The Definitive Guide to Agri Ditcher Clutch Plates For Sale: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for agri ditcher clutch plates for sale

In the competitive landscape of agricultural machinery, sourcing high-quality agri ditcher clutch plates for sale presents a significant challenge for international B2B buyers. With the increasing demand for efficient agricultural practices, understanding the nuances of clutch plate specifications, compatibility, and performance is crucial. This guide serves as an essential resource, meticulously designed to empower buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—by providing a comprehensive overview of clutch plate options available in the global market.

Within this guide, you will explore various types of agri ditcher clutch plates, their specific applications, and the advantages they offer in enhancing agricultural efficiency. We delve into the intricacies of supplier vetting, ensuring you can identify reputable manufacturers and distributors capable of meeting your needs. Additionally, we provide insights into cost considerations, enabling you to make informed purchasing decisions that align with your budget and operational requirements.

By equipping yourself with this knowledge, you can navigate the complexities of the agri ditcher clutch plate market with confidence. Our aim is to facilitate strategic sourcing decisions that not only enhance your agricultural operations but also foster long-term relationships with reliable suppliers. With this guide, you are well-positioned to optimize your procurement process and drive value in your agricultural endeavors.

Understanding agri ditcher clutch plates for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slip Clutch Plates | Designed to slip under excessive load to protect machinery | Agricultural machinery, balers | Pros: Reduces wear, increases durability. Cons: May require frequent maintenance. |

| Friction Clutch Plates | Utilizes friction to engage and disengage power transfer | Tractors, tillers, and other farm equipment | Pros: High torque capacity, reliable performance. Cons: Can overheat under prolonged use. |

| Heavy-Duty Clutch Plates | Engineered for high-torque applications and heavy loads | Large tractors, industrial equipment | Pros: Exceptional durability, suitable for extreme conditions. Cons: Higher cost, may be overkill for smaller operations. |

| PTO Clutch Plates | Designed for Power Take-Off systems in agricultural equipment | Harvesters, mowers, and pumps | Pros: Efficient power transfer, versatile applications. Cons: Specific compatibility requirements. |

| Multi-Plate Clutch Assemblies | Consists of multiple plates for enhanced performance | High-performance tractors and machinery | Pros: Increased torque handling, smoother operation. Cons: More complex installation and higher maintenance. |

What Are Slip Clutch Plates and Their Applications?

Slip clutch plates are vital components in agricultural machinery, specifically designed to prevent damage during excessive load conditions. They allow for controlled slippage, thereby protecting the machinery from potential overloads. These plates are commonly used in balers and other equipment where sudden changes in load can occur. When considering slip clutch plates, buyers should evaluate their machinery’s load requirements and the frequency of maintenance needed to ensure optimal performance.

Understanding Friction Clutch Plates for Agricultural Use

Friction clutch plates are essential for engaging and disengaging power in farm equipment, such as tractors and tillers. These plates rely on friction to transfer torque effectively, making them suitable for a wide range of applications. Buyers should consider the torque capacity and heat dissipation characteristics of friction clutch plates, especially for high-demand tasks. Additionally, the operational environment may influence the choice of materials used in these plates to ensure longevity and reliability.

Why Choose Heavy-Duty Clutch Plates?

Heavy-duty clutch plates are engineered to withstand extreme conditions and high-torque applications, making them ideal for large tractors and industrial equipment. These plates provide exceptional durability and can handle the rigors of heavy agricultural work. While they come at a higher price point, their longevity and reduced need for replacements can make them a cost-effective choice for businesses operating in challenging environments. Buyers should assess the specific load requirements of their machinery to determine the necessity of investing in heavy-duty options.

How Do PTO Clutch Plates Function in Agricultural Machinery?

Power Take-Off (PTO) clutch plates are designed for use in systems that transfer power from a tractor to various implements, such as mowers and pumps. Their efficiency in power transfer makes them crucial for agricultural operations. When purchasing PTO clutch plates, compatibility with existing machinery is paramount. Buyers should ensure that the specifications match the equipment to avoid operational issues and ensure optimal performance.

What Are the Benefits of Multi-Plate Clutch Assemblies?

Multi-plate clutch assemblies consist of several plates working together to enhance performance and torque handling capabilities. They are particularly useful in high-performance tractors and machinery where smooth operation and power efficiency are critical. While these assemblies can be more complex to install and maintain, their benefits in terms of performance and durability often justify the investment. Buyers should carefully evaluate their machinery’s requirements to determine if a multi-plate setup is suitable for their operations.

Key Industrial Applications of agri ditcher clutch plates for sale

| Industry/Sector | Specific Application of agri ditcher clutch plates for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Soil preparation and land leveling | Enhances efficiency in land preparation tasks | Durability and compatibility with existing machinery |

| Construction | Ditch excavation for drainage systems | Reduces downtime and increases project efficiency | Availability of spare parts and service support |

| Landscaping and Gardening | Creating irrigation ditches and landscaping features | Ensures precise and effective land shaping | Adaptability to different soil types and environmental conditions |

| Oil and Gas | Pipeline trenching and utility installations | Improves operational efficiency in trenching | Compliance with international standards and certifications |

| Mining | Ditching for water management and site preparation | Enhances productivity and site accessibility | Reliability under heavy loads and harsh conditions |

How are agri ditcher clutch plates used in agriculture?

In agriculture, agri ditcher clutch plates are vital for soil preparation and land leveling tasks. They are integrated into ditching equipment that creates ditches for irrigation, drainage, and other agricultural needs. By enabling precise control over the equipment’s operation, these clutch plates help farmers optimize their land use and improve crop yields. Buyers in regions like Africa and South America should prioritize sourcing plates that are durable and compatible with their existing machinery to ensure seamless integration and long-term performance.

What is the role of agri ditcher clutch plates in construction?

In the construction sector, agri ditcher clutch plates are employed for ditch excavation to facilitate effective drainage systems. Their use reduces downtime and enhances project efficiency, enabling construction companies to meet tight deadlines. For international buyers, particularly in the Middle East and Europe, it is essential to consider the availability of spare parts and service support when sourcing these plates, ensuring that any maintenance or repair needs can be promptly addressed.

