Top 6 Latch Coolers Suppliers (And How to Choose)

Introduction: Navigating the Global Market for latch coolers

In today’s competitive landscape, sourcing reliable latch coolers can pose a significant challenge for international B2B buyers. With varying product specifications, regional regulations, and diverse supplier offerings, decision-makers must navigate a complex web of options to ensure they select the most suitable products for their needs. This comprehensive guide delves into the multifaceted world of latch coolers, exploring the different types available, their specific applications, and essential supplier vetting strategies.

From Africa to South America, and across the Middle East and Europe, businesses face unique market dynamics that influence their purchasing decisions. This guide is designed to empower B2B buyers by providing actionable insights on cost considerations, quality standards, and the latest innovations in latch cooler technology. By understanding the nuances of the global market and evaluating suppliers effectively, organizations can enhance their operational efficiency and ensure product reliability.

Whether you are seeking durable stainless steel latches or innovative polymer solutions, our guide equips you with the knowledge needed to make informed purchasing decisions. We aim to simplify your sourcing process, allowing you to focus on what matters most: growing your business and meeting your customers’ demands.

Understanding latch coolers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Latches | Durable, rust-resistant, adjustable tension features | Food and beverage distribution, outdoor events | Pros: Long-lasting, secure closure. Cons: Higher cost compared to plastic options. |

| Plastic Latches | Lightweight, cost-effective, available in various colors | Retail, promotional giveaways | Pros: Economical, easy to replace. Cons: Less durable than metal options. |

| Rubber Latches | Soft-touch, environmentally friendly materials | Camping gear, sports equipment | Pros: Flexible, quiet operation. Cons: May wear out faster than hard materials. |

| Lockable Latches | Security features to prevent unauthorized access | Transportation, sensitive cargo handling | Pros: Enhanced security, peace of mind. Cons: Additional mechanism may complicate use. |

| EZCam Replacement Latches | Designed for specific cooler models, easy installation | Outdoor recreation, fishing, hunting | Pros: Custom fit, simple replacement process. Cons: Limited compatibility across brands. |

What Are the Characteristics of Stainless Steel Latches?

Stainless steel latches are known for their durability and resistance to rust and corrosion, making them ideal for harsh outdoor environments. They often feature adjustable tension to ensure a secure fit, which is particularly beneficial for B2B applications in food and beverage distribution where reliability is paramount. When purchasing, buyers should consider the latch’s compatibility with their cooler models and the potential for higher upfront costs, which may be offset by their longevity.

Illustrative image related to latch coolers

How Do Plastic Latches Compare in Terms of Cost and Functionality?

Plastic latches are lightweight and economical, appealing to businesses looking for cost-effective solutions. They come in various colors and styles, making them suitable for promotional items or retail applications. However, while they are easy to replace, their durability is less than that of metal counterparts. Buyers should weigh the lower price against the potential need for more frequent replacements, especially in high-use scenarios.

Why Choose Rubber Latches for Your Equipment?

Rubber latches offer a soft-touch feel and are often made from environmentally friendly materials, making them a popular choice for camping gear and sports equipment. Their flexibility allows for quiet operation, which can be advantageous in settings where noise reduction is desired. However, businesses should be aware that rubber latches may wear out faster than their metal or plastic counterparts, necessitating regular inspections and replacements.

What Benefits Do Lockable Latches Provide for Security?

Lockable latches are designed to enhance security by preventing unauthorized access to cooler contents. This feature is particularly important in industries involving transportation or handling sensitive cargo. While they provide peace of mind, buyers should consider that the added locking mechanism can complicate the user experience. Ensuring that staff is trained in their use may be necessary to avoid operational delays.

Illustrative image related to latch coolers

What Should You Know About EZCam Replacement Latches?

EZCam replacement latches are tailored for specific cooler models, making them a convenient option for businesses needing quick fixes. Their design allows for easy installation, which is beneficial for outdoor recreation companies that require reliable equipment without extensive downtime. However, compatibility is limited to certain brands, so businesses should verify fitment before purchase to avoid issues.

Key Industrial Applications of latch coolers

| Industry/Sector | Specific Application of latch coolers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Transporting perishables for catering and events | Maintains food safety and quality during transport | Durability, insulation efficiency, and lockable features |

| Outdoor Recreation | Camping and expedition gear for adventure tourism | Enhances customer experience with reliable cooling | Lightweight materials, weather resistance, and portability |

| Construction & Mining | On-site storage for food and beverages | Reduces spoilage and improves worker satisfaction | Robustness, ease of access, and compatibility with equipment |

| Agriculture | Transporting vaccines and medical supplies for livestock | Ensures temperature control for sensitive products | Compliance with health regulations and insulation standards |

| Logistics & Distribution | Shipping goods in extreme climates | Minimizes product loss and extends shelf life | Customization options and shipping weight considerations |

How Are Latch Coolers Used in the Food & Beverage Industry?

In the food and beverage sector, latch coolers are essential for transporting perishables to various events, including catering services and outdoor festivals. These coolers maintain the required temperature to ensure food safety and prevent spoilage, thus protecting the business’s reputation and compliance with health regulations. Buyers should look for durable materials that can withstand frequent transport, as well as lockable features to secure contents during transit, especially in regions prone to theft.

