Unlocking Value: A Strategic Analysis of the Tps Sandwich Wall Panel Market

Introduction: Navigating the Global Market for tps sandwich wall panel

In an increasingly interconnected world, sourcing high-quality TPS sandwich wall panels presents both opportunities and challenges for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe seek efficient, energy-saving building materials, the demand for these versatile panels—known for their excellent thermal insulation and moisture resistance—has surged. However, navigating the complexities of sourcing can be daunting, with concerns over supplier reliability, product specifications, and compliance with regional standards often hindering decision-making.

This comprehensive guide aims to empower buyers by providing a deep dive into the TPS sandwich wall panel market. We will explore the various types available, their specific applications—from cold storage facilities to modern office buildings—and critical factors to consider when vetting suppliers. Furthermore, we will analyze cost structures, shipping logistics, and quality assurance measures to ensure that your purchasing decisions are informed and strategic.

By equipping B2B buyers with actionable insights and practical tools, this guide helps mitigate risks and enhance procurement efficiency. Whether you are operating in Germany, Nigeria, or beyond, understanding the nuances of TPS sandwich wall panels will enable you to make sound investments that align with your business goals and contribute to sustainable construction practices.

Understanding tps sandwich wall panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermosetting Polystyrene (TPS) Panel | High compressive strength, excellent thermal insulation, moisture resistant | Warehouses, prefab houses, cold storage facilities | Pros: Lightweight, energy-efficient, long service life. Cons: Limited fire resistance compared to some alternatives. |

| Clean Room TPS Panel | Complies with stringent hygiene standards, high-density polyurethane foam | Laboratories, pharmaceutical manufacturing, food processing | Pros: Superior thermal insulation, easy to clean. Cons: Higher cost due to specialized manufacturing. |

| Acoustic Insulated TPS Panel | Enhanced soundproofing capabilities, often thicker than standard panels | Auditoriums, music studios, residential buildings | Pros: Effective noise reduction, customizable thickness. Cons: May require additional support structures. |

| Fire-Resistant TPS Panel | Specially treated materials for improved fire resistance | Industrial applications, commercial buildings | Pros: Increased safety, compliance with fire codes. Cons: Potentially higher costs and weight. |

| Recyclable TPS Panel | Made from eco-friendly materials, fully recyclable | Green building projects, environmentally conscious construction | Pros: Supports sustainability goals, cost-effective in the long run. Cons: Availability may vary by region. |

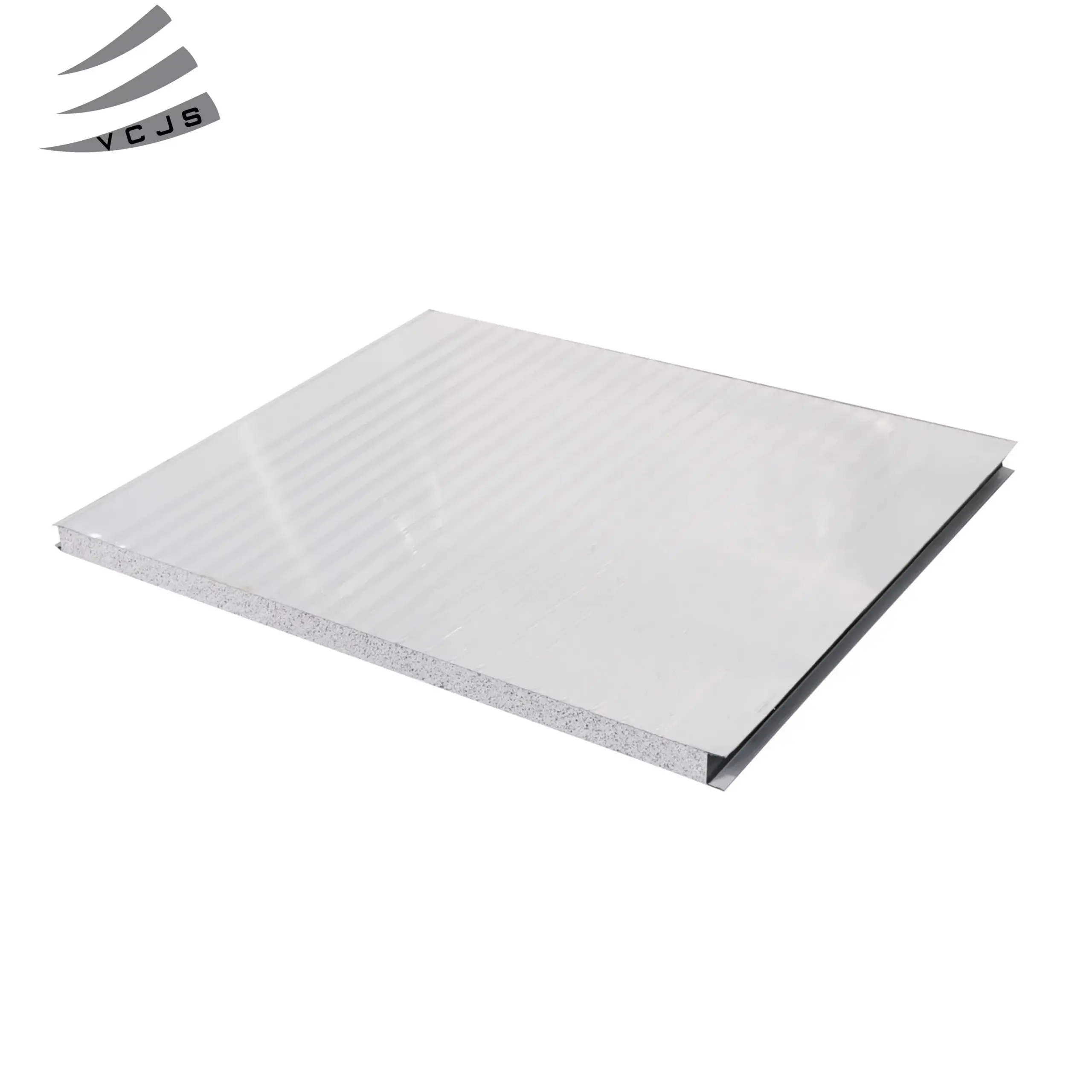

What are the Characteristics of Thermosetting Polystyrene (TPS) Panels?

