Immersion Heater Types Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for immersion heater types

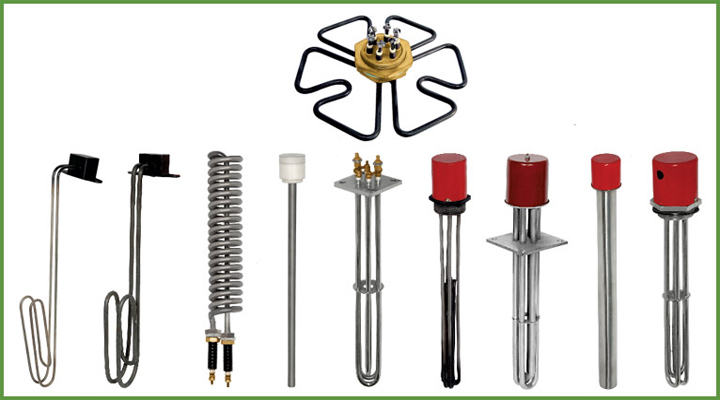

In the ever-evolving global market, sourcing the right immersion heater types presents a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive for energy efficiency and optimal thermal management, understanding the diverse range of immersion heaters becomes crucial. This guide delves into various immersion heater types—including flanged, screw plug, and over-the-side models—tailored for specific applications, from industrial processes to heating liquids in tanks.

Navigating the complexities of supplier vetting, cost considerations, and compliance with regional standards can be daunting. This comprehensive resource empowers buyers with actionable insights, helping them make informed decisions that align with their operational needs and budget constraints. By providing detailed information on heater specifications, applications, and maintenance, we aim to streamline the purchasing process and enhance the performance of thermal systems across various sectors.

Whether you are a procurement manager in Germany or a facility operator in Saudi Arabia, this guide will equip you with the knowledge to select the most suitable immersion heater types, ensuring both efficiency and reliability in your thermal management solutions.

Understanding immersion heater types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Over-the-Side Immersion Heater | Easy installation, portable, and designed for tanks with top access | Plating tanks, rinse tanks, various liquids | Pros: Easy to remove and clean; Cons: May not be suitable for high-pressure applications. |

| Flanged Immersion Heater | Rugged construction, bolted installation, high wattage options | Heating liquids in tanks and pressurized vessels | Pros: High durability and efficiency; Cons: Installation may require additional fittings. |

| Screw Plug Immersion Heater | Compact design, threaded installation, adjustable wattage | Process water heating, oil heating, freeze protection | Pros: Versatile and space-saving; Cons: Limited to certain tank wall thicknesses. |

| Portable Tank Heater | Lightweight, easy to install, integrated temperature control | Temporary heating solutions, small tanks | Pros: Highly portable and flexible; Cons: Lower wattage may limit heating capabilities. |

| Drum Immersion Heater | Designed for high-viscosity solutions, robust construction | Heating oils, adhesives, and other viscous materials | Pros: Effective for thick materials; Cons: Bulkier and less portable than other types. |

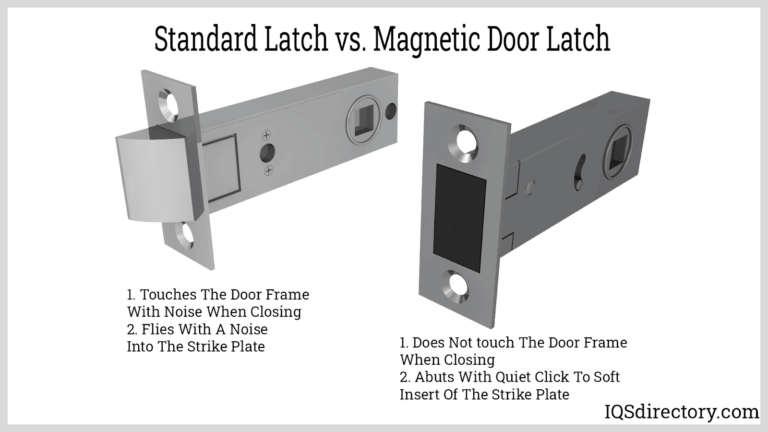

What are the Key Characteristics of Over-the-Side Immersion Heaters?

Over-the-side immersion heaters are designed for easy installation in tanks where side access is impractical. They are typically mounted through the top, allowing the heating element to extend down into the tank. This type is well-suited for applications involving aqueous solutions and is favored in plating and rinse tanks. When considering this option, B2B buyers should evaluate the ease of maintenance and the heater’s compatibility with the specific liquid being heated, as well as potential limitations regarding pressure ratings.

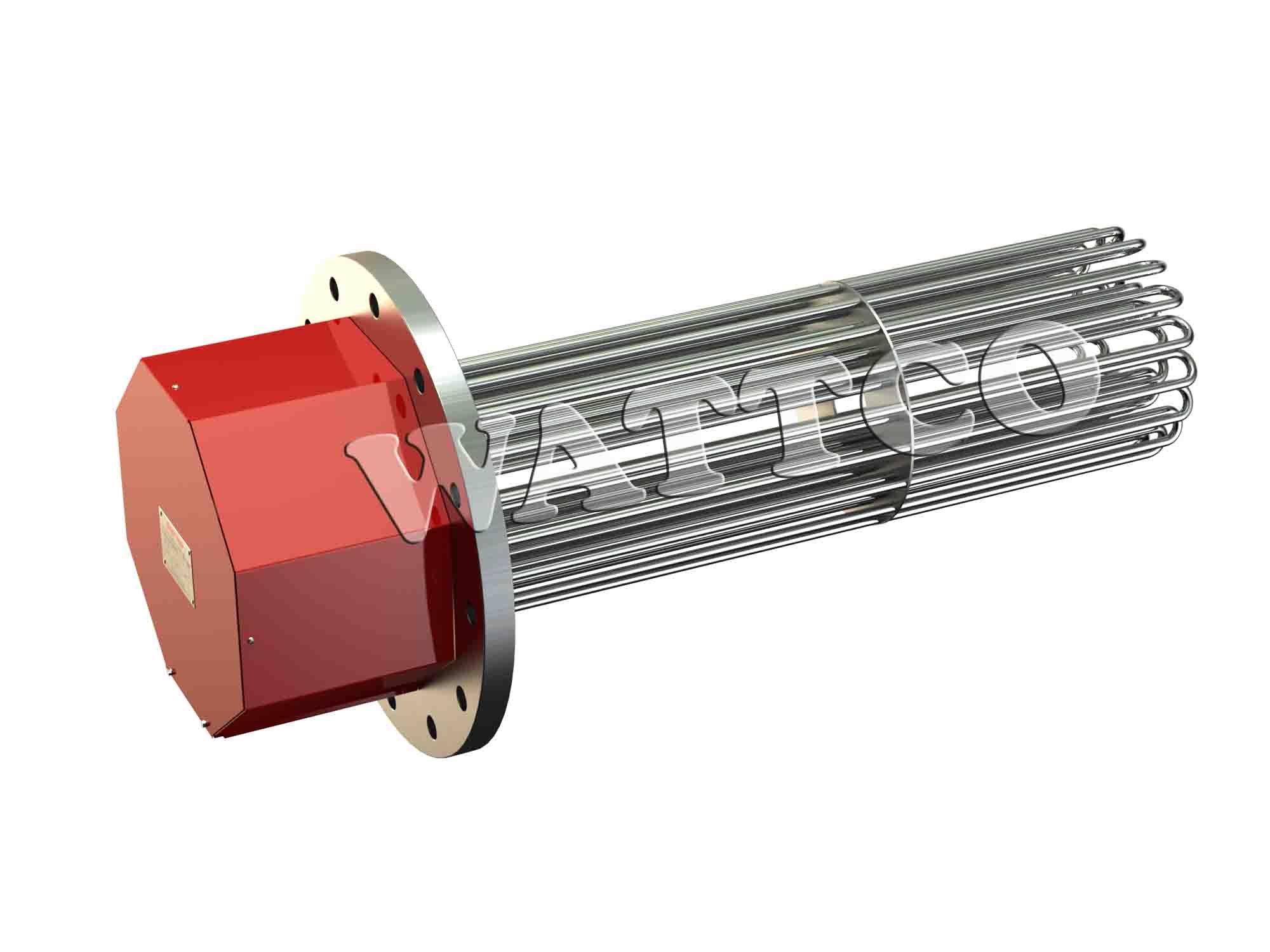

Why Choose Flanged Immersion Heaters for Industrial Applications?