What Role Do Latch Coolers Play in Outdoor Recreation?

For the outdoor recreation industry, latch coolers serve as indispensable equipment for camping and adventure tourism. They provide reliable cooling for food and beverages, enhancing the overall customer experience during excursions. Buyers should prioritize lightweight and weather-resistant designs that can endure rugged conditions while being easy to transport. Features like insulation efficiency and secure latching mechanisms are critical, particularly for international buyers in diverse climates.

How Are Latch Coolers Beneficial in Construction & Mining?

In construction and mining, latch coolers are used to store food and beverages on-site, ensuring that workers have access to refreshment while maintaining product integrity. This practice not only reduces spoilage but also boosts employee morale and productivity. When sourcing latch coolers for these applications, businesses should consider robustness and ease of access, as well as compatibility with other equipment used on-site, ensuring they can withstand harsh environments.

Why Are Latch Coolers Important for Agriculture?

In agriculture, latch coolers are vital for transporting vaccines and medical supplies for livestock. These products require strict temperature control to maintain efficacy, making reliable cooling solutions essential for compliance with health and safety regulations. Buyers in this sector should focus on coolers that meet specific insulation standards and can handle the transportation of sensitive products, particularly in regions with extreme temperatures.

How Do Latch Coolers Enhance Logistics & Distribution?

In the logistics and distribution sector, latch coolers are used to ship goods in extreme climates, helping to minimize product loss and extend shelf life. This is particularly important for businesses dealing with perishable items or temperature-sensitive products. When sourcing latch coolers, companies should consider customization options to meet specific shipping needs, as well as the overall weight of the cooler to optimize transportation costs.

3 Common User Pain Points for ‘latch coolers’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Latches for Harsh Environments

The Problem: B2B buyers often operate in challenging environments where cooler latches are exposed to extreme temperatures, moisture, and abrasive conditions. For instance, companies involved in outdoor recreation, fishing, or transportation across rugged terrains need latches that can withstand heavy use without failing. A common issue arises when buyers select latches made from inadequate materials that corrode or break under stress, leading to costly downtime and replacements.

The Solution: To mitigate this problem, buyers should prioritize sourcing latches made from high-quality materials such as stainless steel or advanced polymers that are designed for durability and resistance to environmental factors. Engaging with suppliers who specialize in industrial-grade latches can provide insights into the best products available. Furthermore, opting for adjustable latches allows for tension customization, which can enhance the latch’s longevity and performance. Buyers should also consider latches with warranties that cover replacements for defects or failures, ensuring that they have a reliable backup plan in case of issues.

Scenario 2: Incompatibility with Existing Cooler Models

The Problem: Many businesses have a fleet of coolers of varying brands and models, and a frequent challenge is finding compatible replacement latches. When a latch fails, the buyer may struggle to find a suitable replacement that fits the existing cooler model, leading to delays in operations and potential loss of product integrity during transport.

Illustrative image related to latch coolers

The Solution: To address this compatibility issue, buyers should maintain a detailed inventory of their cooler models and their corresponding latch specifications. This includes noting the type, size, and manufacturer of the cooler. When sourcing replacement latches, buyers should consult the manufacturer’s specifications and product databases, which often include compatibility information. Additionally, working with suppliers that offer a variety of latches can simplify the process. Creating a proactive maintenance schedule for cooler inspections can help identify latch wear and tear before failure occurs, allowing for timely replacements.

Scenario 3: High Replacement Costs Leading to Budget Constraints

The Problem: Frequent latch replacements can place a significant strain on a company’s budget, especially for businesses that rely heavily on latch coolers for logistics and product delivery. For instance, companies in the food and beverage sector may find that the costs associated with replacing latches impact their overall operational expenses, reducing their profit margins.

The Solution: To alleviate budget constraints, businesses should consider investing in higher-quality latches that may have a higher upfront cost but offer superior durability and performance over time. Conducting a cost-benefit analysis can illustrate the long-term savings associated with investing in premium latches, reducing the frequency of replacements. Additionally, establishing a relationship with a reliable supplier can lead to bulk purchasing discounts, lowering the overall cost per latch. Implementing a routine maintenance program that includes regular inspections and cleaning of latches can also extend their lifespan, ultimately minimizing replacement frequency and expense.

Strategic Material Selection Guide for latch coolers

What Are the Key Materials Used in Latch Coolers?

When selecting latches for coolers, the choice of material significantly impacts performance, durability, and suitability for various applications. Here, we analyze four common materials used in latch coolers: stainless steel, hybrid plastic, rubber, and TPE polymer. Each material offers distinct properties that can influence the decision-making process for international B2B buyers.

How Does Stainless Steel Perform in Latch Coolers?

Stainless steel is renowned for its strength and corrosion resistance, making it an excellent choice for latch coolers exposed to harsh environments. It typically withstands high temperatures and pressures, ensuring reliable performance in diverse conditions.

Pros: Stainless steel latches are highly durable, resistant to rust and wear, and can endure extreme temperatures. They also provide a premium feel and aesthetic appeal, which can enhance the overall product quality perception.

Cons: The primary drawbacks include higher manufacturing costs and potential weight issues, which may not be suitable for all cooler designs. Additionally, stainless steel can be prone to scratches, which may affect its appearance over time.

