Unlocking Value: A Strategic Analysis of the Vias Control Solenoid Valve Market

Introduction: Navigating the Global Market for vias control solenoid valve

In today’s complex global landscape, sourcing high-quality VIAS control solenoid valves presents a significant challenge for international B2B buyers. Whether you are operating in the automotive, industrial, or machinery sectors, understanding the nuances of these critical components is essential for optimizing performance and ensuring compliance with regional standards. This guide delves deep into the various types of VIAS control solenoid valves, their applications across different industries, and the critical factors to consider when selecting a supplier.

Navigating the global market requires more than just identifying products; it involves vetting suppliers, understanding pricing structures, and recognizing the implications of quality assurance and warranty considerations. For buyers from diverse regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—this guide serves as a vital resource to empower informed purchasing decisions.

By providing actionable insights and comprehensive analysis, this guide enables you to mitigate risks associated with sourcing, ensuring that your business benefits from reliable, high-performance solenoid valves. Whether you are looking to enhance operational efficiency or maintain compliance with stringent regulations, the information presented herein will equip you with the knowledge needed to make strategic procurement choices that align with your organization’s goals.

Understanding vias control solenoid valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard VIAS Control Solenoid | Basic design, operates with on/off signals from ECM | Automotive applications, primarily Nissan | Pros: Reliable, cost-effective. Cons: Limited functionality compared to advanced types. |

| Variable Induction Solenoid | Adjusts intake air flow dynamically based on engine load | Performance vehicles, racing applications | Pros: Enhances engine efficiency. Cons: Higher price point, requires precise calibration. |

| Dual-Function Solenoid | Combines two functions (e.g., purge and vent control) in one unit | Heavy machinery, industrial equipment | Pros: Space-saving, versatile. Cons: Complex installation, potential for more failure points. |

| OEM Replacement Solenoid | Original equipment manufacturer parts ensuring compatibility | Aftermarket automotive repairs | Pros: Guaranteed fit and performance. Cons: Typically higher cost than aftermarket alternatives. |

| High-Performance Solenoid | Designed for extreme conditions, enhanced durability | High-performance engines, specialized vehicles | Pros: Superior reliability under stress. Cons: Premium pricing, may require specialized installation. |

What Are the Key Characteristics of Standard VIAS Control Solenoids?

Standard VIAS control solenoids are characterized by their straightforward design, primarily facilitating the on/off operation dictated by the engine control module (ECM). These solenoids are predominantly utilized in automotive applications, especially within Nissan vehicles, to manage air intake effectively. B2B buyers appreciate their reliability and cost-effectiveness, though they may find the limited functionality less appealing for advanced performance needs.

How Do Variable Induction Solenoids Enhance Engine Performance?

Variable induction solenoids are engineered to adjust the intake air flow dynamically, making them suitable for performance vehicles and racing applications. Their ability to optimize air intake based on real-time engine load results in improved efficiency and power output. While these solenoids present a higher price point, their benefits in enhancing engine performance can justify the investment for businesses focused on high-performance automotive sectors.

What Are the Advantages of Dual-Function Solenoids?

Dual-function solenoids combine multiple functionalities, such as purge and vent control, into a single unit. This design is particularly beneficial in heavy machinery and industrial equipment, where space is at a premium. While they offer versatility and efficiency, buyers must consider the complexity of installation and the potential for increased failure points due to their multifunctional nature.

Why Choose OEM Replacement Solenoids?

OEM replacement solenoids are manufactured to meet the exact specifications of the original parts, ensuring compatibility and performance. They are essential for aftermarket automotive repairs, offering peace of mind to B2B buyers who prioritize quality and reliability. Although they typically come at a higher price than aftermarket alternatives, the assurance of a guaranteed fit and performance often outweighs the cost for many businesses.

What Makes High-Performance Solenoids Ideal for Specialized Applications?

High-performance solenoids are specifically designed to withstand extreme conditions, making them ideal for specialized vehicles and high-performance engines. These solenoids provide superior reliability and efficiency under stress, which is crucial for businesses in competitive automotive markets. However, their premium pricing and the need for specialized installation can be a drawback, requiring careful consideration by B2B buyers looking for long-term value.

Key Industrial Applications of vias control solenoid valve

| Industry/Sector | Specific Application of vias control solenoid valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Performance Management | Enhances engine efficiency and reduces emissions | OEM compatibility, warranty, and local regulations |

| Agricultural Machinery | Precision Irrigation Systems | Improves water use efficiency and crop yields | Durability in harsh environments, supplier reliability |

| Oil and Gas | Pressure Control in Pipeline Systems | Ensures safety and operational efficiency | Compliance with industry standards, quality certifications |

| HVAC Systems | Climate Control and Airflow Regulation | Optimizes energy consumption and comfort | Energy efficiency ratings, compatibility with existing systems |

| Industrial Automation | Automated Manufacturing Processes | Increases production efficiency and reduces downtime | Integration capabilities, technical support availability |

How is the Vias Control Solenoid Valve Used in Automotive Applications?

In the automotive sector, the VIAS control solenoid valve plays a crucial role in managing engine performance. It regulates the intake manifold vacuum signal, optimizing air-fuel mixtures for better combustion efficiency. This leads to reduced emissions and enhanced fuel economy, which are vital for meeting regulatory standards, especially in regions like Europe and the Middle East. Buyers should prioritize OEM parts for compatibility and reliability, ensuring that the solenoid valve meets specific engine requirements.

What Role Does the Vias Control Solenoid Valve Play in Agricultural Machinery?

In agricultural machinery, the VIAS control solenoid valve is integral to precision irrigation systems. It controls the flow of water, allowing for targeted irrigation that conserves resources while maximizing crop yields. This is particularly important in regions like Africa and South America, where water scarcity is a significant concern. Buyers should consider the valve’s durability and resistance to environmental factors, ensuring it can withstand the rigors of farming operations.