How do landscaping businesses benefit from agri ditcher clutch plates?

Landscaping and gardening professionals utilize agri ditcher clutch plates to create irrigation ditches and design landscaping features. These plates allow for precise control, ensuring that the land is shaped effectively for aesthetic and functional purposes. Buyers should look for clutch plates that can adapt to various soil types and environmental conditions, particularly in diverse climates across Africa and Europe, to maintain operational efficiency and achieve desired landscaping results.

Why are agri ditcher clutch plates critical in the oil and gas industry?

In the oil and gas sector, agri ditcher clutch plates are essential for pipeline trenching and utility installations. They enhance operational efficiency by allowing for faster and more accurate trenching, which is crucial for timely project completion. International buyers, especially those in regions with stringent regulations, should ensure that the clutch plates comply with international standards and certifications to mitigate operational risks and ensure safety.

What advantages do agri ditcher clutch plates offer in mining operations?

Mining operations benefit from agri ditcher clutch plates during ditching for water management and site preparation. These plates improve productivity by facilitating easier access to various site areas and managing water flow effectively. Buyers should focus on sourcing clutch plates that demonstrate reliability under heavy loads and harsh conditions, as these factors are critical for sustaining performance in challenging mining environments.

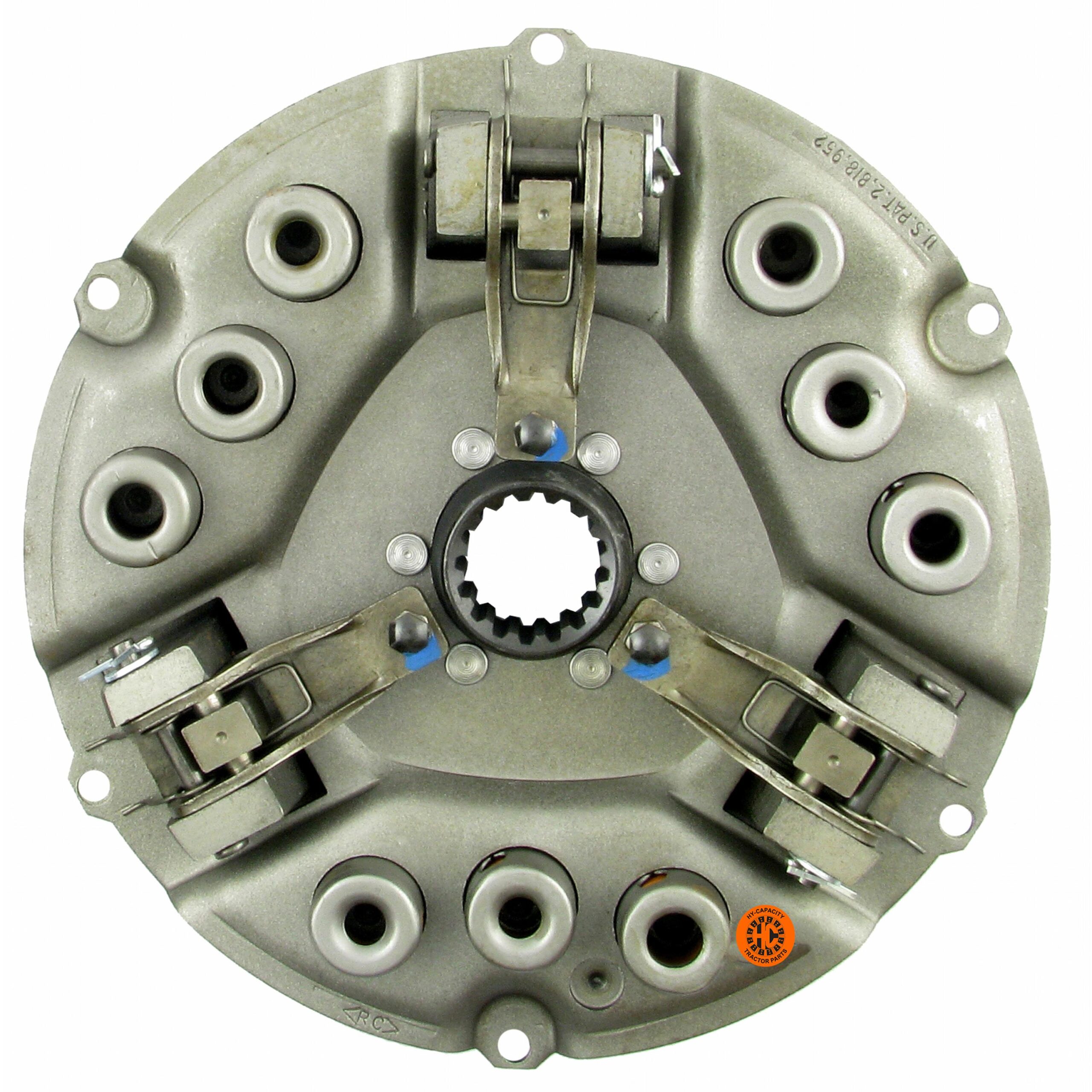

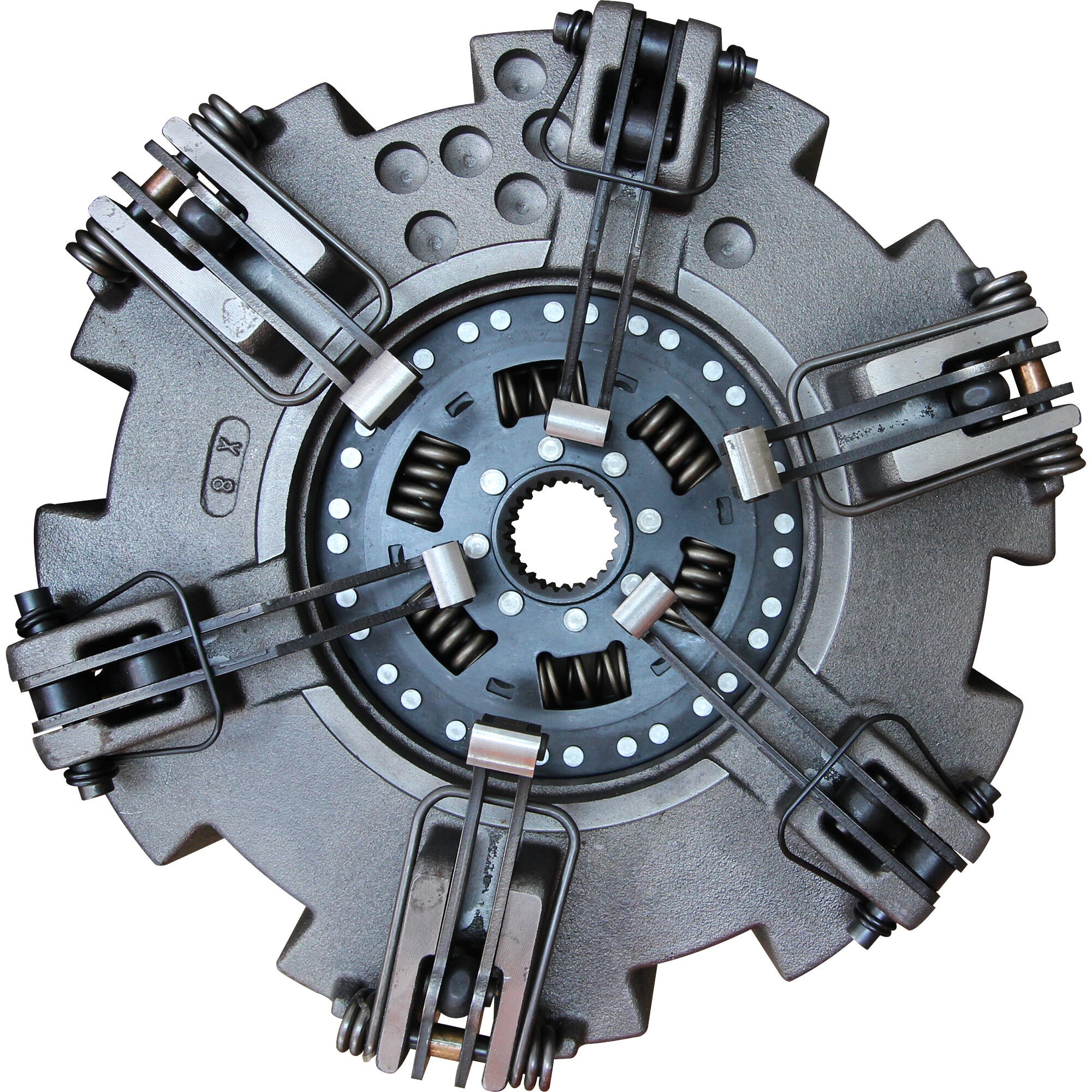

Illustrative image related to agri ditcher clutch plates for sale

3 Common User Pain Points for ‘agri ditcher clutch plates for sale’ & Their Solutions

Scenario 1: Inconsistent Performance from Clutch Plates

The Problem: A frequent challenge faced by B2B buyers of agri ditcher clutch plates is the inconsistency in performance. Many buyers report that after purchasing clutch plates, they encounter issues like slipping under load or not engaging properly, which can lead to equipment downtime and increased operational costs. This inconsistency often stems from poor-quality materials or improper specifications that do not match the agricultural machinery in use. For buyers in regions like Africa or South America, where access to reliable suppliers can be limited, this issue can become particularly detrimental to their operations.

The Solution: To ensure consistent performance, buyers should prioritize sourcing clutch plates from reputable manufacturers known for high-quality products. It’s crucial to verify that the clutch plates are made from durable materials that can withstand the specific loads and operational conditions of their equipment. Buyers should meticulously review product specifications, such as torque ratings and compatibility with their machinery. Additionally, engaging with suppliers who offer guarantees or warranties can provide an extra layer of security. For instance, working with suppliers that have a proven track record in the agricultural sector can lead to better outcomes. Regular maintenance and checking for wear can also preemptively address performance issues, ensuring that clutch plates function optimally throughout their lifecycle.

