Choosing Your Polyamide Tube: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for polyamide tube

Navigating the global market for polyamide tube presents a unique set of challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Sourcing polyamide tubing that meets specific performance requirements can be daunting due to varying standards, availability, and supplier reliability. This guide aims to demystify the complexities of polyamide tubing, offering insights into different types, applications, and critical factors that influence purchasing decisions.

In this comprehensive resource, we will explore the diverse applications of polyamide tubes across industries such as automotive, chemical processing, and food and beverage. We’ll delve into the characteristics that set polyamide apart, including its temperature resistance, corrosion resistance, and flexibility, which make it a preferred choice in many scenarios. Additionally, we will provide actionable strategies for vetting suppliers, understanding cost structures, and ensuring compliance with international standards.

By equipping B2B buyers with the knowledge needed to make informed purchasing decisions, this guide empowers companies to secure high-quality polyamide tubing tailored to their operational needs. With a focus on practical insights and expert recommendations, you will gain the confidence to navigate the global marketplace effectively, ensuring that your sourcing strategy is both efficient and cost-effective. Whether you are in Nigeria, Brazil, or beyond, this guide is your go-to resource for making strategic procurement choices in the polyamide tube sector.

Understanding polyamide tube Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nylon Tubing | High flexibility, lightweight, and moisture resistant | Pneumatics, automotive, packaging | Pros: Cost-effective, versatile; Cons: Limited chemical resistance compared to specialized types. |

| High-Pressure Nylon Tubing | Enhanced strength and pressure rating | Hydraulic systems, industrial machinery | Pros: Suitable for demanding applications; Cons: Higher cost and less flexibility. |

| FDA Approved Nylon Tubing | Compliant with food safety regulations | Food & beverage processing | Pros: Safe for food contact; Cons: Limited color options. |

| Super Soft Nylon Tubing | Increased flexibility and lower stiffness | Medical applications, robotics | Pros: Excellent bend radius; Cons: Not suitable for high-pressure applications. |

| Metric Nylon Tubing | Precise dimensions and high temperature resistance | International trade, automotive, aerospace | Pros: Standardized sizing for global compatibility; Cons: May require specific fittings. |

What Are the Key Characteristics of Standard Nylon Tubing?

Standard nylon tubing is known for its excellent flexibility and lightweight design. It is moisture-resistant, making it suitable for various applications, including pneumatics, automotive systems, and packaging. Buyers should consider its cost-effectiveness and versatility, but note that it may not offer the same level of chemical resistance as other specialized tubing options.

How Does High-Pressure Nylon Tubing Differ from Other Variants?

High-pressure nylon tubing is engineered to withstand elevated pressures, making it ideal for hydraulic systems and industrial machinery. Its enhanced strength is a significant advantage in demanding applications. However, this type of tubing tends to be more expensive and may compromise flexibility, which is a consideration for buyers looking for adaptable solutions.

Why Choose FDA Approved Nylon Tubing for Food Applications?

FDA approved nylon tubing is specifically designed for the food and beverage industry, ensuring compliance with safety regulations. This tubing is safe for direct food contact, making it a preferred choice for processing applications. While its safety features are a major plus, buyers may find limited color options, which could affect aesthetic considerations in certain setups.

What Are the Benefits of Using Super Soft Nylon Tubing?

Super soft nylon tubing offers enhanced flexibility and a lower stiffness profile, making it suitable for applications in medical devices and robotics. Its excellent bend radius allows for more complex installations. However, it is important to note that this type of tubing is not designed for high-pressure environments, which may limit its applications in some industrial settings.

How Does Metric Nylon Tubing Support International Trade?

Metric nylon tubing is manufactured to precise dimensions, which is particularly beneficial for international trade in industries like automotive and aerospace. Its high temperature resistance and standardized sizing facilitate compatibility with global fittings and components. Buyers should be aware that while this tubing offers many advantages, it may require specific fittings, which could impact procurement logistics.

Key Industrial Applications of polyamide tube

| Industry/Sector | Specific Application of Polyamide Tube | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Fuel and Brake Line Systems | High chemical resistance and lightweight properties, reducing overall vehicle weight. | Ensure compliance with automotive standards and certifications. |

| Pneumatics | Compressed Air Systems | Excellent pressure resistance and flexibility, ideal for tight spaces and complex routing. | Verify compatibility with existing pneumatic systems and fittings. |

| Food & Beverage | Beverage Dispensing and Processing Equipment | FDA-approved options ensure safety and compliance with health regulations. | Source from suppliers who provide documentation for food-grade materials. |

| Chemical Processing | Fluid Transfer and Chemical Handling | Corrosion resistance allows for safe transport of aggressive chemicals. | Assess chemical compatibility and temperature ratings for specific applications. |

| Agriculture | Irrigation Systems | Durable and UV-resistant, suitable for outdoor use in diverse climates. | Evaluate the tubing’s resistance to moisture and environmental factors. |

How is Polyamide Tube Used in the Automotive Industry?

In the automotive sector, polyamide tubes are primarily utilized in fuel and brake line systems. Their lightweight nature contributes to overall vehicle efficiency, while their high chemical resistance ensures durability against fuels and oils. International buyers must ensure that the sourced tubing meets stringent automotive standards and certifications, particularly in regions like Europe and the Middle East, where regulations are strict. This is crucial for maintaining vehicle safety and performance.