Thermosetting Polystyrene (TPS) panels are recognized for their high compressive strength and excellent thermal insulation properties. Composed of a rigid foam core, they are moisture resistant and lightweight, making them ideal for various construction applications, such as warehouses and prefab houses. B2B buyers should consider their energy efficiency and long service life, although the fire resistance may be less than some alternatives.

How Do Clean Room TPS Panels Meet Industry Standards?

Clean Room TPS panels are engineered to meet stringent hygiene and safety standards, featuring high-density polyurethane foam for superior insulation. These panels are widely used in laboratories and pharmaceutical manufacturing facilities, where cleanliness and controlled environments are crucial. Buyers must weigh the benefits of enhanced thermal insulation and ease of cleaning against the higher costs associated with specialized manufacturing.

Why Choose Acoustic Insulated TPS Panels for Soundproofing?

Acoustic Insulated TPS panels are designed to provide enhanced soundproofing, making them suitable for auditoriums and music studios. These panels are typically thicker than standard options, offering customizable thickness for varying soundproofing needs. While they are effective in noise reduction, buyers should consider the potential requirement for additional support structures, which may add complexity to installation.

Illustrative image related to tps sandwich wall panel

What are the Benefits of Fire-Resistant TPS Panels?

Fire-Resistant TPS panels incorporate specially treated materials that enhance their fire safety. They are essential in industrial applications and commercial buildings where compliance with fire codes is critical. While these panels offer increased safety and peace of mind, buyers should be prepared for potentially higher costs and weight compared to standard panels.

How Do Recyclable TPS Panels Support Sustainability Goals?

Recyclable TPS panels are crafted from eco-friendly materials, making them an attractive choice for green building projects. These panels not only support sustainability goals but can also be cost-effective in the long run due to their recyclability. However, availability may vary by region, and buyers should assess local supply chains to ensure they can source these materials effectively.

Key Industrial Applications of tps sandwich wall panel

| Industry/Sector | Specific Application of tps sandwich wall panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Prefabricated Buildings | Reduced construction time and labor costs | Compliance with local building regulations and standards |

| Cold Storage | Refrigerated Warehouses | Enhanced thermal insulation and energy efficiency | Certifications for thermal performance and moisture resistance |

| Pharmaceuticals | Clean Room Facilities | Strict adherence to hygiene and safety standards | Quality assurance and compliance with international standards |

| Agriculture | Agricultural Storage Facilities | Protection against moisture and pests | Durability against environmental factors and ease of installation |

| Industrial Manufacturing | Industrial Plant Walls | Improved energy efficiency and reduced maintenance | Availability of custom sizes and colors for specific needs |

How are TPS Sandwich Wall Panels Used in Construction?

In the construction industry, TPS sandwich wall panels are increasingly utilized in the development of prefabricated buildings. These panels allow for rapid assembly, which significantly reduces both construction time and labor costs. For international buyers, especially in regions like Africa and South America where project timelines are critical, sourcing panels that comply with local building regulations is essential. Additionally, buyers should consider the availability of panels in various thicknesses and finishes to meet aesthetic and functional requirements.

What Role Do TPS Sandwich Wall Panels Play in Cold Storage Facilities?

Cold storage facilities leverage TPS sandwich wall panels for their exceptional thermal insulation properties. These panels help maintain temperature control, which is vital for preserving perishable goods. For businesses in the Middle East and Europe, where energy efficiency is a priority, selecting panels with certifications for thermal performance and moisture resistance is crucial. Buyers should also consider the panel’s ability to withstand the rigors of a cold environment to ensure long-term reliability.

How Are TPS Sandwich Wall Panels Essential for Pharmaceutical Clean Rooms?

In the pharmaceutical sector, TPS sandwich wall panels are critical for constructing clean room facilities that meet strict hygiene and safety standards. These panels minimize contamination risks and help maintain controlled environments, essential for sensitive manufacturing processes. International buyers must ensure that the panels meet high-quality assurance standards and comply with international regulations. Additionally, sourcing from reputable manufacturers that provide detailed product specifications can further assure compliance.

Illustrative image related to tps sandwich wall panel

Why Are TPS Sandwich Wall Panels Beneficial for Agricultural Storage?

Agricultural storage facilities benefit from TPS sandwich wall panels due to their moisture-resistant properties, which protect stored goods from spoilage and pests. This is particularly important in regions like Africa and South America, where climate conditions can be challenging. Buyers should look for panels that offer durability against environmental factors and are easy to install, ensuring a quick setup process for storage solutions. Customization options for size and insulation thickness can also provide added value.

How Do TPS Sandwich Wall Panels Enhance Industrial Manufacturing?

In industrial manufacturing, TPS sandwich wall panels are used to create energy-efficient plant walls that contribute to reduced operational costs. The panels’ excellent insulation properties help maintain optimal temperatures, minimizing energy consumption. For B2B buyers in Europe and the Middle East, it is important to consider the availability of panels in various sizes and colors to fit specific manufacturing needs. Additionally, sourcing panels that offer long-term durability and low maintenance can be a significant advantage for manufacturers looking to optimize their facilities.

3 Common User Pain Points for ‘tps sandwich wall panel’ & Their Solutions

Scenario 1: Navigating Compliance and Safety Standards

The Problem: B2B buyers in industries such as pharmaceuticals or food production often face stringent compliance and safety standards that govern the materials used in their facilities. When considering TPS sandwich wall panels, they might struggle to determine whether these panels meet the necessary fire resistance, thermal insulation, and hygiene requirements specific to their sector. Failure to comply can lead to costly fines, project delays, or even shutdowns.

The Solution: To address these compliance challenges, it’s crucial for buyers to conduct thorough research on the specific standards applicable in their region and industry. Begin by obtaining technical data sheets and certifications from manufacturers that clearly outline the fire resistance class, thermal conductivity, and hygiene ratings of the TPS sandwich panels. Additionally, engaging with a consultant who specializes in building materials for regulated industries can provide insights into the right specifications needed. Finally, consider conducting sample tests or pilot installations to ensure the product meets all operational requirements before committing to a large order.

