Velcro Patches For Backpacks: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for velcro patches for backpacks

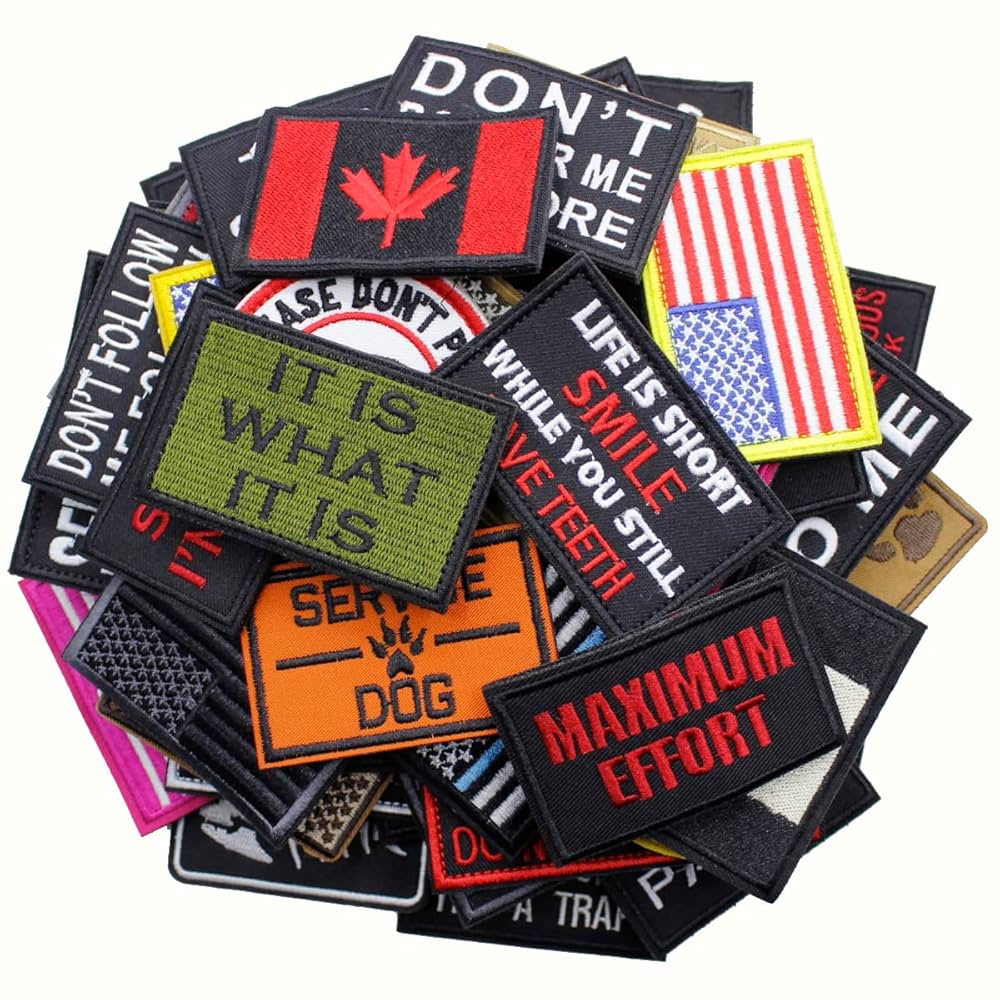

In today’s competitive landscape, sourcing velcro patches for backpacks presents unique challenges for international B2B buyers. With the growing demand for customizable, functional, and aesthetically appealing patches, companies must navigate a myriad of suppliers while ensuring quality, cost-effectiveness, and timely delivery. This comprehensive guide is designed to address these challenges, offering insights into various types of velcro patches, their applications, and best practices for supplier vetting. By understanding the nuances of this market, businesses can enhance their product offerings and meet customer expectations.

This guide will delve into the diverse categories of velcro patches available, from tactical and motivational designs to fun and trendy options that appeal to different demographics. Additionally, it will cover key factors influencing pricing, potential sourcing pitfalls, and tips for negotiating favorable terms with suppliers. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam, this resource empowers informed purchasing decisions by providing actionable strategies and industry insights.

By equipping yourself with the knowledge contained in this guide, you can confidently navigate the global market for velcro patches, ensuring that your business stands out in a crowded marketplace while meeting the evolving needs of your clientele.

Understanding velcro patches for backpacks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactical Patches | Durable materials, often with military insignias | Military gear, outdoor equipment | Pros: High durability; Cons: Typically higher cost. |

| Motivational Patches | Inspirational quotes, vibrant designs | Fitness gear, personal development items | Pros: Appeals to emotional branding; Cons: Niche market. |

| Custom Embroidered Patches | Tailored designs, logos, and text | Corporate branding, promotional items | Pros: Unique branding opportunities; Cons: Longer lead times. |

| PVC Patches | Waterproof, flexible, and easy to clean | Sportswear, outdoor gear | Pros: Weather-resistant; Cons: Less traditional aesthetic. |

| Glow-in-the-Dark Patches | Phosphorescent materials for visibility | Safety gear, night-time activities | Pros: Enhanced visibility; Cons: Limited design options. |

What Are Tactical Patches and Their B2B Relevance?

