The Definitive Guide to Air Break Switch: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for air break switch

In an increasingly interconnected global marketplace, sourcing the right air break switch can pose significant challenges for international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia. As these crucial components play a vital role in power distribution systems, ensuring reliability and safety is paramount. This comprehensive guide aims to demystify the complexities surrounding air break switches, providing insights into various types—including single-pole and gang-operated switches—and their diverse applications in outdoor environments.

Navigating the myriad options available requires a keen understanding of technical specifications, supplier vetting, and cost considerations. This guide will equip you with essential knowledge on how to assess the performance and durability of air break switches, enabling informed purchasing decisions that align with your operational needs. Furthermore, we delve into best practices for supplier selection, ensuring you partner with reputable manufacturers who prioritize quality and innovation. By empowering buyers with actionable insights and critical evaluation criteria, this guide serves as a valuable resource for optimizing your procurement strategy in the global air break switch market.

Understanding air break switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Pole Air-Break Switch | Operates one conductor; simple mechanism | Residential and small commercial systems | Pros: Cost-effective, easy installation. Cons: Limited to single conductor operations. |

| Gang Operated Air-Break Switch | Operates multiple conductors simultaneously | Substations, larger industrial applications | Pros: Efficient for larger systems, simultaneous operation. Cons: Higher initial cost, complex installation. |

| Vertical Break Switch | Compact design, minimal phase spacing | Utility and industrial applications | Pros: Space-saving, versatile. Cons: Requires careful installation to prevent ice buildup. |

| Center Break Switch | Low-profile, suitable for tight spaces | Transformer disconnects | Pros: Ideal for low-clearance areas. Cons: Limited to specific configurations. |

| Hookstick Switch | Operated from a distance using a pole | Maintenance operations in overhead lines | Pros: Enhanced safety for operators. Cons: Manual operation can be slower. |

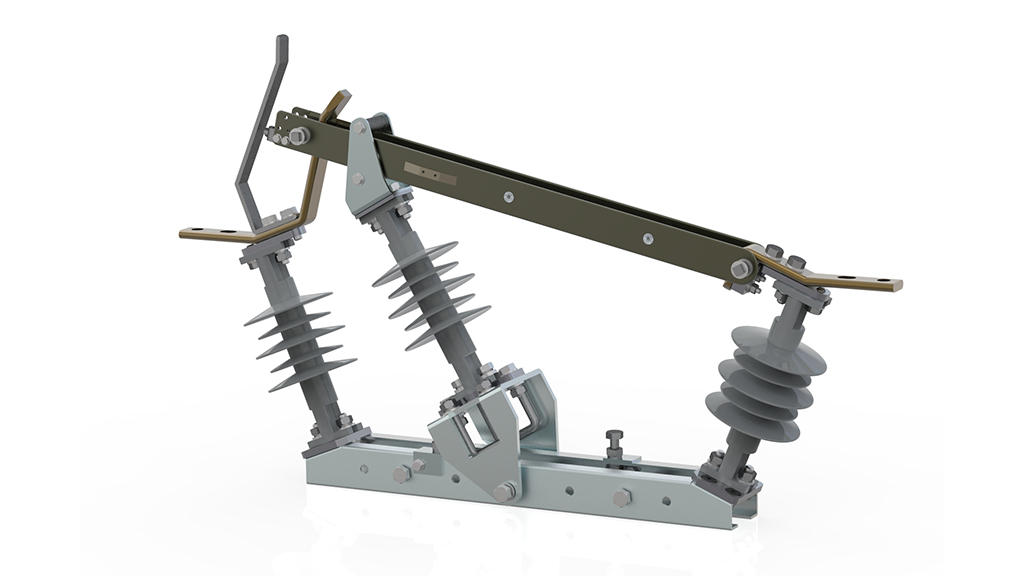

What Are the Characteristics of Single-Pole Air-Break Switches?

Single-pole air-break switches are designed to interrupt the current of a single conductor, making them suitable for residential and small commercial electrical systems. These switches are typically simple in design and easy to install, which makes them a cost-effective option for projects with limited scope. When considering this type, buyers should evaluate their specific requirements for isolation and switching, as these switches cannot manage multiple conductors simultaneously.

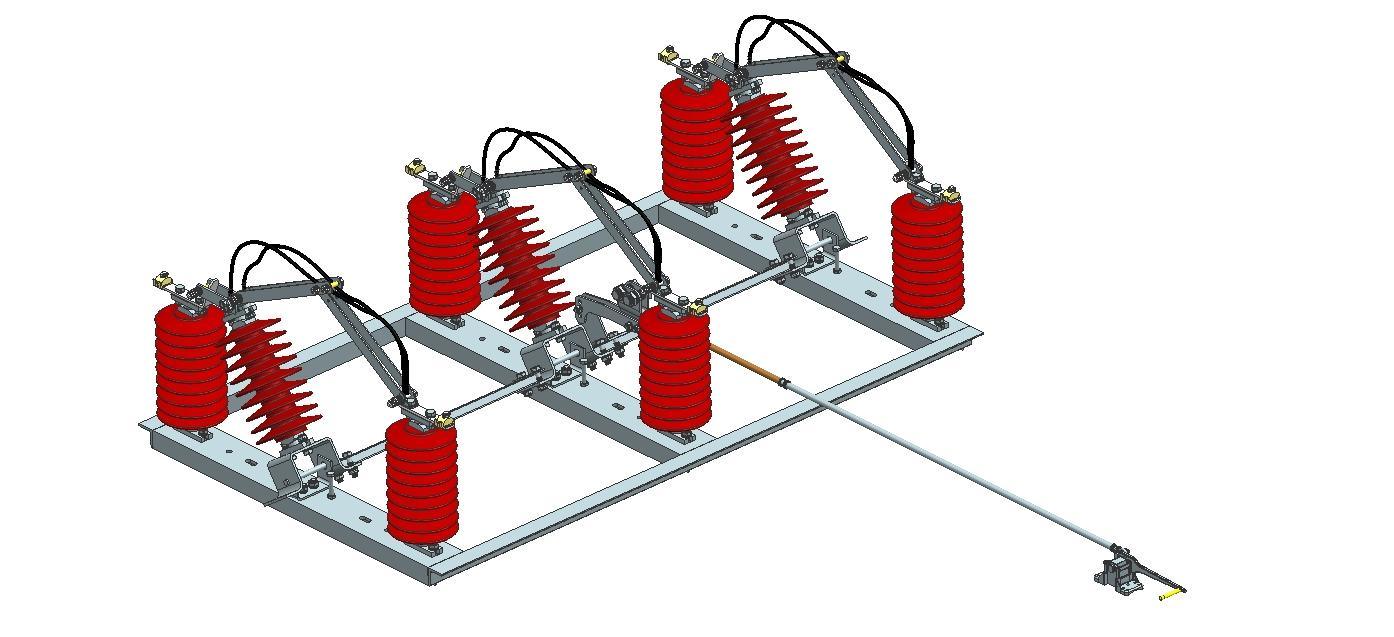

How Do Gang Operated Air-Break Switches Enhance Efficiency?