How Does the Vias Control Solenoid Valve Contribute to Oil and Gas Operations?

In the oil and gas industry, the VIAS control solenoid valve is vital for maintaining pressure control in pipeline systems. It ensures that pressure levels remain within safe limits, preventing leaks and potential hazards. This contributes to operational efficiency and safety, which are paramount in this sector. Buyers must ensure that the sourced valves comply with industry standards and possess the necessary certifications to guarantee reliability in critical applications.

Why is the Vias Control Solenoid Valve Important for HVAC Systems?

For HVAC systems, the VIAS control solenoid valve regulates airflow and climate control, enhancing energy efficiency. By managing the flow of refrigerants and air, it contributes to a more comfortable indoor environment while reducing energy costs. This is particularly relevant in Europe, where energy efficiency is a growing concern. Buyers should focus on energy ratings and compatibility with existing HVAC components when sourcing these valves.

How Does the Vias Control Solenoid Valve Enhance Industrial Automation?

In industrial automation, the VIAS control solenoid valve is used to streamline manufacturing processes. It facilitates the automation of fluid control systems, leading to increased production efficiency and minimized downtime. This is crucial for businesses looking to enhance their operational capabilities. Buyers should evaluate the integration capabilities of the solenoid valves with existing systems and consider the availability of technical support from suppliers to ensure smooth implementation.

3 Common User Pain Points for ‘vias control solenoid valve’ & Their Solutions

Scenario 1: Difficulty Diagnosing VIAS Control Solenoid Valve Failures

The Problem: Many B2B buyers encounter challenges when diagnosing issues related to the VIAS control solenoid valve. A common scenario involves fleet managers who notice a decline in vehicle performance, such as rough shifting in CVT transmissions or unexpected power loss. When the diagnostic trouble code (DTC) P1800 appears, it can be difficult to ascertain whether the solenoid itself is faulty or if other components, such as wiring or the engine control module (ECM), are to blame. This uncertainty can lead to increased downtime and costs as technicians may replace multiple parts unnecessarily.

The Solution: To effectively diagnose problems with the VIAS control solenoid valve, buyers should adopt a systematic troubleshooting approach. Start by checking the vehicle’s electrical system, ensuring that the wiring and connectors are intact and free of corrosion. Utilize diagnostic tools, such as an OBD-II scanner, to read error codes and perform active tests on the solenoid valve. If possible, leverage manufacturers’ guidelines for specific diagnostic procedures that outline the expected voltage and resistance readings. This methodical approach not only streamlines the diagnosis process but also helps identify the root cause of the issue, thereby avoiding costly misdiagnoses.

Scenario 2: Sourcing High-Quality Replacement Parts

The Problem: B2B buyers often face challenges when sourcing replacement VIAS control solenoid valves, particularly in regions with limited access to genuine OEM parts. Unscrupulous suppliers may offer counterfeit or subpar components, which can lead to further mechanical failures and compromise the integrity of the vehicle’s performance. This situation is particularly critical for businesses in transportation or logistics, where reliability is paramount.

Illustrative image related to vias control solenoid valve

The Solution: To ensure the procurement of high-quality VIAS control solenoid valves, buyers should prioritize sourcing from reputable suppliers or directly from OEM manufacturers. Conduct thorough research on potential suppliers, checking for certifications and customer reviews. When possible, request detailed product specifications and warranty information to guarantee the authenticity and quality of the parts. Additionally, consider establishing long-term relationships with trusted suppliers who can provide consistent quality and support. By investing time in proper sourcing, companies can significantly reduce the risk of future failures and enhance overall operational efficiency.

Scenario 3: Installation and Maintenance Challenges

The Problem: Installation and maintenance of the VIAS control solenoid valve can be a daunting task for many technicians, especially if they lack proper training or experience. Incorrect installation can lead to immediate failures or performance issues, which can further complicate a buyer’s operational capabilities. This is particularly concerning in industries that rely on heavy machinery or fleets of vehicles, where operational downtime can result in significant financial losses.

The Solution: To mitigate installation and maintenance challenges, buyers should invest in comprehensive training programs for their technicians. Providing access to manufacturer guidelines and detailed installation manuals can help ensure that the solenoid valves are installed correctly. Furthermore, consider utilizing diagnostic equipment during installation to verify functionality before finalizing the installation process. Regular maintenance checks should also be scheduled to monitor the condition of the solenoid valve and other related components. By equipping technicians with the right knowledge and tools, businesses can enhance the longevity and reliability of their vehicles, ultimately leading to improved performance and reduced costs.

Strategic Material Selection Guide for vias control solenoid valve

What Are the Key Materials for Vias Control Solenoid Valves?

When selecting materials for vias control solenoid valves, several factors come into play, including performance under specific conditions, cost-effectiveness, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of these valves: aluminum, stainless steel, brass, and plastic.

How Does Aluminum Perform in Vias Control Solenoid Valves?

Aluminum is frequently used in solenoid valve bodies due to its lightweight nature and good thermal conductivity. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels.

Pros: Aluminum is relatively inexpensive and easy to machine, which can reduce manufacturing complexity. Its lightweight properties make it suitable for applications where weight is a concern, such as in automotive or aerospace sectors.

Cons: However, aluminum is less corrosion-resistant compared to other metals, particularly in harsh environments. This can lead to premature failure if the valve is exposed to aggressive chemicals or high humidity.

Impact on Application: Aluminum is suitable for applications involving air and non-corrosive fluids. International buyers should ensure that aluminum components meet relevant standards like ASTM B211 for aluminum alloys.

