Choosing Your Pvc Extruder: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for pvc extruder

In an increasingly competitive global market, sourcing a high-quality PVC extruder can be a daunting challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The right extruder not only impacts production efficiency but also influences the quality of the end product, making it essential for businesses to navigate this complex landscape with informed decisions. This comprehensive guide delves into the various types of PVC extruders available, their applications across industries, and critical factors for supplier vetting, including technological advancements and energy efficiency.

By exploring the nuances of cost considerations and operational requirements, this guide empowers international B2B buyers to make strategic purchasing decisions that align with their specific needs. Whether you are looking to optimize production for pipes, profiles, or specialty applications, understanding the capabilities of different extruder types—from single and twin-screw models to innovative recycling solutions—will be crucial.

Moreover, we will provide insights into the latest industry trends and sustainability practices that can significantly enhance your operations. As you navigate the global market for PVC extruders, this guide will serve as a valuable resource, ensuring you are equipped with the knowledge necessary to drive efficiency and quality in your production processes.

Understanding pvc extruder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Screw Extruder | Simple design, cost-effective, suitable for a variety of materials | Pipe and profile production, general plastic processing | Pros: Lower initial investment, easy maintenance. Cons: Limited mixing capabilities compared to twin-screw. |

| Twin Screw Extruder | Enhanced mixing, higher output, suitable for complex materials | High-performance applications like medical devices, advanced profiles | Pros: Superior material homogenization, flexibility. Cons: Higher cost, more complex maintenance. |

| Co-Extruder | Capable of processing multiple materials simultaneously | Multi-layer pipes, films, and profiles | Pros: Cost-effective for producing composite materials. Cons: Requires precise control, more expensive setup. |

| Recycling Extruder | Designed for processing recycled materials efficiently | Recycling PVC, producing regranulated materials | Pros: Supports sustainability efforts, reduces waste. Cons: May require additional processing steps. |

| Laboratory Extruder | Compact and versatile for small-scale testing and development | R&D, product testing, pilot production | Pros: Ideal for prototyping, cost-effective for small batches. Cons: Limited production capacity. |

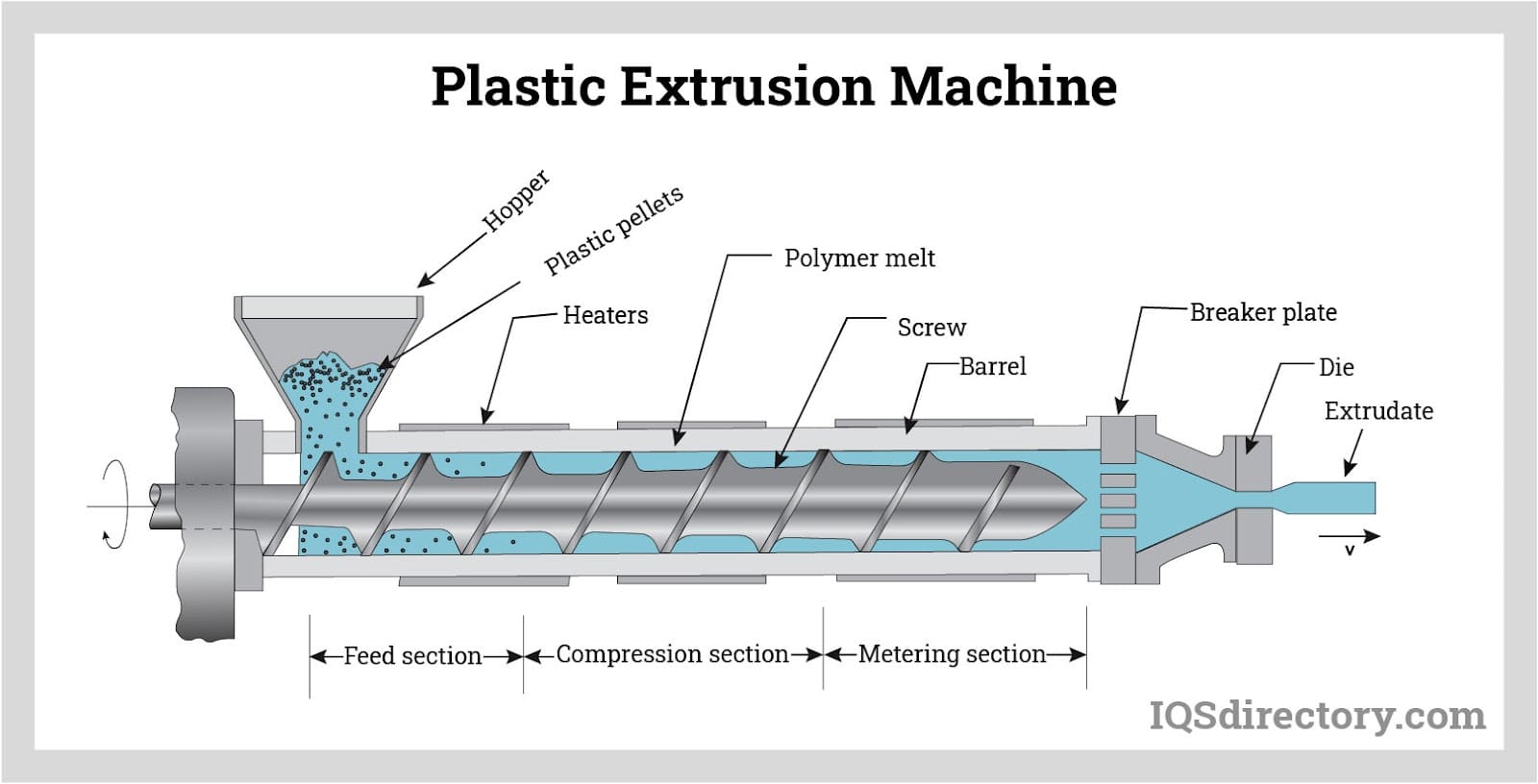

What Are the Key Characteristics of Single Screw Extruders?