Gang operated air-break switches are engineered to operate multiple conductors at once, making them ideal for substations and larger industrial applications. They provide a robust solution for circuit isolation and can handle significant electrical loads. Buyers should consider the initial investment and complexity of installation, as these switches can be more expensive than single-pole options. However, their efficiency in managing larger systems often justifies the cost.

Why Choose Vertical Break Switches for Utility Applications?

Vertical break switches are characterized by their compact design, allowing for minimal phase spacing. They are widely used in utility and industrial applications, particularly in areas where space is at a premium. Their versatility makes them suitable for various interrupting attachments, but buyers must ensure proper installation to mitigate issues such as ice buildup in colder climates.

What Advantages Do Center Break Switches Offer?

Center break switches are designed for low-profile applications, making them suitable for transformer disconnects and environments with limited clearance. Their design allows for easier integration into existing systems, but their configuration options can be limited. Buyers should assess the spatial constraints of their installation site when considering center break switches, as their advantages are most pronounced in tight spaces.

Illustrative image related to air break switch

How Do Hookstick Switches Improve Safety During Maintenance?

Hookstick switches allow operators to manage electrical systems safely from a distance using a long pole, which enhances safety during maintenance operations, especially in overhead line applications. While these switches provide significant safety benefits, they operate manually, which can slow down the switching process. Buyers must weigh the importance of safety against the need for operational speed when considering hookstick switches for their projects.

Key Industrial Applications of air break switch

| Industry/Sector | Specific Application of air break switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Isolation in power plants for maintenance | Enhances safety by providing a visible isolation point for maintenance crews | Voltage ratings and environmental suitability for outdoor use |

| Renewable Energy | Integration in solar and wind energy systems | Facilitates safe switching and maintenance, ensuring uninterrupted power supply | Compatibility with renewable energy systems and regulatory standards |

| Utilities and Distribution | Substation operations for circuit isolation | Improves reliability and reduces downtime during maintenance | Durability under high load conditions and ease of operation |

| Mining and Heavy Industry | Equipment isolation in mining operations | Ensures safety and compliance during equipment servicing | Resistance to harsh environmental conditions and high current capacity |

| Infrastructure and Construction | Temporary power distribution for construction sites | Provides safe and efficient power management, reducing risk of outages | Portability and ease of installation in temporary setups |

How is the Air Break Switch Used in Power Generation?

In power generation facilities, air break switches are critical for ensuring safe isolation during maintenance. These switches allow maintenance crews to visibly confirm that a circuit is open, significantly reducing the risk of accidental energization. For international buyers, particularly in regions like Africa and South America where power infrastructure may be developing, sourcing robust switches that can handle local environmental challenges, such as high humidity or dust, is crucial. The ability to withstand high voltage ratings up to 35kV is essential for reliable operation in such settings.

What Role Does the Air Break Switch Play in Renewable Energy?

In renewable energy systems, such as solar and wind farms, air break switches are employed to manage the safe connection and disconnection of power during maintenance or in response to faults. These switches enhance operational efficiency by minimizing downtime and ensuring that energy production is not compromised. Buyers from the Middle East and Europe should focus on sourcing switches that meet specific regulatory standards for renewable energy integration, ensuring compatibility with the latest technologies while also providing durable construction to withstand harsh weather conditions.

How Do Utilities and Distribution Companies Utilize Air Break Switches?

Utilities use air break switches primarily for circuit isolation in substations, providing a crucial mechanism for safely performing maintenance on electrical systems. This isolation capability enhances the reliability of power distribution networks, reducing the likelihood of outages. B2B buyers in Europe and the Middle East should consider sourcing switches that are not only robust but also designed for easy operation, as well as those that can handle varying load conditions typical in utility applications.

Why Are Air Break Switches Important in Mining and Heavy Industry?

In mining operations, air break switches serve to isolate equipment during maintenance, protecting workers from electrical hazards. This application is vital for compliance with safety regulations and for ensuring uninterrupted operations in high-risk environments. Buyers from regions like Africa, where mining is a key industry, must prioritize sourcing switches that are resistant to dust and moisture while also capable of handling high current loads, ensuring both safety and reliability.

How Are Air Break Switches Used in Infrastructure and Construction?

Air break switches are essential for managing temporary power distribution on construction sites, allowing for safe and efficient power management. They provide a reliable means of connecting and disconnecting power sources, which is crucial for reducing the risk of outages during critical construction phases. International buyers should look for portable and easy-to-install solutions that can withstand the rigors of construction environments, ensuring that they meet the demands of various project timelines and conditions.

3 Common User Pain Points for ‘air break switch’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Air Break Switch for Specific Applications

The Problem: B2B buyers often face challenges in determining which type of air break switch is suitable for their specific operational needs. With various options available, such as single-pole and gang-operated switches, understanding the differences and implications of each type can be overwhelming. Buyers may struggle with factors such as voltage ratings, current carrying capacity, and installation requirements, leading to potential mismatches that can compromise safety and efficiency.

The Solution: To effectively select the right air break switch, buyers should first conduct a thorough needs assessment. This involves evaluating the operational environment, such as outdoor or indoor settings, and understanding the specific electrical loads involved. It is critical to consult with manufacturers who provide detailed specifications and guidance on their products. Look for suppliers that offer customizable solutions based on unique requirements. Additionally, leveraging resources like technical datasheets, installation guides, and industry standards can help clarify which switch type will best fit your operational needs. Engaging in discussions with technical sales representatives can also provide insights into the latest advancements in air break switch technology, ensuring that the chosen solution not only meets current needs but is future-proofed against evolving demands.