What Role Does Polyamide Tube Play in Pneumatics?

Polyamide tubing is essential in pneumatic systems, where it is used for conveying compressed air. Its exceptional flexibility and pressure resistance allow it to navigate tight spaces and complex routing within machinery. Businesses sourcing polyamide tubing for pneumatic applications should verify compatibility with existing systems and fittings to avoid operational disruptions. This consideration is particularly important for industries in South America and Africa, where equipment may vary significantly.

Why is Polyamide Tube Important in the Food & Beverage Sector?

In the food and beverage industry, polyamide tubes are employed in beverage dispensing and processing equipment. The availability of FDA-approved options ensures that these tubes meet safety and health regulations. B2B buyers in this sector should prioritize sourcing from suppliers who provide comprehensive documentation on food-grade materials. This is vital for maintaining compliance and ensuring consumer safety, especially in competitive markets across Europe and Africa.

How Does Polyamide Tube Benefit Chemical Processing?

In chemical processing, polyamide tubes are used for fluid transfer and handling aggressive chemicals. Their inherent corrosion resistance makes them ideal for transporting substances that would degrade other materials. When sourcing for this application, businesses must assess the tubing’s chemical compatibility and temperature ratings to ensure safe and effective operation. This is particularly crucial for industries in regions like the Middle East, where harsh chemicals are commonly used.

How is Polyamide Tube Utilized in Agricultural Irrigation?

Polyamide tubing finds significant application in irrigation systems within agriculture. Its durability and UV resistance make it suitable for outdoor use, allowing it to withstand various environmental conditions. Buyers in the agricultural sector should evaluate the tubing’s moisture resistance and overall durability to ensure longevity in diverse climates, especially in areas like Nigeria and Brazil where irrigation needs are critical for crop production.

3 Common User Pain Points for ‘polyamide tube’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Polyamide Tubing Suppliers

The Problem: B2B buyers often struggle with finding dependable suppliers for polyamide tubing that meet their specific requirements. The challenge can stem from varying quality standards, inconsistent supply chains, and the risk of receiving subpar products that do not perform as expected in critical applications. This is particularly concerning for industries such as automotive or food and beverage, where the integrity of components is crucial for safety and performance. Buyers may also face challenges related to communication barriers, especially when dealing with international suppliers.

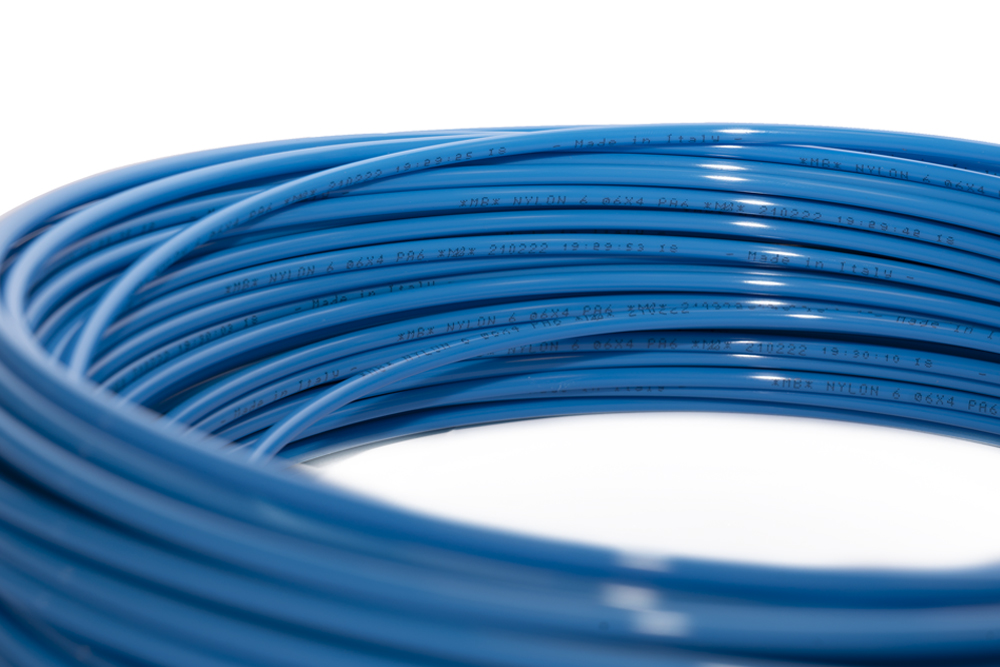

Illustrative image related to polyamide tube

The Solution: To mitigate these sourcing difficulties, buyers should prioritize building relationships with multiple vetted suppliers. Start by conducting thorough market research to identify suppliers with a strong reputation for quality and reliability. Utilize platforms like industry trade shows, online B2B marketplaces, and local chambers of commerce to gather supplier information. Once potential suppliers are identified, request samples and conduct quality testing in-house to verify performance against your specifications. Establish clear communication channels and ensure that suppliers understand your requirements, such as compliance with FDA regulations for food-grade applications. Additionally, consider engaging a third-party quality assurance service to monitor and validate the quality of the polyamide tubing being supplied.