Scenario 2: Addressing Durability Concerns in Harsh Environments

The Problem: Buyers in regions with extreme weather conditions, such as high humidity or fluctuating temperatures, may worry about the long-term durability and performance of TPS sandwich wall panels. Concerns about moisture retention leading to mold growth, or thermal expansion causing structural issues, can make decision-making difficult. This apprehension is heightened when sourcing materials from international suppliers where climate adaptability may not be well documented.

The Solution: To mitigate durability concerns, it is essential to select panels that are specifically designed for the local climate. Look for manufacturers that offer panels with enhanced moisture barriers and thermal insulation properties. Request detailed case studies or testimonials from clients in similar environmental conditions to gauge performance over time. Additionally, consider specifying extra protective coatings that enhance water resistance and UV stability. Establishing a maintenance schedule to periodically inspect the panels can also preemptively address any issues before they escalate.

Scenario 3: Overcoming Sourcing and Supply Chain Challenges

The Problem: Many B2B buyers face significant challenges in sourcing TPS sandwich wall panels due to supply chain disruptions, fluctuating prices, and varying lead times, especially in international transactions. These issues can lead to project delays and increased costs, making it imperative for buyers to find reliable suppliers who can provide consistency in both quality and delivery.

The Solution: Building a robust supply chain strategy is critical for overcoming these sourcing challenges. Start by diversifying your supplier base to include multiple manufacturers from different regions. This approach not only reduces dependency on a single source but also allows for comparison of pricing and quality. Establish clear communication channels with suppliers to stay informed about lead times, potential delays, and inventory levels. Utilizing inventory management tools can help track stock levels and predict future needs, ensuring that you can place orders in a timely manner. Finally, consider forming long-term partnerships with trusted suppliers who demonstrate reliability and flexibility, which can enhance supply chain resilience.

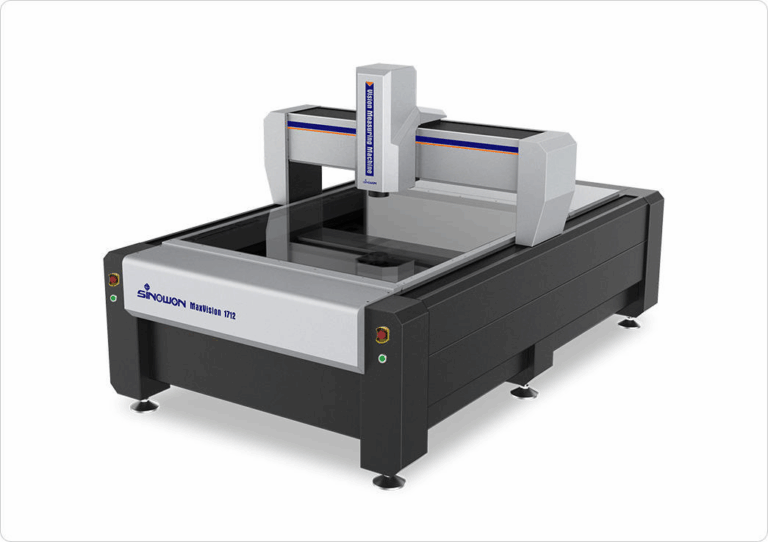

Illustrative image related to tps sandwich wall panel

Strategic Material Selection Guide for tps sandwich wall panel

When selecting materials for TPS sandwich wall panels, it’s essential to evaluate the core materials that significantly influence performance, durability, and cost-effectiveness. This analysis focuses on four common materials: thermosetting polystyrene (TPS), polyurethane (PU), mineral wool, and polyisocyanurate (PIR). Each material has unique properties and implications for various applications, particularly for international B2B buyers.

What are the Key Properties of Thermosetting Polystyrene (TPS) in TPS Sandwich Wall Panels?

Thermosetting polystyrene (TPS) is characterized by its excellent thermal insulation properties, moisture resistance, and fireproof capabilities. With a density typically ranging from 35-50 kg/m³, TPS panels exhibit high compressive strength and dimensional stability, making them suitable for various structural applications. TPS is also resistant to deformation and offers a long service life, which is vital for projects in diverse climates.

Pros & Cons: The advantages of TPS include its lightweight nature, cost-effectiveness, and recyclability. However, it may not perform as well in extreme temperature conditions compared to other materials, which could limit its use in specific applications.

Impact on Application: TPS is particularly effective in environments requiring moisture control, such as cold storage facilities and industrial buildings. Its compatibility with various construction methods makes it a versatile choice for international projects.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that TPS panels comply with local building codes and standards, such as ASTM or DIN. Understanding the thermal performance requirements specific to their climate is crucial.

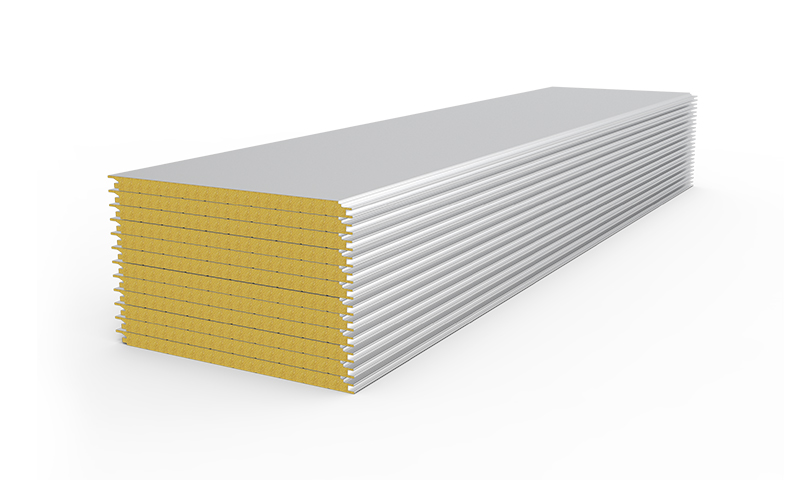

How Does Polyurethane (PU) Compare as a Core Material for TPS Sandwich Wall Panels?

Polyurethane (PU) is another popular choice for the core of sandwich panels, known for its superior thermal insulation properties, with thermal conductivity as low as 0.23 W/mK. PU panels are lightweight and can be manufactured in various thicknesses, allowing for flexibility in design.

