Top 6 Tight Pu Suppliers (And How to Choose)

Introduction: Navigating the Global Market for tight pu

In an increasingly competitive global market, sourcing high-quality tight PU products can pose a significant challenge for international B2B buyers, especially those looking to capitalize on the latest fashion trends. This comprehensive guide delves into the diverse landscape of tight PU offerings, from apparel to accessories, ensuring that you understand the various types, applications, and unique selling propositions that can enhance your product line. By exploring critical aspects such as supplier vetting processes, pricing structures, and market demand, we aim to equip you with the insights necessary for informed purchasing decisions.

As businesses in regions like Africa, South America, the Middle East, and Europe—including key markets like Brazil and Vietnam—seek to expand their product offerings, understanding the nuances of tight PU sourcing becomes essential. This guide empowers you to navigate complexities, ensuring you make strategic investments that align with your brand identity and customer expectations. With actionable insights and expert recommendations, you will be well-prepared to engage with suppliers, optimize your procurement strategies, and ultimately drive sales. Whether you are looking to enhance your fashion line with innovative designs or seeking reliable materials for production, this guide is your go-to resource for unlocking the potential of tight PU in the global marketplace.

Understanding tight pu Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tight PU Leather Pants | Form-fitting design, often with unique embellishments | Fashion retail, costume design | Pros: Trendy, versatile; Cons: Sizing can be challenging |

| Tight PU Leather Bodysuits | Combination of PU leather and mesh, often with zippers | Nightclubs, fashion shows | Pros: Eye-catching, comfortable; Cons: Limited use cases |

| Tight PU Leather Sportswear | Breathable materials, stretchy for comfort during activities | Sports apparel, fitness centers | Pros: Functional, stylish; Cons: May not cater to all styles |

| Tight PU Leather Jackets | Structured fit, often with zippers and embellishments | Fashion retail, cosplay, and festivals | Pros: Durable, stylish; Cons: May be heavier than alternatives |

| Tight PU Leather Skirts | Various lengths, often with slits or unique cuts | Fashion retail, events, and parties | Pros: Versatile styling options; Cons: Fit can vary widely |

What are the Characteristics of Tight PU Leather Pants?

Tight PU leather pants are characterized by their form-fitting design, which often incorporates unique embellishments like zippers or buttons. They are commonly used in fashion retail and costume design, appealing to consumers looking for trendy, edgy styles. When purchasing, B2B buyers should consider the target demographic and market trends, as sizing can be challenging due to the snug fit. Ensuring a variety of sizes can help cater to a broader customer base.

How Do Tight PU Leather Bodysuits Stand Out?

Tight PU leather bodysuits are distinguished by their blend of PU leather and mesh materials, providing both allure and comfort. These bodysuits often feature zippers for easy wear and are ideal for nightclubs and fashion shows. B2B buyers should evaluate the fabric quality and sizing charts to ensure accurate fit for customers. While they are eye-catching and comfortable, their use may be limited to specific events or fashion statements, which is a consideration for retailers.

What Makes Tight PU Leather Sportswear Suitable for Buyers?

Tight PU leather sportswear is designed for breathability and stretch, making them suitable for activewear markets. These items find applications in sports apparel and fitness centers, where style meets functionality. Buyers should focus on the performance characteristics of the materials used, ensuring that they cater to athletes and fitness enthusiasts. While these products are stylish and functional, they may not appeal to all fashion tastes, necessitating careful market research.

Why are Tight PU Leather Jackets Popular?

Tight PU leather jackets are structured to provide a sleek silhouette, often featuring zippers and embellishments that enhance their appeal. They are popular in fashion retail, cosplay, and festivals, where bold statements are desired. B2B buyers should prioritize durability and style when selecting jackets for their inventory. Though they are stylish and long-lasting, they may be heavier than alternatives, which could affect consumer preferences.

What are the Key Features of Tight PU Leather Skirts?

Tight PU leather skirts come in various lengths and styles, often featuring slits or unique cuts that enhance their appeal. They are suitable for fashion retail, events, and parties, allowing for versatile styling options. B2B buyers should assess the fit and design to ensure they meet the fashion needs of their target market. While these skirts offer diverse styling opportunities, fit can vary widely, making it essential to provide accurate sizing information to customers.

Key Industrial Applications of tight pu

| Industry/Sector | Specific Application of tight pu | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of trendy clothing items like bodysuits and pants | Enhances brand appeal through stylish and durable products | Quality of PU material, design adaptability, and market trends |

| Automotive & Transport | Interior upholstery for vehicles | Provides a premium look and feel while being cost-effective | Durability, ease of maintenance, and compliance with safety standards |

| Sports & Fitness | Activewear and performance gear | Combines style with functionality, appealing to fitness enthusiasts | Breathability, stretchability, and moisture-wicking properties |

| Entertainment & Events | Costumes for performances and events | Enables bold expressions and enhances visual impact | Customization options, availability of sizes, and shipping logistics |

| Home Décor | Upholstery for furniture and home accessories | Offers a modern aesthetic while being easy to clean | Color variety, texture options, and environmental compliance |

How is Tight PU Used in the Fashion & Apparel Industry?

In the fashion and apparel industry, tight PU is primarily utilized in the production of stylish clothing items, such as bodysuits and pants. These garments not only appeal to consumers seeking trendy looks but also provide durability and ease of care. For B2B buyers, sourcing high-quality PU materials that align with current fashion trends is crucial. Additionally, understanding consumer preferences in various regions, such as Africa and Europe, can aid in tailoring products that meet local demands.

What Role Does Tight PU Play in the Automotive & Transport Sector?

Tight PU is increasingly used in automotive interiors, such as seat covers and trim. This material enhances the aesthetic appeal of vehicles while offering a cost-effective alternative to traditional leather. For international B2B buyers in the automotive sector, sourcing PU that meets stringent safety and durability standards is essential. Buyers should also consider the environmental implications of their materials, especially in regions where sustainability is becoming a priority.

Why is Tight PU Important for the Sports & Fitness Industry?

In the sports and fitness sector, tight PU is a favored material for activewear due to its combination of style and functionality. It is often used in leggings, tops, and performance gear that require elasticity and breathability. B2B buyers should focus on sourcing PU that offers moisture-wicking properties and a good stretch to enhance comfort during physical activities. Understanding the unique preferences of fitness enthusiasts in different markets, such as South America and the Middle East, can lead to better product offerings.