Scenario 2: Inadequate Technical Support for Polyamide Tube Applications

The Problem: Many B2B buyers encounter challenges when technical support is lacking for the specific applications of polyamide tubing. This can lead to improper installations or usage that ultimately result in product failures or inefficiencies. Industries such as pharmaceuticals and chemical processing often require precise specifications and understanding of material compatibility, yet buyers may find themselves without the necessary guidance to optimize their use of polyamide tubes in their systems.

The Solution: To address the lack of technical support, buyers should actively seek suppliers who offer comprehensive technical assistance as part of their service. This includes detailed product documentation, application guidelines, and access to technical experts. When evaluating suppliers, inquire about their technical support services, such as on-site consultations or training programs for your team. Additionally, leverage online resources such as webinars, technical articles, and forums focused on polyamide tubing applications. Forming a collaborative relationship with your supplier can also yield significant benefits, as they may provide tailored solutions and ongoing support, ensuring that your applications run smoothly and effectively.

Scenario 3: Performance Issues Due to Environmental Conditions

The Problem: Polyamide tubing can face performance issues in extreme environmental conditions, such as high temperatures or exposure to aggressive chemicals. For instance, companies in the oil and gas sector or those operating in hot, humid climates may find that standard polyamide tubing does not maintain its integrity under such conditions. This can lead to leaks, reduced efficiency, and increased maintenance costs, creating a significant operational burden.

The Solution: To counteract performance issues, it’s essential for buyers to carefully assess the environmental conditions their polyamide tubing will encounter and select products specifically designed to withstand these challenges. Seek out suppliers that offer a range of polyamide tubing options with enhanced features such as UV stabilization, increased chemical resistance, and wider temperature tolerances. When specifying polyamide tubing, request detailed material safety data sheets (MSDS) and chemical resistance charts from suppliers to ensure compatibility with the substances the tubing will handle. Additionally, consider conducting field tests to validate the performance of the selected tubing in real-world conditions before full-scale deployment. By taking these proactive steps, buyers can ensure that their polyamide tubing performs reliably and effectively, even in the most demanding environments.

Illustrative image related to polyamide tube

Strategic Material Selection Guide for polyamide tube

What Are the Key Properties of Common Materials Used in Polyamide Tubing?

Polyamide tubing, commonly known as nylon tubing, is favored in various industrial applications due to its unique properties. Understanding the characteristics of different polyamide materials is crucial for B2B buyers, especially those operating in diverse environments across Africa, South America, the Middle East, and Europe. Below, we analyze several common materials used in polyamide tubing, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

How Do Different Polyamide Materials Perform in Terms of Temperature and Pressure Ratings?

-

Standard Nylon (PA 6)

– Key Properties: This material exhibits a temperature range of -40°C to 100°C and can withstand moderate pressure levels. It has good chemical resistance to oils and greases.

– Pros & Cons: Standard nylon is relatively inexpensive and easy to manufacture. However, it may not perform well in extreme temperatures or aggressive chemical environments, leading to potential degradation over time.

– Impact on Application: Suitable for applications involving air, water, and certain chemicals, but not ideal for high-pressure systems or exposure to harsh solvents.

– Considerations for International Buyers: Compliance with ASTM standards is essential for buyers in regions like Europe and the Middle East. Buyers should also consider local climatic conditions that may affect material performance. -

High-Performance Nylon (PA 12)

– Key Properties: PA 12 offers a broader temperature range (-60°C to 120°C) and better impact resistance. It has superior moisture absorption properties, making it ideal for humid environments.

– Pros & Cons: While PA 12 is more durable and flexible, it comes at a higher cost. Manufacturing complexity increases due to the need for specialized processing techniques.

– Impact on Application: Particularly suited for automotive and pneumatic applications where flexibility and durability are critical.

– Considerations for International Buyers: Buyers should ensure compliance with JIS and DIN standards, especially in automotive applications in Europe and Asia. -

UV-Stabilized Nylon

– Key Properties: This variant is treated to resist UV radiation, maintaining its integrity in outdoor applications. It typically has a temperature range of -40°C to 90°C.

– Pros & Cons: The UV stabilization prolongs the lifespan of the tubing in sunlight-exposed environments. However, it may have a slightly higher cost compared to standard nylon.

– Impact on Application: Ideal for outdoor applications such as irrigation systems and construction, where exposure to sunlight is inevitable.

– Considerations for International Buyers: Buyers in regions with high UV exposure, such as parts of Africa and South America, should prioritize this material for long-lasting performance. -

Chemical-Resistant Nylon

– Key Properties: This material is engineered to withstand a wide range of chemicals, with a temperature tolerance of -40°C to 100°C. It is designed to resist degradation from solvents and acids.

– Pros & Cons: Chemical-resistant nylon is highly durable and suitable for harsh environments. However, it is more expensive and may require specific manufacturing processes.

– Impact on Application: Perfect for chemical processing industries, food and beverage applications, and environments where exposure to corrosive substances is common.

– Considerations for International Buyers: Compliance with FDA regulations is crucial for food-grade applications, particularly in North America and Europe. Buyers should also be aware of local chemical regulations.