Scenario 2: Frequent Maintenance and Downtime Due to Switch Failures

The Problem: Another common pain point for B2B buyers is the frequent maintenance required for air break switches, which can lead to significant operational downtime. Issues such as arcing, wear and tear of components, and environmental factors like corrosion can affect the reliability of these switches. This not only disrupts power distribution but also increases maintenance costs and impacts overall productivity.

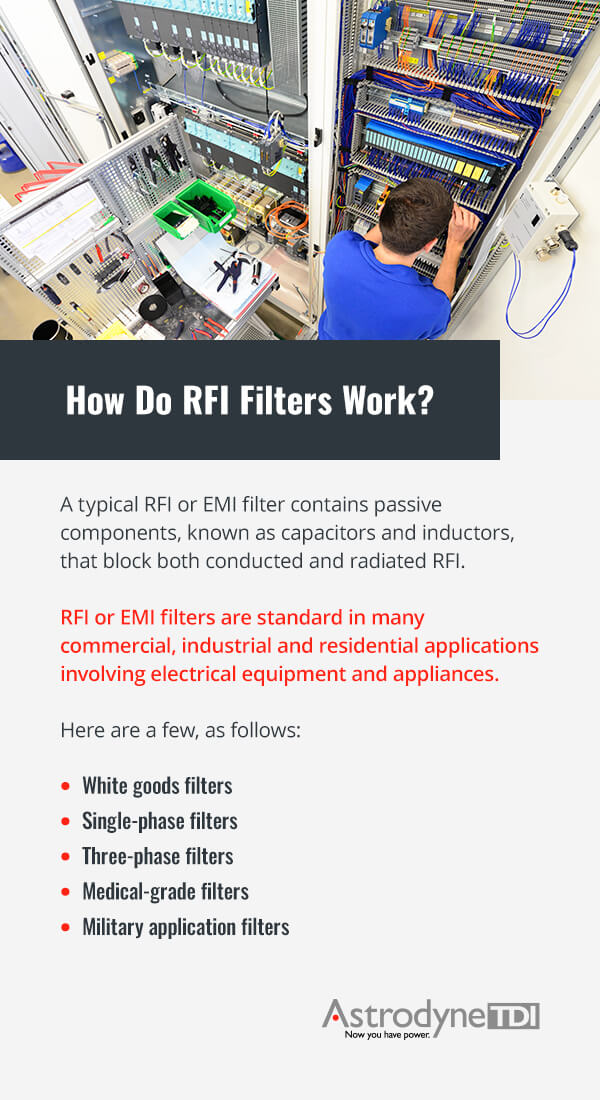

Illustrative image related to air break switch

The Solution: To mitigate these issues, buyers should prioritize the selection of high-quality air break switches designed for durability and low maintenance. Opting for switches with robust construction, such as those made from corrosion-resistant materials, can enhance longevity. Additionally, implementing a proactive maintenance schedule is essential. This includes regular inspections and cleaning to prevent debris accumulation and ensure that moving parts function smoothly. Investing in advanced monitoring technology, such as remote diagnostics, can also provide real-time insights into the switch’s performance, allowing for timely interventions before failures occur. Establishing a partnership with a reliable supplier who offers excellent after-sales support and warranty services can further ensure that any potential issues are addressed quickly, minimizing downtime.

Scenario 3: Compliance with Local Regulations and Standards

The Problem: Navigating the regulatory landscape for air break switches can be daunting for B2B buyers, particularly those operating in multiple regions such as Africa, South America, the Middle East, and Europe. Different countries may have varying standards for electrical equipment, including safety and operational guidelines. Non-compliance can lead to fines, operational restrictions, or even project delays, making it crucial for buyers to stay informed.

The Solution: To effectively comply with local regulations, buyers should invest time in understanding the specific standards applicable in their regions. This involves researching local electrical codes, safety regulations, and industry best practices. Collaborating with suppliers that are knowledgeable about these regulations can provide a significant advantage. Suppliers often offer documentation and certification information that ensures their products meet regional compliance requirements. Additionally, engaging with local industry associations or regulatory bodies can provide insights and updates on changing standards. Incorporating compliance checks into the procurement process can help buyers avoid potential pitfalls and ensure that their air break switches are suitable for their operational environments, thus safeguarding their investments and enhancing their reputation in the industry.

Strategic Material Selection Guide for air break switch

What Materials Are Commonly Used in Air Break Switches?

When selecting materials for air break switches, it’s crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact the switch’s performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in the construction of air break switches.

How Do Copper and Aluminum Compare for Conductive Components?

Copper is widely used for the conductive parts of air break switches due to its excellent electrical conductivity and thermal properties. It typically has a temperature rating of up to 200°C and offers high corrosion resistance, particularly when plated. However, copper is more expensive than other materials, which can increase the overall cost of the switch.

Aluminum, on the other hand, is lighter and more cost-effective. It has a temperature rating similar to copper but is less conductive, which can lead to higher resistive losses. Aluminum’s corrosion resistance is generally good, but it may require additional coatings in harsh environments.

For international buyers, especially in regions like Africa and the Middle East, the choice between copper and aluminum may depend on local material availability and cost considerations, as well as compliance with standards such as ASTM or DIN.

Illustrative image related to air break switch

What Role Does Porcelain Play in Insulation?

Porcelain is often used for insulators in air break switches due to its high dielectric strength and thermal stability. It can withstand high voltages and has excellent resistance to environmental factors like UV radiation and moisture. However, porcelain is brittle, which makes it susceptible to cracking under mechanical stress.

In applications across South America and Europe, porcelain insulators are favored for their reliability in outdoor settings. Buyers should ensure that the porcelain used complies with relevant international standards to guarantee safety and performance.

How Do Composite Materials Enhance Performance?

Composite materials, such as polymer blends, are increasingly used in air break switches due to their lightweight and high strength-to-weight ratio. These materials often have excellent corrosion resistance and can withstand a wide range of temperatures, making them suitable for various environments.