Pros & Cons: The main advantage of PU is its high insulation efficiency, which can lead to significant energy savings. However, PU can be more expensive than other materials, and its production process may involve complex manufacturing techniques.

Impact on Application: PU is ideal for buildings requiring stringent temperature controls, such as laboratories and clean rooms. Its excellent insulation properties help maintain stable internal environments.

Illustrative image related to tps sandwich wall panel

Considerations for International Buyers: Buyers should verify that PU panels meet safety standards, especially regarding fire resistance and environmental impact, which are critical in regions with strict regulations, such as Germany.

What Role Does Mineral Wool Play in TPS Sandwich Wall Panels?

Mineral wool is recognized for its fire-resistant properties and sound insulation capabilities. It is composed of natural or recycled materials and provides excellent thermal performance, making it suitable for various applications, including residential and commercial buildings.

Pros & Cons: The key advantage of mineral wool is its non-combustibility, which enhances building safety. However, it can be heavier than other insulation materials, potentially increasing transportation costs.

Impact on Application: Mineral wool is particularly beneficial in applications where sound insulation is a priority, such as in hotels or multi-family dwellings. Its fire-resistant nature makes it suitable for high-rise buildings.

Considerations for International Buyers: Buyers should confirm that mineral wool products comply with local fire safety regulations and standards, which can vary significantly across regions.

Illustrative image related to tps sandwich wall panel

How Does Polyisocyanurate (PIR) Material Affect TPS Sandwich Wall Panel Performance?

Polyisocyanurate (PIR) is known for its high thermal resistance and fire performance, making it a popular choice for energy-efficient buildings. With a thermal conductivity of around 0.022-0.028 W/mK, PIR panels provide excellent insulation.

Pros & Cons: The primary advantage of PIR is its superior thermal efficiency, which can lead to lower energy costs. However, PIR can be more expensive than other insulation materials, and its installation may require specialized skills.

Impact on Application: PIR is particularly effective in commercial applications where energy efficiency is a priority, such as office buildings and shopping centers. Its fire-resistant properties also make it suitable for industrial settings.

Considerations for International Buyers: Buyers must ensure that PIR panels meet local regulations regarding fire safety and environmental impact, especially in regions with stringent building codes.

Summary Table of Material Selection for TPS Sandwich Wall Panels

| Material | Typical Use Case for tps sandwich wall panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermosetting Polystyrene (TPS) | Cold storage, industrial buildings | Excellent thermal insulation | Limited performance in extreme temperatures | Medium |

| Polyurethane (PU) | Laboratories, clean rooms | High insulation efficiency | Higher cost and complex manufacturing | High |

| Mineral Wool | Residential, commercial buildings | Non-combustible, sound insulation | Heavier, potentially higher transport costs | Medium |

| Polyisocyanurate (PIR) | Energy-efficient commercial buildings | Superior thermal efficiency | Higher cost, requires specialized installation | High |

This guide provides essential insights into material selection for TPS sandwich wall panels, helping international B2B buyers make informed decisions based on performance, application suitability, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for tps sandwich wall panel

What Are the Key Stages in the Manufacturing Process of TPS Sandwich Wall Panels?

The manufacturing process for TPS (thermosetting polystyrene) sandwich wall panels involves several critical stages, each designed to ensure optimal performance and compliance with international standards. Understanding these stages helps B2B buyers assess the quality and reliability of the panels they intend to procure.

1. Material Preparation: Sourcing and Selection

The first stage in the manufacturing process is the careful selection and preparation of raw materials. The core insulation for TPS panels is primarily made from thermosetting polystyrene foam, chosen for its excellent moisture retention, fire resistance, and thermal insulation properties. Quality suppliers often source their polystyrene resin from reputable manufacturers, ensuring that the material meets specific standards for density and purity.

In addition to polystyrene, galvanized steel sheets are used for the outer layers of the sandwich panel, providing structural integrity. Suppliers should also consider incorporating environmentally friendly additives that enhance the panel’s fire resistance and durability without compromising safety or performance.

Illustrative image related to tps sandwich wall panel

2. Forming: Creating the Core and Outer Layers

Once the materials are prepared, the next step involves forming the core and outer layers of the sandwich panel. The polystyrene foam is produced using a heating and extrusion process, which forms a rigid foam with a closed-cell structure. This structure enhances moisture resistance and improves thermal insulation.

Simultaneously, the outer layers of galvanized steel are cut and shaped to the desired dimensions. Advanced machinery is employed to ensure precision in the forming process, which is critical for the overall fit and finish of the panel.

3. Assembly: Joining Layers for Structural Integrity

After forming, the assembly stage involves bonding the core material to the outer layers. High-performance adhesives are typically used to ensure a strong bond between the layers, contributing to the panel’s overall structural integrity. This process may include techniques such as hot pressing or cold pressing, depending on the specific requirements of the panel design.

During assembly, manufacturers often implement automated systems to maintain consistency and reduce human error. This is particularly important for large-scale production, where uniformity across panels is crucial for performance.

4. Finishing: Ensuring Quality and Aesthetic Appeal

The finishing stage involves several processes that enhance the panel’s aesthetics and functionality. This can include surface treatments to improve resistance to corrosion and UV damage, as well as the application of protective coatings. In addition, panels may be painted or finished in a variety of colors, allowing for customization to meet client specifications.

Manufacturers should also conduct visual inspections during this stage to identify any defects or imperfections that may affect the panel’s performance or appearance.

Illustrative image related to tps sandwich wall panel

How Is Quality Assurance Implemented in TPS Sandwich Wall Panel Production?

Quality assurance is a vital component of the manufacturing process for TPS sandwich wall panels. It ensures that the panels meet international standards and comply with industry-specific regulations, making them suitable for various applications, from construction to cold storage.

International Standards: What Should Buyers Know?

To maintain high-quality production, manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This certification indicates that a manufacturer consistently meets customer and regulatory requirements.

Additionally, compliance with CE marking is crucial for products sold in the European market. This certification demonstrates that the product meets safety, health, and environmental protection standards.

Industry-Specific Certifications: Why Are They Important?

Depending on the application, TPS sandwich panels may also need to comply with industry-specific certifications. For instance, panels used in cleanroom environments should meet standards set by organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) for cleanroom construction.