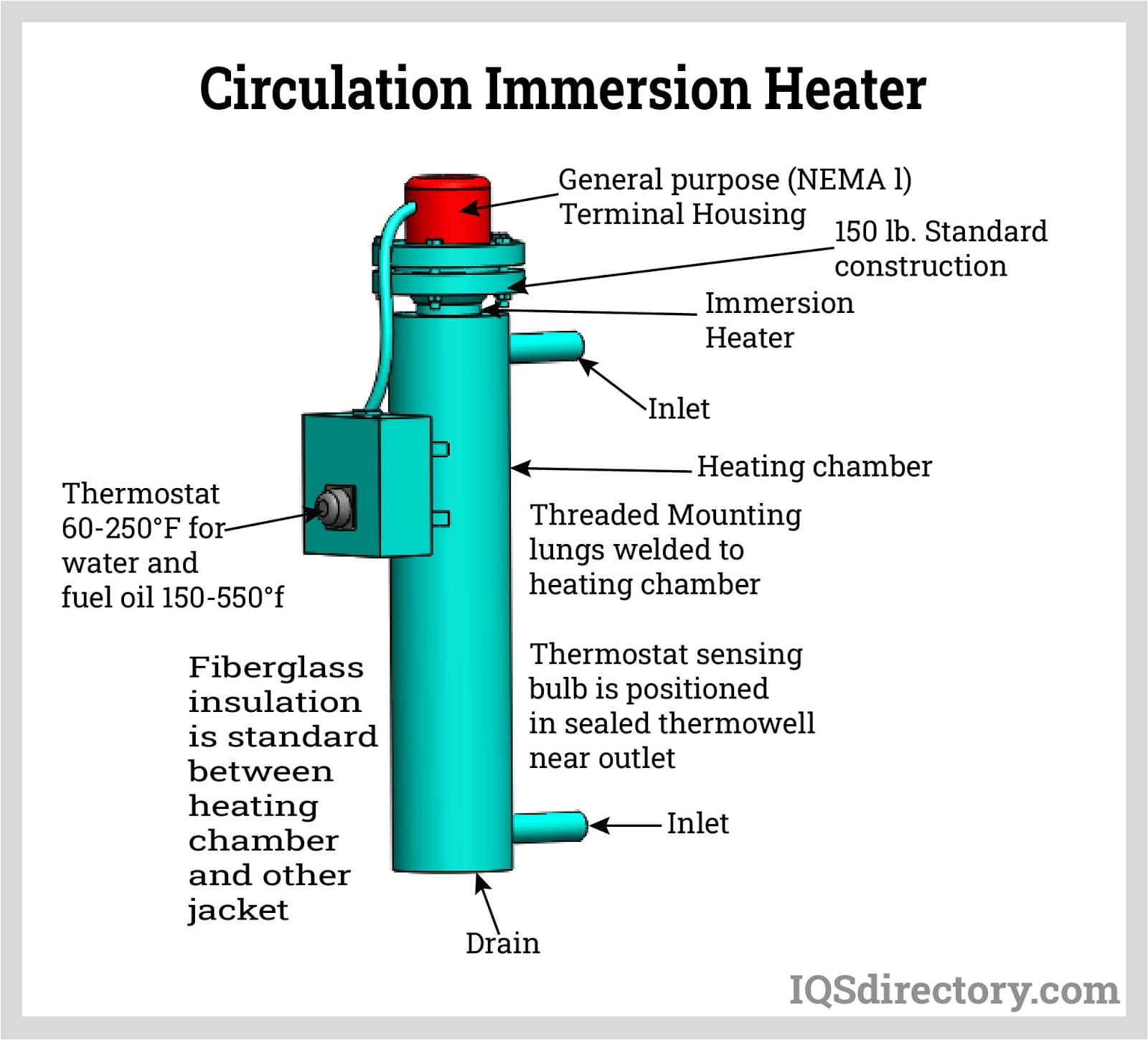

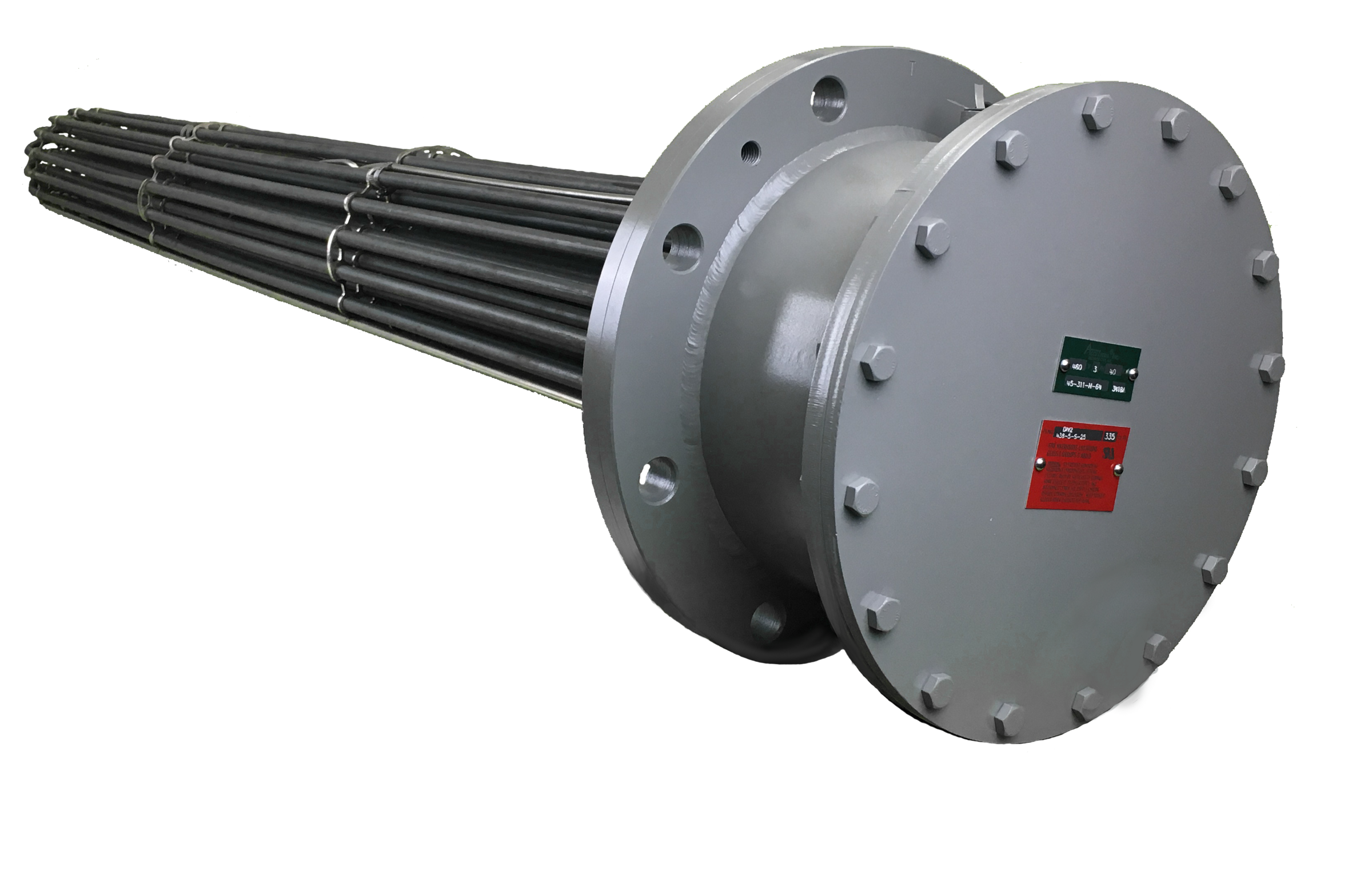

Flanged immersion heaters are characterized by their robust construction, featuring tubular heating elements attached to a flange for secure installation. They are ideal for heating various liquids in tanks and are commonly used in industrial settings due to their ability to withstand high pressures. Buyers should consider the wattage and voltage options available, as well as the materials used for the flanges, to ensure compatibility with their specific heating needs and environmental conditions.

How Do Screw Plug Immersion Heaters Offer Versatility?