Summary Table of Polyamide Tube Materials

| Material | Typical Use Case for Polyamide Tube | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Nylon (PA 6) | Air and water applications | Cost-effective and easy to manufacture | Limited temperature and chemical resistance | Low |

| High-Performance Nylon (PA 12) | Automotive and pneumatic applications | Excellent flexibility and durability | Higher cost and manufacturing complexity | High |

| UV-Stabilized Nylon | Outdoor irrigation and construction | Long-lasting in sunlight exposure | Slightly higher cost than standard nylon | Medium |

| Chemical-Resistant Nylon | Chemical processing and food applications | Superior chemical resistance | More expensive and requires specific processes | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their use of polyamide tubing across various applications and regions. Understanding these materials’ properties and implications will help in making informed purchasing decisions that align with operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for polyamide tube

What Are the Main Stages in the Manufacturing Process of Polyamide Tubes?

The manufacturing process of polyamide tubes involves several critical stages, each designed to ensure the final product meets the necessary quality standards. Here’s a breakdown of the key stages:

-

Material Preparation: The process begins with sourcing high-quality polyamide resin, which is crucial for ensuring the strength and flexibility of the tubes. The resin is typically dried to remove moisture, as excess water can negatively impact the extrusion process. This preparation stage may also involve blending different grades of polyamide to achieve desired characteristics such as enhanced chemical resistance or improved temperature tolerance.

-

Forming: The primary method for shaping polyamide tubing is extrusion. In this process, the dried resin is fed into an extruder, where it is melted and forced through a die to form a continuous tube. The temperature and pressure during extrusion are carefully controlled to ensure uniformity in wall thickness and diameter. After extrusion, the tube is cooled, often using water baths or air cooling methods, to solidify its shape.

-

Assembly: In applications where polyamide tubes are used as part of a larger system, assembly may be required. This can include attaching fittings, connectors, or other components. Depending on the complexity of the assembly, this stage may involve additional processes such as welding or bonding.

-

Finishing: The final stage involves surface treatments and quality inspections. Tubes may undergo processes such as cutting to length, printing for labeling, or applying coatings for added protection against UV rays or chemicals. This stage ensures that the tubes not only meet aesthetic requirements but also function effectively in their intended applications.

How Is Quality Assurance Implemented in Polyamide Tube Production?

Quality assurance (QA) is a critical aspect of polyamide tube manufacturing, ensuring that products meet international standards and customer expectations. Here are the key components of an effective QA process:

-

International and Industry-Specific Standards: Manufacturers often adhere to ISO 9001, which outlines criteria for a quality management system. This certification ensures that companies consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking for European markets or API standards for oil and gas applications may apply. Compliance with these standards is essential for international B2B buyers.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control (QC) checkpoints are established:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to identify any deviations from the manufacturing specifications.

– Final Quality Control (FQC): Before the product is shipped, a final inspection is performed to verify that the polyamide tubes meet all design and performance specifications. -

Common Testing Methods: Various tests are conducted to assess the properties of polyamide tubes, including:

– Tensile Strength Testing: Measures the maximum amount of tensile stress the material can withstand before failure.

– Impact Resistance Testing: Assesses the tube’s ability to resist sudden impacts.

– Chemical Resistance Testing: Evaluates how the material holds up against specific chemicals it may encounter in its applications.

What Actions Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, ensuring the quality of polyamide tubes from suppliers is paramount. Here are actionable steps to verify supplier QC:

-

Conduct Supplier Audits: Regular audits of suppliers’ facilities can provide insight into their manufacturing processes and quality control measures. Buyers should assess the supplier’s adherence to international standards and their commitment to continuous improvement.

-

Request Quality Reports and Certifications: Buyers should ask suppliers for documentation that demonstrates compliance with quality standards, including ISO certifications and test reports. These documents serve as evidence of the supplier’s quality assurance practices.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s production processes and product quality. These services can conduct random inspections and provide detailed reports on compliance with agreed-upon specifications.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate various quality control and certification nuances when sourcing polyamide tubes. Here are some considerations:

-

Regional Standards and Compliance: Different regions may have specific regulations governing the materials and manufacturing processes used in polyamide tube production. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural and Communication Factors: Establishing clear communication channels with suppliers is crucial, especially when dealing with manufacturers in different regions. Buyers should ensure that expectations regarding quality standards and delivery timelines are clearly articulated.

-

Understanding Certification Validity: It is essential for buyers to verify the validity of certifications provided by suppliers. This may involve checking with certifying bodies or requesting additional documentation that confirms ongoing compliance with quality standards.

By understanding the manufacturing processes and implementing robust quality assurance measures, B2B buyers can make informed decisions when sourcing polyamide tubes, ensuring they meet the demands of their specific applications while maintaining high-quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyamide tube’

Introduction

Sourcing polyamide tubes requires careful consideration of various factors to ensure you procure the right product for your specific applications. This checklist serves as a step-by-step guide to streamline your purchasing process, helping you make informed decisions that align with your operational needs and compliance requirements.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications for the polyamide tubes you require. This includes parameters such as diameter, wall thickness, operating temperature range, and chemical compatibility. Understanding these specifications ensures that you select a product that meets the performance requirements of your application.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers of polyamide tubes. Utilize industry directories, trade shows, and online platforms to compile a list of reputable manufacturers. Look for suppliers with a solid track record, particularly those who cater to your industry and region, as this can significantly impact lead times and service quality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their production capabilities, quality control processes, and customer service reputation, as these factors will influence your overall satisfaction and product reliability.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers comply with relevant industry standards and certifications, such as ISO, RoHS, or FDA approvals for food-grade applications. Compliance not only guarantees product quality but also mitigates risks associated with regulatory issues. Request documentation to verify these certifications and ensure they align with your operational requirements.