Scenario 2: Difficulty in Sourcing Compatible Clutch Plates

The Problem: Another common pain point for B2B buyers is the difficulty in sourcing clutch plates that are compatible with their specific agricultural machinery. Many buyers find themselves dealing with outdated or less common models that require specialized parts, leading to frustration and delays in operations. This is particularly true for businesses in remote areas, where the logistics of obtaining specific parts can be cumbersome and time-consuming.

The Solution: To navigate this challenge, buyers should conduct thorough research on the exact specifications required for their machinery, including OEM part numbers. Utilizing online resources, forums, and manufacturer databases can help identify compatible clutch plate models. Establishing relationships with multiple suppliers can also enhance sourcing options, as they may offer alternatives or substitutes that fit the machinery. Buyers should also consider reaching out to local distributors or manufacturers who specialize in agricultural parts, as they might have insights into sourcing hard-to-find components. Implementing a proactive inventory management system can further alleviate sourcing issues by keeping track of which parts are needed and when they should be ordered.

Scenario 3: High Costs of Replacement Parts

The Problem: High costs associated with replacement clutch plates can significantly impact a buyer’s bottom line, especially for agricultural businesses operating on tight margins. Many international buyers, particularly from developing regions, struggle with inflated prices due to import duties, shipping costs, and limited local availability. This can lead to hesitance in replacing worn-out parts, ultimately affecting machinery performance and productivity.

The Solution: To mitigate high replacement costs, buyers should explore various procurement strategies. Bulk purchasing can often lead to discounts, so collaborating with other local businesses to place larger orders can be beneficial. Additionally, investigating local manufacturing options can reduce dependency on imports and associated costs. Some manufacturers may offer refurbished or remanufactured clutch plates at a lower price point without compromising quality. Buyers should also look for suppliers who provide comprehensive support, including installation guidance and maintenance tips, as this can prolong the life of the clutch plates and reduce the frequency of replacements. Investing in quality over quantity can lead to long-term savings, as higher-quality parts tend to have longer lifespans and better performance, ultimately lowering overall costs.