B2B buyers should verify that their suppliers have the necessary certifications relevant to their target markets, ensuring the products are suitable for their intended applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process to ensure that each panel meets stringent quality standards.

1. Incoming Quality Control (IQC)

Before production begins, incoming materials undergo rigorous testing and inspection. Suppliers should verify the quality of polystyrene and steel sheets to ensure they meet the required specifications. Documentation of these inspections should be readily available for buyers to review.

2. In-Process Quality Control (IPQC)

During the manufacturing process, IPQC checkpoints are established to monitor critical parameters such as adhesive bonding strength, dimensional accuracy, and surface finish. Regular sampling and testing allow manufacturers to identify and rectify any deviations from quality standards in real-time.

3. Final Quality Control (FQC)

Once the panels are fully assembled and finished, FQC inspections are conducted. This includes comprehensive testing for thermal conductivity, moisture penetration, and fire resistance, among other performance metrics. The results of these tests should be documented, providing buyers with confidence in the product’s capabilities.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial for ensuring that the TPS sandwich panels meet their specific needs.

1. Conducting Supplier Audits

Buyers should conduct audits of potential suppliers to assess their manufacturing processes and quality control systems. This includes reviewing their certifications, inspecting production facilities, and examining records of past QC inspections.

2. Requesting Quality Reports

Suppliers should provide detailed quality reports that outline their testing procedures, results, and compliance with international standards. This transparency helps buyers understand the reliability of the products they are purchasing.

3. Engaging Third-Party Inspectors

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These organizations can perform independent testing and certification, giving buyers added assurance of the product quality.

What Are the QC and Certification Nuances for Different Markets?

When procuring TPS sandwich wall panels from international suppliers, B2B buyers must be aware of the specific QC and certification nuances that may vary by region. For example, while CE marking is essential for products sold in Europe, different regions, such as Africa and South America, may have their own regulatory requirements.

Buyers should familiarize themselves with local standards and ensure that their suppliers are compliant with these regulations. This knowledge is vital for avoiding potential legal issues and ensuring that the products are suitable for their intended applications.

In conclusion, understanding the manufacturing processes and quality assurance protocols for TPS sandwich wall panels equips B2B buyers with the insights necessary to make informed purchasing decisions. By focusing on quality and compliance, buyers can ensure they are selecting the best products for their projects, ultimately enhancing their operational efficiency and success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tps sandwich wall panel’

Introduction

This practical sourcing guide is designed for B2B buyers aiming to procure TPS sandwich wall panels. By following this step-by-step checklist, buyers can ensure they select high-quality products that meet their specific requirements while minimizing risks associated with procurement.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical specifications for the TPS sandwich wall panels. Consider factors such as thickness, insulation type, dimensions, and performance standards. This will not only help you communicate your needs to suppliers but also ensure that the panels meet the specific requirements of your project, whether it’s thermal insulation, fire resistance, or moisture resistance.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers of TPS sandwich wall panels. Look for companies with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe. Focus on suppliers that provide detailed product information, certifications, and customer testimonials, as these elements indicate reliability and quality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a comprehensive evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their production capabilities, quality management systems, and compliance with international standards, as this will give you confidence in their ability to meet your specifications.

Illustrative image related to tps sandwich wall panel

Step 4: Verify Certifications and Compliance

Ensure that the TPS sandwich panels comply with relevant industry standards and certifications. This includes fire resistance ratings, thermal conductivity values, and environmental certifications. Confirming these details protects your investment and ensures that the panels will perform effectively in your intended applications, such as clean rooms or cold storage facilities.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples from shortlisted suppliers. Testing these samples will allow you to assess their quality, insulation properties, and overall suitability for your project. Pay attention to factors such as weight, durability, and ease of installation, as these can significantly impact your project’s efficiency and cost-effectiveness.

Step 6: Negotiate Pricing and Terms

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget constraints and ensure that the terms align with your project’s timeline. Consider exploring options for bulk discounts or long-term partnerships, which can lead to more favorable pricing structures.

Step 7: Establish a Clear Communication Channel

Effective communication is key to a successful procurement process. Establish a clear line of communication with your chosen supplier to address any concerns, changes, or updates throughout the procurement journey. Regular check-ins and updates will help ensure that both parties are aligned and can promptly resolve any issues that may arise.

By following this checklist, B2B buyers can navigate the complexities of sourcing TPS sandwich wall panels with confidence, ensuring they make informed decisions that align with their project goals.

Comprehensive Cost and Pricing Analysis for tps sandwich wall panel Sourcing

What Are the Key Cost Components in Sourcing TPS Sandwich Wall Panels?

When sourcing TPS sandwich wall panels, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The core of TPS panels is thermosetting polystyrene, which contributes significantly to the overall cost. High-density polyurethane foam or mineral wool may also be used depending on the specific application, affecting the price. It’s essential to evaluate the quality of these materials, as higher-quality options can enhance durability and insulation properties.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. In regions with higher labor costs, such as parts of Europe, this can significantly impact the final price of the panels. Conversely, lower labor costs in some parts of Africa and South America may offer competitive pricing opportunities.

-

Manufacturing Overhead and Tooling: This includes costs associated with factory operations, maintenance, and the equipment used to produce the panels. Efficient manufacturing processes can lower overhead costs, impacting overall pricing.

-

Quality Control: Ensuring that TPS panels meet international standards requires investment in quality control measures. This may involve testing for thermal insulation, fire resistance, and moisture penetration, which can contribute to higher upfront costs but ultimately lead to better products.

-

Logistics: Transportation costs can vary significantly based on the shipping method (e.g., sea, land), distance, and Incoterms agreed upon. For international buyers, understanding the logistics involved in sourcing from different regions can lead to cost savings.

-

Margin: Suppliers will typically add a profit margin to cover their expenses and ensure business viability. This margin can fluctuate based on market demand and competition.

What Influences the Pricing of TPS Sandwich Wall Panels?

Several factors can influence the pricing of TPS sandwich wall panels:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk typically results in lower per-unit costs. Buyers should negotiate MOQs that align with their project needs to maximize cost efficiency.

-

Specifications and Customization: Customized panels, such as those with specific dimensions or features (e.g., fire resistance), will generally incur higher costs due to the additional manufacturing processes involved.

