invaluable resource for complex installations.

Scenario 3: Budget Constraints and Cost Management

The Problem: Budget constraints are a significant pain point for B2B buyers, particularly in emerging markets where cost sensitivity is paramount. The expense associated with high-quality motorcycle footrest brake and shifter replacements can strain financial resources, especially when maintenance needs arise frequently. Buyers may struggle to balance the need for quality with the pressure to keep costs low, leading to potential compromises on safety and performance.

The Solution: Implementing a strategic procurement approach can help buyers navigate budget constraints effectively. This can involve bulk purchasing agreements with suppliers to secure discounts or exploring options for refurbished or OEM surplus parts that provide quality at a lower price point. Additionally, conducting a cost-benefit analysis for different parts can help buyers understand the long-term value of investing in higher-quality components versus cheaper alternatives that may need frequent replacements. Establishing a preventative maintenance schedule can also minimize unexpected costs by addressing wear and tear before they require significant repairs. By aligning procurement strategies with budgetary goals, B2B buyers can maintain their fleet’s safety and performance without exceeding financial limitations.

Strategic Material Selection Guide for motorcycle footrest brake and shifter replacement

What Are the Key Materials for Motorcycle Footrest Brake and Shifter Replacement?

When selecting materials for motorcycle footrest brake and shifter replacements, it’s essential to consider performance, durability, and cost-effectiveness. The most common materials used in these applications include aluminum, steel, plastic, and composite materials. Each material has distinct properties, advantages, and limitations that can significantly impact the end product’s performance and suitability for various markets.

How Does Aluminum Perform in Motorcycle Footrest Brake and Shifter Applications?

Aluminum is widely favored in the motorcycle industry due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of around 150°C (302°F) and can withstand moderate pressure, making it suitable for footrests and shifters that experience regular wear and tear.

