Is Your Dust Extractor Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for dust extractor

In the quest for maintaining a clean and safe workspace, sourcing an effective dust extractor can be a daunting challenge for international B2B buyers. Whether in bustling manufacturing hubs across Africa, the emerging markets of South America, the industrial landscapes of the Middle East, or the established economies of Europe like Germany, the need for robust dust extraction solutions is paramount. This guide delves into the multifaceted world of dust extractors, offering insights into various types, their applications, and critical factors such as supplier vetting and cost analysis.

Navigating the global market for dust extractors requires a nuanced understanding of different technologies and their suitability for specific industries, including woodworking, construction, and manufacturing. Buyers will benefit from an exploration of features like HEPA filtration, airflow capacity, and noise levels, which are essential for ensuring compliance with health and safety regulations. Additionally, the guide will provide actionable strategies for evaluating suppliers, helping businesses make informed decisions that align with their operational needs.

Empowering B2B buyers with comprehensive knowledge, this guide serves as a valuable resource for those looking to enhance their dust management systems, ultimately fostering a cleaner, healthier work environment. With the right insights, international buyers can confidently select dust extraction solutions that not only meet their immediate needs but also support long-term operational excellence.

Understanding dust extractor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Dust Extractor | Compact, often wheeled; designed for mobility | Small workshops, construction sites | Pros: Easy to transport, suitable for small tasks. Cons: Limited capacity and power compared to industrial models. |

| Industrial Dust Collector | High capacity, stationary; often integrated systems | Manufacturing, large-scale woodworking | Pros: Efficient for high-volume dust, durable. Cons: Higher cost, requires dedicated space. |

| HEPA Dust Extractor | Equipped with HEPA filters for fine particle capture | Healthcare, food processing | Pros: Superior air quality, essential for compliance. Cons: Maintenance and filter replacement can be costly. |

| Wet/Dry Vacuum | Versatile for both wet and dry debris | General maintenance, home renovations | Pros: Multi-functional, often lower cost. Cons: Less effective for fine dust, typically lacks HEPA filtration. |

| Pneumatic Dust Extractor | Operated by compressed air, often lightweight | Automotive, pneumatic tool applications | Pros: Lightweight, can be used in remote locations. Cons: Requires a compressor, limited to pneumatic tools. |

What are the characteristics of Portable Dust Extractors?

Portable dust extractors are designed for ease of movement, making them ideal for small workshops and job sites. They typically feature a compact design with wheels for mobility and can connect to various power tools for immediate dust collection. When considering a portable dust extractor, businesses should evaluate the airflow capacity, filter efficiency, and noise levels, as these factors will impact usability in diverse environments.

How do Industrial Dust Collectors differ from other types?

Industrial dust collectors are robust systems built for high-capacity dust extraction in manufacturing and large-scale woodworking operations. These units are often stationary and can handle significant volumes of debris, making them essential for maintaining air quality in large facilities. Buyers should consider installation requirements, maintenance costs, and compatibility with existing equipment when selecting an industrial dust collector.

Why are HEPA Dust Extractors critical in certain industries?

HEPA dust extractors are equipped with filters that capture 99.97% of particles as small as 0.3 microns, making them crucial in sectors such as healthcare and food processing, where air quality is paramount. These extractors ensure compliance with stringent regulations and contribute to a safer working environment. B2B buyers should assess the filter replacement cycle and the overall cost of ownership, as high-quality HEPA filters can be expensive.

What advantages do Wet/Dry Vacuums offer for general maintenance?

Wet/dry vacuums are versatile tools suitable for collecting both wet and dry debris, making them popular in maintenance and renovation tasks. They are generally more affordable and can be used in a variety of settings. However, their effectiveness in handling fine dust is limited compared to specialized dust extractors. Buyers should consider the vacuum’s capacity, filtration system, and ease of use for the intended applications.

What are the benefits and limitations of Pneumatic Dust Extractors?

Pneumatic dust extractors operate using compressed air, providing a lightweight and flexible solution for dust collection in automotive and other pneumatic tool applications. They are ideal for remote locations where electricity may not be available. However, they require a compressor and are limited to pneumatic tools, which may not suit all operational needs. Businesses should evaluate the availability of compressed air infrastructure when considering this option.

Key Industrial Applications of dust extractor

| Industry/Sector | Specific Application of dust extractor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Collecting sawdust and wood shavings from machinery | Enhances air quality, reduces fire hazards, and improves workspace cleanliness | HEPA filtration, portability, compatibility with various tools |

| Construction | Dust control during demolition and renovation projects | Protects worker health, complies with safety regulations, and minimizes cleanup time | Robust filtration systems, mobility on job sites, noise levels |

| Metalworking | Removing metal shavings and dust from machining processes | Improves equipment efficiency, enhances worker safety, and maintains clean work areas | CFM ratings, compatibility with different machines, filter durability |

| Pharmaceuticals | Dust extraction in tablet manufacturing and powder handling | Ensures product purity, complies with health standards, and protects worker health | HEPA or ULPA filters, explosion-proof designs, ease of cleaning |

| Food Processing | Collecting flour, sugar, and other particulate matter | Maintains hygiene, prevents contamination, and improves air quality | Compliance with food safety standards, ease of maintenance, efficiency |

How is Dust Extraction Used in Woodworking?

