The Definitive Guide to Air Filtration Media: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for air filtration media

In an increasingly globalized world, the challenge of sourcing effective air filtration media is paramount for businesses across diverse industries. With rising concerns over indoor air quality and stringent regulatory standards, international B2B buyers must navigate a complex landscape of options to ensure they select the right filtration solutions. This comprehensive guide delves into the various types of air filtration media available, including high-efficiency particulate air (HEPA) filters and activated carbon options, as well as their specific applications across sectors such as manufacturing, healthcare, and commercial buildings.

Understanding the nuances of air filtration media is essential for making informed purchasing decisions, particularly for buyers from regions like Africa, South America, the Middle East, and Europe, including emerging markets like Vietnam and Brazil. This guide not only addresses key factors such as supplier vetting, cost considerations, and performance metrics but also provides actionable insights on how to evaluate the efficacy of different filtration systems. By empowering B2B buyers with the knowledge to assess their unique needs and align them with the right products, this resource aims to facilitate strategic sourcing that enhances operational efficiency and compliance with health standards.

As you explore the sections ahead, you will be equipped with the critical information necessary to navigate the global market for air filtration media, ensuring your organization can achieve optimal air quality while meeting its business objectives.

Understanding air filtration media Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| HEPA Filters | High efficiency, must capture 99.97% of particles ≥0.3 microns | Hospitals, clean rooms, industrial settings | Pros: Superior air quality, regulatory compliance. Cons: Higher initial cost, requires regular replacement. |

| Activated Carbon Filters | Uses carbon to adsorb gases and odors | HVAC systems, air purifiers, industrial applications | Pros: Effective against VOCs and odors. Cons: Limited particulate filtration, needs replacement when saturated. |

| Electrostatic Filters | Utilizes static electricity to capture particles | Commercial buildings, air handling units | Pros: High efficiency, longer lifespan. Cons: Performance can degrade if not maintained. |

| Pleated Filters | Increased surface area for filtration | HVAC systems, residential and commercial spaces | Pros: Compact design, efficient dust capture. Cons: Potential for clogging without maintenance. |

| Nonwoven Media | Made from synthetic fibers, versatile applications | Automotive, industrial, and HVAC systems | Pros: Lightweight, customizable. Cons: May not perform as well in high humidity environments. |

What Are HEPA Filters and Their Applications in B2B Settings?

HEPA (High Efficiency Particulate Air) filters are renowned for their ability to trap at least 99.97% of particles that are 0.3 microns or larger. They are essential in environments requiring stringent air quality standards, such as hospitals, laboratories, and clean rooms. When purchasing HEPA filters, businesses should consider the MERV rating, compatibility with existing systems, and the cost of regular replacements, as these filters can be more expensive upfront but are crucial for maintaining a healthy atmosphere.

How Do Activated Carbon Filters Work and Where Are They Used?

Activated carbon filters leverage the porous structure of carbon to adsorb volatile organic compounds (VOCs), odors, and other gaseous pollutants. They are widely used in HVAC systems, air purifiers, and various industrial applications where air quality is a concern. Buyers should consider the filter’s capacity for adsorption and the frequency of replacement, as saturation can significantly reduce effectiveness. While they excel at removing gases, they do not filter particulates effectively, which may necessitate a multi-stage filtration approach.

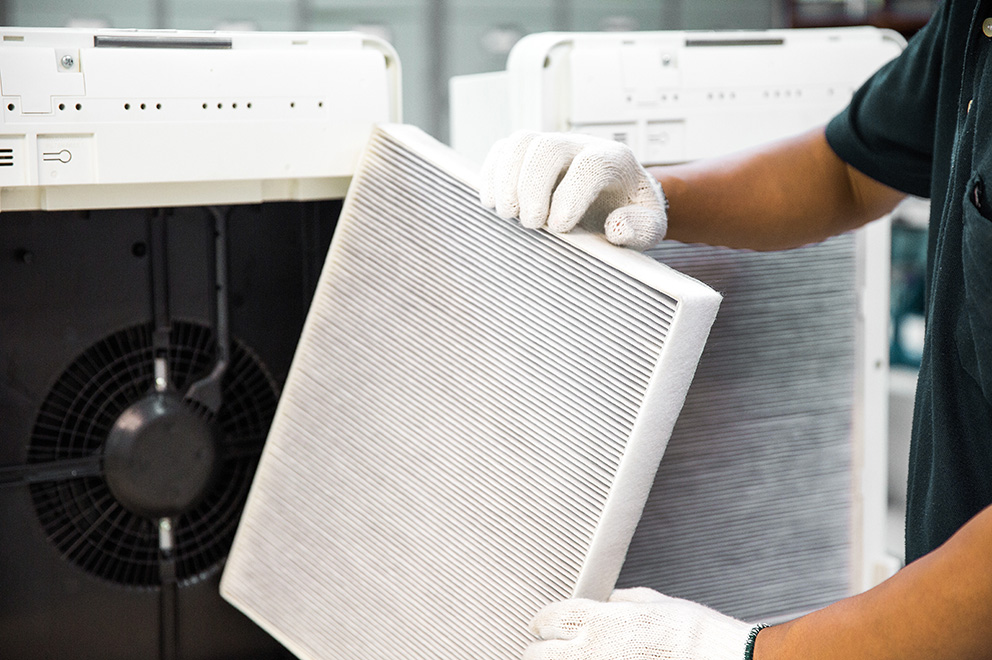

Illustrative image related to air filtration media

Why Choose Electrostatic Filters for Air Quality Management?

Electrostatic filters utilize an electric charge to capture airborne particles, offering a high level of efficiency and a longer lifespan compared to standard filters. These filters are ideal for commercial buildings and air handling units. When selecting electrostatic filters, businesses should evaluate their maintenance requirements and the specific air quality needs of their environment, as performance can decrease if not regularly cleaned or maintained.

What Are the Benefits of Pleated Filters in HVAC Systems?

Pleated filters feature a greater surface area than traditional flat filters, allowing them to capture more dust and debris while maintaining airflow. They are commonly used in HVAC systems for both residential and commercial applications. Buyers should assess the filter’s MERV rating and the recommended replacement schedule, as while they are efficient, they can clog more quickly if not monitored. Proper maintenance is crucial to ensure optimal performance and air quality.

How Does Nonwoven Media Fit into the Air Filtration Landscape?

Nonwoven media, made from synthetic fibers, offer versatility across various applications, including automotive, industrial, and HVAC systems. Their lightweight nature and customizable properties make them suitable for many filtration needs. When considering nonwoven media, businesses should factor in environmental conditions such as humidity, as some types may not perform well in damp environments. Additionally, the absence of chemical binders can be a significant advantage for companies focused on sustainability.

Illustrative image related to air filtration media

Key Industrial Applications of air filtration media

| Industry/Sector | Specific Application of air filtration media | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | HVAC systems for air quality control | Improved worker health and productivity | Ensure compliance with local regulations and standards |

| Food & Beverage | Liquid filtration for processing | Enhanced product safety and quality | Evaluate compatibility with food-grade materials |

| Automotive | Cabin air filters for vehicles | Increased customer satisfaction and safety | Seek high-efficiency filters to meet OEM specifications |

| Pharmaceuticals | Cleanroom air filtration | Compliance with stringent health regulations | Look for HEPA or ULPA filters to meet cleanroom standards |

| Construction | Dust control in construction sites | Reduction in respiratory hazards and improved safety | Consider durability and effectiveness in high-dust environments |

How is Air Filtration Media Used in Manufacturing, and What Problems Does it Solve?

