Unlocking Value: A Strategic Analysis of the The Hose Man Market

Introduction: Navigating the Global Market for the hose man

Navigating the global market for hydraulic hoses and fittings can be a daunting task for B2B buyers, particularly when it comes to sourcing high-quality products that meet specific operational needs. The challenge lies not only in identifying the right suppliers but also in ensuring that the products are durable, reliable, and compliant with industry standards. This guide is designed to equip international buyers—especially from regions such as Africa, South America, the Middle East, and Europe—with the insights necessary to make informed purchasing decisions.

In this comprehensive resource, we delve into various types of hoses including hydraulic, pneumatic, food service, and industrial applications. We will explore critical factors for supplier vetting, from assessing quality assurance processes to understanding pricing structures and delivery timelines. Additionally, we will provide actionable tips for customization options, ensuring you find hoses that fit your unique requirements.

By leveraging this guide, B2B buyers can navigate the complexities of the hose market with confidence, minimizing risks and optimizing operational efficiency. Whether you are in Nigeria, Brazil, or any other global market, you will gain the knowledge needed to select the right hose solutions that drive your business forward.

Understanding the hose man Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Hoses | High-pressure tolerance, durable materials, and custom lengths | Construction, manufacturing, automotive | Pros: Excellent strength and flexibility; Cons: Can be expensive, requires proper maintenance. |

| Pneumatic Hoses | Lightweight, flexible, designed for air and gas applications | Manufacturing, packaging, automotive assembly | Pros: Easy to handle and install; Cons: Limited pressure ratings compared to hydraulic hoses. |

| Food Service Hoses | Compliant with food safety standards, resistant to chemicals | Food processing, beverage production | Pros: Ensures safety and hygiene; Cons: Can be pricier due to compliance standards. |

| Industrial Hoses | Versatile, suitable for various fluids, abrasion-resistant | Agriculture, chemical handling, general industry | Pros: Wide range of applications; Cons: May require specific fittings for compatibility. |

| Specialty Hoses | Customizable for unique applications, designed for specific fluids | Oil and gas, pharmaceuticals, unique industrial uses | Pros: Tailored solutions for complex needs; Cons: Longer lead times for production. |

What Are Hydraulic Hoses and Their B2B Relevance?

Hydraulic hoses are designed to handle high-pressure applications, making them essential in industries such as construction, manufacturing, and automotive. They are typically made from robust materials that withstand harsh environments and heavy loads. When purchasing hydraulic hoses, businesses should consider factors such as pressure ratings, compatibility with hydraulic fluids, and custom length requirements to ensure optimal performance and safety.

How Do Pneumatic Hoses Differ in Applications?

Pneumatic hoses are primarily used to transport compressed air or gases, making them ideal for applications in manufacturing and packaging. They are lighter and more flexible than hydraulic hoses, which facilitates easier installation and movement. Buyers should focus on the hose’s pressure rating and diameter, as these factors significantly influence performance in pneumatic systems.

Why Are Food Service Hoses Critical for Compliance?

Food service hoses are specifically engineered to meet stringent food safety standards, ensuring that they do not contaminate food or beverages. These hoses are often made from materials that can withstand various cleaning agents and temperatures. B2B buyers in the food processing and beverage industries must prioritize compliance with health regulations, which can affect purchasing decisions and overall operational safety.

What Makes Industrial Hoses Versatile for Various Industries?

Industrial hoses are designed for a wide range of applications, from agriculture to chemical handling. Their ability to transport different types of fluids while resisting abrasion makes them a versatile choice for many sectors. When selecting industrial hoses, businesses should evaluate the specific fluids they will be handling, as well as the environmental conditions to ensure the longevity and reliability of the hoses.

How Can Specialty Hoses Address Unique Needs?

Specialty hoses are customized to meet specific requirements, whether for unique fluids or particular environmental conditions. They are particularly valuable in industries like oil and gas or pharmaceuticals, where standard hoses may not suffice. When considering specialty hoses, B2B buyers should account for lead times for customization, as well as the specific performance standards necessary for their unique applications.

Key Industrial Applications of the hose man

| Industry/Sector | Specific Application of the hose man | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom hydraulic hoses for machinery | Enhanced operational efficiency and reduced downtime | Quality materials, pressure ratings, and customization options |

| Construction | High-pressure hoses for concrete pumping | Improved project timelines and safety in heavy-duty applications | Durability, abrasion resistance, and local regulatory compliance |

| Food and Beverage | Food-grade hoses for liquid transport | Compliance with health standards and prevention of contamination | Certifications, material compatibility, and cleaning protocols |

| Oil and Gas | Hoses for fluid transfer in extraction processes | Increased reliability and safety in hazardous environments | Temperature ratings, chemical compatibility, and testing standards |

| Agriculture | Irrigation and chemical application hoses | Enhanced crop yield and efficient resource management | Resistance to environmental factors and flexibility in design |

How Are Custom Hydraulic Hoses Used in Manufacturing?