Illustrative image related to polyamide tube

Step 5: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the polyamide tubes for testing. This step allows you to evaluate the product’s quality and performance under actual operating conditions. Conduct thorough tests, focusing on aspects such as flexibility, temperature resistance, and chemical compatibility to confirm they meet your specifications.

Step 6: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to secure favorable pricing and payment terms. Consider bulk purchase discounts, shipping costs, and delivery timelines in your discussions. Clear communication about your budget and expectations can foster a mutually beneficial relationship, leading to better pricing and service.

Step 7: Establish a Long-term Partnership

After selecting a supplier, aim to establish a long-term partnership. Regular communication and feedback can enhance collaboration, helping both parties to adapt to changing needs and improve product offerings. A reliable supplier can become an integral part of your supply chain, providing consistent quality and support over time.

By following this checklist, B2B buyers can navigate the complexities of sourcing polyamide tubes, ensuring they make informed decisions that support their operational goals.

Comprehensive Cost and Pricing Analysis for polyamide tube Sourcing

What Are the Key Cost Components in Polyamide Tube Sourcing?

When sourcing polyamide tubes, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of polyamide resin significantly influences cost. High-quality materials that offer superior properties, such as chemical resistance and UV stabilization, typically come at a premium. For instance, nylon 6 and nylon 66 are common choices, with varying price points based on performance characteristics.

-

Labor: Labor costs encompass wages for production staff, engineers, and quality control personnel involved in the manufacturing process. Labor costs can vary by region, impacting overall pricing, especially for international buyers.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, maintenance, and facility costs. Efficient manufacturing processes can help reduce these overheads, thus affecting the final price.

-

Tooling: The initial investment in molds and dies used for shaping the polyamide tubes can be substantial. Custom tooling is often required for specialized products, adding to the upfront costs.

-

Quality Control (QC): Ensuring product quality through rigorous testing and certification processes incurs additional costs. Certifications such as ISO or compliance with regional standards may be necessary, especially for industries like food and beverage or pharmaceuticals.

-

Logistics: Shipping and handling fees can vary significantly depending on the distance, weight, and mode of transport. International shipments may also involve tariffs and customs fees, impacting total costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Polyamide Tube Costs?

Several factors influence the pricing of polyamide tubes:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts due to economies of scale. Buyers should negotiate terms that align with their consumption patterns to optimize costs.

-

Specifications and Customization: Custom orders with unique specifications can drive up costs due to the additional work required in tooling and production. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials: The type and quality of materials used can significantly impact pricing. For example, tubes designed for high-pressure applications will generally cost more than standard variants.

-

Quality and Certifications: Products with higher quality standards and necessary certifications (e.g., FDA-approved for food applications) may carry a higher price tag. Buyers must assess the relevance of these certifications to their specific applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to perceived quality and service guarantees.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers in shipping costs and risks. The choice of Incoterms can affect total landed costs.

What Buyer Tips Can Enhance Cost-Efficiency in Polyamide Tube Procurement?

-

Negotiation: Buyers should engage in proactive negotiations with suppliers. Discussing volume discounts, payment terms, and long-term agreements can lead to better pricing.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the total cost of ownership, which includes maintenance, downtime, and potential replacement costs. Opting for higher-quality tubing may lead to lower long-term costs.

-

Pricing Nuances for International Buyers: International buyers, especially from regions like Africa and South America, should consider currency fluctuations, import duties, and shipping costs. Establishing relationships with local distributors can mitigate some of these challenges.

-

Supplier Diversification: Relying on multiple suppliers can provide leverage in negotiations and reduce risks associated with supply chain disruptions.

-

Market Research: Stay informed about market trends and material price fluctuations to make timely purchasing decisions. This knowledge can help buyers anticipate price changes and adjust their procurement strategies accordingly.

Disclaimer

The prices and cost components mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing polyamide tube With Other Solutions

Introduction: Exploring Alternatives to Polyamide Tubes

In the realm of industrial applications, selecting the right tubing material is crucial for operational efficiency and cost-effectiveness. Polyamide tubes, known for their versatility, high-temperature resistance, and chemical stability, are widely used across various sectors. However, it’s essential for B2B buyers to evaluate alternative solutions that might offer specific advantages depending on their unique requirements. This analysis compares polyamide tubes with two viable alternatives: polyurethane tubes and polyethylene tubes.