Tactical patches are crafted from durable materials designed to withstand harsh conditions, often featuring military insignias or symbols. They are primarily used in military gear and outdoor equipment, making them ideal for B2B buyers in defense and survival sectors. When purchasing, consider the material quality and the patch’s adherence to military standards, which can influence both durability and compliance with regulations.

Illustrative image related to velcro patches for backpacks

How Do Motivational Patches Serve Specific Markets?

Motivational patches feature inspirational quotes and vibrant designs, targeting sectors such as fitness and personal development. These patches resonate with brands focusing on emotional engagement, particularly in wellness and lifestyle markets. Buyers should assess the market’s demand for motivational themes and consider the potential for higher margins in niche segments.

What Are the Advantages of Custom Embroidered Patches?

Custom embroidered patches are tailored to feature specific designs, logos, or text, making them an excellent choice for corporate branding and promotional items. Businesses can leverage these patches to enhance brand recognition. However, buyers should be mindful of lead times and minimum order quantities, as customization can significantly affect production schedules.

Why Choose PVC Patches for Outdoor Applications?

PVC patches are known for their waterproof nature, flexibility, and ease of cleaning, making them highly suitable for sportswear and outdoor gear. They offer a practical solution for brands in active markets where durability is critical. When considering PVC patches, businesses should evaluate the balance between aesthetic appeal and functional benefits.

What Are the Benefits of Glow-in-the-Dark Patches?

Glow-in-the-dark patches utilize phosphorescent materials to enhance visibility during nighttime activities, making them ideal for safety gear and outdoor adventures. This unique feature can attract buyers in sectors focused on safety and adventure. However, potential limitations in design complexity should be assessed to ensure alignment with branding strategies.

Illustrative image related to velcro patches for backpacks

Key Industrial Applications of velcro patches for backpacks

| Industry/Sector | Specific Application of Velcro Patches for Backpacks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Military & Tactical | Customization of tactical gear for soldiers | Enhances morale and unit identity; easy patch changes | Durability, weather resistance, and compliance with military standards |

| Education & Schools | Branding and student representation | Promotes school spirit and unity among students | Custom designs, color matching with school uniforms, and bulk ordering options |

| Outdoor & Adventure | Personalization for hiking and camping gear | Increases brand visibility and customer loyalty | Lightweight materials, water resistance, and ease of attachment/detachment |

| Sports & Recreation | Team logos and motivational patches | Boosts team morale and visibility during events | Customization options, durability under physical activity, and colorfastness |

| Fashion & Apparel | Trendy designs for youth-oriented backpacks | Attracts a younger demographic and enhances product appeal | Fashion trends, material quality, and compatibility with various backpack styles |

How Are Velcro Patches Utilized in the Military & Tactical Sector?

In the military and tactical sector, velcro patches are essential for customizing backpacks used by soldiers. These patches often display unit insignias, morale patches, or personal identifiers, allowing quick changes based on mission requirements. The ability to easily attach or detach patches enhances operational flexibility, while the durability of velcro ensures that patches remain securely fastened in rugged conditions. International buyers should focus on sourcing patches that meet specific military standards for durability and weather resistance, particularly in regions with extreme climates.

What Role Do Velcro Patches Play in Educational Institutions?

Educational institutions utilize velcro patches on backpacks to foster school spirit and enhance student representation. Custom patches featuring school logos or motivational slogans can be easily applied and removed, allowing students to personalize their gear. This not only promotes a sense of belonging but also serves as a marketing tool for the institution. B2B buyers in this sector should prioritize high-quality fabrics that match school colors and can withstand daily wear and tear, ensuring longevity and cost-effectiveness.

How Are Velcro Patches Beneficial in the Outdoor & Adventure Market?

In the outdoor and adventure market, velcro patches offer a practical solution for personalizing hiking and camping backpacks. These patches can showcase brand logos or personal achievements, increasing brand visibility among outdoor enthusiasts. The lightweight nature of velcro patches makes them ideal for gear that needs to be easily transportable. Buyers should consider sourcing water-resistant materials that can endure various weather conditions, appealing to the adventurous spirit of their customers.

Why Are Velcro Patches Important for Sports Teams?

Velcro patches are vital for sports teams looking to enhance team identity and morale. Patches can feature team logos or motivational phrases, making them perfect for use during games and events. The flexibility to change patches allows teams to adapt their branding for different competitions or seasons. When sourcing, businesses should ensure that the patches are durable enough to withstand rigorous physical activity and maintain their appearance over time, particularly in humid or rainy environments prevalent in certain regions.

Illustrative image related to velcro patches for backpacks

How Do Velcro Patches Enhance Fashion & Apparel Products?

In the fashion and apparel sector, velcro patches have become a trendy accessory for youth-oriented backpacks. These patches allow for personalization and self-expression, appealing to younger consumers who value individuality. Fashion brands can leverage velcro patches to create limited-edition collections or seasonal designs that attract attention. Buyers should pay attention to current fashion trends and ensure that the materials used for the patches are of high quality, ensuring they complement various backpack styles while being easy to apply and remove.

3 Common User Pain Points for ‘velcro patches for backpacks’ & Their Solutions

Scenario 1: Sourcing Quality Velcro Patches for Bulk Orders

The Problem: B2B buyers often face challenges in sourcing high-quality velcro patches that meet their specific requirements. This is particularly true for companies in regions like Africa and South America, where local suppliers may not offer a diverse selection or the durability expected in tactical environments. Buyers may encounter issues with inconsistent quality, leading to customer dissatisfaction and returns, which can significantly affect their bottom line.