-

Material Quality and Certifications: Panels that meet higher quality standards or possess specific certifications (e.g., fire safety, energy efficiency) tend to be priced higher. Buyers should weigh the long-term benefits of these investments against initial costs.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge a premium for their products due to perceived quality and service reliability.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) can affect the total cost of ownership. Buyers should consider how shipping costs, insurance, and duties will influence the final price.

How Can Buyers Negotiate Better Prices for TPS Sandwich Wall Panels?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can employ several strategies to negotiate better prices:

-

Research and Benchmarking: Conduct market research to understand prevailing prices for TPS panels. Comparing quotes from multiple suppliers can provide leverage during negotiations.

-

Long-Term Relationships: Building strong relationships with suppliers can lead to favorable pricing terms. Suppliers may offer discounts or better terms to repeat customers.

-

Focus on Total Cost of Ownership: Rather than just the purchase price, consider the total cost of ownership, which includes installation, maintenance, and energy efficiency. Highlighting these factors can justify a higher initial investment for long-term savings.

-

Flexibility in Specifications: If buyers can be flexible with panel specifications or colors, they may find opportunities for cost reductions.

What Should Buyers Keep in Mind Regarding Pricing Nuances for International Purchases?

When purchasing TPS sandwich wall panels internationally, buyers should be aware of potential pricing nuances:

-

Currency Fluctuations: Exchange rates can impact the overall cost. It’s advisable to lock in prices when favorable rates are available.

-

Import Duties and Taxes: Different countries have varying import duties and taxes that can significantly affect the final cost. Understanding these obligations upfront is essential for accurate budgeting.

-

Lead Times and Availability: Longer lead times may affect project timelines and costs, particularly if expedited shipping is required. Ensure that the supplier can meet your project deadlines to avoid additional expenses.

Disclaimer: The prices and costs mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek detailed quotes and conduct thorough due diligence when sourcing TPS sandwich wall panels.

Alternatives Analysis: Comparing tps sandwich wall panel With Other Solutions

In the construction industry, selecting the right building material is crucial for achieving optimal performance, cost-effectiveness, and sustainability. The TPS sandwich wall panel is a popular choice due to its thermal insulation, moisture resistance, and lightweight properties. However, various alternatives exist that may suit specific project requirements or regional needs. This analysis compares the TPS sandwich wall panel with two viable alternatives: traditional concrete walls and insulated metal panels (IMPs).

Comparison Table

| Comparison Aspect | Tps Sandwich Wall Panel | Traditional Concrete Walls | Insulated Metal Panels (IMPs) |

|---|---|---|---|

| Performance | Excellent thermal insulation; moisture-resistant | High durability; good thermal mass | Good thermal insulation; lightweight; weatherproof |

| Cost | Moderate initial cost; potential for savings due to energy efficiency | High initial material and labor costs | Variable costs; generally lower than concrete but higher than TPS |

| Ease of Implementation | Quick installation; lightweight and easy to handle | Labor-intensive; requires significant curing time | Moderate ease; requires skilled labor for assembly |

| Maintenance | Low maintenance; resistant to mold and corrosion | Moderate; requires periodic sealing and repairs | Low maintenance; durable and resistant to weather |

| Best Use Case | Ideal for prefabricated structures, warehouses, and temporary facilities | Best for permanent structures and high-load applications | Suitable for industrial buildings, cold storage, and commercial applications |

Pros and Cons of Alternatives

Traditional Concrete Walls

Traditional concrete walls are renowned for their durability and structural integrity, making them a go-to choice for permanent buildings. They offer excellent thermal mass, which can help stabilize indoor temperatures. However, the initial costs can be high due to both material and labor expenses. Additionally, the installation process is time-consuming, as concrete requires curing. While concrete is low-maintenance once installed, it can be prone to cracking and requires periodic sealing to prevent water intrusion.

Insulated Metal Panels (IMPs)

Insulated metal panels combine durability with good thermal insulation, making them an appealing choice for various applications, including industrial and commercial buildings. Their lightweight nature allows for easier handling and faster installation compared to concrete. However, the cost of IMPs can vary widely based on the quality and specifications, potentially making them more expensive than TPS panels. While they are generally low-maintenance, their performance may be affected in extreme weather conditions, requiring careful selection based on local climate.

Making the Right Choice for Your Project

When choosing between the TPS sandwich wall panel and its alternatives, B2B buyers should consider several factors, including project type, budget, and long-term maintenance requirements. The TPS panel stands out for its energy efficiency and ease of installation, making it ideal for temporary or prefabricated structures. In contrast, traditional concrete walls offer unmatched durability for permanent constructions, while insulated metal panels provide a balance of performance and cost-efficiency for industrial applications.

Ultimately, the decision should align with the specific needs of the project and the environmental conditions of the location. Engaging with suppliers to discuss project requirements and obtaining samples can also aid in making an informed choice that meets both budget and performance expectations.

Essential Technical Properties and Trade Terminology for tps sandwich wall panel

What Are the Key Technical Properties of TPS Sandwich Wall Panels?

Understanding the essential technical properties of TPS sandwich wall panels is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications to consider:

-

Material Composition

– TPS stands for thermosetting polystyrene, known for its high efficiency in moisture retention, fire resistance, and energy-saving capabilities. The core material typically consists of polystyrene foam, which is encapsulated between two layers of steel sheets. This composition is vital as it directly impacts the panel’s performance in various environmental conditions, making it suitable for applications such as warehouses and cold storage. -

Thermal Insulation Properties

– The thermal conductivity of TPS sandwich panels ranges from 0.33 W/mK to lower values depending on thickness. This property is significant for energy conservation, as it ensures minimal heat transfer, leading to lower energy costs in heating or cooling buildings. Buyers should prioritize panels with lower thermal conductivity for better insulation. -

Density and Weight

– The density of the core material typically ranges from 35 to 50 kg/m³. A lower density often translates to a lighter panel, which can reduce transportation costs and ease installation. However, it’s essential to balance weight with strength, as higher density can contribute to better structural integrity. -

Fire Resistance Rating

– TPS panels generally achieve a fire resistance classification based on international standards such as FM 4880 and NFPA 259. A strong fire rating is crucial for safety compliance in construction, especially in regions with stringent building codes. Buyers should request fire test reports to ensure the panels meet local regulations. -

Water and Humidity Resistance

– The closed-cell structure of TPS contributes to its excellent moisture resistance, making it suitable for environments prone to humidity. Panels should ideally exhibit a maximum moisture absorption of 0.5% by mass. This characteristic is essential for preventing mold growth and maintaining indoor air quality. -

Durability and Lifecycle

– TPS panels are designed for longevity, often with a service life exceeding 30 years under proper conditions. Their resistance to deformation, corrosion, and aging ensures that they maintain performance over time, which is a key consideration for B2B buyers looking for long-term investments.