Strategic Material Selection Guide for agri ditcher clutch plates for sale

What Are the Key Materials for Agri Ditcher Clutch Plates?

When selecting materials for agri ditcher clutch plates, it is essential to consider the properties and performance characteristics of various materials. The choice of material can significantly impact the durability, cost-effectiveness, and overall functionality of the clutch plates in diverse agricultural applications. Below are analyses of four common materials used in the manufacturing of agri ditcher clutch plates.

How Does Steel Perform in Agri Ditcher Clutch Plates?

Key Properties: Steel is renowned for its high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures, which is critical in agricultural machinery that often operates under strenuous conditions.

Pros & Cons: The primary advantage of steel is its exceptional strength and resistance to wear, which translates to a longer lifespan for clutch plates. However, steel is prone to corrosion if not adequately treated, and its manufacturing process can be complex, leading to higher production costs.

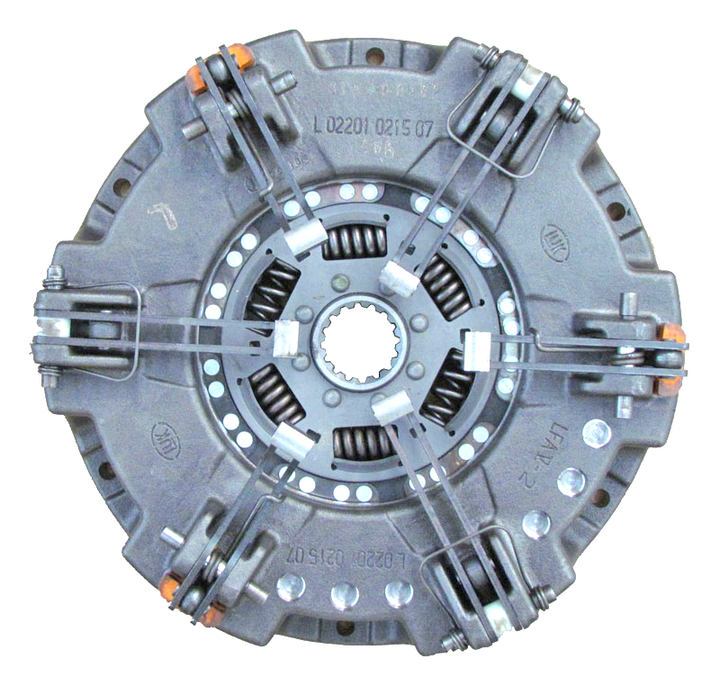

Illustrative image related to agri ditcher clutch plates for sale

Impact on Application: Steel clutch plates are highly compatible with various agricultural equipment, providing reliable performance in harsh environments. However, they may require additional protective coatings to enhance corrosion resistance, especially in humid or saline conditions.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that the steel used complies with international standards like ASTM or ISO to guarantee quality. In Europe, adherence to DIN standards is crucial for market acceptance.

What Role Does Composite Material Play in Agri Ditcher Clutch Plates?

Key Properties: Composite materials, often a blend of resin and reinforcing fibers, offer excellent corrosion resistance and lightweight characteristics. They can operate effectively at moderate temperatures and pressures.

Pros & Cons: The key advantage of composites is their resistance to environmental factors, which reduces maintenance needs. However, they may not withstand extreme mechanical loads as well as steel, making them less suitable for heavy-duty applications.

Illustrative image related to agri ditcher clutch plates for sale

Impact on Application: Composites are particularly effective in applications where weight reduction is critical, such as in portable agricultural equipment. Their compatibility with various media is generally good, but they may not perform well under high-stress conditions.

Considerations for International Buyers: In regions like the Middle East, where temperatures can soar, buyers should verify that composite materials are rated for high-temperature applications. Compliance with local and international standards is also essential to ensure product reliability.

How Do Aluminum Alloys Compare for Agri Ditcher Clutch Plates?

Key Properties: Aluminum alloys are lightweight and exhibit good corrosion resistance, making them an attractive option for agricultural machinery. They can handle moderate temperature and pressure levels effectively.

Pros & Cons: The primary advantage of aluminum alloys is their reduced weight, which can enhance the efficiency of agricultural equipment. However, they are generally less durable than steel and may be more expensive due to the alloying elements used.

Impact on Application: Aluminum clutch plates are suitable for applications where weight savings are essential, but they may not be ideal for high-torque situations. Their compatibility with various media is generally favorable, but care should be taken in high-stress environments.

Illustrative image related to agri ditcher clutch plates for sale

Considerations for International Buyers: Buyers in Europe and Africa should ensure that aluminum alloys meet specific standards, such as EN or ASTM, to guarantee performance. Additionally, understanding local market preferences for materials can aid in procurement decisions.

What Are the Benefits of Using Cast Iron for Agri Ditcher Clutch Plates?

Key Properties: Cast iron is characterized by its excellent wear resistance and ability to absorb vibrations, making it suitable for agricultural applications. It can handle high temperatures and pressures effectively.

Pros & Cons: The main advantage of cast iron is its durability and low cost, making it a popular choice for many agricultural applications. However, it is heavier than other materials, which may impact equipment efficiency.

Impact on Application: Cast iron clutch plates are particularly effective in applications requiring high durability and shock absorption. However, their weight may limit their use in lighter machinery.

Considerations for International Buyers: Buyers should verify that cast iron products adhere to relevant standards such as ASTM or JIS to ensure quality and performance. Additionally, understanding local preferences for material types can help in making informed purchasing decisions.

Summary Table of Material Selection for Agri Ditcher Clutch Plates

| Material | Typical Use Case for agri ditcher clutch plates for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty agricultural machinery | Exceptional strength and durability | Prone to corrosion | Medium |

| Composite | Lightweight portable agricultural equipment | Excellent corrosion resistance | Less suitable for high loads | Medium |

| Aluminum Alloy | Applications requiring weight reduction | Reduced weight | Less durable than steel | High |

| Cast Iron | High-durability applications | Low cost and good wear resistance | Heavier, which may affect efficiency | Low |

This strategic material selection guide provides actionable insights for international B2B buyers in the agricultural sector, helping them make informed decisions based on material properties, performance, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for agri ditcher clutch plates for sale

What Are the Key Stages in the Manufacturing Process of Agri Ditcher Clutch Plates?