Impact on Application: Stainless steel latches are ideal for heavy-duty applications, especially in industries like outdoor recreation and transportation, where reliability is paramount.

Illustrative image related to latch coolers

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe and the Middle East may prioritize certifications that validate the quality and performance of stainless steel components.

What Advantages Do Hybrid Plastics Offer for Latch Coolers?

Hybrid plastics combine the benefits of traditional plastics with enhanced properties, including UV resistance and impact strength. These materials are often used in latches that require a balance between flexibility and durability.

Pros: Hybrid plastics are lightweight, cost-effective, and resistant to environmental factors such as UV rays and moisture. They can also be molded into complex shapes, allowing for innovative designs.

Cons: While they offer good durability, hybrid plastics may not match the strength of metal options. Over time, exposure to extreme temperatures can lead to material degradation.

Illustrative image related to latch coolers

Impact on Application: These latches are suitable for moderate-duty applications where weight savings are essential, such as in portable coolers for camping or picnics.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local climate conditions, as prolonged exposure to UV light can affect the longevity of hybrid plastic latches.

Why Choose Rubber for Latch Coolers?

Rubber is often used in latches for its flexibility and ability to absorb shock, providing a secure closure without compromising the integrity of the cooler.

Illustrative image related to latch coolers

Pros: Rubber latches are highly resilient, providing excellent sealing capabilities and resistance to wear and tear. They are also lightweight and can be produced at a lower cost.

Cons: The main limitation of rubber is its susceptibility to degradation from UV exposure and extreme temperatures, which can lead to cracking or loss of elasticity.

Impact on Application: Rubber latches are best suited for applications requiring frequent opening and closing, such as in soft-sided coolers.

Illustrative image related to latch coolers

Considerations for International Buyers: Compliance with environmental regulations regarding rubber materials is essential. Buyers from Europe may need to ensure that rubber components meet REACH compliance standards.

How Does TPE Polymer Compare for Latch Coolers?

Thermoplastic elastomer (TPE) polymer is a versatile material that combines the properties of rubber and plastic. It is increasingly popular in latch applications for its soft touch and durability.

Pros: TPE is resistant to UV light, chemicals, and temperature variations, making it an excellent choice for outdoor applications. It also provides a comfortable grip, enhancing user experience.

Cons: While TPE offers good performance, it may not be as strong as metal alternatives, limiting its use in heavy-duty applications.

Impact on Application: TPE latches are ideal for consumer-grade coolers, where ease of use and comfort are prioritized.

Considerations for International Buyers: Buyers should verify that TPE products comply with local regulations regarding material safety and environmental impact, especially in regions with strict chemical regulations.

Summary Table of Material Selection for Latch Coolers

| Material | Typical Use Case for latch coolers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty outdoor coolers | High durability and corrosion resistance | Higher cost and weight | High |

| Hybrid Plastic | Portable moderate-duty coolers | Lightweight and cost-effective | Less strength compared to metals | Medium |

| Rubber | Soft-sided coolers | Excellent sealing and shock absorption | Degradation from UV exposure | Low |

| TPE Polymer | Consumer-grade coolers | UV and chemical resistance | Not suitable for heavy-duty use | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions based on specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for latch coolers

What Are the Main Stages of Manufacturing Latch Coolers?

The manufacturing process for latch coolers is a multi-stage operation that ensures durability, functionality, and compliance with international standards. Understanding these stages helps B2B buyers select high-quality products that meet their operational needs.

Illustrative image related to latch coolers

Material Preparation: How Are Raw Materials Selected?

The first stage in the manufacturing of latch coolers involves sourcing and preparing materials. Typically, manufacturers use high-grade plastics, stainless steel, and rubber for latches due to their strength and resistance to environmental factors. Suppliers often conduct rigorous evaluations to ensure materials meet specific performance standards, such as UV resistance for outdoor use and corrosion resistance for wet environments. For B2B buyers, it is essential to inquire about the material specifications and sourcing practices to ensure compliance with regional regulations.

Forming: What Techniques Are Used to Shape Components?

Once materials are prepared, they undergo forming processes. This can include injection molding for plastic components and stamping or machining for metal parts. For instance, advanced injection molding techniques allow for precision in creating complex shapes that fit various cooler designs. Buyers should consider the technology used in the forming process, as this can affect the durability and longevity of the latches. Requesting technical specifications or process descriptions from suppliers can provide insights into their capabilities.

Assembly: How Are Latch Components Put Together?

After forming, the next stage is assembly. This involves integrating various components, such as latches, brackets, and screws, into a cohesive unit. Manufacturers often use automated assembly lines to improve efficiency and consistency, ensuring that each latch meets quality standards. B2B buyers should assess the assembly processes, particularly the use of automated versus manual labor, as this can influence both cost and quality.

Finishing: What Final Touches Are Applied?

The finishing stage involves applying coatings or treatments to enhance durability and aesthetics. This may include powder coating for metal parts or UV protection for plastic components. Finishing not only improves the product’s appearance but also extends its lifespan, making it a crucial consideration for buyers. Companies should inquire about the types of finishes used and their expected performance in different environments.

Illustrative image related to latch coolers

What Quality Control Measures Are Implemented in Latch Cooler Manufacturing?