What Are Common Trade Terms in the TPS Sandwich Wall Panel Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of TPS panels, it indicates that the panels can be customized or branded by another company, which is beneficial for businesses looking to offer unique products. -

MOQ (Minimum Order Quantity)

– This term specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers, as it impacts inventory management and upfront costs. Suppliers might have different MOQs for TPS panels based on customization and order size. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing information for specific products or services. For TPS sandwich panels, it allows buyers to compare costs from different manufacturers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who is responsible for shipping costs and risks, essential for international transactions involving TPS panels. -

Lead Time

– This term refers to the time taken from placing an order to delivery. Understanding lead times for TPS sandwich panels is crucial for project planning and execution, especially in construction where delays can significantly impact timelines. -

Certification Standards

– Refers to the various safety and quality standards that the panels meet, such as ISO or ASTM certifications. Compliance with these standards is vital for ensuring the quality and safety of TPS panels, making it essential for buyers to verify certifications before purchase.

By grasping these technical properties and trade terms, international B2B buyers can navigate the TPS sandwich wall panel market more effectively, ensuring they make well-informed decisions that align with their operational needs.

Illustrative image related to tps sandwich wall panel

Navigating Market Dynamics and Sourcing Trends in the tps sandwich wall panel Sector

What Are the Key Market Drivers for TPS Sandwich Wall Panels?

The global market for TPS sandwich wall panels is experiencing robust growth, driven by increasing demand for energy-efficient and sustainable construction materials. Key trends include a shift towards modular construction, where prefabricated elements like TPS panels are favored for their quick installation and reduced labor costs. International buyers, particularly from Africa, South America, the Middle East, and Europe, are leveraging advancements in manufacturing technology that enhance the thermal insulation and moisture resistance properties of these panels. The ability of TPS panels to meet stringent fire safety and environmental standards has also made them attractive in various sectors, including industrial, commercial, and residential construction.

Emerging technologies such as Building Information Modeling (BIM) and digital procurement platforms are reshaping how businesses source TPS panels. These technologies facilitate better collaboration between suppliers and buyers, enabling more efficient project management and cost control. Additionally, international trade dynamics and regional trade agreements are influencing sourcing strategies, allowing buyers to access competitive pricing and diverse product offerings from manufacturers in different countries.

How Is Sustainability Influencing TPS Sandwich Panel Sourcing?

Sustainability is becoming a critical factor in the sourcing of TPS sandwich wall panels. The environmental impact of construction materials has prompted buyers to prioritize products that offer energy savings and reduced carbon footprints. TPS panels, made from thermosetting polystyrene, are designed to be recyclable and contribute to energy-efficient building designs, aligning with global sustainability goals.

Ethical sourcing practices are also gaining importance, with buyers increasingly seeking suppliers who adhere to responsible production methods and labor standards. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for assessing suppliers. By choosing TPS panels with these certifications, companies can demonstrate their commitment to sustainability and environmental responsibility, which is increasingly expected by clients and regulators alike.

What Is the Historical Context of TPS Sandwich Panels in Construction?

The development of TPS sandwich wall panels can be traced back to the mid-20th century when the construction industry began to embrace lightweight, insulated materials to meet growing demands for energy efficiency and rapid construction. Over the decades, advancements in material science have led to the refinement of TPS panels, enhancing their durability, insulation properties, and fire resistance.

Today, TPS sandwich panels are recognized for their versatility and effectiveness across various applications, from cold storage facilities to modern office buildings. Their evolution reflects a broader trend in the construction industry towards sustainable practices and innovative building solutions, making them a preferred choice for international B2B buyers looking to optimize their projects in an environmentally responsible manner.

Frequently Asked Questions (FAQs) for B2B Buyers of tps sandwich wall panel

-

1. How do I ensure the quality of TPS sandwich wall panels before purchasing?

To ensure quality, request detailed specifications and certifications from suppliers, including fire resistance, thermal insulation values, and compliance with international standards. It’s advisable to ask for samples to assess material properties firsthand. Conducting a factory audit or third-party inspection can also provide insights into the manufacturing processes and quality control measures employed by the supplier. Additionally, consider reviewing previous client testimonials and case studies to gauge their reliability and product performance. -

2. What are the key benefits of using TPS sandwich wall panels in construction?

TPS sandwich wall panels offer several advantages, including excellent thermal insulation, moisture resistance, and fireproof properties. They are lightweight yet structurally strong, making them easy to transport and install. Their closed-cell structure enhances durability and energy efficiency, which can lead to significant cost savings in heating and cooling. Furthermore, their recyclable nature and compliance with environmental standards make them a sustainable choice for modern construction projects. -

3. What customization options are available for TPS sandwich wall panels?

Customization options vary by manufacturer but often include thickness, color, and dimensions to meet specific project requirements. Some suppliers may offer different core materials, such as polyurethane or mineral wool, depending on the desired insulation properties. Discussing your project needs with potential suppliers will help you identify the available options. It’s also essential to confirm lead times for customized orders to avoid delays in your project timeline. -

4. What is the minimum order quantity (MOQ) for TPS sandwich wall panels?

Minimum order quantities can differ significantly among suppliers, typically ranging from a few hundred to several thousand square meters. Factors influencing MOQ include production capabilities, material availability, and shipping logistics. It’s advisable to discuss your project scope with potential suppliers to determine if they can accommodate your needs while meeting MOQ requirements. Some suppliers may offer flexibility for smaller projects, especially for repeat customers. -