In the woodworking industry, dust extractors are essential for collecting sawdust and wood shavings produced by various machines. These systems not only enhance air quality but also mitigate fire hazards associated with combustible wood dust. For international buyers, particularly in regions with stringent safety regulations, investing in extractors with HEPA filtration is crucial. Additionally, the portability and compatibility of dust extractors with different tools can significantly improve workflow efficiency in workshops, especially in smaller spaces common in many African and South American countries.

What Role Does Dust Extraction Play in Construction?

During construction projects, particularly demolition and renovation, dust extractors are vital for controlling airborne dust particles. They help protect workers’ health by reducing exposure to harmful dust and ensuring compliance with occupational safety regulations. Buyers in the Middle East and Europe should consider extractors that are robust enough for job site mobility and equipped with powerful filtration systems to handle various debris types. The ability to easily transport and set up dust extractors can also reduce overall cleanup time, making them a valuable investment.

How is Dust Extraction Beneficial in Metalworking?

In metalworking applications, dust extractors are used to remove metal shavings and particulate matter generated during machining processes. This not only improves equipment efficiency by preventing buildup but also enhances workplace safety by maintaining clean environments. For B2B buyers, particularly in manufacturing hubs in Europe and South America, it is essential to select extractors with high CFM ratings and durability to withstand rigorous use. Compatibility with different types of machinery is another critical consideration, ensuring seamless integration into existing operations.

Why is Dust Extraction Important in Pharmaceuticals?

In the pharmaceutical industry, dust extractors are critical for maintaining cleanliness during tablet manufacturing and powder handling processes. They ensure product purity by preventing contamination from airborne particulates while protecting worker health. Buyers from Africa and the Middle East should prioritize extractors with HEPA or ULPA filters that meet stringent health and safety standards. Additionally, explosion-proof designs may be necessary for certain applications, highlighting the need for careful sourcing to meet regulatory requirements.

How is Dust Extraction Used in Food Processing?

In food processing, dust extractors are employed to collect particulate matter such as flour and sugar, which can contaminate products if not managed properly. This practice is essential for maintaining hygiene and improving air quality within production facilities. International buyers, especially in regions with strict food safety regulations, should look for dust extractors that comply with these standards. Ease of maintenance and efficiency are also vital, as they contribute to the overall effectiveness of dust management systems in food production environments.

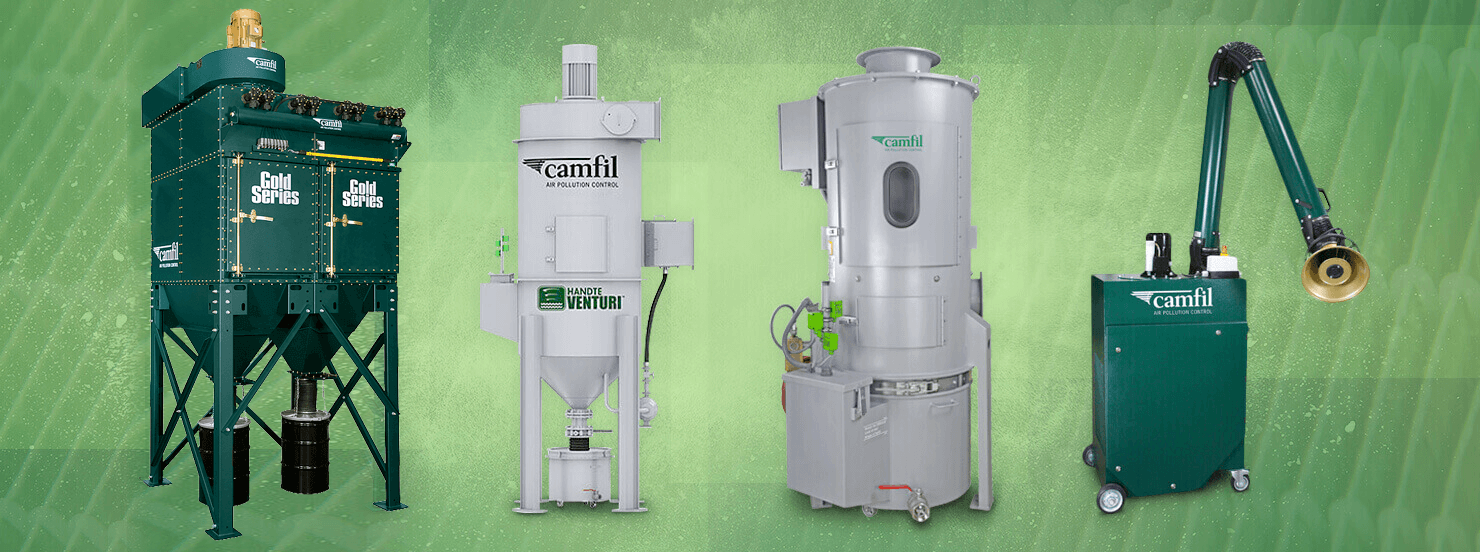

Illustrative image related to dust extractor

3 Common User Pain Points for ‘dust extractor’ & Their Solutions

Scenario 1: Inadequate Dust Collection in High-Volume Operations

The Problem: B2B buyers in industries such as woodworking, metalworking, or construction often face challenges with dust extractors that cannot handle the volume of dust generated by their operations. This inadequacy can lead to poor air quality, health risks for workers, and damage to machinery due to dust buildup. For example, a cabinet manufacturer may find that their current dust extractor fails to capture all the fine particles produced during sanding, resulting in airborne dust that settles on finished products, ultimately affecting quality and increasing rework costs.