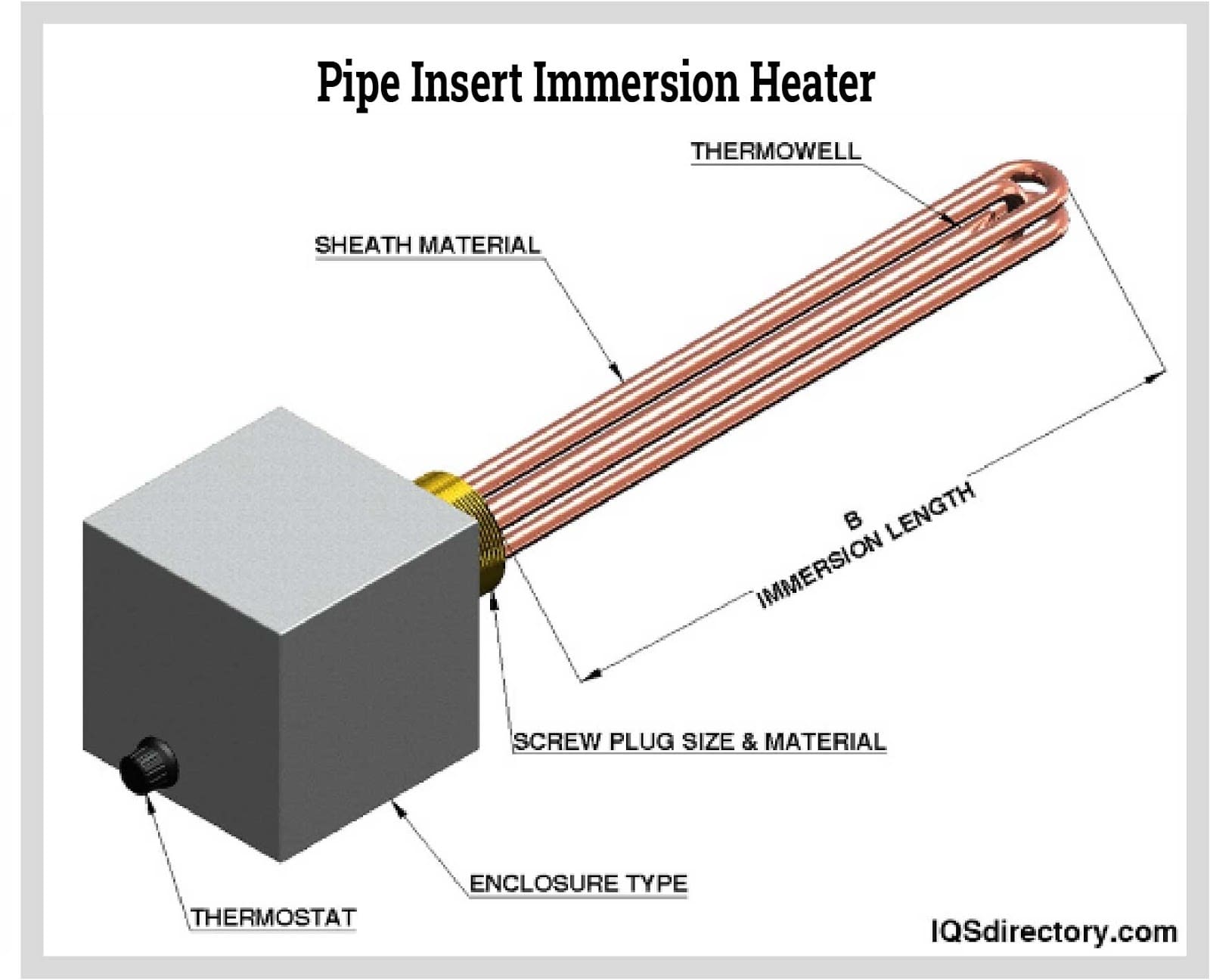

Screw plug immersion heaters are compact and easily installed through threaded openings in tank walls. Their design allows for field adjustments to wattage, making them versatile for multiple applications, including process water heating and freeze protection. When purchasing screw plug heaters, B2B buyers should consider the thickness of their tank walls and the types of liquids being heated, as these factors affect installation and performance.

What Benefits Do Portable Tank Heaters Provide?

Portable tank heaters are designed for flexibility and ease of use, making them ideal for temporary heating needs in smaller tanks. They typically feature integrated temperature controls and can be quickly set up without permanent installation. This type is particularly beneficial for companies that require mobility in their heating solutions. Buyers should assess the wattage capabilities and ensure they meet the specific heating requirements of their applications.

When Should You Consider Drum Immersion Heaters?

Drum immersion heaters are specifically designed for heating high-viscosity solutions such as oils and adhesives. Their robust construction can handle the demands of thicker materials, making them suitable for various industrial processes. B2B buyers should evaluate the heater’s power output and ensure it aligns with the viscosity and volume of the materials being heated, as these factors will significantly impact efficiency and effectiveness.

Key Industrial Applications of immersion heater types

| Industry/Sector | Specific Application of immersion heater types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Heating of water for sanitation and cooking processes | Ensures compliance with hygiene standards and improves efficiency | Material compatibility with food safety regulations |

| Chemical Processing | Heating of corrosive chemicals and solvents in reactors | Enhances reaction rates and process control | Resistance to corrosion and high temperatures |

| Oil & Gas | Heating of crude oil and other viscous fluids for easier pumping | Improves flow rates and reduces energy consumption | Durability under high pressure and temperature conditions |

| Pharmaceuticals | Heating solutions for sterilization and drug formulation | Ensures precise temperature control for product quality | Compliance with industry standards and traceability requirements |

| Water Treatment | Heating of wastewater and sludge for treatment processes | Enhances efficiency in treatment and reduces processing time | Energy efficiency and environmental impact considerations |

How are immersion heater types utilized in the Food & Beverage industry?

In the food and beverage sector, immersion heaters are crucial for heating water used in sanitation and cooking processes. These heaters ensure that water reaches the required temperatures for effective cleaning, thereby maintaining hygiene standards. Buyers in this industry must prioritize materials that comply with food safety regulations, ensuring that heaters do not leach harmful substances. Additionally, energy efficiency is a key consideration, as it impacts operational costs.

What role do immersion heaters play in Chemical Processing?

Immersion heaters are extensively used in chemical processing to heat corrosive chemicals and solvents within reactors. By maintaining optimal temperatures, these heaters enhance reaction rates and facilitate better process control. When sourcing immersion heaters for this application, businesses should focus on materials that offer resistance to corrosion and can withstand high temperatures. This ensures longevity and reliability in demanding environments, crucial for maintaining production schedules.

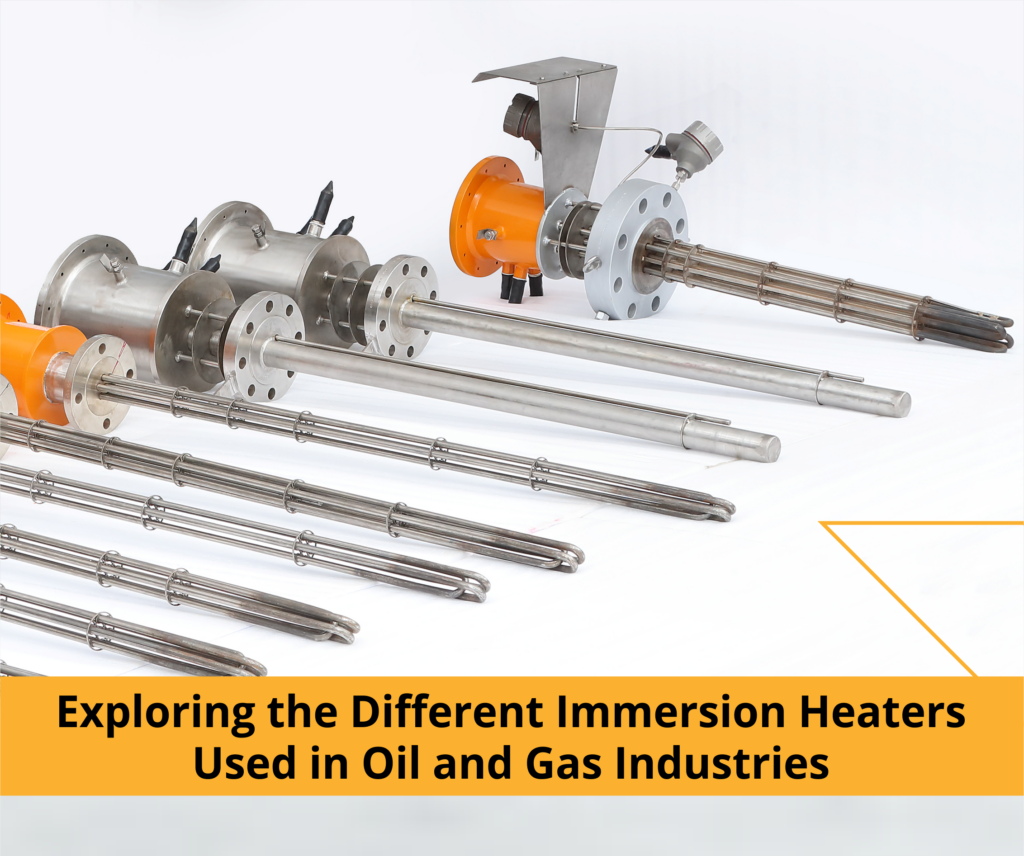

How do immersion heaters benefit the Oil & Gas industry?

In the oil and gas sector, immersion heaters are vital for heating crude oil and other viscous fluids, which facilitates easier pumping and transportation. By lowering the viscosity of the liquids, these heaters improve flow rates and reduce energy consumption during extraction and transport. Buyers should consider the durability of immersion heaters under high pressure and temperature conditions, as this directly affects the operational efficiency and safety of their processes.

What are the applications of immersion heaters in Pharmaceuticals?