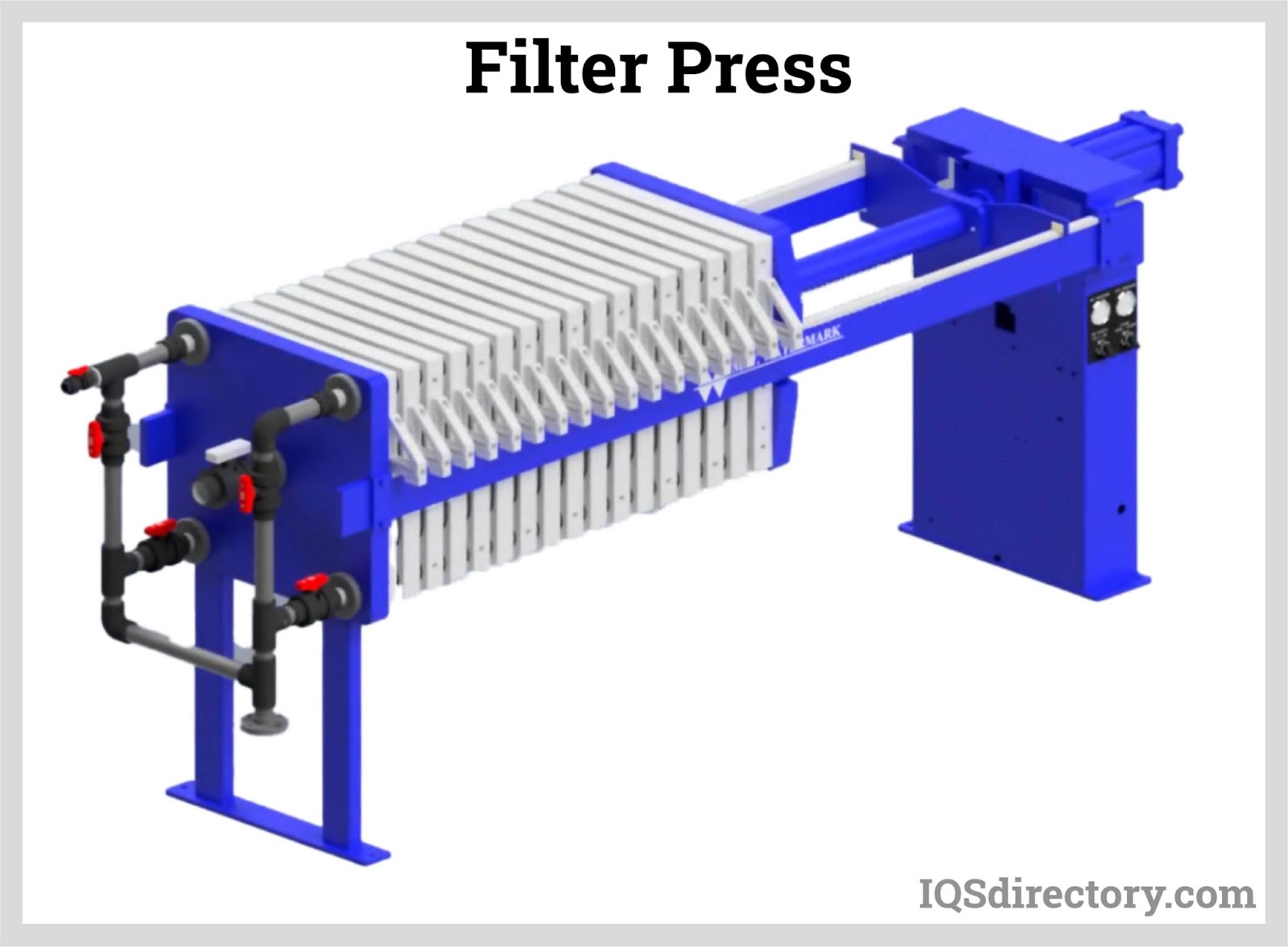

In the manufacturing sector, air filtration media is crucial for HVAC systems that maintain air quality in production facilities. By filtering out particulate matter and volatile organic compounds (VOCs), these systems enhance worker health and productivity. Buyers in this sector should ensure that their filtration solutions comply with local regulations and standards, particularly in regions with stringent environmental controls. This compliance not only protects employees but also minimizes potential legal liabilities.

What Role Does Air Filtration Media Play in the Food & Beverage Industry?

In food and beverage processing, air filtration media is employed in liquid filtration systems to ensure that contaminants are removed effectively. This application is vital for maintaining product safety and quality, as any impurities can lead to significant health risks and product recalls. Buyers should evaluate the compatibility of filtration media with food-grade materials to ensure compliance with health regulations. Additionally, sourcing from reputable suppliers can guarantee the reliability and efficiency of these systems.

How Does Air Filtration Media Enhance Automotive Cabin Air Quality?

For the automotive industry, air filtration media is used in cabin air filters to provide clean air for passengers. High-efficiency filters can trap allergens, dust, and other pollutants, significantly enhancing customer satisfaction and safety. Buyers should seek filters that meet original equipment manufacturer (OEM) specifications to ensure proper fit and function. Additionally, considering the efficiency ratings of filters can help in selecting products that offer the best performance under varying environmental conditions.

Illustrative image related to air filtration media

Why is Air Filtration Media Essential in Pharmaceuticals?

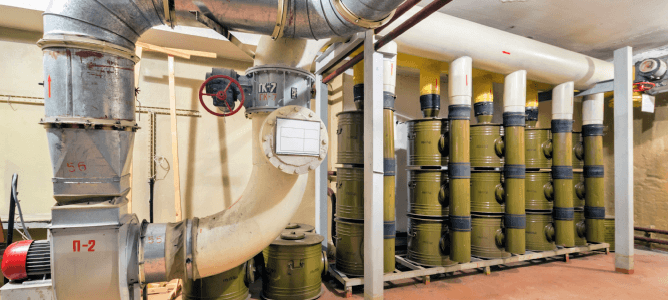

In the pharmaceutical sector, cleanroom environments require stringent air filtration to meet health regulations. Air filtration media, particularly HEPA or ULPA filters, is essential for maintaining the sterile conditions necessary for drug manufacturing. Buyers must prioritize sourcing filters that comply with specific cleanroom standards to avoid contamination and ensure product integrity. Understanding the filtration efficiency and lifespan of these products is also critical for maintaining operational effectiveness.

How Does Air Filtration Media Help in Construction Dust Control?

In construction, air filtration media is utilized to control dust and improve air quality on job sites. This application is vital for reducing respiratory hazards among workers and ensuring compliance with occupational health standards. Buyers should consider the durability and effectiveness of filtration solutions in high-dust environments. Additionally, sourcing from suppliers who provide robust, high-capacity filters can lead to reduced downtime and increased safety for construction crews.

3 Common User Pain Points for ‘air filtration media’ & Their Solutions

Scenario 1: Navigating Compliance and Regulatory Standards in Air Filtration

The Problem:

B2B buyers often face the daunting task of ensuring that their air filtration media complies with various international regulations and industry standards. For businesses operating in sectors like healthcare, food processing, and manufacturing, non-compliance can lead to significant penalties, operational disruptions, and a damaged reputation. This is particularly challenging for companies in regions like Africa and South America, where regulations may change frequently and vary significantly from one country to another.