The Solution: To address this issue, B2B buyers should prioritize selecting a dust extractor with a high cubic feet per minute (CFM) rating and efficient filtration systems, such as HEPA filters, which can effectively capture fine dust particles. When sourcing dust extractors, consider the specific needs of your operation, including the types of tools used and the volume of dust generated. Investing in a system that offers adjustable suction power can help manage varying dust loads throughout the day. Additionally, ensure the extractor has adequate capacity to minimize frequent emptying and downtime. Regular maintenance, such as cleaning filters and inspecting hoses, is essential to maintain optimal performance.

Scenario 2: Compatibility Issues with Existing Tools

The Problem: Many B2B buyers encounter frustration when their dust extractors are not compatible with the tools they already own. For instance, a construction company may purchase a dust extractor that has a unique hose diameter or connection type, making it difficult to use with standard power tools. This can lead to inefficiencies, as workers spend time adapting tools or manually cleaning up dust, which defeats the purpose of having a dust extraction system in the first place.

The Solution: To prevent compatibility issues, B2B buyers should look for dust extractors that feature universal or adjustable connections. Researching models that come with a range of hose attachments or adapters can save time and enhance usability. When specifying a dust extractor, consider the types of tools most frequently used in your operations and ensure that the extractor can accommodate these tools seamlessly. Furthermore, investing in a dust extractor with onboard power outlets can streamline operations by allowing tools to be plugged directly into the extractor, triggering automatic activation when the tool is in use.

Scenario 3: High Noise Levels Disrupting Work Environments

The Problem: Noise pollution is a significant concern in many industrial settings, where workers are already exposed to high noise levels from machinery. Dust extractors can contribute to this issue, with some models operating at decibel levels that exceed safe limits. For instance, a manufacturing facility might find that their dust extractor creates an environment that is not only uncomfortable but also violates occupational health regulations, leading to potential fines and decreased employee morale.

The Solution: To tackle noise issues, B2B buyers should seek dust extractors designed with noise reduction features, such as sound insulation or quieter motor technology. When evaluating options, look for models that provide decibel ratings and compare them to industry standards. Additionally, consider investing in mobile dust extractors equipped with rubber casters, which not only enhance portability but can also help reduce noise when moved. Implementing noise control measures, such as placing the extractor in a dedicated, isolated space or using sound-absorbing materials around the work area, can also mitigate disruptions. Educating staff about the importance of wearing hearing protection can further enhance workplace safety while using dust extractors.

Strategic Material Selection Guide for dust extractor

What Are the Key Materials Used in Dust Extractors?

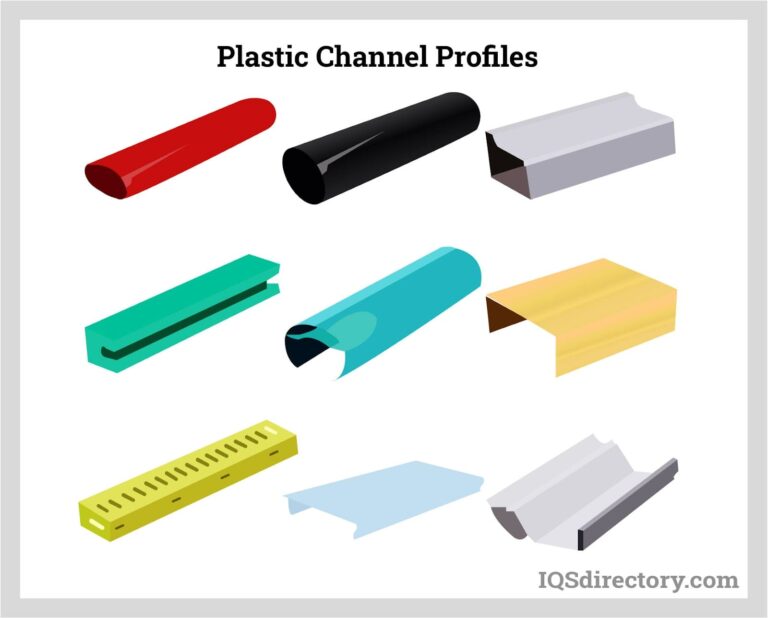

When selecting a dust extractor, the choice of materials significantly impacts performance, durability, and cost. Here, we analyze four common materials used in the construction of dust extractors: plastic, metal, composite, and rubber. Each material has unique properties that cater to different operational needs and environments.

How Does Plastic Perform in Dust Extractors?

Plastic is widely used in dust extractors due to its lightweight nature and resistance to corrosion. Common types include high-density polyethylene (HDPE) and polypropylene. These plastics can typically withstand temperatures up to 80°C (176°F) and pressures of around 5 psi, making them suitable for various dust collection applications.

Pros: Plastic is generally more affordable than metal, making it an attractive option for budget-conscious buyers. Its lightweight nature enhances portability, which is essential for mobile dust extractors.

Cons: While durable, plastic can be less resistant to impact and may degrade over time under UV exposure. This can be a concern in regions with high sun exposure.

Illustrative image related to dust extractor

Impact on Application: Plastic is suitable for collecting non-abrasive dust and particles. However, it may not be ideal for heavy-duty industrial applications where metal dust or sharp particles are prevalent.

Considerations for International Buyers: Compliance with local regulations regarding plastic waste and recycling can influence material choice. Buyers in Europe, for instance, must consider the EU’s REACH regulation, which governs the use of chemicals in plastics.

