Is Your Piston Hydraulic Pump Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for piston hydraulic pump

In today’s competitive industrial landscape, sourcing high-quality piston hydraulic pumps can be a daunting task for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With numerous options available, making informed purchasing decisions requires a deep understanding of specifications, applications, and supplier reliability. This guide aims to demystify the global market for piston hydraulic pumps, providing critical insights into various types, their applications across industries, and strategies for effective supplier vetting.

Throughout this comprehensive resource, we will explore the intricacies of piston hydraulic pumps, including variable volume pumps and their operational efficiencies. Buyers will gain valuable knowledge on how to assess costs, evaluate performance metrics, and identify potential suppliers that meet international quality standards. Additionally, we will delve into the nuances of regional market dynamics, helping businesses in countries like Germany and Nigeria navigate logistical challenges and optimize their procurement processes.

By empowering B2B buyers with actionable insights and best practices, this guide aims to streamline the sourcing journey, ultimately enhancing operational efficiency and ensuring that businesses can harness the full potential of piston hydraulic pumps in their operations. Whether you are a seasoned procurement professional or new to the market, this guide is designed to equip you with the tools necessary to make confident, informed decisions that drive success.

Understanding piston hydraulic pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Displacement Pumps | Constant flow rate, simple design | Construction, agriculture, manufacturing | Pros: Simple to use, cost-effective. Cons: Limited adaptability to varying loads. |

| Variable Displacement Pumps | Adjustable flow rate, complex design | Mobile equipment, automotive, industrial | Pros: Flexible flow control, energy-efficient. Cons: Higher initial cost and maintenance complexity. |

| Axial Piston Pumps | Piston arrangement in a parallel layout, high efficiency | Heavy machinery, aerospace, robotics | Pros: High power density, compact design. Cons: Sensitive to contamination, requires precise alignment. |

| Radial Piston Pumps | Piston arrangement in a radial layout, good for high pressure | Oil and gas, mining, hydraulic presses | Pros: Excellent pressure capabilities, durable. Cons: More complex design, higher cost. |

| Swash Plate Pumps | Uses a swash plate mechanism to vary displacement | Agricultural machinery, construction | Pros: Efficient under variable loads, smooth operation. Cons: More susceptible to wear and tear. |

What Are Fixed Displacement Pumps and Their Applications?

Fixed displacement pumps deliver a constant flow of hydraulic fluid regardless of the pressure in the system. Their simple design makes them cost-effective and easy to maintain, making them popular in construction, agriculture, and manufacturing applications. Buyers should consider the specific flow requirements of their operations, as these pumps lack adaptability to varying load conditions, which can lead to inefficiencies in some applications.

How Do Variable Displacement Pumps Enhance Operational Flexibility?

Variable displacement pumps allow for adjustable flow rates, enabling them to adapt to different operational needs. This flexibility makes them ideal for mobile equipment and automotive applications, where load conditions can change frequently. While they are more energy-efficient and can reduce operational costs over time, buyers should be aware of the higher initial investment and the need for more complex maintenance procedures.

Why Choose Axial Piston Pumps for High-Efficiency Applications?

Axial piston pumps feature a parallel arrangement of pistons, which contributes to their high efficiency and compact design. These pumps are commonly used in heavy machinery, aerospace, and robotics, where space and power density are critical. However, buyers should consider their sensitivity to contamination and the need for precise alignment, which can impact overall reliability and performance.

What Are the Benefits of Radial Piston Pumps in High-Pressure Environments?

Radial piston pumps utilize a radial arrangement of pistons, making them particularly suitable for high-pressure applications in industries like oil and gas and mining. Their robust design provides excellent durability and pressure capabilities. However, the complexity of the design can lead to higher costs, so buyers should evaluate their specific pressure requirements against the associated investment.

How Do Swash Plate Pumps Operate and What Are Their Advantages?

Swash plate pumps employ a swash plate mechanism to vary the displacement, allowing for smooth operation under variable loads. They are widely used in agricultural machinery and construction equipment. Although they offer efficient performance, buyers must consider their susceptibility to wear and tear, which may lead to increased maintenance costs over time.

Key Industrial Applications of piston hydraulic pump

| Industry/Sector | Specific Application of piston hydraulic pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Concrete Pumping | Enhanced efficiency and reduced labor costs | Pressure ratings, compatibility with existing equipment |

| Agriculture | Tractors and Farm Equipment | Improved power delivery for agricultural tasks | Durability, resistance to environmental factors |

| Manufacturing | CNC Machines | Precision in machining processes | Tolerance levels, flow rates, and maintenance requirements |

| Oil & Gas | Hydraulic Fracturing | Increased extraction efficiency | Pressure capacity, reliability in harsh environments |

| Mining | Excavation Equipment | Enhanced operational productivity and safety | Compliance with safety standards, ease of maintenance |

How Are Piston Hydraulic Pumps Used in Construction?

In the construction industry, piston hydraulic pumps are essential for concrete pumping, enabling the efficient transfer of concrete to various heights and distances. This application significantly enhances project timelines and reduces labor costs associated with manual concrete handling. Buyers should consider the pressure ratings of these pumps to ensure they meet the specific requirements of their projects, as well as compatibility with existing machinery to avoid costly retrofitting.

What Role Do Piston Hydraulic Pumps Play in Agriculture?

Piston hydraulic pumps are widely used in agricultural machinery, particularly in tractors and other farm equipment. They provide the necessary power to operate hydraulic systems that control various implements, such as plows and seeders. For international buyers, especially in regions like Africa and South America, it’s crucial to assess the durability of these pumps against harsh environmental conditions, as well as their efficiency in power delivery to maximize productivity on the field.

How Are Piston Hydraulic Pumps Essential for Manufacturing?

In manufacturing, piston hydraulic pumps are integral to the operation of CNC machines, which require precise control of hydraulic movements for machining tasks. These pumps ensure that the necessary force is applied accurately, resulting in high-quality finished products. Buyers in this sector must focus on tolerance levels and flow rates to match their specific machinery needs, as well as consider the ease of maintenance to minimize downtime and maintain productivity.