The manufacturing of agri ditcher clutch plates involves several critical stages, each contributing to the final product’s durability and performance.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing clutch plates is selecting the right materials, typically high-carbon steel or specialized alloys. These materials are chosen for their strength and resistance to wear. Once sourced, raw materials undergo processes such as cutting, shearing, and surface cleaning to ensure they meet the required specifications. This stage is crucial as the quality of raw materials directly affects the performance and longevity of the clutch plates.

What Forming Techniques Are Used in Clutch Plate Production?

After material preparation, the next stage is forming. This process involves various techniques, including stamping, forging, and machining. Stamping is commonly used for producing flat plates, while forging enhances strength through deformation under high pressure. CNC (Computer Numerical Control) machining is often employed to achieve precise dimensions and tolerances. The choice of forming technique is influenced by the design specifications and intended application of the clutch plates.

How Are Clutch Plates Assembled?

Assembly is a crucial step that involves the integration of different components, such as friction discs, springs, and outer covers. Depending on the design, clutch plates may be assembled through welding, riveting, or bolting. Each method has its advantages, with welding providing a seamless finish and bolting allowing for easier disassembly for maintenance. The assembly process should ensure that all components fit together perfectly to withstand the forces encountered during operation.

What Finishing Processes Enhance the Performance of Clutch Plates?

Finishing processes, including heat treatment, surface coating, and polishing, significantly enhance the performance and durability of clutch plates. Heat treatment can improve hardness and wear resistance, while surface coatings, such as zinc plating or powder coating, protect against corrosion. Polishing may also be applied to reduce friction and improve the overall aesthetic of the plates. These finishing touches are essential for ensuring that the clutch plates perform well under harsh agricultural conditions.

How is Quality Assurance Implemented in the Manufacturing of Agri Ditcher Clutch Plates?

Quality assurance (QA) is paramount in the manufacturing of clutch plates to ensure they meet international standards and customer expectations.

Which International Standards Should Buyers Be Aware of?

Manufacturers typically adhere to international standards like ISO 9001, which outlines criteria for a quality management system. Compliance with these standards ensures a systematic approach to managing quality, enhancing customer satisfaction, and continual improvement. Additionally, certifications such as CE (European Conformity) and API (American Petroleum Institute) may be relevant, depending on the intended use of the clutch plates.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that defects are identified and rectified early. These checkpoints typically include:

- Incoming Quality Control (IQC): Assessing raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to catch deviations in real-time.

- Final Quality Control (FQC): Conducting rigorous testing and inspections of the finished product to ensure it meets all design and performance standards.

What Common Testing Methods Are Used to Ensure Clutch Plate Quality?

Manufacturers employ various testing methods to verify the quality of clutch plates, including:

- Dimensional Inspection: Using calipers and gauges to measure the dimensions of the plates.

- Material Testing: Conducting hardness tests and tensile strength tests to ensure the materials used meet required specifications.

- Functional Testing: Simulating operational conditions to assess performance under stress.

- Fatigue Testing: Evaluating the durability of clutch plates under cyclic loading conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. This can include:

- Supplier Audits: Conducting on-site audits to review manufacturing processes, QC systems, and compliance with international standards.

- Requesting Quality Reports: Asking suppliers for detailed QC reports that outline their testing methods, results, and compliance certifications.

- Third-Party Inspections: Engaging independent inspection agencies to assess the quality of products before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Understanding local regulations and standards that may differ from international norms is crucial. For instance, agricultural equipment in Europe may require CE marking, while products sold in Africa may need to comply with local agricultural standards.

- Cultural Differences: Recognizing that quality perceptions may vary across regions can help buyers set clear expectations and ensure that suppliers understand their specific needs.

- Communication: Establishing clear lines of communication with suppliers can help mitigate misunderstandings related to quality specifications and delivery timelines.

Conclusion: What Should B2B Buyers Prioritize in Manufacturing and Quality Assurance?

For B2B buyers in the market for agri ditcher clutch plates, understanding the manufacturing processes and quality assurance practices is essential. By prioritizing suppliers who adhere to international standards, maintain rigorous QC processes, and demonstrate transparency through audits and reports, buyers can ensure they receive high-quality products that meet their operational needs. Investing time in evaluating suppliers’ manufacturing capabilities and quality assurance measures can lead to long-term partnerships that enhance productivity and efficiency in agricultural operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘agri ditcher clutch plates for sale’

Introduction

In today’s competitive agricultural sector, sourcing the right agri ditcher clutch plates is crucial for enhancing operational efficiency and ensuring equipment longevity. This guide provides a practical checklist for international B2B buyers, focusing on essential steps to streamline the procurement process and mitigate risks associated with supplier selection.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the agri ditcher clutch plates. This includes understanding the dimensions, materials, and compatibility with existing machinery.

– Key considerations:

– Review the manufacturer’s guidelines for your equipment.

– Determine load requirements, torque specifications, and environmental factors that may influence performance.

Illustrative image related to agri ditcher clutch plates for sale

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in agri ditcher clutch plates. Utilize online directories, industry trade shows, and referrals from trusted sources to compile a list of candidates.

– Helpful resources:

– Industry-specific platforms and trade associations can provide leads on reputable suppliers.

– Explore customer reviews and ratings to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards. This step is critical to ensuring that the products meet safety and quality requirements.

– What to look for:

– ISO certifications relevant to manufacturing processes.

– Compliance with local regulations in your target market, especially in regions like Europe or the Middle East.

Step 4: Request Samples and Specifications

Once you have shortlisted potential suppliers, request samples of the clutch plates along with detailed specifications. This allows you to assess the quality and fit of the products in real-world applications.

– Evaluation criteria:

– Check for uniformity in manufacturing and adherence to your defined specifications.

– Assess the durability and performance under expected operating conditions.