In the manufacturing sector, custom hydraulic hoses play a critical role in powering machinery and equipment. They are designed to handle high pressure and are tailored to specific machinery requirements, ensuring optimal performance. International buyers, particularly from regions like Africa and South America, must consider factors such as pressure ratings, hose length, and fitting types to prevent operational failures. The ability to customize hoses ensures that manufacturers can maintain efficiency and minimize downtime, leading to significant cost savings.

What Role Do High-Pressure Hoses Play in Construction?

High-pressure hoses are essential in the construction industry, especially for applications like concrete pumping. These hoses must withstand extreme pressures and are often exposed to harsh conditions, making durability a key requirement. Buyers in regions like the Middle East, where construction is booming, need to ensure that the hoses meet local safety standards and can handle the specific demands of their projects. By sourcing high-quality hoses, companies can improve project timelines and enhance safety measures on-site.

Why Are Food-Grade Hoses Crucial in the Food and Beverage Industry?

In the food and beverage industry, using food-grade hoses is imperative for the safe transport of liquids. These hoses must comply with stringent health regulations to prevent contamination during the transfer of food products. International buyers, particularly from Europe and Africa, should look for hoses that are certified for food safety and constructed from materials that withstand cleaning processes. By investing in high-quality food-grade hoses, businesses can ensure compliance and protect their reputation in the market.

How Do Hoses Contribute to Safety in Oil and Gas Operations?

In the oil and gas sector, hoses are vital for the safe transfer of fluids during extraction processes. These hoses must be capable of handling high temperatures and resist corrosive substances, making sourcing critical. Buyers must pay attention to industry standards and certifications to ensure reliability in hazardous environments. Properly sourced hoses enhance operational safety, reduce the risk of leaks, and ensure compliance with environmental regulations, thus protecting both personnel and the environment.

What Benefits Do Irrigation Hoses Provide to Agriculture?

Irrigation and chemical application hoses are essential for efficient agricultural practices. These hoses facilitate the timely delivery of water and fertilizers, significantly impacting crop yield. Buyers, especially in regions like Brazil and Africa where agriculture is a primary industry, should focus on hoses that are resistant to UV rays and weather conditions. By sourcing hoses designed for durability and flexibility, agricultural businesses can optimize their resource management and enhance productivity, leading to better economic outcomes.

Illustrative image related to the hose man

3 Common User Pain Points for ‘the hose man’ & Their Solutions

Scenario 1: Sourcing Customized Hoses for Unique Applications

The Problem: B2B buyers often struggle to find hoses that meet specific requirements for unique applications. For instance, in industries like food and beverage or oil and gas, certain environmental factors and pressure ratings are critical. A buyer may find generic hoses that do not meet their precise specifications, leading to potential downtime, safety hazards, and costly replacements. This frustration is compounded by the lack of clear information on customization options available from suppliers.

The Solution: To overcome this challenge, buyers should engage directly with the Hose-Man’s experienced team to discuss their unique requirements. Begin by outlining the specific conditions under which the hoses will operate—this includes the type of fluids, temperature ranges, and pressure ratings. Use the consultation services offered to obtain expert advice on the best materials and designs. Additionally, consider utilizing Hose-Man’s custom fabrication services to create hoses tailored precisely to your specifications. This proactive approach ensures that the hoses will not only fit seamlessly into your operations but also enhance overall efficiency and safety.

Scenario 2: Ensuring Quick Turnaround Times for Urgent Orders

The Problem: In fast-paced industries like construction and manufacturing, delays in hose supply can lead to significant project delays and increased costs. Buyers often encounter long lead times when ordering hoses, particularly when they require custom solutions. This can create a bottleneck in operations, especially if machinery is rendered inoperable due to faulty or outdated hoses.

The Solution: To mitigate this issue, buyers should communicate their urgency clearly when placing orders. Utilize Hose-Man’s express service, which offers on-site assembly and quick turnaround options for urgent requests. Additionally, maintaining a stock of commonly used hoses and fittings can prevent downtime in critical operations. By establishing a reliable relationship with Hose-Man and setting up a scheduled maintenance and reorder plan, buyers can ensure they have the necessary hoses available when needed, reducing the risk of project delays.

Scenario 3: Navigating Complex Hose Fittings and Accessories

The Problem: Selecting the appropriate hose fittings and accessories can be a complex process that many B2B buyers find overwhelming. Inadequate fittings can lead to leaks, inefficiencies, and safety hazards. Buyers often lack the technical knowledge to make informed decisions regarding the compatibility of materials, pressure ratings, and environmental conditions, leading to costly mistakes.

The Solution: To navigate this complexity, buyers should leverage Hose-Man’s expert consultation services. Schedule a consultation to discuss the specific applications and conditions the hoses will face. The knowledgeable team can provide insights into material compatibility, correct sizing, and configuration options. Furthermore, requesting a checklist of essential factors to consider when choosing fittings can serve as a valuable resource during the selection process. By taking advantage of these resources and guidance, buyers can confidently select the right fittings and accessories, ensuring optimal performance and safety in their operations.