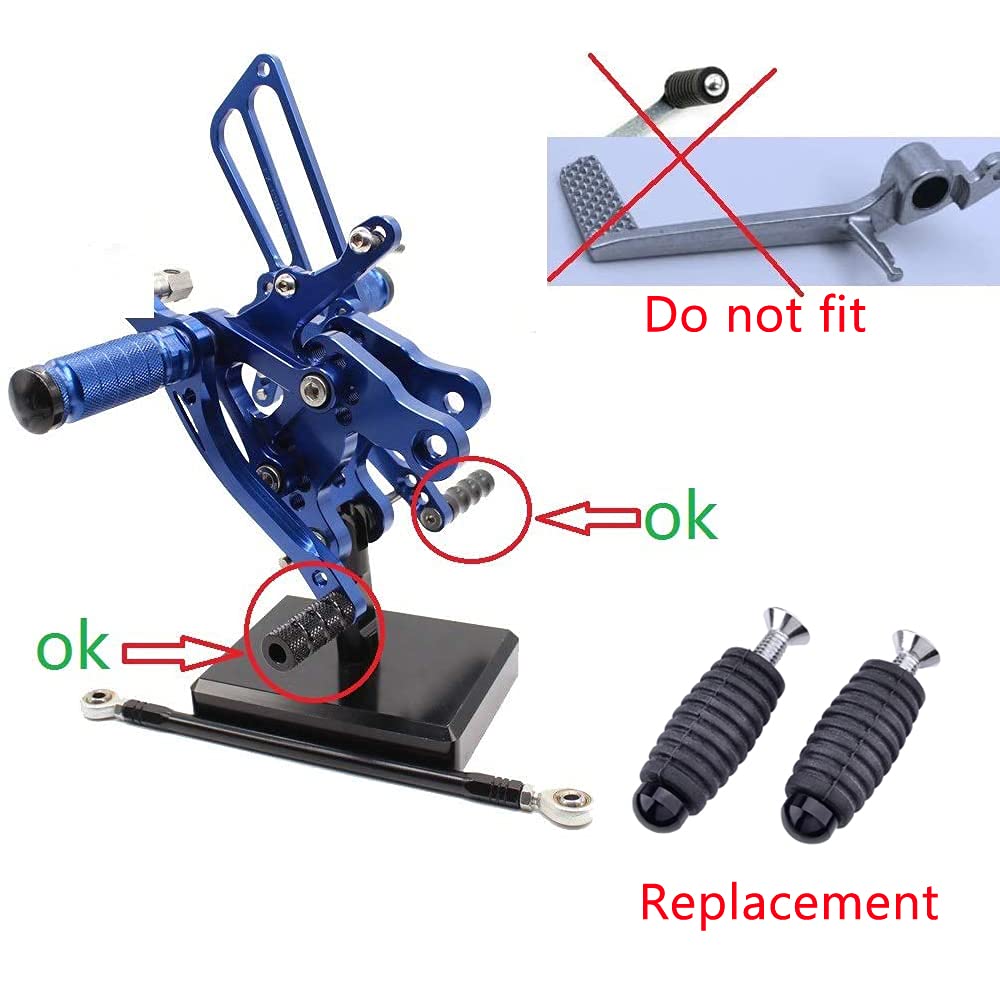

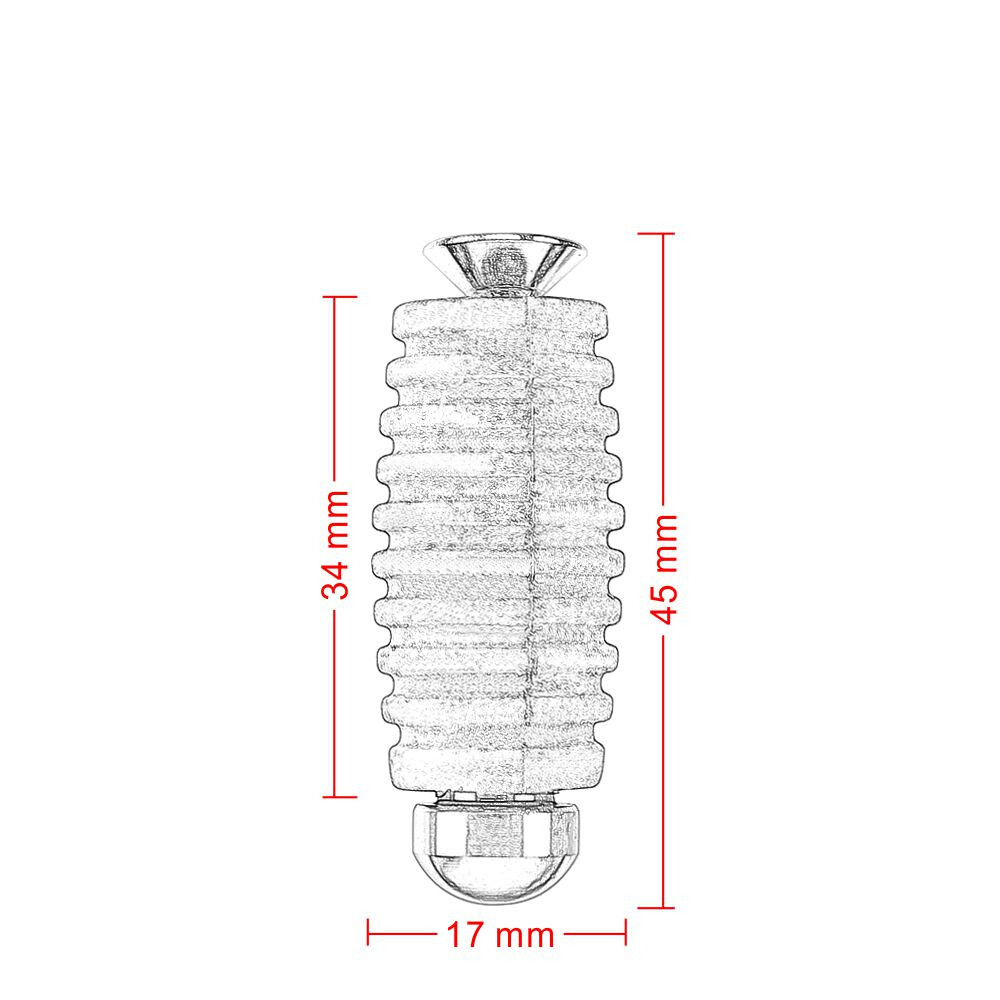

Illustrative image related to motorcycle footrest brake and shifter replacement

Pros: Aluminum is durable yet lightweight, which enhances the overall performance of the motorcycle. Its resistance to corrosion is particularly advantageous in humid or coastal environments, common in regions like Brazil and Nigeria.

Cons: While aluminum is generally cost-effective, high-performance grades can be expensive. Additionally, it may not offer the same level of impact resistance as steel, making it less suitable for aggressive riding conditions.

Impact on Application: Aluminum footrests and shifters are compatible with various motorcycle models and can be anodized for additional protection.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers in Africa and South America should also consider local sourcing options to reduce costs and lead times.

What Role Does Steel Play in Footrest Brake and Shifter Manufacturing?

Steel is another popular choice for motorcycle components due to its high strength and durability. It can handle high temperatures and pressures, making it suitable for heavy-duty applications.

Pros: Steel offers exceptional strength and is less likely to deform under stress. It is also relatively inexpensive compared to aluminum, making it a cost-effective option for manufacturers.

Cons: Steel is prone to corrosion if not properly treated, which can be a significant drawback in humid climates. The weight of steel can also negatively impact the motorcycle’s overall performance.