The Solution:

To navigate this complex landscape, buyers should prioritize sourcing air filtration media from reputable manufacturers that provide comprehensive documentation regarding compliance with relevant standards such as ISO, ASHRAE, and local regulations. Establishing a robust vendor relationship is crucial; inquire about their testing protocols, certifications, and any recent audits. Buyers should also consider engaging with local industry associations or consulting with experts who can provide insights into regulatory updates. By integrating compliance checks into the procurement process, companies can ensure their filtration solutions not only meet but exceed regulatory requirements, thereby safeguarding their operations.

Illustrative image related to air filtration media

Scenario 2: Dealing with Inefficient Air Filtration Systems

The Problem:

Many businesses encounter the issue of inefficient air filtration systems that fail to adequately remove pollutants, leading to poor indoor air quality (IAQ). This inefficiency can result from using subpar filter media or not selecting the right type of filtration for specific applications. In regions with high levels of dust, pollen, or industrial pollutants, inadequate filtration can severely impact employee health and productivity, as well as damage sensitive equipment.

The Solution:

To address this issue, buyers should conduct a thorough assessment of their air quality needs and the specific contaminants present in their environment. Utilizing tools such as air quality monitors can provide valuable data for making informed decisions. When selecting air filtration media, consider investing in high-efficiency particulate air (HEPA) filters or activated carbon filters that are specifically designed for the contaminants identified. Additionally, opting for filters with higher MERV ratings can enhance pollutant capture. Regularly scheduled maintenance and timely replacement of filters should also be a part of the strategy to ensure sustained efficiency in air filtration systems.

Scenario 3: Managing the Cost of Air Filtration Solutions

The Problem:

Cost management is a significant concern for B2B buyers when it comes to air filtration media. The initial investment in high-quality filtration systems can be substantial, and ongoing operational costs—including filter replacements and energy consumption—can add up quickly. In emerging markets, where budgets may be tighter, the challenge is balancing cost with the need for effective air quality solutions.

The Solution:

To effectively manage costs, buyers should consider a total cost of ownership (TCO) approach when evaluating air filtration media options. This involves not only looking at the upfront costs but also the long-term operational costs, including energy usage and maintenance requirements. Opting for energy-efficient filtration systems can lead to significant savings over time. Additionally, exploring bulk purchasing agreements or long-term contracts with suppliers can reduce unit costs. Regularly reviewing performance metrics and conducting cost-benefit analyses can also help in optimizing filtration strategies and ensuring that investments yield the best possible return. By focusing on both quality and cost-effectiveness, businesses can achieve a sustainable air filtration solution that meets their needs without straining their budgets.

Illustrative image related to air filtration media

Strategic Material Selection Guide for air filtration media

What Are the Key Properties of Common Air Filtration Media Materials?

When selecting air filtration media, understanding the properties of different materials is crucial for optimizing performance in various applications. Here, we analyze four common materials used in air filtration media, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Fiberglass Perform as Air Filtration Media?

Fiberglass is a widely used material in air filtration due to its lightweight and high surface area. It typically exhibits good temperature resistance, making it suitable for environments that experience fluctuations. Fiberglass filters can operate efficiently at temperatures up to 500°F (260°C) and can handle moderate pressure differentials.

Pros: Fiberglass filters are cost-effective and have a high dust-holding capacity, which extends their lifespan. They are also resistant to moisture, reducing the risk of microbial growth.

Cons: However, they can be less durable under extreme conditions, such as high humidity or chemical exposure. Additionally, they may not capture smaller particulate matter as effectively as other materials, such as HEPA filters.

Illustrative image related to air filtration media

Impact on Application: Fiberglass is often used in HVAC systems and industrial applications where cost efficiency is prioritized.

Considerations for International Buyers: Compliance with local standards such as ASTM or EN is essential. In regions like Africa and South America, buyers should ensure that the selected fiberglass media meets local environmental regulations.

What Are the Benefits of Using Activated Carbon in Air Filtration?

Activated carbon is renowned for its adsorption capabilities, particularly for gaseous contaminants and odors. Its porous structure allows for high surface area, enhancing its ability to capture volatile organic compounds (VOCs) and other harmful gases.

Pros: Activated carbon filters are highly effective in improving indoor air quality and are often used in combination with other filtration media for enhanced performance.

Cons: The primary limitation is their relatively high cost and the need for regular replacement to maintain effectiveness. Additionally, they may not be suitable for filtering particulate matter unless combined with other media.

Impact on Application: Activated carbon is commonly used in air purifiers and industrial applications where odor control is critical.

Considerations for International Buyers: Buyers should look for products that meet international standards for air quality, such as those set by WHO or local environmental agencies, particularly in urban areas in Europe and the Middle East.

How Do Synthetic Nonwoven Fabrics Compare as Air Filtration Media?

Synthetic nonwoven fabrics, such as polypropylene and polyester, are becoming increasingly popular due to their versatility and efficiency. These materials can be engineered to achieve specific filtration efficiencies, with MERV ratings ranging from 7 to 15.

Pros: They offer excellent durability, are resistant to moisture, and can be produced without chemical binders, making them environmentally friendly. Their high dust-holding capacity also extends their service life.

Cons: The manufacturing process can be complex, leading to higher initial costs compared to traditional materials like fiberglass.

Impact on Application: Synthetic nonwoven fabrics are ideal for HVAC systems and commercial air filtration applications, where high performance and longevity are required.

Considerations for International Buyers: Buyers should verify that the synthetic media complies with local and international standards, such as ISO or JIS, especially when sourcing from regions with strict environmental regulations.

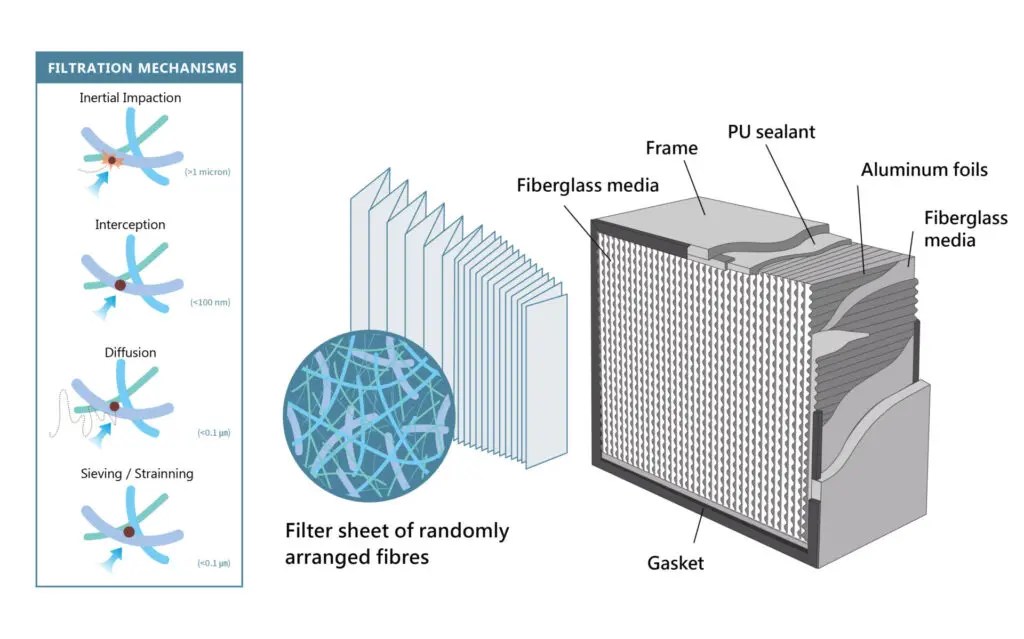

What Role Does HEPA Media Play in Air Filtration?