What Advantages Do Metals Offer in Dust Extractors?

Metal, particularly steel and aluminum, is favored in heavy-duty dust extractors. Steel can handle high temperatures (up to 300°C or 572°F) and pressures, making it suitable for industrial applications. Aluminum offers a lighter alternative with good corrosion resistance.

Pros: Metal dust extractors are robust and have a long lifespan, making them ideal for industrial environments. Their ability to handle high volumes of dust and abrasive materials is unmatched.

Cons: The higher cost of metal materials can be a barrier for some buyers. Additionally, metal extractors are heavier, which may reduce portability.

Impact on Application: Metals are suitable for applications involving wood, metal shavings, and other abrasive materials. They are often preferred in industries like woodworking and metalworking.

Considerations for International Buyers: Compliance with standards such as ASTM for metals is crucial. Buyers should also consider the availability of replacement parts in their region.

How Do Composites Enhance Dust Extractor Performance?

Composite materials, which often combine plastics and metals, offer a balance between weight and strength. These materials can withstand a range of temperatures and pressures, depending on their specific formulation.

Pros: Composites provide excellent durability and resistance to impact and corrosion. They can be engineered for specific applications, allowing for customization.

Illustrative image related to dust extractor

Cons: The manufacturing process for composites can be complex and costly, potentially leading to higher prices for end-users.

Impact on Application: Composites are suitable for specialized applications, such as in environments with extreme temperatures or corrosive substances.

Considerations for International Buyers: Buyers should verify the composite’s compliance with local standards, as different regions may have varying regulations regarding material safety and environmental impact.

What Role Does Rubber Play in Dust Extractors?

Rubber is primarily used for seals, hoses, and gaskets in dust extractors. It provides flexibility and excellent sealing capabilities, which are essential for preventing dust leaks.

Pros: Rubber components can withstand a range of temperatures and are resistant to wear and tear, enhancing the longevity of dust extractors.

Cons: Rubber can degrade over time, especially when exposed to certain chemicals or extreme temperatures. This necessitates regular maintenance and replacement.

Impact on Application: Rubber is critical in ensuring that dust extractors operate efficiently by maintaining airtight seals, which is essential for optimal performance.

Considerations for International Buyers: Buyers should consider the availability of rubber components in their region and any potential import restrictions on specific rubber types.

Summary Table of Material Selection for Dust Extractors

| Material | Typical Use Case for dust extractor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Hobbyist and light industrial use | Lightweight and cost-effective | Less durable, UV degradation risk | Low |

| Metal | Heavy-duty industrial applications | High durability and temperature resistance | Higher cost, reduced portability | High |

| Composite | Specialized applications | Customizable strength and durability | Complex manufacturing process | Medium |

| Rubber | Seals and hoses | Excellent sealing and flexibility | Degrades over time, requires maintenance | Medium |

This guide provides a comprehensive overview of material selection for dust extractors, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for dust extractor

What Are the Key Stages in the Manufacturing Process of Dust Extractors?

The manufacturing of dust extractors involves several critical stages, each designed to ensure the final product meets performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Dust Extractor Manufacturing?

The first step in manufacturing dust extractors is selecting appropriate materials. Common materials include high-density plastics for housings, steel or aluminum for frames, and specialized filters (e.g., HEPA filters) that capture fine particles. Material selection is crucial as it impacts durability, weight, and overall performance. Suppliers often conduct rigorous tests to ensure materials can withstand the operational demands of dust extraction.

How Are Dust Extractors Formed and Assembled?

After materials are prepared, the forming stage takes place. This may involve processes like injection molding for plastic components, metal stamping for structural parts, and welding for frame assembly. Advanced techniques such as CNC machining may also be employed for precision parts.

Once individual components are formed, the assembly stage begins. This involves integrating various parts, including motors, filtration systems, and hoses. Automated assembly lines are commonly used to enhance efficiency and reduce human error. Each dust extractor is assembled according to strict design specifications to ensure optimal performance.

What Finishing Processes Are Applied to Dust Extractors?

The final stage of manufacturing is finishing. This can include painting, coating, or applying finishes that enhance aesthetics and protect against corrosion. For dust extractors, a smooth finish is essential to prevent dust buildup and facilitate cleaning. Quality checks during this stage ensure that all finishes meet industry standards for durability and appearance.

How Is Quality Assurance Implemented in Dust Extractor Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of dust extractors. International standards like ISO 9001 provide a framework for ensuring consistent quality throughout the production cycle. Adhering to these standards helps manufacturers maintain high-quality outputs and enhances customer satisfaction.

Illustrative image related to dust extractor

What Are the Key International and Industry-Specific Standards for Quality Assurance?

In addition to ISO 9001, various industry-specific certifications are relevant. For example, CE marking indicates compliance with European health, safety, and environmental protection standards. In regions like Africa and South America, adherence to local standards and certifications may also be necessary, and manufacturers often seek to align with international norms to facilitate trade.

What Are the Quality Control Checkpoints in Dust Extractor Production?

Quality control (QC) checkpoints are established at various stages of the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to monitor adherence to production specifications.

- Final Quality Control (FQC): Once assembly is complete, a final inspection is conducted to verify that the finished product meets all performance and safety criteria.

Common testing methods used in QC include airflow testing, filtration efficiency tests, and noise level assessments. These tests ensure that the dust extractors perform effectively in real-world conditions.