5. What payment terms are commonly accepted for international purchases of TPS sandwich wall panels?

Most suppliers accept various payment methods, including T/T (telegraphic transfer), L/C (letter of credit), and PayPal, among others. Payment terms may vary based on the order size and supplier policies, typically requiring a deposit upfront with the balance due upon delivery or before shipment. Ensure to clarify payment terms, including any potential discounts for early payment or penalties for late payment, to maintain financial clarity throughout the transaction. -

6. How do I evaluate and vet potential suppliers for TPS sandwich wall panels?

Evaluating suppliers involves assessing their industry experience, production capabilities, and compliance with international standards. Request references and case studies to gauge their reputation and reliability. Consider using third-party platforms or trade associations for supplier ratings. Additionally, checking for certifications such as ISO or CE can indicate adherence to quality standards. Engaging in direct communication and asking pertinent questions about their processes can further clarify their suitability for your needs. -

7. What are the logistics considerations for importing TPS sandwich wall panels?

Logistics considerations include shipping methods, lead times, and customs clearance procedures. Sea freight is commonly used for bulk shipments, but air freight may be an option for urgent needs. Confirm that your supplier can handle logistics and provide necessary documentation for customs. It’s also important to factor in additional costs such as duties, taxes, and insurance. Collaborating with a reliable freight forwarder can streamline the process and ensure timely delivery. -

8. How do I ensure compliance with local building regulations when using TPS sandwich wall panels?

To ensure compliance with local building regulations, research the specific codes and standards applicable in your region. Engage with local authorities or a qualified consultant to understand requirements related to fire safety, thermal performance, and structural integrity. Request documentation from your supplier that demonstrates compliance with international standards and any relevant local certifications. Keeping open communication with local regulatory bodies during the planning and construction phases can also help mitigate potential issues.

Top 6 Tps Sandwich Wall Panel Manufacturers & Suppliers List

1. BrDeco Group – 50mm TPS Sandwich Panel

Domain: brdecogroup.com

Registered: 2017 (8 years)

Introduction: Product Name: 50mm TPS Sandwich Panel

Material: Thermosetting Polystyrene (TPS)

Color Options: 01, 03, 04, 05, 06

Thickness Options: 50mm, 75mm, 100mm

Width Options: 840mm, 1050mm

Steel Sheet Thickness: 0.326mm, 0.376mm, 0.426mm, 0.476mm

Density: 35-50 KG/m3

Features: High Compressive Strength, Excellent Thermal Insulation, Water-resistant, Dimensional Stability, Light Weight, Resistant to Deforma…

2. PK Proflist Moment LLC – TPS Clean Room Panel

Domain: panexus.us

Registered: 2022 (3 years)

Introduction: {‘product_name’: ‘TPS Clean Room Panel’, ‘price’: ‘$1.00’, ‘producer’: ‘PK Proflist Moment LLC’, ‘product_code’: ‘1004082’, ‘availability’: ‘In stock’, ‘filler_options’: [‘Mineral wool’, ‘PIR’, ‘Polyurethane (PU)’, ‘Styrofoam’], ‘humidity_max’: ‘0.5% by mass’, ‘acoustic_insulation’: ’30 db’, ‘thermal_conductivity’: ‘0.33 W/mk’, ‘core_material_density’: ’35-50 kg/m³’, ‘features’: [‘Ease of use’, ‘C…

3. Brdecomy – TPS Foam Insulation Board

Domain: brdecomy.com

Registered: 2020 (5 years)

Introduction: TPS Foam Insulation Board offers excellent thermal insulation performance and fire resistance up to B1 level. It is made from graphite polystyrene board (SEPS), widely used in building interior and exterior wall insulation systems.

4. PortaFab – Key Product Details

Domain: portafab.com

Registered: 1997 (28 years)

Introduction: Key Product Details:

– Type: Sandwich Panels

– Manufacturer: PortaFab

– Core Materials: Foam, wood, honeycomb

– Sizes: Up to 4 ft. x 20 ft.

– Thicknesses: Up to 6 inches

– R-values: Varies by core material

– Fire Rating: Class A non-combustible options available

– Acoustic Properties: Sound deadening panels available

Commonly Requested Sandwich Panels:

1. Infill Sandwich Panels

– Core: Polysty…

5. Synthesia – Sandwich Panels

Domain: blog.synthesia.com

Registered: 1996 (29 years)

Introduction: Sandwich panels are modular building materials designed for covering buildings and structures, consisting of two outer layers and a core that provides thermal and acoustic insulation. Key characteristics include excellent insulation due to low thermal conductivity, quick manufacturing and installation, and a variety of shapes and finishes. Common dimensions are widths of 1,000 mm or 1,150 mm, leng…

6. Wiskind – Sandwich Wall Panels

Domain: wiskindsteelstructure.com

Registered: 2017 (8 years)

Introduction: Super Quality Sandwich Wall Panel, OEM and ODM Factory, Various types including EPS, PU, Rock Wool, Glass Wool Sandwich Panels, Thickness options: 50-150mm, High-quality materials: waterproof rock wool, polyurethane insulation, polystyrene, and glass wool, Excellent thermal insulation, fireproof, noise reduction, environmental protection, Customizable modular clean room sandwich wall panel system,…

Strategic Sourcing Conclusion and Outlook for tps sandwich wall panel

In navigating the competitive landscape of building materials, the strategic sourcing of TPS sandwich wall panels offers significant advantages for international B2B buyers. These panels not only provide exceptional thermal insulation and moisture resistance but also align with modern demands for sustainability and energy efficiency. The lightweight and durable nature of TPS panels makes them suitable for diverse applications, from warehouses to clean rooms, ensuring that they meet the specific needs of various industries.

Investing in high-quality TPS sandwich panels from reputable suppliers can lead to long-term cost savings and enhanced project timelines. By prioritizing strategic sourcing, buyers can leverage competitive pricing and superior product quality, ultimately driving profitability and operational efficiency.

Illustrative image related to tps sandwich wall panel

As the global demand for innovative building solutions continues to rise, now is the opportune time for B2B buyers in regions such as Africa, South America, the Middle East, and Europe to explore partnerships with reliable manufacturers. By securing a consistent supply of TPS sandwich wall panels, businesses can position themselves at the forefront of the construction industry, ready to meet future challenges and opportunities. Take action today to ensure your projects are built on a foundation of quality and reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.