High-Efficiency Particulate Air (HEPA) media is a standard in air filtration, known for its ability to capture at least 99.97% of particles that are 0.3 microns in size. This makes it highly effective for both residential and industrial applications.

Pros: HEPA filters provide superior air quality and are essential in environments requiring stringent air cleanliness, such as hospitals and laboratories.

Illustrative image related to air filtration media

Cons: The primary drawback is the higher cost and the need for proper maintenance to ensure efficiency. They can also create higher pressure drops, requiring more energy for airflow.

Impact on Application: HEPA filters are essential in sensitive environments where air quality is critical, such as healthcare and cleanroom applications.

Considerations for International Buyers: Compliance with standards like EN 1822 or ASHRAE is crucial for buyers in Europe and the Middle East. Understanding local regulations regarding filter disposal is also important.

Illustrative image related to air filtration media

Summary Table of Air Filtration Media Materials

| Material | Typical Use Case for air filtration media | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiberglass | HVAC systems, industrial applications | Cost-effective, high dust-holding capacity | Less effective for small particles | Low |

| Activated Carbon | Air purifiers, odor control applications | Excellent for gaseous contaminants | Higher replacement frequency and cost | High |

| Synthetic Nonwoven Fabrics | Commercial air filtration, HVAC systems | Durable, customizable filtration efficiency | Complex manufacturing process | Medium |

| HEPA Media | Hospitals, cleanrooms | Superior air quality | Higher cost, requires maintenance | High |

This analysis should guide international B2B buyers in selecting the right air filtration media for their specific needs, considering both performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air filtration media

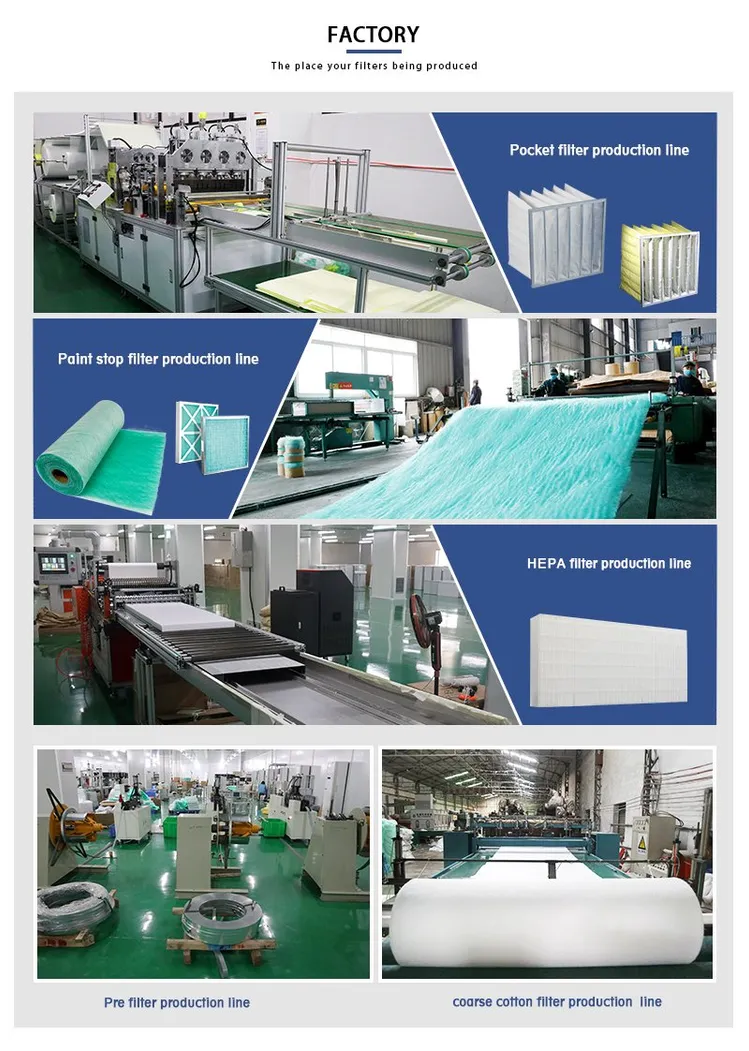

What Are the Main Stages of Manufacturing Air Filtration Media?

The manufacturing process for air filtration media involves several critical stages that ensure high-quality products tailored to meet specific filtration needs. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used in Air Filtration Media?

The first step in manufacturing air filtration media is material preparation. Various materials are utilized, including non-woven fabrics, activated carbon, and synthetic fibers. Manufacturers often select materials based on their filtration efficiency, durability, and specific application requirements. For instance, activated carbon is commonly used for its ability to adsorb gaseous contaminants, while synthetic fibers are preferred for particulate filtration.