Strategic Material Selection Guide for the hose man

What Are the Key Properties of Common Hose Materials?

When selecting hose materials, it’s crucial to understand their properties, as these directly influence performance in various applications. Below, we analyze four common materials used in hose manufacturing: rubber, PVC, polyurethane, and stainless steel.

Rubber Hoses: Versatile and Resilient

Rubber hoses are renowned for their flexibility and resistance to abrasion, making them suitable for a wide range of applications, including hydraulic systems and food service. Key properties include a high-temperature rating (up to 120°C) and excellent pressure ratings (up to 300 PSI).

Pros: Rubber hoses are durable and can withstand harsh environmental conditions. They are also cost-effective and easy to manufacture, making them a popular choice for many industries.

Cons: However, rubber can degrade over time when exposed to certain chemicals and UV light, leading to potential failures. Additionally, they may require more frequent replacement compared to other materials.

Impact on Application: Rubber hoses are compatible with various media, including water, oils, and air, but caution is needed with aggressive chemicals.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO certifications, to guarantee quality and safety.

Illustrative image related to the hose man

PVC Hoses: Cost-Effective and Lightweight

Polyvinyl Chloride (PVC) hoses are lightweight and flexible, ideal for applications in agriculture and construction. They typically have a temperature rating of up to 60°C and can handle pressures up to 150 PSI.

Pros: PVC hoses are generally less expensive than rubber hoses and are resistant to corrosion and chemical degradation, making them suitable for various fluids.

Cons: Their flexibility can be a drawback in high-pressure applications, and they may become brittle in extreme temperatures, limiting their use.

Impact on Application: PVC hoses are excellent for water, chemicals, and air but may not be suitable for high-temperature applications.

Considerations for International Buyers: Buyers should be aware of local regulations regarding plastic materials, especially in the food industry, where compliance with standards like FDA or EU regulations is essential.

Polyurethane Hoses: Durable and Flexible

Polyurethane hoses offer a unique combination of flexibility and durability, making them suitable for a range of applications, including pneumatic systems and automotive uses. They can handle temperatures up to 80°C and pressures of around 200 PSI.

Pros: These hoses are highly resistant to abrasion and tearing, making them long-lasting. They also maintain their flexibility in cold temperatures, which is beneficial for outdoor applications.

Cons: Polyurethane hoses can be more expensive than rubber or PVC, and their chemical resistance is not as extensive, limiting their use with certain solvents.

Impact on Application: They are compatible with air, water, and some chemicals, but users should verify compatibility with specific media.

Considerations for International Buyers: Buyers should check for compliance with international standards and certifications, especially in industries like automotive and manufacturing where quality assurance is critical.

Stainless Steel Hoses: High-Performance and Corrosion-Resistant

Stainless steel hoses are designed for high-pressure applications and extreme environments, often used in the oil and gas industry. They can withstand temperatures exceeding 200°C and high-pressure ratings, making them ideal for demanding applications.

Pros: Their durability and corrosion resistance make them suitable for harsh chemicals and extreme temperatures. They also have a long lifespan, reducing the need for frequent replacements.

Cons: The primary drawback is their high cost and complexity of manufacturing, which can make them less accessible for smaller businesses.

Impact on Application: Stainless steel hoses are compatible with a wide range of media, including corrosive chemicals, but their rigidity may limit flexibility in certain applications.

Considerations for International Buyers: Compliance with industry standards (such as ASME or ASTM) is critical, particularly in sectors like oil and gas, where safety and reliability are paramount.

Summary Table of Hose Materials

| Material | Typical Use Case for the hose man | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Hydraulic systems, food service | Durable and flexible | Degrades under UV and chemicals | Low |

| PVC | Agriculture, construction | Cost-effective and lightweight | Brittle in extreme temperatures | Low |

| Polyurethane | Pneumatic systems, automotive | Highly abrasion-resistant | Higher cost, limited chemical use | Med |

| Stainless Steel | Oil and gas, high-pressure systems | Excellent durability and corrosion resistance | High cost and manufacturing complexity | High |

This guide serves as a foundational resource for B2B buyers navigating the complexities of hose material selection, ensuring informed decisions that align with their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for the hose man

What Are the Main Stages in the Manufacturing Process for High-Quality Hoses?

The manufacturing process for hoses, particularly for B2B applications, involves several critical stages that ensure the final product meets the rigorous demands of various industries. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial phase involves selecting high-quality raw materials, such as rubber compounds, thermoplastics, and reinforcing fibers. These materials are assessed for their physical properties to ensure they meet the specific requirements of the intended application, including temperature resistance, flexibility, and chemical compatibility.

-

Forming: In this stage, the prepared materials are shaped into hose structures. Various techniques are employed, such as extrusion, which allows for the continuous production of hose lengths, and molding, which is often used for creating specific fittings and couplings. Advanced machinery ensures precise dimensions and consistent wall thickness, which are critical for the hose’s performance.