The Solution: To ensure a steady supply of high-quality velcro patches, B2B buyers should establish relationships with reputable manufacturers known for their craftsmanship. Conduct thorough research by requesting samples to assess the quality of the materials used, such as the type of velcro and the stitching technique. Additionally, consider suppliers who provide customizable options tailored to specific branding or functional needs. Utilizing platforms that connect buyers with international manufacturers can also expand sourcing options, allowing buyers to compare quality and pricing before making bulk purchases. Implementing a robust quality control system upon receiving the patches can further mitigate risks associated with subpar products.

Scenario 2: Customization Limitations Impacting Brand Identity

The Problem: Companies that rely on velcro patches for branding often struggle with customization limitations. Many suppliers may offer a limited range of designs, colors, or sizes, making it difficult for businesses to create unique and recognizable branding elements. This is particularly crucial in competitive markets where differentiation is key to capturing customer attention.

The Solution: To overcome customization challenges, buyers should seek suppliers that specialize in bespoke velcro patch designs. Look for manufacturers that offer digital design tools or prototyping services, allowing businesses to visualize their patches before production. Engaging with suppliers who have experience working with a variety of materials and production techniques—such as embroidered, PVC, or sublimated patches—can enhance creative possibilities. Additionally, consider forming partnerships with local artists or designers to develop unique patch designs that resonate with the target audience, ensuring that the brand identity is both memorable and distinct.

Scenario 3: Durability Concerns in Various Environments

The Problem: Durability is a significant concern for B2B buyers, especially those supplying velcro patches for backpacks intended for outdoor or tactical use. Patches that fail to withstand harsh conditions—such as extreme temperatures, moisture, or abrasion—can lead to loss of branding and functionality, resulting in financial losses and reputational damage.

Illustrative image related to velcro patches for backpacks

The Solution: Buyers should prioritize sourcing velcro patches designed for resilience. When evaluating suppliers, inquire about the materials used and their resistance to environmental factors. Look for certifications or testing data that demonstrate the patches’ durability in various conditions. Additionally, consider integrating a warranty or guarantee policy with your supplier to ensure accountability for product performance. Educating end-users on proper care and maintenance of the patches can also extend their lifespan. For instance, advising customers to avoid prolonged exposure to direct sunlight or water can help maintain the patch’s appearance and functionality, ultimately enhancing customer satisfaction and loyalty.

Strategic Material Selection Guide for velcro patches for backpacks

When selecting materials for Velcro patches intended for backpacks, it is essential to consider various factors that influence performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the production of Velcro patches, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Nylon for Velcro Patches?

Nylon is a widely used material for Velcro patches due to its strength and flexibility. It boasts high abrasion resistance and can withstand a temperature range of -40°C to 120°C. This makes nylon suitable for various environments, including outdoor applications where exposure to the elements is common. However, nylon can be susceptible to UV degradation over time, which may affect its longevity when used in direct sunlight.

Pros: Nylon patches are durable and lightweight, making them ideal for tactical and outdoor backpacks. They can also be dyed in various colors, allowing for customization.

Illustrative image related to velcro patches for backpacks

Cons: While nylon is relatively affordable, it may not be as cost-effective as other synthetic materials in bulk production. Additionally, its UV sensitivity can limit its use in sunny regions.

How Does Polyester Compare as a Material for Velcro Patches?

Polyester is another popular choice for Velcro patches, known for its excellent resistance to shrinking and stretching. It can handle a wide temperature range and is less prone to UV damage compared to nylon, making it a better option for outdoor use. Polyester also exhibits good chemical resistance, which is beneficial in environments where exposure to oils or solvents is likely.

Pros: The durability and colorfastness of polyester make it suitable for vibrant designs and long-lasting applications. Its resistance to moisture helps maintain the patch’s integrity.

Illustrative image related to velcro patches for backpacks

Cons: Polyester can be more expensive than nylon and may require more complex manufacturing processes, which could increase production costs.

What Are the Advantages of PVC in Velcro Patch Manufacturing?

Polyvinyl Chloride (PVC) is frequently used for tactical and promotional Velcro patches. It is waterproof, chemical-resistant, and highly durable, making it ideal for patches exposed to harsh conditions. PVC patches can be molded into various shapes and designs, offering flexibility in branding and customization.

Pros: The waterproof nature of PVC makes it suitable for outdoor and marine applications. Its resistance to fading and wear ensures that the patches maintain their appearance over time.

Cons: PVC is generally heavier than nylon or polyester, which may not be suitable for lightweight backpacks. Additionally, the manufacturing process for PVC can be more complex and costly.

Why Consider Cotton as a Material for Velcro Patches?

Cotton is less common but still relevant for Velcro patches, particularly in applications where a softer, more natural feel is desired. Cotton patches are breathable and can be dyed in various colors, making them suitable for fashion-oriented backpacks.

Illustrative image related to velcro patches for backpacks

Pros: Cotton is biodegradable and environmentally friendly, appealing to eco-conscious consumers. It is also comfortable against the skin, making it suitable for patches that may come into contact with the wearer.