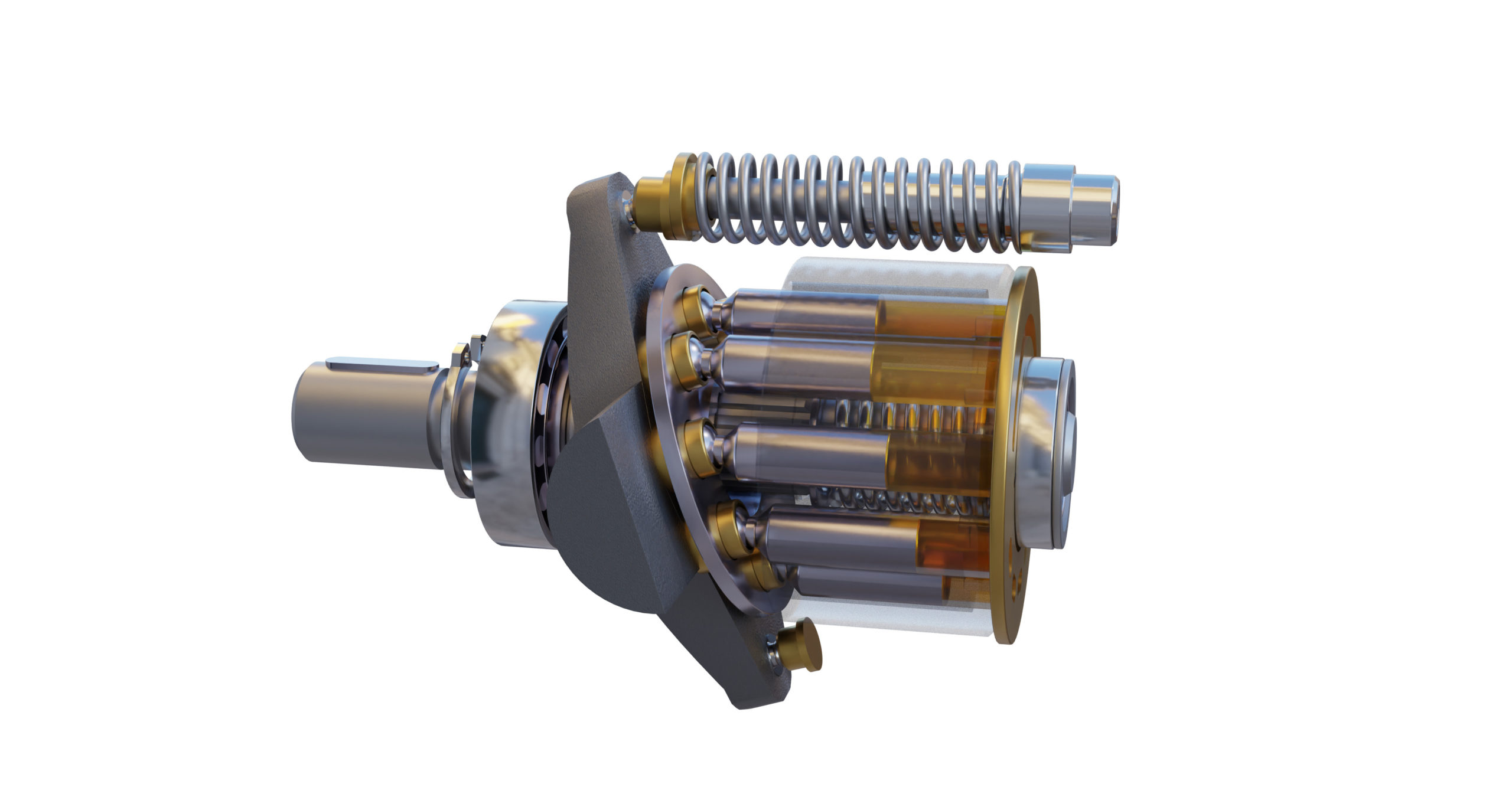

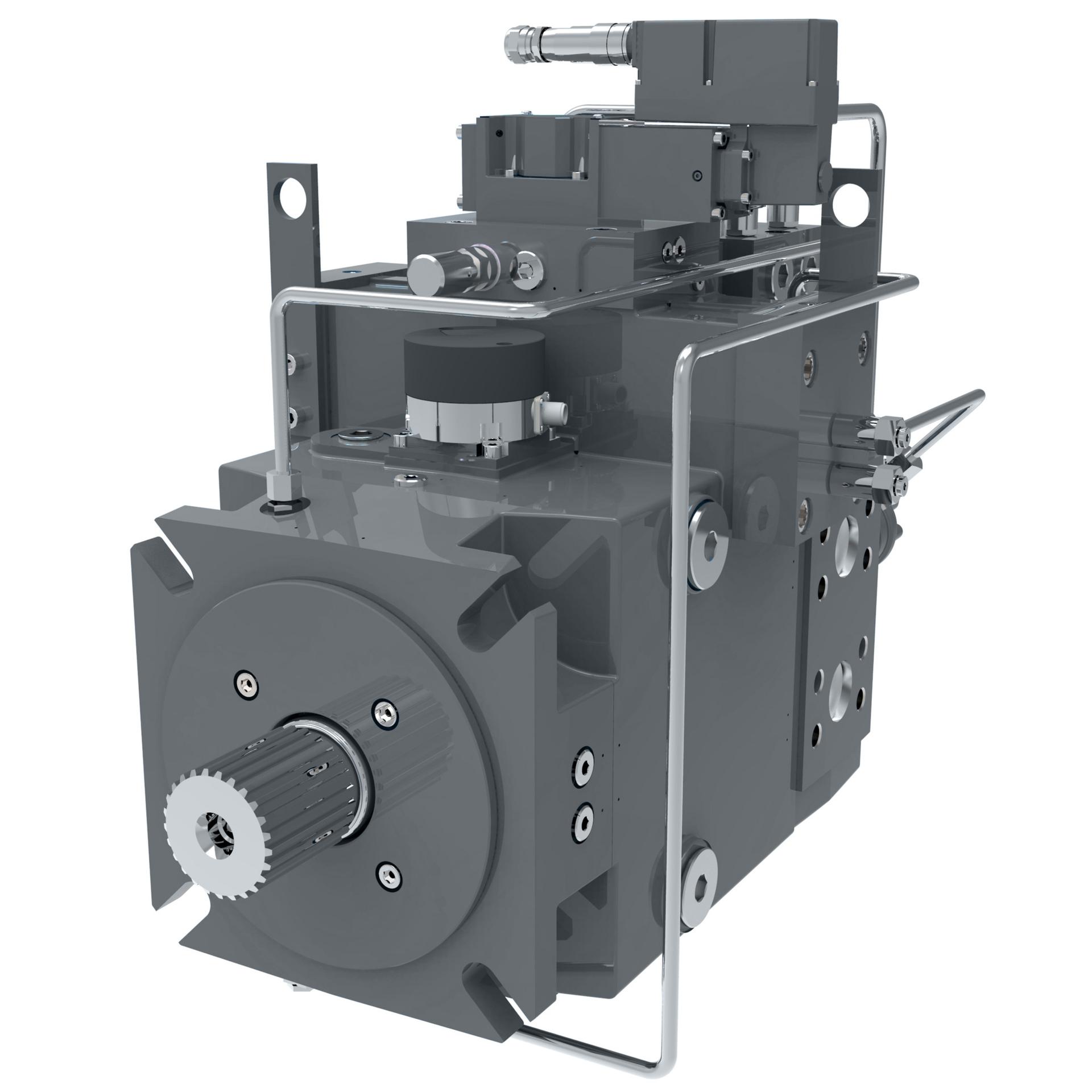

Illustrative image related to piston hydraulic pump

Why Are Piston Hydraulic Pumps Important in Oil & Gas?