Comparison Table

| Comparison Aspect | Polyamide Tube | Polyurethane Tube | Polyethylene Tube |

|---|---|---|---|

| Performance | Excellent flexibility, high strength, good chemical resistance | High abrasion resistance, good flexibility | Good chemical resistance, lower strength |

| Cost | Moderate to high | Generally higher than polyamide | Generally lower |

| Ease of Implementation | Relatively easy to install | Requires careful handling during installation | Easy to install |

| Maintenance | Low maintenance | Low maintenance | Low maintenance |

| Best Use Case | Pneumatics, automotive, chemical treatment | Heavy-duty applications, automotive | Water and chemical transport |

Detailed Breakdown of Alternatives

Polyurethane Tubes: A Flexible Option for Heavy-Duty Applications

Polyurethane tubes are often used in applications requiring high abrasion resistance and flexibility. They can withstand extreme conditions, making them ideal for heavy-duty industrial environments. However, the cost of polyurethane tubes can be higher than that of polyamide tubes, which may deter some budget-conscious buyers. While installation is straightforward, careful handling is necessary to avoid damage during the process. Overall, polyurethane tubes excel in applications where durability and flexibility are paramount.

Polyethylene Tubes: Cost-Effective and Versatile

Polyethylene tubes are known for their affordability and versatility, making them a popular choice for various applications, particularly in water and chemical transport. They offer good chemical resistance but may lack the strength and durability of polyamide and polyurethane options. Installation is simple, and maintenance is minimal, which is advantageous for companies looking to reduce operational downtime. However, for applications that demand high strength or resistance to extreme conditions, polyethylene may not be the best choice.

Conclusion: Choosing the Right Solution for Your Needs

When selecting tubing solutions, B2B buyers should assess their specific operational needs, including performance requirements, budget constraints, and installation capabilities. Polyamide tubes are ideal for applications requiring high strength and chemical resistance, while polyurethane tubes offer enhanced abrasion resistance for heavy-duty uses. On the other hand, polyethylene tubes present a cost-effective option for general applications. By carefully considering these factors, businesses can make informed decisions that align with their operational goals and enhance efficiency.

Essential Technical Properties and Trade Terminology for polyamide tube

What Are the Key Technical Properties of Polyamide Tubing?

Polyamide tubing, commonly known as nylon tubing, is a versatile material widely used across various industries due to its robust technical properties. Understanding these specifications is crucial for B2B buyers looking to make informed purchasing decisions.

1. Temperature Resistance

Polyamide tubing can typically withstand temperatures ranging from -60°F to +200°F (-51°C to +93°C). This extensive temperature range allows it to be used in various applications, including automotive and pneumatic systems. For international buyers, especially in regions with extreme climates, this property ensures reliability and performance under diverse conditions.

2. Chemical Resistance

The chemical resistance of polyamide tubing is significant, allowing it to endure exposure to various solvents, oils, and corrosive substances. This makes it an ideal choice for industries such as chemical processing and food and beverage, where tubing may come into contact with aggressive materials. Buyers must consider this property to ensure long-term durability and safety in their applications.

3. Corrosion Resistance

Polyamide tubing exhibits excellent resistance to moisture absorption and corrosion, making it suitable for use in humid or wet environments. This characteristic is particularly important for industries operating in coastal regions or those dealing with saline solutions. Understanding this property helps buyers select the right tubing for applications where corrosion could lead to costly failures.

4. Flexibility and Bend Radius

Polyamide tubing is noted for its flexibility and ability to accommodate a smaller bend radius compared to other materials. This feature is essential for applications requiring intricate layouts or where space is limited. Buyers should evaluate the flexibility of the tubing to ensure it meets the design specifications of their projects.

5. Lightweight Design

The lightweight nature of polyamide tubing contributes to its ease of handling and installation. In applications such as robotics and aerospace, where weight reduction is crucial, choosing lightweight tubing can enhance overall system performance. B2B buyers should prioritize this property when selecting materials for weight-sensitive applications.

6. UV Stabilization

Polyamide tubing can be UV stabilized to resist degradation when exposed to sunlight. This is particularly beneficial for outdoor applications in regions with high solar exposure. Understanding the UV resistance of the tubing is vital for buyers to ensure longevity and performance in outdoor environments.

What Are Common Trade Terms Related to Polyamide Tubing?

Navigating the procurement process for polyamide tubing involves understanding essential industry terminology. Familiarity with these terms can facilitate smoother transactions and better communication between buyers and suppliers.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another company. In the context of polyamide tubing, understanding whether a supplier is an OEM can help buyers assess the quality and reliability of the products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, especially when sourcing polyamide tubing in bulk.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. Utilizing RFQs can help buyers compare multiple suppliers and secure the best pricing for polyamide tubing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping, insurance, and liability when purchasing polyamide tubing across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For businesses relying on timely delivery for production schedules, understanding lead times for polyamide tubing is vital for operational efficiency.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions regarding their polyamide tubing needs, ensuring optimal performance and cost-effectiveness in their applications.

Illustrative image related to polyamide tube

Navigating Market Dynamics and Sourcing Trends in the polyamide tube Sector

What Are the Key Trends Shaping the Global Polyamide Tube Market?

The global polyamide tube market is witnessing significant growth, driven by the increasing demand for lightweight, durable materials across various industries. Major sectors such as automotive, aerospace, and food and beverage are increasingly adopting polyamide tubing due to its excellent chemical resistance and ability to withstand high temperatures. In regions like Africa, South America, the Middle East, and Europe, buyers are particularly interested in sourcing polyamide tubes that offer superior performance in demanding applications.