Impact on Application: Steel components can be treated with coatings to enhance corrosion resistance, but this adds to manufacturing complexity.

Illustrative image related to motorcycle footrest brake and shifter replacement

Considerations for International Buyers: Buyers should ensure that steel components meet local regulations and standards, particularly in the Middle East, where corrosion resistance is critical due to environmental factors.

How Do Plastics and Composites Compare for Motorcycle Footrests and Shifters?

Plastics and composite materials are increasingly being used in motorcycle components due to their versatility and lightweight properties. They often have good temperature resistance, typically up to 100°C (212°F), and are resistant to corrosion.

Pros: The primary advantage of plastics is their lightweight nature, which can improve fuel efficiency and handling. They can also be molded into complex shapes, allowing for innovative designs.

Cons: While plastics are resistant to corrosion, they may not offer the same level of durability as metals, particularly under extreme conditions. They can also be more expensive to produce in some cases.

Illustrative image related to motorcycle footrest brake and shifter replacement

Impact on Application: Plastic components can be designed for specific applications, such as vibration dampening, which can enhance rider comfort.

Considerations for International Buyers: Compliance with international standards is essential, especially for composite materials, which may have specific regulations regarding their use in automotive applications.

Summary of Material Selection for Motorcycle Footrest Brake and Shifter Replacement

| Material | Typical Use Case for motorcycle footrest brake and shifter replacement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Footrests and shifters for lightweight motorcycles | Lightweight and corrosion-resistant | Less impact resistance | Medium |

| Steel | Heavy-duty footrests and shifters | High strength and durability | Prone to corrosion | Low |

| Plastic | Vibration-dampening footrests and shifters | Lightweight and versatile | Lower durability under stress | Medium |

| Composite | Custom-designed footrests and shifters | Innovative designs and lightweight | Higher production costs | High |

This material selection guide provides B2B buyers with a comprehensive overview of the key materials used in motorcycle footrest brake and shifter replacements, ensuring informed decisions that align with performance requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle footrest brake and shifter replacement

What Are the Key Stages in the Manufacturing Process of Motorcycle Footrest Brake and Shifter Replacements?

Manufacturing motorcycle footrests, brake pedals, and shifter replacements involves several critical stages that ensure the components meet rigorous quality and performance standards.

Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing motorcycle footrests and shifters is material preparation. Most components are made from high-strength materials such as aluminum alloys, stainless steel, or high-grade plastics. These materials are chosen for their durability, corrosion resistance, and ability to withstand significant mechanical stress.

Before processing, raw materials undergo inspection to verify their specifications and quality. This often involves chemical composition testing and physical property assessments to ensure they meet industry standards.

Illustrative image related to motorcycle footrest brake and shifter replacement

How Are the Components Formed?

Once materials are verified, they proceed to the forming stage. Techniques such as casting, forging, or CNC machining are commonly employed.

- Casting involves pouring molten metal into molds, allowing for intricate designs and shapes.

- Forging uses compressive forces to shape the metal, enhancing its structural integrity.

- CNC machining allows for precise cuts and dimensions, ensuring each component fits perfectly within the motorcycle assembly.

These processes not only shape the components but also enhance their performance characteristics, making them more resilient to wear and tear.

What Role Does Assembly Play in the Manufacturing Process?

The assembly stage is crucial for integrating various components into a final product. Footrests and shifters often consist of multiple parts, including pegs, levers, and mounting brackets. During assembly, parts are meticulously fitted together, with attention to detail to ensure smooth operation.

Automated assembly lines may be used for high-volume production, while more complex assemblies might require skilled labor for precision fitting. Proper alignment and torque specifications are essential to ensure that the components function correctly and safely.

How Is Finishing Handled in the Manufacturing Process?

Finishing processes enhance the aesthetic and functional properties of the components. Techniques such as anodizing, powder coating, or plating are commonly used.

- Anodizing increases corrosion resistance and allows for color customization.

- Powder coating provides a durable finish that can withstand harsh environmental conditions.

- Plating can improve wear resistance and provide an attractive appearance.

These finishing touches not only improve the look of the components but also extend their lifespan, making them more appealing to B2B buyers looking for quality products.

What International Standards and Quality Assurance Processes Are Relevant?

Quality assurance is vital in manufacturing motorcycle footrests and shifters, as these components directly impact rider safety and vehicle performance.

Which International Standards Should B2B Buyers Be Aware Of?

Adhering to international standards such as ISO 9001 ensures that manufacturers maintain a high level of quality management throughout their production processes. ISO 9001 focuses on consistent quality and customer satisfaction, making it a benchmark for B2B buyers.

Additionally, specific certifications like CE marking are crucial for products sold within the European market, indicating compliance with health, safety, and environmental protection standards. For certain regions, compliance with local standards, such as those set by the American Petroleum Institute (API) for specific components, may also be required.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that defects are identified and addressed promptly. Typical QC stages include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive checks on the finished products, including functionality tests and visual inspections.