Within the oil and gas sector, piston hydraulic pumps are critical for hydraulic fracturing operations, where they facilitate the injection of fluids into underground formations to enhance oil extraction. The efficiency of these pumps directly impacts extraction rates and operational costs. Buyers should prioritize sourcing pumps with high pressure capacities and proven reliability in extreme conditions, ensuring they can withstand the rigorous demands of oilfield operations.

How Do Piston Hydraulic Pumps Improve Mining Operations?

In the mining industry, piston hydraulic pumps are employed in various excavation equipment to enhance operational productivity and safety. These pumps provide the necessary hydraulic power for digging, lifting, and transporting materials. For buyers, especially in regions with stringent safety regulations, it is essential to consider compliance with safety standards and the ease of maintenance of these pumps to ensure long-term operational efficiency and safety in mining operations.

3 Common User Pain Points for ‘piston hydraulic pump’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Piston Hydraulic Pump for Specific Applications

The Problem: Many B2B buyers face challenges when it comes to selecting the appropriate piston hydraulic pump for their specific applications. With various models available, each with different specifications such as pressure ratings, displacement, and compatibility with fluids, it can be overwhelming to determine which pump will meet the operational needs. This often leads to purchasing equipment that does not perform optimally, resulting in inefficiencies and increased costs.

The Solution: To navigate this complexity, buyers should conduct a thorough needs assessment before purchasing. Begin by evaluating the specific application requirements, including the maximum pressure (PSI), flow rate (GPM), and type of hydraulic fluid that will be used. Consult technical datasheets and product catalogs to compare specifications. Additionally, engaging with a knowledgeable supplier can provide insights into the best options available. Consider using simulation tools or software that can model the hydraulic system to predict performance outcomes based on different pump configurations. This proactive approach will ensure the selection of the right pump, ultimately leading to improved system efficiency and reduced operational costs.

Scenario 2: Managing Maintenance and Downtime of Piston Hydraulic Pumps

The Problem: Maintenance issues and unexpected downtime are significant pain points for businesses relying on piston hydraulic pumps. Inadequate maintenance can lead to pump failures, which not only disrupt production but also incur costly repair or replacement expenses. Buyers may struggle to establish a regular maintenance schedule due to a lack of resources or knowledge about proper pump care.

The Solution: Implementing a comprehensive maintenance plan is crucial to minimize downtime and extend the lifespan of piston hydraulic pumps. Start by developing a maintenance checklist that includes regular inspections for leaks, wear, and fluid levels. Establish a routine schedule for changing hydraulic fluids and filters, as well as checking seals and fittings for integrity. Training staff on maintenance best practices can also enhance performance and reliability. Additionally, consider investing in condition monitoring technology that provides real-time data on pump performance, alerting operators to potential issues before they escalate. This proactive maintenance strategy will lead to increased operational reliability and reduced costs associated with unplanned downtime.

Scenario 3: Navigating Supply Chain Issues and Equipment Availability

The Problem: International buyers, especially in regions such as Africa and South America, often encounter difficulties with supply chain disruptions and availability of piston hydraulic pumps. This can lead to delays in acquiring necessary equipment, impacting project timelines and operational efficiency. Buyers may also face challenges in sourcing pumps that meet local standards and regulations.

The Solution: To mitigate supply chain risks, buyers should establish relationships with multiple suppliers and distributors. This diversification strategy can provide alternative options if one supplier faces delays. It is also essential to communicate clearly with suppliers about lead times and availability, allowing for better planning and inventory management. Additionally, consider sourcing from manufacturers with a strong international presence and those that offer customizable options to align with local standards. Engaging in proactive communication with suppliers can lead to better transparency regarding stock levels and expected delivery timelines. By taking these steps, buyers can ensure a more reliable supply chain, keeping projects on schedule and avoiding costly delays.

Strategic Material Selection Guide for piston hydraulic pump

When selecting materials for piston hydraulic pumps, it is crucial to consider the properties and performance characteristics that will ensure optimal functionality in various applications. Below is an analysis of four common materials used in the construction of piston hydraulic pumps, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to piston hydraulic pump

What are the Key Properties of Aluminum in Piston Hydraulic Pumps?

Aluminum is a widely used material in hydraulic pump manufacturing due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can handle pressures around 250 bar. Its low density makes it ideal for applications where weight reduction is critical, such as in mobile equipment.

Pros & Cons: Aluminum offers good machinability and is less expensive than some high-performance alloys. However, its lower strength compared to steel can be a limitation in high-pressure applications. Additionally, while aluminum is generally resistant to corrosion, it can be susceptible to wear under abrasive conditions.

Impact on Application: Aluminum is compatible with a variety of hydraulic fluids, making it suitable for general-purpose applications. However, it may not be the best choice for environments with high particulate contamination.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards, as aluminum alloys may vary in quality. Understanding the specific grades (like 6061 or 7075) can help in selecting the right material.

How Does Steel Compare as a Material for Piston Hydraulic Pumps?

Steel is another common material, known for its strength and durability. It can withstand high pressures (up to 700 bar) and temperatures (up to 300°C), making it suitable for heavy-duty applications.

Pros & Cons: The primary advantage of steel is its high tensile strength and resistance to deformation under load. However, it is heavier than aluminum, which can be a disadvantage in mobile applications. Steel also requires protective coatings to prevent corrosion, which can add to manufacturing complexity and cost.

Impact on Application: Steel is ideal for high-pressure hydraulic systems and is compatible with a wide range of hydraulic fluids. Its robustness makes it suitable for industrial applications, particularly in demanding environments.

Considerations for International Buyers: Buyers from Europe, particularly Germany, should be aware of compliance with standards such as DIN EN 10025 for structural steels. Additionally, understanding the specific corrosion resistance treatments available is crucial for applications in humid or corrosive environments.

What Role Does Cast Iron Play in Piston Hydraulic Pump Design?

Cast iron is often used in hydraulic pumps for its excellent wear resistance and ability to dampen vibrations. It can handle temperatures up to 250°C and pressures around 400 bar.