Quality assurance is critical in the production of latch coolers, ensuring that each product meets both customer expectations and regulatory requirements. Manufacturers often adhere to international standards like ISO 9001, which outlines requirements for a quality management system.

What International Standards Are Relevant for Latch Coolers?

For B2B buyers, understanding the relevant international standards is vital. ISO 9001 provides a framework for consistent quality, while other certifications like CE (Conformité Européenne) and API (American Petroleum Institute) ensure compliance with specific industry requirements. Buyers should verify that their suppliers hold these certifications, as they can indicate a commitment to quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control in latch cooler manufacturing typically involves several checkpoints throughout the production process:

- Incoming Quality Control (IQC): This initial inspection focuses on raw materials, ensuring they meet predefined standards before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC monitors processes and identifies any deviations from quality standards in real-time.

- Final Quality Control (FQC): This final inspection assesses the complete product before it leaves the factory. It often includes functional testing to ensure that latches operate correctly under various conditions.

B2B buyers should inquire about these quality checkpoints and request documentation to validate the processes used by their suppliers.

What Common Testing Methods Are Employed?

Manufacturers employ various testing methods to ensure product reliability. These may include:

- Mechanical Testing: Evaluating the strength and durability of latches under stress to ensure they can withstand operational demands.

- Environmental Testing: Exposing latches to extreme temperatures, moisture, and UV light to assess performance in different conditions.

- Functionality Testing: Ensuring that latches operate smoothly and securely under normal use conditions.

B2B buyers can request test reports or certifications to confirm that products have passed these assessments.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks. Here are some actionable steps:

What Audits and Reports Should Buyers Request?

Buyers should conduct thorough audits of potential suppliers. This can include:

- Quality Management System Audits: Review the supplier’s adherence to ISO 9001 or other relevant standards.

- Production Process Audits: Assess the manufacturing processes to identify potential risks or inefficiencies.

- Supplier Performance Reports: Request documentation on past performance, including defect rates and customer feedback.

How Can Third-Party Inspections Enhance Assurance?

Engaging third-party inspection services provides an additional layer of assurance. These independent entities can conduct audits and inspections, ensuring that suppliers adhere to quality standards without bias. B2B buyers should consider incorporating third-party inspections into their procurement processes, especially for high-volume orders.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should also be aware of specific nuances in quality control related to their regions. For example:

Illustrative image related to latch coolers

- Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers must ensure that their suppliers comply with local laws to avoid legal issues.

- Cultural Expectations: Understanding cultural differences in quality perception can help buyers communicate their requirements effectively and build stronger relationships with suppliers.

By thoroughly understanding the manufacturing processes and quality assurance measures in the latch cooler industry, B2B buyers can make informed decisions that align with their operational needs and quality expectations. This knowledge not only aids in supplier selection but also helps in establishing long-term partnerships that drive business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch coolers’

In the competitive landscape of B2B procurement, sourcing latch coolers requires a strategic approach to ensure you make informed decisions that align with your business needs. This guide provides a systematic checklist to help international buyers navigate the complexities of sourcing latch coolers effectively.

Step 1: Define Your Technical Specifications

Before diving into the procurement process, clearly outline your requirements for latch coolers. Consider factors such as size, material, insulation type, and intended use (e.g., outdoor adventures, commercial transport). Documenting these specifications will help streamline your search and ensure that potential suppliers can meet your exact needs.

Step 2: Research Market Trends and Pricing

Understanding market trends is crucial for making informed purchasing decisions. Investigate the average price range for latch coolers in your target regions, such as Africa, South America, and Europe. Analyze how different materials (e.g., stainless steel vs. plastic) and features impact pricing, and keep an eye on emerging brands that may offer innovative solutions at competitive prices.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to thoroughly vet your suppliers. Request company profiles, product catalogs, and references from previous clients, particularly those in similar industries or geographic areas. This step will help you assess the supplier’s reliability, product quality, and capacity to meet your demands.

- Look for certifications: Ensure suppliers have necessary certifications and quality assurances relevant to your region, which can indicate a commitment to quality.

- Review customer feedback: Check online reviews and testimonials to gauge overall customer satisfaction.

Step 4: Request Samples for Quality Assessment

Once you’ve narrowed down potential suppliers, request samples of their latch coolers. This allows you to evaluate the product’s quality, durability, and functionality firsthand. Pay attention to the latch mechanism, insulation performance, and overall build quality.

- Test in real conditions: If possible, conduct tests in environments similar to where the coolers will be used to assess performance.

- Compare across suppliers: Evaluate samples from multiple suppliers to identify the best fit for your needs.

Step 5: Negotiate Terms and Conditions

After selecting a supplier based on product quality and performance, negotiate pricing, delivery timelines, and payment terms. A well-structured agreement can lead to better pricing and favorable conditions for future orders.

- Discuss warranty and support: Ensure you understand the warranty terms and after-sales support available, which is crucial for long-term satisfaction.

- Consider bulk order discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

Step 6: Finalize Logistics and Supply Chain Considerations

Before placing your order, confirm logistics details, including shipping methods, estimated delivery times, and customs requirements for international orders. This ensures that you are fully prepared for the arrival of your latch coolers without unexpected delays.

Illustrative image related to latch coolers

- Assess shipping costs: Calculate total costs, including shipping, to avoid surprises that could affect your budget.