Illustrative image related to dust extractor

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical. Here are several strategies:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. This can include reviewing their quality management systems and production capabilities.

- Quality Reports: Requesting detailed quality reports can help buyers understand the QC measures in place. These reports should include data on defect rates, testing results, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection agencies to evaluate suppliers can offer an unbiased assessment of their manufacturing quality. These agencies can conduct inspections at various stages of production and provide detailed reports.

What QC and Certification Nuances Should International Buyers Consider?

When sourcing dust extractors from international suppliers, buyers must be aware of the nuances in quality control and certification processes. Different regions may have varying standards and certifications, which can affect product compliance and marketability.

For instance, while CE marking is essential for selling in Europe, other regions may require different certifications. Understanding these requirements is vital for ensuring that products not only meet local regulations but also align with international quality expectations.

Illustrative image related to dust extractor

Additionally, the cultural and logistical differences in manufacturing processes across regions can impact quality control. Buyers should take the time to understand these aspects to foster effective communication and collaboration with suppliers.

Conclusion: Why Understanding Manufacturing and Quality Assurance is Crucial for B2B Buyers

In conclusion, the manufacturing processes and quality assurance measures for dust extractors are complex but critical for ensuring product reliability and effectiveness. By understanding these processes, B2B buyers can make informed purchasing decisions, ensuring they select suppliers that prioritize quality and compliance. This knowledge is particularly valuable for international buyers navigating diverse regulatory environments and manufacturing standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dust extractor’

To assist B2B buyers in procuring a dust extractor, this guide provides a comprehensive checklist designed to streamline the sourcing process. Whether you’re in woodworking, construction, or manufacturing, selecting the right dust extractor is crucial for ensuring workplace safety and maintaining a clean environment.

Step 1: Define Your Technical Specifications

Begin by establishing the specific requirements for your dust extractor. Consider factors such as the type of materials being processed, the volume of dust generated, and the size of the workspace.

– Airflow Requirements: Look for models with sufficient cubic feet per minute (CFM) ratings to handle your dust load effectively.

– Filtration Standards: Ensure the extractor meets HEPA standards for capturing fine particles, which is essential for maintaining air quality.

Step 2: Assess Power Compatibility

Evaluate the power needs of your tools and the extractor. Most dust extractors come with onboard power outlets that allow for tool activation.

– Voltage and Amperage: Confirm that the extractor’s power specifications match your operational tools to prevent overloads.

– Tool Integration: Consider models that support Bluetooth connectivity if your tools are compatible, providing seamless operation during projects.

Step 3: Evaluate Portability and Size

Portability can significantly impact the efficiency of your operations, especially in dynamic work environments.

– Weight and Design: Assess the weight and design of the extractor. Models with sturdy wheels and handles will facilitate easier transport.

– Space Considerations: Ensure the extractor’s dimensions fit your workspace without obstructing other activities.

Step 4: Verify Supplier Certifications

Before making a purchase, it’s essential to ensure that your supplier meets industry standards.

– Quality Certifications: Look for ISO certifications or compliance with local regulations, which indicate a commitment to quality and safety.

– Reputation in the Market: Research supplier reviews and testimonials from businesses in your industry for insights into reliability and service.

Step 5: Request Demonstrations or Samples

Whenever possible, ask suppliers for demonstrations or samples of the dust extractors.

– Performance Testing: This allows you to evaluate the extractor’s performance in real-world conditions, ensuring it meets your expectations.

– User Experience: Observing the ease of use and maintenance will help in selecting a model that fits your operational workflow.

Step 6: Review Warranty and After-Sales Support

A comprehensive warranty and strong after-sales support are vital when investing in equipment like dust extractors.

– Warranty Terms: Check the duration and coverage of the warranty, ensuring it protects against manufacturing defects.

– Customer Support Availability: Confirm the availability of customer support for troubleshooting and maintenance needs, which can minimize downtime.

Step 7: Compare Pricing and Total Cost of Ownership

Finally, analyze the pricing of various models while considering the total cost of ownership over time.

– Initial Costs vs. Long-Term Value: Compare the upfront costs with potential savings on maintenance and energy efficiency.

– Hidden Costs: Be aware of any additional costs for accessories, filters, or replacement parts that may arise over the lifecycle of the extractor.

Illustrative image related to dust extractor

By following this checklist, you can make informed decisions when sourcing a dust extractor that meets your operational needs while ensuring compliance with safety standards.

Comprehensive Cost and Pricing Analysis for dust extractor Sourcing

What Are the Key Cost Components of Dust Extractor Manufacturing?

When sourcing dust extractors, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of materials significantly influences the cost. High-grade plastics, metals, and HEPA filters are more expensive but essential for durability and performance. Additionally, the type of motor used (e.g., electric vs. pneumatic) can impact material costs.

-

Labor: Labor costs vary by region and manufacturing process. Skilled labor for assembly and quality control can drive costs up, particularly in countries with higher wage standards.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs, but buyers should be aware that they can vary widely depending on the supplier’s location.

-

Tooling: Custom tooling for specific designs or features can add to the initial costs. Buyers should assess whether the additional tooling expense will yield a significant return on investment through enhanced functionality.

-

Quality Control (QC): Robust QC processes ensure product reliability and compliance with international standards. However, these processes add to the overall cost and should be considered when evaluating suppliers.