Illustrative image related to air filtration media

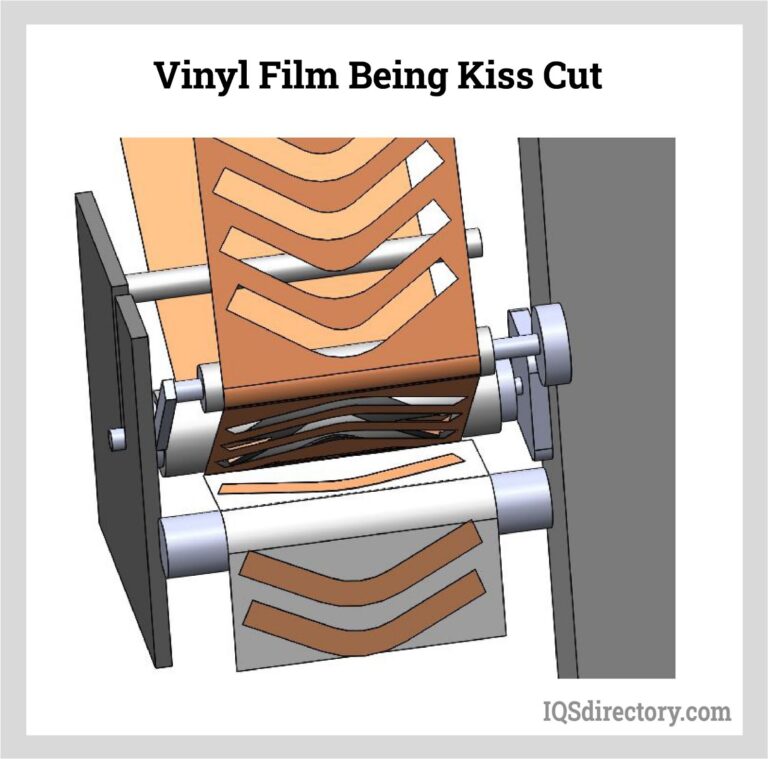

2. Forming: How Is Filtration Media Shaped and Structured?

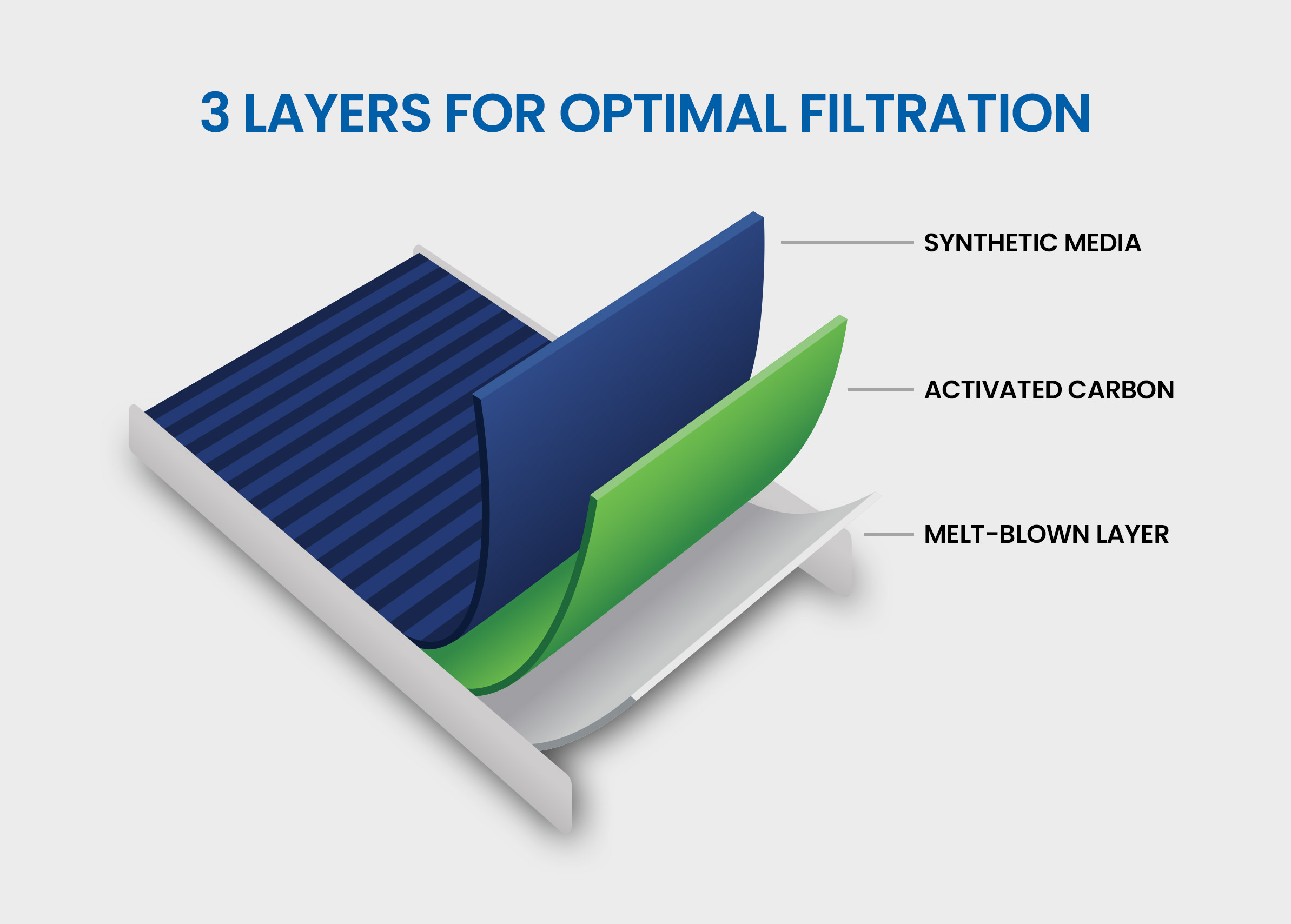

Once the materials are prepared, the forming stage begins. This typically involves processes such as spunbonding or meltblowing, where fibers are laid down to create a web-like structure. The choice of forming technique impacts the media’s filtration efficiency and air permeability. In some cases, manufacturers may employ electret charging, which enhances the electrostatic attraction of particles, improving filtration performance.

3. Assembly: How Are Components Integrated in Filtration Systems?

After the media is formed, it is assembled into filter configurations. This can include pleated filters, pocket filters, or mini-pleat designs, depending on the intended application. The assembly process may involve cutting, folding, and sealing the media to ensure structural integrity and optimal airflow. Attention to detail during assembly is crucial, as it directly influences the filter’s overall performance and longevity.

4. Finishing: What Final Touches Ensure Product Quality?

The final stage is finishing, where filters undergo treatments to enhance their functionality. This may include coatings for odor removal or antimicrobial properties. Additionally, filters are often subjected to rigorous quality checks before packaging. Proper finishing ensures that the final product meets industry standards and performs effectively in real-world applications.

Illustrative image related to air filtration media

What Quality Control Measures Are Essential in Air Filtration Media Manufacturing?

Quality control (QC) is paramount in the production of air filtration media, ensuring that products meet international standards and customer expectations. B2B buyers should be familiar with key QC measures and industry-specific certifications.

Relevant International Standards: Which Certifications Should Buyers Look For?

Manufacturers of air filtration media often adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. This certification demonstrates a commitment to consistent quality and customer satisfaction. Additionally, specific products may need to comply with standards such as CE marking for products sold in Europe or API standards for those in the oil and gas sector.

QC Checkpoints: What Are the Key Stages of Quality Control?

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects early, ensuring that any issues are addressed promptly.

- Final Quality Control (FQC): Before products are packaged, a final inspection is conducted to verify that they meet the required specifications and performance standards.

Common Testing Methods: How Are Filters Evaluated for Performance?

B2B buyers should be aware of the common testing methods used to evaluate air filtration media. These can include:

Illustrative image related to air filtration media

- MERV Testing: This assesses the Minimum Efficiency Reporting Value of filters, indicating their ability to capture particles of different sizes.

- DOP Testing: This method measures the efficiency of HEPA filters by using dioctyl phthalate (DOP) aerosol to simulate real-world conditions.

- Dust Holding Capacity Tests: These evaluate how much particulate matter a filter can hold before its performance degrades.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain robust quality control processes, B2B buyers can take several steps:

Conducting Audits: What Should Buyers Look For?

One effective method is to conduct audits of potential suppliers. During an audit, buyers should assess the supplier’s quality management system, including documentation of processes, compliance with industry standards, and the effectiveness of their QC checkpoints. Regular audits can help establish trust and ensure ongoing compliance.

Reviewing Quality Reports: How Can Documentation Inform Decisions?

Buyers should request quality reports from suppliers, which detail testing results, production processes, and any deviations from standards. These documents provide insight into a supplier’s commitment to quality and can help identify any potential risks associated with sourcing from them.

Engaging Third-Party Inspections: What Are the Benefits?

Another approach is to engage third-party inspection services. These independent entities can provide unbiased assessments of a supplier’s manufacturing processes and quality control measures. This is particularly beneficial for international buyers who may not have the resources to conduct on-site inspections.

Illustrative image related to air filtration media

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

Regulatory Compliance: How Do Local Regulations Affect Quality Standards?

Different countries may have varying regulatory requirements for air filtration products. Buyers should ensure that suppliers comply with local regulations in their target markets, which may necessitate additional certifications or testing.

Cultural Differences: How Can Communication Impact Quality Assurance?

Cultural differences can also influence quality assurance practices. Effective communication is essential to ensure that expectations are clear and that suppliers understand the importance of adhering to quality standards. Establishing strong relationships with suppliers can facilitate better compliance and responsiveness to quality issues.

Illustrative image related to air filtration media

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Critical for B2B Buyers?

A comprehensive understanding of the manufacturing processes and quality assurance measures for air filtration media empowers B2B buyers to make informed sourcing decisions. By focusing on material preparation, forming techniques, assembly, and finishing, along with robust quality control practices, buyers can ensure they partner with reliable suppliers that meet their air quality needs. Ultimately, investing time in evaluating manufacturing and QC processes can lead to long-term success in achieving cleaner air and improved operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air filtration media’

To successfully procure air filtration media, international B2B buyers must navigate a complex landscape of technical requirements, supplier evaluations, and industry standards. This checklist serves as a practical guide to streamline the sourcing process, ensuring that buyers make informed decisions that align with their operational needs and regulatory requirements.