-

Assembly: Once the hoses are formed, they undergo an assembly process where fittings and couplings are attached. This step may also include the installation of additional components like protective sleeves or outer layers that enhance durability. Skilled technicians ensure that all connections are secure and meet the specified standards.

-

Finishing: The final stage focuses on the application of surface treatments and the final inspection of the hoses. This may involve cleaning, marking, and packaging the hoses for shipment. Finishing processes may also include the application of coatings that improve resistance to environmental factors, enhancing the hose’s longevity and reliability.

How Is Quality Assurance Integrated Into Hose Manufacturing Processes?

Quality assurance (QA) is paramount in the hose manufacturing process to ensure that every product delivered meets international and industry-specific standards. Key components of the QA process include adherence to standards like ISO 9001, CE, and API, which guide the quality management systems in place.

-

International Standards: Compliance with ISO 9001 ensures that the manufacturer has a robust quality management system that focuses on customer satisfaction and continuous improvement. CE marking indicates conformity with health, safety, and environmental protection standards set by the European Union, while API standards are crucial for products used in the oil and gas industry.

-

Quality Control Checkpoints: Quality control is integrated at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify that they meet the required specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from established standards. This ensures that any issues are addressed immediately, minimizing waste and rework.

– Final Quality Control (FQC): Before shipment, each hose undergoes rigorous testing to ensure it meets performance and safety standards. This may include pressure testing, dimensional checks, and visual inspections. -

Common Testing Methods: Various testing methods are employed to verify the quality of hoses:

– Hydrostatic Testing: This method assesses the hose’s ability to withstand pressure without leaking or bursting.

– Temperature and Flexibility Tests: Hoses are subjected to extreme temperatures and bending to ensure they maintain structural integrity under operational conditions.

– Chemical Compatibility Testing: Hoses are tested against various chemicals to ensure they will not degrade or fail in service.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing hoses from international suppliers, especially for businesses in Africa, South America, the Middle East, and Europe, it’s crucial to verify the quality control practices of potential partners. Here are several strategies to ensure suppliers meet your quality expectations:

Illustrative image related to the hose man

-

Conduct Audits: Regular audits can provide insights into the supplier’s manufacturing processes and quality control systems. Buyers should request access to audit reports from third-party organizations that assess compliance with international standards.

-

Request Documentation: Suppliers should be able to provide documentation that outlines their quality assurance processes. This includes certifications (e.g., ISO, CE) and test reports for the hoses they manufacture. Buyers should seek clarity on the specific tests conducted and their results.

-

Third-Party Inspections: Engaging third-party inspection services can help verify that the hoses meet specified standards before shipment. This adds an additional layer of assurance, particularly for buyers in regions where quality may vary significantly.

-

Establish Clear Communication: Open lines of communication with suppliers can facilitate discussions about quality expectations and any concerns that may arise. Buyers should inquire about the supplier’s approach to quality issues and how they handle non-conformities.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly in developing markets, face unique challenges and considerations regarding quality control in hose manufacturing. Understanding these nuances can help mitigate risks associated with sourcing products from abroad.

-

Local Regulations: Different regions may have varying regulations concerning product safety and quality. Buyers must familiarize themselves with local compliance requirements to ensure that the hoses meet the necessary standards in their market.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chain. This includes knowledge of where raw materials are sourced and how they are processed. Transparency can be a strong indicator of quality and ethical practices.

-

Cultural Considerations: Understanding cultural nuances in communication and business practices can enhance the relationship between buyers and suppliers. This can lead to more effective negotiations and a better understanding of quality expectations.

-

Long-Term Partnerships: Establishing long-term relationships with reliable suppliers can foster better quality control over time. As trust builds, suppliers may be more inclined to prioritize quality and proactively address any issues that arise.

By comprehensively understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they receive high-quality hoses that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘the hose man’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring hoses and related products from suppliers like ‘the hose man’. With a focus on quality, customization, and reliability, this checklist will help you navigate the essential steps to ensure you select the right partner for your hose needs.

Step 1: Define Your Technical Specifications

Clearly articulating your technical requirements is critical for successful procurement. Specify the types of hoses you need (e.g., hydraulic, pneumatic, industrial), including pressure ratings, sizes, and material compatibility. This clarity will streamline communication with suppliers and ensure they can meet your exact needs.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reputation and capabilities. Look for companies with a robust portfolio, client testimonials, and industry certifications. Utilize resources such as trade publications, online reviews, and industry forums to gather insights about their reliability and service quality.

Step 3: Evaluate Supplier Customization Capabilities

Customization is often necessary for specialized applications. Assess whether the supplier can tailor hoses to your specific requirements, including custom lengths, fittings, and materials. This flexibility can significantly enhance the performance and longevity of the hoses in your operations.