- Plan for contingencies: Have a plan in place for potential supply chain disruptions, particularly if sourcing from overseas.

Step 7: Establish a Relationship for Future Sourcing

Once your order is fulfilled, maintain a good relationship with your supplier for future needs. Regular communication can lead to better pricing, priority service, and insights into new products or technologies that may benefit your business.

- Provide feedback: Share your experiences with the supplier to help them improve their services and products.

- Stay informed: Keep abreast of any updates or changes in the supplier’s offerings that could enhance your procurement strategy.

By following these steps, B2B buyers can navigate the procurement process for latch coolers with confidence, ensuring they select the right products and suppliers to meet their specific needs.

Comprehensive Cost and Pricing Analysis for latch coolers Sourcing

What Are the Key Cost Components in Latch Cooler Manufacturing?

When sourcing latch coolers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. For example, latches made from stainless steel are generally more expensive than those made from plastic due to higher raw material costs and durability. Hybrid materials may offer a balance of cost and performance.

-

Labor: Labor costs vary by region and the complexity of the latch design. In regions with higher labor costs, manufacturers may need to optimize production processes or consider automation to remain competitive.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and administrative expenses. Efficient operations can help lower these overhead costs.

-

Tooling: Custom molds and tools for latch production can require significant investment. The initial tooling costs are often amortized over larger production runs, making it crucial to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring that latches meet required specifications adds to the overall cost. Investing in robust QC processes can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs, which can be influenced by distance, shipping methods, and packaging, are vital in determining the total landed cost of latches. International buyers should factor in customs duties and taxes.

-

Margin: Manufacturers will include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Affect Latch Cooler Sourcing?

Several factors influence the pricing of latch coolers:

-

Volume and Minimum Order Quantities (MOQs): Bulk orders can lead to significant discounts, making it essential for buyers to assess their needs and negotiate MOQs that align with their budget.

-

Specifications and Customization: Customized latches will typically incur higher costs due to the need for bespoke tooling and design work. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, ASTM) can increase costs but may lead to better durability and performance. Assessing the total cost of ownership (TCO) is crucial here.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer higher quality but at a premium, while emerging manufacturers might provide competitive pricing but less reliability.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is essential for accurately calculating total costs, as these terms dictate who is responsible for shipping costs and risks.

What Tips Can Help Buyers Negotiate Better Prices for Latch Coolers?

-

Negotiate Wisely: Leverage volume purchases to negotiate better pricing. Suppliers are often willing to provide discounts for larger orders, which can significantly reduce unit costs.

-

Focus on Total Cost of Ownership: Evaluate the long-term costs associated with latches, including maintenance and potential replacements. Investing in higher-quality products may reduce overall expenses.

-

Research Market Rates: Understanding the market pricing for latch coolers can empower buyers during negotiations. Collect quotes from multiple suppliers to gauge competitive pricing.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have unique pricing structures due to varying labor costs, tariffs, and shipping expenses. Buyers from Africa, South America, the Middle East, and Europe should consider these factors in their negotiations.

-

Consider Long-Term Relationships: Building a strong relationship with suppliers can lead to better pricing and more favorable terms over time. Suppliers may prioritize loyal customers during pricing discussions.

Conclusion

Sourcing latch coolers involves a multifaceted cost and pricing analysis. By understanding the key cost components, price influencers, and negotiation tactics, international B2B buyers can make informed decisions that enhance their purchasing strategy. Always remember that prices can fluctuate, and it is advisable to request quotes that reflect current market conditions.

Alternatives Analysis: Comparing latch coolers With Other Solutions

Exploring Alternatives to Latch Coolers for Temperature Control Solutions

When evaluating temperature control solutions, latch coolers stand out for their durability and effectiveness in preserving cold temperatures. However, various alternatives can serve similar purposes, each with its unique advantages and disadvantages. Understanding these options allows B2B buyers to make informed purchasing decisions tailored to their operational needs.

Illustrative image related to latch coolers

| Comparison Aspect | Latch Coolers | Insulated Shipping Containers | Refrigerated Trucks |

|---|---|---|---|

| Performance | Excellent insulation; maintains temperature for extended periods | High thermal efficiency; suitable for bulk transport | Superior temperature control; ideal for perishable goods |

| Cost | Moderate investment; costs vary by brand and features | Higher upfront costs; potential for savings in bulk shipping | Significant investment; ongoing operational costs |

| Ease of Implementation | Simple to use; portable and easy to handle | Requires proper loading; may need special training | Requires logistics management; can be complex to operate |

| Maintenance | Low maintenance; occasional cleaning needed | Moderate maintenance; cleaning and inspection required | High maintenance; regular checks and repairs necessary |

| Best Use Case | Outdoor events, camping, and small-scale transport | Long-distance shipping of temperature-sensitive goods | Large-scale distribution of perishable products |

What Are the Advantages and Disadvantages of Insulated Shipping Containers?

Insulated shipping containers are designed to maintain stable temperatures during transit. They offer high thermal efficiency, making them suitable for transporting bulk items over long distances. One of the key advantages is their ability to protect against external temperature fluctuations, ensuring product integrity. However, they come with higher upfront costs, which might not be justifiable for smaller operations. Additionally, proper loading techniques and potential training for staff can complicate their use.

How Do Refrigerated Trucks Compare to Latch Coolers?