Common testing methods include dimensional checks, load testing, and fatigue testing to evaluate the performance of the components under stress.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence to verify the quality control measures employed by suppliers. Here are some actionable steps:

What Steps Can Buyers Take for Supplier Audits and Reports?

-

Supplier Audits: Buyers should consider conducting on-site audits to assess the manufacturing processes, quality control measures, and overall production environment. This allows buyers to evaluate the supplier’s adherence to quality standards firsthand.

-

Requesting Quality Reports: Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These reports should outline any defects found and corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the supplier’s quality control processes and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

How Do Regional Standards Impact Quality Assurance?

Different regions may have specific regulations and standards that manufacturers must comply with. For instance, products exported to Europe must meet CE marking requirements, while those in the Middle East may need to adhere to local regulatory frameworks.

B2B buyers should be aware of these regional differences and ensure that their suppliers can navigate the complexities of international compliance. This understanding can significantly impact the efficiency of the supply chain and the overall satisfaction with the product quality.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing motorcycle footrests, brake pedals, and shifter replacements, ensuring they meet the necessary performance and safety standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle footrest brake and shifter replacement’

This guide provides a practical checklist for B2B buyers looking to source motorcycle footrest, brake, and shifter replacement parts. By following these steps, you can ensure that you procure the right components for your needs, from identifying specifications to evaluating suppliers.

Step 1: Define Your Technical Specifications

Before starting the procurement process, clearly outline the technical specifications of the footrest and shifter components you need. Consider factors such as material, size, compatibility with specific motorcycle models, and any additional features like adjustability or weight capacity. Detailed specifications help to avoid confusion later and ensure that you receive parts that meet your exact requirements.

Step 2: Research Available Suppliers

Conduct thorough research on suppliers who specialize in motorcycle parts, particularly footrests and shifters. Utilize online marketplaces, industry directories, and trade shows to compile a list of potential vendors. Pay attention to their reputation, product range, and customer reviews, as these factors can significantly influence the reliability of your sourcing decisions.

Step 3: Evaluate Supplier Certifications

It’s essential to verify the certifications and compliance of your potential suppliers. Look for relevant industry certifications such as ISO or other quality assurance standards that demonstrate a commitment to quality and safety. Suppliers with these certifications are more likely to provide reliable products that meet international standards, reducing the risk of defects.

Step 4: Request Samples for Testing

Before making a bulk order, request samples of the footrest and shifter components. Testing these samples allows you to assess their quality, fit, and functionality directly. This step can prevent costly mistakes and ensure that the components meet your performance standards before full-scale procurement.

Step 5: Inquire About Warranty and Return Policies

Discuss warranty terms and return policies with your selected suppliers. A solid warranty indicates confidence in product quality, while a flexible return policy can safeguard against receiving defective or incompatible parts. Make sure you understand the terms clearly to avoid potential disputes in the future.

Step 6: Negotiate Pricing and Payment Terms

Engage in negotiations regarding pricing and payment terms. Aim for competitive pricing without compromising on quality, and explore options for bulk purchase discounts or payment plans that suit your budget. Clear agreements on payment terms can facilitate smoother transactions and foster long-term relationships with suppliers.

Step 7: Finalize Logistics and Delivery Arrangements

Once you’ve selected a supplier and agreed on terms, finalize the logistics of your order. Discuss shipping options, delivery timelines, and any customs regulations that might apply to international shipments. Ensuring that these details are clearly outlined can help avoid delays and ensure that your parts arrive on time and in good condition.

By following this checklist, B2B buyers can streamline the sourcing process for motorcycle footrest, brake, and shifter replacements, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for motorcycle footrest brake and shifter replacement Sourcing

What are the Key Cost Components in Motorcycle Footrest Brake and Shifter Replacement?

When evaluating the cost structure for motorcycle footrest brake and shifter replacements, several key components must be considered:

-

Materials: The primary materials typically include aluminum, steel, or composite materials, depending on the desired strength and weight. Sourcing high-quality materials is crucial, as they directly affect performance and durability. Prices can fluctuate based on global commodity markets, so it’s essential to stay updated on material costs.

-

Labor: Labor costs vary significantly by region and the complexity of the replacement process. Skilled labor is often needed for precise installation, particularly when custom modifications are required. In regions like Africa or South America, labor costs may be lower, but the availability of skilled technicians can impact overall pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and administrative costs. Manufacturers often spread these costs over their total production volume, which means larger orders can lead to lower per-unit overhead costs.

-

Tooling: The cost of specialized tools for manufacturing or assembly can be substantial, particularly for custom or complex designs. Buyers should inquire about whether these costs are factored into the pricing or charged separately.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection can add to the overall cost. However, investing in QC can reduce long-term costs associated with returns and warranty claims.