How is Tight PU Beneficial in Entertainment & Events?

Tight PU finds its application in the entertainment industry, particularly for costumes used in performances and events. This material allows for bold designs that can captivate audiences while providing comfort for performers. B2B buyers in this sector should prioritize customization options and a variety of sizes to cater to diverse performance needs. Additionally, efficient shipping logistics are crucial, especially for international events where timely delivery is essential.

What Are the Applications of Tight PU in Home Décor?

In the home décor sector, tight PU is often used for upholstery in furniture and decorative items. Its modern aesthetic and ease of maintenance make it a popular choice among consumers looking for stylish yet practical solutions. B2B buyers should consider the variety of colors and textures available, as well as the environmental compliance of the materials sourced. This is particularly important in regions like Europe, where sustainability trends are influencing consumer choices.

3 Common User Pain Points for ‘tight pu’ & Their Solutions

Scenario 1: Sizing Confusion Leading to Returns

The Problem: One of the most common challenges B2B buyers face with tight PU products is sizing inconsistency. Variations in sizing charts and the subjective nature of “tight” can lead to significant confusion, resulting in orders that do not fit as expected. This not only impacts the end consumer’s satisfaction but also increases return rates, which can be costly and time-consuming for businesses. For international buyers, the problem is exacerbated by different sizing standards across regions, making it even harder to find the right fit.

The Solution: To mitigate sizing issues, it’s crucial for B2B buyers to establish a clear and comprehensive sizing guide that aligns with their target market’s preferences. This guide should include precise measurements in both metric and imperial units, alongside clear illustrations of how to measure for size. Additionally, consider implementing a “fit guarantee” policy that allows for easy exchanges or returns for sizing issues. This approach not only builds trust with customers but also helps streamline the return process, reducing operational burdens. Finally, leveraging customer feedback on sizing can help refine the sizing guide over time, ensuring that future buyers have a better understanding of what to expect.

Scenario 2: Durability Concerns with Tight PU Materials

The Problem: Buyers are often wary of the durability of tight PU products, as they need to balance aesthetic appeal with longevity. Many PU leather items are marketed for their stylish looks but may not withstand the rigors of everyday wear, leading to concerns about the cost-effectiveness of their purchase. This is particularly relevant in regions where climatic conditions can exacerbate wear and tear, raising questions about the material’s resilience and overall value.

The Solution: To address durability concerns, B2B buyers should prioritize sourcing tight PU products that utilize high-quality materials and manufacturing processes. Look for suppliers who provide detailed information about the fabric composition and durability testing results. Establishing relationships with manufacturers who specialize in high-performance PU can also ensure that the products meet rigorous standards. Additionally, buyers should consider investing in product samples to assess the material’s quality firsthand before committing to larger orders. This proactive approach not only enhances buyer confidence but also ensures that the products will satisfy end consumers in terms of longevity and performance.

Scenario 3: Limited Supplier Options in Emerging Markets

The Problem: Many B2B buyers, particularly in emerging markets, struggle with finding reliable suppliers of tight PU products. Limited supplier options can lead to challenges in securing quality products, resulting in delays and inconsistent inventory levels. This is a significant pain point for businesses looking to meet customer demand while maintaining quality and affordability.

Illustrative image related to tight pu

The Solution: To overcome the challenges of limited supplier options, buyers should consider diversifying their sourcing strategies. This may involve exploring partnerships with both local and international suppliers to create a robust supply chain. Attend industry trade shows and expos to discover new suppliers and establish direct relationships. Furthermore, leveraging technology such as online marketplaces can expand the pool of potential suppliers, allowing for easier comparison of products and prices. Conducting thorough due diligence, including reviewing supplier credentials and past performance, will help ensure that the selected partners align with the quality and service expectations of the business. This multi-faceted approach not only strengthens supply chain resilience but also enhances the buyer’s ability to respond to market demands effectively.

Strategic Material Selection Guide for tight pu

What Are the Key Materials Used in Tight PU Manufacturing?

When selecting materials for tight PU applications, it’s essential to consider the properties, advantages, and limitations of each option. Here, we analyze four common materials used in the production of tight PU garments, focusing on their performance characteristics and suitability for international markets.

