Two Prong Electrical Plug: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for two prong electrical plug

In an increasingly interconnected world, sourcing two-prong electrical plugs presents unique challenges for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. As the demand for reliable and safe electrical components grows, understanding the nuances of these plugs becomes essential for maintaining compliance and ensuring safety in various applications, from home appliances to industrial equipment. This comprehensive guide serves as a vital resource, covering a wide array of topics including types of two-prong plugs, their applications, and key factors to consider when vetting suppliers.

Navigating the global market for two-prong electrical plugs can be daunting, especially with the varying standards and regulations across regions. This guide aims to empower international B2B buyers by providing actionable insights into sourcing high-quality products that meet local compliance requirements. It delves into critical aspects such as cost analysis, supplier reliability, and the importance of product certifications. By equipping buyers with the knowledge to make informed purchasing decisions, this guide helps mitigate risks associated with substandard products and enhances operational efficiency.

In an era where electrical safety is paramount, understanding the specifications and applications of two-prong plugs not only aids in compliance but also fosters innovation and reliability in electrical solutions. Whether you are looking to upgrade existing equipment or source components for new projects, this guide is designed to be your go-to reference for successful procurement in the global market.

Understanding two prong electrical plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Non-Polarized Two-Prong Plug | Lacks a grounding pin; symmetrical design | Vintage appliances, lamps, radios | Pros: Versatile for older devices; Cons: Less safe due to lack of grounding. |

| Polarized Two-Prong Plug | One prong wider than the other; provides a specific orientation | Home appliances, electronics | Pros: Improved safety over non-polarized; Cons: Limited to specific socket types. |

| Vintage Style Two-Prong Plug | Antique design; often made of Bakelite or hard plastic | Restoration projects, decorative items | Pros: Aesthetic appeal for vintage restorations; Cons: May not meet modern safety standards. |

| Heavy-Duty Two-Prong Plug | Robust construction; suitable for higher current loads | Industrial machinery, tools | Pros: Durable and reliable; Cons: Bulkier design may not fit all applications. |

| Compact Two-Prong Plug | Smaller footprint; designed for space-constrained applications | Portable devices, compact electronics | Pros: Space-saving design; Cons: May not handle high wattage. |

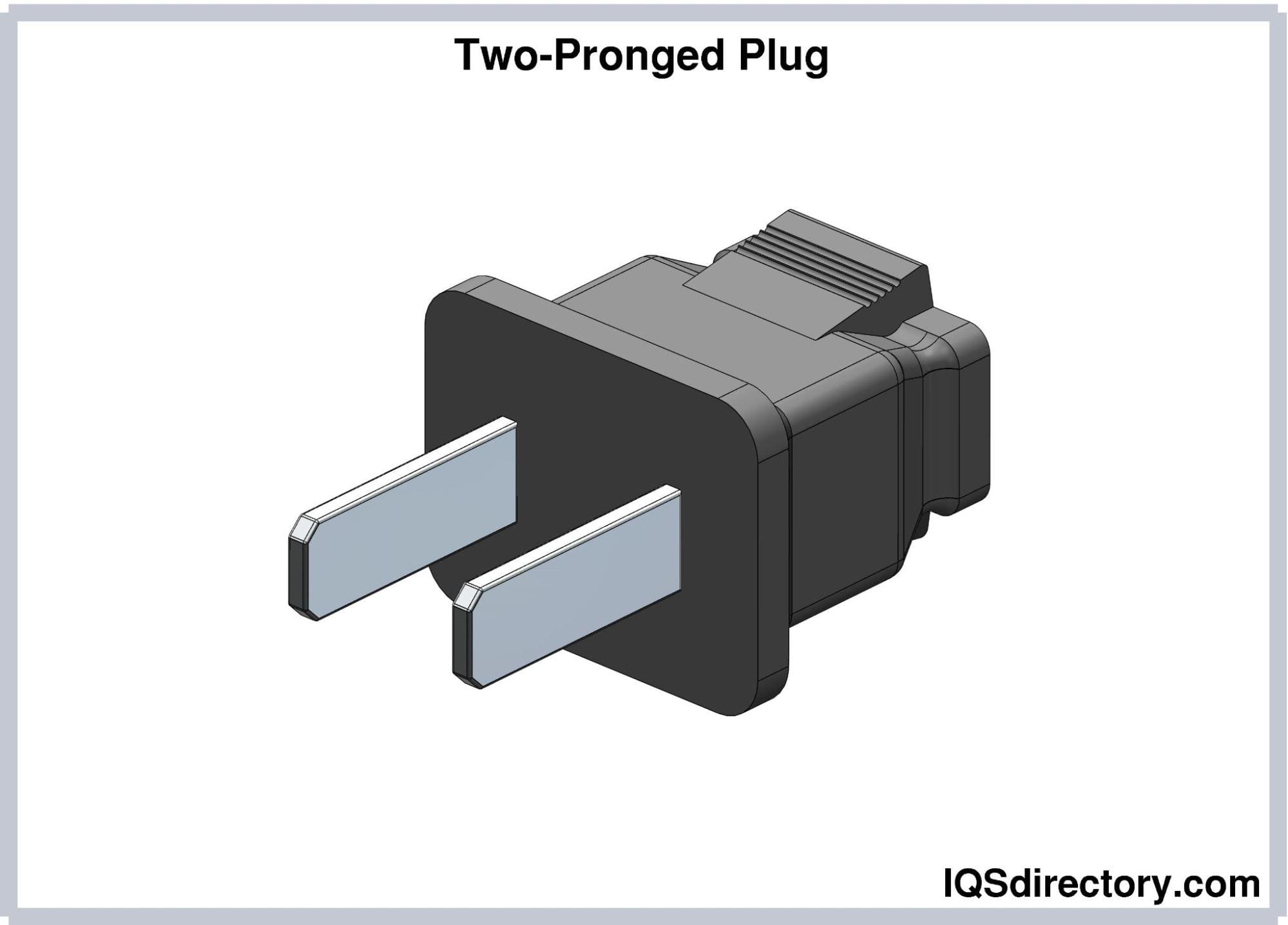

What Are the Key Characteristics of Non-Polarized Two-Prong Plugs?