-

Logistics: Transportation costs can vary depending on the location of the supplier and the buyer. International shipments might incur additional fees such as customs duties and taxes, which should be factored into the total cost.

-

Margin: Suppliers will typically apply a markup to cover their costs and generate profit. Understanding the typical margins in the industry can aid buyers in evaluating the fairness of quotes received.

How Do Price Influencers Affect Sourcing Decisions for Motorcycle Footrests and Shifters?

Several factors can influence pricing, especially in international markets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to price reductions due to economies of scale. Understanding a supplier’s MOQ is essential for pricing negotiations.

-

Specifications and Customization: Customized components may incur higher costs due to additional design and manufacturing efforts. Buyers should clearly communicate their specifications to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certified components (e.g., ISO, CE certifications) can increase costs but may provide better performance and durability. Buyers should balance cost with the expected lifecycle of the product.

-

Supplier Factors: The reputation and reliability of the supplier can significantly affect pricing. Established suppliers may charge more but often provide better service, warranty terms, and quality assurance.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for international purchases. These terms define responsibilities for shipping costs, insurance, and risk, impacting the total cost.

What Buyer Tips Can Help Optimize Costs for Motorcycle Footrest and Shifter Sourcing?

-

Negotiation Strategies: Effective negotiation can yield significant savings. Buyers should research market prices and be prepared to discuss alternatives or volume discounts.

-

Focus on Total Cost of Ownership (TCO): Instead of merely comparing upfront costs, consider the total cost of ownership, including maintenance, durability, and potential warranty claims over the product’s lifespan.

-

Pricing Nuances for International Buyers: When sourcing from different regions, be aware of currency fluctuations, import taxes, and local economic conditions that might affect pricing. It’s advisable to work with suppliers familiar with international trade to navigate these complexities.

-

Build Long-term Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and more favorable terms in future transactions.

-

Stay Informed on Market Trends: Keeping up with global market trends can help buyers anticipate price changes and make informed sourcing decisions.

Disclaimer on Indicative Prices

Pricing for motorcycle footrest brake and shifter replacements can vary widely based on the factors discussed above. Buyers should always obtain multiple quotes and conduct thorough market research to ensure competitive pricing.

Alternatives Analysis: Comparing motorcycle footrest brake and shifter replacement With Other Solutions

Exploring Alternative Solutions for Motorcycle Footrest Brake and Shifter Replacement

In the realm of motorcycle maintenance, particularly concerning footrest brake and shifter replacement, various alternatives exist that can meet the needs of B2B buyers looking for cost-effective and efficient solutions. This section examines the primary method of traditional replacement against two viable alternatives: custom aftermarket parts and upgraded floorboard systems.

Comparison Table

| Comparison Aspect | Motorcycle Footrest Brake And Shifter Replacement | Custom Aftermarket Parts | Upgraded Floorboard Systems |

|---|---|---|---|

| Performance | High; restores original functionality | Variable; depends on part quality | High; offers enhanced ergonomics |

| Cost | Moderate; varies by model and part availability | Potentially lower; depends on sourcing | Higher initial investment |

| Ease of Implementation | Straightforward; DIY-friendly with basic tools | Varies; may require specialized tools | More complex; may need professional installation |

| Maintenance | Standard; routine checks required | Variable; depends on part durability | Lower; typically more robust design |

| Best Use Case | General maintenance for standard motorcycles | Custom builds or modifications for performance | Long-distance touring or comfort-oriented rides |

Detailed Breakdown of Alternatives

Custom Aftermarket Parts

Utilizing custom aftermarket parts provides an alternative to traditional replacements. These parts can be tailored to enhance performance or aesthetics, allowing motorcycle enthusiasts to personalize their ride. However, the quality of these parts can vary significantly, leading to potential issues with fit and durability. While they often come at a lower price point, the risk of needing to replace them frequently can lead to higher long-term costs.

Illustrative image related to motorcycle footrest brake and shifter replacement

Upgraded Floorboard Systems

Upgrading to floorboard systems is a more comprehensive solution that not only replaces footrests and shifters but also enhances rider comfort. This option is particularly beneficial for long-distance riders, as it provides a more stable and spacious foot placement. The installation process can be more complicated, often requiring professional assistance, which can lead to higher upfront costs. However, the maintenance of these systems tends to be lower due to their robust design, making them a worthwhile investment for serious riders.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the most appropriate solution for motorcycle footrest brake and shifter replacement, B2B buyers should consider their specific requirements, including performance expectations, budget constraints, and ease of installation. For those looking for a straightforward replacement with guaranteed functionality, traditional replacement remains a reliable choice. Conversely, custom aftermarket parts can offer unique enhancements at a potentially lower cost, while upgraded floorboard systems provide superior comfort and durability for long rides. Ultimately, the decision should align with the operational demands and financial strategies of the buyer’s business model.