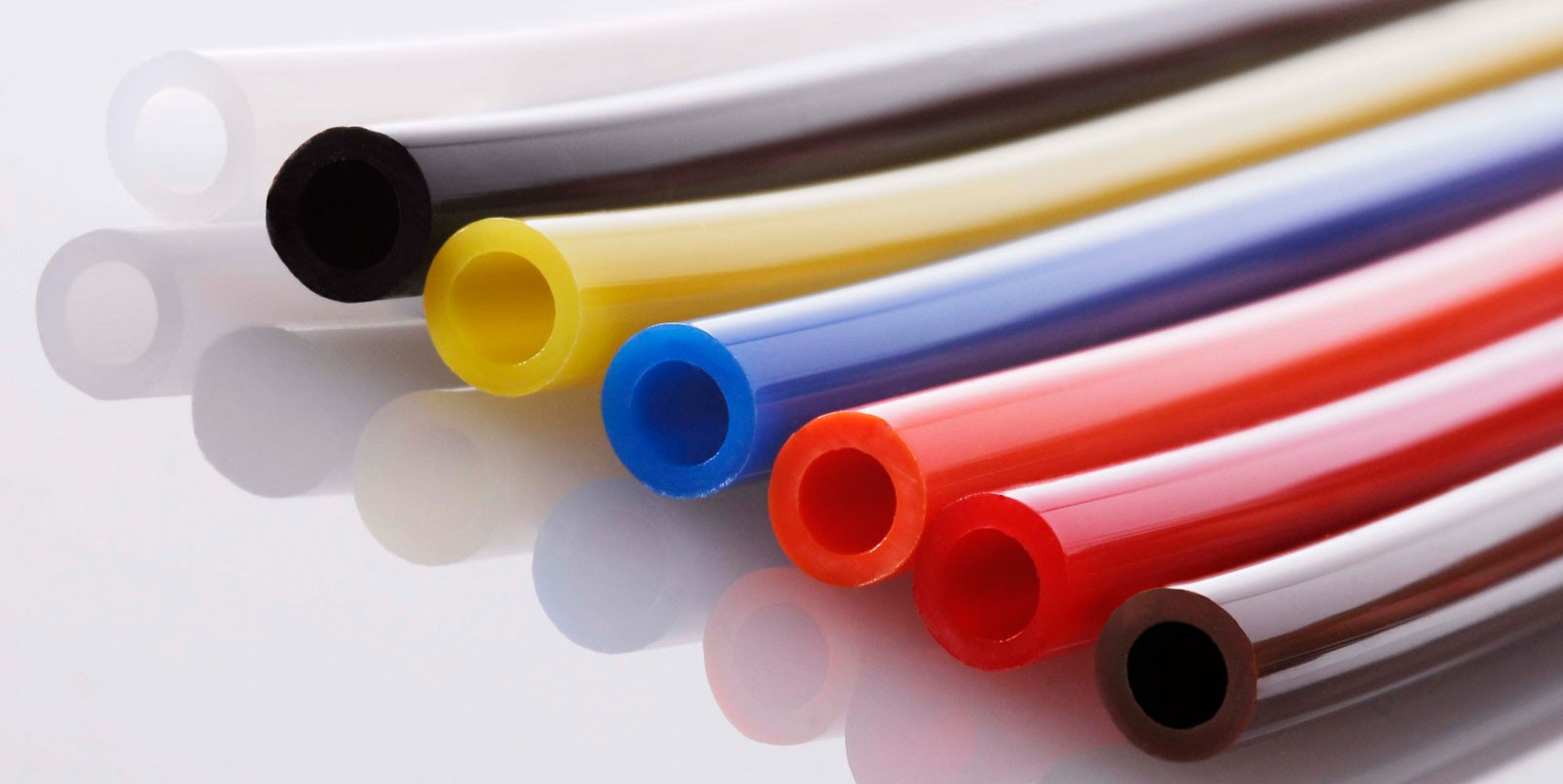

1. PU Leather (Polyurethane Leather)

Key Properties: PU leather is known for its flexibility, durability, and resistance to wear and tear. It can withstand moderate temperatures and is generally water-resistant, making it suitable for various environments.

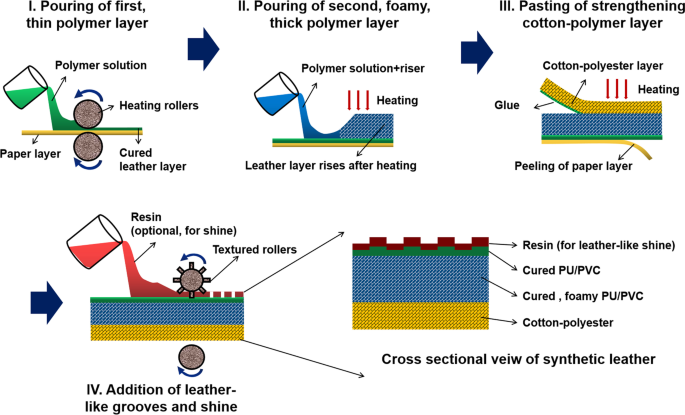

Illustrative image related to tight pu

Pros & Cons: The primary advantage of PU leather is its cost-effectiveness compared to genuine leather, providing a similar aesthetic without the high price tag. However, it may not be as breathable as other materials, leading to discomfort in hot climates. Additionally, while it is durable, it can be less resistant to punctures and tears than higher-end materials.

Impact on Application: PU leather is compatible with a range of dyes and finishes, allowing for vibrant color options. It is commonly used in fashion items like bodysuits and pants, appealing to a broad demographic.

Considerations for International Buyers: Buyers in regions like Africa and South America may prefer PU leather for its affordability. Compliance with local regulations regarding synthetic materials is crucial, as some countries have stringent environmental guidelines.

