Top 3 Dynaflex Exhaust Suppliers (And How to Choose)

Introduction: Navigating the Global Market for dynaflex exhaust

In an increasingly competitive global landscape, sourcing high-quality Dynaflex exhaust systems can pose significant challenges for international B2B buyers. Whether you’re looking to enhance the performance of heavy-duty trucks or seeking custom solutions for specialized vehicles, understanding the nuances of Dynaflex products is crucial. This comprehensive guide addresses the various types of Dynaflex exhaust systems, their applications across different sectors, and the critical factors to consider when vetting suppliers.

From performance enhancements to compliance with regional regulations, this resource is tailored for B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Germany. It empowers decision-makers to navigate the complexities of global sourcing, ensuring that they can make informed purchasing choices that align with their operational needs and budget constraints.

By exploring critical aspects such as pricing structures, material options, and installation requirements, buyers will gain valuable insights into the Dynaflex exhaust market. Additionally, the guide will highlight best practices for supplier evaluation and negotiation, equipping readers with the knowledge to foster successful partnerships that drive long-term value. With this guide in hand, international buyers can confidently navigate the global market for Dynaflex exhaust systems, ensuring they meet both performance standards and business objectives.

Understanding dynaflex exhaust Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monster Stacks | Large diameter, high shine, customizable designs | Heavy-duty trucks, show vehicles | Pros: Eye-catching, enhances vehicle aesthetics. Cons: Higher cost, may require specialized installation. |

| Muffler Kits | Integrated noise reduction, varied performance options | Fleet maintenance, noise-sensitive operations | Pros: Quieter operation, improved performance. Cons: Installation complexity, may require additional parts. |

| Curved Top Stacks | Unique aesthetic appeal, varied heights and finishes | Custom trucks, regional transport vehicles | Pros: Distinctive look, enhances brand visibility. Cons: Limited functionality compared to straight stacks. |

| Lower Stacks | Compact design, often used in conjunction with larger systems | Urban delivery trucks, short-haul vehicles | Pros: Space-saving, easy to install. Cons: Reduced exhaust flow, may impact performance. |

| Replacement Parts | Individual components like elbows and brackets for repairs | Maintenance and repair operations | Pros: Cost-effective, allows for targeted upgrades. Cons: Compatibility issues with non-Dynaflex systems. |

What Are the Key Characteristics of Monster Stacks in Dynaflex Exhaust Systems?

Monster stacks are characterized by their large diameter and high-polish chrome finish, making them a popular choice for heavy-duty trucks and show vehicles. They offer a range of customizable designs that can enhance the aesthetic appeal of a truck while also providing improved exhaust flow. B2B buyers should consider the installation requirements, as these stacks often need specialized fittings and can come at a premium price. While they boost visual impact, the cost and complexity of installation are important factors to weigh.

How Do Muffler Kits Enhance Dynaflex Exhaust Performance?

Muffler kits are designed to integrate noise reduction with performance enhancements, making them ideal for fleet maintenance and operations where noise control is critical. They provide options for varying levels of sound attenuation while maintaining exhaust efficiency. For businesses prioritizing quieter operations, investing in muffler kits can lead to better compliance with local noise regulations. However, buyers should be aware of potential installation complexities, which may necessitate additional components to ensure optimal performance.

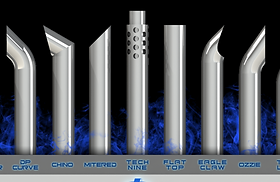

What Advantages Do Curved Top Stacks Offer for Custom Trucks?

Curved top stacks are known for their unique aesthetic appeal, available in various heights and finishes. They are particularly favored by custom truck builders and operators of regional transport vehicles, as they can significantly enhance brand visibility on the road. While they provide a distinctive look, their functionality may not match that of straight stacks. Buyers should assess the trade-off between aesthetics and performance, especially if they operate in performance-sensitive environments.

Why Are Lower Stacks Popular Among Urban Delivery Trucks?

Lower stacks are favored for their compact design, making them suitable for urban delivery trucks and short-haul vehicles where space is at a premium. They can be installed easily and offer a practical solution for businesses operating in tight spaces. However, it’s essential to note that lower stacks may reduce exhaust flow, potentially impacting overall vehicle performance. Buyers should consider the balance between space-saving benefits and the need for adequate exhaust efficiency.

How Do Replacement Parts Facilitate Dynaflex Exhaust Maintenance?

Replacement parts for Dynaflex exhaust systems, such as elbows and brackets, are crucial for ongoing maintenance and repair operations. They allow businesses to perform targeted upgrades or repairs without the need to replace entire exhaust systems, which can be cost-effective. However, compatibility issues can arise when integrating these parts with non-Dynaflex systems, so it’s vital for buyers to ensure compatibility before making purchases. This flexibility in maintenance can lead to improved operational efficiency and longevity of exhaust systems.

Key Industrial Applications of dynaflex exhaust

| Industry/Sector | Specific Application of dynaflex exhaust | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Heavy-duty trucks and commercial vehicles | Enhanced engine performance and reduced emissions | Compatibility with specific truck models and regulations |

| Mining and Construction | Equipment exhaust systems for heavy machinery | Improved operational efficiency and lower downtime | Durability to withstand harsh environments and vibrations |

| Agriculture | Exhaust systems for farming equipment | Increased fuel efficiency and reduced noise levels | Customization options for various machinery types |

| Oil and Gas | Exhaust solutions for drilling rigs and vehicles | Compliance with environmental standards and safety | Certification for high-temperature and corrosive environments |

| Automotive Aftermarket | Custom exhaust systems for performance vehicles | Enhanced aesthetics and performance tuning options | Availability of a wide range of sizes and styles |

How is Dynaflex Exhaust Used in the Transportation Sector?

In the transportation industry, dynaflex exhaust systems are integral to heavy-duty trucks and commercial vehicles. These exhaust systems enhance engine performance by allowing for better exhaust flow, which can lead to improved fuel efficiency and reduced emissions. For international buyers, particularly from regions like Africa and South America, it’s crucial to ensure that the exhaust systems comply with local environmental regulations and are compatible with specific truck models. Buyers should also consider the availability of parts for maintenance and repairs.

Illustrative image related to dynaflex exhaust

What Role Does Dynaflex Exhaust Play in Mining and Construction?

In mining and construction, dynaflex exhaust systems are used in heavy machinery such as bulldozers and excavators. The robust design of these exhaust systems helps to improve operational efficiency by ensuring that machinery operates smoothly under heavy loads. Additionally, these exhaust systems are engineered to withstand the harsh conditions often found in mining environments. Buyers in this sector should prioritize sourcing durable products that can handle vibrations and extreme temperatures to minimize equipment downtime.

How Does Dynaflex Exhaust Benefit the Agriculture Industry?

For the agriculture sector, dynaflex exhaust systems are applied to various farming equipment, including tractors and harvesters. These systems contribute to increased fuel efficiency, which is essential for cost management in large-scale farming operations. Moreover, they help in reducing noise levels, making for a more pleasant working environment. Buyers should look for customization options that fit different machinery types and ensure that the exhaust systems meet the operational requirements of their specific equipment.

In What Ways Does Dynaflex Exhaust Support the Oil and Gas Sector?

In the oil and gas industry, dynaflex exhaust solutions are critical for drilling rigs and associated vehicles. These exhaust systems are designed to meet stringent environmental standards while ensuring safe operation in challenging conditions. Buyers must consider the certification of exhaust systems for high-temperature and corrosive environments, as well as their compliance with safety regulations. This ensures that the equipment operates efficiently without compromising safety or environmental integrity.

How is Dynaflex Exhaust Used in the Automotive Aftermarket?

The automotive aftermarket benefits significantly from dynaflex exhaust systems, particularly for performance vehicles. These systems offer enhanced aesthetics and performance tuning options, appealing to car enthusiasts looking to improve their vehicles. Buyers should seek a wide range of sizes and styles to suit various vehicle models and personal preferences. Additionally, they should consider the availability of replacement parts to facilitate ongoing maintenance and customization.

Illustrative image related to dynaflex exhaust

3 Common User Pain Points for ‘dynaflex exhaust’ & Their Solutions

Scenario 1: Sourcing the Right Dynaflex Exhaust Kit for Specific Truck Models

The Problem: B2B buyers often face challenges when sourcing exhaust kits that are compatible with specific truck models, particularly in regions where information on fitment may be limited. For instance, a logistics company operating a fleet of trucks in Nigeria may struggle to find exhaust systems that not only meet local emissions regulations but also fit their specific truck makes and models, such as Peterbilt or Freightliner. This can lead to extended downtimes, increased maintenance costs, and frustration due to miscommunication with suppliers.

The Solution: To effectively source the right Dynaflex exhaust kit, buyers should start by compiling detailed specifications of their truck models, including the make, model, year, and engine type. Utilizing manufacturer resources and product catalogs from trusted suppliers can provide clarity on compatibility. Engaging with experienced suppliers who specialize in exhaust systems can also facilitate finding tailored solutions. When ordering, consider opting for suppliers that provide a guarantee of fitment or offer a return policy in case the part does not match. Furthermore, establishing a direct line of communication with suppliers to discuss specific needs can help mitigate errors in ordering.

Scenario 2: Managing Exhaust System Installation Challenges

The Problem: Installation of Dynaflex exhaust systems can be a daunting task, especially for businesses with limited mechanical expertise or resources. A construction company in South America might find that their teams lack the necessary skills to install complex exhaust systems, leading to improper installation, which can cause performance issues and potentially void warranties. This not only affects vehicle uptime but can also lead to costly repairs down the line.

The Solution: To alleviate installation challenges, businesses should invest in training sessions for their maintenance teams, focusing on the specifics of Dynaflex exhaust system installation. Many suppliers offer instructional materials or can connect businesses with certified technicians for on-site training. Additionally, utilizing online resources, such as video tutorials or detailed installation guides provided by manufacturers, can empower teams to perform installations correctly. For companies with multiple vehicles, considering a partnership with local service centers that specialize in exhaust systems can ensure professional installations, thus maintaining system integrity and performance.

Scenario 3: Addressing Performance and Maintenance Issues

The Problem: Over time, B2B buyers may encounter performance issues with their Dynaflex exhaust systems, which can manifest as decreased engine efficiency or increased noise levels. For example, a logistics firm operating in the Middle East may notice that their trucks are struggling to maintain power during heavy loads, leading to delays and increased fuel consumption. These performance drops can often be attributed to wear and tear or improper maintenance of the exhaust systems.

The Solution: To proactively address performance issues, businesses should implement a routine maintenance schedule that includes regular inspections of the exhaust system. This should involve checking for leaks, corrosion, and blockages that could hinder exhaust flow. Investing in high-quality exhaust system components, such as Dynaflex’s durable mufflers and stacks, can also enhance longevity and performance. Establishing a relationship with a knowledgeable supplier can provide valuable insights into the best maintenance practices and replacement intervals. For performance enhancement, consider consulting with exhaust system specialists who can recommend upgrades or modifications based on specific operational needs, ensuring that the exhaust system continues to perform optimally under varying loads and conditions.

Strategic Material Selection Guide for dynaflex exhaust

When selecting materials for Dynaflex exhaust systems, it’s crucial to consider various factors that influence performance, durability, and overall cost. Below is an analysis of four common materials used in the manufacturing of Dynaflex exhaust systems, highlighting their key properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Stainless Steel for Dynaflex Exhaust?

Stainless steel is widely regarded for its excellent corrosion resistance and high-temperature performance. It typically withstands temperatures up to 1,600°F (870°C) and maintains structural integrity under high pressure, making it suitable for exhaust applications. The alloy composition often includes chromium and nickel, enhancing its resistance to oxidation and scaling.

Pros and Cons:

Stainless steel is highly durable and can endure harsh environmental conditions, which is vital for exhaust systems exposed to extreme heat and corrosive substances. However, it tends to be more expensive than other materials, which can impact the overall cost of the exhaust system. Additionally, manufacturing processes for stainless steel can be complex, requiring specialized equipment.

Impact on Application:

Stainless steel is compatible with various exhaust gases, including those from diesel engines, making it a versatile choice for Dynaflex exhaust systems. Its resistance to rust and corrosion ensures longevity, especially in humid or coastal regions.

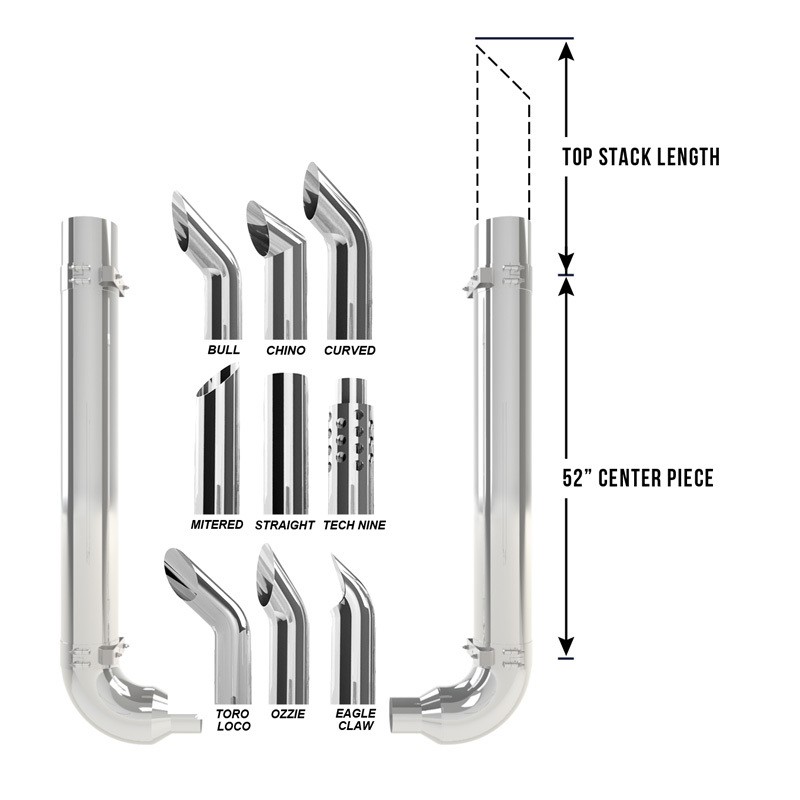

Illustrative image related to dynaflex exhaust

Considerations for International Buyers:

Buyers from regions like Nigeria and Germany should ensure compliance with local standards such as ASTM or DIN. The higher initial cost may be offset by the longevity and reduced maintenance needs, making it a worthwhile investment.

How Does Aluminized Steel Compare for Dynaflex Exhaust Systems?

Aluminized steel is a cost-effective alternative to stainless steel, featuring a coating that provides decent corrosion resistance. It can withstand temperatures up to approximately 1,200°F (650°C) but is less effective against extreme heat compared to stainless steel.

Pros and Cons:

The primary advantage of aluminized steel is its lower cost, making it an attractive option for budget-conscious buyers. However, it is not as durable as stainless steel and may require more frequent replacements, especially in corrosive environments. The manufacturing process is generally simpler, which can reduce production costs.

Impact on Application:

Aluminized steel is suitable for light to moderate exhaust applications but may not perform well in extreme conditions or with high-performance engines. Its coating can degrade over time, especially in high-heat scenarios.

Considerations for International Buyers:

For buyers in South America and the Middle East, where environmental conditions can be harsh, the longevity of aluminized steel may be a concern. Compliance with local standards should also be verified to ensure quality.

What Role Does Mild Steel Play in Dynaflex Exhaust Manufacturing?

Mild steel is often used in budget-friendly exhaust systems. It offers good strength and can handle moderate temperatures but lacks the corrosion resistance of stainless or aluminized steel.

Pros and Cons:

Mild steel is typically the least expensive option, making it attractive for cost-sensitive projects. However, its susceptibility to rust and corrosion means it may require regular maintenance or replacement, which can lead to higher long-term costs.

Impact on Application:

Mild steel is best suited for non-corrosive environments or where the exhaust system can be easily maintained. It is less ideal for heavy-duty applications or regions with high humidity.

Considerations for International Buyers:

Buyers should consider the local climate and maintenance capabilities when opting for mild steel. Compliance with relevant standards is essential to ensure safety and performance.

How Does Titanium Stand Out in Dynaflex Exhaust Applications?

Titanium is known for its exceptional strength-to-weight ratio and corrosion resistance, making it an ideal choice for high-performance exhaust systems. It can withstand extreme temperatures, often exceeding 1,800°F (982°C).

Pros and Cons:

The key advantage of titanium is its lightweight nature, which can enhance vehicle performance. However, it is significantly more expensive than other materials and requires specialized manufacturing techniques, making it less accessible for budget-conscious buyers.

Impact on Application:

Titanium is particularly beneficial in racing or high-performance applications where weight savings and durability are critical. Its resistance to corrosion ensures longevity, even in the most demanding environments.

Illustrative image related to dynaflex exhaust

Considerations for International Buyers:

For buyers in Europe and the Middle East, the high cost of titanium may be a barrier. However, its performance benefits can justify the investment for specialized applications.

Summary Table of Material Selection for Dynaflex Exhaust

| Material | Typical Use Case for dynaflex exhaust | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty and high-performance systems | Excellent corrosion resistance | Higher initial cost and complexity | High |

| Aluminized Steel | Budget-friendly exhaust applications | Cost-effective | Less durable, moderate temperature handling | Medium |

| Mild Steel | Basic exhaust systems | Low cost | Prone to rust and corrosion | Low |

| Titanium | High-performance racing applications | Lightweight and durable | Very high cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for Dynaflex exhaust systems, enabling international B2B buyers to make informed decisions based on their specific needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for dynaflex exhaust

What Are the Key Stages in the Manufacturing Process of Dynaflex Exhaust Systems?

The manufacturing of Dynaflex exhaust systems involves several meticulously coordinated stages that ensure high-quality output. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-grade materials, primarily stainless steel and aluminum, known for their durability and resistance to corrosion. These materials are sourced from reputable suppliers who adhere to international standards. Once the materials are received, they undergo an inspection to verify their quality and specifications.

-

Forming: After preparation, the materials are subjected to various forming techniques. This may include cutting, bending, and welding, which are performed using advanced machinery such as CNC machines and robotic welders. These technologies ensure precision and consistency in the components, reducing the likelihood of defects.

-

Assembly: The next stage is assembly, where individual components are meticulously brought together. This process often involves the use of fixtures and jigs to maintain alignment and ensure the structural integrity of the exhaust systems. Skilled technicians oversee this stage, applying their expertise to guarantee that each assembly meets design specifications.

-

Finishing: Finally, finishing processes such as polishing, coating, or painting are applied to enhance aesthetics and protect against environmental factors. This stage is crucial for the appearance and longevity of the exhaust systems. Quality checks are performed at this stage to ensure that the finish is even and meets the required standards.

How Is Quality Assurance Implemented in Dynaflex Exhaust Manufacturing?

Quality assurance (QA) is a critical aspect of Dynaflex exhaust manufacturing, ensuring that products meet both international standards and customer expectations. The QA process typically adheres to several key international standards, including ISO 9001, which provides a framework for effective quality management systems.

-

International and Industry-Specific Standards: Compliance with ISO 9001 ensures that manufacturers have established quality management systems that are regularly audited for effectiveness. Additionally, products may need to meet specific industry standards such as CE marking for safety in the European market or API standards for performance in North America.

-

Quality Control Checkpoints: The QA process involves several checkpoints:

– Incoming Quality Control (IQC): This phase assesses the quality of raw materials upon receipt. Any non-conformance is documented and addressed before processing.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to catch defects early. This includes monitoring forming techniques and assembly processes.

– Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is performed to ensure that all specifications have been met. This may involve functional testing and visual inspections. -

Common Testing Methods: Various testing methods are employed to validate the performance and durability of the exhaust systems. These can include:

– Pressure Testing: To ensure that the exhaust system can withstand operational pressures without leaking.

– Thermal Cycling Tests: To assess the resilience of materials under varying temperature conditions.

– Corrosion Resistance Testing: To evaluate how materials hold up against environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control systems. During these audits, buyers can assess compliance with international standards and review documentation related to quality practices.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s historical performance. These reports should include data on defect rates, compliance with standards, and results from quality tests.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control practices. These agencies can perform thorough inspections and provide certification that the products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances is crucial for international B2B buyers. Different regions may have varying expectations regarding quality standards, certifications, and compliance.

-

Regional Compliance Requirements: Buyers from Europe, for instance, must ensure that products comply with CE marking regulations, whereas those in the Middle East might focus on specific regional certifications. Understanding these nuances is key to preventing potential compliance issues.

-

Documentation and Traceability: Maintaining thorough documentation of quality processes is vital for B2B transactions. This includes certificates of conformity, testing results, and material traceability records. Buyers should ensure that suppliers can provide this documentation upon request.

-

Cultural Considerations: Cultural differences can also affect quality perceptions and expectations. Engaging with local experts or consultants can provide insights into specific market requirements and help buyers navigate these complexities.

Conclusion

Understanding the manufacturing processes and quality assurance practices of Dynaflex exhaust systems is essential for B2B buyers looking to make informed purchasing decisions. By focusing on key manufacturing stages, robust quality control measures, and the verification of supplier practices, international buyers can ensure they source reliable and high-quality exhaust systems that meet their operational needs. This not only enhances their supply chain efficiency but also contributes to long-term business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dynaflex exhaust’

This guide aims to provide B2B buyers with a structured approach to sourcing Dynaflex exhaust systems. Whether you are upgrading your fleet or establishing new partnerships, following these steps will help ensure that you make informed decisions that align with your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. This includes the type of vehicle (e.g., Peterbilt, Freightliner), the specific exhaust system needed (e.g., stacks, mufflers), and any custom specifications. Understanding these details will help you communicate effectively with suppliers and ensure that the products meet your performance and regulatory requirements.

Illustrative image related to dynaflex exhaust

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in Dynaflex exhaust products. Look for companies with a strong presence in the market, positive reviews, and a history of reliability. Key considerations should include:

– Geographical reach: Ensure they can service your region effectively, especially for international shipping.

– Product range: Verify that they offer a variety of exhaust systems and components tailored to your specifications.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it’s crucial to verify the certifications and compliance of potential suppliers. This ensures that the products meet industry standards for quality and safety. Look for certifications such as ISO 9001 or relevant local standards, as these can indicate the supplier’s commitment to excellence. Additionally, ask for product warranties and guarantees.

Step 4: Request Samples or Prototypes

If possible, request samples or prototypes of the Dynaflex exhaust systems you are considering. This allows you to assess the quality, fit, and finish of the products firsthand. Testing samples can also help you determine if the exhaust systems will meet your performance needs and compatibility with existing equipment.