Essential Technical Properties and Trade Terminology for motorcycle footrest brake and shifter replacement

What Are the Essential Technical Properties for Motorcycle Footrest Brake and Shifter Replacement?

When sourcing motorcycle footrest brake and shifter components, understanding critical technical properties is vital for ensuring compatibility, safety, and performance. Here are several key specifications to consider:

-

Material Grade

The material used in footrests and shifters significantly impacts durability and performance. Common materials include aluminum alloys, stainless steel, and high-strength plastics. Aluminum offers a favorable strength-to-weight ratio, while stainless steel provides superior corrosion resistance, essential for motorcycles operating in diverse environments. Choosing the right material ensures longevity and reliability, crucial for B2B buyers in regions with varying climates, such as Africa and South America. -

Tolerance Levels

Tolerance refers to the acceptable range of variation in a component’s dimensions. For footrests and shifters, tight tolerances are critical to ensure proper fitment and function. For instance, a tolerance of ±0.1 mm might be standard for critical mounting points. This precision is essential to avoid misalignment, which can lead to operational issues or safety hazards. Ensuring proper tolerances can reduce returns and enhance customer satisfaction. -

Load Capacity

Load capacity indicates the maximum weight that a component can safely support. This specification is vital for footrests, which must endure the weight of the rider and the forces exerted during operation. A component designed to handle a load capacity of at least 200 kg is common in heavy-duty motorcycles. Understanding load capacity helps B2B buyers ensure that the components they source can withstand the demands of their end-users. -

Surface Finish

The surface finish of footrests and shifters affects both aesthetics and functionality. Anodized or powder-coated finishes provide enhanced corrosion resistance and can improve grip. For example, a textured surface finish can prevent slipping during use, which is particularly important for safety in wet conditions. Selecting the right surface finish can also influence the overall brand perception of the motorcycle. -

Mounting Compatibility

Different motorcycle models may have unique mounting configurations for footrests and shifters. Compatibility with existing mounts is essential to ensure a hassle-free installation. Buyers should verify that the components meet OEM specifications or are designed as direct replacements. This reduces the need for additional modifications, saving time and costs during the installation process.

What Are Common Trade Terms Relevant to Motorcycle Footrest Brake and Shifter Replacement?

Familiarity with trade terminology is crucial for effective communication and negotiation in the B2B motorcycle parts industry. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

OEM parts are components made by the original manufacturer of the motorcycle. These parts are typically designed to fit perfectly and maintain the performance standards of the original equipment. B2B buyers often prefer OEM parts to ensure quality and compatibility, especially in markets where reliability is paramount. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for B2B buyers to plan their inventory and manage costs effectively. For instance, a supplier may set an MOQ of 100 units for footrests, which can impact purchasing decisions based on projected sales. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. This term is critical in B2B transactions, as it facilitates the procurement process. By issuing an RFQ, buyers can compare multiple suppliers and negotiate terms effectively, ensuring they secure the best deals. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and customs clearance. Familiarity with Incoterms is vital for B2B buyers sourcing components from different countries, as it clarifies who bears the risk at various stages of the shipping process. -

Lead Time

Lead time refers to the duration from placing an order to receiving the goods. Understanding lead times is crucial for inventory management, particularly for businesses that rely on just-in-time delivery models. A shorter lead time can enhance a company’s agility in responding to market demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their motorcycle footrest brake and shifter replacements meet the required standards and expectations.

Navigating Market Dynamics and Sourcing Trends in the motorcycle footrest brake and shifter replacement Sector

What Are the Current Market Dynamics and Key Trends in the Motorcycle Footrest Brake and Shifter Replacement Sector?

The motorcycle footrest brake and shifter replacement sector is witnessing significant growth, driven by a surge in motorcycle ownership and an increasing emphasis on aftermarket customization. Global drivers include the rising popularity of motorcycling as a leisure activity and the growing demand for high-performance parts that enhance rider safety and comfort. In regions such as Africa, South America, the Middle East, and Europe, the market is particularly influenced by the expanding middle class and increasing disposable incomes, which enable more consumers to invest in motorcycle upgrades and replacements.

Emerging B2B technology trends include the use of e-commerce platforms for direct sourcing, which allows buyers to access a broader range of products from global suppliers. Additionally, advancements in supply chain technology, such as blockchain, are improving transparency and traceability in sourcing practices. B2B buyers are increasingly looking for suppliers who can offer not only quality products but also quick turnaround times, efficient logistics, and responsive customer service. The demand for customization is also on the rise, leading to an increase in suppliers offering bespoke solutions tailored to specific motorcycle models.