Cons: Cotton lacks the durability of synthetic materials and is more prone to wear and tear. It also has limited resistance to moisture and UV light, which may reduce its lifespan in outdoor applications.

Summary Table of Material Selection for Velcro Patches

| Material | Typical Use Case for Velcro Patches for Backpacks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Tactical and outdoor backpacks | High abrasion resistance | Susceptible to UV degradation | Medium |

| Polyester | Vibrant, long-lasting patches | Excellent moisture and UV resistance | Higher production costs | Medium to High |

| PVC | Tactical and promotional patches | Waterproof and highly durable | Heavier than other materials | Medium to High |

| Cotton | Fashion-oriented backpacks | Eco-friendly and breathable | Less durable and moisture-resistant | Low |

In conclusion, the choice of material for Velcro patches should align with the intended use, environmental conditions, and target market preferences. International buyers should consider local standards and regulations, such as ASTM or DIN, while also factoring in the specific demands of their regional markets in Africa, South America, the Middle East, and Europe.

Illustrative image related to velcro patches for backpacks

In-depth Look: Manufacturing Processes and Quality Assurance for velcro patches for backpacks

What Are the Main Stages in the Manufacturing Process of Velcro Patches for Backpacks?

The manufacturing process for velcro patches tailored for backpacks involves several critical stages, each designed to ensure the final product is both high-quality and durable. Understanding these stages can help B2B buyers assess potential suppliers effectively.

1. Material Preparation

The manufacturing process begins with material selection. High-quality nylon or polyester fabrics are often chosen due to their durability and resistance to wear and tear. The hook and loop fasteners, commonly known as Velcro, are also sourced from reputable suppliers to guarantee their adhesive strength.

Once the materials are sourced, they undergo pre-treatment processes such as dyeing or waterproofing. This step ensures that the colors are vibrant and that the patches can withstand environmental factors, particularly important for outdoor and tactical applications.

Illustrative image related to velcro patches for backpacks

2. Forming

In the forming stage, the prepared materials are cut into the desired shapes and sizes. Advanced cutting techniques, such as laser cutting or die-cutting, are often employed to ensure precision and consistency in the dimensions of each patch.

Embellishments, such as embroidery or screen printing, are added during this stage. This is crucial for tactical or motivational patches, where branding and visual appeal significantly impact consumer choice.

3. Assembly

Once formed, the patches undergo assembly. This involves attaching the hook and loop fasteners to the patch, ensuring they are securely affixed to withstand repeated use. Techniques such as heat sealing or stitching are commonly used, depending on the design and materials involved.

For patches that include additional features like glow-in-the-dark elements or reflective materials, this is also the stage where those components are integrated.

4. Finishing

The final stage involves quality checks and finishing touches. This may include trimming excess material, applying protective coatings, or packaging the patches for shipment.

Finishing ensures that the patches are not only visually appealing but also functional, with no sharp edges or loose threads that could compromise their durability.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of velcro patches. A structured QA process helps to identify defects early and ensures that all products meet international quality standards.

Illustrative image related to velcro patches for backpacks

Relevant International and Industry-Specific Standards

International standards such as ISO 9001 play a significant role in the quality assurance processes of manufacturers. This standard focuses on consistent quality management systems, ensuring that organizations can meet customer and regulatory requirements effectively.

Additionally, specific industry standards such as CE marking for safety and compliance in the European market or API standards in the military sector may also be relevant. These certifications indicate that the products have been tested and meet rigorous safety and quality benchmarks.

Key Quality Control Checkpoints

Quality control is typically implemented at various checkpoints throughout the manufacturing process, including:

Illustrative image related to velcro patches for backpacks

- Incoming Quality Control (IQC): Initial inspections of raw materials to ensure they meet specified requirements before production begins.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify and rectify defects immediately, ensuring that the patches maintain quality throughout production.

- Final Quality Control (FQC): A thorough inspection of the finished product, checking for defects in design, stitching, and attachment of fasteners.

These checkpoints help maintain high standards and can reduce the likelihood of defects reaching the customer.

What Testing Methods Are Commonly Used for Velcro Patches?

Various testing methods are employed to ensure the durability and functionality of velcro patches:

- Adhesion Tests: These tests measure the strength of the hook and loop fasteners. Ensuring the patches can withstand repeated use without losing adhesion is critical for customer satisfaction.

- Colorfastness Tests: Evaluating how well the colors hold up against washing and exposure to sunlight is essential, particularly for outdoor gear.

- Tensile Strength Tests: This assesses the fabric’s ability to withstand pulling forces, ensuring that the patch remains intact under stress.

B2B buyers can request reports or certifications from suppliers detailing these tests, providing assurance of the product’s quality.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing velcro patches for backpacks, B2B buyers must ensure that their suppliers adhere to stringent quality control measures. There are several ways to verify supplier QC:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. This can include facility tours and discussions with quality assurance teams.

-

Quality Reports: Requesting documentation of quality control processes and testing results can help verify that the supplier maintains high standards. Suppliers should provide data on IQC, IPQC, and FQC results.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. This is particularly important for international transactions, where local regulations and standards may vary.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital:

-

Regulatory Compliance: Different regions have varying regulations concerning materials and manufacturing processes. Buyers must ensure that suppliers comply with local laws to avoid potential legal issues.