Step 4: Verify Quality Assurance Processes

Quality should be a non-negotiable aspect of your procurement process. Inquire about the supplier’s quality assurance protocols, including material sourcing, manufacturing processes, and testing procedures. Ensure that their products meet international standards and are backed by certifications to mitigate risks associated with subpar materials.

Step 5: Request Samples and Prototypes

Before making a large-scale purchase, request samples or prototypes of the hoses you intend to buy. Testing these samples in your operational environment will allow you to evaluate their performance under real conditions. Look for aspects such as flexibility, durability, and compatibility with existing systems.

Step 6: Assess Customer Support and Service

Robust customer support is essential for ongoing maintenance and troubleshooting. Evaluate the supplier’s responsiveness and willingness to provide technical assistance, installation support, and after-sales service. A dedicated support team can save you time and resources in the long run.

Step 7: Review Pricing and Payment Terms

Finally, analyze the pricing structure and payment terms offered by the suppliers. While cost is a crucial factor, it should not be the only consideration. Look for competitive pricing that aligns with the quality of the products offered, and ensure payment terms are manageable for your business’s cash flow.

By following this step-by-step checklist, you can make informed decisions and establish a reliable sourcing strategy for your hose requirements, ensuring that your operations run smoothly and efficiently.

Comprehensive Cost and Pricing Analysis for the hose man Sourcing

What Are the Key Cost Components Influencing Hose Pricing?

When analyzing the cost structure for sourcing hoses from suppliers like Hose-Man, several components come into play. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. High-quality rubber, plastics, and metal fittings are essential for ensuring durability and performance. Suppliers often source materials from different regions, which can affect pricing based on local availability and market conditions.

-

Labor: Skilled labor is necessary for the production and assembly of hoses. Labor costs vary by region; for instance, sourcing from countries with lower labor costs might reduce overall expenses but could impact quality.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, which, in turn, can lower prices.

-

Tooling: Customization often requires specific tooling or molds, which adds to the initial costs. These expenses are typically amortized over the production volume, affecting the price per unit.

-

Quality Control (QC): Rigorous testing and inspection processes ensure that hoses meet industry standards. While this adds to costs, it ultimately protects buyers by reducing the risk of product failure.

-

Logistics: Transportation costs, including shipping and handling, can vary significantly based on the destination and the chosen Incoterms. Efficient logistics management can mitigate costs but may also require investment in reliable partners.

-

Margin: Suppliers will include a profit margin in their pricing, which is influenced by market demand, competition, and the perceived value of their products.

How Do Price Influencers Affect Hose Sourcing Costs?

Several factors can influence the pricing of hoses, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from bulk pricing, reducing the cost per unit. Buyers should negotiate MOQs to ensure they are getting the best value for their needs.

-

Specifications and Customization: Custom hoses with specific requirements generally incur higher costs due to the need for specialized materials and tooling. Clearly defining specifications upfront can help avoid unexpected costs later in the process.

-

Quality and Certifications: Hoses that meet international quality standards or have certifications may command higher prices. However, investing in quality can lead to long-term savings by reducing maintenance and replacement costs.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a track record of quality may charge more, but they can also provide peace of mind and assurance of product performance.

-

Incoterms: Understanding shipping terms is crucial for international transactions. Different Incoterms can shift responsibilities and costs between buyers and sellers, impacting the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency in Hose Sourcing?

To maximize cost-efficiency when sourcing hoses, international B2B buyers should consider the following strategies:

-

Effective Negotiation: Engage in open discussions with suppliers about pricing and payment terms. Building a long-term relationship can lead to better deals and preferential pricing.

-

Total Cost of Ownership (TCO): When evaluating suppliers, consider not just the initial price but the total cost of ownership, including maintenance, downtime, and replacement costs. High-quality hoses may have a higher upfront price but offer significant savings over time.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and potential tariffs. Understanding these factors can help in budgeting and cost forecasting.

-

Requesting Indicative Prices: Always ask for indicative pricing before committing to an order. This can provide a benchmark for evaluating different suppliers and ensure you are making informed decisions.

Conclusion

Sourcing hoses requires a comprehensive understanding of cost components and pricing influencers. By leveraging effective negotiation strategies and considering the total cost of ownership, B2B buyers can secure the best deals while ensuring they meet their operational needs. Remember, prices can vary widely based on numerous factors, so it’s essential to conduct thorough research and engage in open dialogue with suppliers to achieve optimal outcomes.

Alternatives Analysis: Comparing the hose man With Other Solutions

Understanding Alternatives in Hose Solutions

In the competitive landscape of hydraulic and industrial hoses, businesses have various options to meet their unique needs. Evaluating alternatives can help buyers identify solutions that align best with their operational requirements, budget constraints, and performance expectations. In this section, we will compare ‘The Hose Man’ with two viable alternatives: Custom Hose Fabrication and Off-the-Shelf Hose Products.