Step 5: Analyze Pricing and Payment Terms

Compare pricing structures among your shortlisted suppliers, keeping in mind that the lowest price does not always equate to the best value. Understand the payment terms and conditions to avoid any hidden costs.

– Considerations:

– Inquire about bulk order discounts and shipping costs.

– Look for transparent terms regarding warranties and after-sales support.

Step 6: Establish Communication Protocols

Effective communication with your chosen supplier is essential for a successful partnership. Establish clear lines of communication regarding timelines, expectations, and any potential issues.

– Best practices:

– Set regular check-ins to monitor order progress and address concerns promptly.

– Document all agreements and communications to ensure clarity and accountability.

Step 7: Finalize Contracts and Terms

After selecting a supplier, finalize contracts that outline all agreed-upon terms, including delivery schedules, quality assurance processes, and dispute resolution mechanisms. This step protects both parties and sets clear expectations.

– Contract essentials:

– Include clauses that cover product returns and warranty claims.

– Ensure that all legal requirements pertinent to your region and industry are addressed.

By following this practical sourcing checklist, B2B buyers can effectively navigate the complexities of procuring agri ditcher clutch plates, ensuring they make informed decisions that support their operational needs.

Comprehensive Cost and Pricing Analysis for agri ditcher clutch plates for sale Sourcing

What Are the Key Cost Components for Agri Ditcher Clutch Plates?

When sourcing agri ditcher clutch plates, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. High-quality steel or composite materials may be more expensive but offer better durability and performance, leading to lower maintenance costs over time.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with higher wage standards may increase overall costs, while countries with lower labor costs might offer competitive pricing.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and administrative costs associated with production facilities. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Specialized tooling for producing clutch plates can require significant investment. This cost is often amortized over large production runs, making it essential to consider minimum order quantities (MOQ).

-

Quality Control (QC): Rigorous quality assurance processes ensure that the clutch plates meet industry standards. Implementing robust QC can add to upfront costs but can reduce long-term expenses related to failures or replacements.

-

Logistics: Shipping and handling costs can vary widely based on distance, method of transport, and the volume of goods ordered. Understanding logistics costs is crucial for accurate budgeting.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on supplier reputation, service level, and market demand.

How Do Price Influencers Affect Agri Ditcher Clutch Plate Pricing?

Several factors influence the pricing of agri ditcher clutch plates:

-

Volume/MOQ: Higher order volumes usually lead to lower per-unit costs due to economies of scale. Negotiating for bulk orders can yield significant savings.

-

Specifications and Customization: Custom specifications or features will increase costs. Buyers should assess whether standard products can meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: High-quality materials with specific certifications (such as ISO or CE) may command higher prices. However, they often provide better performance and longevity, which can justify the investment.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Buyer Tips Should You Consider for Cost-Efficiency?

To optimize costs when sourcing agri ditcher clutch plates, consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing. Presenting data on competitor pricing or discussing long-term partnership opportunities can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, durability, and potential downtime costs associated with lower-quality products.

-

Understand Pricing Nuances for International B2B Transactions: Different regions may have varying pricing structures influenced by local market conditions, tariffs, and regulations. For instance, buyers in Africa and South America might face additional logistical costs compared to those in Europe.

-

Stay Informed on Market Trends: Regularly monitoring industry trends can help identify shifts in pricing and availability. Being proactive allows buyers to make timely decisions that can result in cost savings.

Disclaimer on Indicative Prices

It’s essential to note that the prices for agri ditcher clutch plates can fluctuate based on market conditions, supplier changes, and the specifics of the order. Always request quotes from multiple suppliers to ensure competitive pricing and verify that all costs are accounted for in your budget.

Alternatives Analysis: Comparing agri ditcher clutch plates for sale With Other Solutions

Understanding Alternatives for Agri Ditcher Clutch Plates

When considering agri ditcher clutch plates, it’s essential to evaluate various alternatives that can fulfill similar operational roles in agricultural machinery. This analysis helps international B2B buyers make informed decisions based on performance, cost, and maintenance requirements. Below, we compare agri ditcher clutch plates with two viable alternatives: Power Take-Off (PTO) Clutches and Slip Clutch Systems.

Illustrative image related to agri ditcher clutch plates for sale

| Comparison Aspect | Agri Ditcher Clutch Plates for Sale | Power Take-Off (PTO) Clutches | Slip Clutch Systems |

|---|---|---|---|

| Performance | High torque handling for ditching | Versatile for various implements | Protects against overloads |

| Cost | Moderate (around $38 to $179) | Varies widely ($50 to $300+) | Generally lower ($20 to $100) |

| Ease of Implementation | Requires specific fitting and adjustments | Installation can be complex | Simple installation, less adjustment needed |

| Maintenance | Regular checks needed for wear | Needs periodic servicing | Low maintenance, but check for lubrication |

| Best Use Case | Ideal for ditching applications | Suitable for multiple farm operations | Effective for variable load situations |

What Are the Advantages and Disadvantages of Power Take-Off (PTO) Clutches?

Power Take-Off (PTO) Clutches are widely used in agricultural machinery to transfer engine power to implements like mowers and balers. They excel in versatility, allowing for connection to multiple equipment types. However, the installation can be complex, often requiring specialized knowledge and tools. Additionally, while the initial cost may be higher, they can offer substantial long-term value when used across different applications. Maintenance is crucial, as wear can lead to decreased performance and potential failure during operation.

How Do Slip Clutch Systems Compare?

Slip Clutch Systems are designed to protect machinery from overload by allowing slippage under excessive load conditions. This feature prevents damage to both the clutch and the equipment. Their installation is typically more straightforward compared to PTO clutches, making them an attractive choice for many farmers. Additionally, they generally require less maintenance, with a focus on ensuring proper lubrication. However, they may not provide the same level of torque handling as agri ditcher clutch plates, which could limit their effectiveness in specific high-torque applications.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between agri ditcher clutch plates and alternative solutions like PTO clutches or slip clutch systems, B2B buyers should assess their specific operational needs. Factors such as the type of machinery being used, the nature of the tasks, and budget constraints will play a significant role in the decision-making process. While agri ditcher clutch plates offer robust performance for specific ditching tasks, PTO clutches provide versatility across multiple applications, and slip clutches offer an easier installation and lower maintenance. Understanding these dynamics will help buyers make a strategic choice that aligns with their operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for agri ditcher clutch plates for sale

What Are the Key Technical Properties of Agri Ditcher Clutch Plates?