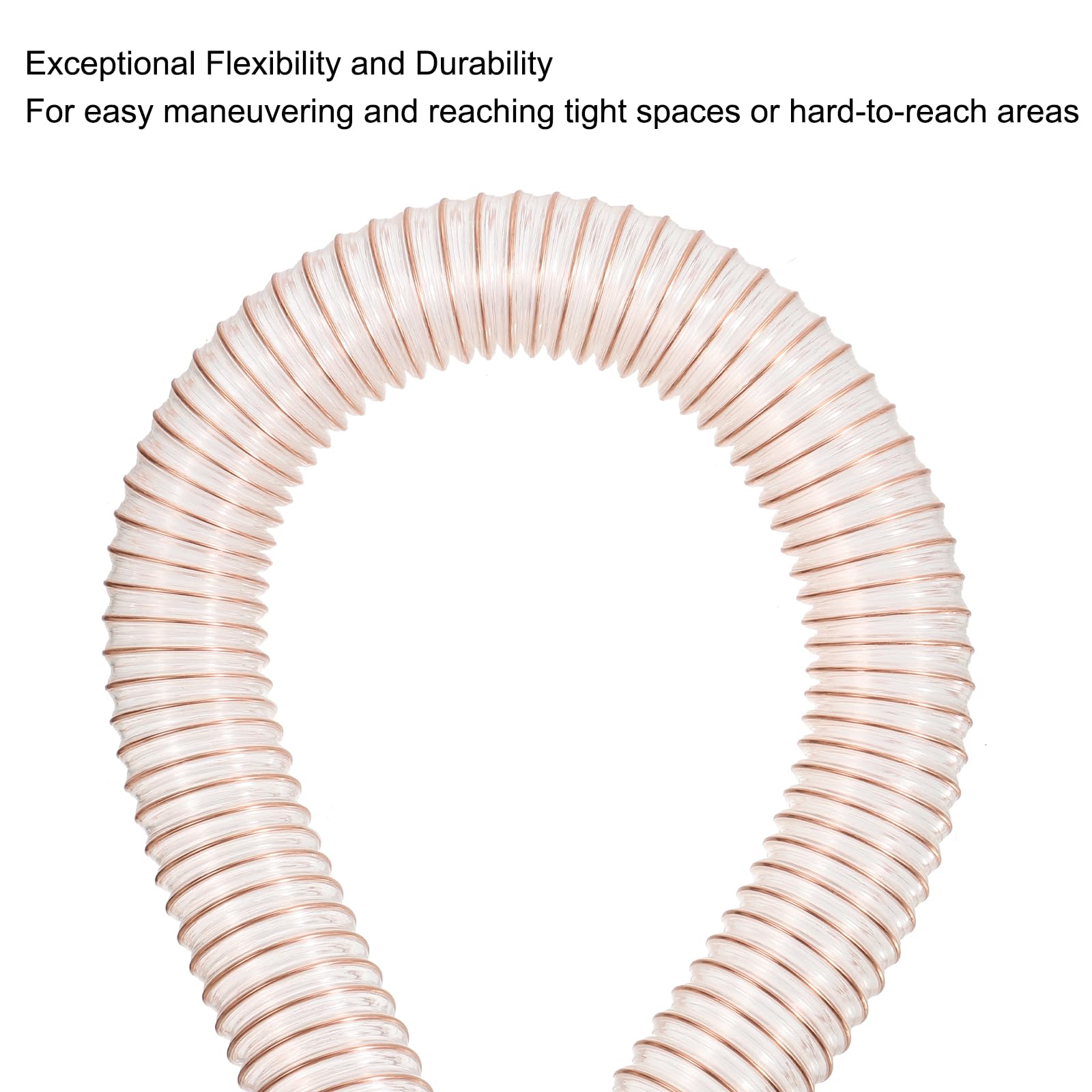

2. Spandex (Elastane)

Key Properties: Spandex is renowned for its exceptional elasticity and comfort, allowing garments to stretch significantly without losing shape. It can handle a wide range of temperatures and is resistant to UV light.

Pros & Cons: The major advantage of spandex is its ability to provide a snug fit, enhancing the wearer’s silhouette. However, it can be more expensive than other materials and may require careful washing to maintain its elasticity over time.

Impact on Application: Spandex is often blended with other materials like polyester to improve comfort and fit. This makes it ideal for tight PU applications where movement and flexibility are essential, such as in dancewear or activewear.

Considerations for International Buyers: Buyers from Europe and the Middle East may prioritize spandex blends for their performance benefits. Understanding the local textile regulations and standards, such as those set by ASTM or DIN, is important for compliance.

3. Polyester

Key Properties: Polyester is known for its strength, durability, and resistance to shrinking and stretching. It also dries quickly and resists wrinkles, making it a practical choice for tight PU garments.

Pros & Cons: The key advantage of polyester is its affordability and availability, making it a popular choice for mass production. However, it can be less breathable than natural fibers, which may be a drawback in warmer climates.

Illustrative image related to tight pu

Impact on Application: Polyester’s compatibility with various finishes allows for a range of textures and appearances in tight PU garments. It is often used in fashion applications where durability and ease of care are priorities.

Considerations for International Buyers: Buyers in regions with humid climates, such as parts of Africa and South America, should consider the moisture-wicking properties of polyester. Familiarity with local textile standards is essential to ensure product acceptance.

4. Nylon

Key Properties: Nylon is characterized by its high tensile strength and resistance to abrasion. It performs well under pressure and is generally resistant to mildew and mold, making it suitable for various applications.

Pros & Cons: The primary advantage of nylon is its durability and lightweight nature, which enhances comfort in tight-fitting garments. However, it can be more expensive than polyester and may not be as environmentally friendly due to its petrochemical origins.

Illustrative image related to tight pu

Impact on Application: Nylon’s strength makes it ideal for tight PU applications that require robust performance, such as outdoor or performance wear. It can withstand rigorous use while maintaining its shape and appearance.

Considerations for International Buyers: Buyers from Europe may be more inclined to choose nylon for its performance characteristics, especially in outdoor applications. Understanding the environmental impact and compliance with local regulations is crucial for market acceptance.

Summary Table of Material Selection for Tight PU

| Material | Typical Use Case for tight pu | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PU Leather | Fashion garments like bodysuits | Cost-effective with a leather-like look | Less breathable, can puncture easily | Medium |

| Spandex | Activewear and dancewear | Exceptional stretch and comfort | Higher cost, requires careful washing | High |

| Polyester | Everyday fashion and casual wear | Durable and quick-drying | Less breathable than natural fibers | Low |

| Nylon | Performance wear and outdoor apparel | High durability and lightweight | More expensive, less eco-friendly | Medium |

This material selection guide provides a comprehensive overview for B2B buyers to make informed decisions when sourcing tight PU garments, considering both performance and regional market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for tight pu

What Are the Key Manufacturing Processes for Tight PU Products?

The manufacturing of tight PU (polyurethane) products involves several critical stages, each designed to ensure the final product meets the required specifications for quality and durability. The main stages include material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess potential suppliers effectively.

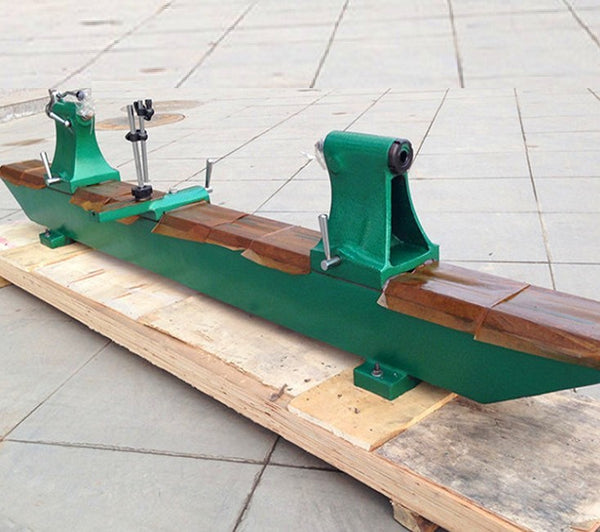

How Is Material Prepared for Tight PU Products?

The first step in the manufacturing process is material preparation. This begins with sourcing high-quality PU leather, which is often combined with other materials such as polyester and spandex to enhance elasticity and comfort. The selected materials undergo rigorous testing to ensure they meet specific performance standards, such as breathability and stretchability.

Illustrative image related to tight pu

Once the materials are sourced, they are cut into the desired shapes and sizes using precision cutting machines. This process minimizes waste and ensures consistency across products. Manufacturers often use patterns and templates to maintain uniformity, which is critical in industries where fit and appearance are paramount.

What Techniques Are Employed in the Forming Stage?