Single screw extruders are characterized by their straightforward design, featuring a single rotating screw that pushes material through a heated barrel. They are widely used in the production of pipes and profiles, making them a staple in many manufacturing processes. For B2B buyers, the advantages include a lower initial investment and simpler maintenance routines. However, their limitations in mixing capabilities may affect applications requiring high material homogeneity.

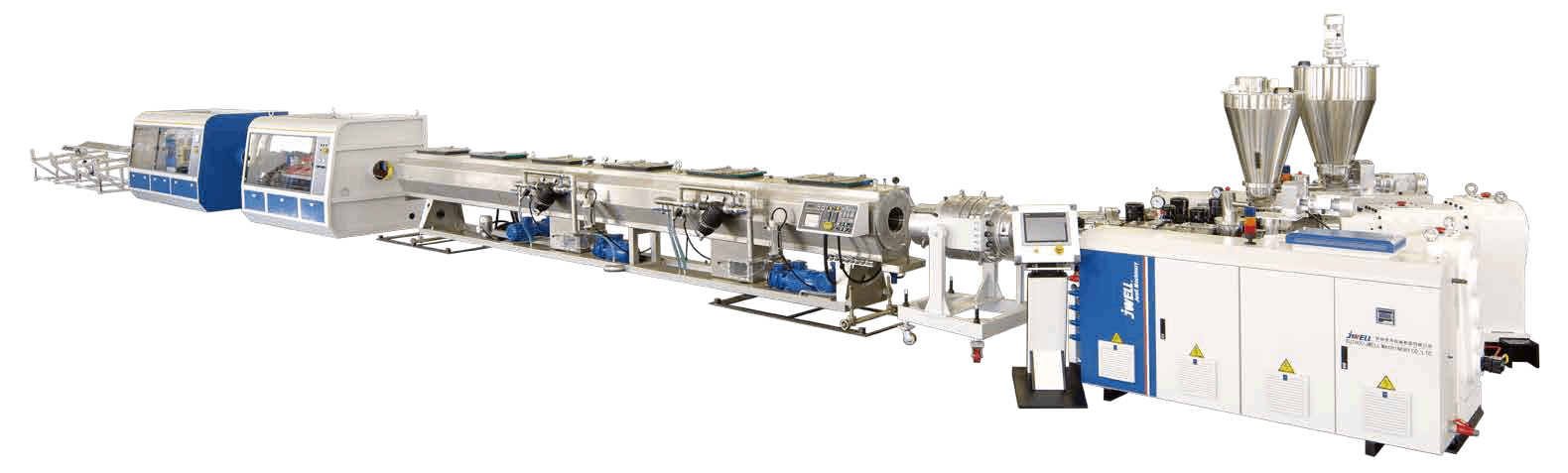

How Do Twin Screw Extruders Enhance Production Efficiency?

Twin screw extruders consist of two intermeshing screws that provide enhanced mixing and higher output rates. They are particularly effective for processing complex materials, such as those used in medical devices and advanced profiles. B2B buyers appreciate the flexibility and superior homogenization offered by twin screw extruders, though these benefits come at a higher cost and require more sophisticated maintenance.

What Advantages Do Co-Extruders Offer for Material Processing?

Co-extruders are designed to process multiple materials simultaneously, allowing for the creation of multi-layer products such as pipes and films. This type of extruder is particularly beneficial for manufacturers looking to produce composite materials efficiently. While co-extruders can lead to cost savings by optimizing production, they require precise control and a more substantial initial investment, which may be a consideration for budget-conscious buyers.

How Do Recycling Extruders Contribute to Sustainability Efforts?

Recycling extruders are specifically engineered for processing recycled materials, making them a vital component in sustainability initiatives. They efficiently convert scrap PVC and other polymers into usable materials, supporting eco-friendly manufacturing practices. For B2B buyers, investing in recycling extruders can enhance their corporate responsibility profile, although they may necessitate additional processing steps to ensure material quality.

What Are the Benefits of Using Laboratory Extruders in R&D?

Laboratory extruders are compact and versatile, making them ideal for research and development applications. They allow manufacturers to conduct product testing and pilot runs with small quantities of material, facilitating innovation without the need for large-scale production. While they offer cost-effective solutions for prototyping, laboratory extruders are limited in production capacity, which may restrict their use in high-volume manufacturing scenarios.

Key Industrial Applications of pvc extruder

| Industry/Sector | Specific Application of PVC Extruder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Production of PVC Pipes | High durability and resistance to environmental factors | Energy efficiency, output capacity, and customizability |

| Automotive | Manufacturing of PVC Profiles for Interior Components | Lightweight and cost-effective materials | Material compatibility and processing speed |

| Medical Devices | Creation of PVC Tubing and Medical Profiles | Compliance with health standards and safety regulations | Precision in design and material sourcing |

| Packaging | Production of PVC Sheets and Films | Versatile applications in various packaging solutions | Quality of extruder technology and after-sales support |

| Recycling | Recycling of PVC Waste into New Products | Sustainability and cost savings on raw materials | Efficiency of recycling technology and maintenance needs |

How is PVC Extruder Used in Construction and What Problems Does It Solve?

In the construction industry, PVC extruders are pivotal in producing PVC pipes that are essential for plumbing, drainage, and irrigation systems. These pipes are lightweight yet strong, providing resistance to corrosion and chemicals. For international buyers, especially in regions like Africa and South America, sourcing high-output, energy-efficient extruders can significantly reduce production costs while ensuring high-quality outputs. Specific requirements include robust machine durability and the ability to customize pipe dimensions to meet local standards.

What Role Does PVC Extruder Play in the Automotive Sector?