Comparison Table

| Comparison Aspect | ‘The Hose Man’ | Custom Hose Fabrication | Off-the-Shelf Hose Products |

|---|---|---|---|

| Performance | High-quality, tailored hoses for specific needs | Exceptional performance; fully customized | Standard performance; may not fit all needs |

| Cost | Competitive pricing with value for quality | Potentially higher due to customization | Generally lower cost due to mass production |

| Ease of Implementation | Quick turnaround for custom orders | Longer lead times due to design and fabrication | Instant availability; easy to source |

| Maintenance | Requires regular checks, but durable | Durability varies by material; regular checks needed | Varies by product; may have limited lifespan |

| Best Use Case | Specialized applications across various industries | Unique or demanding applications needing precision | General applications with standard specifications |

Detailed Breakdown of Alternatives

Custom Hose Fabrication

Custom hose fabrication offers a tailored solution for businesses that require hoses designed to meet specific operational demands. The primary advantage of this approach is its ability to provide exceptional performance through bespoke designs. However, the process can be time-consuming and may incur higher costs due to the intricacies of custom production. Businesses with unique requirements, such as high-pressure or specialty applications, will benefit the most from this option.

Off-the-Shelf Hose Products

Off-the-shelf hose products are readily available and typically come at a lower price point compared to custom solutions. They provide convenience and quick access for businesses that need standard hoses for general applications. However, the downside is that these products may not meet specific needs, leading to potential inefficiencies or failures in demanding environments. Companies looking for a quick fix without specialized requirements may find this option appealing, but they should be cautious about the long-term implications.

Conclusion: How to Choose the Right Hose Solution for Your Business

Selecting the right hose solution requires a careful assessment of your business’s specific needs. Factors such as performance requirements, budget, and the urgency of implementation play crucial roles in this decision-making process. ‘The Hose Man’ offers a balanced approach, delivering customized quality with competitive pricing. In contrast, custom hose fabrication is ideal for specialized applications while off-the-shelf products may suit businesses with less demanding requirements. Ultimately, understanding the pros and cons of each alternative will empower B2B buyers to make informed choices that enhance operational efficiency and reliability.

Essential Technical Properties and Trade Terminology for the hose man

What Are the Key Technical Properties of Hoses in B2B Applications?

Understanding the technical properties of hoses is vital for B2B buyers, especially when selecting products that will be subjected to various operational stresses. Here are several critical specifications to consider:

1. Material Grade

Hoses are constructed from various materials, including rubber, PVC, and thermoplastics. The material grade affects durability, flexibility, and resistance to environmental factors such as UV light, chemicals, and abrasion. For instance, hoses made from high-grade rubber can withstand higher pressures and are more resilient in harsh conditions, making them suitable for demanding applications in industries like oil and gas.

2. Pressure Rating

The pressure rating indicates the maximum pressure a hose can handle safely. It is crucial for ensuring the hose performs effectively without risk of failure. In B2B settings, selecting a hose with an appropriate pressure rating is essential to prevent leaks or bursts, which can lead to costly downtime and safety hazards.

3. Temperature Range

Each hose material has a specific temperature range it can endure. Understanding this range is critical for applications involving hot or cold fluids. For example, hoses used in food service must maintain structural integrity at high temperatures, whereas those used in refrigeration must perform well in low temperatures. Proper selection helps maintain operational efficiency and safety.

4. Size and Diameter

The inner diameter of a hose affects fluid flow and pressure. Selecting the correct size is vital for ensuring that the hose can handle the required flow rates without causing back pressure that may damage equipment. In a B2B context, working with suppliers who can provide customized sizes ensures that your specific operational needs are met.

Illustrative image related to the hose man

5. Tolerance

Tolerance refers to the allowable variation in the dimensions of the hose. Tight tolerances are crucial in applications where precise fitting is required. For instance, in hydraulic systems, even minor deviations can lead to system inefficiencies or failures. Therefore, understanding the tolerance levels of hoses is essential for ensuring optimal performance.

What Are Common Trade Terms Relevant to Hose Solutions?

Navigating the hose supply market involves familiarity with specific trade terminology. Here are several key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are sold under another company’s brand. Understanding OEM products is crucial for buyers looking for compatibility with existing systems and ensuring quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is particularly important for B2B buyers as it can impact inventory costs and procurement strategies. Knowing the MOQ helps businesses plan their purchasing effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. It’s a critical step in the procurement process that allows buyers to compare pricing and terms from different vendors, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers engaged in global trade, as they clarify shipping costs, risk management, and delivery obligations.

5. Custom Fabrication

Custom fabrication refers to the process of creating hoses tailored to specific requirements. This is essential for businesses with unique operational needs, as it ensures that the hoses will function effectively in their intended applications.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing hoses for your business needs. This knowledge not only enhances operational efficiency but also strengthens supplier relationships and optimizes procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the the hose man Sector

What Are the Key Drivers Shaping the Hose Man Market?