The main advantage of composites is their durability and lower maintenance requirements. However, they can be more expensive to manufacture, which may affect the overall cost of the switch. For buyers in regions like Vietnam or Saudi Arabia, the long-term savings on maintenance may justify the higher initial investment.

Why is Steel Important for Structural Components?

Steel is commonly used for the structural components of air break switches, providing the necessary strength and durability. It can withstand significant mechanical stress and has a high temperature rating. However, steel is prone to corrosion, so it often requires protective coatings or galvanization.

In the Middle East and Africa, where environmental conditions can be harsh, the choice of steel should consider local climate factors. Compliance with international standards for corrosion resistance can also be a critical factor for B2B buyers in these regions.

Summary of Material Properties and Considerations

| Material | Typical Use Case for air break switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Conductive components | Excellent conductivity and thermal properties | Higher cost than alternatives | High |

| Aluminum | Conductive components | Lightweight and cost-effective | Lower conductivity and higher resistive losses | Medium |

| Porcelain | Insulators | High dielectric strength and durability | Brittle and susceptible to cracking | Medium |

| Composite | Structural and insulative components | Lightweight and corrosion-resistant | Higher manufacturing costs | High |

| Steel | Structural components | Strong and durable | Prone to corrosion without coatings | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in air break switches, enabling informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for air break switch

What Are the Key Stages in the Manufacturing Process of Air Break Switches?

The manufacturing of air break switches involves several critical stages to ensure functionality, reliability, and safety. Understanding these processes is essential for B2B buyers looking for high-quality products.

1. Material Preparation: What Materials Are Used?

The first step in manufacturing air break switches is the selection and preparation of materials. Common materials include:

- Conductive Metals: Copper and aluminum are the primary choices for electrical contacts due to their excellent conductivity.

- Insulating Materials: Porcelain, composite, or hybrid materials are used for insulators to ensure electrical isolation and mechanical strength.

- Mechanical Components: Steel or reinforced polymers are used for structural elements and housing to withstand environmental stresses.

These materials undergo rigorous quality checks before being processed, ensuring they meet industry standards.

2. Forming: How Are Components Shaped?

Once materials are prepared, they undergo forming processes, which typically involve:

- Casting and Forging: Conductive parts may be cast or forged to create specific shapes and sizes. This method enhances the material’s strength and durability.

- Machining: Precision machining processes are applied to ensure that all components fit together seamlessly. This includes milling, turning, and drilling operations.

- Molding: For insulators, injection molding is often used, allowing for complex designs that enhance performance and reduce weight.

Each forming technique must be monitored to maintain dimensional accuracy and surface quality.

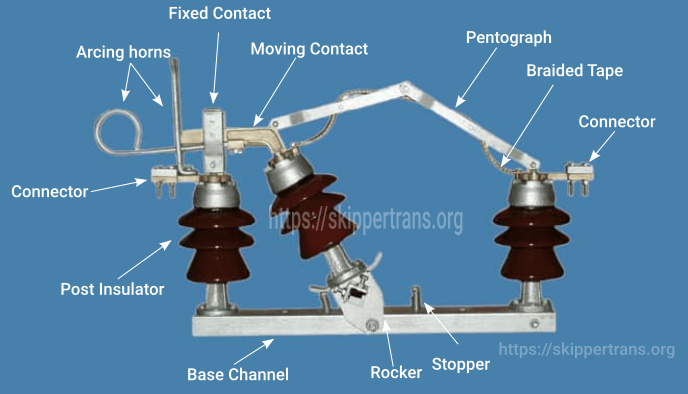

3. Assembly: What Techniques Ensure Proper Functionality?

The assembly stage involves bringing together all the individual components. This process includes:

- Mechanical Assembly: Components such as blades, contacts, and arcing horns are assembled using bolts, screws, and welds. The assembly is designed to allow for easy operation and maintenance.

- Electrical Connections: Ensuring reliable electrical connections is critical. The assembly includes soldering or crimping wires to ensure low-resistance connections.

- Final Adjustments: After initial assembly, adjustments are made to ensure that the switch operates smoothly, including the alignment of blades and checking the functionality of mechanical linkages.

4. Finishing: How Is the Product Prepared for Market?

The finishing stage is crucial for enhancing the durability and aesthetics of air break switches. Key activities include:

- Surface Treatment: Components undergo treatments such as galvanization, powder coating, or painting to protect against corrosion and environmental degradation.

- Quality Marking: Manufacturers often mark products with relevant certifications and standards to ensure traceability and compliance with international regulations.

Finishing not only improves the lifespan of the product but also aligns with the aesthetic requirements of different markets.

What Quality Assurance Practices Are Essential for Air Break Switches?

Quality assurance is vital for ensuring that air break switches perform reliably under various conditions. Here’s a breakdown of the key quality assurance practices.

Relevant International Standards: Which Standards Should Buyers Look For?

B2B buyers should ensure that their suppliers adhere to international quality standards, such as:

- ISO 9001: This standard ensures a quality management system that consistently meets customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Standards: If applicable, API standards ensure that products meet the specific needs of the petroleum and natural gas industries.

These certifications provide reassurance regarding the quality and reliability of the air break switches.

Quality Control Checkpoints: What Are the Key Stages?

Quality control (QC) checkpoints are integral to the manufacturing process. They typically include:

- Incoming Quality Control (IQC): This stage involves checking raw materials for compliance with specifications before they enter production.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that processes are followed and components meet quality standards.

- Final Quality Control (FQC): Before products are shipped, a comprehensive examination is performed to ensure that each air break switch meets the required specifications and standards.

These checkpoints help identify and rectify issues early in the production process, reducing the risk of defects.

What Testing Methods Are Commonly Used in Air Break Switch Manufacturing?

Testing is a critical aspect of quality assurance. Common testing methods include:

- Electrical Testing: This includes high-voltage testing to ensure that switches can handle specified voltage levels without failure.

- Mechanical Testing: Mechanical strength tests assess the durability of components under stress, ensuring they can withstand operational conditions.

- Environmental Testing: Products are tested under various environmental conditions (temperature, humidity, and exposure to chemicals) to ensure reliability.