The automotive industry utilizes PVC extruders to manufacture profiles used in interior components, such as trims and seals. These profiles are lightweight and cost-effective, enhancing vehicle fuel efficiency without compromising on quality. Buyers in the Middle East and Europe should consider sourcing extruders that offer high-speed processing and flexibility to adapt to various profile designs. Compliance with automotive standards for safety and material performance is also crucial in this sector.

How is PVC Extruder Essential for Medical Device Manufacturing?

In the medical sector, PVC extruders are instrumental in producing medical tubing and profiles that adhere to stringent health regulations. These products must be manufactured with precision to ensure safety and functionality. For B2B buyers in Europe and Africa, sourcing extruders with capabilities for cleanroom environments and material traceability is vital. Additionally, the ability to customize production lines for specific medical applications enhances operational efficiency and compliance with regulatory standards.

What Benefits Does PVC Extruder Offer in Packaging Applications?

PVC extruders are widely used in producing sheets and films for packaging solutions across various industries, including food and consumer goods. The versatility of PVC allows for the creation of flexible, durable, and moisture-resistant packaging. Businesses in South America and Africa should focus on sourcing high-performance extruders that can handle diverse material types and thicknesses, ensuring high-quality production while optimizing energy consumption and waste reduction.

How Does PVC Extruder Contribute to Recycling Initiatives?

The recycling sector benefits from PVC extruders designed to process recycled PVC waste into new products. This application not only supports sustainability efforts but also provides significant cost savings on raw materials. For international buyers, particularly in regions with growing environmental regulations, sourcing efficient recycling extruders that maximize output and minimize energy consumption is essential. Key considerations include the technology used for processing and the availability of after-sales support to maintain operational efficiency.

3 Common User Pain Points for ‘pvc extruder’ & Their Solutions

Scenario 1: Navigating High Energy Costs in PVC Extrusion

The Problem:

In the current landscape, many B2B buyers are grappling with soaring energy costs, which significantly impact the operational expenses of running PVC extrusion lines. This challenge is especially pronounced in regions like Africa and South America, where energy reliability can be inconsistent and prices continue to rise. Buyers often find themselves torn between maintaining production efficiency and managing these escalating costs, leading to tough decisions on whether to invest in newer, more energy-efficient machinery or continue using outdated equipment that consumes excessive power.

The Solution:

To mitigate high energy costs, B2B buyers should prioritize sourcing energy-efficient PVC extruders. When selecting machinery, look for models designed with optimized screw geometries and advanced insulation technologies that minimize energy consumption while maximizing output. Manufacturers such as Bausano and KraussMaffei offer extruders specifically engineered for energy efficiency, which can drastically reduce operational costs. Additionally, consider integrating automation systems that optimize energy use by adjusting machine settings in real time based on production demands. This proactive approach not only curtails energy expenses but also enhances overall production efficiency.

Illustrative image related to pvc extruder

Scenario 2: Ensuring Consistent Product Quality

The Problem:

Another prevalent issue for buyers in the PVC extrusion industry is maintaining consistent product quality. Variability in the extrusion process can lead to defects, such as surface imperfections or dimensional inaccuracies in the final product. This inconsistency can be particularly damaging for businesses that supply high-stakes industries, like construction or medical devices, where quality standards are stringent. Buyers often face pressure to meet these standards while managing production timelines and costs.

The Solution:

To address quality concerns, it’s crucial to invest in advanced extrusion technology that includes precise temperature control and material handling systems. Look for PVC extruders that feature real-time monitoring capabilities, allowing operators to adjust parameters on-the-fly. Manufacturers like Battenfeld-Cincinnati and Bausano provide systems with built-in quality assurance features, enabling consistent monitoring of material flow and temperature. Furthermore, implementing a robust quality control process that includes regular maintenance checks and calibration of machinery can help sustain high production standards. Collaborating with suppliers who offer comprehensive after-sales support can also be advantageous in addressing any emerging quality issues swiftly.

Scenario 3: Managing Material Waste and Sustainability Concerns

The Problem:

As sustainability becomes increasingly important in global markets, B2B buyers in the PVC extrusion sector are facing pressure to minimize material waste and enhance recycling efforts. Many companies find themselves with significant scrap material that not only represents a loss in revenue but also poses environmental concerns. Buyers are challenged to balance profitability with the need to adopt more sustainable practices, particularly in regions where environmental regulations are tightening.

The Solution:

To effectively manage material waste, buyers should seek PVC extruders equipped with recycling capabilities. Investing in machines that can process scrap material into usable products is crucial. For instance, extruders designed for regranulation allow for the recovery of production waste and post-consumer plastics, effectively reducing overall material costs. Additionally, implementing a closed-loop system within the production line can help streamline the recycling process. Collaborating with manufacturers that focus on sustainability, like Bausano, will ensure that the equipment not only meets current needs but also aligns with future environmental goals. Training employees on best practices for waste management and recycling processes can further enhance sustainability efforts and contribute to a more efficient operation.

Strategic Material Selection Guide for pvc extruder

What Are the Key Materials for PVC Extruders in B2B Applications?

When selecting materials for PVC extruders, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in PVC extrusion, providing insights that can aid international B2B buyers in making informed decisions.

Illustrative image related to pvc extruder

What Are the Key Properties of PVC for Extrusion?

PVC (Polyvinyl Chloride) is widely used in extrusion due to its favorable properties. It has excellent chemical resistance, making it suitable for various applications. PVC can withstand moderate temperatures, typically up to 60°C (140°F), and is available in rigid and flexible forms.

Pros: PVC is cost-effective, lightweight, and easy to process, which enhances productivity. It also has good mechanical strength and can be modified to meet specific application requirements.

Cons: PVC has limitations in high-temperature applications and can become brittle over time when exposed to UV light unless stabilized.

Impact on Application: PVC is ideal for producing pipes, profiles, and sheets, particularly in construction and plumbing.

Illustrative image related to pvc extruder

Considerations for Buyers: International buyers should ensure compliance with local standards such as ASTM and DIN, particularly in regions like Africa and South America, where regulations may vary significantly.