In the pharmaceutical industry, immersion heaters are used to heat solutions for sterilization and drug formulation processes. Precise temperature control is essential to ensure product quality and compliance with stringent industry standards. When sourcing these heaters, companies must ensure that they meet regulatory requirements for traceability and quality assurance. Additionally, the ability to integrate with existing systems for monitoring and control is a significant factor for efficiency.

How do immersion heaters enhance Water Treatment processes?

Immersion heaters are employed in water treatment facilities to heat wastewater and sludge, improving treatment efficiency. By raising the temperature of the materials, these heaters expedite the breakdown of contaminants, thereby reducing processing time. Buyers in this sector should prioritize energy-efficient models that minimize environmental impact and operational costs. Furthermore, compliance with local environmental regulations is essential when selecting immersion heaters for these applications.

3 Common User Pain Points for ‘immersion heater types’ & Their Solutions

Scenario 1: Choosing the Right Immersion Heater for Specific Applications

The Problem: B2B buyers often struggle with selecting the correct type of immersion heater for their specific application needs. With various types such as flanged, screw plug, and over-the-side heaters available, the decision can become overwhelming. Misjudging the specifications can lead to inefficiencies, increased operational costs, and even equipment failures. For instance, a buyer may choose a flanged heater for a low-pressure tank application, only to find that it’s over-engineered and incurs higher energy costs than necessary.

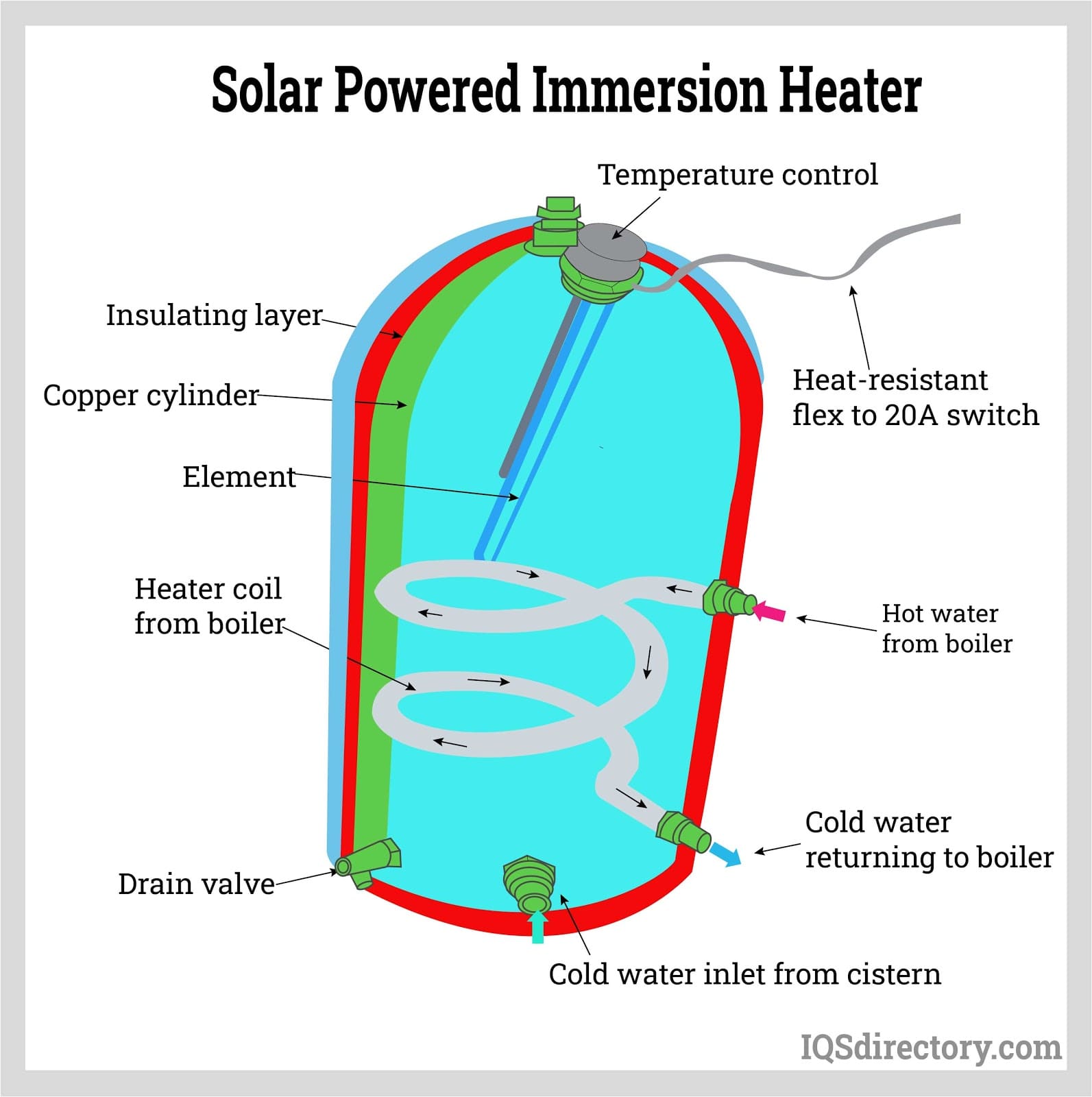

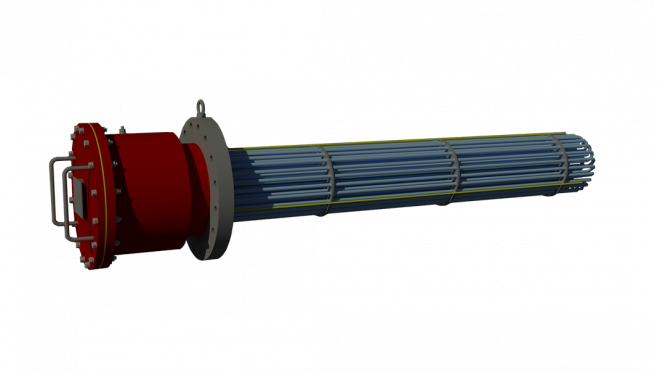

Illustrative image related to immersion heater types

The Solution: To effectively select the right immersion heater, buyers should begin by conducting a thorough needs assessment. This includes evaluating the type of liquid being heated (water, oil, corrosive materials), the required temperature range, and the tank’s physical characteristics (size, pressure, and material). Once the requirements are clear, buyers should consult with manufacturers or suppliers to understand the nuances of each heater type. For example, flanged heaters are suitable for high-pressure applications and provide robust heating, while screw plug heaters offer versatility for smaller tanks and more straightforward installations. Engaging with suppliers can also provide insights into energy efficiency ratings and long-term operational costs, ensuring that the selected heater aligns with both immediate and future needs.

Scenario 2: Managing Maintenance and Downtime

The Problem: Regular maintenance of immersion heaters can be a significant pain point for B2B buyers, especially in industries where downtime translates to lost revenue. Buyers may face challenges with heaters that are difficult to access for maintenance, leading to prolonged outages. For instance, a company might experience unexpected heater failure due to corrosion or scaling, which could have been prevented with regular maintenance but was complicated by the heater’s installation design.

The Solution: To mitigate maintenance challenges, buyers should prioritize immersion heaters that facilitate easy access and inspection. Choosing over-the-side or portable heaters can simplify the maintenance process, allowing for quick removal and servicing without extensive downtime. Furthermore, implementing a routine maintenance schedule that includes regular inspections for signs of wear, scaling, or corrosion can enhance the lifespan of the heaters. Buyers should also consider heaters with built-in diagnostic features that provide alerts for maintenance needs, allowing proactive management rather than reactive repairs. Partnering with a reliable supplier who offers maintenance training and support can further ensure that teams are well-equipped to handle upkeep efficiently.

Scenario 3: Dealing with Energy Efficiency Concerns

The Problem: As energy costs continue to rise, B2B buyers are increasingly pressured to find immersion heating solutions that are both effective and energy-efficient. Many businesses face the challenge of outdated heating systems that consume excessive amounts of energy, leading to higher operational costs and a negative environmental impact. A common scenario includes a manufacturing facility that has not updated its heating technology in years, resulting in escalating energy bills and operational inefficiencies.

The Solution: To address energy efficiency concerns, buyers should consider investing in modern immersion heaters that utilize advanced technology for better energy management. For example, heaters with adjustable watt densities and built-in thermostatic controls can optimize energy use based on real-time heating needs. Additionally, buyers should explore options for insulation and heat recovery systems that can minimize energy loss during the heating process. Conducting an energy audit can also help identify inefficiencies and provide a baseline for potential savings. Engaging with suppliers who specialize in energy-efficient solutions can lead to tailored recommendations that meet specific operational needs, ultimately lowering energy costs and enhancing sustainability efforts.

Strategic Material Selection Guide for immersion heater types

What Are the Key Materials Used in Immersion Heaters?