Non-polarized two-prong plugs are characterized by their symmetrical design, allowing insertion in either direction. They are commonly used in older appliances, lamps, and radios. For B2B buyers, these plugs are suitable for retrofitting vintage equipment or less critical applications where safety is less of a concern. However, the lack of grounding makes them less safe than modern alternatives, which is a critical consideration for businesses focused on compliance and safety standards.

How Do Polarized Two-Prong Plugs Enhance Safety?

Polarized two-prong plugs have one prong wider than the other, ensuring correct orientation when plugged in. This design helps prevent electrical accidents by ensuring that the hot and neutral wires connect properly. They are widely used in home appliances and consumer electronics. For B2B buyers, the increased safety makes these plugs a preferred choice for products that require reliable electrical connections. However, their compatibility with existing infrastructure must be assessed to avoid installation issues.

Why Choose Vintage Style Two-Prong Plugs for Restoration Projects?

Vintage style two-prong plugs are often made from materials like Bakelite, providing an authentic look for restoration projects. These plugs are popular in the restoration of antique lamps and other vintage appliances. B2B buyers in sectors like home decor and vintage appliance repair find these plugs valuable for maintaining aesthetic integrity. However, they might not comply with modern safety regulations, making it essential for buyers to weigh aesthetic value against safety compliance.

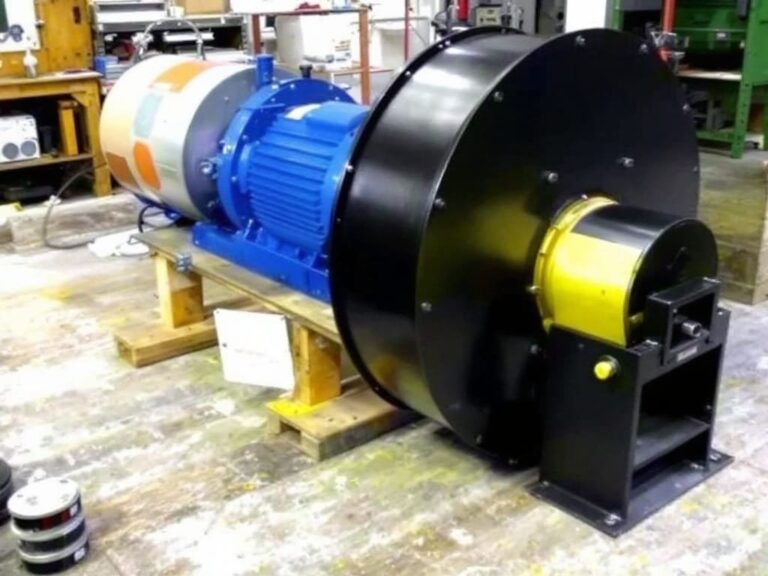

What Are the Benefits of Heavy-Duty Two-Prong Plugs in Industrial Settings?

Heavy-duty two-prong plugs are designed for high current applications, featuring robust construction to withstand demanding environments. They are ideal for industrial machinery and tools where reliability is paramount. B2B buyers in manufacturing and construction should consider these plugs for their durability and performance under load. However, their bulkier design may limit compatibility with standard outlets, necessitating careful planning in electrical setups.

How Do Compact Two-Prong Plugs Meet Space Constraints?

Compact two-prong plugs are designed for applications where space is limited, such as portable devices and compact electronics. Their smaller footprint makes them ideal for modern, sleek product designs. B2B buyers in consumer electronics should consider these plugs for their products aimed at the growing market for portable technology. However, buyers should ensure that these plugs can handle the required wattage, as their size may limit their electrical capacity.

Key Industrial Applications of two prong electrical plug

| Industry/Sector | Specific Application of two prong electrical plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Lighting & Decor | Replacement plugs for vintage lamps and fixtures | Enhances aesthetic appeal while maintaining functionality | Quality materials, compatibility with existing wiring, and compliance with local electrical standards |

| Small Appliances | Powering kitchen appliances like toasters and blenders | Cost-effective solution for refurbishing older appliances | Voltage ratings, durability, and ease of installation are critical factors |

| Consumer Electronics | Rewiring older audio equipment and radios | Preserves vintage value and ensures safe operation | Historical accuracy in design, insulation quality, and wire gauge compatibility |

| Retail Displays | Connecting decorative lighting in retail environments | Improves customer experience through enhanced ambiance | Aesthetic design options and safety certifications are essential |

| Industrial Equipment | Used in less critical machinery and tools | Provides a reliable power source for non-essential devices | Assessing load requirements and ensuring compliance with industrial safety standards |

How Is the Two-Prong Electrical Plug Used in Lighting & Decor?

In the lighting and decor sector, two-prong electrical plugs are commonly utilized for replacing plugs on vintage lamps and fixtures. These plugs allow businesses to restore antique lighting solutions, maintaining their aesthetic appeal while ensuring they operate safely. Buyers in this sector must consider the quality of materials used, compatibility with existing wiring systems, and adherence to local electrical standards to prevent hazards and ensure longevity.

What Role Does the Two-Prong Plug Play in Small Appliances?

Small appliances, such as toasters and blenders, often require two-prong plugs for power connections. These plugs serve as cost-effective solutions for refurbishing older appliances, enabling businesses to extend the life of their products. When sourcing these plugs, buyers should focus on voltage ratings, durability, and ease of installation to ensure a reliable and safe operation in various markets, including Africa and South America, where older appliances are prevalent.

How Are Two-Prong Plugs Relevant to Consumer Electronics?

In the realm of consumer electronics, two-prong plugs are essential for rewiring older audio equipment and radios, helping to preserve their vintage value while ensuring safe operation. This application is particularly important for businesses catering to audiophiles and collectors. Buyers should prioritize historical accuracy in design, insulation quality, and wire gauge compatibility to meet the specific needs of this niche market.

Why Are Two-Prong Plugs Used in Retail Displays?

Two-prong electrical plugs are frequently employed in connecting decorative lighting within retail environments. This application enhances the customer experience by creating an inviting ambiance that encourages purchases. Retailers looking to source these plugs should focus on aesthetic design options and ensure that the products meet safety certifications, especially in regions where electrical standards may vary.