How Does Polypropylene (PP) Compare for PVC Extrusion?

Polypropylene is another common material used in conjunction with PVC in extrusion processes. It offers good chemical resistance and a higher temperature tolerance, typically up to 100°C (212°F).

Pros: PP is lightweight, has excellent impact resistance, and can be recycled. Its higher melting point allows for faster processing speeds and better performance in high-temperature applications.

Illustrative image related to pvc extruder

Cons: The initial cost of PP can be higher than PVC, and it may require more complex processing techniques, which could lead to increased manufacturing costs.

Impact on Application: PP is often used for applications that require durability and flexibility, such as automotive parts and packaging.

Considerations for Buyers: Buyers should consider the availability of PP in their region and the associated costs, as well as compliance with recycling standards, particularly in Europe and the Middle East.

Illustrative image related to pvc extruder

What Role Does High-Density Polyethylene (HDPE) Play in PVC Extrusion?

HDPE is known for its high strength-to-density ratio and is used in various extrusion applications. It has a melting point around 120°C (248°F) and exhibits excellent chemical resistance.

Pros: HDPE is durable, resistant to impact and environmental stress, and has a long service life. It is also recyclable, making it a sustainable choice.

Cons: HDPE can be more expensive than PVC and may require specialized equipment for processing, which can complicate manufacturing.

Impact on Application: HDPE is suitable for applications requiring high durability, such as pipes and containers, especially where chemical exposure is a concern.

Considerations for Buyers: B2B buyers should be aware of the environmental regulations regarding HDPE in their regions and ensure compliance with local standards.

How Does Polycarbonate (PC) Enhance PVC Extrusion Applications?

Polycarbonate is a thermoplastic known for its high impact resistance and transparency. It can withstand temperatures up to 135°C (275°F), making it suitable for high-performance applications.

Pros: PC offers excellent durability, clarity, and UV resistance, making it ideal for outdoor applications. It also has good thermal stability.

Cons: The cost of polycarbonate is significantly higher than PVC, which may not be feasible for all applications. Additionally, it can be more challenging to process.

Illustrative image related to pvc extruder

Impact on Application: PC is often used in applications requiring high strength and transparency, such as safety goggles and lighting fixtures.

Considerations for Buyers: Buyers should evaluate the cost-benefit ratio of using polycarbonate in their applications and ensure compliance with relevant safety standards in their respective markets.

Summary Table of Material Selection for PVC Extruders

| Material | Typical Use Case for PVC Extruder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Pipes, profiles, sheets | Cost-effective and easy to process | Limited high-temperature resistance | Low |

| Polypropylene | Automotive parts, packaging | Higher temperature tolerance | Higher initial cost and complexity | Medium |

| High-Density Polyethylene | Pipes, containers | Durable and recyclable | More expensive and requires special equipment | Medium |

| Polycarbonate | Safety goggles, lighting fixtures | High impact resistance and clarity | Significantly higher cost and processing challenges | High |

This analysis provides a comprehensive overview of the materials used in PVC extrusion, highlighting their properties and implications for B2B buyers in various international markets. Understanding these factors will aid in making informed decisions tailored to specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc extruder

What Are the Main Stages in the Manufacturing Process of PVC Extruders?

The manufacturing process of PVC extruders encompasses several critical stages, ensuring that the final product meets the rigorous demands of the industry. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for PVC Extruders?

Material preparation is the first step and involves selecting high-quality raw materials, typically in the form of PVC pellets. These pellets are subjected to a series of processes that may include drying to remove moisture, which is crucial for ensuring optimal melting and processing. Advanced manufacturers may employ material blending, where additives like stabilizers, plasticizers, and colorants are mixed with the PVC to enhance performance characteristics. This step is essential for achieving the desired properties in the finished product.

Illustrative image related to pvc extruder

What Techniques Are Used in the Forming Stage of PVC Extruder Manufacturing?

The forming stage is where the prepared materials are transformed into the desired shape through extrusion. This process typically involves the use of single or twin-screw extruders, which apply heat and pressure to melt the PVC and push it through a die to create the specific profile or pipe. The choice between single and twin-screw extruders depends on the application; twin-screw extruders are often preferred for their superior mixing capabilities and better control over the material properties.

During this stage, manufacturers focus on optimizing screw design and barrel temperature to ensure uniform melting and efficient flow. Advanced techniques like co-extrusion can also be employed to produce multi-layer products, enhancing functionality and aesthetic appeal.

What Is Involved in the Assembly Process of PVC Extruders?

Once the extruded material is formed, the assembly process begins. This involves integrating various components such as the drive system, control panels, and auxiliary equipment like cooling systems and cutters. Precision in assembly is critical to ensure that all parts function seamlessly together, maintaining the integrity of the extrusion process.

In this phase, manufacturers often rely on automated systems to enhance accuracy and reduce assembly time. Quality checks are integrated into the assembly line to verify that each component meets specifications before moving to the next stage.

How Is the Finishing Process Conducted for PVC Extruders?

The finishing stage involves final adjustments and treatments to enhance the functionality and appearance of the extruder. This may include surface treatments, painting, or coating to protect against corrosion and wear. Additionally, manufacturers often conduct thorough inspections to ensure that the extruder adheres to quality standards before packaging and shipping.

What International Standards and Quality Assurance Practices Are Relevant to PVC Extruder Manufacturing?

Quality assurance is paramount in the manufacturing of PVC extruders, particularly for B2B buyers who rely on consistent performance and reliability. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers follow best practices in every aspect of production.

Specific industry certifications, such as CE marking for compliance with European safety standards or API standards for the oil and gas industry, may also be applicable. These certifications help buyers assess the quality and safety of the equipment they are purchasing.

Illustrative image related to pvc extruder

What Are the Key Quality Control Checkpoints in PVC Extruder Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process with several checkpoints:

- Incoming Quality Control (IQC): This initial step involves inspecting raw materials upon receipt to ensure they meet required specifications.

- In-Process Quality Control (IPQC): During the manufacturing stages, various parameters such as temperature, pressure, and material consistency are monitored. This real-time monitoring helps in identifying issues before they escalate.

- Final Quality Control (FQC): After assembly, the completed extruders undergo rigorous testing to ensure they meet performance criteria. This may include functional tests, stress tests, and visual inspections.

What Common Testing Methods Are Used to Ensure Quality in PVC Extruder Production?

Manufacturers employ a variety of testing methods to ensure quality, including:

- Mechanical Testing: Evaluating the strength and durability of the extruder components.

- Thermal Analysis: Assessing the thermal stability and behavior of the materials used.

- Dimensional Checks: Ensuring that all parts meet specified dimensions for proper fit and function.

These testing methods are vital for confirming that the extruder will perform reliably in demanding environments.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

B2B buyers must be proactive in verifying the quality control processes of their suppliers. Here are several strategies:

- Conduct Supplier Audits: Regular audits can provide insights into the manufacturer’s quality management practices and adherence to standards.

- Request Quality Assurance Reports: Suppliers should provide documentation that outlines their quality control processes, results from testing, and certifications obtained.

- Engage Third-Party Inspectors: Hiring independent inspectors to evaluate the quality of the equipment before shipment can offer an additional layer of assurance.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of the specific quality requirements and certifications relevant to their markets. Understanding local regulations and standards is crucial for compliance and successful importation.

Illustrative image related to pvc extruder

For instance, buyers in Europe must ensure that products meet CE marking requirements, while those in Africa may need to consider local compliance standards that could vary significantly from international norms. Establishing clear communication with suppliers regarding these requirements can mitigate risks and ensure smooth transactions.

Conclusion

In summary, the manufacturing processes and quality assurance practices for PVC extruders are multifaceted and require a meticulous approach to ensure high-quality outcomes. By understanding the various stages of production, the importance of quality control checkpoints, and how to verify supplier practices, B2B buyers can make informed decisions that align with their operational needs and compliance standards. This comprehensive knowledge not only fosters better supplier relationships but also enhances the overall efficiency and effectiveness of their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc extruder’

Introduction

Navigating the procurement of a PVC extruder is a critical step for businesses in the plastic processing industry. This guide provides a structured checklist to help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, make informed decisions. By following these steps, you can ensure that you select the right extruder to meet your operational needs and sustainability goals.

Illustrative image related to pvc extruder

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential before engaging with suppliers. Consider the type of PVC products you intend to produce, such as pipes, profiles, or sheets, and the expected output capacity. Specify features such as the type of extruder (single or twin screw), energy efficiency ratings, and compatibility with recycling materials, as these factors directly influence performance and cost.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in PVC extruders. Look for manufacturers with a strong reputation in the industry, especially those with experience in your target market. Utilize online platforms, trade shows, and industry publications to gather a list of suppliers who offer high-quality machines tailored to your specifications.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with international standards. This includes ISO certifications, CE markings, and any other relevant quality assurance credentials. These certifications not only indicate adherence to quality standards but also assure you of the machine’s reliability and safety during operation.

Step 4: Request Product Demonstrations or Samples

Whenever possible, request a demonstration of the extruder or samples of the end products it can produce. This allows you to assess the machine’s performance, energy consumption, and output quality firsthand. Pay close attention to the extruder’s efficiency in processing PVC and its ability to meet your specific production needs.

Step 5: Assess After-Sales Support and Service

Evaluate the after-sales support offered by potential suppliers. Reliable customer service is crucial for addressing any issues that may arise post-purchase. Ensure that the supplier provides comprehensive maintenance options, spare parts availability, and training for your staff to operate the extruder effectively.

Step 6: Compare Total Cost of Ownership

Look beyond the initial purchase price and consider the total cost of ownership (TCO) of the extruder. This includes energy consumption, maintenance costs, and the expected lifespan of the machine. Understanding the TCO will help you gauge the long-term financial implications and return on investment of your purchase.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to finalize the terms and conditions of the purchase. Discuss payment terms, delivery schedules, warranty agreements, and any additional services. A clear agreement will protect your interests and ensure that both parties are aligned on expectations moving forward.

By following this structured checklist, B2B buyers can confidently procure a PVC extruder that meets their operational needs and contributes to their business’s success.

Comprehensive Cost and Pricing Analysis for pvc extruder Sourcing

What Are the Key Cost Components in Sourcing PVC Extruders?

When sourcing PVC extruders, buyers must consider various cost components that contribute to the overall price. The primary elements include:

-

Materials: The cost of raw materials such as steel, aluminum, and specialized components like screws and barrels can vary significantly based on market conditions and the specific requirements of the extruder. Higher-quality materials often lead to increased durability and efficiency, but they also elevate the initial cost.

-

Labor: Labor costs involve the expenses associated with skilled technicians and engineers who design, assemble, and test the extruder. Countries with higher labor costs may see inflated prices, whereas regions with a lower cost of living may offer more competitive rates.

-

Manufacturing Overhead: This encompasses indirect costs such as facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these costs, making the final product more competitive.

-

Tooling: Custom tooling for specialized extruder designs can add to the initial investment. Buyers should inquire about the tooling costs upfront, as they can significantly affect the total expenditure.

-

Quality Control (QC): Ensuring that the extruder meets industry standards and customer specifications requires rigorous testing and quality assurance processes. Effective QC can prevent costly issues down the line, but it also adds to the upfront costs.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the buyer’s destination. International buyers should consider potential tariffs, freight charges, and insurance when calculating logistics costs.

-

Margin: Suppliers will include a margin in their pricing to cover their profit expectations. Understanding the typical margins in the industry can help buyers gauge whether they are receiving a fair price.