When considering agri ditcher clutch plates for sale, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

The material used in clutch plates significantly affects durability and performance. Common materials include high-carbon steel and composites that provide a balance between strength and flexibility. High-quality materials resist wear and can withstand the stress of heavy agricultural machinery, reducing maintenance costs. -

Torque Capacity

This specification indicates the maximum torque the clutch plate can handle before failure. It is vital for ensuring that the clutch can operate under the specific demands of various agricultural equipment. Buyers should select clutch plates with a torque capacity that matches or exceeds the requirements of their machinery to avoid premature wear or failure. -

Friction Coefficient

The friction coefficient determines how effectively the clutch engages and disengages. A higher friction coefficient generally means better performance, especially in challenging agricultural environments. This property is crucial for ensuring smooth operation and preventing slippage during use. -

Thickness and Dimensions

The thickness and overall dimensions of clutch plates must align with the specific machinery they are intended for. These measurements influence how well the plates fit within the clutch assembly and how they interact with other components. Accurate specifications are essential to ensure compatibility and optimal performance. -

Temperature Resistance

Agri ditcher clutch plates should be able to withstand high temperatures generated during operation. Materials that can endure elevated temperatures without degrading are essential for maintaining performance under heavy loads. This characteristic is particularly important in regions with extreme weather conditions. -

Tolerance Levels

Tolerance refers to the allowable deviation in the dimensions of the clutch plates. Tight tolerances ensure proper fit and function, which is critical for preventing mechanical failures. Buyers should look for manufacturers that maintain high tolerance levels to ensure quality and reliability.

What Are Common Trade Terms Related to Agri Ditcher Clutch Plates?

Understanding industry jargon can facilitate smoother negotiations and transactions. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the equipment. Purchasing OEM clutch plates ensures compatibility and reliability, as they are designed specifically for the machinery. Buyers often prefer OEM parts for their guaranteed quality and fit. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. This term is important for B2B buyers as it can impact inventory management and cash flow. Understanding MOQ helps businesses plan their purchases more effectively. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for pricing and availability of specific products. In the context of agri ditcher clutch plates, submitting an RFQ can streamline the procurement process and ensure that buyers receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps mitigate risks related to shipping, insurance, and delivery. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. This term is crucial for B2B buyers who need to manage inventory levels and production schedules effectively. Knowing lead times helps in planning and ensuring that machinery downtime is minimized. -

Aftermarket Parts

Aftermarket parts are components made by companies other than the original manufacturer. They can often provide cost-effective alternatives to OEM parts. Buyers should evaluate the quality and compatibility of aftermarket clutch plates to ensure they meet operational standards.

Understanding these technical properties and trade terminologies will empower B2B buyers in making informed decisions when sourcing agri ditcher clutch plates, ultimately enhancing operational efficiency and productivity.

Navigating Market Dynamics and Sourcing Trends in the agri ditcher clutch plates for sale Sector

What Are the Current Market Dynamics and Key Trends Affecting Agri Ditcher Clutch Plates for Sale?

The global market for agricultural machinery, including agri ditcher clutch plates, is experiencing significant growth driven by several factors. Increasing demand for efficient farming practices, the rise of mechanization in agriculture, and the need for higher crop yields are key drivers. Regions such as Africa and South America are witnessing a surge in agricultural investments, fostering a robust market for specialized components. In Europe, particularly in countries like Germany, there is a strong emphasis on innovation and technology integration in agricultural machinery, which is influencing the sourcing trends of clutch plates.

Illustrative image related to agri ditcher clutch plates for sale

Emerging technologies, such as predictive maintenance and IoT (Internet of Things), are transforming how agricultural businesses approach equipment management. B2B buyers are increasingly leveraging digital platforms for sourcing, enabling them to access a wider range of suppliers and products. The trend towards e-commerce in B2B transactions is reshaping traditional procurement processes, allowing for better price comparisons and streamlined logistics. Additionally, the adoption of automation in agricultural operations is pushing manufacturers to design clutch plates that can withstand higher torque levels and operate under demanding conditions.

How Are Sustainability and Ethical Sourcing Influencing the Agri Ditcher Clutch Plates Market?

Sustainability is becoming a critical consideration in the sourcing of agri ditcher clutch plates. Environmental impacts associated with manufacturing processes, such as carbon emissions and resource depletion, are prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. Ethical sourcing is gaining traction, with international buyers seeking to establish supply chains that not only comply with regulations but also promote social responsibility.

The use of ‘green’ materials and certifications is increasingly important. Suppliers who utilize recyclable or sustainably sourced materials are more attractive to buyers looking to enhance their environmental footprint. Certifications such as ISO 14001 (Environmental Management) and other sustainability labels serve as indicators of a supplier’s commitment to ethical practices. This focus on sustainability not only meets regulatory requirements but also resonates with consumers who are increasingly aware of the environmental impact of their purchases.

Illustrative image related to agri ditcher clutch plates for sale

What Is the Historical Context of Agri Ditcher Clutch Plates in the B2B Market?

The evolution of agri ditcher clutch plates reflects broader trends in agricultural machinery development. Initially designed for basic functionality, these components have evolved significantly due to advancements in materials science and engineering. The introduction of high-strength alloys and improved manufacturing techniques has enhanced the durability and performance of clutch plates, enabling them to handle the demands of modern farming equipment.

Over the years, the agricultural sector has shifted towards more specialized machinery, necessitating the production of tailored clutch solutions. This evolution has been particularly pronounced in regions with intensive agricultural practices, where efficiency and reliability are paramount. As the market continues to evolve, B2B buyers can expect ongoing innovations that will further enhance the performance and sustainability of agri ditcher clutch plates.

Frequently Asked Questions (FAQs) for B2B Buyers of agri ditcher clutch plates for sale

-

How do I solve issues with agri ditcher clutch plates malfunctioning?