Refrigerated trucks provide superior temperature control, making them ideal for transporting perishable goods across longer distances. Their main advantage lies in their ability to maintain precise temperature settings, which is crucial for food safety and quality. However, the investment required for refrigerated trucks is significantly higher, along with ongoing operational costs such as fuel and maintenance. Moreover, managing logistics and ensuring compliance with safety regulations adds complexity to their operation.

Making the Right Choice: How Can B2B Buyers Select the Best Solution?

When choosing between latch coolers and alternative solutions like insulated shipping containers or refrigerated trucks, B2B buyers should assess their specific needs and operational scale. For businesses focused on outdoor events or small-scale distribution, latch coolers may offer the right balance of performance and cost. Conversely, companies needing to transport larger quantities of perishable items over long distances may find insulated shipping containers or refrigerated trucks more suitable despite their higher costs and complexity.

Ultimately, understanding the unique advantages of each option allows buyers to align their investment with their operational goals, ensuring they select the most effective solution for their temperature control needs.

Illustrative image related to latch coolers

Essential Technical Properties and Trade Terminology for latch coolers

What Are the Key Technical Properties of Latch Coolers?

When selecting latch coolers, understanding critical specifications is essential for ensuring product durability, functionality, and compatibility with specific use cases. Here are several key technical properties to consider:

-

Material Composition

The materials used in latch coolers typically include plastic, stainless steel, and polymer blends. Stainless steel is favored for its strength and resistance to corrosion, making it ideal for outdoor and marine environments. Hybrid materials, such as TPE (thermoplastic elastomer), provide a soft touch while being durable and resistant to UV rays. Choosing the right material affects longevity and performance, especially in harsh conditions. -

Load Capacity

Each latch is designed to withstand a specific load, which is crucial for maintaining the integrity of the cooler during transport. It is important to match the latch’s load capacity with the cooler’s intended use, ensuring that it can securely hold the cooler lid closed under various conditions. In B2B transactions, knowing the load capacity helps buyers avoid product failures that could lead to costly losses. -

Adjustability

Many high-performance latches feature adjustable tension settings. This allows users to customize the latch according to the cooler’s conditions and contents. Adjustable latches can enhance the sealing capability of the cooler, leading to better temperature retention and improved user satisfaction. For B2B buyers, this flexibility can reduce the need for multiple latch types, simplifying inventory management. -

Compatibility and Fit

Latches are often designed to fit specific cooler models or types. Understanding the compatibility of latches with different cooler brands and models is critical to ensure proper function. Buyers should verify that the latches fit their existing coolers or that they are purchasing latches designed for their specific needs. This specificity can help prevent operational disruptions and the need for returns or replacements. -

Warranty and Lifecycle

A robust warranty often accompanies quality latches, indicating the manufacturer’s confidence in the product. This aspect is particularly important for B2B buyers who require assurance that they are investing in durable components. Evaluating warranty terms can provide insights into the expected lifespan and potential return on investment for latch coolers.

What Are Common Trade Terms Related to Latch Coolers?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s end product. Understanding OEM relationships can help buyers identify reliable sources for latches that meet their quality standards and specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their orders and manage inventory effectively. It is particularly relevant for international buyers who may face logistical challenges with smaller quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. Crafting a comprehensive RFQ ensures that buyers receive accurate quotes, allowing for informed decision-making in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, as it clarifies the obligations of each party and can affect overall costs. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for managing supply chain efficiency and ensuring that products are available when needed. This is particularly important in industries where timely delivery can impact operations. -

After-Sales Support

This term encompasses the services provided by a manufacturer or supplier after the purchase has been made, including installation, maintenance, and warranty services. Strong after-sales support can enhance customer satisfaction and loyalty, making it an essential consideration for B2B buyers when selecting suppliers.

By grasping these technical properties and trade terms, buyers can make informed decisions that align with their operational needs and strategic objectives.

Illustrative image related to latch coolers

Navigating Market Dynamics and Sourcing Trends in the latch coolers Sector

What Are the Current Market Trends Impacting the Latch Coolers Sector?

The latch coolers market is experiencing dynamic shifts driven by several global factors. Increasing outdoor recreational activities, the rise in food and beverage preservation needs, and a growing demand for portable cooling solutions are propelling market growth. Particularly in regions like Africa, South America, the Middle East, and Europe, there is a noticeable rise in consumer interest in high-quality, durable cooler products. B2B buyers are increasingly looking for versatile latch systems that can fit a variety of cooler models, thus driving demand for universal and customizable latch solutions.

Emerging technologies are also influencing sourcing trends within this sector. The integration of e-commerce platforms allows buyers to easily compare products, read reviews, and access warranties, thereby enhancing the purchasing experience. Additionally, advancements in materials science are leading to the development of latches made from hybrid plastics and stainless steel, which offer improved durability and weather resistance. As businesses prioritize efficiency, suppliers offering streamlined logistics and transparent communication are becoming more appealing.

Moreover, the ongoing trend towards personalization is evident, with companies providing customizable latch options that cater to specific customer needs. International buyers should consider these trends when sourcing latch coolers to ensure they remain competitive and meet evolving consumer expectations.

How Does Sustainability Influence Sourcing Decisions in the Latch Coolers Industry?

