Mech Lock Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for mech lock

In the dynamic landscape of global commerce, sourcing reliable mechanical locks—commonly referred to as mech locks—poses a significant challenge for international B2B buyers. As security concerns escalate across various industries, understanding the nuances of mech lock systems becomes paramount for companies aiming to enhance their safety measures. This comprehensive guide delves into the myriad types of mech locks available, exploring their applications across diverse sectors, from residential buildings to commercial facilities and industrial settings.

We will also cover essential aspects of supplier vetting, ensuring that buyers can identify trustworthy manufacturers who meet stringent quality standards. Additionally, the guide will provide insights into cost structures, helping businesses navigate pricing models that align with their budgets while ensuring optimal security solutions.

Designed specifically for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—this guide empowers decision-makers to make informed purchasing choices. By equipping you with actionable insights and expert knowledge, we aim to facilitate a smoother procurement process, ultimately enhancing your operational security and efficiency in a competitive global market.

Understanding mech lock Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dial Combination Locks | Numeric dial interface, mechanical operation | Commercial offices, schools, gyms | Pros: High reliability, no power required. