Everything You Need to Know About Snowflake Ice Machine Sourcing in 2025

Introduction: Navigating the Global Market for snowflake ice machine

In an increasingly competitive global market, sourcing the right snowflake ice machine can present significant challenges for B2B buyers. Whether you are operating a bustling café in Brazil or a seafood restaurant in the Middle East, understanding the nuances of different machines—from production capacities to ice textures—can be pivotal to your success. This guide is designed to provide a comprehensive overview of the snowflake ice machine landscape, covering various types, applications, and essential factors to consider during the purchasing process.

We delve into critical aspects such as supplier vetting, ensuring quality and reliability, as well as the cost implications that come with different machines. By equipping international buyers, particularly those from Africa, South America, Europe, and the Middle East, with actionable insights, this guide aims to empower you to make informed purchasing decisions. With the right knowledge, you can enhance your product offerings, streamline operations, and ultimately meet the diverse needs of your clientele.

Navigating the complexities of the snowflake ice machine market doesn’t have to be daunting. With this guide, you will gain the confidence to select the ideal equipment that aligns with your business goals and customer expectations, setting you on the path to success in your food and beverage ventures.

Understanding snowflake ice machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Snowflake Ice Maker | High production capacity, stainless steel construction | Restaurants, cafes, and bars | Pros: Durable, efficient ice production. Cons: Higher upfront cost. |

| Automatic Ice Shaver | Touch control panel, fast operation, variety of ice textures | Dessert shops, food trucks, and catering services | Pros: Easy to use, versatile ice shapes. Cons: Maintenance required for optimal performance. |

| Countertop Snowflake Ice Machine | Compact design, suitable for small businesses | Small cafes, kiosks, and home use | Pros: Space-saving, affordable. Cons: Limited ice production capacity. |

| Industrial Ice Flaker | Large-scale ice production, robust cooling systems | Seafood processing, large-scale catering | Pros: High output, ideal for bulk needs. Cons: Requires significant space and investment. |

| Portable Snowflake Ice Maker | Lightweight, easy to transport | Events, outdoor catering, and small parties | Pros: Convenient for mobile use. Cons: Lower ice production capacity compared to commercial models. |

What Are the Key Characteristics of Commercial Snowflake Ice Makers?

Commercial snowflake ice makers are designed for high-volume ice production, often capable of generating hundreds of pounds of ice daily. Made from durable stainless steel, these machines are built to withstand rigorous use in bustling environments like restaurants, bars, and cafes. When considering a purchase, B2B buyers should evaluate the machine’s output capacity, energy efficiency, and maintenance requirements to ensure it meets their operational demands.

How Do Automatic Ice Shavers Enhance Business Operations?

Automatic ice shavers are equipped with advanced features such as touch control panels and adjustable roller speeds that allow operators to create a variety of ice textures quickly. This versatility is particularly beneficial for dessert shops and food trucks that offer unique ice-based products. Buyers should consider the machine’s ease of use, cleaning capabilities, and the range of textures it can produce to maximize their investment.

Why Choose Countertop Snowflake Ice Machines for Small Businesses?

Countertop snowflake ice machines are ideal for small businesses with limited space, such as cafes and kiosks. They offer a compact design while still delivering quality ice, making them a practical choice for businesses looking to enhance their beverage offerings without requiring extensive floor space. Buyers should assess the machine’s ice production capacity and energy consumption to find a balance between functionality and cost.

Illustrative image related to snowflake ice machine

What Are the Advantages of Industrial Ice Flakers for Large-Scale Operations?

Industrial ice flakers are designed for environments that require large quantities of ice, such as seafood processing facilities and large catering operations. These machines can produce significant amounts of ice quickly, supporting businesses that need to keep products fresh and maintain optimal temperatures. However, potential buyers must consider the investment required for such machinery and ensure they have the necessary space to accommodate it.

How Do Portable Snowflake Ice Makers Benefit Event Catering?

Portable snowflake ice makers provide flexibility and convenience for mobile catering services and events. Their lightweight design allows for easy transport, making them suitable for outdoor gatherings and parties. However, buyers should be aware of the trade-off in ice production capacity, as these machines typically produce less ice than their commercial counterparts. Evaluating the expected demand during events will help businesses choose the right model for their needs.

Key Industrial Applications of snowflake ice machine

| Industry/Sector | Specific Application of Snowflake Ice Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Production of Shaved Ice Desserts | Enhances menu offerings and attracts more customers | Capacity requirements, energy efficiency, and durability |

| Seafood and Fresh Produce | Ice for Seafood Display and Preservation | Maintains freshness and quality of products, reducing spoilage | Ice production capacity, stainless steel construction, and ease of cleaning |

| Hospitality and Catering | Ice for Cocktails and Beverages | Improves drink presentation and customer experience | Speed of ice production, machine size, and ease of operation |

| Retail Ice Cream Shops | Creation of Snowflake Ice for Specialty Flavors | Differentiates product offerings and boosts sales | Texture variability, maintenance support, and warranty options |

| Event Management | On-site Ice Production for Events and Festivals | Provides fresh ice on demand, ensuring guest satisfaction | Portability, production capacity, and ease of use |

How is Snowflake Ice Machine Utilized in the Food and Beverage Industry?

In the food and beverage sector, snowflake ice machines are primarily used to produce shaved ice desserts, enhancing menu offerings in restaurants and cafes. By providing a variety of textures and flavors, these machines attract customers looking for unique dessert experiences. For international buyers, especially in Africa and South America, sourcing machines with high production capacities is crucial to meet demand during peak seasons.

What Role Does Snowflake Ice Play in Seafood and Fresh Produce Preservation?

Snowflake ice machines are essential in the seafood and fresh produce industries for maintaining the quality and freshness of products. The fine texture of snowflake ice allows for better coverage and cooling, which helps in reducing spoilage during transportation and display. Buyers in the Middle East and Europe should consider machines that offer robust stainless steel construction for durability and ease of cleaning to ensure compliance with hygiene standards.

Illustrative image related to snowflake ice machine

How Can Hospitality and Catering Benefit from Snowflake Ice Machines?

In hospitality and catering, snowflake ice machines are used to produce ice for cocktails and beverages, enhancing both presentation and taste. The ability to quickly produce ice on-site ensures that events run smoothly and guests are satisfied. For buyers in Europe, particularly Germany, it’s important to focus on machines that offer rapid production speeds and user-friendly operations to cater to high-volume events.

Why are Retail Ice Cream Shops Investing in Snowflake Ice Machines?

Retail ice cream shops leverage snowflake ice machines to create specialty flavors that stand out in a competitive market. The unique texture of snowflake ice allows for innovative dessert creations, appealing to diverse customer preferences. Buyers from South America should prioritize machines that allow for texture variability and easy maintenance to ensure consistent product quality and operational efficiency.

How Do Event Management Companies Utilize Snowflake Ice Machines?

Event management companies benefit from snowflake ice machines by providing on-site ice production for festivals and large gatherings. This capability ensures that fresh ice is available as needed, enhancing guest satisfaction and operational flexibility. For international buyers, especially in regions with hot climates, sourcing portable machines with high production capacities is essential to meet the demands of outdoor events.

3 Common User Pain Points for ‘snowflake ice machine’ & Their Solutions

Scenario 1: Ice Production Inefficiency During Peak Seasons

The Problem: B2B buyers, particularly those operating in the food and beverage industry, often face the challenge of insufficient ice production during peak seasons, such as summer or festive periods. For example, a restaurant or café may experience a sudden surge in customer demand for iced beverages or desserts. If their snowflake ice machine cannot keep up with the demand, it leads to dissatisfied customers, lost sales opportunities, and potential damage to the brand’s reputation.

The Solution: To address this issue, businesses should invest in a high-capacity snowflake ice machine that can produce ice efficiently. When sourcing such equipment, consider machines with a production capacity of at least 400 lbs per day to accommodate spikes in demand. Additionally, look for models with quick recovery times and efficient cooling systems, allowing for continuous ice production without significant downtime. It’s also beneficial to implement a regular maintenance schedule to ensure optimal performance, especially before anticipated busy periods. Training staff on how to operate and maintain the machines properly can further enhance efficiency and reliability.

Illustrative image related to snowflake ice machine

Scenario 2: Difficulty in Achieving Desired Ice Texture

The Problem: Many B2B buyers struggle with achieving the perfect texture of snowflake ice, which is crucial for various applications like desserts or cocktails. Inconsistent ice texture can result from using outdated machines or improper operation, leading to a subpar customer experience. For instance, a dessert shop that relies on fluffy snowflake ice for its bingsu may find that their current machine produces ice that is either too coarse or too fine, affecting the overall quality of their offerings.

The Solution: To ensure the desired ice texture, businesses should select a snowflake ice machine equipped with adjustable settings for roller speed and ice density. This feature allows operators to customize the ice texture according to specific recipes or customer preferences. Additionally, investing in a machine that utilizes advanced cooling technology can help maintain consistent ice quality. Regular training for staff on machine settings and ice production techniques is essential, as is conducting routine quality checks to ensure the ice meets the desired standards. Consider creating a feedback loop with customers to refine the ice texture based on their preferences.

Scenario 3: Maintenance and Cleaning Challenges

The Problem: B2B buyers often find that maintaining and cleaning their snowflake ice machines can be cumbersome and time-consuming, especially in high-volume settings. Neglecting proper maintenance can lead to equipment breakdowns, costly repairs, and food safety issues. For instance, a busy bar or café may struggle to keep their ice machine clean and functioning, resulting in poor ice quality and health code violations.

Illustrative image related to snowflake ice machine

The Solution: To alleviate maintenance challenges, businesses should choose snowflake ice machines designed for easy cleaning and maintenance. Look for models with self-cleaning features or accessible components that simplify the cleaning process. Establishing a regular maintenance schedule that includes daily cleaning routines and periodic professional servicing can help maintain optimal performance. Additionally, training staff on proper cleaning protocols and the importance of maintenance can foster a culture of care and responsibility around the equipment. Keeping a log of maintenance activities can also help in tracking performance and addressing any issues proactively.

Strategic Material Selection Guide for snowflake ice machine

What Are the Key Materials Used in Snowflake Ice Machines?

When selecting materials for snowflake ice machines, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact the machine’s performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the construction of snowflake ice machines.

How Does Stainless Steel Benefit Snowflake Ice Machines?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating that can handle the cooling processes involved in ice production.

Pros & Cons: The durability of stainless steel makes it a favored choice for commercial applications. It is easy to clean, which is essential for maintaining hygiene in food-related environments. However, stainless steel can be more expensive than other materials, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with various media, including water and ice, making it ideal for machines that produce food-grade ice. Its resistance to rust and corrosion ensures a longer lifespan, especially in humid environments often found in regions like Africa and South America.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure that the stainless steel used complies with relevant standards like ASTM or DIN. The high cost may be justified by the long-term savings on maintenance and replacement.

What Role Does Aluminum Play in Snowflake Ice Machines?

Key Properties: Aluminum is lightweight and has good thermal conductivity, which is beneficial for heat exchange processes in ice machines.

Pros & Cons: The primary advantage of aluminum is its lower cost compared to stainless steel. It is easier to manufacture and can be formed into complex shapes. However, aluminum is less durable and more prone to corrosion, especially in salty or acidic environments.

Impact on Application: While aluminum can be used in less demanding applications, it may not be suitable for machines that require high durability and resistance to corrosion. This limitation can affect its lifespan in tropical climates.

Illustrative image related to snowflake ice machine

Considerations for International Buyers: Buyers should be aware of the local environmental conditions and whether aluminum will withstand them. Compliance with industry standards is also crucial, as some regions may have strict regulations regarding food safety and material quality.

Why Is Plastic Used in Some Snowflake Ice Machines?

Key Properties: Plastics are lightweight, resistant to corrosion, and can be molded into various shapes. They also have good insulation properties.

Pros & Cons: The main advantage of plastic is its cost-effectiveness and versatility. It is easy to manufacture and can be produced in large quantities. However, plastics may not withstand high temperatures or pressures as effectively as metals, which can limit their application in high-performance machines.

Impact on Application: Plastic components can be suitable for non-critical parts of the machine, like housing or insulation. However, they may not be ideal for parts that come into direct contact with ice or water due to potential leaching of chemicals.

Considerations for International Buyers: Buyers should check for compliance with food safety standards, as not all plastics are food-grade. Additionally, the environmental impact of plastic waste is becoming a concern in many regions, prompting buyers to consider sustainable alternatives.

Illustrative image related to snowflake ice machine

How Does Copper Enhance Snowflake Ice Machines?

Key Properties: Copper has excellent thermal conductivity, making it ideal for heat exchange applications. It is also naturally antimicrobial, which is beneficial for food safety.

Pros & Cons: The primary advantage of copper is its efficiency in heat transfer, which can enhance the overall performance of the ice machine. However, copper is more expensive than aluminum and can be prone to corrosion if not properly coated or maintained.

Impact on Application: Copper is particularly effective in components that require rapid cooling or heating, such as condenser coils. Its antimicrobial properties add a layer of safety in food applications.

Considerations for International Buyers: Buyers should be aware of the maintenance requirements for copper components, as they may need regular cleaning to prevent corrosion. Compliance with international standards for food safety is also essential, especially in regions with stringent regulations.

Summary Table of Material Selection for Snowflake Ice Machines

| Material | Typical Use Case for snowflake ice machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Main body and structural components | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Non-critical components | Lightweight and cost-effective | Less durable and prone to corrosion | Medium |

| Plastic | Housing and insulation | Cost-effective and versatile | Limited temperature and pressure resistance | Low |

| Copper | Heat exchange components | Excellent thermal conductivity | Higher cost and maintenance required | High |

This guide provides actionable insights for international B2B buyers, enabling informed decisions regarding material selection for snowflake ice machines.

In-depth Look: Manufacturing Processes and Quality Assurance for snowflake ice machine

What Are the Main Stages of the Manufacturing Process for Snowflake Ice Machines?

The manufacturing process of snowflake ice machines involves several critical stages, each ensuring that the final product meets the required performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials, primarily stainless steel, which is known for its durability and resistance to corrosion. Components such as the ice-making unit, cooling systems, and blades require specific grades of stainless steel (e.g., SUS304 for food contact surfaces) to ensure safety and longevity. Suppliers often provide material certification to guarantee compliance with international standards.

-

Forming: This stage includes various processes such as cutting, bending, and welding to create the machine’s body and internal components. Precision machinery is employed to ensure that all parts fit together seamlessly. Advanced CNC (Computer Numerical Control) machines are commonly used for high precision, enabling manufacturers to maintain tight tolerances necessary for optimal performance.

-

Assembly: Once the components are formed, they are assembled into the final product. This stage may involve both manual and automated processes. Skilled technicians ensure that all electrical components, such as the control panel and cooling system, are integrated correctly. The assembly line may also include stations for quality checks at various intervals to catch any defects early.

-

Finishing: The finishing stage involves surface treatment, painting, or polishing to enhance aesthetic appeal and protect against environmental factors. A final inspection is conducted to ensure that all components are functioning correctly. This may include a test run of the machine to verify its operational efficiency and ice production capabilities.

How Is Quality Assurance Implemented in Snowflake Ice Machine Manufacturing?

Quality assurance (QA) in the manufacturing of snowflake ice machines is crucial to ensure reliability and customer satisfaction. Manufacturers adhere to both international standards and industry-specific certifications to maintain high quality.

-

International Standards: Compliance with ISO 9001 is common among manufacturers, as it outlines a framework for quality management systems. This certification ensures that companies consistently provide products that meet customer and regulatory requirements. Additionally, the CE marking signifies that the product conforms to European health, safety, and environmental protection standards, which is particularly relevant for buyers in Europe.

-

Industry-Specific Certifications: Manufacturers may also pursue certifications such as API (American Petroleum Institute) for components used in specific applications or food safety certifications like HACCP (Hazard Analysis and Critical Control Points) to ensure the safety of food contact materials.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified standards before they are used in production.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any issues early, minimizing waste and rework.

– Final Quality Control (FQC): This comprehensive inspection assesses the finished product against predefined specifications. It often includes performance testing, such as measuring ice production rates and checking for any operational inconsistencies.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are employed to ensure that snowflake ice machines meet performance and safety standards:

-

Performance Testing: This involves running the machine under simulated operating conditions to verify its ice production capacity, cooling efficiency, and energy consumption. Machines are often tested for their ability to produce ice within a specific time frame, ensuring they meet the claims made by manufacturers.

-

Durability Testing: Stress tests are conducted to evaluate the machine’s ability to withstand prolonged use. This may include running the machine continuously for an extended period to identify any potential failures in components.

-

Safety Testing: Electrical safety tests ensure that all electrical components comply with safety regulations. This includes checks for short circuits, insulation resistance, and grounding.

-

Hygiene Testing: For machines intended for food contact, hygiene tests are crucial. These tests verify that materials used in the machine do not leach harmful substances and that the design allows for easy cleaning and maintenance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to procure snowflake ice machines should consider several strategies to verify the quality control processes of potential suppliers:

Illustrative image related to snowflake ice machine

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing facilities, processes, and quality management systems firsthand. This provides insights into the supplier’s commitment to quality and adherence to standards.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the supplier’s quality control processes, including IQC, IPQC, and FQC results. These reports can provide transparency regarding any issues encountered and how they were resolved.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of the manufacturing process and product quality. Such services can provide additional assurance that the products meet international standards.

-

Certifications and Documentation: Buyers should verify the authenticity of certifications such as ISO 9001 and CE markings. Reviewing documentation related to material safety and compliance can also help ensure that the products meet required standards.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

-

Regulatory Compliance: Different regions may have varying regulatory requirements for food equipment. Understanding local regulations is essential to ensure compliance and avoid potential issues during importation.

-

Cultural and Market Differences: Buyers should consider how regional preferences and market demands may influence the design and functionality of snowflake ice machines. Engaging with suppliers who understand these nuances can enhance the product’s market fit.

-

Logistical Considerations: Shipping and handling practices can affect product quality. Buyers should inquire about the supplier’s packaging methods and shipping practices to ensure that the machines arrive in optimal condition.

-

After-Sales Support: Quality assurance does not end with the purchase. Buyers should evaluate the supplier’s after-sales support, including warranty terms, maintenance services, and availability of spare parts. A reliable support system is crucial for long-term satisfaction and machine performance.

In conclusion, understanding the manufacturing processes and quality assurance practices of snowflake ice machines is vital for B2B buyers aiming to make informed purchasing decisions. By focusing on these aspects, buyers can ensure they invest in high-quality equipment that meets their operational needs and complies with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘snowflake ice machine’

To assist international B2B buyers in sourcing snowflake ice machines effectively, this guide provides a structured checklist. By following these steps, you can ensure that your procurement process is thorough and leads to a successful purchase.

Step 1: Define Your Technical Specifications

Begin by outlining the technical requirements of the snowflake ice machine you need. Consider factors such as daily ice production capacity (e.g., 400 lbs/day), power supply compatibility, and cooling methods (air-cooled vs. water-cooled). This clarity will help you communicate your needs to suppliers and ensure you select a machine that fits your operational requirements.

Step 2: Research Market Trends and Applications

Understanding the market trends and applications of snowflake ice machines is crucial. Research how these machines are used across different sectors such as restaurants, cafes, and food trucks. This knowledge will help you identify specific features that may be beneficial for your intended use, such as ice texture options for various beverages or desserts.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request company profiles, product certifications, and references from other buyers in similar industries. This step is vital for minimizing risks associated with quality and reliability, especially when sourcing from international suppliers.

Step 4: Verify Compliance with International Standards

Ensure that the snowflake ice machine complies with relevant international standards and regulations. Look for certifications such as CE, ISO, or UL, which indicate that the equipment meets safety and quality standards. This compliance is particularly important in regions with strict import regulations, such as Europe and North America.

Step 5: Assess Warranty and After-Sales Support

Before making a purchase, evaluate the warranty terms and after-sales support offered by the supplier. A good warranty can protect your investment, while robust after-sales support ensures that you have access to maintenance and repair services when needed. Look for suppliers that provide clear guidelines on service availability and response times.

Illustrative image related to snowflake ice machine

Step 6: Request Samples and Conduct Product Trials

If possible, request samples or conduct product trials before finalizing your purchase. This step allows you to assess the machine’s performance, ease of use, and maintenance requirements firsthand. Engaging with the product in real-world conditions can provide invaluable insights into its suitability for your business needs.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a supplier and evaluated the machine, engage in negotiations to finalize the terms of purchase. Discuss pricing, payment options, delivery timelines, and any additional services included in the agreement. Clear communication during this phase can lead to a more favorable deal and a better overall purchasing experience.

By adhering to this checklist, B2B buyers can streamline their sourcing process for snowflake ice machines, ensuring they select the best equipment to meet their operational needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for snowflake ice machine Sourcing

What Are the Key Cost Components in Sourcing Snowflake Ice Machines?

When sourcing snowflake ice machines, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials, such as stainless steel for the machine body and food-grade components for internal mechanisms, significantly affects the price. Machines made from higher-grade materials typically cost more but offer better durability and performance.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. In countries with higher labor costs, such as Germany, prices may be elevated compared to those sourced from regions with lower labor costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient production facilities can lower these costs, thereby impacting the final pricing.

-

Tooling: Initial costs for tooling—such as molds and fixtures necessary for production—are often amortized over the production run. Custom designs may incur higher tooling costs, influencing the overall price.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet industry standards. Suppliers investing in advanced QC protocols might charge more, but this can lead to better reliability and lower maintenance costs.

-

Logistics: Shipping costs vary based on the supplier’s location, mode of transportation, and destination. International shipping can add significant costs, especially for bulky machinery.

-

Margin: Supplier margins can vary widely based on market competition, brand reputation, and customer service levels. High-quality suppliers often justify higher margins through better service and product reliability.

How Do Price Influencers Affect Snowflake Ice Machine Costs?

Several factors can influence the pricing of snowflake ice machines:

-

Volume/MOQ (Minimum Order Quantity): Buying in bulk typically reduces the unit price. B2B buyers should negotiate MOQs that align with their operational needs to optimize costs.

-

Specifications and Customization: Custom features or specifications tailored to specific applications can increase costs. It’s essential to evaluate whether these enhancements are necessary for your operations.

-

Materials and Quality Certifications: Machines that are certified for food safety and quality (e.g., CE, ISO) may come at a premium. However, these certifications can reduce liability and enhance brand reputation.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality often charge more, but they may provide better support and warranty services.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital as they define the responsibilities of buyers and sellers in shipping. Choosing terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect final costs.

What Are the Best Negotiation Tips for B2B Buyers?

To maximize value when sourcing snowflake ice machines, consider the following negotiation strategies:

-

Research Market Prices: Familiarize yourself with current market prices to negotiate effectively. This knowledge empowers you to identify fair pricing and recognize inflated offers.

-

Leverage Volume Discounts: If your business anticipates future purchases, negotiate volume discounts. Suppliers may be willing to offer better pricing for long-term commitments.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes maintenance, operational costs, and energy efficiency. A lower upfront cost might lead to higher long-term expenses.

-

Factor in Logistics: Negotiate terms that include shipping costs to avoid unexpected expenses. Understanding the impact of logistics on total cost is crucial for international buyers.

-

Tailor Contracts: Ensure that contracts reflect all agreed-upon terms, including warranties, service agreements, and payment terms. Clear documentation helps prevent disputes later.

Why Are Pricing Nuances Important for International Buyers?

For international B2B buyers, pricing nuances can significantly impact sourcing decisions. Currency fluctuations, import tariffs, and local regulations can alter costs. Buyers from regions like Africa and South America should be particularly aware of these factors, as they can influence the total investment required for snowflake ice machines. Additionally, establishing strong relationships with suppliers may yield better pricing and support tailored to specific regional challenges.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing, actual prices may vary based on market conditions, supplier negotiations, and specific buyer needs. Always conduct thorough market research and supplier evaluations before making purchasing decisions.

Alternatives Analysis: Comparing snowflake ice machine With Other Solutions

Understanding Alternatives to Snowflake Ice Machines

In the competitive landscape of food and beverage equipment, businesses often seek alternatives to enhance their service offerings while considering factors such as efficiency, cost-effectiveness, and ease of maintenance. The snowflake ice machine is a popular choice for producing fine, fluffy ice for desserts and beverages, but it is essential to explore other viable options. This analysis compares the snowflake ice machine with two alternative solutions: traditional ice shavers and commercial ice makers.

Comparison Table

| Comparison Aspect | Snowflake Ice Machine | Traditional Ice Shaver | Commercial Ice Maker |

|---|---|---|---|

| Performance | Produces 300-600 lbs/day of snow ice; ideal for desserts. | Slower output; typically produces less fine ice. | High output, producing up to 1,000 lbs/day of various ice types. |

| Cost | Moderate initial investment ($600 – $2,000). | Lower cost ($200 – $800). | Higher initial investment ($800 – $3,000), depending on capacity. |

| Ease of Implementation | Requires minimal setup; plug-and-play functionality. | Simple to use but requires manual operation. | Requires installation and plumbing connections. |

| Maintenance | Low maintenance; easy cleaning with water. | Moderate maintenance; blades need regular sharpening. | Moderate to high; routine servicing needed for optimal performance. |

| Best Use Case | Ideal for dessert shops, cafes, and food trucks. | Suitable for small-scale operations and home use. | Best for high-demand environments like restaurants and bars. |

In-Depth Look at Alternatives

What are the Pros and Cons of Traditional Ice Shavers?

Traditional ice shavers are often favored for their lower price point and simplicity. They operate by manually feeding blocks of ice into a blade, creating a snow-like texture. While they are easy to use and maintain, their output is considerably lower compared to snowflake ice machines. This makes them less suitable for businesses with high volume demands. Additionally, the ice produced may not have the same fine texture desired for premium desserts.

How Do Commercial Ice Makers Compare?

Commercial ice makers are an excellent alternative, especially for businesses that require a high volume of ice quickly. They can produce a variety of ice shapes, including cubes and flakes, making them versatile for different applications. However, they come with a higher initial investment and require plumbing for water supply, which can complicate installation. Maintenance can also be more demanding, as these machines need regular servicing to ensure optimal performance and hygiene.

Conclusion: Choosing the Right Solution for Your Business

When selecting the right ice production solution, B2B buyers should assess their specific needs, including the volume of ice required, budget constraints, and the types of products offered. Snowflake ice machines are ideal for businesses focused on creating high-quality desserts, while traditional ice shavers may be better suited for smaller operations or home use. For establishments with significant ice demands, commercial ice makers can provide the necessary capacity and versatility, albeit with a higher investment and maintenance commitment. Careful consideration of these factors will help businesses make informed decisions that align with their operational goals and customer expectations.

Illustrative image related to snowflake ice machine

Essential Technical Properties and Trade Terminology for snowflake ice machine

What Are the Key Technical Properties of a Snowflake Ice Machine?

When evaluating a snowflake ice machine, several critical technical specifications must be considered to ensure optimal performance and suitability for your business needs. Below are essential properties that B2B buyers should understand:

-

Production Capacity

This specification indicates the amount of snowflake ice the machine can produce in a given timeframe, typically measured in pounds per day (lbs/day). For example, a machine with a capacity of 397 lbs/day is suitable for high-demand environments like restaurants or cafes. Understanding production capacity helps businesses select equipment that meets their operational needs without frequent downtime. -

Cooling System Type

Snowflake ice machines utilize either air-cooled or water-cooled systems. Air-cooled machines are generally more energy-efficient and easier to install, while water-cooled units often have higher production rates but require a water supply. Selecting the right cooling system is vital for operational efficiency and can affect the total cost of ownership. -

Material Grade

The materials used in the construction of the ice machine significantly impact durability and hygiene. High-grade stainless steel, such as SUS304, is commonly used for the body and components, ensuring rust resistance and ease of cleaning. This property is essential for B2B buyers focusing on long-term investment and compliance with health regulations. -

Ice Texture and Shape

The ability to produce various ice textures and shapes is crucial for businesses that offer diverse beverage options. Machines may allow adjustments in roller speed to create different ice types, such as fine snow or coarse ice. Understanding these capabilities can enhance product offerings and customer satisfaction. -

Energy Efficiency Rating

Machines with higher energy efficiency ratings can result in lower operational costs over time. Look for models that comply with energy standards relevant to your region, as this can influence overall profitability and sustainability efforts. -

Ease of Operation and Maintenance

Features such as intuitive control panels, one-touch cleaning, and automatic shut-off can significantly reduce the learning curve for staff and minimize maintenance time. These aspects are critical for busy environments where efficiency is paramount.

What Are Common Trade Terms Related to Snowflake Ice Machines?

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are key terms relevant to snowflake ice machines:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce equipment or components that may be marketed by another company under its brand name. In the context of snowflake ice machines, knowing the OEM can help buyers assess quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For snowflake ice machines, understanding MOQ is crucial for businesses to plan their inventory and manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers ask suppliers to provide pricing information for specific products. Submitting an RFQ for snowflake ice machines allows businesses to compare costs and negotiate terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to understand their obligations and manage logistics effectively. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For snowflake ice machines, shorter lead times can be crucial for businesses needing quick replacements or expansions. -

Warranty Period

The warranty period is the timeframe during which the manufacturer guarantees the machine against defects. A longer warranty period can provide peace of mind for B2B buyers, indicating confidence in product quality and longevity.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their business objectives and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the snowflake ice machine Sector

What Are the Key Trends Influencing the Snowflake Ice Machine Market?

The snowflake ice machine market is experiencing significant growth driven by several global factors. The rising demand for innovative dessert offerings in cafes, restaurants, and food trucks, particularly in regions such as Africa, South America, the Middle East, and Europe, is pushing businesses to adopt advanced ice-making technologies. The growing popularity of desserts like bingsu and snow cones is a notable trend, influencing the design and functionality of ice machines to cater to diverse customer preferences.

Illustrative image related to snowflake ice machine

Emerging technologies such as intelligent control systems and energy-efficient designs are becoming critical in the sourcing decisions of B2B buyers. Machines equipped with features like one-touch cleaning, variable ice texture settings, and rapid production capabilities are increasingly sought after. Additionally, the trend toward online sourcing platforms and direct manufacturer engagements is reshaping purchasing practices, allowing buyers to access a wider array of options and competitive pricing.

Market dynamics are also influenced by regional factors. For instance, in Europe, stringent regulations regarding energy consumption and environmental standards are prompting manufacturers to innovate sustainably. In contrast, buyers in Africa and South America are often looking for cost-effective solutions that do not compromise on quality. Understanding these regional nuances is vital for international buyers to navigate the complexities of sourcing snowflake ice machines effectively.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in Snowflake Ice Machine Procurement?

Sustainability is becoming a crucial consideration for B2B buyers in the snowflake ice machine sector. The environmental impact of ice production, particularly in terms of energy consumption and waste generation, is driving demand for machines that utilize eco-friendly technologies. Buyers are increasingly favoring equipment that incorporates energy-efficient compressors and environmentally friendly refrigerants, thereby reducing their carbon footprint.

Furthermore, ethical sourcing practices are gaining prominence as buyers seek to ensure that their suppliers adhere to fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can provide assurance of a supplier’s commitment to sustainability.

Buyers should also consider the lifecycle of the equipment, opting for machines made from recyclable materials and designed for longevity to minimize waste. Engaging with manufacturers who prioritize sustainability not only enhances brand reputation but also aligns with the growing consumer preference for environmentally responsible products. By integrating these considerations into their sourcing strategies, B2B buyers can contribute positively to environmental sustainability while meeting their operational needs.

What Is the Historical Context of Snowflake Ice Machines in B2B Markets?

The evolution of snowflake ice machines can be traced back to the increasing demand for innovative dessert and beverage options in the late 20th century. Originally designed for commercial use in ice cream parlors and restaurants, these machines have undergone significant technological advancements, enhancing their efficiency and versatility.

The early models were manual and less efficient, producing ice that lacked the desired texture. However, advancements in refrigeration technology, including the introduction of automatic systems and improved cooling methods, have transformed the snowflake ice machine into a staple in various food service settings. Today, these machines are not only essential for producing snow cones and shaved ice but are also utilized in creating a variety of gourmet desserts, showcasing the adaptability and importance of snowflake ice machines in the global food industry.

Understanding this historical context helps B2B buyers appreciate the technological advancements and market evolution, enabling them to make informed decisions when sourcing equipment that meets contemporary demands.

Illustrative image related to snowflake ice machine

Frequently Asked Questions (FAQs) for B2B Buyers of snowflake ice machine

-

How do I solve issues with ice machine performance?

To address performance issues with snowflake ice machines, first, check the power supply and ensure the machine is plugged in correctly. Inspect the water supply for any blockages or leaks, as insufficient water can hinder ice production. Regular cleaning and maintenance are crucial; follow the manufacturer’s instructions for descaling and cleaning to prevent buildup. If problems persist, consult the supplier for troubleshooting support or consider professional servicing. -

What is the best snowflake ice machine for small businesses?

For small businesses, a compact snowflake ice machine that produces around 200-400 lbs per day is typically ideal. Models like the JX100F2 or similar options offer a balance of size and output, catering to cafes, food trucks, and small restaurants. Look for features such as energy efficiency, ease of operation, and maintenance requirements. Additionally, consider machines with a durable stainless steel build to withstand daily use. -

What are the key factors to consider when sourcing snowflake ice machines internationally?

When sourcing internationally, focus on the supplier’s reputation, product quality, and compliance with local regulations. Verify certifications such as CE or UL, which indicate adherence to safety and performance standards. Evaluate logistics capabilities, including shipping times and costs, and consider the supplier’s ability to provide after-sales support and warranty services. Engaging in thorough due diligence can help mitigate risks associated with international procurement. -

What customization options are available for snowflake ice machines?

Many manufacturers offer customization options, such as branding, specific production capacities, and additional features like automated cleaning systems. Discuss your needs with the supplier to determine available modifications. Customization can enhance operational efficiency and align the equipment with your specific business requirements, ensuring the machine meets your unique operational demands. -

What is the minimum order quantity (MOQ) for snowflake ice machines?

The MOQ for snowflake ice machines varies by supplier, typically ranging from one unit for smaller manufacturers to several units for larger companies. It’s essential to clarify MOQ terms during initial discussions. If you are a small business, inquire about sample orders or trial units to assess quality before committing to larger purchases. This approach can help manage risk while establishing a relationship with the supplier. -

What payment terms should I expect when purchasing a snowflake ice machine?

Payment terms vary widely among suppliers, but common practices include a deposit (usually 30% to 50%) upon order confirmation, with the balance due before shipping. Some suppliers may offer financing options or letters of credit for larger purchases. Ensure that you clearly understand the payment structure and any potential fees associated with international transactions, such as currency conversion or wire transfer costs. -

How can I ensure quality assurance (QA) for my snowflake ice machine?

To ensure quality assurance, request detailed product specifications, including materials and production processes, before purchase. Verify if the supplier conducts regular quality inspections and has relevant certifications. Consider establishing a QA agreement that outlines inspection rights upon delivery and includes warranties or guarantees. Additionally, seek customer reviews and testimonials to gauge the machine’s reliability and performance in real-world applications. -

What logistics considerations are important when importing snowflake ice machines?

When importing, consider shipping methods (air vs. sea), costs, and delivery times, as these can significantly impact your supply chain. Ensure that you understand customs regulations and duties applicable to your country to avoid unexpected fees. Collaborate with logistics partners experienced in handling refrigeration equipment to facilitate smooth transport and delivery. Proper planning can mitigate delays and ensure your machines arrive in optimal condition.

Top 2 Snowflake Ice Machine Manufacturers & Suppliers List

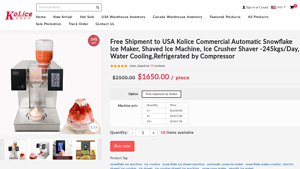

1. Kolice – Commercial Automatic Snowflake Ice Maker

Domain: kolicedepot.com

Registered: 2018 (7 years)

Introduction: Kolice Commercial Automatic Snowflake Ice Maker, Shaved Ice Machine, Ice Crusher Shaver – Capacity: 245kgs/Day, Water Cooling, Refrigerated by Compressor. Price: $1650.00 (originally $2500.00). Machine Size: 40x60x57cm (15.75”x23.62”x22.44”), Net Weight: 63kg (138.6lbs). Power: 110V 60HZ, 1600W, US plug. Features: High efficiency water cooling, stainless steel blade, quality compressor filled w…

2. Accio – Top Snowflake Maker Machines

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Top Snowflake Maker Machines for Restaurants, Home & Parties. Product attributes: Stainless Steel 304, 10 GPM Flow Rate, 220V Voltage, 50Hz Frequency, 1.5kW Power, R404A Refrigerant, 60kg/24h Capacity, Air Cooling, Digital Control Panel. Price range: $31.28 – $30000+. MOQ: < 5. Verified Supplier: 5+ Years Supplier Exp., Manufacturer Only, 4.5+ Supplier Rating. Ice Size, Voltage, Compressor, Power …

Strategic Sourcing Conclusion and Outlook for snowflake ice machine

How Can Strategic Sourcing Enhance Your Snowflake Ice Machine Procurement?

In conclusion, strategic sourcing of snowflake ice machines is pivotal for B2B buyers looking to optimize their operations and enhance their product offerings. By focusing on high-quality equipment that ensures efficiency, durability, and adaptability, businesses can not only meet customer demands but also improve their bottom line. Key considerations include evaluating suppliers based on their product specifications, customer service, and after-sales support, which are essential for long-term partnerships.

For international buyers from regions such as Africa, South America, the Middle East, and Europe, the potential for growth in the frozen dessert market is substantial. Investing in advanced snowflake ice machines can cater to evolving consumer tastes, particularly in the booming café and restaurant sectors.

As you navigate your sourcing decisions, consider leveraging supplier expertise to identify the best solutions tailored to your business needs. The future of your business hinges on making informed choices today. Embrace this opportunity to elevate your offerings and position your business for success in a competitive landscape. Now is the time to act—explore your options and connect with trusted suppliers to revolutionize your ice production capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.