When selecting immersion heaters for industrial applications, the choice of material is crucial. Different materials offer distinct properties that can significantly affect performance, durability, and suitability for specific applications. Below, we analyze four common materials used in immersion heaters: copper, stainless steel, Incoloy, and titanium.

How Does Copper Perform in Immersion Heater Applications?

Copper is a highly conductive material, making it an excellent choice for immersion heaters that require rapid heating. Its thermal conductivity allows for efficient heat transfer, which is essential in applications where time is critical. Copper immersion heaters typically have a temperature rating of up to 200°C and can handle moderate pressure levels.

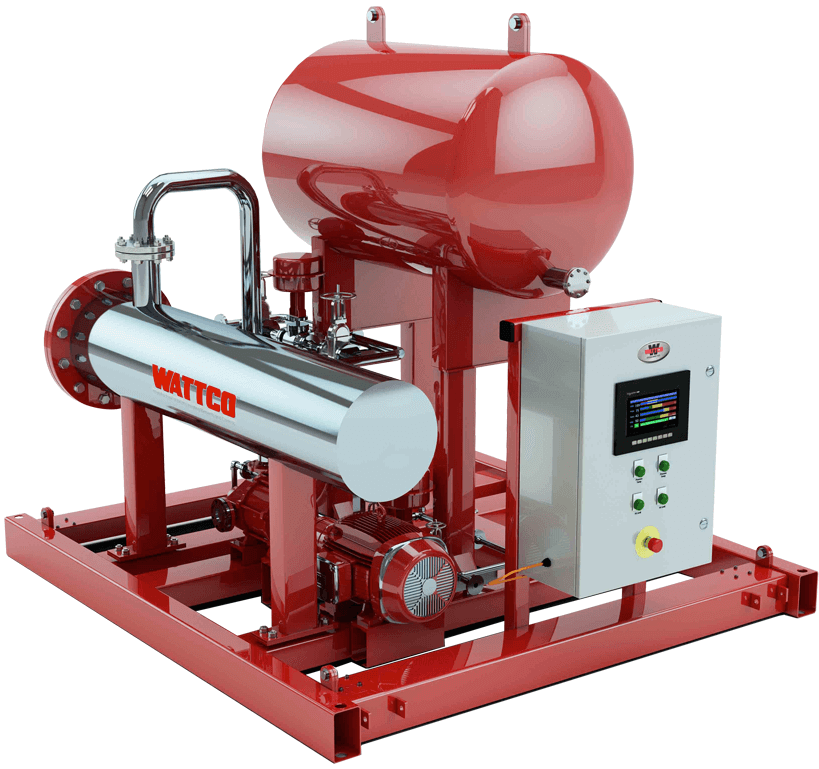

Illustrative image related to immersion heater types

Pros: Copper heaters are generally less expensive than their stainless steel or titanium counterparts. They are easy to manufacture and provide quick heating capabilities.

Cons: However, copper is susceptible to corrosion, especially in acidic or chlorinated environments. This limits its use to less aggressive media, such as clean water and certain oils.

Impact on Application: Buyers in regions with high humidity or corrosive environments, such as coastal areas in Africa or South America, should be cautious when considering copper immersion heaters.

What Advantages Does Stainless Steel Offer for Immersion Heaters?

Stainless steel, particularly grades 304 and 316, is a popular choice for immersion heaters due to its excellent corrosion resistance and durability. It can withstand temperatures up to 300°C and is suitable for high-pressure applications, making it versatile for various industries.

Pros: The long lifespan of stainless steel heaters makes them a cost-effective option in the long run, despite a higher initial investment. They are also compliant with many international standards, which is advantageous for global buyers.

Illustrative image related to immersion heater types

Cons: The primary drawback is that stainless steel heaters can be more expensive to manufacture and purchase compared to copper options. Additionally, they may not provide the same level of thermal conductivity as copper.

Impact on Application: In regions like Germany or Saudi Arabia, where industries often deal with corrosive liquids, stainless steel immersion heaters are preferred for their reliability and compliance with local standards.

Why Choose Incoloy for High-Temperature Applications?

Incoloy is a nickel-iron-chromium alloy known for its ability to withstand high temperatures and corrosive environments. It can operate efficiently at temperatures exceeding 600°C, making it ideal for extreme conditions.

Pros: The high-temperature tolerance and corrosion resistance of Incoloy make it suitable for harsh applications, such as oil and gas industries or chemical processing.

Cons: The main disadvantage is the high cost of Incoloy, which can be a significant consideration for budget-conscious buyers. Additionally, the manufacturing process can be complex, leading to longer lead times.

Impact on Application: Companies in the Middle East, involved in oil extraction, may find Incoloy immersion heaters to be a necessary investment for their operations, despite the higher costs.

What Makes Titanium a Premium Choice for Immersion Heaters?

Titanium is renowned for its exceptional corrosion resistance and strength-to-weight ratio. It is particularly effective in highly corrosive environments, such as seawater or aggressive chemicals, and can operate effectively at temperatures up to 400°C.

Illustrative image related to immersion heater types

Pros: Titanium immersion heaters are long-lasting and require minimal maintenance, making them a premium choice for critical applications. They are also lightweight, which can simplify installation.

Cons: The primary limitation is the high cost, which can deter some buyers. Additionally, titanium can be challenging to machine, resulting in longer production times.

Impact on Application: For industries in Africa or South America that deal with corrosive substances, titanium immersion heaters may be worth the investment due to their durability and performance.

Summary Table of Material Selection for Immersion Heaters

| Material | Typical Use Case for immersion heater types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Heating clean water and oils | Excellent thermal conductivity | Susceptible to corrosion | Low |

| Stainless Steel | Corrosive liquids, high-pressure applications | High durability and corrosion resistance | Higher cost than copper | Med |

| Incoloy | Extreme temperature and corrosive environments | High-temperature tolerance | Expensive and complex to manufacture | High |

| Titanium | Seawater and aggressive chemicals | Exceptional corrosion resistance | Very high cost and machining difficulty | High |

This material selection guide provides B2B buyers with the necessary insights to make informed decisions based on their specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for immersion heater types

What Are the Key Stages in the Manufacturing Process of Immersion Heaters?

The manufacturing process for immersion heaters involves several critical stages, each designed to ensure the final product meets rigorous performance and safety standards. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Immersion Heaters?

Material preparation is the foundational step in the manufacturing of immersion heaters. Manufacturers begin by selecting high-quality materials such as stainless steel, copper, or Incoloy, which are chosen based on their thermal conductivity and corrosion resistance. These materials undergo rigorous inspection to ensure they meet specified standards.

After selection, the materials are cut into required dimensions using advanced cutting tools. This stage may also involve the treatment of materials, such as surface polishing, to enhance their durability and resistance to corrosion. Proper material preparation is crucial, as it directly affects the heater’s efficiency and lifespan.