Pros & Cons: Cast iron’s durability and low cost make it a popular choice for many industrial applications. However, it is brittle and can fracture under sudden impact, which limits its use in certain dynamic applications. Additionally, its weight can be a disadvantage in portable equipment.

Impact on Application: Cast iron is particularly effective in applications where vibration damping is critical, such as in stationary hydraulic systems. It is compatible with most hydraulic fluids but may require additional treatment for corrosive environments.

Considerations for International Buyers: Buyers from the Middle East should consider the impact of high temperatures on cast iron’s performance. Compliance with ASTM A48 standards for gray iron can also be a critical factor in material selection.

How Does Composite Material Benefit Piston Hydraulic Pumps?

Composite materials, such as reinforced plastics or carbon fiber composites, are increasingly being used in hydraulic pump applications. They offer unique properties, including a high strength-to-weight ratio and excellent corrosion resistance.

Pros & Cons: The primary advantage of composites is their lightweight nature, which can significantly reduce the overall weight of hydraulic systems. However, they can be more expensive to manufacture and may have lower temperature and pressure ratings compared to metals.

Impact on Application: Composites are suitable for specialized applications where weight savings are paramount, such as in aerospace or high-performance automotive applications. Their chemical resistance makes them ideal for aggressive hydraulic fluids.

Considerations for International Buyers: Buyers in regions with stringent environmental regulations may prefer composites due to their lower environmental impact. Understanding the specific standards for composite materials is essential for compliance.

Illustrative image related to piston hydraulic pump

Summary Table of Material Selection for Piston Hydraulic Pumps

| Material | Typical Use Case for piston hydraulic pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General-purpose hydraulic applications | Lightweight and corrosion-resistant | Lower strength under high pressure | Medium |

| Steel | Heavy-duty industrial applications | High tensile strength | Heavier and requires coatings | Medium to High |

| Cast Iron | Stationary hydraulic systems | Excellent wear resistance | Brittle and heavy | Low |

| Composite | Specialized applications (aerospace, automotive) | High strength-to-weight ratio | Higher manufacturing cost | High |

This strategic material selection guide provides valuable insights for B2B buyers, helping them make informed decisions based on performance requirements, cost considerations, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for piston hydraulic pump

What Are the Key Manufacturing Processes for Piston Hydraulic Pumps?

The manufacturing of piston hydraulic pumps involves several critical stages that ensure high performance, durability, and reliability. Understanding these processes helps B2B buyers select suppliers who prioritize quality and efficiency.

Material Preparation: What Materials Are Used in Piston Hydraulic Pumps?

The first step in the manufacturing process is material preparation. Typically, high-grade materials such as cast iron, aluminum alloys, and various steels are utilized. These materials are chosen for their strength, resistance to wear, and ability to withstand high pressure. The preparation phase involves cutting and shaping the raw materials into specific dimensions, ensuring they meet the required specifications. This stage is crucial for ensuring that the components of the pump can endure the operational stresses they will face in the field.

Forming: How Are Components Shaped for Hydraulic Pumps?

Once the materials are prepared, the next phase is forming. This involves techniques such as machining, forging, and casting. Machining is often used to achieve tight tolerances on critical components like the cylinder block and pistons. Forging may be employed for parts that require enhanced structural integrity, while casting is used for complex shapes that are difficult to machine. These processes are vital for producing components that not only fit together perfectly but also function effectively under pressure.

What Assembly Techniques Are Common in Piston Hydraulic Pump Manufacturing?

The assembly of piston hydraulic pumps is a meticulous process that combines precision and expertise. During this stage, various components—including the pump body, pistons, valves, and seals—are brought together.

Illustrative image related to piston hydraulic pump

How Is the Assembly Process Conducted?

- Sub-Assembly: Many manufacturers begin with sub-assemblies, where smaller components like pistons and valves are assembled separately before being integrated into the main pump.

- Alignment and Fitting: Accurate alignment is crucial, as even minor misalignments can lead to performance issues. Manufacturers often use jigs and fixtures to maintain precision during assembly.

- Sealing: Seals are critical in hydraulic pumps to prevent fluid leakage. Manufacturers typically use O-rings or gaskets that are installed under controlled conditions to ensure they perform effectively under pressure.

What Finishing Processes Enhance the Quality of Hydraulic Pumps?

After assembly, the pump undergoes finishing processes that enhance its performance and longevity.

Which Finishing Techniques Are Commonly Used?

- Surface Treatment: Techniques such as anodizing or powder coating are applied to improve corrosion resistance and surface durability.

- Balancing: Pumps are balanced to minimize vibrations during operation, which can lead to premature wear and failure.

- Final Inspection: Each unit goes through a final inspection to ensure it meets the specified design criteria and performance standards.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for piston hydraulic pumps. International and industry-specific standards guide these efforts, ensuring that products meet regulatory and customer expectations.

What International Standards Apply to Piston Hydraulic Pump Manufacturing?

- ISO 9001: This quality management standard focuses on customer satisfaction and continuous improvement, ensuring that manufacturers have robust processes in place.

- CE Marking: This certification indicates that the product meets EU safety, health, and environmental protection standards, which is particularly important for buyers in Europe.

- API Standards: For pumps used in the oil and gas sector, compliance with American Petroleum Institute (API) standards ensures reliability and safety in demanding environments.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is essential for ensuring that each pump performs as intended. Manufacturers typically implement several QC checkpoints throughout the production process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, in-process checks monitor critical dimensions and tolerances, allowing for immediate corrections if discrepancies arise.

- Final Quality Control (FQC): After assembly, the final inspection includes functional tests and performance evaluations to confirm the pump operates within specified parameters.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, verifying supplier quality assurance practices is critical.

What Methods Can Buyers Use to Ensure Quality?

- Supplier Audits: Conducting on-site audits helps buyers assess the manufacturing processes, quality control measures, and compliance with international standards.

- Quality Reports: Requesting detailed quality reports from suppliers, including inspection results and compliance certifications, provides insights into their QA practices.

- Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance processes.

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of specific nuances regarding quality control and certifications.

What Should Buyers Consider When Sourcing Internationally?

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should ensure that suppliers can meet the specific standards required in their target markets.

- Documentation and Traceability: Comprehensive documentation is crucial for international transactions. Buyers should ensure that suppliers maintain traceability of materials and components used in the manufacturing process.

- Cultural and Communication Considerations: Understanding cultural differences in business practices can facilitate smoother negotiations and enhance collaboration with international suppliers.

By comprehensively understanding the manufacturing processes and quality assurance practices involved in piston hydraulic pumps, B2B buyers can make informed decisions and establish partnerships with reliable suppliers that meet their operational needs and quality standards.