The global hose market is currently influenced by several key drivers, including industrial growth, technological advancements, and an increasing focus on safety and efficiency. In regions like Africa and South America, infrastructure development and agricultural expansion are propelling demand for high-quality hoses, particularly in sectors such as construction, food and beverage, and oil and gas. Buyers from the Middle East and Europe are also experiencing a surge in the need for specialized hoses that can withstand extreme temperatures and pressures, especially in harsh environments.

Emerging B2B technologies, such as digital supply chain management and IoT-enabled monitoring systems, are transforming how international buyers engage with suppliers. These technologies facilitate real-time tracking of inventory levels and order statuses, leading to improved efficiency and reduced downtime. The rise of e-commerce platforms has also made it easier for buyers to source custom hose solutions tailored to their specific needs, fostering a more competitive market landscape.

Furthermore, global sourcing trends are leaning toward collaborative partnerships between manufacturers and buyers. This collaboration enhances product customization and allows for quicker turnaround times, which is essential in today’s fast-paced market. International buyers should be aware of these dynamics to make informed purchasing decisions and leverage the best opportunities available.

How Is Sustainability and Ethical Sourcing Impacting the Hose Man Sector?

Sustainability and ethical sourcing are becoming increasingly important in the hose manufacturing sector. The environmental impact of traditional manufacturing processes has prompted many companies to adopt greener practices. Buyers should look for suppliers that prioritize sustainability, such as those using recyclable materials or eco-friendly manufacturing methods.

Ethical supply chains are also crucial for ensuring that all materials sourced are obtained responsibly. This includes verifying that suppliers adhere to labor laws and environmental regulations. For B2B buyers, the importance of ‘green’ certifications, such as ISO 14001 or other environmental management standards, cannot be overstated. These certifications not only signify compliance with sustainability practices but also enhance brand reputation in a market that is becoming more eco-conscious.

Investing in sustainable and ethically sourced hose solutions can yield long-term benefits, including reduced operational costs and enhanced customer loyalty. As regulations regarding environmental standards tighten globally, buyers who prioritize sustainable sourcing will be better positioned to navigate future market challenges.

What Is the Historical Context of the Hose Man Sector?

The hose manufacturing industry has evolved significantly over the decades, driven by advancements in material science and engineering. Initially focused on basic rubber hoses, the sector has expanded to include a wide variety of specialized products designed for specific applications. This evolution has been fueled by the increasing complexity of industrial processes and the need for hoses that can withstand higher pressures and harsher conditions.

In the early 20th century, the industry primarily served local markets with limited customization options. However, as global trade expanded, so did the demand for specialized hoses across various sectors, including automotive, food service, and energy. The advent of synthetic materials in the latter half of the century revolutionized the industry, enabling the production of hoses that are not only more durable but also resistant to chemicals and extreme temperatures.

Today, the hose man sector is characterized by a focus on customization, quality assurance, and customer-centric services, making it essential for B2B buyers to align themselves with manufacturers who can meet their specific needs and ensure reliable performance across diverse applications.

Illustrative image related to the hose man

Frequently Asked Questions (FAQs) for B2B Buyers of the hose man

-

How do I solve issues with hose compatibility for my machinery?

To address compatibility issues, start by identifying the specifications required for your machinery, including pressure ratings, temperature ranges, and fluid types. Consult with a hose supplier who specializes in hydraulic and industrial hoses, like Hose-Man, to discuss your unique requirements. They can provide expert recommendations and custom solutions tailored to your equipment, ensuring optimal performance and safety. Always verify that the materials used in the hoses are compatible with the fluids to prevent leaks and failures. -

What is the best type of hydraulic hose for high-pressure applications?

For high-pressure applications, look for hydraulic hoses specifically designed to withstand elevated pressures, such as those made from reinforced synthetic rubber or thermoplastic materials. These hoses typically feature multiple layers of reinforcement, ensuring durability and resistance to bursting under pressure. It’s essential to select hoses that meet or exceed industry standards, such as SAE or ISO specifications, and consult with suppliers for expert guidance on the best options based on your specific application. -

How can I customize hoses to meet my specific operational needs?

Customization is a key service offered by specialized hose suppliers. Start by clearly defining your operational requirements, including dimensions, pressure ratings, and specific fittings. Reach out to a supplier like Hose-Man, who can collaborate with you to develop hoses tailored to your specifications. Their experienced team can provide insights on material choices and design considerations, ensuring that the final product meets the unique demands of your application, whether for construction, food service, or industrial use. -

What are the minimum order quantities (MOQ) for hose products?

Minimum order quantities can vary significantly among suppliers and depend on the type of hoses and fittings you require. Typically, custom hoses may have higher MOQs due to production setup costs. It’s advisable to discuss your needs directly with suppliers like Hose-Man, who can provide flexibility based on your business’s specific requirements. Understanding MOQs upfront can help you plan your procurement strategy effectively, especially for international transactions. -

What payment terms should I expect when sourcing hoses internationally?