Following material preparation, the forming stage involves shaping the cut materials into the desired product. This can include techniques such as heat pressing, molding, or sewing. For tight PU garments, sewing is the most common technique, utilizing specialized machines that can handle the unique properties of PU leather.

During this stage, manufacturers pay close attention to details such as stitching quality and seam strength. Reinforced seams are often used in areas subject to stress, ensuring that the final product is durable and resistant to wear and tear. Additionally, the incorporation of features like zippers or mesh panels occurs during this stage, enhancing the functionality and aesthetic appeal of the products.

How Is Assembly Conducted for Tight PU Products?

Once the components are formed, they proceed to the assembly phase. This is where all parts of the product are brought together to create the final piece. Assembly often involves multiple steps, including attaching linings, inserting zippers, and final adjustments to ensure a snug fit.

Manufacturers typically use assembly lines to streamline this process, enhancing efficiency and reducing production time. Quality control measures are integrated throughout this stage, with workers trained to identify and rectify potential defects before the product moves to the finishing stage.

Illustrative image related to tight pu

What Finishing Techniques Are Used in Tight PU Manufacturing?

The finishing stage is crucial for enhancing the product’s appearance and functionality. This may involve applying coatings for additional water resistance, treating the surface for a glossy or matte finish, or adding decorative elements that align with current fashion trends.

Quality checks during this stage often include visual inspections for color consistency and surface defects. Additionally, manufacturers may conduct functional tests to ensure that features such as zippers and seams operate smoothly.

How Do Quality Assurance Processes Work in Tight PU Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that tight PU products meet international and industry-specific standards. For B2B buyers, understanding these quality assurance processes is essential for making informed purchasing decisions.

What International Standards Are Relevant for Tight PU Products?

International standards like ISO 9001 are widely recognized in manufacturing, providing a framework for quality management systems. This standard emphasizes the importance of consistent quality and customer satisfaction. Compliance with ISO 9001 indicates that a manufacturer has established processes to monitor and enhance product quality continually.

Illustrative image related to tight pu

In addition to ISO standards, other certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the product’s intended use. These certifications ensure that the products meet safety and performance standards relevant to specific industries.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically implemented throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This may involve random sampling and testing of products at various stages.

- Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to verify that they meet all quality standards and customer specifications.

What Common Testing Methods Are Used for Tight PU Products?

Common testing methods include tensile strength tests, abrasion resistance tests, and colorfastness tests. Tensile strength tests assess the material’s ability to withstand pulling forces, while abrasion resistance tests evaluate how well the product can endure wear over time. Colorfastness tests ensure that colors remain vibrant after exposure to washing or environmental factors.

B2B buyers should request detailed testing reports from suppliers to verify compliance with these standards. This transparency can help build trust and ensure that the products meet the expected quality levels.

Illustrative image related to tight pu

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits help assess the supplier’s adherence to quality standards and manufacturing processes. Audits can be conducted in-person or remotely, depending on geographical constraints.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, testing results, and any relevant certifications. This documentation serves as evidence of their commitment to quality.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process and product quality. This is especially useful for buyers who cannot physically inspect the products.

-

Understand Regional Nuances: Different regions may have varying regulations and standards. B2B buyers should familiarize themselves with these nuances to ensure compliance and quality assurance in their sourcing practices.

By understanding the manufacturing processes and quality assurance measures involved in tight PU production, B2B buyers can make more informed decisions and partner with reliable suppliers that align with their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tight pu’

To assist B2B buyers in successfully sourcing tight PU products, this guide provides a structured checklist that ensures a thorough and informed procurement process. Tight PU items, such as clothing or accessories made from polyurethane leather, require careful consideration to meet quality, supplier reliability, and compliance standards.

Illustrative image related to tight pu

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the tight PU products you wish to source. This includes material composition, design details, and any specific functionality, such as stretchability or breathability. Having well-defined criteria helps streamline the selection process and ensures that the products meet your quality expectations.

Step 2: Research Market Trends

Stay updated on current fashion trends and market demands, particularly in your target regions like Africa, South America, the Middle East, and Europe. Understanding market preferences can help you tailor your offerings and make informed decisions about the types of tight PU products that are likely to succeed. Utilize industry reports and competitor analysis for insights.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, client references, and examples of previous work to assess their reliability and product quality. This step is essential to mitigate risks associated with supplier failures or product defects that could impact your business.

Illustrative image related to tight pu

- Check Certifications: Ensure that the supplier adheres to international quality standards and sustainability practices, particularly if you are sourcing from regions with varying regulations.

- Review Production Capabilities: Verify that the supplier can meet your volume requirements and delivery timelines.

Step 4: Request Samples

Always request samples of the tight PU products before placing a bulk order. This allows you to evaluate the quality, fit, and overall aesthetics of the items. It’s an opportunity to assess whether the product aligns with your specifications and market standards.

Step 5: Negotiate Terms and Pricing

Engage in negotiations to secure favorable pricing and terms. Consider factors such as minimum order quantities, payment terms, and shipping costs. Establishing clear terms upfront can prevent misunderstandings and ensure a smooth transaction.

Step 6: Assess Shipping and Logistics

Understand the logistics involved in shipping tight PU products from the supplier to your location. Investigate shipping methods, estimated delivery times, and any potential customs duties or tariffs that may apply, especially for international shipments. This knowledge can help you manage inventory and plan for timely product launches.

Illustrative image related to tight pu

Step 7: Implement Quality Control Procedures

Once you have sourced your tight PU products, establish quality control measures to ensure that incoming shipments meet your standards. This might involve random inspections or setting specific criteria for product acceptance. Consistent quality checks protect your brand reputation and ensure customer satisfaction.

By following this checklist, B2B buyers can navigate the sourcing process for tight PU products with confidence, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for tight pu Sourcing

What Are the Key Cost Components in Tight PU Sourcing?

When evaluating the cost structure of tight PU products, several components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. PU leather, often preferred for its durability and aesthetic appeal, can vary in price based on quality and sourcing location. The inclusion of additional materials, such as mesh or stitching details, can further increase costs.

-

Labor: Labor costs will vary depending on the manufacturing location. Countries with lower labor costs can offer competitive pricing, but this may affect quality. It’s essential to balance labor cost savings with the need for skilled craftsmanship to ensure product quality.