-

Logistics: Shipping and handling costs can be substantial, especially for larger, heavier extractors. Buyers should consider the distance from the manufacturer and the chosen shipping method.

-

Margin: Suppliers typically add a margin to cover risks and profits. The margin can vary based on market demand, competition, and the supplier’s business model.

How Do Price Influencers Affect Dust Extractor Costs?

Several factors influence the pricing of dust extractors, including:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs without overcommitting.

-

Specifications and Customization: Custom features or specifications can significantly affect pricing. Buyers must balance the need for tailored solutions against potential cost increases.

-

Material Quality and Certifications: Dust extractors with certifications (like HEPA) and higher-quality materials command higher prices. These certifications ensure compliance with safety and environmental regulations, which can be crucial for international buyers.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers with a track record of quality may charge a premium but offer better reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. They define the responsibilities of buyers and sellers in shipping and can significantly affect overall costs.

What Tips Can Help Buyers Navigate Dust Extractor Pricing?

To effectively navigate the pricing landscape of dust extractors, buyers should consider the following tips:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your position as a bulk buyer to negotiate better terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A cheaper upfront cost may lead to higher long-term expenses if the product is not durable or efficient.

-

International Pricing Nuances: When sourcing from different regions, understand the local market conditions, tariffs, and trade agreements that may affect pricing. For instance, import duties in Nigeria or Brazil can significantly affect the final cost.

-

Research and Comparison: Conduct thorough market research to compare prices and features across different suppliers. Utilize industry reports and peer reviews to gauge value.

Disclaimer on Indicative Prices

Prices for dust extractors can vary widely based on specifications, supplier agreements, and market conditions. It is advisable for buyers to obtain quotes from multiple suppliers and conduct due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing dust extractor With Other Solutions

Understanding Alternatives to Dust Extractors

When it comes to managing dust and debris in industrial and workshop environments, dust extractors are a popular choice. However, businesses must also consider other viable solutions that may align better with their specific needs, operational scale, or budget constraints. This section will compare dust extractors against two alternatives: wet/dry vacuums and industrial-grade air filtration systems. Each option has unique characteristics that can influence its effectiveness and suitability for various applications.

Comparison Table

| Comparison Aspect | Dust Extractor | Wet/Dry Vacuum | Industrial-Grade Air Filtration System |

|---|---|---|---|

| Performance | High airflow and suction, HEPA filtration options | Moderate suction, typically lacks HEPA filtration | Exceptional air purification, captures particles as small as 0.3 microns |

| Cost | Generally higher ($300-$1,500) | Lower ($100-$500) | High ($1,000 and above) |

| Ease of Implementation | Requires setup and may need additional fittings | Simple to use, plug-and-play | Installation may require professional assistance |

| Maintenance | Regular filter changes, cleaning required | Basic cleaning, filter replacements as needed | Regular filter changes, potential for complex maintenance |

| Best Use Case | Woodworking, fine dust collection | General cleanup, construction sites | Large facilities, continuous air quality control |

Detailed Breakdown of Alternatives

Wet/Dry Vacuum

Wet/dry vacuums are versatile tools that can handle both liquid spills and dry debris. They are typically less expensive than dust extractors and are easy to use, making them suitable for a variety of environments, including construction sites and workshops. However, their performance may fall short when it comes to fine dust collection, as many models do not feature HEPA filters. This limitation can lead to airborne particles that pose health risks, particularly in settings like woodworking or metalworking.

Industrial-Grade Air Filtration System

Industrial-grade air filtration systems are designed for environments that require stringent air quality controls, such as manufacturing plants or laboratories. These systems excel at removing airborne particles, including allergens and harmful dust, making them ideal for facilities that prioritize worker health and safety. While they offer superior filtration and continuous air purification, the initial investment is significantly higher than both dust extractors and wet/dry vacuums. Additionally, installation may require professional expertise, adding to the overall cost and complexity of implementation.

Conclusion

Choosing the right dust management solution depends on the specific needs and circumstances of a business. Dust extractors offer advanced performance for fine dust collection, making them ideal for woodworking and similar applications. Wet/dry vacuums provide a cost-effective and versatile option for general cleaning tasks, while industrial-grade air filtration systems are the best choice for maintaining air quality in large facilities. B2B buyers should assess their operational requirements, budget, and long-term goals when deciding which solution aligns best with their needs.

Essential Technical Properties and Trade Terminology for dust extractor

What Are the Key Technical Properties of Dust Extractors?

When evaluating dust extractors, several technical specifications are vital for ensuring optimal performance in industrial and professional settings. Here are some critical properties to consider:

1. Airflow Rate (CFM)

The airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air the extractor can move. A higher CFM means better dust collection efficiency, especially when used with powerful tools like table saws or planers. For B2B buyers, understanding CFM is crucial as it directly impacts productivity and workplace safety by reducing airborne particles.

2. Filtration Efficiency (HEPA Rating)

HEPA (High-Efficiency Particulate Air) filters are designed to capture at least 99.97% of particles as small as 0.3 microns. Dust extractors with HEPA-rated filters are essential for maintaining air quality in environments where fine dust can be harmful. For buyers in industries like woodworking or construction, investing in machines with superior filtration capabilities not only meets regulatory standards but also enhances worker health and safety.

3. Tank Capacity

The tank capacity, usually measured in gallons or liters, determines how much dust and debris the extractor can hold before needing to be emptied. A larger capacity is beneficial for extended use without interruptions, making it a key consideration for businesses with high dust generation. Selecting an appropriate tank size can lead to increased operational efficiency and reduced downtime.