Emerging technologies, such as advanced manufacturing techniques and automation, are transforming the sourcing landscape. B2B buyers can leverage these innovations for cost-effective solutions and enhanced product quality. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers, allowing businesses to source polyamide tubes from a global market without geographical constraints.

Market dynamics are also influenced by fluctuating raw material prices and supply chain disruptions, which can impact lead times and availability. Buyers must remain vigilant and establish strong relationships with suppliers to navigate these challenges effectively. Understanding the trends in polyamide tube applications, such as the growing preference for lightweight alternatives to metal, can provide strategic advantages in sourcing decisions.

How Important Is Sustainability and Ethical Sourcing in the Polyamide Tube Sector?

Sustainability has become a crucial consideration for B2B buyers in the polyamide tube sector. The environmental impact of manufacturing processes and the lifecycle of materials are under scrutiny, leading many companies to prioritize eco-friendly options. Polyamide tubes can be sourced from suppliers that emphasize sustainability, such as those using recycled materials or employing energy-efficient manufacturing practices.

Ethical sourcing is equally significant, as buyers are increasingly aware of the importance of transparent supply chains. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances can serve as indicators of a supplier’s commitment to sustainable practices. By choosing suppliers with these certifications, B2B buyers can mitigate risks associated with unethical labor practices and environmental violations.

Incorporating ‘green’ materials, such as bio-based polyamides, into sourcing strategies can also enhance a company’s brand reputation and appeal to environmentally conscious consumers. As sustainability becomes a competitive differentiator, businesses that prioritize ethical sourcing will be better positioned to meet the expectations of their customers and stakeholders.

What Is the Historical Context of Polyamide Tubes in the B2B Market?

Polyamide tubes, commonly known as nylon tubing, have evolved significantly since their introduction in the early 20th century. Initially developed for military applications due to their strength and resilience, polyamide tubes have expanded into various industries, including automotive, healthcare, and industrial manufacturing.

Over the decades, advancements in polymer chemistry have led to the development of specialized grades of polyamide, enhancing properties such as temperature resistance, flexibility, and chemical stability. Today, B2B buyers can choose from a wide range of polyamide tubing options tailored to specific applications, underscoring the material’s versatility and reliability. As the market continues to evolve, understanding the historical context of polyamide tubes can provide valuable insights for strategic sourcing and product development.

Frequently Asked Questions (FAQs) for B2B Buyers of polyamide tube

-

How do I choose the right polyamide tube for my application?

Selecting the appropriate polyamide tube involves considering several key factors such as the operating temperature, pressure ratings, and chemical exposure. Assess the environmental conditions where the tubing will be used, including temperature extremes and potential exposure to corrosive substances. It’s also vital to evaluate the flexibility required for your specific application, as polyamide tubing can vary in rigidity and bend radius. Consult with suppliers about the specific requirements of your application to ensure you choose a product that offers optimal performance and durability. -

What is the best polyamide tube for high-pressure applications?

For high-pressure applications, look for polyamide tubing that is specifically rated for high pressure, often referred to as high-pressure nylon tubing. This type of tubing is engineered to withstand significant pressure without compromising integrity. Ensure that the tubing meets the necessary safety factors and standards, such as a 4:1 safety factor for working pressure. Additionally, consider the tubing’s chemical resistance properties, as high-pressure systems often involve various fluids that can affect material performance. -

What are the minimum order quantities (MOQs) for polyamide tubes?

Minimum order quantities can vary significantly between suppliers and are often influenced by factors such as the type of polyamide tube, customization options, and production costs. Typically, MOQs may range from a few hundred meters for standard products to larger quantities for specialized or custom tubing. It’s advisable to discuss your specific needs with potential suppliers to negotiate suitable MOQs that align with your purchasing capabilities. -

How do I vet suppliers of polyamide tubes?

When vetting suppliers, consider their industry experience, product certifications, and customer reviews. Request samples to evaluate the quality and performance of their polyamide tubes. Additionally, inquire about their production processes, quality assurance measures, and compliance with international standards. Establishing clear communication channels and checking references from other clients can also provide insights into their reliability and service quality, ensuring you partner with a reputable supplier. -

What customization options are available for polyamide tubing?

Customization options for polyamide tubing can include variations in size, color, wall thickness, and specific chemical resistance properties. Many suppliers offer tailored solutions based on your application requirements, which may also encompass specific fittings or lengths. Discuss your needs with potential suppliers to understand their capabilities and lead times for custom orders. This can help ensure that the final product meets your exact specifications for optimal performance in your application. -

What are the payment terms typically offered for polyamide tube purchases?

Payment terms can vary by supplier but typically include options such as upfront payment, net 30, or net 60 days. Some suppliers may offer discounts for bulk purchases or early payments. It’s essential to clarify payment terms before finalizing an order to ensure they align with your financial processes. Additionally, inquire about payment methods accepted, which may include bank transfers, credit cards, or letters of credit, especially for international transactions. -

How do I ensure quality assurance for polyamide tubing?