-

Cultural Differences in Quality Standards: What is deemed acceptable in one region may not be in another. Buyers should communicate their quality expectations clearly to avoid misunderstandings.

-

Logistical Challenges: Shipping and handling can affect product quality. Buyers should discuss packaging and handling procedures with suppliers to ensure products arrive in optimal condition.

By understanding the manufacturing processes and quality assurance measures involved in producing velcro patches for backpacks, B2B buyers can make informed decisions and foster successful partnerships with suppliers.

Illustrative image related to velcro patches for backpacks

Practical Sourcing Guide: A Step-by-Step Checklist for ‘velcro patches for backpacks’

Introduction

Sourcing velcro patches for backpacks requires a systematic approach to ensure you meet your quality, design, and budgetary needs. This checklist is designed to guide international B2B buyers through the essential steps of procuring velcro patches, enabling you to make informed decisions that align with your business goals.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline the technical specifications for your velcro patches. This includes size, material (e.g., PVC, embroidered), and adhesive strength. Having precise specifications helps in communicating your needs effectively and ensures the patches will fit the intended backpacks.

- Considerations: Identify if you need custom designs, colors, or logos. Ensure compatibility with various backpack types, especially if your market spans diverse regions.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in velcro patches. Utilize online marketplaces, trade directories, and industry networks to compile a list of candidates.

- Sources: Look for suppliers with positive reviews and a solid track record in your target regions, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each supplier to ensure they can meet your demands. This includes production capacity, lead times, and quality control processes.

- Documentation: Request samples of their work and inquire about their manufacturing processes. Understanding their capabilities will help you gauge whether they can fulfill large orders or specialized designs.

Step 4: Verify Certifications and Compliance

Ensure that your chosen suppliers comply with relevant international standards and certifications. This is particularly important when sourcing from different countries, as regulations can vary significantly.

- Key Certifications: Look for ISO certifications, safety standards, and any country-specific compliance that may impact your order. This step mitigates risks associated with quality and legality.

Step 5: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes that outline pricing, minimum order quantities, and payment terms.

- Cost Breakdown: Pay attention to the inclusions and exclusions in each quote, such as shipping costs or additional fees for custom designs. Comparing these elements will help you make a cost-effective choice.

Step 6: Check References and Customer Feedback

Before finalizing your decision, reach out to other businesses that have worked with your potential suppliers. Customer feedback can provide insights into reliability, quality, and overall satisfaction.

Illustrative image related to velcro patches for backpacks

- Questions to Ask: Inquire about the supplier’s responsiveness, issue resolution, and whether they met delivery timelines. This step can reveal potential red flags that may not be apparent from online research alone.

Step 7: Establish a Clear Communication Plan

Effective communication is key to a successful supplier relationship. Clearly outline expectations, timelines, and points of contact for both parties.

- Tools: Consider using project management tools or dedicated channels for ongoing communication. This ensures that both you and the supplier stay aligned throughout the sourcing process.

By following these steps, you can navigate the complexities of sourcing velcro patches for backpacks with confidence, ultimately leading to successful procurement that meets your business’s unique needs.

Comprehensive Cost and Pricing Analysis for velcro patches for backpacks Sourcing

What Are the Key Cost Components in Sourcing Velcro Patches for Backpacks?

When sourcing velcro patches for backpacks, several cost components play a crucial role in determining the overall pricing structure. Understanding these components can help international B2B buyers make informed purchasing decisions.

Materials: The primary cost driver is the materials used in the production of velcro patches. High-quality hook and loop fasteners, fabric, and embroidery threads can vary significantly in price. Buyers should consider the type of fabric (e.g., polyester, cotton, or nylon) and the quality of the velcro itself, as these factors directly affect durability and appearance.

Labor Costs: Labor costs encompass the wages paid to workers involved in the production process. These can fluctuate based on the country of manufacture and the skill level required for production. For instance, sourcing from countries with lower labor costs may reduce overall expenses, but it could also affect the quality of the finished product.

Illustrative image related to velcro patches for backpacks

Manufacturing Overhead and Tooling: Overhead costs include utilities, rent, and equipment maintenance, which can vary by region. Tooling costs, related to the machinery and molds needed for patch production, also contribute to initial investment expenses. Efficient manufacturers can optimize these costs through economies of scale.

Quality Control (QC): Implementing robust quality control measures is essential to ensure product consistency and reliability. This can involve additional costs, particularly if third-party inspections are needed. Buyers should factor in QC costs when evaluating overall pricing.

Logistics and Shipping: Logistics encompass all costs related to transporting the patches from the manufacturer to the buyer. This includes shipping, customs duties, and insurance. The choice of Incoterms (e.g., FOB, CIF) can significantly influence these costs, with different responsibilities for buyers and sellers.

Margin: Finally, the supplier’s margin is added on top of the production costs to ensure profitability. This margin can vary widely based on market competition, supplier reputation, and the uniqueness of the product.

How Do Price Influencers Affect Velcro Patch Costs?

Several factors influence the pricing of velcro patches, making it essential for buyers to understand these dynamics.

Volume and Minimum Order Quantity (MOQ): Bulk orders typically lead to lower per-unit costs. Suppliers often offer discounts for larger purchases, incentivizing buyers to increase order sizes. Understanding the MOQ is crucial for negotiating better pricing.