Illustrative image related to vias control solenoid valve

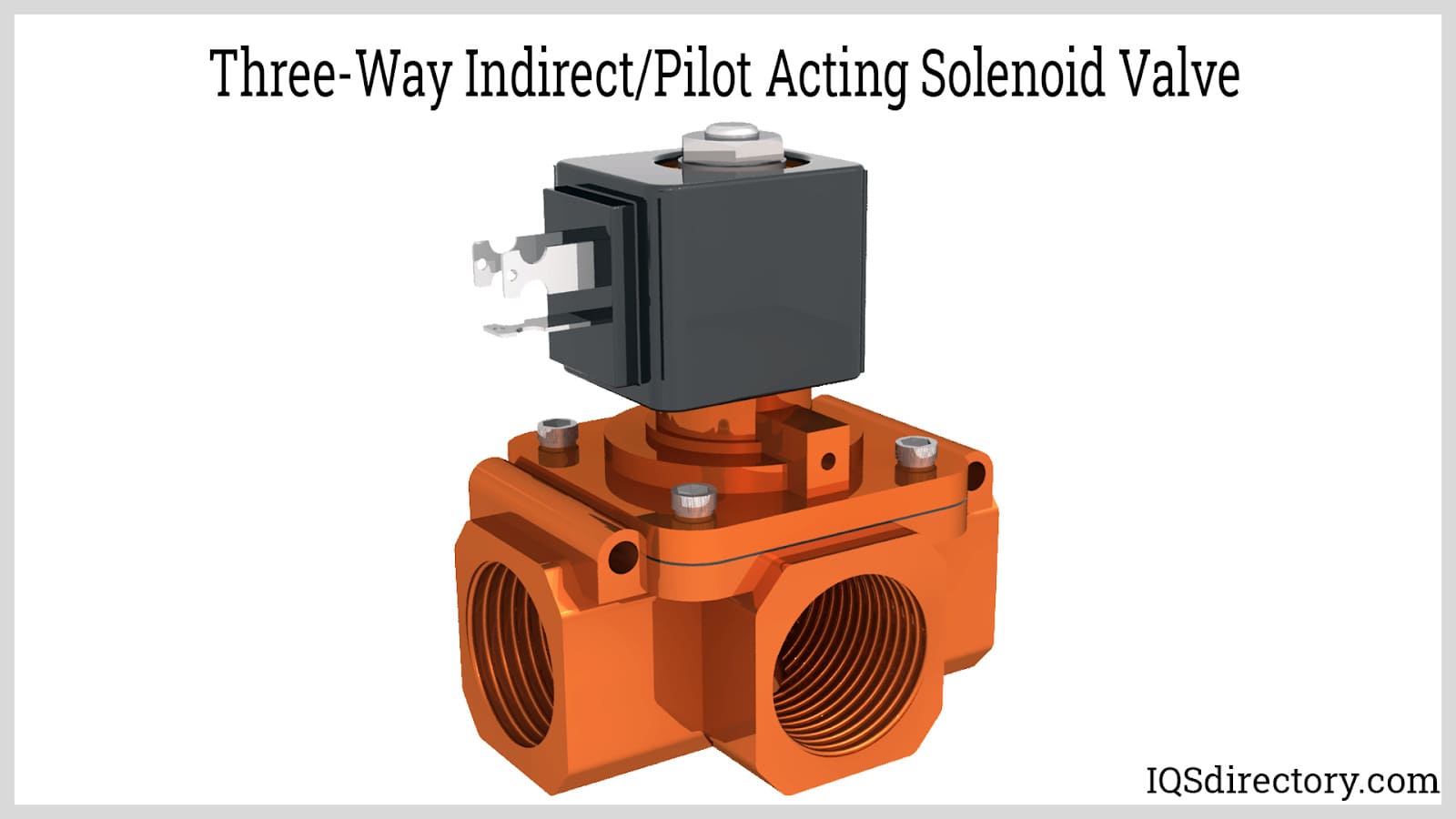

What Are the Advantages of Stainless Steel in Solenoid Valves?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it a preferred choice for solenoid valves exposed to harsh environments. It can handle high temperatures (up to 400°C) and pressures, making it versatile for various applications.

Pros: The durability of stainless steel ensures a longer lifespan and reduced maintenance costs. Its ability to resist oxidation and pitting makes it ideal for applications involving corrosive media.

Cons: The primary drawback is its higher cost compared to aluminum and brass. Additionally, stainless steel can be more challenging to machine, which may increase manufacturing complexity.

Illustrative image related to vias control solenoid valve

Impact on Application: Stainless steel is suitable for applications involving aggressive chemicals or high-pressure systems. Buyers in regions like the Middle East should verify compliance with standards such as ASTM A276 for stainless steel bars.

Why Choose Brass for Vias Control Solenoid Valves?

Brass is often used in solenoid valves due to its excellent machinability and good corrosion resistance, particularly in water and air applications. It typically operates effectively at temperatures up to 200°C.

Pros: Brass offers a good balance between cost and performance, making it an attractive option for many manufacturers. Its antimicrobial properties can also be beneficial in applications requiring hygiene.

Illustrative image related to vias control solenoid valve

Cons: However, brass can be susceptible to dezincification in certain environments, which can compromise its structural integrity over time.

Impact on Application: Brass is suitable for applications involving water and air but may not be ideal for aggressive chemicals. Buyers should ensure compliance with standards like ASTM B16 for brass fittings.

How Does Plastic Compare in Solenoid Valve Applications?

Plastic materials, such as polyamide or polycarbonate, are increasingly used in solenoid valves due to their lightweight and corrosion-resistant properties. They can handle moderate temperatures (up to 80°C) and pressures.

Illustrative image related to vias control solenoid valve

Pros: The primary advantage of plastic is its low cost and ease of manufacturing. It is also highly resistant to corrosion, making it suitable for various media.