4. Power Consumption (Amps)

Understanding the power consumption, typically measured in amps, is vital for ensuring that the extractor can be used effectively with existing electrical systems. Higher power consumption often correlates with better performance but can also lead to higher operational costs. B2B buyers should assess their power supply capabilities to ensure compatibility with their selected dust extractors.

5. Portability Features

Portability is an essential feature for many businesses, especially those that require frequent movement of equipment. Considerations include weight, wheel design, and cord length. A lightweight extractor with robust wheels and a long cord can significantly enhance mobility, making it easier to transport between job sites or around a workshop.

What Are Common Trade Terms Related to Dust Extractors?

Familiarity with industry terminology can greatly assist B2B buyers in making informed purchasing decisions. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality and compatibility when sourcing dust extractors and their components.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for businesses looking to manage inventory costs effectively while ensuring they meet their operational needs. Knowing the MOQ can influence purchasing strategies, especially for smaller firms.

Illustrative image related to dust extractor

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products. In the context of dust extractors, submitting an RFQ can help buyers compare costs and negotiate better deals, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms can help B2B buyers understand shipping costs, risks, and responsibilities associated with importing dust extractors, which is particularly important for those sourcing from diverse global markets.

5. Warranty and Service Agreements

These terms refer to the commitments made by manufacturers regarding the repair and maintenance of dust extractors. Understanding warranty terms and service agreements is crucial for B2B buyers to ensure ongoing support and protection against defects, which can lead to significant cost savings in the long run.

Illustrative image related to dust extractor

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right dust extractor for their specific needs while optimizing their purchasing processes.

Navigating Market Dynamics and Sourcing Trends in the dust extractor Sector

What Are the Key Market Dynamics and Trends Influencing the Dust Extractor Sector?

The dust extractor market is experiencing significant growth driven by increasing awareness of air quality and health implications associated with dust exposure. Globally, industries such as woodworking, construction, and manufacturing are adopting advanced dust collection systems to comply with stricter environmental regulations and to enhance worker safety. In regions like Africa and South America, rapid industrialization is propelling demand, while in Europe and the Middle East, there is a pronounced shift towards high-efficiency particulate air (HEPA) filtration systems that minimize airborne contaminants.

Emerging technologies, such as IoT-enabled dust extractors, are also reshaping the landscape. These systems provide real-time monitoring and analytics, optimizing performance and maintenance schedules. As international B2B buyers seek more efficient solutions, there is a noticeable trend towards portable and compact extractors that offer flexibility in various work environments. Additionally, the integration of cordless technology is becoming popular, allowing for greater mobility without compromising suction power.

Sourcing trends are leaning towards suppliers who can provide comprehensive product lines that include accessories and service support. Buyers are increasingly prioritizing partnerships with manufacturers that offer robust warranty programs and customer service, ensuring long-term reliability and performance. This trend is particularly relevant for buyers in developing markets, where service infrastructure may not be as established.

How Is Sustainability and Ethical Sourcing Shaping the Dust Extractor Market?

Sustainability is no longer an optional consideration in the dust extractor sector; it has become a vital factor in B2B purchasing decisions. Environmental concerns regarding the disposal of dust and the materials used in manufacturing dust extractors are pushing buyers to seek products that are designed with sustainability in mind. Manufacturers are responding by utilizing recyclable materials and developing products that minimize waste.

Moreover, ethical sourcing is gaining traction. Buyers are increasingly interested in the supply chain integrity of their products. They prefer to work with suppliers who can demonstrate compliance with labor laws and environmental standards. Certifications such as ISO 14001 (Environmental Management) and other green certifications are becoming essential credentials for manufacturers aiming to appeal to conscientious buyers.

The demand for eco-friendly dust extractors that utilize low-energy technologies and HEPA filters to ensure minimal environmental impact is on the rise. Buyers are encouraged to consider the total lifecycle impact of their purchases, including energy consumption, material sourcing, and end-of-life recyclability. This shift not only helps in meeting regulatory compliance but also enhances brand reputation in a market that is increasingly influenced by sustainability metrics.

How Has the Dust Extractor Market Evolved Over Time?

The dust extractor market has undergone significant transformation since its inception. Initially, dust collection systems were rudimentary, focusing mainly on basic suction capabilities. However, as awareness of health risks associated with dust exposure grew, so did the technology and efficiency of these systems.

Illustrative image related to dust extractor

The introduction of HEPA filters in the late 20th century marked a pivotal moment, ensuring that even the smallest particulate matter could be captured. As industries evolved, the need for portable and versatile solutions became evident, leading to the development of mobile dust extractors tailored for various applications, from woodworking to construction.

Today, the dust extractor market is characterized by innovation, with advancements in filtration technology, energy efficiency, and smart features. As global standards for workplace safety and environmental sustainability continue to rise, the market will likely see further evolution, driven by both regulatory demands and the expectations of increasingly informed B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of dust extractor

-

How do I solve dust collection issues in my workshop?

To effectively solve dust collection issues, invest in a high-quality dust extractor that suits your specific needs. Assess the type of dust generated in your workspace—larger particles from woodworking or fine dust from sanding—and choose an extractor with appropriate filtration, ideally with HEPA filters for fine particulate matter. Ensure the extractor has sufficient airflow (CFM) and suction power for the tools you use. Additionally, ensure proper hose connections and consider using additional ducting systems for larger setups to improve efficiency. -

What is the best dust extractor for woodworking projects?