Step 1: Define Your Technical Specifications

Before engaging suppliers, it’s essential to establish clear technical specifications for the air filtration media you require. Consider factors such as the type of contaminants you need to filter (e.g., particulate matter, gaseous pollutants), required efficiency ratings (MERV ratings), and the physical dimensions of the filters. This initial step helps prevent miscommunication and ensures that suppliers can meet your specific needs.

Step 2: Research Regulatory Compliance Requirements

Understanding the regulatory landscape in your target region is crucial. Different countries and regions may have specific standards for air quality and filtration efficiency. Familiarize yourself with local regulations, such as those set by ASHRAE or EPA guidelines, to ensure that the products you procure are compliant. This knowledge will protect your business from potential legal issues and enhance your reputation as a responsible buyer.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Look for established manufacturers with a solid track record in air filtration. Request company profiles, case studies, and references from buyers in similar industries or regions. Consider supplier certifications, such as ISO 9001 or environmental standards, to ensure they adhere to industry best practices.

Step 4: Assess Product Quality and Innovation

Quality and innovation are paramount in air filtration media. Investigate the materials used in the products, such as the presence of recycled content or the absence of harmful chemicals. Suppliers that offer advanced technologies, like electret-charged media or activated carbon filters, may provide better filtration efficiency and longer service life, thus reducing overall operational costs.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the filtration media for testing. This step allows you to evaluate the performance of the media in real-world conditions specific to your application. Conduct tests for efficiency, pressure drop, and lifespan to ensure that the product meets your operational standards and expectations.

Step 6: Consider Logistics and Lead Times

Evaluate the supplier’s logistics capabilities, including lead times for production and shipping. In regions like Africa and South America, where supply chains can be unpredictable, it’s vital to ensure that your supplier can meet your delivery timelines. Clarify shipping terms and costs upfront to avoid unexpected expenses or delays.

Illustrative image related to air filtration media

Step 7: Negotiate Terms and Finalize the Purchase

Once you’ve selected a supplier, negotiate terms that reflect your purchasing power. Discuss pricing, payment terms, and warranties or service agreements. Ensure all aspects of the agreement are documented to protect both parties and facilitate a smooth transaction.

By following this checklist, B2B buyers can effectively navigate the sourcing process for air filtration media, ensuring that they select the right products and suppliers to meet their operational requirements while adhering to regional standards.

Comprehensive Cost and Pricing Analysis for air filtration media Sourcing

What Are the Key Cost Components in Air Filtration Media Sourcing?

When sourcing air filtration media, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of filtration media significantly affects pricing. For instance, activated carbon and HEPA materials tend to be more expensive due to their advanced filtration capabilities. The use of recycled polymers can offer cost advantages while meeting environmental standards.

-

Labor: Manufacturing air filtration media involves skilled labor, particularly when producing high-efficiency filters that require precision. Labor costs can vary significantly based on the location of the manufacturing facility.

-

Manufacturing Overhead: This encompasses costs related to factory operations, utilities, and equipment maintenance. Facilities that use advanced technology or automation may have higher initial overhead but can offer cost efficiencies in the long run.

-

Tooling: Custom tooling for specific filter designs or sizes can add to upfront costs. Buyers should consider whether a supplier has the capacity to meet their specific requirements without excessive tooling expenses.

-

Quality Control (QC): Ensuring the filters meet industry standards involves rigorous testing, which can increase costs. Suppliers with ISO certifications or similar quality standards may charge a premium, but this investment can lead to better reliability and performance.

-

Logistics: Shipping costs can vary widely depending on the origin of the materials, destination, and chosen Incoterms. Buyers should account for potential tariffs, customs duties, and the cost of freight when budgeting.

-

Margin: Supplier profit margins can fluctuate based on competition, market demand, and the perceived value of their products. Understanding the supplier’s positioning in the market can aid in negotiations.

How Do Price Influencers Affect Air Filtration Media Costs?

Several factors influence the pricing of air filtration media, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can yield significant discounts. Suppliers often offer tiered pricing models, making it beneficial for larger orders.

-

Specifications and Customization: Custom-designed filters tailored to specific applications may incur additional costs. Buyers should weigh the need for customization against standard options to optimize spending.

-

Materials and Quality Certifications: Higher-grade materials and certifications (e.g., MERV ratings, ISO certifications) typically command higher prices. However, these certifications often translate to better performance and longer lifespans, impacting the total cost of ownership.

-

Supplier Factors: Supplier reputation and reliability can influence pricing. Established suppliers with a proven track record may charge more, but the assurance of quality and service can justify the higher costs.

-

Incoterms: The choice of Incoterms can significantly affect the total landed cost. Buyers should be aware of the implications of different terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), as these will dictate who bears the shipping risk and costs.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of Air Filtration Media?

To achieve cost efficiency when sourcing air filtration media, consider these actionable tips:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Leverage your purchasing power, especially if you represent a large organization or have potential for repeat business.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate factors such as longevity, maintenance costs, and energy efficiency of the filters, which can impact overall expenses.

-

Understand Pricing Nuances for International Transactions: Buyers from Africa, South America, the Middle East, and Europe should consider currency fluctuations, local regulations, and potential trade barriers that could affect pricing and availability.

-

Stay Informed on Market Trends: Awareness of changes in material costs, regulatory requirements, and technological advancements can provide leverage in negotiations and sourcing strategies.

-

Build Strong Relationships: Establishing long-term partnerships with suppliers can lead to better pricing, priority service, and collaborative problem-solving.

Disclaimer: The prices mentioned in sources are indicative and may vary based on specific requirements, market conditions, and supplier negotiations. Always conduct thorough market research and supplier evaluations to ensure optimal sourcing decisions.

Alternatives Analysis: Comparing air filtration media With Other Solutions

Introduction to Alternative Solutions for Air Quality Management

In the quest for improved indoor air quality, businesses often explore various solutions to mitigate airborne contaminants. Air filtration media is a popular choice, but alternatives exist that may offer unique benefits or cost efficiencies. Understanding these alternatives can help international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Air Filtration Media | UV Air Purification | Electrostatic Air Cleaners |

|---|---|---|---|

| Performance | High efficiency (MERV ratings up to 16) | Effective against bacteria and viruses | Captures particles as small as 0.1 microns |

| Cost | Moderate initial investment; ongoing costs for replacements | Higher upfront costs; low ongoing maintenance | Moderate initial investment; low maintenance |

| Ease of Implementation | Relatively simple installation; integration with HVAC systems | Requires professional installation | Standalone units; easy to set up |

| Maintenance | Regular replacement needed (every 3-12 months) | Minimal maintenance; bulb replacement needed every year | Filter cleaning or replacement every 6-12 months |

| Best Use Case | Commercial buildings, industrial applications | Hospitals, clinics, and high-traffic areas | Residential and small commercial spaces |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of UV Air Purification?

UV air purification systems utilize ultraviolet light to deactivate airborne pathogens, offering an effective solution for reducing bacteria and viruses. The primary advantage of this technology is its ability to provide continuous disinfection without the need for consumables, resulting in low ongoing maintenance costs. However, the initial installation can be costly, and the effectiveness may diminish if the UV bulbs are not replaced regularly. This solution is ideal for environments requiring stringent air quality standards, such as hospitals and laboratories.