Cons: However, plastic materials may not withstand high temperatures or pressures as effectively as metals. They can also be less durable in mechanical applications.

Impact on Application: Plastic is ideal for applications involving non-corrosive fluids at lower pressures. Buyers should ensure compliance with standards like ASTM D638 for plastic materials.

Summary Table of Material Selection for Vias Control Solenoid Valves

| Material | Typical Use Case for vias control solenoid valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive air control systems | Lightweight and cost-effective | Poor corrosion resistance | Low |

| Stainless Steel | Chemical processing and high-pressure systems | Excellent durability and corrosion resistance | Higher cost and machining complexity | High |

| Brass | Water and air applications | Good machinability and antimicrobial properties | Susceptible to dezincification | Medium |

| Plastic | Low-pressure fluid applications | Low cost and corrosion resistance | Limited temperature and pressure tolerance | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with relevant standards.

Illustrative image related to vias control solenoid valve

In-depth Look: Manufacturing Processes and Quality Assurance for vias control solenoid valve

What Are the Main Stages of Manufacturing a VIAS Control Solenoid Valve?

The manufacturing process of a VIAS control solenoid valve involves several critical stages, each designed to ensure the final product meets both performance and quality standards.

Material Preparation: What Materials Are Used?

The first stage is material preparation, where high-quality materials are selected for durability and performance. Common materials include:

- Aluminum and Zinc Alloys: These are often used for the valve body due to their lightweight and corrosion-resistant properties.

- Copper: Used for electrical components such as coils, copper provides excellent conductivity.

- Rubber and Plastics: Used for seals and insulation, these materials ensure that the valve operates under various environmental conditions without leakage.

Each material undergoes rigorous checks for composition and integrity to ensure they meet the specifications required for high-performance applications.

How Is the Forming Process Carried Out?

Following material preparation, the forming process takes place. This involves various machining techniques such as:

Illustrative image related to vias control solenoid valve

- CNC Machining: Computer Numerical Control (CNC) machines are employed to create precise dimensions for each component of the solenoid valve. This technique ensures that parts fit together perfectly, which is crucial for function.

- Die Casting: For parts that require complex shapes, die casting is often used. This process allows for high-volume production while maintaining quality.

- Injection Molding: Used for rubber and plastic components, injection molding ensures that seals and insulation fit perfectly within the assembly.

These forming techniques are essential for achieving the dimensional accuracy necessary for the valve’s operation.

What Does the Assembly Process Involve?

The assembly stage combines all the individual components into a complete solenoid valve. This stage includes:

- Component Assembly: Skilled technicians or automated systems assemble the valve components, including the solenoid coil, valve body, and actuator.

- Wiring and Electrical Connections: Proper wiring is crucial for the solenoid’s functionality. Each connection is soldered or crimped according to strict specifications to ensure reliable operation.

- Testing During Assembly: As components are assembled, preliminary tests may be conducted to check for electrical continuity and mechanical function.

This stage is critical, as improper assembly can lead to malfunctioning valves that may not meet operational standards.

What Finishing Techniques Are Used to Ensure Quality?

Once assembled, the solenoid valves undergo various finishing processes, which may include:

- Surface Treatment: Techniques such as anodizing or powder coating are used to enhance corrosion resistance and improve aesthetics.

- Leak Testing: Each valve is subjected to pressure tests to ensure there are no leaks, which is vital for maintaining performance and safety.

- Final Inspection: Before packaging, each valve goes through a comprehensive inspection, ensuring that it meets all design specifications.

These finishing processes enhance the durability and performance of the solenoid valves in real-world applications.

What Quality Assurance Standards Are Relevant for VIAS Control Solenoid Valves?

Quality assurance (QA) is a vital aspect of the manufacturing process for VIAS control solenoid valves. Adhering to international and industry-specific standards helps ensure that products meet global performance and safety requirements.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized international standards is ISO 9001, which outlines a framework for quality management systems. Companies that achieve ISO 9001 certification demonstrate their commitment to maintaining high-quality processes and continual improvement. Other important standards include:

- CE Marking: Required for products sold in the European Economic Area, this marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For valves used in oil and gas applications, the American Petroleum Institute (API) provides standards that ensure reliability and safety.

These certifications can provide B2B buyers with confidence in the quality and reliability of the products they are sourcing.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components to ensure they meet specified requirements before production begins.

- In-Process Quality Control (IPQC): As components are being manufactured and assembled, ongoing inspections are conducted to catch any deviations from quality standards early in the process.

- Final Quality Control (FQC): After assembly and finishing, the final product undergoes rigorous testing and inspection to ensure it meets all quality specifications before shipment.

These checkpoints help to minimize defects and ensure that only high-quality products reach the market.

Illustrative image related to vias control solenoid valve

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some strategies to consider:

What Actions Can Buyers Take for Supplier Audits?

- Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes reviewing their quality management systems, production capabilities, and compliance with industry standards.

- Request Quality Reports: Buyers should request and review quality control reports, including test results and compliance certificates, to verify that the supplier adheres to established standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes. This can be particularly beneficial for buyers who are unable to visit suppliers in person.

What Are the QC Certification Nuances for International Buyers?

Understanding the nuances of quality control certifications is important for B2B buyers operating in different regions. For instance:

- Regional Compliance: Certain markets may have specific compliance requirements, such as CE marking in Europe or API standards for oil and gas applications. Buyers should ensure that suppliers can provide the necessary certifications for their target markets.

- Cultural and Regulatory Differences: Buyers should be aware of cultural differences in business practices and regulatory environments that may affect quality assurance processes. This understanding can help build stronger relationships and ensure smoother transactions.