What Is the Industrial Application of Two-Prong Plugs?

In industrial settings, two-prong plugs are often used in less critical machinery and tools. While these plugs provide a reliable power source for non-essential devices, it is crucial for businesses to assess load requirements and ensure compliance with industrial safety standards. Buyers in this sector should be vigilant about sourcing plugs that can withstand the rigors of industrial use, particularly in developing markets where infrastructure may be lacking.

3 Common User Pain Points for ‘two prong electrical plug’ & Their Solutions

Scenario 1: Navigating Safety Compliance in Electrical Installations

The Problem: B2B buyers, particularly in regions where two-prong electrical plugs are still prevalent, often face the challenge of ensuring compliance with local electrical safety regulations. Many older installations utilize two-prong plugs, which lack grounding capabilities, raising concerns about safety and liability. Buyers must grapple with the risks associated with using outdated electrical components, which can lead to electrical shocks or fires, potentially resulting in significant financial and reputational damage.

The Solution: To mitigate these risks, it’s crucial for buyers to perform a comprehensive audit of their electrical systems. Start by evaluating the existing infrastructure to identify where two-prong plugs are still in use. Engage with local electrical safety authorities to understand the specific compliance requirements in your region. Transitioning to three-prong outlets is often the most effective route. Consider sourcing high-quality three-prong plugs and hiring certified electricians to upgrade the existing two-prong systems. This proactive approach not only enhances safety but also aligns with best practices in electrical installations, ultimately protecting your investment and reputation.

Scenario 2: Managing Compatibility Issues with Equipment

The Problem: Businesses that rely on older machinery or appliances often encounter compatibility issues when trying to connect modern equipment to two-prong electrical plugs. For instance, manufacturers in industries like woodworking or textiles may have legacy machines designed for two-prong connections, while their newer equipment requires three-prong outlets. This disconnect can lead to operational delays and increased costs as companies scramble to find compatible solutions.

The Solution: A strategic approach involves assessing your equipment’s power requirements and determining the best path forward. For existing two-prong machines, consider investing in adapter solutions that allow for safe and compliant connections to three-prong outlets without compromising safety. Additionally, when sourcing new equipment, prioritize suppliers who offer compatibility with both two-prong and three-prong systems. Implementing a phased approach to upgrade machinery can also be beneficial—invest in modern equipment that meets current safety standards while gradually phasing out outdated machines.

Illustrative image related to two prong electrical plug

Scenario 3: Reducing Maintenance Costs for Electrical Systems

The Problem: Frequent maintenance issues often plague businesses still using two-prong electrical plugs. The lack of grounding can lead to equipment malfunctions, increased wear and tear, and higher repair costs. For instance, manufacturing facilities using outdated plugs may experience unexpected downtime due to electrical failures, significantly impacting productivity and profitability.

The Solution: To reduce maintenance costs, businesses should prioritize upgrading to three-prong plugs and outlets. This shift not only enhances safety but also decreases the likelihood of electrical failures and associated repair costs. When selecting new plugs, opt for durable, high-quality components that meet international safety standards. Additionally, implement a regular maintenance schedule for electrical systems, including inspections and testing of all equipment. By investing in preventive measures and upgrading to modern, compliant electrical solutions, businesses can achieve long-term savings and operational efficiency.

Strategic Material Selection Guide for two prong electrical plug

What Are the Key Materials for Two-Prong Electrical Plugs?

When selecting materials for two-prong electrical plugs, it’s essential to consider various factors that influence performance, safety, and compliance with international standards. Here, we analyze four common materials used in the construction of two-prong electrical plugs, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to two prong electrical plug

How Do Different Materials Affect the Performance of Two-Prong Electrical Plugs?

1. Thermoplastic (e.g., Nylon or Polycarbonate)

Key Properties:

Thermoplastics like nylon and polycarbonate offer excellent electrical insulation properties and can withstand temperatures up to 120°C (248°F). They are also resistant to impact and provide good mechanical strength.

Pros & Cons:

Thermoplastics are relatively inexpensive and easy to mold, which simplifies manufacturing. However, they may not be as durable as other materials under extreme conditions, such as high temperatures or exposure to certain chemicals.

Impact on Application:

These materials are suitable for general-purpose plugs used in household appliances and lighting fixtures, where high durability is not a primary concern.

Considerations for International Buyers:

Thermoplastics must comply with standards like UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) for safety. Buyers in regions like Africa and South America should ensure that the materials meet local regulations.

2. Bakelite

Key Properties:

Bakelite is a type of thermosetting plastic known for its high heat resistance (up to 150°C or 302°F) and excellent electrical insulating properties. It is also resistant to chemical corrosion.

Pros & Cons:

Bakelite is highly durable and provides a classic aesthetic, making it ideal for vintage-style applications. However, it can be more expensive than thermoplastics and may require more complex manufacturing processes.

Impact on Application:

Ideal for retro or antique electrical devices, Bakelite is commonly used in lamps and appliances where aesthetics are as important as functionality.

Considerations for International Buyers:

Bakelite products should adhere to ASTM standards for electrical safety. Buyers in Europe may have specific preferences for vintage aesthetics, making Bakelite a popular choice.

3. Rubber

Key Properties:

Rubber provides excellent flexibility and resilience, with a temperature range typically between -40°C to 90°C (-40°F to 194°F). It is also resistant to moisture and provides good insulation.

Pros & Cons:

Rubber plugs are durable and can withstand harsh environmental conditions, making them suitable for outdoor applications. However, they can be more costly to produce and may degrade over time when exposed to UV light.

Impact on Application:

Rubber is particularly useful for plugs in outdoor or industrial settings, where exposure to moisture and varying temperatures is common.

Illustrative image related to two prong electrical plug

Considerations for International Buyers:

Buyers should ensure that rubber materials comply with local electrical safety standards, especially in humid regions like Southeast Asia.

4. Metal (e.g., Brass or Copper)

Key Properties:

Metals like brass and copper offer excellent conductivity and mechanical strength. They can handle high current loads and have a high melting point, making them suitable for heavy-duty applications.