Specifications and Customization: Customized patches with unique designs or specific features (e.g., glow-in-the-dark materials or special shapes) can significantly increase costs. Buyers should weigh the need for customization against their budget constraints.

Illustrative image related to velcro patches for backpacks

Material Quality and Certifications: The quality of materials used impacts both the price and the durability of the patches. Certifications (e.g., ISO, OEKO-TEX) can assure buyers of material safety and environmental compliance, potentially adding to costs but providing long-term value.

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Established suppliers may charge more due to their track record of quality and service.

What Are Effective Buyer Tips for Negotiating Velcro Patch Prices?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should keep several negotiation strategies in mind to ensure cost-efficiency.

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors such as durability, potential return rates, and the cost of replacements, which can impact long-term expenses.

Negotiate Terms and Conditions: Don’t hesitate to negotiate payment terms, shipping costs, and lead times. Flexible payment terms can help manage cash flow and reduce upfront costs.

Research Market Prices: Understanding the market average for velcro patches can empower buyers during negotiations. Utilize online resources and industry reports to benchmark prices and identify potential suppliers.

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Regular communication and feedback can foster a partnership that benefits both parties.

Conclusion

In summary, sourcing velcro patches for backpacks involves a complex interplay of costs, pricing influencers, and negotiation strategies. Buyers should conduct thorough research and consider all cost components to make informed decisions that align with their business objectives. As the market evolves, staying updated on trends and supplier capabilities will be key to securing favorable terms and high-quality products.

Alternatives Analysis: Comparing velcro patches for backpacks With Other Solutions

Exploring Alternative Solutions for Customization in Backpacks

When it comes to customizing backpacks, Velcro patches are a popular choice due to their versatility and ease of use. However, there are several alternative solutions that can provide similar functionalities. This analysis will compare Velcro patches with alternative customization methods to help international B2B buyers make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Velcro Patches For Backpacks | Alternative 1: Iron-On Patches | Alternative 2: Embroidered Logos |

|---|---|---|---|

| Performance | High attachment strength, reusable | Moderate strength, permanent | High quality, permanent |

| Cost | $2.50 – $11.95 per patch | $1.50 – $5.00 per patch | $5.00 – $20.00 per logo |

| Ease of Implementation | Easy to apply and remove | Requires heat application | Requires setup and sewing |

| Maintenance | Minimal, can be cleaned easily | May peel off over time | Durable but can fade or fray |

| Best Use Case | Tactical, promotional, and personal expression | Casual wear, simple designs | Corporate branding and logos |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Iron-On Patches?

Iron-on patches are a widely used alternative for customizing backpacks. They are typically less expensive than Velcro patches and provide a permanent solution, ensuring the patch stays in place even with regular use. However, they require a heat source for application, which can be a drawback in environments where heat tools are not available. Additionally, over time, iron-on patches may peel off, especially in high-friction areas or if not applied properly.

How Do Embroidered Logos Compare to Velcro Patches?

Embroidered logos offer a high-quality finish and are often seen as a more professional option for branding purposes. They are durable and can withstand wear and tear, making them suitable for corporate clients looking to enhance their brand visibility on backpacks. However, they come at a higher cost and typically require more setup time for design and application. Unlike Velcro patches, embroidered logos are not removable, which may limit customization flexibility.

Conclusion: Which Customization Solution is Right for Your Backpack Needs?

Choosing the right customization solution for backpacks depends on several factors, including cost, desired permanence, and ease of implementation. Velcro patches are ideal for businesses looking for flexibility and reusability, making them suitable for tactical applications or promotional events. Iron-on patches offer a cost-effective solution but may require careful handling to maintain their integrity. Embroidered logos, while more expensive, provide a polished appearance for corporate branding. B2B buyers should evaluate their specific needs and target market to select the solution that best aligns with their branding strategy and operational requirements.

Illustrative image related to velcro patches for backpacks

Essential Technical Properties and Trade Terminology for velcro patches for backpacks

What Are the Key Technical Properties of Velcro Patches for Backpacks?

When sourcing velcro patches for backpacks, understanding their technical specifications is crucial for ensuring quality and compatibility with your products. Below are some essential technical properties to consider:

-

Material Composition

– Velcro patches are typically made from synthetic materials like nylon or polyester. These materials offer durability, resistance to wear and tear, and the ability to withstand various environmental conditions. For B2B buyers, selecting the right material ensures that the patches can endure the rigors of daily use, especially in outdoor or tactical applications. -

Adhesive Strength

– The adhesive strength of the velcro (hook and loop) system is vital. It determines how securely the patch will attach to the backpack. High-quality patches should have a strong adhesive that maintains its integrity over time, even with frequent removals and reattachments. This is particularly important for military or tactical applications, where reliability is paramount. -

Size and Dimension Tolerance

– Velcro patches come in various sizes, and it’s essential to specify dimensions with acceptable tolerances. For instance, a patch might be required to fit a specific area on a backpack. Tolerances of ±0.5 cm can ensure that the patches fit snugly without compromising aesthetics or functionality. -

Color Fastness

– The ability of the patch to retain its color under exposure to sunlight and washing is known as color fastness. This property is significant for maintaining the visual appeal of the patches over time. Buyers should inquire about color fastness ratings, especially for products intended for outdoor use. -

Weight and Thickness

– The weight and thickness of the velcro patches can impact the overall design and usability of the backpack. Lightweight and thin patches are often preferable for casual use, while thicker patches might be required for tactical or decorative purposes. Understanding these properties helps in selecting the right product for your target market. -

Embroidered vs. Printed Designs

– Patches can be embroidered or printed, each offering different aesthetics and durability. Embroidered patches are generally more durable and offer a premium look, while printed patches can be more cost-effective for complex designs. Knowing the difference allows buyers to align their product offerings with customer preferences.