How Is Sustainability and Ethical Sourcing Impacting the Motorcycle Footrest Brake and Shifter Replacement Market?

As global awareness of environmental issues grows, sustainability has become a key consideration for B2B buyers in the motorcycle parts sector. The environmental impact of manufacturing processes and materials used in footrest brake and shifter replacements is under scrutiny, prompting buyers to seek out eco-friendly alternatives. This shift includes the use of recycled materials and sustainable manufacturing practices, which not only reduce waste but also appeal to environmentally-conscious consumers.

Ethical sourcing is equally important, as buyers are increasingly demanding transparency regarding the origins of materials and labor practices involved in production. Suppliers that can demonstrate adherence to ethical standards, such as fair labor practices and responsible resource extraction, are more likely to gain the trust of international buyers. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming essential benchmarks that B2B buyers consider when selecting suppliers. By prioritizing sustainability and ethical sourcing, businesses can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

What Is the Brief Evolution of the Motorcycle Footrest Brake and Shifter Replacement Sector?

The motorcycle footrest brake and shifter replacement sector has evolved significantly over the decades, transitioning from basic functionality to a focus on performance and aesthetics. Initially, replacements were limited to OEM (Original Equipment Manufacturer) parts, which prioritized durability and compliance with safety standards. However, with the rise of the aftermarket industry, a vast array of customizable options has emerged, catering to diverse consumer preferences and enhancing the riding experience.

Technological advancements have also played a crucial role in this evolution. Innovations in materials, such as lightweight alloys and high-strength plastics, have improved the performance and longevity of footrest and shifter components. Additionally, the integration of ergonomic design principles has led to products that not only function well but also enhance rider comfort and control. This evolution reflects a broader trend in the motorcycle industry, where personalization and performance are increasingly prioritized, offering B2B buyers a wealth of options to meet the demands of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle footrest brake and shifter replacement

-

How do I determine the right specifications for motorcycle footrest brake and shifter replacements?

To identify the correct specifications for replacements, first consult the motorcycle’s service manual, which typically outlines OEM (Original Equipment Manufacturer) parts. Additionally, consider the model, year, and make of the motorcycle, as compatibility can vary significantly. Engaging with suppliers who offer customization options can also ensure you receive parts tailored to your specific needs. Requesting samples or detailed product specifications can further aid in making informed purchasing decisions. -

What is the best material for motorcycle footrest brake and shifter replacements?

The best materials for footrest brake and shifter replacements are typically aluminum, steel, or high-grade plastics, depending on the intended use. Aluminum is lightweight and resistant to corrosion, making it ideal for performance applications. Steel, while heavier, offers greater durability and strength, suitable for heavy-duty use. High-grade plastics can be used for cost-effective solutions, but ensure they are designed for high-impact situations. Evaluate your target market’s preferences to determine the best material choice. -

How can I ensure the quality of motorcycle footrest brake and shifter replacements?

To guarantee quality, partner with reputable suppliers who adhere to international quality standards such as ISO 9001. Request product certifications and conduct thorough inspections upon receipt. Implementing a quality assurance process, including random sampling and testing, can help maintain high standards. Additionally, consider suppliers that offer warranties or guarantees on their products, as this indicates their confidence in the quality of their offerings. -

What is the minimum order quantity (MOQ) for motorcycle footrest brake and shifter replacements?

MOQs can vary significantly among suppliers, often ranging from 50 to 1,000 units depending on the item’s complexity and production costs. When negotiating, consider discussing your projected sales volume to potentially lower the MOQ. Some manufacturers may offer flexibility for first-time buyers or smaller businesses, so it’s advisable to inquire about potential exceptions or tiered pricing based on order size. -

What payment terms should I expect when sourcing motorcycle footrest brake and shifter replacements?

Payment terms can vary widely, but most suppliers require a deposit (often 30% to 50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer credit terms based on your purchasing history or volume. It’s crucial to establish clear payment expectations upfront to avoid any misunderstandings. Be sure to inquire about payment methods accepted, such as letters of credit, bank transfers, or online payment platforms. -

How do I assess the reliability of a supplier for motorcycle footrest brake and shifter replacements?

To assess supplier reliability, start by checking their credentials, including years in business, industry certifications, and customer reviews. Request references from other B2B clients and examine their response times and communication quality. Conducting a factory audit, if feasible, can provide insights into their manufacturing processes and quality control measures. Additionally, participating in trade shows or industry events can help gauge a supplier’s reputation within the market. -

What logistics considerations should I keep in mind when sourcing motorcycle footrest brake and shifter replacements?