To ensure quality assurance, request detailed product specifications and test results from your supplier. Look for compliance with relevant industry standards such as ISO certifications and material safety data sheets (MSDS). Consider suppliers that offer guarantees or warranties on their products, as this indicates confidence in their quality. Conducting periodic inspections and audits of the supplier’s manufacturing processes can also help maintain quality standards throughout your partnership. -

What logistics considerations should I be aware of when sourcing polyamide tubes internationally?

When sourcing polyamide tubes internationally, consider shipping options, lead times, and customs regulations. Evaluate the supplier’s ability to handle logistics, including packaging, documentation, and delivery schedules. It’s crucial to be aware of import duties and taxes that may apply in your country. Partnering with a logistics provider experienced in international shipping can facilitate smoother transactions and help mitigate potential delays or complications in the supply chain.

Top 7 Polyamide Tube Manufacturers & Suppliers List

1. Polyconn – Nylon Tubing Solutions

Domain: polyconn.com

Registered: 1995 (30 years)

Introduction: Nylon tubing, also known as polyamide tubing, can withstand higher temperatures, making it suitable for various applications. It features a lighter weight wall, greater flexibility, and smaller bend radius compared to other Nylon resins. This nylon plastic tubing is more corrosion resistant due to its moisture absorption resistance. It is heat and UV stabilized, which helps prevent stress-cracking…

2. Freelin-Wade – Metric Flexible Nylon Tubing

Domain: freelin-wade.com

Registered: 1997 (28 years)

Introduction: Metric flexible nylon (polyamide) tubing offers high temperature and pressure resistance, lightweight, and corrosion resistance. It maintains exceptional chemical, abrasion, impact, and moisture resistance, as well as dimensional stability. Specifications include: Temperature Range: -60° F to 200° F, Vacuum Rating: To 28” Hg, Working Pressure: 4:1 Safety Factor, UV Stabilized: Yes, Resin Complianc…

3. Serto – Versatile High-Performance Solutions

Domain: serto.com

Registered: 1997 (28 years)

Introduction: This company, Serto – Versatile High-Performance Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Mebraplastik – Polyamide Tubing

Domain: mebraplastik.com

Registered: 2008 (17 years)

Introduction: Polyamide tubing is characterized by optimal mechanical properties and excellent chemical resistance, making it suitable for various applications including as metal substitutes and elastomers. It can withstand both protected and aggressive environments, such as UV rays and harsh weather conditions. The primary types include Polyamide 6, 6.6, 11, 12, and Polyphthalamide (PPA). Polyamide 6.6 offers …

5. Polyhose – High Quality Polyamide Tubing

Domain: polyhose.com

Registered: 1999 (26 years)

Introduction: High Quality Polyamide Tubing, Long & Stable Service Life

6. Zecspa – PA12 PHL Polyamide Tubing

Domain: zecspa.com

Registered: 1998 (27 years)

Introduction: PA12 PHL Polyamide tubing

– Pressure Range: 7 to 68 bar

– Compliance: DIN 74324, DIN 73378

– Working Temperature: -40°C to +100°C

– Technical Features:

– Material: Plasticized polyamide 12, heat and light stabilized

– Reduced moisture absorption

– Recommended color for outdoor applications: Black

– Applications: Air conveying in industrial automation, braking systems, chemicals, hydrocarbons…

7. Hi-Tech – Polyamide Hose 8 x 6 LONGLIFE™

Domain: e-pneumatic.com

Registered: 2007 (18 years)

Introduction: {“name”:”Polyamide hose 8 x 6 LONGLIFE™”,”SKU”:”SN-PA-08″,”manufacturer”:”Hi-Tech”,”outer_diameter”:”8 mm”,”inner_diameter”:”6 mm”,”work_pressure”:”19 bar”,”bursting_pressure”:”57 bar”,”min_bending_radius”:”40 mm”,”temperature_range”:”-40 – 80 °C”,”type”:”polyamide”,”weight”:”0.03 kg”,”warranty”:”12 months”,”condition”:”new”,”price”:”€1.66 excl. tax”}

Strategic Sourcing Conclusion and Outlook for polyamide tube

How Can Strategic Sourcing Maximize Value in Polyamide Tube Procurement?

In the competitive landscape of polyamide tubing, strategic sourcing emerges as a critical factor for B2B buyers aiming to optimize both cost and quality. By prioritizing suppliers that offer advanced features such as high temperature resistance, chemical stability, and corrosion resistance, businesses can ensure they are equipped with products that meet diverse application needs across various industries, from automotive to food and beverage.

Furthermore, understanding regional market dynamics is essential. For buyers in Africa, South America, the Middle East, and Europe, leveraging local suppliers can enhance supply chain efficiency and reduce lead times. This localized approach not only fosters stronger supplier relationships but also supports sustainability initiatives by minimizing transportation impacts.

As you look ahead, consider the evolving demands of your industry and the potential for innovation in polyamide tubing solutions. Engage with suppliers who are committed to quality and compliance, and explore customized options that align with your specific requirements. By embracing strategic sourcing practices, you position your business for long-term success in a dynamic marketplace. Now is the time to evaluate your sourcing strategy and seize opportunities that will drive growth and efficiency.

Illustrative image related to polyamide tube

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.