The best dust extractor for woodworking depends on your workshop’s size and the volume of dust produced. For hobbyists, portable models like those from Festool or Makita are ideal due to their balance of power and mobility. For larger operations, consider industrial-grade systems that can handle high CFM and have multiple tool connections. Look for features such as onboard power outlets for easy tool activation, HEPA filtration for improved air quality, and options for customization based on specific woodworking applications. -

What should I consider when sourcing a dust extractor supplier internationally?

When sourcing a dust extractor supplier internationally, prioritize manufacturers with a proven track record in quality and reliability. Verify their certifications, such as ISO or CE marks, which indicate adherence to international standards. Request samples to assess product quality and performance. Additionally, evaluate their customer service, warranty policies, and responsiveness to inquiries. Establishing a strong communication channel is crucial to ensure smooth transactions and support throughout the sourcing process. -

What are the typical minimum order quantities (MOQs) for dust extractors?

Minimum order quantities for dust extractors can vary significantly depending on the supplier and product type. Generally, MOQs can range from a single unit for smaller suppliers to several dozen units for larger manufacturers. Always clarify MOQs before negotiating terms. For customized products, MOQs may be higher due to the additional costs involved in production. Discussing your specific needs and potential for future orders can sometimes lead to more favorable MOQ terms. -

What payment terms are standard when purchasing dust extractors internationally?

Standard payment terms for international purchases of dust extractors often include options such as a deposit followed by balance payment upon shipment or delivery. Common methods include wire transfers, letters of credit, or payment through platforms like PayPal or Escrow services for added security. It’s essential to negotiate terms that protect your investment and ensure timely delivery. Be aware of any currency exchange implications and consider using forward contracts to mitigate risks associated with currency fluctuations. -

How can I ensure quality assurance when buying dust extractors?

To ensure quality assurance when purchasing dust extractors, request detailed product specifications and certifications from the supplier. Conduct factory audits or third-party inspections to assess manufacturing processes and compliance with quality standards. Ask for customer references or case studies that demonstrate the performance and reliability of their products. Implement a quality control plan that includes regular inspections upon receipt of goods to identify any issues before they impact your operations. -

What logistics considerations should I keep in mind when importing dust extractors?

Logistics considerations for importing dust extractors include understanding shipping methods (air vs. sea), costs, and transit times. Ensure compliance with local regulations and import duties that may apply to industrial equipment. Work with a reliable freight forwarder who can assist with customs clearance and documentation. Additionally, consider warehousing options if you need to store inventory before distribution. It’s also wise to plan for potential delays in shipping, especially during peak seasons or due to unforeseen circumstances. -

Are there customization options available for dust extractors?

Many manufacturers offer customization options for dust extractors to meet specific operational needs. Customizations may include modifications to airflow capacity, filtration systems, size, and additional features such as integrated tool ports or noise-reduction technology. Discuss your requirements with potential suppliers early in the sourcing process to explore available options. Be prepared to meet certain MOQs for customized products, and ensure that changes do not compromise the performance or reliability of the extractor.

Top 3 Dust Extractor Manufacturers & Suppliers List

1. Popular Woodworking – Top 8 Portable Dust Extractors

Domain: popularwoodworking.com

Registered: 1998 (27 years)

Introduction: The article reviews eight portable dust extractors for woodworking, focusing on their usability and features rather than performance metrics. Key features include: plug-in functionality for all-day use, onboard power outlets for tool activation, HEPA filter ratings for effective dust capture, and compatibility with various tools. The extractors are designed for hobbyist woodworkers rather than ind…

2. WEN – Induction Dust Collector

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Dust Collector: WEN induction DC; Dust Extractor: Fein Turbo 1; Tools mentioned: Dewalt 10in contractor saw (2.5in dust port), hand tools (1.5-2in dust ports), 6in bench top jointer (2.25in dust port), Dewalt 13in bench top planer (2.5in or 4in compatible).

3. Festool – Dust Extraction Solutions

Domain: festoolusa.com

Registered: 2004 (21 years)

Introduction: Dust extraction products including mobile dust extractors, air filters, suction hoses, cleaning accessories, filters and filter bags, pre-separators, and various accessories for efficient dust collection and management in woodworking and construction applications.

Strategic Sourcing Conclusion and Outlook for dust extractor

In the competitive landscape of woodworking and industrial applications, the strategic sourcing of dust extractors is crucial for ensuring operational efficiency and maintaining a safe working environment. Key considerations include the type of filtration system—prioritizing HEPA-rated filters for superior dust capture—and the functionality of the equipment, such as onboard power outlets for seamless integration with tools. Understanding the unique requirements of your operations can help in selecting the right extractor, whether for small workshops or larger industrial setups.

Illustrative image related to dust extractor

International buyers from regions such as Africa, South America, the Middle East, and Europe must leverage strategic partnerships with reputable suppliers to access high-quality dust extractors that meet their specific needs. This approach not only enhances productivity but also aligns with global sustainability practices by reducing airborne pollutants.

As the demand for efficient dust extraction solutions continues to grow, now is the time to invest in advanced technologies that will future-proof your operations. Explore your options, assess your requirements, and connect with trusted manufacturers to secure the best solutions for your business. The right dust extractor can transform your workspace, ensuring cleaner air and improved health outcomes for all employees.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.