Step 5: Analyze Pricing and Payment Terms

Once you’ve shortlisted potential suppliers, analyze their pricing structures and payment terms. Look beyond the initial cost; consider factors such as:

– Volume discounts: Inquire if bulk purchases lead to reduced prices.

– Payment flexibility: Understand the payment terms, including deposit requirements and payment methods.

Step 6: Review Shipping and Delivery Options

Discuss shipping logistics with suppliers to understand their delivery capabilities. Ensure they can meet your timelines, especially if you are working under tight schedules. Considerations should include:

– Lead times: Ask about average processing and shipping times.

– International shipping: Confirm that they can handle customs and duties if you are importing products.

Step 7: Establish Long-term Relationships

Building a long-term relationship with a supplier can lead to better service and pricing in the future. Engage with your selected supplier regularly, provide feedback, and discuss potential future needs. This can foster a partnership that benefits both parties and enhances supply chain efficiency.

Illustrative image related to dynaflex exhaust

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring Dynaflex exhaust systems with confidence, ensuring they select the right products and suppliers for their operational needs.

Comprehensive Cost and Pricing Analysis for dynaflex exhaust Sourcing

What Are the Key Cost Components of Dynaflex Exhaust Systems?

When sourcing Dynaflex exhaust systems, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used, such as stainless steel or chrome, significantly impacts pricing. Higher-grade materials often lead to increased durability and performance, which can justify a higher cost.

-

Labor: Labor costs are influenced by the complexity of manufacturing and assembly. Skilled labor, especially in regions with higher wage standards, can increase production costs.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and administrative expenses. Efficient production methods can help reduce these costs.

-

Tooling: Custom tooling for specific exhaust designs or configurations adds to initial costs. However, this investment can lead to cost savings in large-volume production.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but can add to the overall expense. Certifications and compliance with international standards may also contribute to QC costs.

-

Logistics: Shipping costs vary based on distance, mode of transport, and freight terms. Buyers should consider the total logistics cost when evaluating suppliers.

-

Margin: Suppliers typically include a profit margin that varies based on market competition and perceived value of the product.

How Do Price Influencers Affect Dynaflex Exhaust Pricing?

Several factors influence the pricing of Dynaflex exhaust systems:

-

Volume/MOQ: Larger order volumes often lead to lower per-unit costs. Negotiating minimum order quantities (MOQs) can significantly impact overall pricing.

-

Specifications and Customization: Customized exhaust solutions tailored to specific vehicle models or performance requirements can increase costs. Standard configurations generally offer more competitive pricing.

-

Materials and Quality Certifications: The choice of materials affects durability and performance. Additionally, products with recognized quality certifications (e.g., ISO) may command higher prices due to increased trust and assurance of quality.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to their perceived value and service quality.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can significantly affect the total landed cost. Understanding these terms is crucial for international transactions to avoid unexpected expenses.

What Buyer Tips Can Help Optimize Costs When Sourcing Dynaflex Exhaust?

To maximize cost-efficiency in sourcing Dynaflex exhaust systems, consider the following tips:

-

Effective Negotiation: Engage suppliers in negotiations to secure better pricing. Discussing potential discounts for larger orders or repeat business can yield favorable terms.

-

Understanding Total Cost of Ownership (TCO): Assess not just the initial purchase price but also the long-term costs associated with maintenance, durability, and operational efficiency. A higher upfront investment in quality may lead to lower TCO.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should be aware of currency fluctuations and import duties, which can impact final costs. Researching local regulations and tariffs is essential to avoid surprises.

-

Quality vs. Cost: While it may be tempting to choose the lowest-priced option, consider the long-term implications of quality. Investing in higher-quality exhaust systems can lead to reduced maintenance costs and better performance.

-

Supplier Diversification: Explore multiple suppliers to compare pricing and terms. This competitive analysis can provide leverage in negotiations and help identify the best value.

Disclaimer on Indicative Prices

Prices for Dynaflex exhaust systems can fluctuate based on market conditions, supplier pricing strategies, and changes in raw material costs. The figures provided in various sources should be viewed as indicative rather than definitive. Always consult suppliers for the most accurate and up-to-date pricing information tailored to your specific requirements.

Alternatives Analysis: Comparing dynaflex exhaust With Other Solutions

Exploring Alternatives to Dynaflex Exhaust Systems

In the competitive landscape of heavy-duty trucking and transportation, selecting the right exhaust system is crucial for optimizing performance, ensuring compliance with environmental regulations, and managing operational costs. While Dynaflex exhaust systems are renowned for their durability and efficiency, several alternative solutions exist that may better suit specific needs or preferences. Below is a comparative analysis of Dynaflex exhaust against two other viable alternatives: traditional stainless steel exhaust systems and high-performance aftermarket exhaust systems.

| Comparison Aspect | Dynaflex Exhaust | Traditional Stainless Steel Exhaust | High-Performance Aftermarket Exhaust |

|---|---|---|---|

| Performance | Excellent flow, improved power | Good, but limited by design | Superior power and torque gains |

| Cost | Moderate to high | Generally lower | Higher initial investment |

| Ease of Implementation | Straightforward installation | Standard installation procedures | May require professional installation |

| Maintenance | Low maintenance, corrosion-resistant | Moderate maintenance required | Varies by brand and model |

| Best Use Case | Versatile for various truck models | Standard replacement for OEM | Ideal for performance upgrades |

What Are the Benefits and Drawbacks of Traditional Stainless Steel Exhaust Systems?

Traditional stainless steel exhaust systems are a popular choice for many truck owners looking for a budget-friendly solution. They typically offer good durability and moderate performance improvements over OEM systems. However, they may not provide the same level of exhaust flow or power enhancement as Dynaflex systems, potentially leading to lower overall efficiency. Maintenance can be more frequent due to susceptibility to rust and corrosion, especially in harsh environments, though stainless steel does offer better longevity than standard mild steel.