How Do Electrostatic Air Cleaners Work and What Are Their Pros and Cons?

Electrostatic air cleaners operate by charging particles in the air, causing them to adhere to plates within the unit. This technology is capable of capturing ultra-fine particles, including smoke and allergens, which makes it a strong candidate for residential and smaller commercial spaces. The advantages include lower energy consumption and less frequent filter replacements compared to traditional filters. However, they can require periodic cleaning of the collection plates, and their performance may vary based on humidity levels.

Conclusion: How Can B2B Buyers Choose the Right Air Quality Solution?

Selecting the appropriate air quality solution involves evaluating specific business needs, such as the types of contaminants present, budget constraints, and installation capabilities. Air filtration media remains a robust choice for many industries due to its high efficiency and effectiveness against particulate matter. However, for facilities focused on microbial control or those operating in high-traffic environments, UV air purification may be more suitable. Alternatively, electrostatic air cleaners offer flexibility and energy efficiency for smaller spaces. Ultimately, a thorough assessment of the operational environment and intended application will guide B2B buyers to the most effective air quality management solution.

Essential Technical Properties and Trade Terminology for air filtration media

What Are the Key Technical Properties of Air Filtration Media for B2B Buyers?

When selecting air filtration media, understanding its technical properties is crucial for ensuring optimal performance and compliance with industry standards. Here are several essential specifications to consider:

1. Material Grade

The material grade of air filtration media can significantly affect its durability and filtration efficiency. Common materials include synthetic fibers, activated carbon, and natural fibers. Each material has specific characteristics that determine its application suitability. For instance, activated carbon is excellent for adsorbing gaseous contaminants, while synthetic fibers may provide higher particulate removal efficiency. Understanding material grades helps buyers choose the right media that aligns with their air quality requirements.

2. Filtration Efficiency (MERV Rating)

The Minimum Efficiency Reporting Value (MERV) rating indicates how effectively a filter media can capture particles of varying sizes. MERV ratings range from 1 to 16, with higher numbers signifying better filtration capability. For businesses concerned with indoor air quality, selecting media with an appropriate MERV rating is critical, as it directly impacts the health and comfort of occupants. Higher-rated filters can trap smaller particles, including allergens and pollutants, which is especially important in regions with high air contamination levels.

3. Dust Holding Capacity

Dust holding capacity refers to the amount of particulate matter a filter can retain before it requires replacement. This specification is essential for determining maintenance schedules and operational costs. Filters with higher dust holding capacities can operate longer without frequent changes, resulting in lower maintenance costs and reduced downtime. Businesses should evaluate this property to optimize their filtration systems for efficiency and cost-effectiveness.

4. Temperature and Humidity Resistance

The ability of air filtration media to withstand varying temperature and humidity levels is vital, particularly in industrial settings or regions with extreme climates. Filters that can maintain performance under these conditions reduce the risk of media degradation and ensure consistent air quality. Buyers should assess the environmental conditions of their facilities and select media designed to handle those specific challenges.

5. Adsorption Capacity

For media designed to remove gaseous pollutants, such as activated carbon filters, adsorption capacity is a key specification. This property indicates how much gas the media can absorb before becoming saturated. In B2B applications where air quality is paramount, understanding adsorption capacity helps in selecting the right filter to effectively mitigate harmful gases and odors.

What Are Common Trade Terminology and Concepts Relevant to Air Filtration Media?

Familiarity with industry jargon can streamline the procurement process and enhance communication between buyers and suppliers. Here are several terms frequently encountered in the air filtration media market:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the air filtration sector, buyers may need to source media from OEMs to ensure compatibility with their existing systems. Understanding this term is essential for businesses looking to integrate new filtration solutions into their operations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and budgeting. Understanding the MOQ helps businesses plan their purchases and avoid excess inventory or stockouts.

Illustrative image related to air filtration media

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It typically outlines product specifications, quantities, and delivery terms. For B2B buyers, issuing RFQs can lead to competitive pricing and better supplier terms, making it a vital tool for procurement strategy.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border procurement of air filtration media, as they define shipping responsibilities, risk transfer, and cost allocation.

5. Lifecycle Cost

Lifecycle cost encompasses all costs associated with a product from acquisition through disposal, including initial purchase, installation, maintenance, and disposal costs. Understanding lifecycle costs allows buyers to make informed decisions that balance upfront expenses with long-term savings, particularly in air filtration systems where efficiency and durability can significantly impact operational costs.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the most suitable air filtration media for their specific needs and operational contexts.

Navigating Market Dynamics and Sourcing Trends in the air filtration media Sector

What Are the Current Market Dynamics and Key Trends in Air Filtration Media?

The global air filtration media market is experiencing significant growth, driven by increasing awareness of indoor air quality (IAQ) and stringent regulations aimed at improving environmental health. As emerging markets in Africa, South America, the Middle East, and Europe (including Vietnam and Brazil) develop, there is a heightened demand for advanced filtration solutions. Key trends include the adoption of smart filtration technologies, which integrate IoT capabilities to monitor air quality in real-time, and the growing preference for high-efficiency particulate air (HEPA) and activated carbon filters that cater to both commercial and residential applications.

International buyers are also witnessing a shift towards customizable filtration solutions that can be tailored to specific industrial needs. This trend is particularly relevant in sectors such as healthcare, manufacturing, and food processing, where air quality is critical. Additionally, the emphasis on sustainability is reshaping sourcing strategies, with buyers increasingly prioritizing suppliers that offer environmentally friendly products and practices. The rise of e-commerce platforms for filtration media procurement is also revolutionizing the market, enabling faster sourcing and competitive pricing.

How Does Sustainability and Ethical Sourcing Impact Air Filtration Media?

Sustainability and ethical sourcing are becoming paramount in the air filtration media sector. As environmental concerns grow, companies are under pressure to adopt practices that minimize their ecological footprint. The use of recycled materials in filter media, such as non-woven fabrics made from post-consumer plastics, is gaining traction. Additionally, suppliers that demonstrate compliance with green certifications, such as ISO 14001 or ENERGY STAR, are more appealing to international buyers focused on sustainability.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices to ensure that they are not only compliant with environmental regulations but also socially responsible. This includes fair labor practices and transparency in sourcing materials. Investing in sustainable air filtration solutions not only enhances corporate responsibility but also leads to long-term cost savings through improved efficiency and reduced waste.

Illustrative image related to air filtration media

What Is the Historical Context of Air Filtration Media Development?

The evolution of air filtration media dates back to the early 20th century, when basic fabric and mesh filters were used in industrial applications. The introduction of HEPA filters in the 1940s marked a significant advancement, especially in healthcare settings, where the need for clean air became critical. Over the decades, innovations such as electrostatic filters and activated carbon media have emerged, enhancing the efficiency of air filtration systems.

Today, the focus is on developing smart filtration technologies that incorporate digital monitoring and automation. This evolution reflects the growing recognition of indoor air quality as a vital component of public health, prompting continuous research and development in the air filtration media sector. As the industry adapts to modern challenges, including climate change and urbanization, the future promises even more sophisticated and sustainable filtration solutions that cater to diverse global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of air filtration media

-

How do I choose the right air filtration media for my application?

Choosing the appropriate air filtration media involves assessing your specific needs, including the types of contaminants present, airflow requirements, and regulatory standards. Start by identifying the MERV rating required for your facility; higher ratings filter smaller particles more effectively. Consider the filter’s material composition—like HEPA or activated carbon—as each offers unique benefits. Additionally, consult with suppliers who can provide data on filter performance, longevity, and maintenance requirements to ensure you select the best solution for your operational demands. -

What is the best filter media for industrial applications?