By focusing on these quality assurance aspects, B2B buyers can significantly mitigate risks associated with sourcing VIAS control solenoid valves from international suppliers. Understanding the manufacturing processes and quality control practices not only enhances product reliability but also builds trust in supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vias control solenoid valve’

Introduction

When sourcing a VIAS control solenoid valve, it is essential for B2B buyers to follow a structured approach to ensure they procure a high-quality product that meets their specific needs. This guide provides a step-by-step checklist to help you navigate the sourcing process effectively, ensuring you consider all critical aspects before making a purchase.

Illustrative image related to vias control solenoid valve

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the VIAS control solenoid valve. Specifications may include dimensions, voltage ratings, and compatibility with specific vehicle models. This step is crucial as it helps narrow down potential suppliers and ensures that the valves you consider will fit your application.

- Compatibility: Ensure that the valve meets the specifications required for your vehicle or machinery.

- Performance Standards: Identify the necessary performance metrics, such as response time and operational lifespan.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of VIAS control solenoid valves. This includes looking for manufacturers and distributors with a proven track record in the automotive parts industry. A well-established supplier is likely to offer better reliability and quality assurance.

- Market Presence: Check how long the supplier has been in the industry.

- Customer Feedback: Look for reviews or testimonials from other B2B buyers.

Step 3: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and comply with international quality standards. Certifications such as ISO 9001 indicate that the manufacturer adheres to quality management practices, which is vital for ensuring product reliability.

- Quality Assurance: Certifications can often reflect a commitment to producing high-quality products.

- Safety Standards: Verify that the products meet safety regulations relevant to your market.

Step 4: Request Quotes and Compare Prices

Once you have shortlisted potential suppliers, request detailed quotes for the VIAS control solenoid valves. Comparing prices is essential, but also consider the total cost of ownership, which includes shipping, taxes, and potential import duties.

Illustrative image related to vias control solenoid valve

- Bulk Discounts: Inquire about pricing for larger orders, as many suppliers offer discounts.

- Payment Terms: Understand the payment options available and any associated terms.

Step 5: Evaluate Warranty and Return Policies

Assess the warranty and return policies offered by the suppliers. A robust warranty indicates confidence in the product’s quality and can provide peace of mind for your purchase. Additionally, clear return policies will protect you against receiving defective or incompatible parts.

- Duration of Warranty: Look for warranties that extend beyond a year for added security.

- Return Process: Ensure the return process is straightforward and well-documented.

Step 6: Check Shipping and Delivery Options

Consider the shipping methods and delivery times offered by suppliers. Efficient logistics are crucial for minimizing downtime, especially if you rely on the VIAS control solenoid valve for operational needs.

- Shipping Locations: Confirm that the supplier can ship to your location without excessive delays.

- Tracking Options: Ensure that the supplier provides tracking information for your shipment.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement. Clearly outline all terms, including delivery schedules, payment terms, and any additional services such as installation support or technical assistance.

- Clarity in Terms: Ensure that all terms are explicitly stated to avoid misunderstandings.

- Legal Review: Consider having the agreement reviewed by legal counsel to protect your interests.

By following this checklist, B2B buyers can ensure a smooth procurement process for VIAS control solenoid valves, ultimately leading to a successful and efficient sourcing experience.

Comprehensive Cost and Pricing Analysis for vias control solenoid valve Sourcing

What Are the Key Cost Components in Sourcing VIAS Control Solenoid Valves?

When sourcing VIAS control solenoid valves, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

Illustrative image related to vias control solenoid valve

-

Materials: The choice of materials significantly impacts the cost. High-quality materials that meet industry standards are essential for reliability and performance, but they also increase the initial cost.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. This can vary based on the region, skill level required, and whether the manufacturing is done in-house or outsourced.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient overhead management can help reduce overall costs.

-

Tooling: Custom tooling for specific solenoid valve designs can be a significant initial investment. However, once established, this tooling can lead to lower per-unit costs for larger production runs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, which is especially important for components used in automotive applications. While this adds to costs, it can prevent expensive recalls or failures in the long run.

-

Logistics: Transportation and warehousing costs must be factored into the total cost. These can vary greatly depending on the shipping methods, distance, and whether the supplier offers direct shipping to the buyer’s location.

-

Margin: Suppliers will add a margin to cover their costs and profit. This can vary based on market conditions and competition.

How Do Pricing Influencers Affect the Cost of VIAS Control Solenoid Valves?

Several factors can influence the pricing of VIAS control solenoid valves:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Negotiating the MOQ can significantly impact overall expenditure.

-

Specifications and Customization: Custom-engineered solenoid valves will incur higher costs. Buyers should balance the need for customization with cost-effectiveness.

-

Materials: The quality of materials used can affect both performance and price. Premium materials may be necessary for high-stress applications, but they will increase costs.

-

Quality and Certifications: Products that come with certifications for quality and safety can command higher prices. Buyers should consider whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can influence pricing. Suppliers from regions with lower labor costs might offer competitive prices, but buyers must consider potential quality trade-offs.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the total landed cost of the valves.

What Are Some Buyer Tips for Effective Sourcing of VIAS Control Solenoid Valves?

To maximize value when sourcing VIAS control solenoid valves, consider the following strategies:

-

Negotiation: Engage in negotiations to secure better pricing and payment terms. Building a strong relationship with suppliers can lead to favorable deals.

-

Cost-Efficiency: Evaluate total cost of ownership rather than just the purchase price. This includes maintenance, potential failures, and the longevity of the product.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates, tariffs, and import duties when sourcing from international suppliers. These factors can significantly affect overall costs.

-

Supplier Audits: Conduct thorough audits of potential suppliers to ensure they meet your quality and reliability standards. This can help mitigate risks associated with low-quality products.

-

Market Research: Stay informed about market trends and pricing shifts. This knowledge can empower buyers to make informed decisions and time their purchases strategically.