Illustrative image related to dynaflex exhaust

How Do High-Performance Aftermarket Exhaust Systems Compare?

High-performance aftermarket exhaust systems are designed to maximize engine output and improve efficiency. They are often crafted from lightweight materials such as aluminum or high-grade stainless steel, contributing to weight reduction and enhanced performance. While these systems can offer significant power and torque gains, the initial investment is typically higher than both Dynaflex and traditional stainless steel options. Installation can also be complex, often requiring professional help, which adds to the overall cost. Maintenance requirements can vary widely, depending on the specific brand and model chosen.

Conclusion: How to Select the Right Exhaust System for Your Needs

When choosing the appropriate exhaust system for your fleet, consider factors such as budget, performance goals, and the specific operational environment. Dynaflex exhaust systems stand out for their balance of performance and durability, making them suitable for a wide range of applications. However, if cost is a primary concern, traditional stainless steel systems may suffice. For those prioritizing maximum performance and efficiency, high-performance aftermarket systems could be the best fit, despite the higher costs and installation complexities. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational needs and financial objectives.

Essential Technical Properties and Trade Terminology for dynaflex exhaust

What Are the Key Technical Properties of Dynaflex Exhaust Systems?

When considering Dynaflex exhaust systems, understanding the critical technical properties is essential for B2B buyers to make informed purchasing decisions. Below are several key specifications that are vital to the performance and reliability of these exhaust systems:

-

Material Grade

Dynaflex exhaust products are typically manufactured from high-grade stainless steel or aluminized steel. The choice of material affects the system’s durability, resistance to corrosion, and overall lifespan. Stainless steel offers superior resistance to rust and wear, making it ideal for harsh environments often found in international markets like Africa and South America. B2B buyers should prioritize high-grade materials to ensure long-term performance and reduce replacement costs. -

Diameter and Length

Exhaust systems come in various diameters, commonly ranging from 5 inches to 8 inches, and lengths that can vary significantly based on the vehicle model. The diameter influences exhaust flow efficiency, affecting engine performance and fuel economy. Choosing the correct diameter and length is crucial for compatibility with specific truck models, ensuring optimal performance and compliance with regional regulations. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. In exhaust systems, precise tolerances are critical for ensuring proper fitment and function. Poor tolerances can lead to exhaust leaks, decreased performance, and increased emissions. B2B buyers should ensure that the products they procure meet industry standards for tolerance to avoid costly installation issues. -

Muffler Design

The design of the muffler plays a significant role in noise reduction and exhaust flow management. Different designs, such as straight-through or baffled mufflers, can impact both performance and sound levels. Understanding the specific needs of your market—whether it’s noise regulations in urban areas or performance requirements for long-haul trucking—will guide purchasing decisions. -

Heat Resistance

Exhaust systems must withstand high temperatures generated by engine operations. Heat resistance properties are crucial to prevent warping or failure over time. B2B buyers should look for exhaust systems that can handle the high thermal loads typical in heavy-duty applications, especially in regions with extreme climates.

What Are Common Trade Terms Associated with Dynaflex Exhaust Systems?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in B2B transactions. Here are some essential trade terms relevant to Dynaflex exhaust systems:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. For buyers, choosing OEM parts can ensure compatibility and maintain the vehicle’s warranty. Understanding OEM specifications can help in sourcing the right Dynaflex exhaust products that align with original vehicle designs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ for Dynaflex exhaust systems can help businesses plan their purchases effectively, especially when dealing with international suppliers. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing for specific products. Crafting a clear RFQ for Dynaflex exhaust products ensures that suppliers provide accurate and competitive pricing, enabling better budgeting and procurement decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers to mitigate risks and ensure compliance with international shipping regulations when sourcing Dynaflex exhaust systems. -

Lead Time

Lead time is the amount of time between placing an order and receiving the goods. For B2B buyers, understanding lead times is critical for inventory planning and project timelines. Knowing the lead times for Dynaflex products can help businesses avoid delays in operations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately leading to enhanced operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the dynaflex exhaust Sector

What Are the Key Market Dynamics and Trends Influencing the Dynaflex Exhaust Sector?

The global dynaflex exhaust market is experiencing significant growth driven by several key factors. Firstly, the rise in freight transportation demand, particularly in regions like Africa and South America, is spurring the need for efficient exhaust systems that enhance vehicle performance. Additionally, advancements in technology are leading to the development of high-performance exhaust systems that improve fuel efficiency and reduce emissions, aligning with stricter environmental regulations worldwide.

Emerging trends in B2B sourcing include a shift towards digital platforms for procurement. Buyers are increasingly utilizing e-commerce sites and online catalogs to compare products, prices, and specifications, streamlining the purchasing process. This trend is particularly pronounced in Europe and the Middle East, where digital transformation is reshaping traditional supply chains. Furthermore, customization options are gaining traction as buyers look for exhaust systems tailored to specific truck models and operational needs, enhancing the overall value proposition.

International B2B buyers should also be aware of fluctuating material costs, particularly stainless steel and chrome, which are essential for manufacturing durable exhaust components. Supply chain disruptions caused by geopolitical tensions and the lingering effects of the pandemic may impact sourcing strategies, necessitating agile procurement practices and diversified supplier relationships.

How Is Sustainability Shaping Sourcing Decisions in the Dynaflex Exhaust Market?

Sustainability is becoming a pivotal consideration for B2B buyers in the dynaflex exhaust sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. This includes the use of recyclable materials and energy-efficient manufacturing techniques, which not only minimize carbon footprints but also resonate with customers who are increasingly environmentally conscious.

Ethical sourcing is equally important, as buyers are now more inclined to partner with suppliers that demonstrate transparency in their supply chains. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with these certifications, businesses can mitigate risks associated with unethical practices and enhance their brand reputation.