Pros & Cons:

Metal connectors are durable and provide reliable electrical connections. However, they are susceptible to corrosion and may require additional coatings to enhance longevity, which can increase costs.

Impact on Application:

Metal components are ideal for high-performance plugs used in industrial applications or heavy-duty appliances where electrical efficiency is critical.

Illustrative image related to two prong electrical plug

Considerations for International Buyers:

Metal plugs must comply with corrosion resistance standards, especially in coastal regions. Buyers should verify compliance with international standards such as ISO and IEC to ensure safety and reliability.

Summary of Material Selection for Two-Prong Electrical Plugs

| Material | Typical Use Case for two prong electrical plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic (Nylon/Polycarbonate) | General household appliances and lighting | Cost-effective and easy to mold | Less durable under extreme conditions | Low |

| Bakelite | Vintage-style lamps and appliances | High durability and aesthetic appeal | More expensive and complex to manufacture | High |

| Rubber | Outdoor and industrial applications | Excellent flexibility and moisture resistance | Can degrade under UV exposure | Medium |

| Metal (Brass/Copper) | Heavy-duty industrial plugs | Superior conductivity and strength | Susceptible to corrosion | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with performance requirements, safety standards, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for two prong electrical plug

What Are the Main Stages in the Manufacturing Process of Two Prong Electrical Plugs?

Manufacturing two-prong electrical plugs involves several critical stages that ensure both functionality and safety. Understanding these stages is essential for B2B buyers seeking reliable products.

1. Material Preparation

The first step in manufacturing involves sourcing high-quality raw materials. Common materials for two-prong plugs include thermoplastic for the outer casing and copper or brass for the internal connectors. Buyers should prioritize suppliers that adhere to international standards for material quality, as this impacts the durability and safety of the finished product.

Material preparation also includes rigorous testing to ensure that the materials meet specifications. This may involve checking for electrical conductivity, thermal resistance, and mechanical strength. Materials that do not meet the required standards can compromise product safety and performance.

2. Forming Processes

Once the materials are prepared, the next stage involves forming the components of the plug. This typically includes molding the outer casing and stamping or machining the internal components. Injection molding is a common technique used to create the thermoplastic shell, providing a durable and insulated exterior.

For the metal parts, processes like die-casting or extrusion may be used. These techniques ensure precise dimensions and enhance the electrical conductivity of the connectors. B2B buyers should inquire about the specific forming techniques used by their suppliers, as this can affect product quality and performance.

3. Assembly of Components

After forming, the various components are assembled. This stage involves attaching the metal connectors to the molded plastic casing. Quality control measures during assembly are crucial to ensure that components fit securely and function correctly.

Illustrative image related to two prong electrical plug

Automated assembly lines are often employed to enhance efficiency and consistency. However, manual assembly may still be utilized for intricate parts or specialized plugs. Buyers should confirm that the assembly process includes checks for proper alignment and secure connections to prevent electrical failures.

4. Finishing Touches

The final stage of manufacturing involves finishing processes that enhance the plug’s appearance and functionality. This may include applying surface treatments to improve resistance to corrosion or wear, as well as conducting electrical safety tests.

Finishing also encompasses packaging, which should protect the plugs during shipping and storage. Suppliers should provide clear labeling that complies with international regulations, ensuring that buyers can easily identify product specifications and safety information.

What Are the Key Quality Assurance Measures for Two Prong Electrical Plugs?

Quality assurance (QA) is critical in the manufacturing of electrical plugs, as it directly impacts safety and reliability. B2B buyers must understand the standards and checkpoints involved in the QA process.

Relevant International Standards

Manufacturers of two-prong electrical plugs must comply with various international standards, such as ISO 9001 for quality management systems. This certification demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, products may need to meet specific regional standards, such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

Key Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before they are used in production. Materials are assessed for compliance with specifications to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, various tests are conducted to monitor quality. This may include checking the dimensions of molded parts and ensuring that assembly processes are carried out correctly.

-

Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted. This includes electrical testing to verify that the plugs meet safety standards and functional requirements. Common tests may involve checking for insulation resistance, continuity, and mechanical strength.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies to ensure that suppliers maintain high standards.

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control is through on-site audits. These audits can reveal the actual manufacturing practices and adherence to quality standards. Buyers should prepare a checklist that covers all critical aspects, including material sourcing, manufacturing processes, and quality control measures.

Requesting Quality Assurance Documentation

Buyers should request documentation that demonstrates a supplier’s compliance with international standards. This includes ISO certifications, test reports, and quality control manuals. Suppliers should also provide details about their quality management system and any relevant third-party certifications.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct random inspections, testing, and audits to ensure that products meet specified standards before shipment. This is especially valuable for buyers in regions where local regulations may differ from international standards.

Illustrative image related to two prong electrical plug

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances in quality control that can affect their purchasing decisions. These include differing regional regulations, cultural perceptions of quality, and logistical challenges.

Understanding Regional Regulations

Different regions may have varying regulations regarding electrical products. For instance, European countries may have stricter requirements for safety and environmental impact compared to other regions. Buyers must ensure that their suppliers are familiar with these regulations and can provide products that meet local compliance standards.

Cultural Perceptions of Quality

Cultural differences can influence perceptions of quality and reliability. Buyers should take the time to communicate their quality expectations clearly and understand the supplier’s quality assurance processes. Building strong relationships can help bridge any gaps in understanding.

Addressing Logistical Challenges

Logistics can pose challenges in maintaining quality control, particularly when shipping products internationally. Buyers should discuss packaging and transportation methods with suppliers to ensure that products are protected during transit. Additionally, implementing a clear return policy for defective products can help mitigate risks associated with international shipping.

Conclusion

By comprehensively understanding the manufacturing processes and quality assurance measures for two-prong electrical plugs, B2B buyers can make informed decisions that ensure product safety and reliability. Engaging with suppliers who prioritize quality at every stage of production will lead to successful partnerships and satisfied customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘two prong electrical plug’

This guide serves as a comprehensive checklist for B2B buyers seeking to procure two-prong electrical plugs. It outlines essential steps that will help ensure you select the right products and suppliers while minimizing risks associated with quality and safety.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the two-prong electrical plugs you need is critical. Consider factors such as the voltage rating, amperage, and whether the plugs should be polarized or non-polarized. Knowing these specifications will help in identifying suitable suppliers who can meet your exact needs.