Disclaimer

The prices and cost structures discussed are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing vias control solenoid valve With Other Solutions

Understanding Alternatives for Vias Control Solenoid Valve

When evaluating the Vias Control Solenoid Valve, it’s essential to consider alternative solutions that serve similar functions in automotive applications. Various technologies and methods can achieve comparable outcomes, allowing buyers to make informed decisions that align with their operational needs, budget constraints, and maintenance capabilities. Below is a comparative analysis that highlights the strengths and weaknesses of the Vias Control Solenoid Valve against other viable alternatives.

| Comparison Aspect | Vias Control Solenoid Valve | Electric Actuator | Mechanical Linkage |

|---|---|---|---|

| Performance | High precision control of air intake; responsive to ECM signals | Excellent control and adaptability; can handle various loads | Simple operation; reliable in low-stress applications |

| Cost | Moderate ($194.73 – $282.22) | Higher initial investment (varies widely) | Low cost; often less than solenoid valves |

| Ease of Implementation | Requires specific vehicle compatibility and expertise for installation | May require complex integration with existing systems | Simple installation; often DIY-friendly |

| Maintenance | Moderate; regular checks needed to ensure functionality | Low; typically requires less frequent maintenance | Minimal; mostly mechanical wear and tear |

| Best Use Case | Ideal for vehicles requiring precise air control for performance | Suitable for advanced automotive systems needing adaptability | Best for basic systems where precision is not critical |

Detailed Breakdown of Alternatives

Electric Actuator

Electric actuators provide superior control and adaptability compared to solenoid valves. They operate using electrical signals to control movement, allowing for precise adjustments in various automotive applications. While they offer excellent performance, the initial cost is generally higher than that of a Vias Control Solenoid Valve. Moreover, their complexity may necessitate professional installation, making them less accessible for DIY enthusiasts. However, their low maintenance requirements make them attractive for long-term use in advanced systems.

Mechanical Linkage

Mechanical linkages are simple, cost-effective solutions that rely on physical connections to operate. These systems can be more reliable in low-stress applications where precision is less critical. Their installation is straightforward, often allowing for DIY implementation, which can significantly reduce overall costs. However, they may lack the responsiveness and adaptability of the Vias Control Solenoid Valve and electric actuators, making them less suitable for high-performance vehicles where precise control is paramount.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate solution among the Vias Control Solenoid Valve, electric actuators, and mechanical linkages ultimately depends on specific operational requirements. B2B buyers should consider factors such as performance needs, budget constraints, maintenance capabilities, and installation expertise. For high-performance applications that require precise air control, the Vias Control Solenoid Valve or electric actuators may be the best fit. Conversely, for simpler systems or budget-sensitive projects, mechanical linkages could provide a reliable and cost-effective alternative. By aligning the choice with operational priorities, buyers can enhance their vehicle performance while ensuring optimal resource utilization.

Essential Technical Properties and Trade Terminology for vias control solenoid valve

What Are the Key Technical Properties of a Vias Control Solenoid Valve?

Understanding the technical specifications of a Vias control solenoid valve is crucial for B2B buyers, as these properties directly impact performance, compatibility, and reliability in various applications. Here are some essential specifications to consider:

-

Material Grade

The material used in the construction of a solenoid valve significantly influences its durability and resistance to environmental factors. Common materials include brass, stainless steel, and plastic composites. For instance, stainless steel offers excellent corrosion resistance, making it ideal for applications in harsh environments. Selecting the appropriate material ensures longevity and reduces the risk of failure, which is critical for maintaining operational efficiency. -

Operating Pressure Range

This specification refers to the maximum and minimum pressure levels at which the solenoid valve can operate effectively. Typically measured in psi (pounds per square inch), understanding this range is vital for compatibility with existing systems. If the valve operates outside its rated pressure, it may lead to premature failure or inefficiencies, affecting overall system performance. -

Electrical Specifications (Voltage and Current)

The electrical characteristics of a solenoid valve, including voltage ratings (e.g., 12V, 24V) and current draw, are critical for ensuring compatibility with the control system. Mismatched specifications can lead to inadequate operation or even damage to the valve or electrical components. Buyers should verify these specifications to align with their specific applications. -

Response Time

This parameter indicates how quickly the solenoid valve can open or close when an electrical signal is applied. Measured in milliseconds, a shorter response time is crucial in applications requiring precise control, such as automotive systems or industrial automation. Understanding the response time helps buyers select valves that meet the speed requirements of their operations. -

Flow Rate

The flow rate, often measured in liters per minute (LPM) or gallons per minute (GPM), indicates the volume of fluid that can pass through the valve under specific conditions. This specification is essential for ensuring that the valve can handle the required flow demands of the system. Selecting a valve with an appropriate flow rate is vital for maintaining efficiency and performance in fluid control applications. -

Temperature Range

The temperature tolerance of a solenoid valve indicates the range of temperatures in which it can operate effectively. This specification is particularly important in environments with extreme conditions. Selecting a valve with an appropriate temperature range ensures that it will perform reliably without degradation, which is essential for maintaining system integrity.

What Are Common Trade Terms Related to Vias Control Solenoid Valves?

Familiarity with industry jargon is essential for B2B buyers to navigate the procurement process effectively. Here are some common terms:

Illustrative image related to vias control solenoid valve

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that are marketed by another manufacturer. For solenoid valves, OEM parts are often preferred due to their guaranteed compatibility and quality assurance. Buyers should prioritize OEM products to ensure reliability and optimal performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when planning inventory and budgeting. Suppliers often set MOQs to cover production costs, so negotiating this aspect can lead to better pricing and terms. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare multiple suppliers and make informed purchasing decisions. A well-prepared RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for understanding shipping costs and responsibilities, particularly in cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for project planning and inventory management. Buyers should inquire about lead times to ensure timely delivery and minimize disruptions. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and lifespan of the product. Understanding warranty terms is essential for buyers to assess the risk of potential defects and the recourse available in case of failure. A solid warranty can provide peace of mind and indicate the manufacturer’s confidence in their product.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing vias control solenoid valves, ensuring compatibility and reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the vias control solenoid valve Sector

What Are the Current Market Dynamics and Key Trends in the Vias Control Solenoid Valve Sector?