Moreover, the demand for ‘green’ exhaust solutions is on the rise, with manufacturers innovating to produce systems that reduce emissions and comply with stringent regulations. Buyers who invest in sustainable products not only contribute to environmental preservation but also position themselves favorably in a market that increasingly values corporate responsibility.

What Is the Historical Context of Dynaflex Exhaust Systems for B2B Buyers?

The evolution of dynaflex exhaust systems traces back to the increasing demand for high-performance truck components in the late 20th century. Originally designed to improve exhaust flow and reduce back pressure, these systems have transformed significantly, incorporating advanced materials and technologies that enhance durability and efficiency.

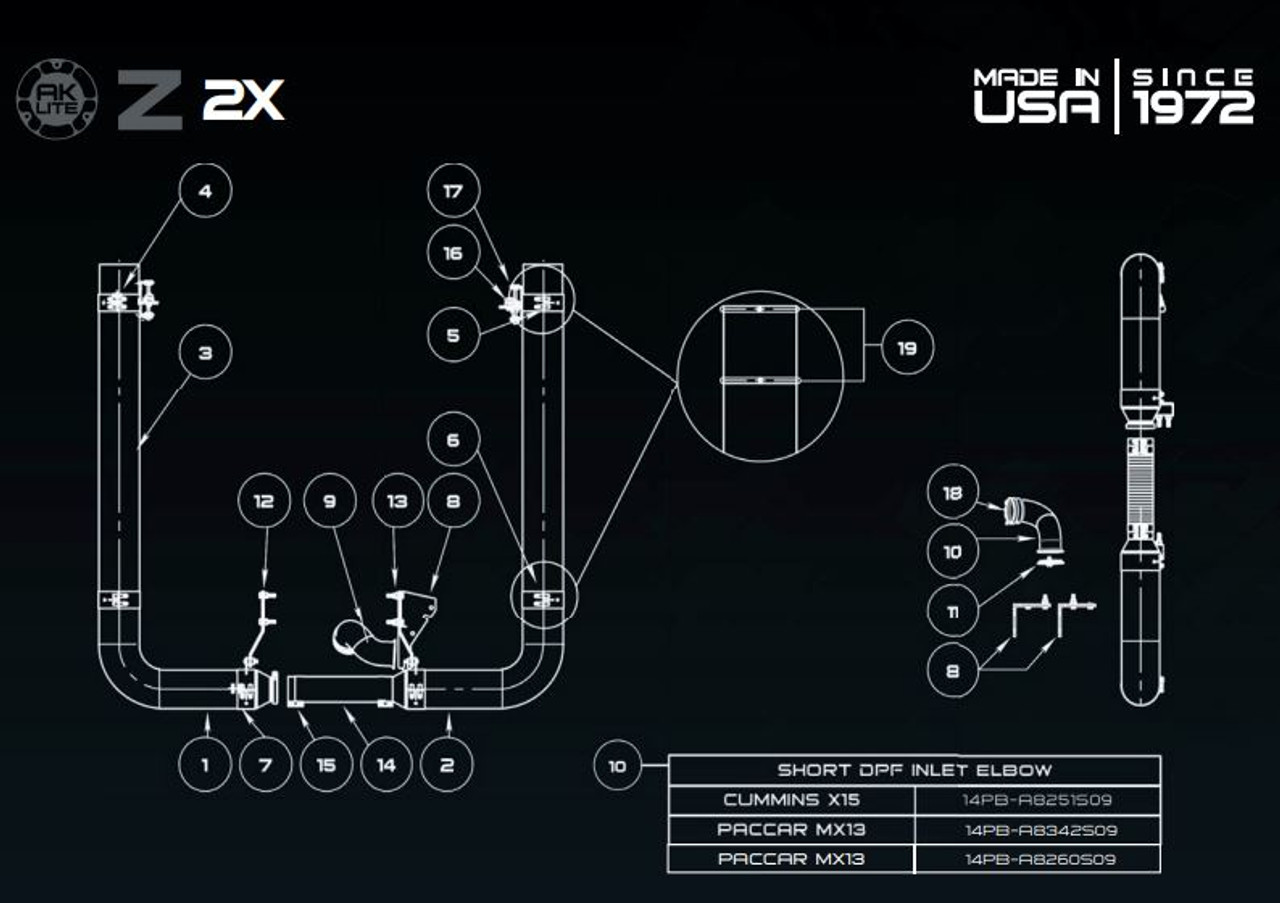

Illustrative image related to dynaflex exhaust

Over the years, the advent of stricter emission regulations has further shaped the dynaflex exhaust market. Manufacturers have had to innovate continuously, developing products that not only meet performance standards but also adhere to environmental guidelines. This historical context is vital for B2B buyers, as it highlights the importance of choosing suppliers that are not only well-established but also forward-thinking in their approach to product development and sustainability.

By understanding these dynamics, buyers can make informed decisions that align with their operational needs and corporate values, ensuring they remain competitive in a rapidly evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of dynaflex exhaust

-

How do I select the right Dynaflex exhaust system for my truck?

Choosing the right Dynaflex exhaust system involves several factors. First, identify your truck model and engine specifications, as compatibility is key. Next, consider the type of performance you need; for instance, if you’re looking for enhanced power, opt for larger diameter stacks. Lastly, think about aesthetics; Dynaflex offers various styles, from polished chrome to matte finishes. Consulting with suppliers who can provide fitment guides and expert advice can also simplify the selection process. -

What is the best Dynaflex exhaust system for increased performance?

For optimal performance, the Dynaflex Monster Stack system is highly recommended. This system is designed to enhance exhaust flow, which can lead to improved engine efficiency and power output. Depending on your truck type, choosing a larger diameter stack can further boost performance during heavy loads or steep climbs. Additionally, integrating a quality muffler can help reduce noise while maintaining performance levels. -

What are the common customization options available for Dynaflex exhaust systems?