Documentation of these tests is crucial for compliance and can be provided to B2B buyers upon request.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are some strategies:

- Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and QC practices.

- Quality Reports: Requesting detailed quality assurance reports can help assess compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control measures.

By utilizing these verification methods, B2B buyers can mitigate risks and ensure they are sourcing high-quality air break switches.

What Are the Specific Quality Control Nuances for International B2B Buyers?

When engaging with suppliers from different regions, it’s important to be aware of specific quality control nuances:

- Cultural Considerations: Different regions may have varying approaches to quality and compliance. Understanding these can help foster better communication and collaboration.

- Regulatory Differences: Familiarize yourself with the local regulations and standards that may impact product specifications and testing requirements.

- Supply Chain Transparency: Ensure that suppliers provide clear information about their sourcing, manufacturing, and quality control processes to build trust and reliability.

By being informed about these nuances, international buyers can make more educated decisions when selecting suppliers for air break switches.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air break switch’

In this practical sourcing guide, we aim to assist international B2B buyers in navigating the procurement process for air break switches. This checklist will help you ensure that you select the right product and supplier to meet your operational needs, particularly focusing on reliability, safety, and compliance with regional standards.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the air break switch you need. Consider factors such as voltage ratings (up to 35kV), current capacity, and whether you need single-pole or gang-operated switches. Clearly defined specifications help in narrowing down options and ensure that the product meets your operational demands.

Step 2: Research Local Regulations and Standards

Understanding the local regulations and industry standards is crucial for compliance and operational safety. Research the specific requirements in your region—such as IEC standards in Europe or ANSI standards in the U.S.—to ensure that the air break switch you procure adheres to these regulations. This step helps avoid potential legal issues and ensures the safety of your electrical systems.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. Look for companies with a solid track record in manufacturing air break switches and request company profiles, case studies, and customer references. Pay special attention to suppliers who have experience in your specific region, as they will be more familiar with local conditions and requirements.

- Check Certifications: Ensure that the suppliers have the necessary certifications, such as ISO 9001, which demonstrates their commitment to quality management.

- Review Product Range: A supplier with a diverse range of products may offer better options to meet your needs.

Step 4: Request Samples and Perform Testing

Once you have shortlisted suppliers, request samples of the air break switches for testing. Performing on-site tests or simulations can help verify that the switches operate effectively under your specific conditions. This step is vital for confirming the reliability and performance of the products before making a bulk purchase.

Step 5: Analyze Pricing and Payment Terms

Compare pricing among different suppliers, but be cautious of selecting the cheapest option without considering quality. Look for suppliers that offer transparent pricing structures and favorable payment terms. Discuss bulk purchase discounts or credit terms to optimize your cash flow.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by the suppliers, as this can significantly impact your long-term operational efficiency. Ensure that the supplier provides adequate warranty coverage and is willing to offer technical support for installation and maintenance. Good after-sales service can save you time and costs in the future.

Step 7: Finalize the Purchase Agreement

Once you have completed the previous steps, draft a detailed purchase agreement that outlines all terms and conditions, including delivery schedules, payment terms, and warranty information. Ensure that both parties understand their obligations to prevent disputes later on.

By following this step-by-step checklist, you can streamline the procurement process for air break switches, ensuring that you make informed decisions that align with your operational needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for air break switch Sourcing

What Are the Key Cost Components in Sourcing Air Break Switches?

When evaluating the cost structure for sourcing air break switches, several components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The primary materials for air break switches are typically aluminum or copper for electrical components, along with porcelain or composite materials for insulators. The quality and type of materials can significantly affect the price.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process and the skill level of the workforce. In regions with higher labor costs, such as Europe, this can be a significant factor.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or large-scale production. Buyers should inquire about tooling costs as they can affect the overall pricing structure.

-

Quality Control (QC): Ensuring the reliability and safety of air break switches necessitates rigorous QC processes. This adds to the overall cost but is essential for compliance with international standards.

-

Logistics: Shipping and handling costs vary based on the location of the supplier and the buyer. These costs can become significant, particularly for international shipments.

-

Margin: The supplier’s margin will vary based on market positioning, competition, and the perceived value of the product.

How Do Price Influencers Impact the Cost of Air Break Switches?

Several factors influence the pricing of air break switches beyond the basic cost components. Understanding these can help buyers make more informed purchasing decisions.

-

Volume/MOQ: Purchasing in larger volumes can lead to significant discounts. Suppliers often have minimum order quantities (MOQs) that buyers should be aware of to optimize their costs.

-

Specifications and Customization: Custom designs or specific technical requirements may incur additional costs. Buyers should evaluate whether off-the-shelf products meet their needs to avoid unnecessary expenses.

-

Materials: The choice of materials can influence not just the initial price but also the long-term durability and maintenance costs of the switches.

-

Quality and Certifications: Compliance with international standards (e.g., IEC, ANSI) often entails higher costs due to the additional testing and certification processes. However, these certifications can enhance product reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the terms of shipping and delivery can significantly impact total costs. Incoterms dictate who is responsible for various shipping costs, which can affect the final price to the buyer.

What Buyer Tips Can Help Optimize Costs in Air Break Switch Sourcing?

To enhance cost-efficiency in sourcing air break switches, international B2B buyers should consider the following strategies:

-

Negotiation: Engage in thorough negotiations with suppliers. Leverage bulk purchasing and long-term contracts to negotiate better pricing and terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the TCO, which includes installation, maintenance, and potential downtime costs. A cheaper initial price may lead to higher costs down the line if the product is of lower quality.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local regulations that may affect pricing when importing products. Understanding these factors is crucial for budgeting.

-

Supplier Research: Conduct comprehensive research to identify suppliers that offer the best combination of quality, price, and service. Consider suppliers that have experience in your region and understand local market conditions.

In summary, a comprehensive understanding of the cost structure and pricing influencers is essential for effective sourcing of air break switches. By employing strategic purchasing techniques and thoroughly evaluating supplier options, international B2B buyers can optimize their procurement processes and achieve significant cost savings.