Sustainability is increasingly shaping the sourcing decisions of B2B buyers in the latch coolers sector. As awareness of environmental issues grows, companies are under pressure to adopt ethical sourcing practices and reduce their carbon footprint. This shift is particularly relevant for international buyers from regions where regulatory frameworks are becoming stricter regarding environmental impact.

The use of environmentally responsible materials, such as recycled plastics and sustainably sourced metals, is gaining traction. Buyers should seek suppliers that emphasize sustainable manufacturing processes, which not only reduce waste but also enhance product lifecycle. Certifications for ‘green’ materials can serve as a benchmark for evaluating potential partners.

Furthermore, ethical supply chains are becoming a focal point for consumers, leading to increased scrutiny of sourcing practices. Buyers can leverage this trend by aligning with manufacturers who prioritize fair labor practices and transparency in their supply chains. This alignment not only meets consumer demand but also bolsters brand reputation in a competitive market.

What Is the Historical Context of the Latch Coolers Market?

The latch coolers market has evolved significantly over the past few decades. Initially, coolers were basic, utilitarian products designed for functionality rather than durability or style. However, as outdoor activities gained popularity, consumer expectations shifted towards more robust and aesthetically pleasing designs.

The introduction of advanced materials like rotomolded plastics revolutionized the industry, offering enhanced insulation and sturdiness. This change paved the way for innovative latch designs that improved usability and security. As brands began to compete on quality and performance, the importance of reliable latching mechanisms became evident, leading to the diverse array of products available today.

In conclusion, understanding market dynamics, sustainability imperatives, and the historical evolution of latch coolers can empower B2B buyers to make informed sourcing decisions that align with both business goals and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of latch coolers

-

How do I choose the right latch cooler for my business needs?

Selecting the appropriate latch cooler involves assessing several factors including size, material, and intended use. Determine the volume of goods you need to store and transport, as cooler sizes can vary significantly. Additionally, consider the cooler’s material; rotomolded coolers tend to offer superior durability and insulation. If you operate in extreme conditions, latches made from stainless steel or robust polymers are preferable. Finally, evaluate any specific features, such as lockable latches for security or adjustable tension for ease of use, to ensure the cooler meets your operational requirements. -

What are the advantages of using stainless steel latches in coolers?

Stainless steel latches provide enhanced durability and corrosion resistance, making them ideal for harsh environments and frequent use. They are less likely to break or wear out compared to plastic alternatives, ensuring long-term reliability. Additionally, stainless steel latches often offer a more secure closure, which is essential for transporting valuable or sensitive items. This is particularly important for businesses operating in sectors like food service or pharmaceuticals, where maintaining temperature control is critical. Investing in stainless steel latches can ultimately reduce maintenance costs and improve customer satisfaction. -

What customization options are available for latch coolers?

Many manufacturers offer customization options for latch coolers to meet specific business needs. Customizations can include branding with your company logo, unique color schemes, or specialized latch designs tailored to fit particular cooler models. Some suppliers may also provide different latch styles, such as T-grip or rubber latches, depending on your operational requirements. When considering customization, communicate clearly with your supplier about your needs and confirm minimum order quantities (MOQs) to ensure you meet their production requirements. -

What should I consider when vetting suppliers for latch coolers?

When vetting suppliers, evaluate their experience and reputation in the industry. Request references and check customer reviews to gauge reliability and product quality. Assess their production capabilities, including lead times and customization options, to ensure they can meet your specific demands. Additionally, inquire about their quality assurance processes and warranty policies, as these can indicate the supplier’s commitment to quality. Lastly, consider their communication responsiveness and after-sales support, as these factors are crucial for a successful long-term partnership. -

What are the typical minimum order quantities (MOQs) for latch coolers?

Minimum order quantities (MOQs) can vary significantly among suppliers, typically ranging from 50 to several hundred units. MOQs are influenced by factors such as manufacturing processes, customization options, and shipping logistics. It’s essential to communicate your requirements clearly to potential suppliers to determine their specific MOQs. If your business needs are lower than the MOQ, some suppliers may offer flexibility, such as splitting orders or providing samples. Always factor in the cost implications of MOQs when budgeting for purchases. -

What payment terms can I expect when sourcing latch coolers internationally?

Payment terms can differ based on the supplier and the nature of the transaction. Common arrangements include upfront payments, partial payments, or net terms, such as 30 or 60 days post-delivery. It’s crucial to discuss payment options upfront to ensure they align with your cash flow requirements. Additionally, consider using secure payment methods like letters of credit or escrow services for large transactions to mitigate financial risks. Always ensure that the payment terms are clearly outlined in the contract to avoid misunderstandings. -

How do I ensure quality assurance when sourcing latch coolers?

To ensure quality assurance, request certifications or compliance documentation from your supplier that verifies their adherence to industry standards. Implementing a quality control process, such as pre-shipment inspections, can help catch any defects before products reach your facility. Additionally, establish clear specifications and standards in your purchase agreement, including acceptable tolerance levels for latches and materials. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and potential issues. -

What logistics considerations should I keep in mind when importing latch coolers?