To address malfunctions with agri ditcher clutch plates, first, perform a thorough inspection to identify signs of wear or damage. Check for proper installation, ensuring that all components align correctly. If issues persist, consider replacing worn parts or upgrading to higher-quality clutches designed to handle specific load requirements. Regular maintenance, including lubrication and timely replacements, can significantly reduce the likelihood of future problems. Engaging a reliable supplier for quality parts is crucial to ensure longevity and performance. -

What is the best agri ditcher clutch plate for heavy-duty applications?

For heavy-duty applications, look for agri ditcher clutch plates made from high-strength materials that can withstand increased torque and stress. Brands that offer heavy-duty specifications, often made from reinforced steel or composite materials, are ideal. Additionally, choose plates with features like slip clutches to prevent damage under excessive load. Consult with suppliers who specialize in agricultural equipment to find models that are specifically designed for your type of machinery and operational requirements. -

How can I verify the quality of agri ditcher clutch plates from suppliers?

To verify the quality of agri ditcher clutch plates, request samples or detailed specifications from potential suppliers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, research supplier reviews and testimonials, focusing on their reputation in the agricultural sector. It may also be beneficial to inquire about their manufacturing processes and warranty policies to ensure you are investing in durable, high-quality products. -

What customization options are available for agri ditcher clutch plates?

Customization options for agri ditcher clutch plates can vary by supplier. Common modifications include adjustments in dimensions, materials, and friction coefficients to suit specific machinery requirements. Some suppliers may also offer custom branding or packaging solutions. When discussing customization, provide clear specifications and operational conditions to ensure the final product meets your needs. Always confirm the supplier’s capability to deliver custom solutions within your timeline. -

What are the typical minimum order quantities (MOQs) for agri ditcher clutch plates?

Minimum order quantities (MOQs) for agri ditcher clutch plates can range from a few pieces to several hundred, depending on the supplier and product type. For bulk purchases, suppliers often provide better pricing, while smaller orders may incur higher per-unit costs. It’s advisable to negotiate MOQs with suppliers, especially if you have ongoing needs or plan to establish a long-term partnership. Discussing your requirements upfront can lead to more favorable terms. -

What payment terms are common in international trade for clutch plates?

Common payment terms in international trade for agri ditcher clutch plates include advance payment, letters of credit, and net payment terms (e.g., net 30 or net 60 days). Advance payments may be required for custom orders or new suppliers, while letters of credit offer security for both parties. It’s essential to clarify payment terms before finalizing contracts to avoid misunderstandings. Ensure you understand any additional fees related to currency conversion or international banking. -

How do I handle logistics and shipping for agri ditcher clutch plates?

Handling logistics for agri ditcher clutch plates involves coordinating with your supplier to determine the best shipping method, considering factors like cost, speed, and destination. Common options include air freight for urgent deliveries and sea freight for bulk orders. Ensure your supplier provides tracking information and confirm that they comply with international shipping regulations. Additionally, consider working with a freight forwarder to streamline the process and handle customs clearance. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of agri ditcher clutch plates should implement strict quality assurance measures, including routine inspections and testing of materials. Expect documentation of quality control processes, such as ISO certifications, and the ability to provide test reports for the products. Additionally, inquire about their return and warranty policies, as these can be indicators of their commitment to product quality. Establishing clear communication about quality expectations can help build a trustworthy supplier relationship.

Top 3 Agri Ditcher Clutch Plates For Sale Manufacturers & Suppliers List

1. HR Clutch – Agricultural Clutches

Domain: hrclutch.com

Registered: 2000 (25 years)

Introduction: Agricultural clutches for farm vehicles and equipment, including rebuilt clutches for manufacturers like John Deere, Massey-Ferguson, IHC, and Ford New-Holland. Upgradable to heavy duty specifications, guaranteed to perform under heavy loads. New agricultural clutches manufactured by O.E. producers such as AP, Borg/Beck, and Alma, fitting applications including Fiat, Ford, Holland, and Kubota. Var…

2. Case – Clutch Plate Set – 3 Pc

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {‘title’: ‘Clutch Plate Set – 3 Pc (N14252)’, ‘fits’: ‘Case Astec Toro TF300 Trencher’, ‘condition’: ‘New’, ‘price’: ‘$72.03’, ‘shipping_cost’: ‘$71.16’, ‘estimated_delivery’: ‘Wed, Oct 15 – Thu, Nov 6’, ‘quantity_available’: ‘More than 10 available’, ‘item_number’: ‘264890665388’, ‘MPN’: ‘bn14252’, ‘category’: ‘Business & Industrial > Heavy Equipment, Parts & Attachments > Heavy Equipment Parts &…

3. PEC Manufacturing – Mechanical Power Take-Off Clutches

Domain: pec-clutches.com

Registered: 2001 (24 years)

Introduction: PEC Manufacturing specializes in Mechanical Power Take-Off (PTO) clutches for stationary industrial engines. Their clutches are designed to fit all internal combustion engines with standard SAE flywheel housing dimensions from No. 6 through No. 0. The clutches range in size from one plate 6″ to three plate 14″ and are suitable for engines in industrial installations up to 583 horsepower. PEC PTOs …

Strategic Sourcing Conclusion and Outlook for agri ditcher clutch plates for sale

In summary, strategic sourcing of agri ditcher clutch plates is essential for international B2B buyers seeking reliable and high-quality components for their agricultural machinery. By focusing on suppliers with a proven track record of performance and durability, businesses can enhance their operational efficiency and reduce long-term costs. It is crucial to evaluate potential partners not only on price but also on the quality of their products, customer service, and the availability of technical support.

As the agricultural sector continues to evolve, embracing advancements in manufacturing and distribution will be key to maintaining a competitive edge. Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage local market insights and global sourcing strategies to secure the best deals.

Illustrative image related to agri ditcher clutch plates for sale

Moving forward, consider establishing long-term relationships with suppliers who demonstrate a commitment to quality and innovation. This proactive approach will not only streamline your supply chain but also ensure that your agricultural operations remain robust and efficient. Engage with suppliers today to explore customized solutions that meet your specific needs and contribute to your business’s sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.