Which Trade Terminology Is Important for Sourcing Velcro Patches?

Familiarity with industry jargon is essential for effective communication and negotiation with suppliers. Here are some common terms to understand:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of velcro patches, an OEM may produce customized patches based on your specifications. Understanding OEM relationships can lead to better pricing and quality control. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management. Suppliers often set MOQs to ensure that production runs are cost-effective. -

RFQ (Request for Quotation)

– An RFQ is a standard business process to invite suppliers to bid on specific products or services. For velcro patches, an RFQ should include specifications, desired quantities, and delivery timelines. This process helps in obtaining competitive pricing and understanding supplier capabilities. -

Incoterms (International Commercial Terms)

– These are pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international trade. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears costs and risks during transport, impacting overall pricing strategies. -

Lead Time

– Lead time refers to the time taken from placing an order until it is received. Understanding lead times is essential for inventory planning and meeting customer demand. Different suppliers may have varying lead times based on their production capabilities and supply chain logistics. -

Customization Options

– This term encompasses the various ways in which a buyer can tailor patches to meet specific requirements, such as size, color, or design. Knowing the extent of customization available helps buyers create unique products that stand out in the marketplace.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, streamline sourcing processes, and ultimately enhance their product offerings in the competitive backpack market.

Illustrative image related to velcro patches for backpacks

Navigating Market Dynamics and Sourcing Trends in the velcro patches for backpacks Sector

What Are the Key Trends Shaping the Velcro Patches for Backpacks Market?

The global market for velcro patches, especially in the context of backpacks, is witnessing dynamic growth driven by multiple factors. Firstly, the rising demand for customization among consumers is propelling businesses to offer unique and personalized options. This trend is particularly strong in regions like Africa and South America, where local artisans and small businesses are increasingly leveraging customizable patches to appeal to niche markets. The growing popularity of tactical and motivational patches is another significant driver, especially among youth and outdoor enthusiasts, fostering a vibrant sub-market that thrives on self-expression.

Technological advancements in manufacturing and digital design tools are enabling suppliers to produce high-quality patches at lower costs. Automated embroidery and digital printing techniques facilitate rapid prototyping and short-run production, making it easier for international B2B buyers to source unique products without committing to large inventories. Additionally, e-commerce platforms have transformed sourcing practices, allowing buyers from diverse regions such as Europe and the Middle East to access a broader range of suppliers and products with comparative ease.

Emerging trends also include the incorporation of smart technology into patches, such as QR codes or NFC chips that can be integrated into backpacks. This innovative feature not only serves functional purposes but also enhances the consumer experience, particularly in tech-savvy markets.

How Is Sustainability Influencing the Sourcing of Velcro Patches for Backpacks?

Sustainability is becoming a critical factor in sourcing decisions within the velcro patches market. Increasingly, businesses are recognizing the environmental impact of textile waste and are seeking to implement ethical sourcing practices. This shift is driven by consumer demand for transparency and sustainability, especially in regions where eco-consciousness is on the rise, such as Europe and parts of South America.

B2B buyers are now looking for suppliers who utilize eco-friendly materials and processes in their production of velcro patches. Organic cotton, recycled polyester, and biodegradable materials are gaining traction as alternatives to traditional fabrics. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® can enhance a supplier’s credibility and appeal to environmentally conscious buyers.

Illustrative image related to velcro patches for backpacks

Moreover, ethical supply chains that prioritize fair labor practices and reduce carbon footprints are becoming essential criteria for many international buyers. Companies that can demonstrate their commitment to sustainability not only mitigate environmental risks but also enhance their brand image, making them more competitive in a crowded marketplace.

How Have Velcro Patches for Backpacks Evolved Over Time?

The evolution of velcro patches can be traced back to their initial use in military applications, where they served practical purposes for identification and morale. Over the decades, these patches have transitioned into mainstream fashion and outdoor gear, particularly backpacks. The rise of outdoor activities and the DIY culture has fueled the demand for patches that allow individuals to express their personal style or affiliation.

In recent years, the customization aspect has taken center stage, with businesses offering a plethora of designs that cater to various consumer interests—from tactical motifs to pop culture references. This evolution reflects a broader trend of personalization in consumer products, wherein buyers seek items that resonate with their identities. Today, velcro patches not only serve functional purposes but have become a canvas for creativity, appealing to a diverse audience across different markets.

Frequently Asked Questions (FAQs) for B2B Buyers of velcro patches for backpacks

-

How can I ensure the quality of velcro patches from suppliers?

To ensure the quality of velcro patches, start by requesting samples from potential suppliers. Evaluate these samples based on durability, color accuracy, and stitching quality. Additionally, verify if the supplier adheres to international quality standards, such as ISO certifications. Engaging in third-party quality assurance checks can also provide peace of mind regarding the patches’ quality before bulk orders. -

What customization options are available for velcro patches?