Illustrative image related to piston hydraulic pump

Practical Sourcing Guide: A Step-by-Step Checklist for ‘piston hydraulic pump’

To successfully procure a piston hydraulic pump, international B2B buyers must navigate a complex landscape of technical specifications, supplier evaluations, and logistical considerations. This checklist serves as a practical guide to streamline your sourcing process, ensuring that you make informed decisions that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your piston hydraulic pump. Consider factors such as:

– Pressure Ratings: Ensure that the pump can handle the maximum pressure your application requires.

– Flow Rate: Determine the gallons per minute (GPM) needed for optimal performance.

– Mounting Options: Identify the flange and shaft configurations that fit your existing systems.

Establishing these specifications early on will help you narrow down suitable products and avoid costly mistakes later in the procurement process.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers of piston hydraulic pumps. Look for:

– Industry Experience: Suppliers with a proven track record in hydraulic systems are more likely to understand your needs.

– Geographical Reach: For buyers in Africa, South America, the Middle East, and Europe, consider suppliers that can efficiently ship to your location.

A well-researched supplier list will provide a solid foundation for your negotiations and future interactions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request:

– Company Profiles: Understand their history, capabilities, and market reputation.

– Case Studies and References: Seek testimonials from other businesses in similar industries or regions to gauge reliability and service quality.

Assessing suppliers through these lenses can help mitigate risks associated with product quality and supplier reliability.

Illustrative image related to piston hydraulic pump

Step 4: Verify Certifications and Compliance

Ensure that your chosen suppliers adhere to relevant industry standards and certifications. Check for:

– ISO Certifications: These indicate adherence to quality management standards.

– Local Compliance: Depending on your region, specific certifications may be required for hydraulic equipment.

Verifying these credentials safeguards your operations against potential legal and operational issues.

Step 5: Request Samples or Demonstrations

Before finalizing your order, request samples or demonstrations of the piston hydraulic pumps. This allows you to:

– Test Performance: Ensure the pump meets your operational requirements in real-world conditions.

– Assess Quality: Inspect the build quality and materials used.

Illustrative image related to piston hydraulic pump

This step is essential for confirming that the product aligns with your expectations before making a significant investment.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations regarding pricing, delivery schedules, and payment terms. Consider:

– Volume Discounts: Inquire about bulk purchasing options to reduce costs.

– Warranty and Support: Ensure that the supplier offers adequate support and warranty options to protect your investment.

Effective negotiation can lead to more favorable terms and enhance your overall procurement strategy.

Step 7: Plan Logistics and Delivery

Finally, develop a logistics plan for the delivery of your piston hydraulic pumps. Consider:

– Shipping Methods: Choose a reliable shipping option that balances cost and delivery time.

– Customs and Duties: Familiarize yourself with any import regulations or tariffs that may apply.

A well-thought-out logistics plan will ensure a smooth transition from supplier to your operations, minimizing delays and unexpected costs.

By following this checklist, B2B buyers can navigate the complexities of sourcing piston hydraulic pumps with confidence, ensuring that they secure the best products for their needs.

Comprehensive Cost and Pricing Analysis for piston hydraulic pump Sourcing

What Are the Key Cost Components Involved in Sourcing Piston Hydraulic Pumps?

When sourcing piston hydraulic pumps, understanding the detailed cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly affects the durability and performance of the pump. High-quality steel, aluminum, or composite materials may increase initial costs but can lead to longer lifespan and reduced maintenance.

-

Labor: Labor costs encompass wages for skilled workers involved in manufacturing and assembly. In regions with higher labor costs, such as parts of Europe, these expenses can significantly impact overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory operations. Efficient production processes can help minimize these overheads.

-

Tooling: Tooling costs pertain to the equipment needed for the production of custom parts. If a buyer requires unique specifications, the tooling investment can be substantial.

-

Quality Control (QC): Ensuring the pump meets industry standards necessitates rigorous QC processes. This is especially important for buyers in sectors requiring certifications, as it adds to the overall cost.

-

Logistics: Shipping costs vary significantly based on location and supplier. International buyers should consider these logistics costs, which include freight charges, customs duties, and insurance.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margins. Understanding the margin structure helps buyers gauge the reasonableness of pricing.

How Do Price Influencers Affect Piston Hydraulic Pump Costs?

Several factors influence the pricing of piston hydraulic pumps:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually secure better pricing. Buyers should negotiate MOQs to optimize costs, particularly when sourcing for large-scale projects.

-

Specifications and Customization: Custom pumps designed for specific applications can significantly increase costs. Buyers should weigh the need for customization against the benefits it provides.

-

Materials: The choice between standard and premium materials impacts pricing. Premium materials may enhance performance but will also increase the initial investment.

-

Quality and Certifications: Pumps that meet higher quality standards or have specific certifications (like ISO) may command higher prices. Buyers in regulated industries should factor this into their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer higher prices but often provide better support and warranty options.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, which can influence the total purchase price.

What Tips Can Help Buyers Optimize Costs When Sourcing Piston Hydraulic Pumps?

B2B buyers can adopt several strategies to enhance cost efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially when placing large orders. Leverage competitive offers from multiple suppliers to negotiate better terms.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with pump operation, including maintenance, energy consumption, and potential downtime. A lower upfront price may lead to higher TCO if the pump is less reliable or efficient.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of additional costs like tariffs and taxes. Understanding local market conditions can provide leverage in negotiations.

-

Supplier Relationships: Build long-term relationships with suppliers to gain access to discounts and better service. Trust and reliability can lead to more favorable terms over time.

-

Market Research: Keep abreast of market trends and pricing variations. This knowledge empowers buyers to make informed decisions and recognize when pricing is inflated.

Disclaimer

The prices mentioned in this analysis are indicative and may fluctuate based on market conditions, supplier negotiations, and specific project requirements. Always consult with multiple suppliers to obtain accurate and competitive pricing tailored to your needs.

Alternatives Analysis: Comparing piston hydraulic pump With Other Solutions

Understanding Alternative Solutions to Piston Hydraulic Pumps

When selecting a hydraulic pump, businesses must evaluate various technologies that can deliver similar functionalities. While piston hydraulic pumps are renowned for their efficiency and performance, other alternatives like gear pumps and diaphragm pumps can also serve specific applications effectively. This analysis compares these alternatives based on key performance indicators to help buyers make informed decisions.

| Comparison Aspect | Piston Hydraulic Pump | Gear Pump | Diaphragm Pump |

|---|---|---|---|

| Performance | High pressure & flow | Moderate pressure & flow | Moderate pressure, variable flow |

| Cost | Moderate to high | Low to moderate | Moderate to high |

| Ease of Implementation | Requires precise installation | Simple installation | Relatively easy installation |

| Maintenance | Moderate (periodic checks) | Low (less frequent) | Moderate (seal replacements) |

| Best Use Case | Heavy machinery, industrial applications | General-purpose fluid transfer | Chemical handling, food processing |

What Are the Pros and Cons of Gear Pumps as an Alternative?