-

Manufacturing Overhead: This includes costs related to the factory’s operation, such as utilities, rent, and equipment maintenance. Efficient production processes can help reduce these overheads, allowing for more competitive pricing.

-

Tooling: Custom designs may require specific tooling, which can be a significant upfront cost. However, investing in high-quality tooling can enhance production efficiency and product quality in the long run.

-

Quality Control: Implementing rigorous QC processes is vital to maintaining product standards, especially for international markets where quality expectations are high. While it adds to costs, effective QC can prevent costly returns and damage to reputation.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. International shipping may incur customs duties and taxes, which should be factored into the total cost.

-

Margin: Lastly, the profit margin will vary by supplier and can be influenced by brand positioning and market demand. Buyers should be aware of typical margins in their target markets to negotiate effectively.

How Do Price Influencers Affect Tight PU Product Costs?

Several factors can influence the pricing of tight PU products, which are crucial for buyers to consider:

-

Volume/MOQ: Larger orders typically qualify for lower per-unit prices due to economies of scale. Establishing a minimum order quantity (MOQ) can help buyers negotiate better deals.

-

Specifications and Customization: Customized products often come at a premium. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials: The choice of high-quality or specialized materials can significantly influence pricing. Buyers should assess whether the benefits of premium materials justify the higher costs.

-

Quality Certifications: Products that meet specific quality certifications or standards may command higher prices. However, these certifications can also enhance marketability and customer trust.

-

Supplier Factors: Relationships with suppliers can impact pricing. Long-term partnerships may lead to better pricing and terms, while new suppliers might offer introductory pricing to build relationships.

-

Incoterms: Understanding Incoterms is essential for international transactions. They determine the responsibilities of buyers and sellers in shipping and handling costs, which can affect the total landed cost of products.

What Tips Can Help Buyers Navigate Tight PU Sourcing Costs?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, there are several strategies to ensure cost-efficiency:

-

Negotiate Effectively: Establish clear communication and negotiate terms upfront. Understanding the supplier’s cost structure can provide leverage during negotiations.

-

Consider Total Cost of Ownership (TCO): Beyond initial purchase price, consider ongoing costs such as shipping, duties, and potential returns. A lower purchase price may not always equate to a better deal if additional costs are high.

-

Understand Pricing Nuances: Be aware of regional pricing differences. Factors such as local demand, market trends, and currency fluctuations can impact pricing strategies.

-

Conduct Market Research: Analyze competitor pricing and market trends to inform your sourcing strategy. This knowledge can enhance negotiation power and help identify optimal suppliers.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better terms, increased flexibility, and priority during production schedules.

Conclusion

Navigating the complexities of tight PU sourcing requires a comprehensive understanding of cost components, pricing influencers, and strategic negotiation techniques. By being informed and proactive, international buyers can optimize their purchasing decisions and enhance their supply chain efficiency.

Alternatives Analysis: Comparing tight pu With Other Solutions

Understanding the Alternatives to Tight PU

In the world of fashion and apparel, especially within the realm of performance and aesthetic appeal, tight PU (polyurethane) has carved a niche for itself. However, it is essential for B2B buyers to consider alternative solutions that may better fit their specific needs, such as cost, durability, and style. Below, we explore two viable alternatives to tight PU, comparing them across critical aspects to help buyers make informed decisions.

Comparison Table

| Comparison Aspect | Tight PU | Faux Leather | Stretch Denim |

|---|---|---|---|

| Performance | Highly flexible, durable | Durable but less flexible | Good flexibility and comfort |

| Cost | Mid-range ($50-$130) | Generally lower ($30-$100) | Varies ($40-$120) |

| Ease of Implementation | Requires specific care | Easy to care for | Easy to implement in designs |

| Maintenance | Needs careful cleaning | Machine washable | Machine washable |

| Best Use Case | Fashion-forward events | Casual wear, everyday use | Casual and semi-formal events |

Detailed Breakdown of Alternatives

Faux Leather

Faux leather is a popular alternative that mimics the look of genuine leather without the ethical concerns and higher costs. It is generally more affordable than tight PU and easier to maintain, as it can often be machine washed. However, faux leather may not provide the same level of flexibility and durability as PU, which can limit its use in high-performance or fashion-forward applications. Buyers seeking a balance between cost and aesthetic appeal will find faux leather suitable for casual wear or everyday use.

Stretch Denim

Stretch denim is another viable alternative that offers excellent comfort and breathability. This fabric provides good flexibility while ensuring that the garment maintains its shape, making it ideal for a variety of settings, from casual outings to semi-formal events. While its cost can vary, it often falls within the mid-range, similar to tight PU. However, stretch denim does not have the same high-fashion appeal as tight PU, which may be a drawback for buyers focused on style over comfort.

Conclusion: How to Choose the Right Solution

When selecting between tight PU and its alternatives, B2B buyers should evaluate their specific needs and the context in which the garments will be used. If the focus is on high-fashion events where aesthetics are paramount, tight PU may be the ideal choice. Conversely, for everyday applications where comfort and ease of maintenance are more critical, faux leather or stretch denim might be more suitable. Ultimately, understanding the unique attributes of each material will empower buyers to make informed decisions that align with their brand’s identity and customer expectations.

Essential Technical Properties and Trade Terminology for tight pu

What Are the Key Technical Properties of Tight PU Products?

When sourcing tight PU (polyurethane) products, understanding their technical properties is crucial for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

-

Material Composition

Tight PU products are typically made from a blend of polyurethane, polyester, and spandex. The polyurethane layer provides durability and a leather-like appearance, while polyester offers breathability and moisture-wicking properties. Spandex ensures elasticity, allowing the garment to fit snugly without restricting movement. Knowing the exact material composition helps buyers assess the product’s suitability for specific applications, such as fashion or performance wear. -

Thickness and Weight

The thickness of PU leather can vary significantly, affecting the product’s durability and feel. Thicker materials generally offer more protection and longevity, while thinner options may be more lightweight and breathable. Weight is also an essential factor; lighter garments are often preferred for activewear, while heavier weights are suitable for colder environments. Buyers should align thickness and weight with their target market’s preferences. -

Stretch and Recovery

Stretch refers to the fabric’s ability to expand, while recovery indicates how well it returns to its original shape after being stretched. For tight PU products, a high stretch and recovery rate are critical for maintaining comfort and fit, especially in active applications. Understanding these properties ensures that buyers select products that will perform well over time, minimizing returns and enhancing customer satisfaction. -

Finish and Texture

The finish of the PU material can influence its appearance and functionality. Common finishes include matte, glossy, or textured surfaces. Each finish can cater to different market segments, such as high-fashion or everyday wear. Buyers must consider the aesthetic appeal of the finish in relation to their brand image and target demographic. -

Breathability and Moisture Management

Breathability refers to how well a fabric allows air to circulate, which is vital for comfort in tight-fitting garments. Moisture management properties help wick sweat away from the body, enhancing wearability during physical activities. Buyers should prioritize these features to ensure product performance aligns with consumer expectations.