For industrial applications, high-efficiency particulate air (HEPA) filters are often the best choice due to their ability to capture 99.97% of particles as small as 0.3 microns. Activated carbon filters are also beneficial for removing gaseous contaminants and odors. The selection may vary depending on the specific industry; for example, food and beverage industries may require media that prevents microbial growth, while manufacturing plants may need robust filters that handle high dust loads. Always assess the specific environmental conditions and regulations relevant to your sector. -

What are the minimum order quantities (MOQ) for air filtration media?

Minimum order quantities (MOQ) for air filtration media can vary significantly between suppliers and product types. Generally, MOQs range from 100 to 1,000 square feet of media, depending on the customization and manufacturing processes involved. It’s essential to discuss your specific needs with potential suppliers to understand their MOQ policies. Some suppliers may offer flexibility for first-time buyers or bulk orders, so negotiating terms can be beneficial for cost-effective purchasing. -

How do I verify the credibility of an air filtration media supplier?

Verifying a supplier’s credibility involves several key steps. Start by researching their industry reputation through reviews and testimonials from other B2B buyers. Check for certifications relevant to air filtration standards, such as ISO or ASHRAE compliance. Additionally, request references and inquire about their production processes, quality control measures, and after-sales support. Attending industry trade shows can also provide insights into their operations and allow for direct communication with company representatives. -

What payment terms are typically offered by suppliers of air filtration media?

Payment terms in the air filtration media industry can vary widely, often influenced by the supplier’s policies and the buyer’s creditworthiness. Common terms include net 30 or net 60 days, meaning payment is due 30 or 60 days after invoice receipt. Some suppliers may offer discounts for early payment or require a deposit for large orders. It’s essential to negotiate terms that align with your cash flow needs while ensuring they are reasonable and competitive within the market. -

How can I ensure quality assurance in my air filtration media purchase?

To ensure quality assurance, request documentation of the supplier’s quality control processes, including any certifications like ISO 9001. Ask for product samples to evaluate performance metrics such as filtration efficiency and dust-holding capacity. Additionally, inquire about warranty policies and post-purchase support, including installation and maintenance services. Regular communication with the supplier about quality expectations and performance feedback can also help maintain high standards throughout the purchasing process. -

What logistics considerations should I be aware of when sourcing air filtration media internationally?

When sourcing air filtration media internationally, consider factors such as shipping costs, delivery times, and import/export regulations. Ensure the supplier can provide appropriate documentation, including certificates of origin and compliance with local regulations. Evaluate the logistics partners they work with to guarantee timely delivery and reliability. Additionally, assess the potential impact of customs duties and tariffs on your overall budget to avoid unexpected costs. -

Can I customize air filtration media to meet specific needs?

Yes, many suppliers offer customization options for air filtration media to meet unique application requirements. Customizations may include variations in size, thickness, material composition, and filtration efficiency ratings. Discuss your specific needs with potential suppliers, including performance goals and environmental conditions. A reputable supplier will work closely with you to develop a tailored solution that aligns with your operational objectives while ensuring compliance with industry standards.

Top 8 Air Filtration Media Manufacturers & Suppliers List

1. Filtra Supply – Activated Carbon Charcoal Replacement

Domain: filtrasupply.com

Registered: 2018 (7 years)

Introduction: {“products”:[{“name”:”Activated Carbon Charcoal Replacement, 30 Lbs for Air Cleaners”,”sale_price”:”$125.00″,”regular_price”:”$175.00″,”weight”:”30 lbs”},{“name”:”TRION 55900-0004-01 Activated Carbon Charcoal Replacement, 30 Lbs”,”sale_price”:”$115.90″,”regular_price”:”$240.00″,”weight”:”30 lbs”}],”applications”:[“Air Filtration”,”Fume”,”Odor”,”Oil Mist”,”Welding Fume”],”OEMs”:[“Aercology”,”Trion”…

2. Clean Comfort – AM13 Media Air Cleaner

Domain: cleancomfort.com

Registered: 2001 (24 years)

Introduction: Clean Comfort offers a range of Media Air Cleaners including the CleanFit series with MERV 13 and MERV 11 ratings. Key products include: 1. AM13 – MERV 13 media air cleaner designed to match original equipment furnace and air handler cabinets. 2. AM11-CleanFit – MERV 11 media air cleaner with similar design features. 3. AMB11-Builder – MERV 11 media air cleaner suitable for vertical or horizontal …

3. McMaster – Filter Media Solutions

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Filter Media Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Camfil – Premium Clean Air Solutions

Domain: cleanair.camfil.us

Registered: 2002 (23 years)

Introduction: Camfil is a leading manufacturer of premium clean air solutions, providing commercial and industrial systems for air filtration and air pollution control. Key product details include: 1. Filter Media: Typically a non-woven fabric that separates and holds contaminants as air passes through. 2. HEPA Filter: Must remove 99.97% of particles with a diameter of 0.3 microns. 3. MERV Ratings: Filters are …

5. KC Professional – High Efficiency Air Filtration Media

Domain: kcprofessional.com

Registered: 2001 (24 years)

Introduction: This company, KC Professional – High Efficiency Air Filtration Media, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Air Filter USA – Air Filter Media Rolls & Bulk

Domain: airfilterusa.com

Registered: 2000 (25 years)

Introduction: Air Filter Media – Rolls & Bulk Material

– Made in the USA

– Stock and Custom Filters Available

– Size Options: 1″, 2″, and 4″ AIR FILTERS with various dimensions (e.g., 10 X 10 X 1″, 12 X 20 X 2″, 16 X 25 X 4″)

– Types of Air Filter Media:

– Synthetic / Polyester: 100% non-woven polyester fibers, available in single or multi-ply grades.

– Fiberglass: Continuous filament fiberglass with gradua…

7. Ahlstrom – High Efficiency Air Filter Media

Domain: ahlstrom.com

Registered: 1993 (32 years)

Introduction: HVAC and High Efficiency Air filter media for industrial applications, including gas turbine filter media, air oil separation media, and air pollution control. Designed for high efficiency in air filtration systems.

8. Koch Filter – Panel Air Filter 25 Wide

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, Koch Filter – Panel Air Filter 25 Wide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for air filtration media

What Are the Key Insights for Strategic Sourcing in Air Filtration Media?

In today’s global landscape, the demand for high-quality air filtration media has surged, driven by heightened awareness of indoor air quality and health concerns. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of air filtration solutions is essential. Buyers should focus on identifying suppliers that offer advanced technologies, such as activated carbon filters and HEPA filtration, which significantly enhance air quality. Understanding the MERV ratings and the efficiency of various filter types will also aid in making informed purchasing decisions.

How Can Effective Sourcing Impact Your Business Operations?

By prioritizing reliable sourcing strategies, businesses can optimize operational efficiency, reduce downtime, and minimize costs associated with air filtration systems. Engaging with reputable manufacturers that emphasize sustainability and innovation—like those utilizing recycled materials and chemical-free processes—can lead to both environmental and economic benefits.

What Should International Buyers Consider Moving Forward?

As the market evolves, staying informed about emerging trends and technologies in air filtration will be crucial. Buyers are encouraged to foster partnerships with manufacturers who demonstrate a commitment to quality and customer service. As we look to the future, investing in superior air filtration media is not just a choice; it’s a necessity for safeguarding public health and enhancing overall operational performance. Take action today to secure the best air filtration solutions for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.