The global market for VIAS control solenoid valves is experiencing robust growth driven by several factors. Increasing demand for fuel-efficient vehicles, particularly in developing regions like Africa and South America, is a significant driver. As manufacturers seek to enhance engine performance while reducing emissions, the integration of advanced solenoid technology is becoming essential. Additionally, the rise of electric vehicles (EVs) is prompting traditional automotive suppliers to adapt their offerings, which includes sourcing solenoids that can support hybrid and electric powertrains.

Emerging technologies such as IoT and automation are reshaping sourcing trends. B2B buyers are increasingly seeking suppliers who can provide smart solenoid valves equipped with sensors for real-time monitoring and diagnostics. This trend not only enhances operational efficiency but also reduces maintenance costs and downtime. Furthermore, international buyers are favoring suppliers that offer transparent supply chains and just-in-time delivery options, reflecting a shift towards more agile and responsive sourcing strategies.

In regions like the Middle East and Europe, regulatory pressures aimed at reducing carbon footprints are pushing manufacturers to invest in more sustainable components. This has led to an uptick in demand for solenoid valves that comply with stringent environmental standards, further influencing sourcing decisions. Overall, international B2B buyers must stay attuned to these market dynamics and trends to make informed procurement choices that align with their operational goals.

How Can Sustainability and Ethical Sourcing Influence B2B Purchasing Decisions in the Vias Control Solenoid Valve Sector?

Sustainability has become a cornerstone of procurement strategy, particularly in the automotive sector. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, prompting B2B buyers to prioritize suppliers that demonstrate a commitment to sustainable practices. In the context of VIAS control solenoid valves, this includes sourcing materials that have lower environmental footprints and adopting manufacturing techniques that minimize waste and emissions.

Illustrative image related to vias control solenoid valve

Ethical sourcing is equally critical. Buyers are increasingly demanding transparency in the supply chain, looking for partners who adhere to ethical labor practices and provide fair working conditions. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria in supplier evaluations. These certifications not only enhance a supplier’s credibility but also align with the growing consumer preference for socially responsible products.

Furthermore, the incorporation of ‘green’ materials—such as recyclable metals and biodegradable components—into the production of solenoid valves can significantly influence purchasing decisions. As the market evolves, B2B buyers who prioritize sustainability and ethical sourcing will not only contribute to environmental conservation but will also differentiate themselves in a competitive landscape, appealing to eco-conscious consumers and stakeholders alike.

What Is the Brief Evolution and History of the Vias Control Solenoid Valve?

The VIAS control solenoid valve has evolved significantly since its inception in the automotive industry. Initially designed to optimize engine performance through variable induction control, these valves have undergone numerous advancements in technology and functionality. The integration of electronic controls has transformed traditional mechanical systems into sophisticated, responsive components that enhance both fuel efficiency and emissions control.

Over the years, the increasing complexity of automotive systems, particularly with the rise of CVT (Continuously Variable Transmission) systems, has necessitated more precise control mechanisms. Modern VIAS control solenoid valves now include features such as integrated sensors for real-time performance monitoring and advanced diagnostic capabilities. This evolution reflects the industry’s broader trend towards automation and connectivity, setting the stage for the next generation of automotive innovation. As B2B buyers navigate this landscape, understanding the historical context of these components will aid in making informed sourcing decisions that align with current and future market demands.

Illustrative image related to vias control solenoid valve

Frequently Asked Questions (FAQs) for B2B Buyers of vias control solenoid valve

-

How do I solve issues with a VIAS control solenoid valve?

To address problems with a VIAS control solenoid valve, start by diagnosing the specific issue, which often manifests as error codes like P1800. Inspect the electrical connections and wiring for any signs of damage or disconnection. If the valve is not functioning correctly, it may require replacement. Conducting a thorough check of the valve’s operation using diagnostic tools can help confirm whether the solenoid is defective. Always refer to the manufacturer’s guidelines for troubleshooting procedures specific to your vehicle model. -

What is the best way to source a VIAS control solenoid valve for my vehicle?

When sourcing a VIAS control solenoid valve, prioritize OEM parts for reliability and compatibility. Research reputable suppliers who specialize in automotive components and have positive reviews. Compare prices and warranty options, ensuring that the supplier can guarantee fitment for your specific vehicle model. Additionally, inquire about bulk purchasing options if you are a dealer or repair shop, as this could lead to significant cost savings. -

What are the typical lead times for importing VIAS control solenoid valves?

Lead times for importing VIAS control solenoid valves can vary based on the supplier’s location, shipping method, and customs processing. Generally, expect lead times of 2-4 weeks for standard shipping from manufacturers in Asia or Europe to regions in Africa or South America. For urgent requirements, express shipping options may be available but can be significantly more expensive. Always confirm the estimated delivery time with your supplier before placing an order. -

What are the minimum order quantities (MOQs) for VIAS control solenoid valves?

Minimum order quantities for VIAS control solenoid valves typically range from 10 to 100 units, depending on the supplier’s policies and production capabilities. Some manufacturers may offer flexibility for first-time buyers or small businesses. If you are unsure about committing to a large order, consider discussing your needs with the supplier to see if they can accommodate a smaller initial purchase or a trial order. -

How can I ensure the quality of the VIAS control solenoid valves I purchase?