When importing latch coolers, consider shipping methods, costs, and delivery timelines. Air freight is faster but more expensive than sea freight, which is often more economical for bulk orders. Be aware of customs regulations and duties applicable in your country, as these can significantly impact your overall costs. Working with a reliable freight forwarder can streamline the logistics process and ensure compliance with international shipping laws. Additionally, plan for potential delays by allowing extra time in your supply chain to accommodate unforeseen circumstances.

Top 6 Latch Coolers Manufacturers & Suppliers List

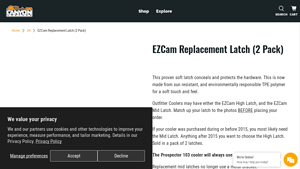

1. Canyon Coolers – EZCam Replacement Latch (2 Pack)

Domain: canyoncoolers.com

Registered: 2010 (15 years)

Introduction: EZCam Replacement Latch (2 Pack) – Price: $10.00 USD – Material: Sun resistant, environmentally responsible TPE polymer – Compatibility: EZCam High Latch (post-2015) and EZCam Mid Latch (pre-2016); Prospector 103 cooler always uses High Latch – Warranty: Covered under warranty; free replacements available within a week or two – Pack Size: Sold in a pack of 2 latches – Note: Replacement mid latches…

2. Yukon Outfitters – Legacy Hard Cooler Latch

Domain: yukon-outfitters.com

Registered: 2012 (13 years)

Introduction: Legacy Hard Cooler Latch – Price: $4.99 USD. Includes 1 latch and 2 screws. Fits YKO Legacy Rotomolded Hard Coolers: 20 qt, 45 qt, 65 qt, 110 qt. Does NOT fit New Wind River or Snake River Coolers. Backordered and will ship as soon as back in stock. Discount available for Current/Former Military & First Responders.

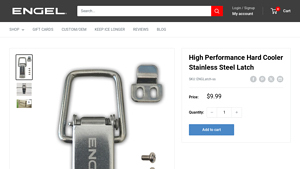

3. Engel – High Performance Stainless Steel Latch Assembly

Domain: engelcoolers.com

Registered: 2008 (17 years)

Introduction: High Performance Hard Cooler Stainless Steel Latch Assembly

– Fits all Engel High Performance Roto-molded Coolers

– Adjustable tension feature

– Material: Stainless Steel

– Includes: 1 lower latch, 1 upper keeper, and 4 stainless M4 mounting screws

– SKU: ENGLatch-ss

– Price: $9.99

– Note: Does not fit UltraLite cooler range.

4. Pierce Arrow Inc – PCOOL-LATCH

Domain: piercearrowinc.com

Registered: 2013 (12 years)

Introduction: Product Name: PCOOL-LATCH

Regular Price: $0.00

Sale Price: $10.00

Stock Status: Low stock (83 left)

Shipping: Free shipping on parcel orders over $100 (Contiguous U.S. only)

Freight Credit: $150 on LTL Orders (Pallet Shipments)

Location: 549 US Highway 287 S, Henrietta, Texas 76365

Contact: Phone – (940) 538-5643

Payment Options: Amazon, American Express, Apple Pay, Discover, Google Pay, Mastercar…

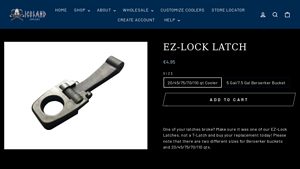

5. Iceland Cooler – EZ-Lock Latch

Domain: icelandcooler.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “EZ-Lock Latch”, “regular_price”: “$4.99”, “sizes_available”: [“20/45/75/70/110 qt Cooler”, “5 Gal/7.5 Gal Berserker Bucket”], “description”: “Replacement latch for coolers and Berserker buckets. Ensure you are purchasing the correct latch type (EZ-Lock Latch, not T-Latch).”, “shipping_info”: {“free_shipping_threshold”: “$50”, “handling_time”: “1-2 business days”, “shipping_time”:…

6. Icytek – PM200 Cooler Replacement Latches

Domain: mountainbuzz.com

Registered: 1998 (27 years)

Introduction: 1. Icytek Cooler (PM200) – 160 true quarts, latch breaking off, needs replacement latches. 2. Frontier Play latches – recommended for dry boxes. 3. Butterfly latches – high quality stainless latches found on eBay, better than standard dry box replacement latches. 4. Compression Spring Metal Fastening Toggle Draw Latch – 2.2″ long, considered for cooler replacement. 5. Grizzly Replacement Latch – c…

Strategic Sourcing Conclusion and Outlook for latch coolers

As the demand for latch coolers continues to rise across global markets, strategic sourcing emerges as a critical factor for B2B buyers aiming to optimize their supply chains. By focusing on high-quality materials, such as stainless steel and advanced polymers, companies can ensure durability and reliability in their cooler products. Additionally, understanding regional preferences and local market conditions can help buyers make informed decisions that align with their customers’ needs.

Investing in efficient logistics and supplier relationships not only enhances product availability but also fosters brand loyalty among end-users. For international buyers from regions such as Africa, South America, the Middle East, and Europe, leveraging partnerships with reputable manufacturers can lead to significant cost savings and improved product performance.

Illustrative image related to latch coolers

Looking ahead, it is essential for businesses to stay agile and responsive to evolving market trends. By prioritizing strategic sourcing and embracing innovation, companies can position themselves for success in the competitive latch cooler market. We encourage you to explore sourcing opportunities that align with your business goals and drive sustainable growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.