Most suppliers offer a range of customization options, including size, shape, colors, and designs. You can choose to add logos, text, or specific images to the patches. Make sure to discuss your requirements clearly and request digital proofs before production to ensure the final product meets your expectations. Some suppliers may also offer different materials, such as PVC or embroidered options. -

What is the typical minimum order quantity (MOQ) for velcro patches?

The minimum order quantity for velcro patches can vary significantly based on the supplier and the complexity of the design. Generally, MOQs range from 50 to 500 pieces. It’s advisable to clarify the MOQ upfront during negotiations, as some suppliers may offer lower MOQs for specific product lines or during promotional periods. -

What payment terms should I expect when ordering velcro patches?

Payment terms can vary among suppliers, but commonly, you’ll find options such as a 30% deposit before production and the remaining balance prior to shipping. Some suppliers may also accept letters of credit or payment through secure online platforms. Always negotiate terms that align with your cash flow and ensure they are documented in your purchase agreement. -

How do I handle logistics and shipping for international orders of velcro patches?

When managing logistics for international orders, consider working with suppliers who have experience in export processes. Discuss shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Ensure you are aware of import duties and customs regulations in your country to avoid unexpected costs or delays upon arrival. -

What are the common uses of velcro patches in the backpack market?

Velcro patches are commonly used in backpacks for branding, personalization, and functionality. They can display logos, motivational phrases, or decorative elements that appeal to specific demographics. Additionally, tactical and military backpacks often incorporate velcro patches for morale statements or identification, making them versatile for various market segments. -

How can I vet potential suppliers for velcro patches?

To vet suppliers, start by researching their reputation online through reviews and testimonials. Request references from previous clients and check their production capabilities. Consider visiting their facilities if possible or conducting virtual audits. It’s also wise to ensure they comply with ethical manufacturing practices and have a robust return policy in case of quality issues. -

What factors influence the pricing of velcro patches?

The pricing of velcro patches is influenced by several factors, including material quality, size, complexity of the design, and the volume of the order. Customization options, such as embroidered versus printed patches, can also affect cost. Additionally, consider shipping costs and any potential tariffs that may apply for international orders, as these can significantly impact the overall price.

Top 5 Velcro Patches For Backpacks Manufacturers & Suppliers List

1. WOLFpak – Tactical & Motivational Patches

Domain: wolfpak.com

Registered: 1996 (29 years)

Introduction: Velcro Tactical & Motivational Patches | WOLFpak

2. In The Bag – Velcro Patches Collection

Domain: inthebagcornhole.com

Registered: 2022 (3 years)

Introduction: Collection: Velcro Patches

– Patches designed for Zuca or backpacks with velcro fronts.

– All pictures are actual photographs of the patches.

– Special Deal: Buy 3 or more patches and save $1 each. Free shipping on patches with orders of $49.99 or more.

Patch Categories:

– All Patches

– Funny Memes

– Brand & Brand Satire

– Beer

– Movies/TV

– Confidence

– Women

– Video Games

– Patriotic & Flags

– …

3. Etsy – Custom Velcro Patches

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Velcro Patches for Backpacks available on Etsy. Price range: Under $10 to Over $25. Custom options available for personalized name tags and patches. Examples include: Custom Name Patch “Your Name” for $1.48 (originally $1.98, 25% off), Custom Your Name Tag 3″ W x 2″ T for $6.09 (originally $10.15, 40% off), and Custom Name Patch for $5.95 (originally $8.50, 30% off). Free shipping on some items. V…

4. Koala Outdoor – Backpacks & Accessories

Domain: koalaoutdoor.com.au

Introduction: Backpacks: Strike 35 Backpack, Combat Backpack, Evatac Hybrid Duffel; Accessories: Patches.

5. Sprayground – 32 Removable Patches Velcro Backpack

Domain: sprayground.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “32 Removable Patches Velcro Backpack”, “price”: “$100.00”, “color_code”: “99000”, “features”: {“patches”: “32 Interchangeable Velcro Patches Included”, “exterior_dimensions”: “17.5” x 6″ x 11.5″”, “pockets”: [“Front zipper pocket”, “Side pockets”, “Zippered Stash pocket”, “Separate velour sunglass compartment”], “back_padding”: “Ergonomic mesh back padding”, “adjustable_straps”: …

Strategic Sourcing Conclusion and Outlook for velcro patches for backpacks

In conclusion, the strategic sourcing of velcro patches for backpacks presents a myriad of opportunities for B2B buyers across Africa, South America, the Middle East, and Europe. Leveraging the growing popularity of customizable and tactical patches can enhance product offerings, attract diverse consumer segments, and ultimately drive sales. Buyers should prioritize suppliers who offer a wide range of designs, competitive pricing, and flexible sourcing options to meet the unique demands of their markets.

As we look to the future, it is crucial for businesses to stay ahead of trends in personalization and functionality. The demand for high-quality, durable patches is set to rise, driven by both recreational and professional use. By forging strong partnerships with reliable manufacturers, buyers can ensure they are equipped to capitalize on this expanding market.

Now is the time to act—explore potential suppliers, assess product quality, and consider innovative designs that resonate with your target audience. Embrace the possibilities that velcro patches offer and position your brand for success in this dynamic landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.