What Are Common Trade Terms Associated with Tight PU Products?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms relevant to tight PU sourcing:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces products that are marketed under another company’s brand. In the context of tight PU products, this could mean a manufacturer that creates garments based on a buyer’s specifications. Understanding OEM relationships can help buyers find reliable partners who can deliver high-quality products tailored to their needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand their purchasing limits and negotiate bulk orders, which can lead to cost savings. Knowing the MOQ helps in planning inventory and production schedules effectively. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Providing clear specifications for tight PU items in an RFQ can streamline the procurement process, ensuring that suppliers understand the buyer’s needs and can respond accurately. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics when sourcing tight PU products globally. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Understanding lead times is crucial for inventory management and meeting customer demands, especially in fast-moving fashion sectors. Buyers should communicate their timelines clearly to suppliers to ensure timely delivery.

By grasping these technical properties and industry terms, B2B buyers can make better-informed decisions when sourcing tight PU products, ultimately leading to successful business outcomes.

Illustrative image related to tight pu

Navigating Market Dynamics and Sourcing Trends in the tight pu Sector

What Are the Key Trends Driving the Tight PU Market?

The global market for tight PU (polyurethane) products has seen significant growth, driven by a combination of fashion trends, technological advancements, and changing consumer preferences. As industries such as fashion, automotive, and furniture increasingly adopt PU materials for their versatility, durability, and aesthetic appeal, international B2B buyers must stay attuned to these dynamics. Notably, the rise of e-commerce has facilitated broader access to PU products, enabling suppliers from regions like Africa, South America, the Middle East, and Europe to reach new markets effectively.

Emerging trends include the integration of smart textiles within tight PU applications, enhancing functionality with features such as moisture management and temperature regulation. Additionally, the demand for customization is growing, with buyers seeking unique designs that cater to specific regional tastes and cultural preferences. In countries like Brazil and Vietnam, where fashion is deeply intertwined with identity, the ability to offer localized products can set suppliers apart in a competitive landscape.

Moreover, the shift towards sustainable practices is reshaping sourcing strategies. B2B buyers are increasingly evaluating suppliers based on their environmental impact and commitment to ethical production. This trend is especially relevant in the Middle East and Europe, where regulatory frameworks around sustainability are becoming more stringent. As a result, suppliers that leverage innovative sourcing techniques, such as direct-to-consumer models and localized manufacturing, can enhance their market presence while reducing lead times.

How Is Sustainability Influencing Sourcing Decisions in the Tight PU Market?

Sustainability and ethical sourcing are becoming paramount in the tight PU sector as environmental concerns and consumer awareness continue to rise. The production of traditional PU materials often involves toxic chemicals and processes that can harm the environment. As a result, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices and utilize eco-friendly materials.

One of the key aspects of sustainable sourcing is the use of recycled and bio-based PU materials. These alternatives not only minimize environmental impact but also cater to a growing consumer base that values sustainability. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 have become important benchmarks for buyers seeking ethically produced products. These certifications assure businesses that the materials used are free from harmful substances and produced under fair labor conditions.

Furthermore, transparency in the supply chain is critical. Buyers are now more inclined to partner with suppliers who provide traceability of their materials, ensuring that each step of the production process adheres to ethical standards. This focus on sustainability not only aligns with global environmental goals but also enhances brand reputation, fostering customer loyalty and trust.

What Is the Historical Context of Tight PU Development for B2B Buyers?

The evolution of tight PU materials can be traced back to the early development of synthetic fabrics in the mid-20th century. Initially, PU was seen as a cost-effective alternative to leather, gaining popularity in various sectors, including fashion and upholstery. Over the decades, advancements in manufacturing processes have led to enhanced qualities, such as improved durability, flexibility, and aesthetic appeal.

Illustrative image related to tight pu

In recent years, the emergence of fashion trends focused on body positivity and self-expression has propelled the popularity of tight PU garments. This shift has led to increased demand for high-quality, form-fitting products that cater to diverse body types and fashion sensibilities. As a result, suppliers who can adapt to these changing consumer demands while maintaining high standards of quality and sustainability are well-positioned to thrive in the competitive landscape of the tight PU market.

By understanding these historical developments, B2B buyers can make informed decisions when sourcing tight PU products, ensuring they align with both market trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of tight pu

-

How do I solve sizing issues when sourcing tight PU products?

To address sizing challenges, always request detailed sizing charts from suppliers, including measurements for key areas such as bust, waist, and hips. Ensure that the sizing charts are in both metric and imperial units to accommodate international buyers. If possible, obtain samples to verify fit and comfort before placing larger orders. Communicating clearly about your sizing requirements with suppliers can also help mitigate potential issues down the line. -

What is the best material for tight PU garments?

The best material for tight PU garments typically combines a blend of polyurethane with other fabrics like polyester and spandex. This combination offers durability, stretch, and comfort, making it suitable for various applications, from fashion to sportswear. When sourcing, inquire about the specific composition and quality certifications to ensure the material meets your business’s standards and customer expectations. -

What should I consider when vetting suppliers for tight PU products?

When vetting suppliers, assess their production capabilities, material quality, and compliance with international standards. Request references and reviews from previous clients to gauge reliability. Additionally, consider visiting their manufacturing facilities if feasible, or conduct virtual audits to evaluate their operations. It’s also beneficial to check for certifications related to sustainability and ethical labor practices, which are increasingly important in global sourcing. -

What are common payment terms for international purchases of tight PU items?