Alternatives Analysis: Comparing air break switch With Other Solutions

Exploring Alternatives to Air Break Switches in Power Distribution

In the realm of electrical power distribution, selecting the right switching technology is crucial for ensuring reliability and efficiency. While air break switches are widely utilized for their robust design and effective operation in outdoor settings, it is beneficial for B2B buyers to consider alternative solutions. This analysis provides a comparative overview of air break switches against other viable technologies: vacuum circuit breakers and load break switches.

Comparison Table

| Comparison Aspect | Air Break Switch | Vacuum Circuit Breaker | Load Break Switch |

|---|---|---|---|

| Performance | Handles voltages up to 35kV, effective in interrupting small currents | Handles higher voltages (up to 38kV) and provides superior interruption capabilities | Suitable for medium voltage applications, good for load interruption |

| Cost | Generally lower initial cost | Higher upfront investment, but lower long-term maintenance costs | Moderate cost, balancing initial investment and operational savings |

| Ease of Implementation | Requires manual operation, can be complex in multi-switch setups | More straightforward installation; often automatic | Simple installation with clear operational protocols |

| Maintenance | Requires regular inspections due to exposure to elements | Lower maintenance due to sealed design; infrequent checks needed | Moderate maintenance, generally routine checks required |

| Best Use Case | Ideal for outdoor distribution networks and switching points | Best for substations and industrial applications where high reliability is critical | Effective for distribution networks needing frequent load switching |

Detailed Breakdown of Alternatives

Vacuum Circuit Breaker

Vacuum circuit breakers (VCBs) are known for their ability to interrupt current within a vacuum, making them highly effective for handling high-voltage applications. One of their primary advantages is the minimal maintenance required due to their sealed design, which protects internal components from environmental factors. However, VCBs come with a higher initial investment, which may deter some buyers, particularly in regions with budget constraints. They excel in environments where reliability and performance are paramount, such as industrial settings and substations.

Load Break Switch

Load break switches (LBS) serve as a middle ground between air break switches and more complex solutions. They are designed for medium voltage applications, allowing for safe operation during load interruptions. Their installation is relatively straightforward, and they require moderate maintenance compared to air break switches. The cost of load break switches is generally moderate, making them an appealing option for organizations looking for a balance between initial investment and operational efficiency. However, they may not be suitable for high-voltage applications, limiting their use in some sectors.

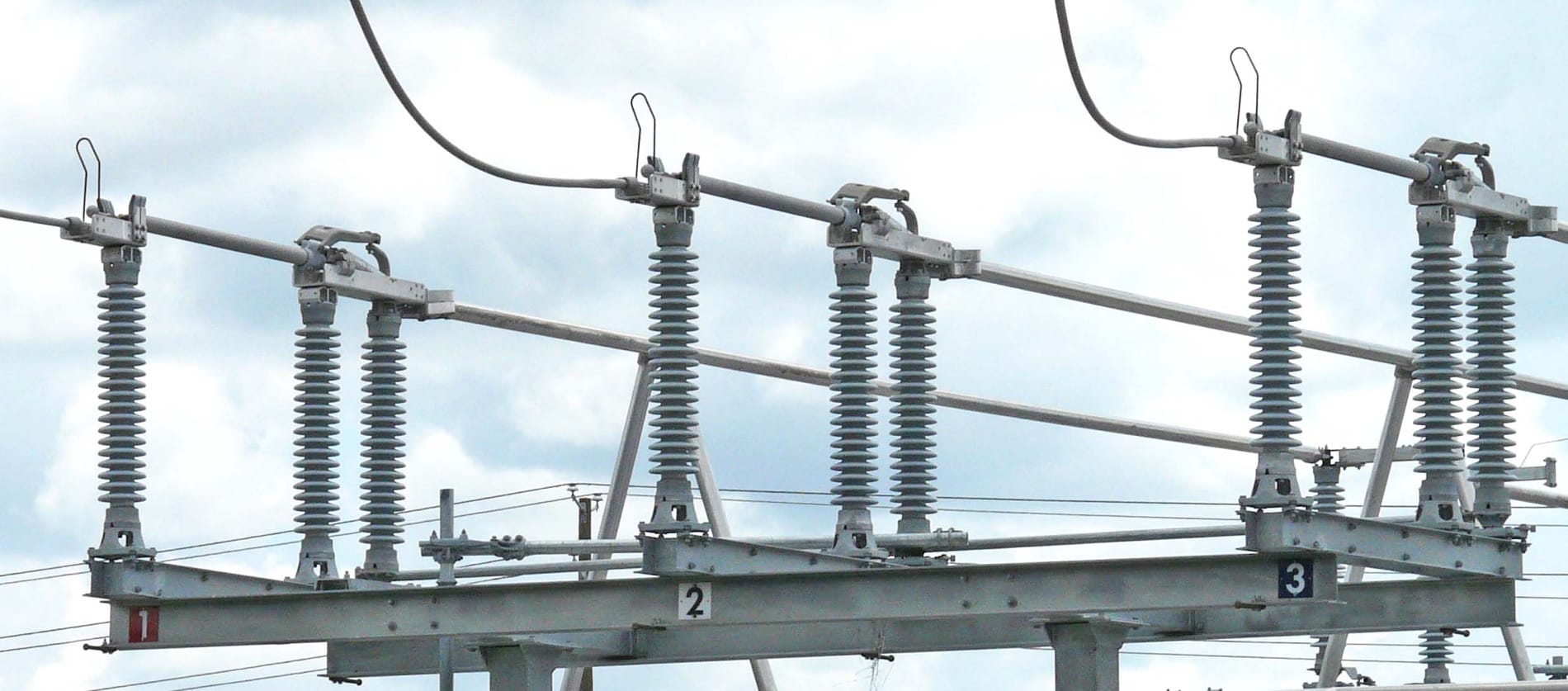

Illustrative image related to air break switch

Conclusion: Choosing the Right Solution for Your Needs

When selecting a switching solution, B2B buyers must consider their specific operational requirements, budget constraints, and long-term maintenance capabilities. Air break switches are an excellent choice for outdoor applications where manual operation is feasible. However, for those requiring higher performance and reliability, vacuum circuit breakers may justify their higher cost through enhanced durability and reduced maintenance. Load break switches offer a versatile alternative for medium voltage environments, balancing cost and performance effectively. Ultimately, the decision should align with the operational context and strategic goals of the organization, ensuring that the selected technology meets both immediate and future power distribution needs.