Illustrative image related to two prong electrical plug

- Voltage rating: Ensure the plugs can handle the electrical load for your applications.

- Polarization: Decide if you need polarized plugs for added safety in specific configurations.

Step 2: Research Compliance Standards

It’s essential to verify that the plugs adhere to relevant safety and quality standards specific to your region. Different countries have varying regulations regarding electrical components, and compliance is crucial for market acceptance.

- Look for certifications such as CE in Europe, UL in the USA, or SABS in South Africa.

- Request documentation from suppliers to confirm compliance with local and international standards.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct a thorough evaluation of potential suppliers. This includes checking their industry reputation, financial stability, and customer service history.

- Request company profiles and product catalogs.

- Seek references from other businesses in your industry to gauge their reliability and quality.

Step 4: Assess Product Quality and Materials

Quality is paramount when sourcing electrical components. Inquire about the materials used in the plugs, as inferior materials can lead to safety hazards and product failures.

- Ask for samples to conduct your own quality assessments.

- Investigate the supplier’s manufacturing processes and quality control measures.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to ensure competitive pricing. However, be cautious of prices that seem too low, as they may indicate compromised quality.

- Analyze the total cost of ownership, including shipping, taxes, and potential tariffs.

- Discuss payment terms to align with your cash flow needs and establish trust with the supplier.

Step 6: Understand Lead Times and Supply Chain Reliability

Assess the lead times associated with your orders and the supplier’s ability to fulfill them consistently. Delays can impact your business operations, so it’s vital to choose a supplier with a reliable supply chain.

- Confirm the average production and shipping times for your orders.

- Inquire about their contingency plans for handling supply chain disruptions.

Step 7: Establish a Communication Channel

Effective communication is key to a successful partnership. Establish clear lines of communication with your suppliers to facilitate ongoing discussions regarding orders, quality issues, and potential improvements.

- Set up regular check-ins or updates to stay informed on your orders.

- Ensure that both parties understand the terms of engagement, including escalation processes for resolving disputes.

By following this checklist, B2B buyers can confidently navigate the sourcing process for two-prong electrical plugs, ensuring they select the best products and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for two prong electrical plug Sourcing

What Are the Key Cost Components for Sourcing Two-Prong Electrical Plugs?

When sourcing two-prong electrical plugs, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly affects the overall cost. Common materials include high-quality plastics, metal for contacts, and insulation. Vintage-style plugs may utilize specialized materials that can elevate costs. Buyers should consider the long-term durability and safety standards associated with these materials.

-

Labor: Labor costs encompass the workforce involved in production, assembly, and quality assurance. Regions with lower labor costs may offer competitive pricing, but this could impact quality. In contrast, manufacturers in developed countries may have higher labor costs due to stricter regulations and higher wage standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help keep these costs down, making it crucial for buyers to assess the production capabilities of potential suppliers.

-

Tooling: Tooling costs pertain to the creation of molds and equipment necessary for production. Custom designs or specifications can significantly increase these costs, making it important for buyers to evaluate whether their needs justify the investment.

-

Quality Control: Implementing rigorous QC processes is vital for ensuring product safety and performance. This can add to the overall cost but is essential for maintaining compliance with international standards, especially for buyers in regions with strict electrical safety regulations.

-

Logistics: Transportation and shipping costs are critical components, particularly for international buyers. Factors such as distance, shipping method, and freight costs influence logistics expenses. Incoterms also play a crucial role in determining who bears these costs.

-

Margin: Suppliers typically add a profit margin to cover their expenses and provide a return on investment. Understanding the typical margins within the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Two-Prong Electrical Plugs?

Several factors can influence the pricing of two-prong electrical plugs, making it crucial for buyers to be aware of them.

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Suppliers may have MOQs that, if met, can significantly lower unit prices. Buyers should evaluate their needs to determine if bulk purchases are feasible.

-

Specifications and Customization: Custom specifications, such as color, design, and additional features, can raise costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials that meet specific safety certifications may lead to increased costs. However, investing in certified products can reduce the risk of safety issues and related liabilities.

-

Supplier Factors: The reputation and reliability of suppliers can also impact pricing. Established suppliers may charge a premium for their proven quality and reliability. In contrast, newer or lesser-known suppliers might offer lower prices but could present risks regarding quality and service.

-

Incoterms: The chosen Incoterms can influence the total cost by determining who is responsible for shipping, insurance, and tariffs. Buyers should select terms that align with their logistics strategy and cost expectations.

What Are Essential Buyer Tips for Sourcing Two-Prong Electrical Plugs?

To optimize the sourcing process, B2B buyers should consider the following tips:

-

Negotiate Terms: Effective negotiation can lead to better pricing and terms. Buyers should be prepared to discuss volume discounts, payment terms, and delivery schedules to maximize cost-efficiency.

-

Assess Total Cost of Ownership (TCO): Consider all costs associated with the product, including maintenance, potential failures, and shipping. This holistic view can help buyers make informed decisions beyond just the initial purchase price.

-

Understand Pricing Nuances for International Transactions: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local regulations. These factors can significantly impact the final cost.

-

Research Supplier Credentials: Prioritize suppliers with a solid track record of quality and reliability. Verifying certifications and seeking references can mitigate risks associated with sourcing.

-

Stay Informed About Market Trends: Keeping abreast of industry trends, such as technological advancements and changes in safety standards, can help buyers make proactive sourcing decisions.

By taking these factors into account, international B2B buyers can effectively navigate the complexities of sourcing two-prong electrical plugs, ensuring they achieve both quality and cost-efficiency.

Alternatives Analysis: Comparing two prong electrical plug With Other Solutions

Exploring Alternatives to the Two Prong Electrical Plug

When considering electrical connections for appliances and devices, the two prong electrical plug is a common choice, particularly in older systems. However, various alternatives exist that may offer enhanced performance, safety, and functionality. This analysis aims to compare the traditional two prong electrical plug with two viable alternatives: the three prong electrical plug and the USB Type-C connector.