Gear pumps are a widely used alternative for hydraulic applications, known for their simplicity and efficiency. They operate by using two gears to move fluid, providing a consistent flow rate. The primary advantages of gear pumps include their lower initial cost and ease of maintenance. However, they typically handle lower pressures compared to piston pumps and may not be suitable for high-performance applications. Gear pumps are ideal for general-purpose fluid transfer in applications where precise pressure control is not critical.

How Do Diaphragm Pumps Compare to Piston Hydraulic Pumps?

Diaphragm pumps utilize a flexible diaphragm to create a pumping action, making them suitable for transferring corrosive or viscous fluids. One of the main advantages of diaphragm pumps is their ability to handle a wide range of fluids, including those that are sensitive to shear. They are relatively easy to install and maintain, with fewer moving parts than piston pumps. However, diaphragm pumps generally provide lower pressure and flow rates, which limits their use in heavy-duty applications. They are best suited for chemical handling and food processing, where fluid integrity is paramount.

Conclusion: How Should B2B Buyers Choose the Right Pump?

When selecting the right hydraulic pump, B2B buyers should consider their specific operational needs, including the type of fluid being pumped, the required flow rate, and the pressure levels necessary for their applications. Piston hydraulic pumps are best for high-pressure scenarios, while gear pumps offer a cost-effective solution for less demanding tasks. Diaphragm pumps shine in applications involving sensitive or corrosive fluids. By thoroughly evaluating these aspects, buyers can make informed choices that align with their operational goals and budget constraints.

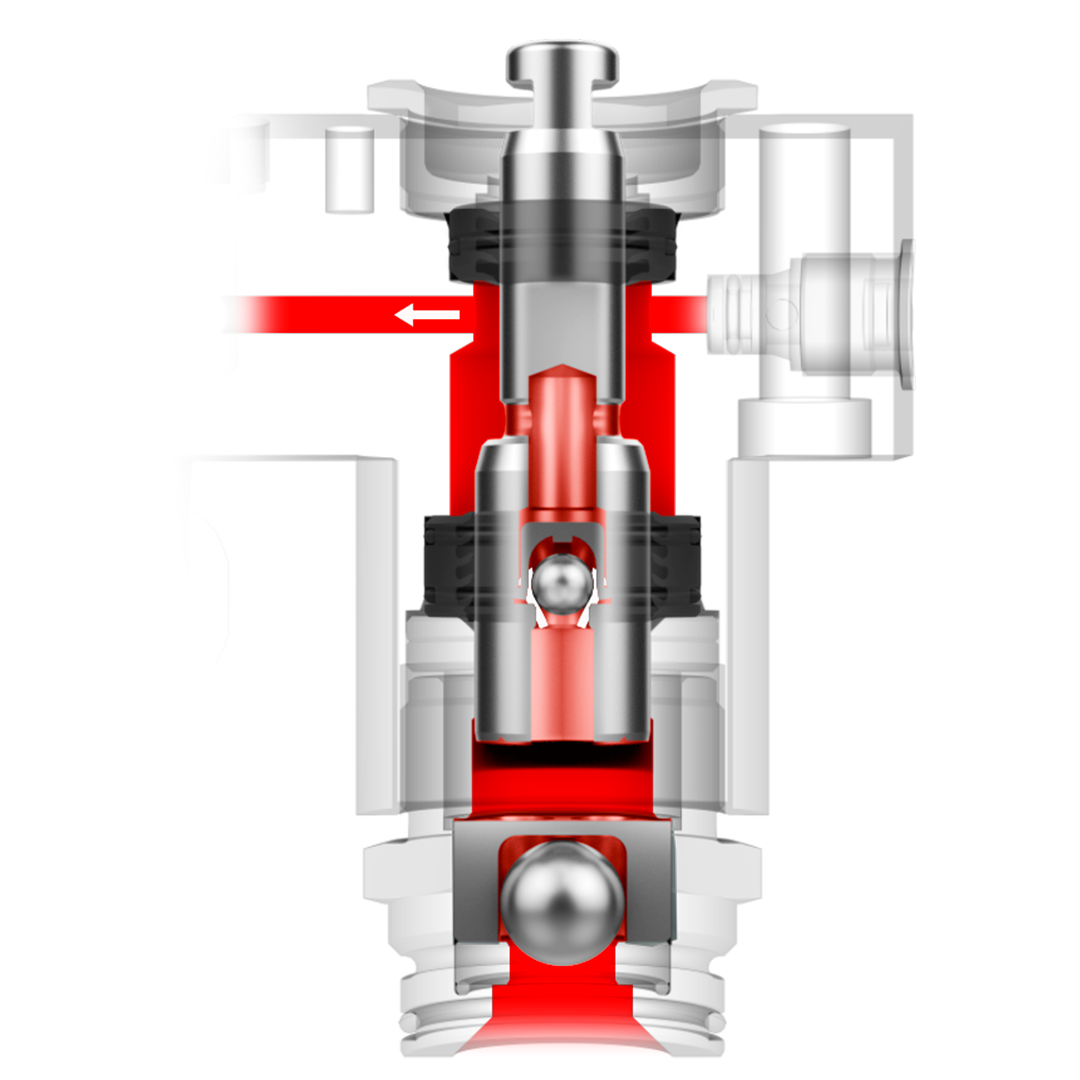

Essential Technical Properties and Trade Terminology for piston hydraulic pump

What Are the Key Technical Properties of Piston Hydraulic Pumps?

Piston hydraulic pumps are essential components in various industrial applications. Understanding their technical specifications is crucial for B2B buyers to ensure they select the right equipment for their needs. Here are several critical specifications to consider:

-

Pressure Rating (PSI)

The pressure rating indicates the maximum pressure the pump can handle safely. Typically expressed in pounds per square inch (PSI), this specification is vital for determining the pump’s suitability for specific applications. Buyers should match the pressure rating to their system’s requirements to prevent potential failures or inefficiencies. -

Flow Rate (GPM)

The flow rate, measured in gallons per minute (GPM), defines the volume of fluid the pump can move within a given time frame. A higher flow rate is essential for applications requiring rapid fluid movement. Understanding flow rate helps buyers assess the pump’s performance relative to their operational needs. -

Displacement Volume (CID)

Displacement volume, often expressed in cubic inches (CID), refers to the volume of fluid displaced with each pump cycle. This specification is crucial as it directly affects the efficiency and power output of the hydraulic system. Buyers should consider the displacement volume to ensure compatibility with their machinery. -

Mounting Configuration

The mounting configuration specifies how the pump is attached to other components. Options may include flange mounting or direct mounting styles. Proper alignment and secure mounting are essential for optimal operation and longevity. Buyers must ensure that the selected pump’s mounting configuration aligns with their existing setups. -

Shaft Size and Type

The shaft size and type influence the compatibility of the pump with other mechanical components. Different pumps may feature various shaft diameters and configurations, such as keyed or spline shafts. Buyers should assess their system’s requirements to choose a pump with a compatible shaft design. -

Material Composition

The material used in the construction of the pump affects durability and performance. Common materials include cast iron, aluminum, and composite materials. Understanding the material properties helps buyers evaluate the pump’s resistance to wear, corrosion, and temperature variations.