Essential Technical Properties and Trade Terminology for air break switch

What Are the Key Technical Properties of Air Break Switches?

Understanding the essential technical properties of air break switches is crucial for B2B buyers, particularly in regions with diverse electrical infrastructure needs. Here are several key specifications to consider:

-

Voltage Rating

Voltage rating indicates the maximum voltage the switch can handle safely, typically up to 35kV for air break switches. This property is critical for ensuring that the switch can operate effectively within the electrical system without risk of failure or arcing. For international buyers, knowing the voltage requirements of their specific applications can prevent costly mistakes and downtime. -

Current Rating

The current rating, measured in amperes, determines the maximum continuous current the switch can carry. Air break switches can handle ratings from 600 to 6500 amperes, depending on the model. For B2B buyers, selecting a switch with an appropriate current rating is essential for ensuring operational efficiency and safety in power distribution systems. -

Material Composition

The materials used in manufacturing air break switches, such as aluminum and copper for live parts, affect durability, conductivity, and resistance to environmental factors. High-quality materials enhance the lifespan and reliability of the switch. Buyers should prioritize switches made from robust materials to minimize maintenance costs and ensure long-term performance. -

Mechanical Strength and Insulation

The mechanical strength of the switch, often indicated by its design and material quality, is vital for withstanding physical stresses in outdoor installations. Insulation properties, determined by the type of insulator used (porcelain, composite, or hybrid), are crucial for preventing electrical failures. Understanding these factors helps buyers select switches suitable for their operational environments, particularly in regions with extreme weather conditions. -

Installation Configuration

Air break switches can be installed in various configurations (horizontal or vertical) and may require specific mounting conditions. Knowing the installation requirements helps buyers ensure compatibility with existing infrastructure and facilitates smoother project execution. -

Operating Mechanism

The mechanism used for operation, whether manual or automated, affects ease of use and maintenance. For instance, gang-operated switches allow multiple conductors to be operated simultaneously, improving efficiency. Buyers should assess their operational needs to determine the most suitable operating mechanism for their applications.

What Are Common Trade Terms Related to Air Break Switches?

Familiarity with industry terminology is essential for effective communication and negotiation in the procurement process. Here are key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For air break switches, understanding OEM relationships can help buyers source high-quality products directly from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for international buyers who may face shipping and storage constraints. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. It is a vital step in the purchasing process, allowing buyers to compare costs and make informed decisions based on their budgetary constraints. -

Incoterms (International Commercial Terms)

These are predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks in cross-border transactions. -

Lead Time

Lead time refers to the duration between placing an order and receiving the products. Understanding lead times is essential for project scheduling and ensuring that operations are not disrupted due to delayed deliveries. -

Warranty and Support

Warranty terms dictate the manufacturer’s commitment to repair or replace defective products. Knowing the warranty conditions can provide peace of mind and influence purchase decisions, particularly for critical infrastructure components like air break switches.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing air break switches, ensuring they meet their operational requirements effectively.

Illustrative image related to air break switch

Navigating Market Dynamics and Sourcing Trends in the air break switch Sector

What Are the Current Market Dynamics Affecting Air Break Switch Sourcing?

The air break switch market is experiencing significant growth driven by the increasing demand for reliable electrical distribution systems across various sectors. Key factors include rising urbanization, expanding industrialization, and the need for infrastructure upgrades in emerging markets, particularly in Africa, South America, and the Middle East. In regions like Vietnam and Saudi Arabia, investments in renewable energy and smart grid technologies are further propelling the demand for efficient switching solutions.

Emerging trends in B2B sourcing highlight the integration of advanced technologies, such as IoT and AI, into air break switch systems. These innovations are enhancing operational efficiency and predictive maintenance, reducing downtime, and ensuring better performance. International buyers are also increasingly gravitating towards suppliers that offer customizable solutions tailored to specific operational requirements. Furthermore, the shift towards digital procurement platforms is streamlining the sourcing process, allowing buyers to access a wider range of products and suppliers globally.

How Can Sustainability and Ethical Sourcing Impact the Air Break Switch Market?

Sustainability is becoming a cornerstone of procurement strategies in the air break switch sector. The environmental impact of manufacturing and operating electrical equipment is under scrutiny, prompting companies to adopt greener practices. Buyers are increasingly focused on sourcing from manufacturers that utilize sustainable materials and processes, which can include recycled metals and eco-friendly insulation materials.

Illustrative image related to air break switch

Ethical sourcing is equally important, as stakeholders demand transparency in supply chains. Companies that can demonstrate adherence to ethical practices, such as fair labor conditions and minimal environmental impact, are likely to gain a competitive edge. Green certifications, such as ISO 14001 for environmental management, can serve as valuable indicators for B2B buyers looking to ensure their suppliers meet high sustainability standards. By prioritizing sustainable and ethical sourcing, businesses can not only comply with regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious customers.

What Is the Historical Context of Air Break Switch Technology?

The evolution of air break switch technology can be traced back to the early 20th century when the need for efficient and safe electrical distribution became paramount. Initially designed for low-voltage applications, air break switches have undergone significant advancements in design and functionality to accommodate higher voltage requirements, now reaching up to 35kV and beyond.

Historically, these switches were primarily manual, requiring operators to be in close proximity to the equipment. However, advancements in materials and technology have led to the development of automated systems that enhance safety and efficiency. As the global energy landscape continues to evolve, particularly with the integration of renewable energy sources, air break switches are increasingly being recognized for their critical role in maintaining reliable power distribution networks. This historical context underscores the importance of understanding the technological advancements that shape current and future sourcing decisions in the air break switch market.

Frequently Asked Questions (FAQs) for B2B Buyers of air break switch

-

How do I select the right air break switch for my application?

Selecting the appropriate air break switch requires a thorough understanding of your specific application. Consider factors such as voltage rating, current-carrying capacity, and the environment in which the switch will be installed (indoor vs. outdoor). Assess whether you need a single-pole or gang-operated switch based on the number of conductors you intend to manage. Additionally, review the manufacturer’s specifications for compatibility with your existing infrastructure and ensure that the switch meets local regulatory standards. -

What are the typical voltage ratings for air break switches?