Dynaflex exhaust systems offer a variety of customization options to meet specific needs. Buyers can select from different stack sizes, styles, and finishes, including chrome and black powder-coated options. You can also customize the exhaust length and bend angles to fit your truck’s unique configuration. Furthermore, many suppliers allow for custom orders, ensuring you receive a system tailored to your specifications. -

What should I consider when vetting a supplier for Dynaflex exhaust systems?

When vetting suppliers, consider their reputation in the market, especially regarding product quality and customer service. Look for suppliers with a proven track record in B2B transactions and positive reviews from other buyers. Additionally, inquire about their warranty policies, return procedures, and the availability of technical support. It’s also wise to assess their compliance with international shipping regulations, particularly when sourcing from regions like Africa or South America. -

What are the minimum order quantities (MOQ) for Dynaflex exhaust systems?

Minimum order quantities for Dynaflex exhaust systems can vary by supplier. Typically, MOQs may range from a single unit for smaller distributors to larger quantities for bulk purchases. If you’re a new business or a smaller buyer, it’s advisable to communicate your needs directly with suppliers, as many are willing to accommodate smaller orders, especially if they see potential for long-term partnership. -

What payment terms should I expect when purchasing Dynaflex exhaust systems internationally?

Payment terms for international purchases can vary widely. Common arrangements include upfront payment, net 30 days, or letter of credit terms. It’s essential to clarify payment methods accepted, such as bank transfers, credit cards, or escrow services. Discussing these terms upfront can help avoid misunderstandings and ensure a smooth transaction process, especially when dealing with suppliers from different regions. -

How can I ensure quality assurance (QA) for my Dynaflex exhaust systems?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Many reputable manufacturers conduct rigorous testing on their exhaust systems to meet industry standards. Ask about their QA processes, such as inspections and testing protocols. Additionally, consider ordering samples for evaluation before committing to larger orders, allowing you to assess the product’s quality firsthand. -

What logistics considerations should I keep in mind when importing Dynaflex exhaust systems?

When importing Dynaflex exhaust systems, consider the logistics of shipping, including freight options, customs duties, and delivery timelines. Choose a reliable freight forwarder experienced in handling automotive parts to navigate international shipping complexities. Additionally, be aware of your country’s import regulations, as they may impact costs and delivery times. Proper documentation, including invoices and certificates of origin, will also facilitate smoother customs clearance.

Top 3 Dynaflex Exhaust Manufacturers & Suppliers List

1. Dynaflex – Exhaust Systems

Domain: bigrigchromeshop.com

Registered: 2003 (22 years)

Introduction: Dynaflex Exhaust Systems products include: 1. Universal Replacement Graphite Gasket (For Expand-O-Flex Joints) – Starting at $25.99 2. Zinc Plated Mounting Bracket Clamp – Starting at $24.89 3. Kenworth Exhaust Mounting Bracket – Starting at $160.99 4. 45 Degree Rain Cap – Starting at $179.99 5. Carbon Steel Mounting Bracket Clamp – Starting at $20.29 6. Chrome Plated Rain Cap for Straight Stacks …

2. Dynaflex – Chrome Exhaust Stack

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “Dynaflex Chrome Exhaust Stack”, “condition”: “New”, “price”: “$275.00”, “shipping”: “$62.58”, “estimated_delivery”: “Wed, Sep 10 – Sat, Sep 13”, “quantity_available”: “2”, “brand”: “Dynaflex”, “category”: “eBay Motors > Parts & Accessories > Commercial Truck Parts > Exhaust & Emissions > Other Exhaust & Emissions”, “item_number”: “125426851571”, “returns”: “Accepted within 30 days”}

3. Dynaflex – Chino Stacks & Exhaust Clamps

Domain: 43northparts.com

Registered: 2017 (8 years)

Introduction: [{‘product_name’: ‘Dynaflex Chino Stacks’, ‘stock_status’: ‘In Stock’}, {‘product_name’: ‘Dynaflex 6″ 50 Series Monster Stack Exhaust Clamp’, ‘price’: ‘$185.50’, ‘stock_status’: ‘In Stock’}, {‘product_name’: ‘Dynaflex 7″ 50 Series Monster Stack Exhaust Clamp’, ‘price’: ‘$194.50’, ‘stock_status’: ‘In Stock’}, {‘product_name’: ‘Dynaflex 8″ 50 Series Monster Stack Exhaust Clamp’, ‘price’: ‘$201.50’, …

Strategic Sourcing Conclusion and Outlook for dynaflex exhaust

In navigating the complexities of sourcing Dynaflex exhaust systems, international B2B buyers must prioritize strategic partnerships and an understanding of local market dynamics. The versatility and performance-enhancing capabilities of Dynaflex products make them an attractive option for fleet operators looking to optimize their operations. By leveraging local distributors and manufacturers, buyers can ensure access to a diverse range of exhaust kits tailored to specific truck models, ultimately reducing lead times and enhancing service reliability.

Illustrative image related to dynaflex exhaust

Furthermore, as environmental regulations tighten globally, sourcing high-quality exhaust systems that meet compliance standards will become increasingly critical. Buyers should consider suppliers that offer not only performance but also eco-friendly solutions, as this will position their fleets favorably in the eyes of regulators and customers alike.

Looking ahead, the demand for Dynaflex exhaust systems is expected to grow, particularly in emerging markets across Africa, South America, and the Middle East. This presents a significant opportunity for B2B buyers to invest in superior exhaust solutions that enhance operational efficiency. Engaging with reputable suppliers will be key to capitalizing on this trend. Now is the time to act—evaluate your sourcing strategy, establish strong supplier relationships, and ensure your fleet is equipped for the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.