Payment terms for international transactions can vary widely depending on the supplier and the nature of the order. Common arrangements include advance payments, letters of credit, or payment upon delivery. It’s essential to clarify payment terms with your supplier, considering factors such as order size, shipping methods, and any applicable tariffs or duties. Establishing clear terms can help mitigate risks and ensure a smooth transaction process, particularly when dealing with international logistics. -

How does Hose-Man ensure quality assurance for their products?

Hose-Man adheres to stringent quality assurance protocols to guarantee the reliability of their hoses. Each product undergoes comprehensive testing to meet industry standards, including pressure tests, material inspections, and performance evaluations. They source materials from trusted manufacturers and maintain rigorous quality control throughout the production process. This commitment to quality ensures that customers receive durable and dependable hoses that meet their operational demands. -

What logistics options are available for international shipping of hose products?

When sourcing hoses internationally, various logistics options are available, including air freight for urgent deliveries and sea freight for cost-effective shipping. Hose-Man can assist in coordinating shipping arrangements to ensure timely delivery, considering factors such as destination, order size, and urgency. It’s essential to discuss logistics with your supplier to understand lead times, customs clearance processes, and any documentation required for smooth transit across borders. -

How can I vet suppliers when sourcing hoses for my business?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching potential suppliers’ industry reputation, customer reviews, and certifications. Request samples or case studies to evaluate product quality. Additionally, inquire about their manufacturing processes, quality assurance measures, and experience in your specific industry. Engaging in direct communication with potential suppliers can also help gauge their responsiveness and customer service commitment, ensuring a trustworthy partnership for your hose needs.

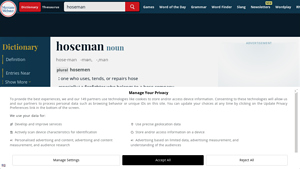

Top 6 The Hose Man Manufacturers & Suppliers List

1. Hose-Man – Custom Hydraulic & Pneumatic Hoses

Domain: hose-man.com

Registered: 2000 (25 years)

Introduction: Hose-Man, Inc. specializes in custom hydraulic, pneumatic, food service, and industrial hoses. Key features include:

– Customization: Hoses tailored to specific requirements including pressure ratings, sizes, and fittings.

– Quality Assurance: Use of high-quality materials and rigorous testing to meet industry standards.

– Industry Expertise: Experience serving manufacturing, construction, automot…

2. The Hose Man – High-Quality Hydraulic Hoses

Domain: thehoseman.com

Registered: 2024 (1 years)

Introduction: The Hose Man offers high-quality hydraulic hoses, fittings, and accessories at affordable prices for industrial and commercial needs. Key products include:

– Hydraulic hoses designed for high pressure, abrasion resistance, and environmental durability, suitable for construction, agriculture, and other applications.

– Flanges, flange adapters, and pads to complete hose setups and enhance performanc…

3. The Hoseman – Mobile Hydraulic Hose Repair

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, The Hoseman – Mobile Hydraulic Hose Repair, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. The Hose Guys – Hydraulic Hoses and Fittings

Domain: thehoseguys.net

Registered: 2005 (20 years)

Introduction: The Hose Guys Inc. offers a variety of hydraulic hoses and fittings, including braided and multi-spiral hydraulic hoses, jack hoses, power wash hoses, and carpet cleaning hoses. They provide no skive hydraulic hose crimp fittings in K, J, and H series. The company has a large inventory, with 1,000,000 feet of 1 and 2 wire braid hydraulic hose, 100,000 feet of 4 and 6 wire multi-spiral hydraulic ho…

5. The Hose-Man – Hose Solutions

Domain: craft.co

Registered: 2010 (15 years)

Introduction: This company, The Hose-Man – Hose Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Merriam-Webster – Hoseman Definition

Domain: merriam-webster.com

Registered: 1999 (26 years)

Introduction: Hoseman: noun; plural hosemen; definition: one who uses, tends, or repairs hose, especially a firefighter who belongs to a hose company.

Strategic Sourcing Conclusion and Outlook for the hose man

In navigating the complexities of sourcing hoses for diverse applications, international B2B buyers must prioritize quality, customization, and supplier reliability. Strategic sourcing allows companies to not only reduce costs but also enhance operational efficiency and ensure compliance with industry standards. By partnering with reputable suppliers like Hose-Man, businesses can access a wide range of high-quality hydraulic, pneumatic, and industrial hoses tailored to their specific needs.

Investing in hoses that withstand rigorous conditions is essential for maintaining productivity and safety. Buyers should actively engage with suppliers to understand their capabilities in customization and quality assurance, as these factors can significantly impact performance and longevity. Moreover, leveraging local suppliers can lead to quicker turnaround times and more responsive service, which is invaluable in fast-paced markets.

Looking ahead, the demand for innovative and durable hose solutions will continue to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Now is the time for buyers to assess their sourcing strategies and forge partnerships that align with their operational goals. Embrace the opportunity to elevate your hose procurement process and experience the difference that quality and service can make in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to the hose man

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.