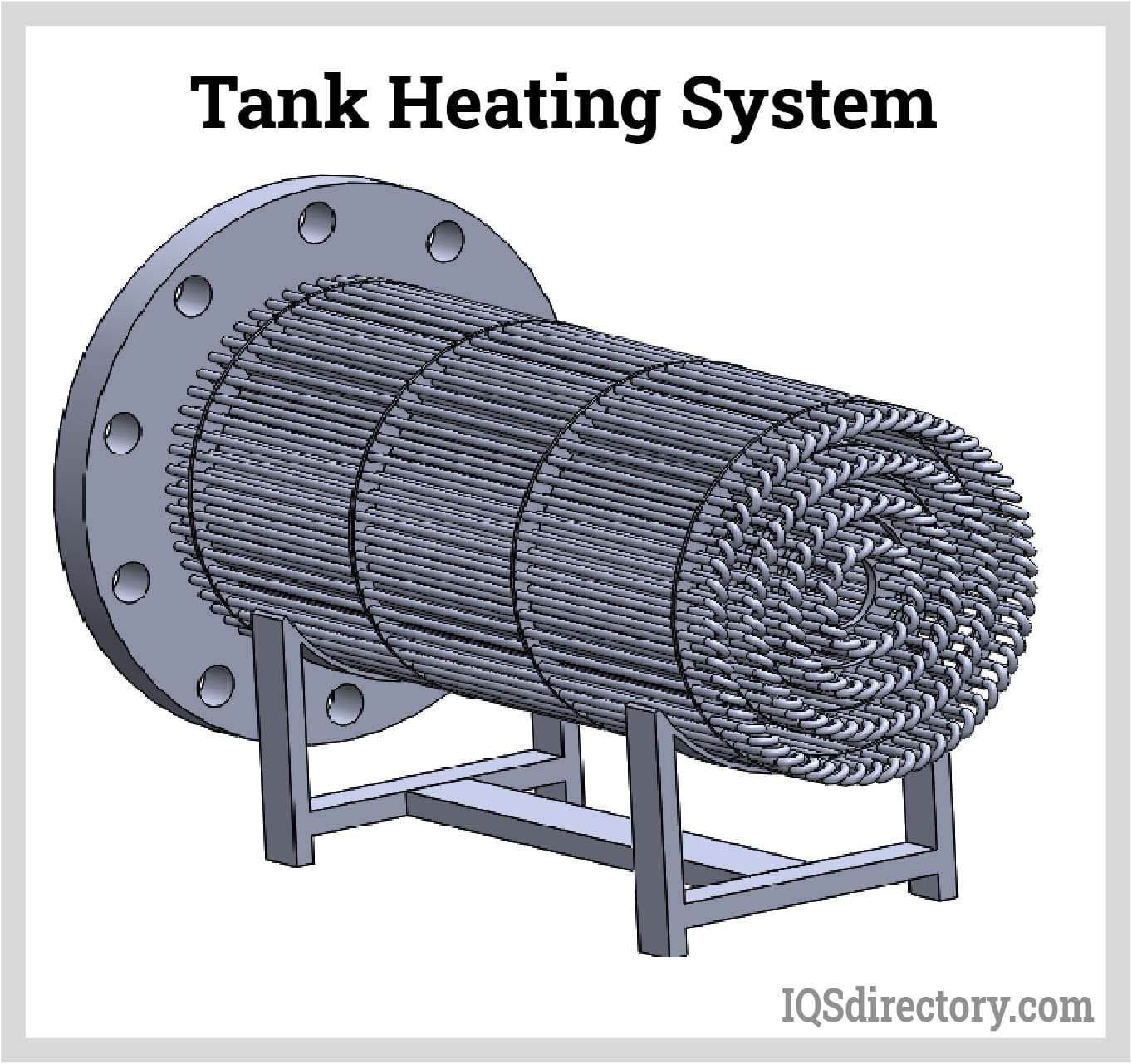

What Forming Techniques Are Commonly Used in Immersion Heater Manufacturing?

Once materials are prepared, the next stage is forming, which involves shaping the components of the immersion heater. This is typically achieved through processes such as bending, welding, and machining.

For instance, tubular elements are formed into the desired shape using bending techniques, which are essential for creating the heat transfer surfaces. Welding techniques are employed to attach various components, such as flanges or screw plugs, ensuring a robust construction that can withstand high temperatures and pressures. Precision machining may also be utilized to create threaded openings or to produce custom flanges, enabling the heaters to fit into various tank designs.

How Are Immersion Heaters Assembled?

The assembly stage involves combining all the formed components into a complete immersion heater unit. This process often includes the installation of electrical components, such as thermostats and temperature sensors, which are critical for controlling the heater’s operation.

During assembly, manufacturers must adhere to strict guidelines to ensure that all connections are secure and that the unit is assembled in a way that allows for efficient heat transfer. This stage may also include the implementation of protective measures, such as moisture-resistant enclosures, to enhance safety and reliability.

What Finishing Techniques Are Applied to Immersion Heaters?

Finishing processes are essential for enhancing the performance and aesthetics of immersion heaters. Common techniques include surface treatment, painting, and coating.

Surface treatments, such as passivation, help to protect stainless steel components from corrosion by forming a protective layer. Coatings may also be applied to improve resistance to chemicals or high temperatures, depending on the intended application of the heater. Finally, the heaters are cleaned and prepared for packaging, ensuring that they arrive at their destination in optimal condition.

What Are the Key Quality Assurance Measures for Immersion Heaters?

Quality assurance (QA) is a critical aspect of the manufacturing process for immersion heaters. It encompasses a series of measures and standards aimed at ensuring the reliability and safety of the final product.

Which International Standards Are Relevant for Immersion Heater Manufacturing?

To meet global market demands, manufacturers adhere to various international standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Illustrative image related to immersion heater types

In addition to ISO standards, industry-specific certifications such as CE marking in Europe or API standards in the oil and gas sector may be required. These certifications indicate that the immersion heaters have been tested and comply with safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure that each immersion heater meets the required specifications.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Materials are verified against specifications to ensure they meet quality standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor the quality of the components being produced. This may include dimensional checks, visual inspections, and functional testing of electrical components.

-

Final Quality Control (FQC): Once the immersion heaters are fully assembled, they undergo final testing to ensure they perform as expected. This may include pressure testing, thermal cycling tests, and electrical safety inspections to verify that the heaters function correctly and safely.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability.

Illustrative image related to immersion heater types

Buyers can take several steps to assess QC practices:

-

Conduct Audits: Requesting audits of the manufacturing facility can provide insights into the supplier’s adherence to quality standards and their manufacturing processes.

-

Request Certification Copies: Suppliers should provide copies of relevant certifications (e.g., ISO, CE) to verify compliance with international standards.

-

Ask for Quality Reports: Buyers can request quality control reports that detail testing results, including any failures or issues encountered during production.

-

Third-Party Inspections: Engaging third-party inspection services can offer an independent assessment of the manufacturer’s quality control measures and product reliability.

What Are the QC and Certification Nuances for International Buyers?

International buyers need to be aware of specific nuances related to quality control and certification when sourcing immersion heaters. Different regions may have varying regulatory requirements, which can impact product specifications and certifications.

For instance, European markets may have stricter CE marking requirements compared to other regions. Buyers should familiarize themselves with the local regulations in their respective markets and ensure that suppliers meet these requirements.

Additionally, buyers should consider the logistics of transporting certified products across borders. Certifications may be recognized differently in various regions, necessitating additional documentation or compliance checks upon importation.

By understanding these nuances and actively engaging with suppliers regarding their quality assurance processes, international buyers can make informed decisions and secure reliable immersion heating solutions tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘immersion heater types’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring the right type of immersion heater for their specific applications. Given the variety of immersion heater types available, understanding the key considerations and steps in the sourcing process is essential for making informed decisions that align with operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s vital to establish the technical requirements of your immersion heater. Consider factors such as the heating medium (water, oil, or corrosive substances), required temperature range, watt density, and the physical dimensions of the installation site. Clearly defined specifications help streamline the selection process and ensure compatibility with existing systems.

Step 2: Research Immersion Heater Types

Familiarize yourself with the various types of immersion heaters—flanged, screw plug, and over-the-side. Each type has distinct advantages and applications:

– Flanged heaters are suitable for high-pressure applications and provide robust installation options.

– Screw plug heaters are compact and ideal for straightforward installation and maintenance.

– Over-the-side heaters offer portability and ease of cleaning. Understanding these differences will guide you in choosing the most suitable option for your needs.

Illustrative image related to immersion heater types

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request detailed company profiles, technical documentation, and case studies relevant to your industry. Additionally, seek references from other buyers, particularly those in similar geographic regions or sectors, to gauge supplier performance and customer satisfaction.

Step 4: Verify Compliance with Standards

Ensure that the immersion heaters and suppliers comply with relevant international and local standards. This includes certifications such as ISO, CE, or UL, which indicate adherence to quality and safety regulations. Compliance is crucial to avoid legal issues and ensure the longevity and efficiency of your heating solutions.

Step 5: Assess Warranty and Support Options

Investigate the warranty terms and after-sales support provided by suppliers. A robust warranty can protect your investment against defects and failures, while strong customer support can assist with troubleshooting and maintenance. Look for suppliers that offer comprehensive service agreements and technical assistance to enhance your operational reliability.

Step 6: Request Quotes and Compare Pricing

After narrowing down potential suppliers, request detailed quotes that outline pricing, delivery timelines, and payment terms. Ensure that you are comparing similar products by reviewing specifications and included services. This step is essential for budget planning and achieving cost-effective procurement.

Illustrative image related to immersion heater types

Step 7: Plan for Installation and Maintenance

Finally, consider the logistics of installation and ongoing maintenance for your selected immersion heater type. Engage with suppliers to understand installation requirements and any specialized tools or skills needed. Additionally, establish a maintenance schedule to prolong the lifespan of the heaters and ensure optimal performance.

By following this checklist, B2B buyers can navigate the complexities of sourcing immersion heaters more effectively, ensuring they select the right products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for immersion heater types Sourcing

What Are the Key Cost Components in Immersion Heater Sourcing?

When sourcing immersion heaters, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The choice of materials directly influences the cost. Common materials include stainless steel, copper, and Incoloy, each varying in price and suitability for specific applications. For instance, heaters made from high-grade stainless steel tend to be more expensive due to their durability and resistance to corrosion.

-

Labor: Labor costs encompass the wages for skilled workers involved in manufacturing, assembly, and quality assurance. The complexity of the heater design can lead to higher labor costs, especially for custom solutions.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. The need for specialized molds or machining tools can add to the upfront investment.

-

Quality Control (QC): Ensuring that immersion heaters meet industry standards requires a robust QC process. This can involve testing, certifications, and inspections, which contribute to the overall cost.

-

Logistics: Shipping and handling fees can vary widely based on the destination, weight, and volume of the order. International shipments may incur additional tariffs or customs fees, further impacting the total cost.