What Are Common Trade Terms Associated with Piston Hydraulic Pumps?

Navigating the landscape of hydraulic pumps often involves encountering specific trade terminology. Familiarity with these terms can streamline the purchasing process and improve communication with suppliers.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of hydraulic pumps, buyers may seek OEM components to ensure compatibility and reliability in their systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage their inventory effectively and avoid over-committing to purchases that exceed their immediate needs. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. When purchasing piston hydraulic pumps, an RFQ allows buyers to compare costs and terms from various vendors, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is essential for buyers engaged in international transactions to clarify shipping costs, risks, and delivery timelines. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Buyers must consider lead times when planning their operations to ensure that equipment is available when needed, minimizing downtime. -

Hydraulic Efficiency

Hydraulic efficiency indicates how effectively a hydraulic pump converts input power into hydraulic energy. Higher efficiency ratings are desirable as they lead to reduced energy costs and improved system performance. Buyers should evaluate hydraulic efficiency to optimize their operations.

By understanding these critical specifications and trade terms, B2B buyers can make informed decisions when sourcing piston hydraulic pumps, ensuring they meet their operational needs effectively.

Illustrative image related to piston hydraulic pump

Navigating Market Dynamics and Sourcing Trends in the piston hydraulic pump Sector

What Are the Current Market Dynamics and Key Trends in the Piston Hydraulic Pump Sector?

The global piston hydraulic pump market is experiencing significant growth driven by increased industrial automation, the rise of renewable energy projects, and heightened demand for efficient hydraulic systems across various sectors. In regions such as Africa, South America, the Middle East, and Europe, particularly in Germany and Nigeria, international B2B buyers are looking for products that offer reliability and efficiency. The shift towards variable volume piston pumps is a notable trend, as they allow for better control and adaptability to varying operational conditions, making them highly desirable in manufacturing and construction applications.

Emerging technologies, including IoT integration and advanced predictive maintenance analytics, are influencing sourcing strategies. These technologies enable companies to monitor pump performance in real-time, minimizing downtime and maintenance costs. Additionally, the adoption of digital platforms for sourcing and procurement is becoming prevalent, allowing buyers to compare products, prices, and suppliers more efficiently. As a result, businesses can make informed decisions and enhance their supply chain agility.

Moreover, the geopolitical landscape is impacting supply chain dynamics, with fluctuations in raw material costs and trade policies requiring buyers to navigate sourcing challenges. B2B buyers must remain vigilant and adaptable to these changes, ensuring they partner with suppliers who can provide not only quality products but also competitive pricing and reliable delivery times.

Illustrative image related to piston hydraulic pump

How Are Sustainability and Ethical Sourcing Impacting the Piston Hydraulic Pump Industry?

Sustainability is becoming increasingly crucial in the piston hydraulic pump sector, as environmental regulations tighten and consumers demand more eco-friendly products. The manufacturing process of hydraulic pumps can have a considerable environmental impact, from energy consumption to waste generation. Therefore, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainability through responsible sourcing practices and the use of environmentally friendly materials.

Ethical sourcing is also gaining traction, with buyers seeking suppliers that adhere to fair labor practices and maintain transparency throughout their supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential benchmarks for evaluating suppliers. Additionally, the use of ‘green’ materials, such as recycled metals and eco-friendly lubricants, is increasingly viewed as a competitive advantage.

By aligning with suppliers who prioritize sustainability and ethical practices, B2B buyers can enhance their corporate social responsibility (CSR) initiatives and appeal to environmentally conscious customers. This not only fosters brand loyalty but also mitigates risks associated with non-compliance and reputational damage.

Illustrative image related to piston hydraulic pump

What Is the Historical Context of Piston Hydraulic Pumps in B2B Markets?

The evolution of piston hydraulic pumps dates back to the late 19th century, with advancements in hydraulic technology significantly enhancing industrial processes. Initially, these pumps were primarily utilized in heavy machinery and construction equipment. Over the decades, the development of variable displacement pumps and improvements in materials science have expanded their application across various sectors, including agriculture, automotive, and aerospace.

As industries became more automated, the demand for reliable and efficient hydraulic systems surged, driving innovation in pump design and functionality. Today, piston hydraulic pumps are integral to numerous applications, from powering machinery to facilitating complex hydraulic circuits. The historical progression of this technology reflects the broader trends in industrialization and the ongoing pursuit of efficiency and performance in B2B operations.

Frequently Asked Questions (FAQs) for B2B Buyers of piston hydraulic pump

-

How do I solve issues with piston hydraulic pump performance?

To address performance issues with piston hydraulic pumps, start by checking the fluid levels and ensuring the correct type of hydraulic fluid is being used. Inspect for any leaks or blockages in the hydraulic lines and connections, as these can significantly impact performance. Additionally, evaluate the pump’s pressure settings and ensure they are calibrated correctly. Regular maintenance, including filter changes and thorough cleaning, can also prevent performance problems. If issues persist, consult with a qualified technician or the manufacturer for further diagnostics. -

What is the best piston hydraulic pump for high-pressure applications?

For high-pressure applications, consider piston hydraulic pumps designed to handle pressures above 4000 PSI. Look for variable displacement models, such as the Fluidyne A10V series, known for their efficiency and adaptability in demanding environments. Ensure the pump has suitable specifications for your application, including flow rate and shaft size. It’s also essential to evaluate the pump’s compatibility with your system’s hydraulic fluid and operational requirements to maximize performance and longevity. -

What factors should I consider when vetting suppliers of piston hydraulic pumps?

When vetting suppliers, consider their reputation, industry experience, and customer reviews. Verify their certifications and compliance with international quality standards to ensure product reliability. It’s also important to assess their production capabilities, lead times, and after-sales support, including warranty options. Engage with suppliers to understand their sourcing practices and whether they can accommodate customization requests. Establishing clear communication can help gauge their responsiveness and reliability. -

What is the typical minimum order quantity (MOQ) for piston hydraulic pumps?