What Influences the Pricing of PVC Extruders?

Several factors can influence the pricing of PVC extruders, making it essential for buyers to understand the nuances involved:

-

Volume/MOQ: The volume of the order significantly impacts pricing. Suppliers often offer discounts for larger orders, so negotiating minimum order quantities (MOQs) can lead to substantial savings.

-

Specifications and Customization: Custom-built extruders tailored to specific applications or processes typically come at a higher cost. Buyers should clearly define their requirements to avoid unnecessary expenses associated with over-engineering.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO) can affect both the cost and the value of the extruder. Buyers should weigh the benefits of higher-quality components against their budget constraints.

-

Supplier Factors: Established suppliers with a solid reputation may charge premium prices due to their reliability and track record. Newer or less-known suppliers might offer lower prices to gain market share, but buyers should assess the risk involved.

-

Incoterms: The terms of shipping and delivery (Incoterms) can greatly influence total costs. Buyers should understand how these terms affect shipping responsibilities, insurance, and customs clearance to avoid unexpected charges.

What Are the Best Practices for Negotiating PVC Extruder Prices?

To achieve cost-efficiency in purchasing PVC extruders, buyers should adopt strategic negotiation practices:

-

Research Market Prices: Familiarize yourself with industry benchmarks and pricing trends to enhance your negotiating position. Understanding the typical price range for similar products can empower buyers during discussions.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term operational costs, including energy consumption, maintenance, and potential downtime. This holistic approach ensures that the selected extruder provides value over its lifecycle.

-

Build Relationships with Suppliers: Establishing a rapport with suppliers can lead to better pricing, improved service, and priority access to new technologies. Long-term partnerships often yield benefits that go beyond immediate cost savings.

-

Leverage Local Insights: For international buyers, understanding local market conditions, regulations, and cultural factors can provide leverage in negotiations. Engaging local experts can help navigate these complexities effectively.

-

Request Detailed Quotes: Ensure that all quotes break down the costs associated with each component. This transparency allows for better comparison and understanding of what factors influence pricing.

Conclusion

Sourcing PVC extruders involves a multifaceted analysis of costs and pricing influencers. By understanding these elements and employing effective negotiation strategies, international B2B buyers can make informed purchasing decisions that align with their operational needs and budget constraints. Keep in mind that prices can vary widely based on numerous factors, and it is crucial to approach each sourcing opportunity with diligence and clarity.

Alternatives Analysis: Comparing pvc extruder With Other Solutions

Introduction to Alternative Solutions for PVC Processing

When considering the production of PVC products, the choice of extrusion technology is crucial. While PVC extruders are a popular option, there are alternative solutions that may better suit specific needs, depending on factors such as application, budget, and production scale. This section explores viable alternatives to PVC extruders, providing a comparative analysis to assist B2B buyers in making informed decisions.

Illustrative image related to pvc extruder

Comparison Table

| Comparison Aspect | PVC Extruder | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|---|

| Performance | High output, excellent homogenization | Moderate output, suitable for specific applications | High output, versatile for various materials |

| Cost | Medium to high initial investment | Generally lower initial cost | Higher initial investment but offers greater efficiency |

| Ease of Implementation | Requires skilled setup and operation | Easier to set up, ideal for smaller operations | More complex setup, requires skilled labor |

| Maintenance | Moderate maintenance needs | Lower maintenance, simpler design | Higher maintenance due to complexity |

| Best Use Case | Large-scale PVC pipe and profile production | Specific applications like small parts | Versatile applications, including recycling and compounding |

Detailed Breakdown of Alternatives

Single Screw Extruder

Single screw extruders are simpler in design and operation compared to PVC extruders. They are often more cost-effective, making them suitable for smaller operations or businesses just starting in plastic processing. Their ease of setup allows for quick implementation, though they may have limitations in handling complex materials or achieving high outputs. This solution is ideal for production runs that focus on specific types of products, such as small parts or certain profiles.

Twin Screw Extruder

Twin screw extruders offer versatility and high performance, making them a strong alternative to PVC extruders. They can handle a wide range of materials, including recycled plastics, which is increasingly important in today’s sustainability-focused market. While they typically involve a higher initial investment and more complex maintenance, the efficiency gains and ability to process diverse materials can justify the costs for larger manufacturers. This makes them suitable for businesses aiming for high-volume production and product variety.

Conclusion: Choosing the Right Solution for PVC Processing Needs

Selecting the appropriate extrusion technology requires a thorough understanding of your production goals, budget constraints, and operational capabilities. PVC extruders are excellent for high-output applications but may not always be the best fit for every business. Single screw and twin screw extruders present viable alternatives, particularly for those focused on specific applications or looking to incorporate recycling into their processes. By carefully evaluating the comparative advantages and limitations of each option, B2B buyers can make strategic decisions that align with their manufacturing objectives and market demands.

Essential Technical Properties and Trade Terminology for pvc extruder

What Are the Key Technical Properties of PVC Extruders?

When evaluating PVC extruders, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

-

Screw Configuration

The screw configuration, whether single or twin-screw, significantly impacts the extrusion process. Twin-screw extruders offer better mixing and homogenization of materials, making them ideal for complex formulations and high-output applications. In contrast, single-screw extruders are simpler and more cost-effective for standard applications. Choosing the right configuration can lead to improved product quality and operational efficiency. -

Material Grade

The material grade of the extruder components, such as the barrel and screw, is vital for durability and performance. Common materials include high-strength steel and specialized alloys that resist wear and corrosion. Selecting the appropriate material grade ensures longevity and reduces maintenance costs, which is essential for companies looking to maximize their return on investment. -

Output Capacity

Measured in kilograms per hour (kg/h), output capacity determines how much material can be processed in a given time. High-output extruders are crucial for large-scale production facilities aiming to meet demand efficiently. Buyers should assess their production needs and choose an extruder that can handle their expected output without compromising quality. -

Temperature Control

Effective temperature control systems are essential for maintaining the optimal melting point of PVC during extrusion. Features such as cooling and heating zones help achieve consistent material processing, which is critical for product quality. Inadequate temperature control can lead to defects, making this property a vital consideration for manufacturers. -

Energy Efficiency

Energy-efficient extruders not only reduce operational costs but also contribute to sustainability goals. Look for models that utilize advanced technologies, such as induction heating or high-torque drives, which can significantly decrease energy consumption. This consideration is particularly important for businesses aiming to lower their carbon footprint. -

Tolerances

Tolerances refer to the permissible limits of variation in the dimensions of the extruded products. High precision in tolerances is necessary for applications where parts must fit together accurately, such as in construction or automotive industries. Understanding the required tolerances can guide buyers in selecting the right extruder for their specific applications.