Comparison Table

| Comparison Aspect | Two Prong Electrical Plug | Three Prong Electrical Plug | USB Type-C Connector |

|---|---|---|---|

| Performance | Basic functionality; ungrounded | Enhanced safety with grounding | Versatile, supports data transfer and power |

| Cost | Low-cost option | Slightly higher cost | Moderate cost |

| Ease of Implementation | Simple installation | Requires grounding | Requires compatible ports |

| Maintenance | Minimal maintenance | Low maintenance; check grounding | Low; compatible devices often self-regulate |

| Best Use Case | Vintage appliances, simple devices | Modern appliances requiring safety | Mobile devices, laptops, and fast-charging applications |

Detailed Breakdown of Alternatives

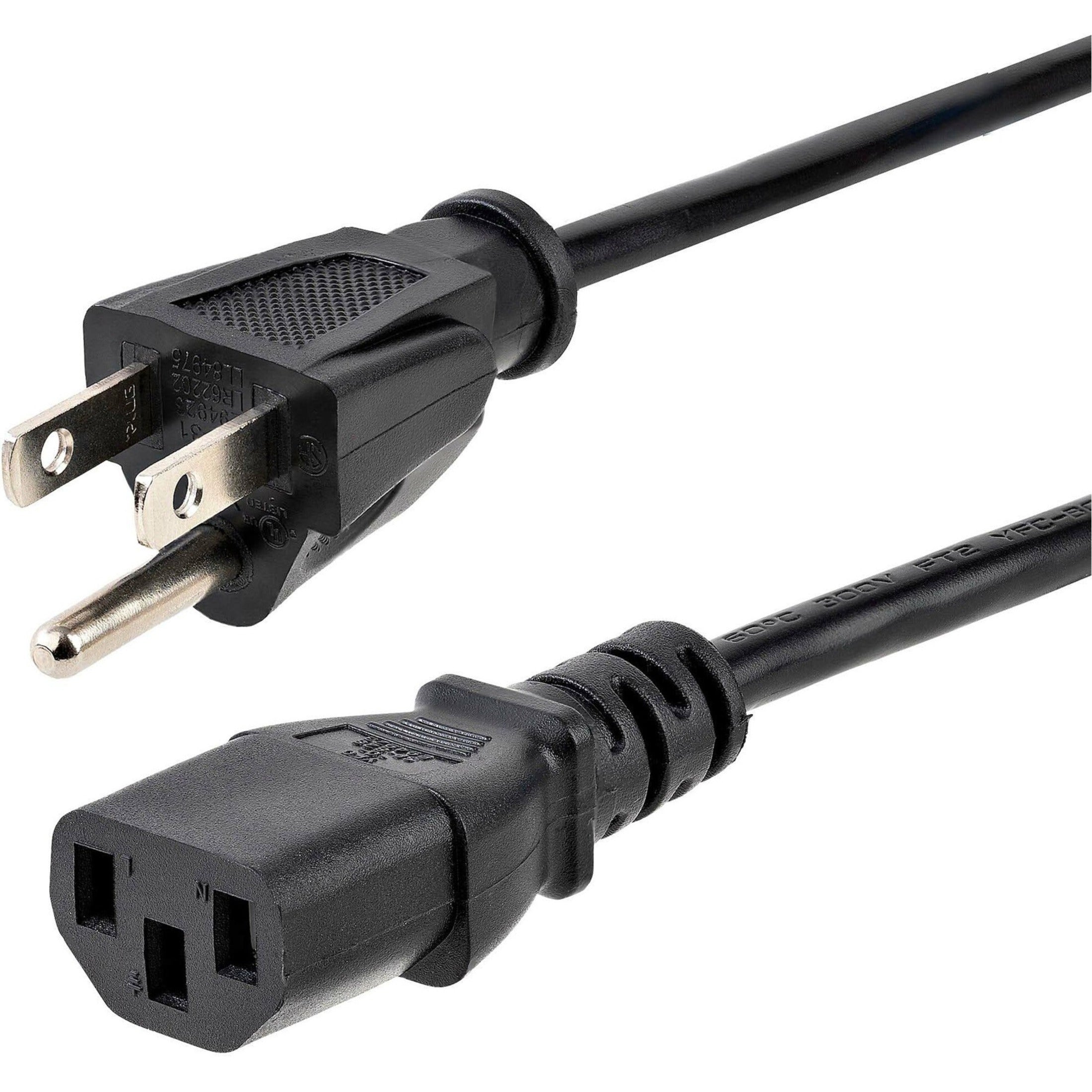

Three Prong Electrical Plug

The three prong electrical plug includes an additional grounding pin, significantly enhancing safety compared to its two prong counterpart. This grounding feature minimizes risks of electrical shocks and equipment damage, making it suitable for modern appliances that require higher safety standards. However, the installation process can be more complex, as it necessitates a compatible outlet with grounding. While the cost is slightly higher than that of a two prong plug, the investment is justified by the added safety and reliability, particularly in environments where electrical safety is paramount.

USB Type-C Connector

The USB Type-C connector represents a modern evolution in electrical connections, offering versatility beyond mere power transfer. It supports high-speed data transfer, video output, and rapid charging capabilities, making it ideal for contemporary mobile devices and laptops. The ease of use is a notable advantage, as the connector is reversible and compatible with numerous devices. However, it may not be suitable for all applications, especially traditional appliances that require standard AC plugs. While the cost is moderate, the additional functionalities can justify the investment for businesses focusing on technology-driven solutions.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate electrical connection solution hinges on your specific requirements and applications. For businesses dealing with vintage appliances or environments where simplicity is key, the two prong electrical plug remains a viable choice. Conversely, if safety and modern functionality are priorities, the three prong electrical plug is advisable, particularly for new installations. For tech-savvy applications requiring fast charging and data transfer, the USB Type-C connector is the optimal solution. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that best suit their operational needs.

Illustrative image related to two prong electrical plug

Essential Technical Properties and Trade Terminology for two prong electrical plug

What Are the Key Technical Properties of a Two Prong Electrical Plug?

Understanding the technical specifications of two prong electrical plugs is essential for B2B buyers looking to source reliable and compliant products. Here are several critical specifications that play a significant role in product selection.