Minimum order quantities for piston hydraulic pumps can vary significantly depending on the supplier and the specific product. Generally, MOQs may range from a single unit for standard models to larger quantities for custom or specialized pumps. It’s advisable to discuss your requirements directly with suppliers to negotiate MOQs that suit your purchasing needs. Some suppliers may offer flexible terms for first-time buyers or bulk orders, so exploring these options can be beneficial. -

What payment terms are common when purchasing piston hydraulic pumps internationally?

Common payment terms for international purchases of piston hydraulic pumps include upfront payment, partial payment upfront with the balance upon delivery, or letters of credit. Terms can vary based on supplier policies, order size, and buyer-supplier relationships. Ensure you discuss and agree on payment terms before finalizing the purchase to avoid misunderstandings. It’s also prudent to consider secure payment methods that offer buyer protection, particularly for larger transactions. -

How can I ensure quality assurance (QA) for my piston hydraulic pump purchases?

To ensure quality assurance, request detailed product specifications and compliance certificates from your supplier. It’s beneficial to inquire about their manufacturing processes and quality control measures, including testing protocols for their hydraulic pumps. If possible, arrange for third-party inspections or audits to verify the quality of the products before shipment. Establishing a clear return policy for defective items can also protect your investment and ensure satisfaction with your purchase. -

What logistics considerations should I keep in mind when importing piston hydraulic pumps?

When importing piston hydraulic pumps, consider shipping methods, customs duties, and import regulations specific to your country. Work with logistics providers experienced in handling industrial equipment to ensure timely and secure transportation. Be aware of lead times and plan for any potential delays due to customs clearance. It’s also important to confirm that the pumps are packaged appropriately to prevent damage during transit. Understanding these logistics aspects can streamline the import process and minimize risks. -

Can I customize piston hydraulic pumps for specific applications?

Yes, many manufacturers offer customization options for piston hydraulic pumps to meet specific application needs. Customizations may include adjustments to flow rates, pressure settings, and even physical dimensions to fit your existing systems. When discussing custom options, provide detailed specifications of your requirements to the supplier. It’s advisable to collaborate closely with the manufacturer during the design phase to ensure that the final product meets your operational expectations and performance standards.

Top 6 Piston Hydraulic Pump Manufacturers & Suppliers List

1. Hydro-Gear – Key Product

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Key product details for Piston Hydraulic Pumps include:

– Brands: Bondioli & Pavesi, DynaPac, Hydro-Gear, Lincoln Industrial, Reliance, Rexroth, SM Oleodinamica, VSG Hydraulics

– Price Range: $59.99 to $3,495.95

– Available Models:

1. Hydro-Gear TW-QFFB-NFFB-1XBX Hydraulic Pump – 0.36/0.36 cu in – $199.95

2. SM Oleodinamica P0A16LVUMIB1055 Pump – 0.97 cu in – $299.95

3. Rexroth A11VG19HW1/11…

2. Hi-Low – OG Series Pump

Domain: hi-low.net

Registered: 2005 (20 years)

Introduction: {“products”: [{“name”: “OG Series Pump”, “price”: “$395.00”}, {“name”: “Hollywood Series Pumps”, “price”: “$435.00”}, {“name”: “PERFORMANCE 2000 SERIES PUMP”, “price”: “$439.00”}, {“name”: “Eliminator series pump 1/2 inch ports”, “price”: “$459.00”}, {“name”: “Hi-low Signature Series Competition Pump”, “price”: “$469.00”}, {“name”: “Pro-hi-low elite series pump 3/4 inch ports”, “price”: “$499.00”}…

3. Panagon Systems – Hydraulic Piston Pumps

Domain: panagonsystems.com

Registered: 2000 (25 years)

Introduction: Hydraulic piston pumps move fluids in professional equipment and industrial machinery, known for high efficiency in high-pressure applications. Two major types: axial and radial, with fixed or variable displacement. Axial piston pumps have components like a shaft, swashplate, cylinder block, and valve plate, while radial piston pumps consist of a cylinder block, rotating camshaft, and pistons arra…

4. Yuken – Variable Displacement Piston Pumps

Domain: yuken-usa.com

Registered: 2004 (21 years)

Introduction: Yuken offers low noise/high efficiency, swash plate type variable displacement piston pumps. Key product series include: “AR” Series Variable Displacement Piston Pumps, “A” Series Variable Displacement Piston Pumps, “A3H” Series Variable Displacement Piston Pumps, “A3HG” Series High Pressure Variable Displacement Piston Pumps, “A7H” Series High Pressure Variable Displacement Piston Pumps, PAL Pump…

5. Black Magic Hydraulics – Piston Pumps

Domain: blackmagichydraulics.com

Registered: 2003 (22 years)

Introduction: Piston Pumps category includes 7 products, with subcategories for Piston Accumulated (5) and Piston Pump Assemblies (3).

6. Continental Hydraulics – PVX Series Variable Vane Pumps

Domain: continentalhydraulics.com

Registered: 1998 (27 years)

Introduction: Hydraulic Pumps – Continental Hydraulics offers a range of hydraulic pumps including Variable Vane Pumps, Piston Pumps, and Gear Pumps. Key product details include:

1. **PVX Series – Variable Vane Pumps**:

– Type: Hydraulically Compensated

– Displacements: 1 to 10 cu.in. (16.8 to 164 cc)

– Continuous Duty Pressures: up to 3000 PSI (210 Bar)

– Features: Application flexibility, su…

Strategic Sourcing Conclusion and Outlook for piston hydraulic pump

In today’s competitive landscape, strategic sourcing of piston hydraulic pumps is crucial for international B2B buyers aiming to optimize operational efficiency and cost-effectiveness. By carefully evaluating suppliers, assessing product specifications, and considering factors such as performance metrics and availability, businesses can ensure they are investing in high-quality pumps that meet their specific needs.

Moreover, the ability to source these pumps from diverse markets—including Europe, Africa, and South America—opens up opportunities to capitalize on varying pricing structures and technological advancements. Buyers should prioritize partnerships with reputable manufacturers and distributors who can provide reliable support and timely delivery, ultimately enhancing productivity and reducing downtime.

Illustrative image related to piston hydraulic pump

Looking ahead, the demand for advanced hydraulic solutions is expected to rise, driven by industrial growth in sectors such as construction, agriculture, and manufacturing. Now is the time for B2B buyers to seize this opportunity by aligning their sourcing strategies with market trends and technological innovations. Engage with trusted suppliers and invest in piston hydraulic pumps that will not only meet current requirements but also adapt to future demands. Take action today to secure your competitive edge in the evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.