What Are Common Trade Terms Related to PVC Extruders?

Navigating the landscape of PVC extrusion involves familiarizing oneself with specific industry jargon. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When sourcing PVC extruders, understanding OEM relationships can help buyers identify reliable suppliers and ensure they receive quality products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, as it can affect cash flow and storage capabilities, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a company solicits bids from suppliers to obtain pricing and terms for specific products or services. For buyers, issuing an RFQ for PVC extruders allows for comparison among different suppliers and aids in making cost-effective decisions. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms is crucial for understanding shipping costs, risks, and logistics when importing or exporting PVC extruders. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for production planning and can influence decisions regarding suppliers, especially in industries where time-to-market is critical. -

After-Sales Support

This term encompasses the services provided after a product has been purchased, including maintenance, training, and technical support. Strong after-sales support can enhance the longevity and performance of PVC extruders, making it an important factor in supplier selection.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing PVC extruders more effectively, ensuring they select the right equipment for their operational needs.

Illustrative image related to pvc extruder

Navigating Market Dynamics and Sourcing Trends in the pvc extruder Sector

What Are the Key Market Drivers and Trends in the PVC Extruder Sector?

The PVC extruder market is witnessing robust growth driven by increasing demand for PVC products across various industries, including construction, automotive, and packaging. A significant factor propelling this growth is the ongoing urbanization and infrastructure development in emerging markets, particularly in Africa and South America. These regions are investing heavily in construction and infrastructure projects, which in turn boosts the demand for PVC pipes and profiles.

Another trend shaping the market is the advancement of extrusion technology, focusing on energy efficiency and high output. Companies are increasingly adopting state-of-the-art extruders with optimized screw geometries that enhance homogenization and product quality while reducing energy consumption. Additionally, the rise of Industry 4.0 technologies, such as IoT and automation, is transforming the sourcing landscape, enabling manufacturers to achieve real-time monitoring and predictive maintenance, thereby minimizing downtime and operational costs.

International buyers must also consider regional variations in demand. For instance, in the Middle East, the focus is on high-performance extruders that can handle diverse materials for complex applications. Meanwhile, in Europe, sustainability is becoming a crucial factor, driving the demand for recycling extruders capable of processing post-consumer waste. Buyers should remain agile and informed about these dynamics to make strategic sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact the PVC Extruder Sector?

Sustainability is no longer a mere trend; it has become a business imperative in the PVC extruder sector. The environmental impact of plastic production, particularly PVC, has led to increasing scrutiny from regulators and consumers alike. Companies are now prioritizing the reduction of their carbon footprint through energy-efficient machinery and sustainable practices. For instance, advancements in recycling technology have enabled the creation of recycling extruders that can process both PVC and polyolefin materials, thus contributing to a circular economy.

Ethical sourcing has emerged as a critical aspect of supply chain management. Buyers are encouraged to engage with suppliers who adhere to environmental standards and certifications, such as ISO 14001, which demonstrate a commitment to sustainable practices. Furthermore, the use of eco-friendly raw materials and additives can significantly enhance product sustainability and marketability. As consumers become more environmentally conscious, partnering with suppliers who prioritize sustainability can enhance brand reputation and customer loyalty.

In summary, B2B buyers in the PVC extruder sector should focus on sourcing from manufacturers that prioritize sustainability and ethical practices, as these factors are increasingly influencing purchasing decisions and regulatory compliance.

What Is the Historical Context of the PVC Extruder Industry?

The PVC extruder industry has a rich history dating back to the mid-20th century. Initially, the focus was on the production of PVC pipes, which were rapidly adopted for various applications due to their durability and cost-effectiveness. Over the decades, advancements in technology have led to the development of more sophisticated extruders, including single-screw and twin-screw systems that cater to a broader range of applications, from profiles to sheets and pellets.

The evolution of the PVC extruder sector has also been marked by a growing emphasis on energy efficiency and automation. As global demand for PVC products surged, manufacturers began investing in high-performance extruders designed to optimize production processes while minimizing waste. This historical context is vital for B2B buyers, as it highlights the industry’s adaptability and ongoing innovation, essential for meeting the diverse needs of international markets. Understanding this evolution can guide buyers in selecting the most suitable extruder technology for their specific applications and regional demands.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc extruder

-

How do I solve issues with my PVC extruder’s output quality?

To address output quality issues with your PVC extruder, first assess the raw materials used, as impurities or inconsistencies can affect the final product. Next, check the temperature settings and ensure they align with the recommended processing parameters for PVC. Regular maintenance of the extruder, including cleaning and checking screw and barrel wear, is crucial. Implementing a quality control process that includes testing samples can also help identify problems early. Collaborating with your supplier for technical support can provide insights into optimizing your extrusion process. -

What is the best type of PVC extruder for producing pipes?

For producing PVC pipes, twin-screw extruders are often considered the best option due to their ability to provide excellent mixing and homogenization, resulting in consistent product quality. They also offer higher output rates, making them suitable for large-scale production. However, single-screw extruders can be effective for specific applications where cost and simplicity are priorities. Evaluate your production capacity, product specifications, and budget to determine the most appropriate extruder type for your needs. -

How can I customize my PVC extruder for specific applications?