Common payment terms in international B2B transactions include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer letters of credit or escrow services for added security. Always negotiate terms that align with your cash flow needs while ensuring the supplier’s confidence in the transaction. Clear communication about payment timelines can help avoid misunderstandings. -

What is the minimum order quantity (MOQ) for tight PU products?

The MOQ for tight PU products can vary significantly depending on the supplier and the complexity of the design. Typically, MOQs range from 100 to 500 units per style, but some suppliers may offer lower MOQs for custom designs. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are a smaller business or testing a new product line. -

How can I ensure quality assurance (QA) for tight PU garments?

To ensure quality assurance, establish a clear QA process that includes pre-production samples, in-line inspections, and final product evaluations. Specify quality standards in your contracts and consider appointing a third-party inspection service to conduct evaluations at various stages of production. Regular communication with your supplier regarding quality expectations can also help in maintaining high standards throughout the manufacturing process. -

What logistics considerations should I keep in mind when importing tight PU products?

When importing tight PU products, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who can handle documentation and customs clearance efficiently. It’s essential to be aware of the lead times for shipping and factor in any delays due to customs processes, especially when sourcing from international suppliers. Discuss delivery terms (Incoterms) with your supplier to clarify responsibilities regarding shipping costs and risks. -

What customization options are typically available for tight PU products?

Customization options for tight PU products often include variations in color, design, size, and material composition. Many suppliers offer services such as branding with custom labels, unique prints, and specific styling adjustments. When discussing customization, provide detailed specifications and samples of desired designs to ensure that the final product aligns with your vision. Be mindful of how customization impacts lead times and MOQs.

Top 6 Tight Pu Manufacturers & Suppliers List

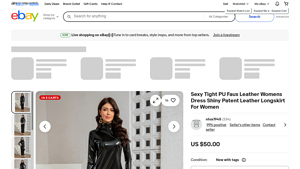

1. PU Faux Leather Dress – Shiny Black Longskirt

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”Sexy Tight PU Faux Leather Womens Dress Shiny Patent Leather Longskirt For Women”,”condition”:”New with tags”,”color”:”Black”,”sizes”:[“XS”,”S”,”M”,”L”,”XL”,”XXL”],”quantity_available”:2,”price”:”$50.00″,”shipping”:”Free eBay SpeedPAK Standard”,”location”:”Xiamen, China”,”delivery_estimate”:”Estimated between Thu, Sep 18 and Wed, Sep 24 to 19805″,”returns”:”30 days returns, seller pays f…

2. Punk Rave – Punk Handsome Tight PU Leather Pants

Domain: punk-rave.com

Registered: 2008 (17 years)

Introduction: {“product_name”: “Punk Handsome Tight PU Leather Pants WK-429XCF”, “material”: “Imitation pressed woven fabric combined with denim fabric”, “design_features”: [“Knee with zipper design”, “Stitching mesh cloth to enhance personality”, “Tight version accentuates the curve”], “comparison”: “Same design as WK-428, but WK-428 is made of denim fabric”, “market_price”: “$135.51”, “sale_price”: “$36.05”, …

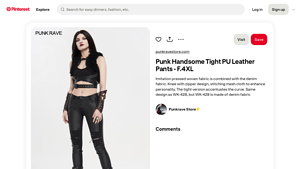

3. Punk Rave – Punk Handsome Tight PU Leather Pants

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Punk Handsome Tight PU Leather Pants – F.4XL, Sold out, US$123.20, Product sold by punkravestore.com

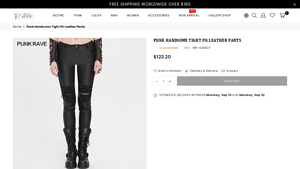

4. Punk Rave – Handsome Tight PU Leather Pants

Domain: punkravestore.com

Registered: 2016 (9 years)

Introduction: Product Name: Punk Handsome Tight PU Leather Pants

SKU: WK-429XCF

Price: $123.20

Availability: In Stock (Sizes F.XS, F.S, F.M, F.L, F.XL, F.2XL, F.3XL, F.4XL are sold out)

Material: Imitation pressed woven fabric combined with denim fabric

Design Features: Knee with zipper design, stitching mesh cloth to enhance personality, tight version accentuates curves

Shipping: Free shipping on orders over $…

5. Whitefox Boutique – Hold Tight PU Jacket Camel

Domain: listful.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “Hold Tight PU Jacket Camel”, “size”: “XS/S”, “price”: “$89.00”, “available_at”: “Whitefoxboutique”}

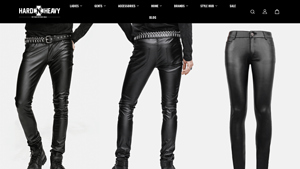

6. Devil Fashion – Black Skinny Elastic Stretch Tight PU Leather Pants

Domain: hardnheavy.style

Introduction: {“Product Name”: “Black Skinny Elastic Stretch Tight PU Leather Pants”, “Brand”: “Devil Fashion”, “Gender”: “Male”, “Style”: [“Gothic”, “Punk”, “Alternative Fashion”], “Color”: “Black”, “Fabric Composition”: “Synthetic Leather 100%”, “Weight”: “0.4kg/0.88lbs”, “Fit”: “Slim-Fitting”, “Soft Index”: “Softer”, “Elastic Index”: “Good”, “Elastic Thickness Index”: “Thin”, “Size Chart”: {“S”: {“Waist”: “8…

Strategic Sourcing Conclusion and Outlook for tight pu

In summary, strategic sourcing for tight PU products presents an opportunity for international buyers to capitalize on the growing demand for stylish, versatile apparel. By understanding the unique characteristics of tight PU materials—such as their elasticity, breathability, and aesthetic appeal—businesses can enhance their product offerings and cater to diverse consumer preferences across various markets, including Africa, South America, the Middle East, and Europe.

Investing in strategic sourcing not only ensures a reliable supply chain but also fosters partnerships with manufacturers who prioritize quality and innovation. This collaboration can lead to the development of exclusive designs that resonate with local trends and cultural expressions, thereby differentiating your brand in a competitive landscape.

As we look to the future, it is essential for B2B buyers to remain agile and responsive to market shifts, leveraging data-driven insights to make informed sourcing decisions. By embracing the dynamic nature of the tight PU market, businesses can position themselves for sustained growth and success. Engage with suppliers who share your vision and commitment to excellence, and seize the opportunity to elevate your brand’s presence in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.