-

Margin: Suppliers typically build a margin into the pricing structure, which can vary based on market conditions and competitive landscape.

How Do Price Influencers Affect Immersion Heater Costs?

Several factors can influence the pricing of immersion heaters, making it essential for buyers to understand these dynamics:

-

Volume/MOQ: Purchasing in bulk often leads to cost reductions. Minimum Order Quantities (MOQs) can significantly affect pricing, with larger orders usually qualifying for discounts.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials: The choice of materials impacts not only the upfront cost but also the long-term performance and maintenance costs. Buyers should consider the trade-off between initial investment and durability.

-

Quality and Certifications: High-quality heaters with certifications (e.g., ISO, CE) may come at a premium but can lead to lower failure rates and extended lifespans, ultimately saving costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. These terms dictate responsibilities for shipping, insurance, and tariffs, which can affect overall pricing.

What Are the Best Buyer Tips for Cost-Efficiency in Immersion Heater Procurement?

To maximize cost-efficiency in sourcing immersion heaters, consider the following strategies:

-

Negotiate Pricing: Always engage in negotiations. Suppliers may have room to adjust prices, especially for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as energy efficiency, maintenance costs, and expected lifespan when assessing the overall investment.

-

Understand Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, be aware of currency fluctuations and import duties. Engage local suppliers when possible to mitigate international shipping costs and tariffs.

-

Assess Supplier Capabilities: Choose suppliers who can provide flexibility in production. This can be crucial for adapting to changes in demand or specific project requirements.

-

Research Market Trends: Stay informed about market trends and fluctuations in material costs. This knowledge can provide leverage in negotiations and help anticipate price changes.

Disclaimer for Indicative Prices

Prices for immersion heaters can vary widely based on the factors discussed above. This analysis provides a framework for understanding cost components and pricing influencers but should not be considered as definitive pricing. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing immersion heater types With Other Solutions

Exploring Alternatives to Immersion Heater Types in Industrial Applications

In the quest for efficient heating solutions in industrial settings, immersion heaters are a popular choice due to their direct heating capabilities and versatility. However, there are alternative technologies available that can also serve heating needs, each with its own set of advantages and disadvantages. Understanding these alternatives is essential for B2B buyers seeking the most effective solution for their specific applications.

| Comparison Aspect | Immersion Heater Types | Electric Resistance Heaters | Steam Heating Systems |

|---|---|---|---|

| Performance | High efficiency with rapid heating and precise temperature control. | Good efficiency; slower heating compared to immersion heaters. | Excellent for large volumes but may require additional equipment for effective control. |

| Cost | Moderate initial investment; operational costs depend on electricity rates. | Generally lower upfront costs but can have higher operational costs due to energy consumption. | Higher initial investment due to boiler and infrastructure needs, but low operational costs if steam is readily available. |

| Ease of Implementation | Simple installation; requires minimal additional infrastructure. | Easy to install; may require additional space for electric panels. | Complex installation; requires space for boiler and piping systems. |

| Maintenance | Low maintenance; occasional checks on elements and controls needed. | Low maintenance; mainly electrical checks and inspections. | Higher maintenance due to boiler upkeep and potential corrosion issues in piping. |

| Best Use Case | Ideal for small to medium-sized tanks and applications requiring precise temperature control. | Best suited for applications with lower temperature requirements and less precision needed. | Optimal for large-scale processes where high heat capacity is necessary, such as in food processing or chemical manufacturing. |

Detailed Breakdown of Alternatives

Electric Resistance Heaters

Electric resistance heaters convert electrical energy into heat through resistive elements. They are easy to install and often have lower upfront costs compared to immersion heaters. However, they can have higher operational costs due to energy consumption, particularly in applications requiring constant heating. While they perform well for lower temperature applications, they may not provide the rapid heating or precise temperature control that immersion heaters offer.

Steam Heating Systems

Steam heating systems use boilers to generate steam, which is then circulated through pipes to heat various processes. These systems excel in large-scale operations and can deliver high heat capacity effectively. While they can be cost-effective in terms of operational expenses when steam is readily available, the initial investment in infrastructure can be significant. Additionally, the complexity of installation and the need for regular maintenance on boilers and piping systems can be a drawback for some businesses.

Conclusion: Making the Right Choice for Your Heating Needs

When selecting a heating solution, B2B buyers must carefully consider their specific requirements, including the scale of their operation, heating precision, and available budget. Immersion heaters provide efficient and precise heating ideal for many industrial applications, but alternatives like electric resistance heaters and steam heating systems may offer advantages depending on the context. By evaluating the pros and cons of each option, businesses can make informed decisions that align with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for immersion heater types

What Are the Key Technical Properties of Immersion Heaters?

When selecting immersion heaters, understanding the technical specifications is crucial for optimizing performance and ensuring compatibility with specific applications. Here are essential properties to consider:

1. Material Grade

The material grade of an immersion heater, such as stainless steel (e.g., 304 or 316), determines its resistance to corrosion and heat. For instance, 316 stainless steel is often preferred in harsh environments due to its superior corrosion resistance compared to 304. The choice of material impacts durability and lifespan, which are critical for reducing maintenance costs and downtime in industrial settings.

Illustrative image related to immersion heater types

2. Watt Density

Watt density refers to the power output per unit area of the heating element, typically expressed in watts per square inch (W/in²). This specification is vital as it influences how quickly a heater can raise the temperature of the fluid. Higher watt densities can lead to faster heating but may also increase the risk of overheating and premature failure if not managed properly.

3. Voltage Rating

Voltage rating indicates the electrical supply required for the immersion heater, commonly found in 120V, 240V, or higher. Understanding voltage requirements is essential for ensuring compatibility with existing electrical systems and for optimizing energy efficiency. Incorrect voltage ratings can lead to equipment failure or safety hazards.

4. Thermostatic Control

Thermostatic control options, such as built-in thermostats or external control systems, play a critical role in maintaining the desired temperature. These controls ensure efficient energy use and prevent overheating, which can lead to equipment damage. In industrial applications, precise temperature control is often necessary for product quality and process stability.

Illustrative image related to immersion heater types

5. Mounting Type

The mounting type of an immersion heater—over-the-side, flanged, or screw plug—affects installation flexibility and maintenance. Over-the-side heaters are easier to install and remove, making them suitable for applications requiring frequent cleaning. In contrast, flanged heaters provide robust support for high-pressure systems. Selecting the appropriate mounting type can optimize operational efficiency and minimize downtime.

6. Sheath Material

The sheath material encasing the heating element can vary (e.g., copper, titanium, PFA coated) based on the application and the type of fluid being heated. For instance, titanium is excellent for aggressive chemicals, while copper is typically used for less corrosive applications. The choice of sheath material is crucial for ensuring compatibility with the liquid being heated, thus preventing degradation and extending the heater’s lifespan.

What Are Common Trade Terms in the Immersion Heater Industry?

Familiarity with industry jargon is essential for effective communication and decision-making in B2B transactions. Here are some common terms:

Illustrative image related to immersion heater types

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers to ensure they are sourcing high-quality components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cost. Knowing the MOQ can help businesses plan their purchases effectively, minimizing excess stock.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers. This term is essential for initiating the procurement process and ensuring that buyers receive competitive pricing based on their specific needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B transactions, especially in international markets, as they dictate the cost and risk associated with shipping.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For B2B buyers, understanding lead times is critical for inventory planning and ensuring that production schedules remain uninterrupted.

Illustrative image related to immersion heater types

6. Certification Standards

Certification standards, such as ISO or CE marking, indicate that products meet specific quality and safety requirements. For international buyers, these certifications can assure compliance with local regulations and enhance trust in product quality.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, optimizing their procurement processes for immersion heaters across various applications.

Navigating Market Dynamics and Sourcing Trends in the immersion heater types Sector

What Are the Key Market Drivers for Immersion Heater Types?

The immersion heater market is witnessing robust growth fueled by several global drivers. The increasing demand for energy-efficient heating solutions across various industries, including food processing, pharmaceuticals, and chemical manufacturing, is a significant factor. As businesses strive to reduce operational costs and energy consumption, the adoption of electric immersion heaters has surged, particularly in regions like Africa and South America, where industrialization is rapidly advancing. Additionally, the growing focus on automation and smart technologies in manufacturing is shaping sourcing trends. The integration of IoT devices with immersion heaters enables real-time monitoring and control, enhancing efficiency and reliability.

Emerging sourcing trends reflect a shift toward localized manufacturing and supply chains to mitigate risks associated with global disruptions, such as the COVID-19 pandemic. Buyers are increasingly seeking suppliers that can provide quick turnarounds and flexibility in production. This trend is particularly relevant for international B2B buyers in the Middle East and Europe, where there is a strong emphasis on reducing lead times and improving supply chain resilience. Furthermore, the rise in renewable energy initiatives is influencing the market dynamics, as businesses look for innovative heating solutions that align with their sustainability goals.