Air break switches are commonly available with voltage ratings up to 35kV. When sourcing switches, ensure that the voltage rating aligns with your system requirements. Higher voltage applications may necessitate specialized designs or equipment, so confirm the specifications with suppliers. It’s crucial to match the switch’s rating with the operational voltage to ensure safety and reliability in your electrical distribution system. -

What customization options are available for air break switches?

Many manufacturers offer customization options for air break switches to meet specific operational needs. These may include variations in materials, sizes, and configurations, such as vertical or horizontal installations. Additional features like specific arcing horn designs or enhanced insulation materials can also be requested. Engage directly with suppliers to discuss your requirements and ensure they can provide a tailored solution that fits your application. -

What is the minimum order quantity (MOQ) for air break switches?

The minimum order quantity for air break switches varies by supplier and may depend on factors such as manufacturing capabilities and the specific model requested. Typically, manufacturers may have an MOQ ranging from a few units to several dozen. To optimize costs, consider discussing bulk purchasing options with suppliers, which might allow for lower per-unit pricing and better overall terms. -

What payment terms should I expect when sourcing air break switches internationally?

Payment terms for international purchases of air break switches can vary significantly depending on the supplier and the buyer’s location. Common arrangements include advance payment, letters of credit, or payment upon delivery. Be sure to clarify payment terms before finalizing your order, and consider using secure payment methods to mitigate risks associated with international transactions. Familiarize yourself with any currency exchange implications as well. -

How can I ensure the quality of the air break switches I purchase?

To ensure the quality of air break switches, look for suppliers with a robust quality assurance process. Request certifications such as ISO 9001 or specific industry standards relevant to electrical components. Additionally, inquire about testing procedures and ask for product samples or references from previous clients. Engaging in thorough supplier vetting can help you avoid issues related to product reliability and performance. -

What are the logistics considerations for importing air break switches?

When importing air break switches, consider logistics factors such as shipping methods, lead times, and import duties. Understand the regulations in your country regarding electrical equipment imports, including compliance with safety standards. Work with logistics partners experienced in handling industrial equipment to ensure timely delivery and proper handling. Additionally, factor in potential delays at customs and plan accordingly to avoid disruptions in your supply chain. -

What are the common applications for air break switches in various industries?

Air break switches are widely used in electrical distribution networks, particularly in utility applications for switching and isolation. They are essential in substations, transmission lines, and renewable energy systems like wind and solar farms. Industries such as mining, oil and gas, and manufacturing also utilize air break switches for safe equipment operation and maintenance. Understanding the specific applications can help you identify the best product for your business needs.

Top 5 Air Break Switch Manufacturers & Suppliers List

1. Hubbell – Airbreak Switchgear

Domain: hubbell.com

Registered: 1995 (30 years)

Introduction: Hubbell’s airbreak switchgear is designed to enhance the reliability and efficiency of power distribution systems. It handles high electrical loads, ensuring smooth and safe operations across various utility applications. The switches feature robust construction and advanced switching technology for superior performance and durability. They are suitable for both indoor and outdoor settings and are…

2. Circuit Globe – Air Break Switch

Domain: circuitglobe.com

Registered: 2015 (10 years)

Introduction: Air Break Switch is a switch whose contacts open in the air, using compressed air to quench the arc. It operates manually at ground level and is primarily used for switching and isolation in outdoor settings, particularly in distribution networks. The maximum voltage rating is up to 35kV. There are two types: Single-Pole Air-Break Switch (for one conductor) and Gang Operated Air-Break Switch (for …

3. Southern States – Air Break Disconnect Switches

Domain: southernstatesllc.com

Registered: 2003 (22 years)

Introduction: Southern States manufactures a broad array of group operated air break disconnect switches utilized in substations and transmission line applications. These switches provide circuit isolation for breakers, transformers, capacitor banks, reactors, and more, allowing utility crews to confirm an open-air gap for safe maintenance. Key components include aluminum or copper live parts (jaw, blade, hinge…

4. Larson Electronics – Gang Operate Air Break Switch

Domain: larsonelectronics.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Gang Operate Air Break Switch”, “Part Number”: “MPD-GOAB-NFDS-3P-4W-38KV-3000A-EF-BM-HM-N3R”, “Price”: “$134,810.52”, “Current Rating”: “3000 Amp”, “Voltage Rating”: “38KV AC”, “Number of Poles”: “3”, “Number of Wires”: “4”, “Break Type”: “Vertical Break”, “Mounting Type”: “Horizontally Mounted”, “NEMA Rating”: “NEMA 3R”, “Enclosure Material”: “11GA Sheet Steel”, “Enclosure Finis…

5. Daykin – 15/25 Amp OMDGTC-15-208 Disconnect Switch

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: Used Air Break Disconnect Switches for Sale from various manufacturers including Daykin, Federal Pioneer, Hubbell, and more. Key products include: 1. 15/25 Amp Daykin OMDGTC-15-208, 3000 VA transformer disconnect, $199, used, located in Indianapolis, IN. 2. 250 Amp Federal Pioneer No.-CJL4250NA, Molded Case Switch, 600 V, 3 phase, $2,196, used, located in Langley, BC. 3. 400 Amp Stainless disconne…

Strategic Sourcing Conclusion and Outlook for air break switch

How Can Strategic Sourcing Enhance Your Procurement of Air Break Switches?

In summary, the strategic sourcing of air break switches is essential for ensuring reliability and efficiency in electrical distribution systems. By focusing on high-quality products that meet the operational demands of your specific environment, international buyers can secure robust solutions that minimize downtime and enhance safety. The versatility of air break switches, whether single-pole or gang-operated, allows for tailored applications across diverse settings, from substations to outdoor installations.

Furthermore, engaging with reputable suppliers who prioritize advanced technology and durable construction can lead to significant long-term cost savings. This proactive approach to procurement not only fosters strong supplier relationships but also aligns with global best practices in the power utility sector.

As the demand for reliable electrical infrastructure continues to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe, now is the time to evaluate your sourcing strategies. Prioritize partnerships with manufacturers known for innovation and performance. By doing so, you position your organization for future success in a rapidly evolving energy landscape. Take action today to ensure your procurement strategies align with the industry’s best, securing the quality and reliability you need for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.