To ensure quality, select suppliers who provide documentation, including certification of authenticity, warranty information, and testing results. Request samples if possible to evaluate the product before committing to a larger order. Additionally, verify the supplier’s reputation by checking reviews and industry ratings. Engaging in regular quality audits and establishing a clear communication channel with your supplier can also help maintain product standards. -

What payment terms should I expect when purchasing VIAS control solenoid valves internationally?

Payment terms can vary widely based on the supplier’s policies and your relationship with them. Common options include upfront payment, partial payment upon order confirmation, and the balance upon delivery. In some cases, suppliers may offer credit terms for established customers. Always clarify payment methods accepted (e.g., bank transfer, PayPal, letters of credit) and ensure that these terms are documented in your purchase agreement to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing VIAS control solenoid valves?

When importing VIAS control solenoid valves, consider logistics factors such as shipping costs, customs duties, and potential delays. Choose a reliable freight forwarder familiar with automotive parts to help navigate international shipping regulations. Be aware of your country’s import restrictions and tariffs, which can affect the overall cost. Lastly, ensure proper packaging to prevent damage during transit and consider insurance for high-value shipments. -

Are there customization options available for VIAS control solenoid valves?

Many manufacturers offer customization options for VIAS control solenoid valves, including specific configurations or adaptations for unique vehicle models. Customization can also extend to branding, packaging, and performance specifications. To explore these options, communicate directly with the supplier, detailing your requirements and the intended application. Keep in mind that custom orders may have longer lead times and higher costs than standard products.

Top 7 Vias Control Solenoid Valve Manufacturers & Suppliers List

1. Nissan – OEM NEW VIAS Control Solenoid Valve

Domain: parts.conicellinissan.com

Registered: 1999 (26 years)

Introduction: {“part_number”:”14955-8J10A”,”description”:”OEM NEW VIAS Control Solenoid Valve P1800 Code”,”manufacturer”:”Nissan”,”condition”:”New”,”replaces”:”14955-8J100″,”MSRP”:”$282.22″,”discount”:”$87.49 (31% off)”,”sale_price”:”$194.73″,”warranty”:”12 Month Manufacturer Warranty”,”fitment_years”:”2002-2020″,”compatible_models”:[“Murano 4.0L (2009-2019)”,”Quest”,”Frontier 4.0L”,”Maxima”,”Xterra”,”Altima”,”…

2. VIAS – Solenoid for Nissan Altima 2002-2006

Domain: altimaforums.net

Registered: 2006 (19 years)

Introduction: VIAS solenoid for Nissan Altima 2002-2006, part numbers 14956-40U10 or 14956-40U1B (supersession). Mounted on the vacuum reserve tank underneath the intake manifold. Related issues include P1800 error code, which indicates a potential electrical problem with the solenoid or wiring.

3. Nissan – VIAS Control Solenoid Valve

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: 2004 Nissan Maxima VIAS Control Solenoid Valve; Engine: 3.5L; Function: Interrupts intake manifold vacuum signal for power valve control; Reacts to ON/OFF signals from ECM; Faulty if it fails to open the runner control valve during active tests; Runner vacuum control should maintain vacuum when tested with a vacuum pump; Recommended to replace if malfunctioning.

4. Nissan – Genuine OEM VIAS Control Solenoid Valve

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Genuine OEM Nissan VIAS Control Solenoid Valve (P1800 Code)”, “Part Number”: “14955-8J10A”, “Condition”: “New”, “Price”: “$58.99”, “Shipping Cost”: “$47.00”, “Seller”: “DEALPARTS”, “Seller Rating”: “97.2% positive”, “Quantity Available”: “5”, “Compatibility”: “Compatible with 557 vehicle(s)”, “Notable Compatibility”: [{“Year”: “2021”, “Make”: “Nissan”, “Model”: “Maxima”, “Trim”: …

5. Nissan – Solenoid Valve

Domain: parts.nissanusa.com

Registered: 2001 (24 years)

Introduction: Part Number: 14955-8J10A

Product Name: Solenoid Valve

Compatibility: 2001-2025 Nissan models

Promotion: Labor Day Savings – Up to 15% off select Genuine Nissan Parts (Aug 29–Sep 8)

6. VIAS – Control Solenoid Valve

Domain: b15u.com

Registered: 2009 (16 years)

Introduction: VIAS Control Solenoid Valve, DTC code P1800, part number 14956-40U1B, associated with Nissan Sentra, necessary for controlling butterfly valves in certain intake manifolds, potential replacement needed if deleted during engine install.

7. Verdian Power – Genuine OEM Nissan VIAS Control Solenoid Valve

Domain: verdianpower.com

Registered: 2023 (2 years)

Introduction: This company, Verdian Power – Genuine OEM Nissan VIAS Control Solenoid Valve, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for vias control solenoid valve

How Can Strategic Sourcing Enhance Your Procurement of VIAS Control Solenoid Valves?

In conclusion, leveraging strategic sourcing for VIAS control solenoid valves can significantly optimize procurement processes for international buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the critical function of these valves in vehicle performance enables businesses to prioritize quality and reliability. By sourcing from reputable manufacturers like Nissan, buyers can ensure compatibility and longevity, backed by warranties that protect their investments.

Moreover, establishing strong supplier relationships can lead to favorable pricing, access to the latest technologies, and improved supply chain efficiency. Buyers should engage in comprehensive market research to identify the best sourcing partners who align with their operational needs and budget constraints.

As the automotive industry continues to evolve with advancements in technology, the demand for high-quality components like the VIAS control solenoid valve is set to rise. Now is the time to act—invest in strategic sourcing strategies that will position your business for success. By prioritizing quality and fostering strong supplier partnerships, you can enhance your operational efficiency and drive long-term growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.