Customization of a PVC extruder can be achieved by selecting specific screw designs, barrel configurations, and downstream equipment tailored to your application. Many manufacturers offer modular systems that allow you to adapt the extruder based on production requirements, such as adding co-extrusion capabilities or specialized heating systems for improved energy efficiency. Engaging directly with the manufacturer during the design phase ensures that your unique specifications are met, enhancing performance for your specific applications. -

What are the typical minimum order quantities (MOQs) for PVC extruders?

Minimum order quantities (MOQs) for PVC extruders can vary significantly based on the manufacturer and the complexity of the machine. Generally, standard models may have lower MOQs, while custom configurations could require larger orders to justify production costs. It is advisable to discuss your requirements with suppliers to understand their MOQ policies and explore options for smaller initial orders or leasing arrangements if you’re testing the market. -

What payment terms should I expect when purchasing a PVC extruder?

Payment terms for purchasing a PVC extruder typically range from 30% to 50% upfront, with the remainder due upon delivery or installation. Some suppliers may offer financing options or extended payment terms for larger orders. It’s essential to clarify payment conditions before finalizing the purchase, including any potential discounts for early payment or penalties for late payments. Additionally, consider the implications of international payment methods, such as currency exchange rates and transaction fees. -

How can I effectively vet PVC extruder suppliers?

To vet PVC extruder suppliers, begin by researching their industry reputation and track record. Look for customer reviews, case studies, and testimonials. Request references from other businesses that have purchased similar equipment. Verify their certifications and compliance with international standards, which is crucial for quality assurance. Additionally, assess their after-sales support, including warranty terms and availability of spare parts. Engaging in direct communication with suppliers can also provide insights into their responsiveness and willingness to meet your specific needs. -

What logistics considerations should I keep in mind when importing a PVC extruder?

When importing a PVC extruder, consider logistics factors such as shipping methods, customs regulations, and lead times. Ensure that the supplier provides detailed information about shipping costs and delivery timelines. Familiarize yourself with import duties and tariffs applicable in your country, as these can significantly impact overall costs. Partnering with a reliable freight forwarder can facilitate smoother logistics management, ensuring compliance with international shipping regulations and timely delivery of your equipment. -

What quality assurance measures should I implement for my PVC extruder?

Implementing quality assurance measures for your PVC extruder involves regular inspections and maintenance checks. Establish a routine for monitoring key performance indicators such as output consistency, temperature control, and material feed rates. Utilize in-process testing to identify issues early and ensure that the produced PVC meets industry standards. Collaborate with your supplier to receive training on best practices for operation and maintenance, and consider investing in technology that allows for real-time monitoring of the extrusion process for enhanced quality control.

Top 4 Pvc Extruder Manufacturers & Suppliers List

1. Bausano – Custom Plastic Extruders

Domain: bausano.com

Registered: 2000 (25 years)

Introduction: Bausano offers a range of high-quality custom plastic extruders, including: 1. **Single Screw Extruders** – E-GO series for pipes and profiles, customizable with Digital Extruder Control 4.0. 2. **Twin-Screw Extruders** – MD Nextmover series, known for durability, performance, and energy savings. 3. **Co-Extruders** – Designed for processing popular thermoplastics with screw diameters up to 60 mm….

2. KraussMaffei – 36D Series Parallel Twin-Screw Extruders

Domain: kraussmaffei.com

Registered: 1996 (29 years)

Introduction: Powerful machine technology, flexible application; Parallel twin-screw extruders of the 36D series designed for PVC processing; Goal: maximum economic efficiency through high output and best product quality; Broad product range with modular concept for economical and high-performance production solutions tailored to pipe extrusion; Low maintenance; Safe degassing; Wide processing spectrum; Increas…

3. Extruded Plastics – PVC Extrusion Solutions

Domain: extrudedplastics.com

Registered: 2000 (25 years)

Introduction: PVC (Polyvinyl Chloride) extrusion is a high-volume manufacturing process used to form continuous profiles by melting raw PVC plastic. PVC is the most commonly extruded rigid plastic, known for being cheap, recyclable, and versatile for both indoor and outdoor use. Rigid PVC extrusions are popular in various industrial, commercial, and residential applications due to their strong chemical resilien…

4. Rollepaal – High Capacity Pipe Production Solutions

Domain: rollepaal.com

Registered: 1998 (27 years)

Introduction: Key Features: High production capacity (up to 1800kg/hr or 4000lb/hr), precision control, durability, enhanced screw design for homogeneous melt, direct torque control for consistent output, direct AC drive for energy efficiency, operator-friendly Windows-based controls with recipe storage, precise temperature control with internal screw cooling and air-cooled barrel. Range: T-Rex type Twin Screw …

Strategic Sourcing Conclusion and Outlook for pvc extruder

As the demand for PVC extruders continues to grow globally, particularly in emerging markets across Africa, South America, the Middle East, and Europe, the importance of strategic sourcing cannot be overstated. Businesses looking to invest in PVC extrusion technology should prioritize suppliers that offer energy-efficient solutions, customizable machinery, and robust after-sales support. This approach not only enhances production efficiency but also aligns with sustainability goals, which are increasingly vital in today’s market landscape.

Key takeaways include recognizing the diverse applications of PVC extruders—from pipe and profile production to recycling initiatives—and the necessity of selecting technology that meets specific operational needs. By engaging with reputable manufacturers that provide tailored solutions, companies can secure a competitive edge while ensuring quality and reliability in their production processes.

Looking ahead, international buyers should leverage this moment of innovation and sustainability in the extrusion sector. By partnering with the right suppliers, businesses can not only optimize their operations but also contribute positively to environmental stewardship. Engage with leading manufacturers today to explore how strategic sourcing can drive your business forward in the PVC extrusion market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to pvc extruder

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.