Logistics considerations include shipping methods, lead times, and customs regulations. Determine the most cost-effective shipping option based on urgency and volume, whether by air, sea, or land. Familiarize yourself with the customs requirements for your destination country, as these can affect delivery times and costs. Establishing a good relationship with a freight forwarder can streamline the process and mitigate potential delays. -

Can I customize motorcycle footrest brake and shifter replacements to fit specific branding needs?

Yes, many suppliers offer customization options for motorcycle footrest brake and shifter replacements, including color, material, and design modifications. Discuss your branding requirements, such as logos or unique designs, during the initial negotiations. Be aware that customization may affect lead times and pricing, so it’s essential to factor these elements into your planning. Request prototypes to evaluate the final product before mass production to ensure it meets your branding standards.

Top 7 Motorcycle Footrest Brake And Shifter Replacement Manufacturers & Suppliers List

1. OLIVER MOTO – Motorcycle Foot Peg

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”Motorcycle 6mm M6 Footrest Gear Shift Foot Peg Pedal M6 thread Shift Brake lever”,”Condition”:”New”,”Brand”:”OLIVER MOTO”,”Type”:”Foot Peg”,”Color”:”Silver”,”Manufacturer Part Number”:”FP012GOOL”,”Material”:”Aluminum”,”Country/Region of Manufacture”:”China”,”Shipping Cost”:”US $5.00″,”Returns”:”30 days returns, buyer pays for return shipping”,”Quantity Available”:”5 available, 3 s…

2. Yamaha – Shift Lever & Left Foot Peg

Domain: yamahastarstryker.com

Registered: 2010 (15 years)

Introduction: Shift lever and left foot peg for Yamaha Star Stryker; replacement needed after fall; quoted price for left peg is $114; user is looking for a cheap replacement until upgrading to floorboards.

3. KLR Forum – JNS Peg Lowering Brackets

Domain: klrforum.com

Registered: 2005 (20 years)

Introduction: 1. JNS Peg Lowering Brackets – Designed to lower foot pegs for improved comfort and eliminate the need for bar risers. Pre-production sets available for the 2022 KLR 650. 2. Tusk Shifter – Extended shifter option that improves shifting experience for larger boots. 3. Pivot Pegz – High-quality foot pegs available in larger sizes, priced at $189.00 for the No Topper Mk 4s, with payment options avail…

4. Kawasaki – Foot Rest Screw Replacement

Domain: vulcanforums.com

Registered: 2007 (18 years)

Introduction: Foot rest screw for Kawasaki Vulcan motorcycle; broken screw issue affecting gear shifting; replacement screw needed; repair cost approximately €5.6; user successfully drilled out broken screw and replaced it.

5. Banke – Shifter and Brake Levers

Domain: badweatherbikers.com

Registered: 1999 (26 years)

Introduction: Banke shifter and brake levers, LSL pegs and mounts, Aluminum Millenium X1 Pegs (Part # Left Peg N0403.Q $6.95, Right Peg N0404.Q $6.95), Buell accessory pegs ($85), aftermarket copies on eBay ($44), billet toe pegs, Crossroads rearsets, Banke peg relocator kit.

6. RevZilla – Custom Motorcycle Shifter Pegs & Extensions

Domain: revzilla.com

Registered: 2006 (19 years)

Introduction: This company, RevZilla – Custom Motorcycle Shifter Pegs & Extensions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Ducati – Shifter Toe Peg

Domain: ducatihyper.com

Registered: 2023 (2 years)

Introduction: The shifter toe peg is a removable part of the shift lever assembly for Ducati Hypermotard motorcycles. Users have reported difficulty in finding the specific part number for the toe peg, leading to discussions about whether it can be purchased separately or if the entire shift lever assembly must be replaced. The cost for a complete assembly is around $120. Some users have suggested alternative s…

Strategic Sourcing Conclusion and Outlook for motorcycle footrest brake and shifter replacement

In the competitive landscape of motorcycle footrest brake and shifter replacements, strategic sourcing remains paramount for B2B buyers. Establishing relationships with reliable suppliers ensures access to quality parts, which can significantly reduce operational costs and enhance customer satisfaction. By leveraging regional suppliers from diverse markets, businesses can mitigate risks associated with supply chain disruptions and fluctuating prices.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize sourcing strategies that embrace local market dynamics. Understanding regional preferences and regulatory requirements can lead to more tailored offerings, positioning businesses to better serve their customers. Additionally, exploring innovative materials and manufacturing techniques can provide a competitive edge in product quality and durability.

As we look to the future, the motorcycle parts market is poised for growth, driven by rising demand for customization and performance upgrades. B2B buyers are encouraged to actively engage in market research, foster supplier partnerships, and stay informed about emerging trends. By doing so, they can capitalize on new opportunities and enhance their market presence. Embrace strategic sourcing today to secure a prosperous tomorrow in the motorcycle parts industry.

Illustrative image related to motorcycle footrest brake and shifter replacement

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.