1. Material Composition

Two prong plugs are typically made from durable materials such as thermoplastic or Bakelite. Thermoplastic is favored for its heat resistance and durability, while Bakelite offers a vintage aesthetic and electrical insulation properties. The choice of material affects not only the plug’s longevity but also its performance in various environmental conditions, which is crucial for international markets.

2. Ampacity Rating

The ampacity rating indicates the maximum current a plug can safely handle, typically measured in amperes (amps). Common ratings for two prong plugs range from 10A to 15A. Buyers must ensure that the plugs match the electrical requirements of the devices they will power, as exceeding this rating can lead to overheating and potential hazards.

3. Voltage Compatibility

Voltage compatibility is another essential property, usually specified in volts (V). Most two prong plugs are designed for 110-120V or 220-240V systems, depending on the regional electrical standards. Understanding voltage ratings is critical for international procurement, ensuring that plugs function safely within the local electrical infrastructure.

4. Polarity

Two prong plugs can be polarized or non-polarized. Polarized plugs have one prong wider than the other, ensuring correct electrical connection and enhancing safety by preventing incorrect insertion. Non-polarized plugs, while more flexible, lack this safety feature. Buyers should consider the safety implications of polarity in their applications.

5. Cord Compatibility

The compatibility of cords with plugs is typically indicated by wire gauge, such as 18/2 or 16/2. This specification tells buyers which cord types can be used with the plugs. Ensuring compatibility is vital to maintain electrical safety and performance, especially in custom applications.

6. Compliance and Certification

Many regions have specific safety standards and certifications for electrical components, such as UL (Underwriters Laboratories) or CE (Conformité Européenne). Compliance with these standards not only ensures product safety but also enhances marketability in regions with strict electrical regulations.

What Are Common Trade Terminologies Related to Two Prong Electrical Plugs?

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B marketplace. Here are several key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. In the context of two prong plugs, buyers may seek OEM partnerships to ensure that the plugs are manufactured to their specifications, providing consistency and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and ensure that they meet their supply chain needs without overcommitting capital.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products, such as two prong electrical plugs. This process helps buyers compare costs and evaluate potential suppliers based on price, quality, and delivery terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for international transactions, as they clarify who bears risk and cost at various stages of the shipping process.

5. CE Marking

CE marking indicates that a product complies with European health, safety, and environmental protection standards. For two prong plugs being sold in Europe, CE marking is crucial for legal compliance and market access.

6. RoHS Compliance (Restriction of Hazardous Substances)

RoHS compliance refers to the regulation that restricts the use of certain hazardous materials in electrical and electronic equipment. Buyers should ensure that their sourced two prong plugs meet RoHS standards, especially when targeting markets that prioritize environmental safety.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their procurement strategies and ensure compliance in international markets.

Navigating Market Dynamics and Sourcing Trends in the two prong electrical plug Sector

What are the Current Market Dynamics and Key Trends in the Two Prong Electrical Plug Sector?

The global market for two-prong electrical plugs is shaped by various factors, including technological advancements, evolving consumer preferences, and regulatory changes. Emerging economies in Africa and South America are witnessing a surge in demand for electrical components as infrastructure development accelerates. Countries like Nigeria and Vietnam are investing heavily in electrification, which presents a significant opportunity for international B2B buyers.

Key trends include the rise of non-polarized and polarized plugs, catering to both vintage aesthetics and modern safety standards. As consumers increasingly favor retro designs, suppliers are capitalizing on this trend by offering vintage-style plugs that maintain the classic look while enhancing functionality. Additionally, there’s a shift toward incorporating smart technology into electrical components, allowing for features like surge protection and energy monitoring.

Furthermore, the growing emphasis on sustainability is impacting sourcing practices. Buyers are becoming more discerning, opting for suppliers that prioritize eco-friendly materials and ethical manufacturing processes. This is particularly relevant in regions where regulatory frameworks are tightening around environmental standards, compelling manufacturers to innovate while remaining compliant. Overall, international B2B buyers must stay abreast of these market dynamics to make informed sourcing decisions.

How are Sustainability and Ethical Sourcing Influencing the Two Prong Electrical Plug Market?

Sustainability and ethical sourcing are increasingly at the forefront of the two-prong electrical plug market. As global awareness of environmental issues rises, buyers are prioritizing suppliers who demonstrate a commitment to reducing their ecological footprint. The production of electrical plugs can have significant environmental impacts, from the extraction of raw materials to energy consumption during manufacturing.

In response, manufacturers are exploring alternatives such as recycled plastics and sustainable materials to create more environmentally friendly products. Certifications like ISO 14001 and RoHS compliance are becoming essential for suppliers seeking to distinguish themselves in a competitive marketplace. These certifications not only signify adherence to environmental standards but also reassure buyers of the sustainability of their supply chains.

Furthermore, ethical sourcing practices are gaining traction, with buyers increasingly scrutinizing the labor conditions under which products are manufactured. Companies that demonstrate transparency in their supply chains and prioritize fair labor practices are more likely to attract business from conscientious buyers. In summary, incorporating sustainability and ethical sourcing into procurement strategies can yield long-term benefits for B2B buyers, enhancing brand reputation while aligning with global sustainability goals.

What is the Brief Evolution and History of Two Prong Electrical Plugs?

The two-prong electrical plug has a rich history that dates back to the early 20th century. Initially designed as a simple means to connect electrical devices to power sources, these plugs evolved alongside advancements in electrical engineering. The two-prong design, lacking a grounding wire, was widely adopted in homes built before the 1960s, reflecting the technological limitations and safety standards of the time.

Over the decades, as electrical safety became a priority, the introduction of three-prong plugs, which include a grounding wire, marked a significant evolution in design. Despite being considered outdated, two-prong plugs remain prevalent in many markets, especially in older infrastructure. In recent years, however, there has been a resurgence in interest due to the vintage aesthetic and practicality in certain applications, such as retrofitting antique appliances. This ongoing evolution highlights the need for international B2B buyers to understand the historical context and current relevance of two-prong electrical plugs in their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of two prong electrical plug

-

How do I ensure the quality of two prong electrical plugs from suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Verify their certifications, such as ISO or relevant safety standards, and request product samples for testing. Engaging third-party quality assurance services can also help assess the manufacturing process and material quality. Additionally, review customer feedback and ratings to gauge the reliability of the supplier. Regular audits and inspections during the production phase are crucial for maintaining consistent quality. -

What is the best type of two prong electrical plug for my market?