How Does Sustainability Impact the Sourcing of Immersion Heaters?

Sustainability has become a critical consideration in the procurement of immersion heater types. The environmental impact of manufacturing processes, including carbon emissions and waste generation, is under scrutiny. B2B buyers are increasingly prioritizing ethical sourcing practices, favoring suppliers that demonstrate a commitment to sustainable operations. This includes utilizing eco-friendly materials and adhering to stringent environmental regulations.

The importance of ethical supply chains cannot be overstated, as consumers and businesses alike demand transparency in sourcing practices. Certifications such as ISO 14001 for environmental management systems and energy efficiency labels serve as indicators of a supplier’s commitment to sustainability. Buyers are encouraged to seek immersion heater products that incorporate ‘green’ materials, such as recycled metals and non-toxic coatings, which contribute to reduced ecological footprints. By aligning their sourcing strategies with sustainability principles, companies not only enhance their brand image but also position themselves favorably in increasingly environmentally conscious markets.

What Is the Historical Evolution of Immersion Heaters in B2B Applications?

The evolution of immersion heaters can be traced back to the early 20th century, when the first electric heating elements were developed. Initially, immersion heaters were primarily used for residential applications, but as industrial processes evolved, so did the technology. The introduction of materials like stainless steel and Incoloy enhanced the durability and efficiency of immersion heaters, making them suitable for a wider range of industrial applications.

By the mid-20th century, immersion heaters had established themselves as essential components in various sectors, including food processing, chemical manufacturing, and water treatment. The integration of advanced controls and automation in the late 20th century further transformed their functionality, allowing for precise temperature management and energy savings. Today, immersion heaters are recognized not only for their heating capabilities but also for their adaptability to emerging technologies, such as IoT and smart manufacturing systems, ensuring their relevance in an ever-evolving industrial landscape.

Conclusion

In summary, international B2B buyers must navigate a complex landscape characterized by dynamic market drivers, sustainability considerations, and a rich historical context in the immersion heater sector. Understanding these factors is crucial for making informed sourcing decisions that align with both operational goals and broader environmental objectives. As the industry continues to evolve, staying abreast of technological advancements and sourcing trends will be imperative for success in this competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of immersion heater types

-

How do I choose the right immersion heater type for my application?

Selecting the appropriate immersion heater involves assessing your specific heating requirements, such as the type of liquid being heated, the desired temperature range, and the tank size. Consider the three main types: screw plug, flanged, and over-the-side heaters. Each type has unique features and applications; for instance, screw plug heaters are ideal for small tanks and applications requiring easy maintenance, while flanged heaters are better for large volumes and higher pressures. Consulting with suppliers about your specific needs can also yield tailored recommendations. -

What is the best immersion heater for heating viscous liquids?

For viscous liquids, flanged immersion heaters are often the best choice due to their robust construction and ability to handle high watt densities. These heaters provide efficient heating and can be customized to fit various tank sizes and liquid types. If portability is a concern, over-the-side heaters can also be effective as they allow for easy installation and removal, facilitating cleaning and maintenance. Always ensure that the materials used in the heater are compatible with the specific liquid to avoid corrosion or degradation. -

What are the typical lead times for sourcing immersion heaters internationally?

Lead times for international orders of immersion heaters can vary significantly based on the supplier’s location, manufacturing capabilities, and shipping methods. Generally, you can expect lead times ranging from 4 to 12 weeks. Factors like customization, stock availability, and the shipping destination (considering customs and import regulations) can also impact delivery times. It’s advisable to discuss timelines with your supplier early in the negotiation process to set clear expectations. -

What payment terms should I expect when sourcing immersion heaters?

Payment terms can differ widely among suppliers, but common practices include options for upfront deposits (typically 30-50%) with the balance due upon delivery or after installation. Some suppliers may offer net payment terms (e.g., net 30, net 60) for established relationships. Always clarify the terms before finalizing your order and consider using letters of credit for larger transactions to enhance security. Ensure that the payment method is suitable for your region and complies with international trade regulations. -

How can I ensure the quality of immersion heaters from international suppliers?

To ensure product quality, it’s crucial to vet potential suppliers thoroughly. Look for certifications such as ISO 9001 or specific industry standards relevant to immersion heaters. Request samples or product specifications, and consider visiting the manufacturing facility if feasible. Engaging in third-party quality inspections before shipment can also help mitigate risks. Additionally, review previous customer testimonials and case studies to gauge the supplier’s reliability and product performance. -

What customization options are available for immersion heaters?

Customization options for immersion heaters typically include variations in wattage, sheath materials, and mounting styles to suit specific applications. You can also request features like built-in thermostats, specific flanges, or length adjustments based on your tank dimensions. Discuss your precise requirements with the supplier to explore available options and ensure that the customizations meet your operational needs. Be aware that extensive customization may lead to longer lead times. -

What are the minimum order quantities (MOQs) for immersion heaters?

Minimum order quantities for immersion heaters can vary widely depending on the manufacturer and the specific type of heater. Some suppliers may offer MOQs as low as one unit for standard products, while custom designs might require higher quantities, sometimes ranging from 10 to 50 units. Always inquire about MOQs when contacting suppliers, as negotiating lower MOQs can be possible, especially for ongoing business relationships or larger contracts. -

What logistics considerations should I be aware of when importing immersion heaters?

Logistics considerations for importing immersion heaters include understanding shipping methods (air vs. sea), customs clearance processes, and potential tariffs or duties based on your country’s import regulations. It’s essential to work with a reliable logistics provider experienced in handling industrial equipment to ensure smooth delivery. Additionally, factor in lead times, potential delays, and the need for proper insurance during transit to protect your investment.

Top 4 Immersion Heater Types Manufacturers & Suppliers List

1. HeatMax – Key Products

Domain: heatmaxheaters.com

Registered: 2017 (8 years)

Introduction: Key Product Details:

1. **Metal Plating**

– TF Series: Fluoropolymer Heaters

– SW Series: Over-the-Side Heaters

– L Series: L-Shaped Heaters

– TCD Series: Heater Controls

– Process Heat F Series: Flanged Heaters

– R Series: Screwplug Heaters

– LS Series: L-Shaped Heaters

– Tubular Elements

– Glo-Quartz® Series: Quartz Infrared Elements

– DH Series: Duct Heaters

– …

2. Toolstation – Immersion Heaters

Domain: toolstation.com

Registered: 1999 (26 years)

Introduction: Immersion heaters are essential for homes with system boilers, providing hot water in case of boiler failure. They consist of a metal rod immersed in water, heating it through electrical resistance. Key types include: 1. Incoloy Immersion Heaters: Durable, corrosion-resistant, suitable for high temperatures, but slower to heat and more expensive. 2. Titanium Immersion Heaters: Highly corrosion-res…

3. Omega – Electric Immersion Heaters

Domain: omega.co.uk

Registered: 1996 (29 years)

Introduction: Electric immersion heaters are devices installed in tanks or containers to heat liquids. They come in three main types: Over-the-side, Flanged, and Screw Plug heaters.

1. **Screw Plug Immersion Heaters**:

– Suitable for clean water and oil applications.

– Features field-adjustable ratings through connections to six elements.

– Compact design with 5/8″, ¾”, or 1¼” diameter 316 SS shea…

4. Pentair AES – Resistance Immersion Heaters

Domain: pentairaes.com

Registered: 2012 (13 years)

Introduction: Resistance Immersion Heaters from Pentair AES, priced from $239.94 to $3,028.91. SKU range: ESA10 to LH60T. Heavy-Duty Resistance Immersion heaters suitable for aquaculture applications. Requires a controller for operation (sold separately). Available models include: 1000W, 115V, 1PH, 8.4A, Stainless Steel, 11″L, 7″ Hot Zone; 1800W, 230V, 1PH, 7.5A, Stainless Steel, 17″L, 12″ Hot Zone; 1000W, 115V…

Strategic Sourcing Conclusion and Outlook for immersion heater types

In the competitive landscape of industrial heating solutions, understanding the diverse types of immersion heaters is crucial for strategic sourcing. Whether opting for screw plug, flanged, or over-the-side immersion heaters, each design offers unique advantages tailored to specific applications, from heating clean water to processing viscous fluids. The ability to customize wattage, materials, and installation methods enhances operational efficiency and aligns with various industry requirements, making informed selection paramount.

Strategic sourcing not only ensures cost-effective procurement but also fosters long-term partnerships with manufacturers who can provide reliable, high-quality products. As international markets, particularly in Africa, South America, the Middle East, and Europe, continue to expand, the demand for versatile and efficient heating solutions will rise.

Looking ahead, B2B buyers should prioritize comprehensive assessments of suppliers, focusing on their technological capabilities and support services. By doing so, businesses can secure the best immersion heating solutions that meet their operational needs while also driving innovation in their processes. Engage with manufacturers today to explore how tailored immersion heater solutions can propel your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.