The best type of two prong electrical plug depends on your target market’s electrical standards and appliance compatibility. For regions with older infrastructure, non-polarized plugs may be suitable; however, for safety and modern applications, polarized plugs are preferable. Research local regulations and consumer preferences to make informed decisions. Consider factors like durability, ease of installation, and aesthetic design, especially if targeting vintage or retro markets. -

What are the minimum order quantities (MOQ) for two prong electrical plugs?

MOQs for two prong electrical plugs vary by supplier, often depending on manufacturing capacity and material costs. Typically, MOQs can range from 500 to several thousand units. When negotiating with suppliers, consider your projected sales volume and storage capabilities. Discuss flexibility in MOQs if you are testing new products or entering a new market. Some suppliers may offer lower MOQs for first-time orders to build a relationship. -

What payment terms should I negotiate with suppliers for two prong electrical plugs?

When negotiating payment terms, consider options such as a letter of credit, advance payment, or payment upon delivery. It’s common to negotiate a 30-50% upfront payment with the balance due upon shipment. Ensure that the terms are favorable for cash flow while providing security for both parties. Additionally, inquire about any discounts for early payments or bulk orders, which can enhance your profit margins. -

How do I handle logistics and shipping for two prong electrical plugs?

Effective logistics management is crucial for international trade. Choose reliable freight forwarders who understand the complexities of shipping electrical components. Consider factors such as shipping costs, lead times, and customs clearance procedures. Ensure that all products comply with local regulations to prevent delays. Tracking shipments and maintaining communication with suppliers during transit can help mitigate risks associated with lost or damaged goods. -

What certifications should I look for in two prong electrical plugs?

Look for certifications relevant to your target market, such as CE for Europe, UL for North America, or SABS for South Africa. These certifications indicate that the plugs meet safety and performance standards. Suppliers should provide documentation proving compliance with these certifications. Additionally, inquire about any specific regional requirements that may affect product acceptance in your market. -

Can I customize two prong electrical plugs for my brand?

Yes, many manufacturers offer customization options, including branding, color, and design modifications. Customization can help differentiate your products in a competitive market. Discuss your specific requirements with potential suppliers and request samples to evaluate quality. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly to align with your market launch timelines. -

What should I include in a supplier contract for two prong electrical plugs?

A comprehensive supplier contract should outline product specifications, pricing, payment terms, delivery schedules, and quality assurance measures. Include clauses for handling defects, returns, and liability issues. Clearly define the consequences of non-compliance with agreed terms. Establishing clear communication protocols and timelines for updates can help manage expectations and foster a positive supplier relationship.

Top 5 Two Prong Electrical Plug Manufacturers & Suppliers List

1. Snakehead Vintage – Vintage Style 2 Prong Electrical Plug

Domain: snakeheadvintage.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “Vintage Style 2 Prong Electrical Plug”, “Type”: “Non-polarized”, “Color Options”: [“Black (round, long neck)”, “Brown (flat wide)”, “White (flat wide)”], “Price”: “$3.29”, “SKU”: “plug-2prong-unpolarized”, “Discounts”: {“4-9”: “$3.15 each”, “10-19”: “$2.95 each”, “20 or above”: “$2.79 each”}, “Description”: “These historically accurate reproduction plugs add the perfect finishing…

2. Tubes and More – Vintage Style Two-Prong Plug

Domain: tubesandmore.com

Registered: 1997 (28 years)

Introduction: {“name”: “Plug – AC, Flat, Brown, vintage style two prong”, “price”: “$2.75”, “availability”: “In Stock”, “description”: “A new two-prong plug, acceptable as a retro or vintage substitute. The plug easily accepts our twisted 18 and 16 gauge wires (two-conductor only).”, “wire_opening_diameter”: “11.2 mm x 8.4 mm”, “wire_opening_dimensions”: “~\frac{7}{16}~ \” x ~\frac{5}{16}~ \””, “UL_rating”: “15…

3. HowStuffWorks – Electrical Plug Types

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Type A prong: ungrounded plug with two flat parallel prongs, invented in 1904 by Harvey Hubbell II. Type B plug: similar to Type A but includes a round or U-shaped pin for grounding. Both types have holes near the tips of the prongs. The holes allow for a firmer grip in the outlet, preventing the plug from being pulled out and improving contact. Some devices may be factory-sealed with a plastic ti…

4. Hubbell – 2 Prong Plug Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 2 prong plug products for sale on eBay include various types and brands such as Hubbell, Leviton, and Eaton. Key specifications include output voltage options ranging from 30 V to 600 V, maximum input current options from 2-60 A, and features like heavy-duty construction, polarized designs, and different plug styles (e.g., flat, right-angle). Products are available in new and used conditions, with…

5. Facebook – Ground Fault Circuit Interrupting Receptacle

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Ground Fault Circuit Interrupting Receptacle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for two prong electrical plug

In summary, strategic sourcing for two-prong electrical plugs is essential for international B2B buyers looking to optimize their procurement processes. Understanding the unique specifications, safety considerations, and market demands for these plugs can significantly enhance product offerings and customer satisfaction. The insights gained from various suppliers highlight the importance of quality, compatibility, and compliance with international standards, especially in regions like Africa, South America, the Middle East, and Europe.

As electrical systems evolve, the shift from outdated two-prong to more modern solutions is inevitable. Buyers must remain proactive in sourcing high-quality, reliable plugs that meet both current and future electrical safety requirements. Engaging with trusted manufacturers and suppliers can ensure access to superior products that reflect both aesthetic and functional value, catering to diverse markets.

Illustrative image related to two prong electrical plug

Looking ahead, the demand for two-prong electrical plugs will continue to grow, driven by refurbishment projects and the need for reliable electrical solutions. We encourage international buyers to leverage strategic sourcing to strengthen their supply chains and capitalize on emerging opportunities. Connect with reputable suppliers today to ensure your inventory meets the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.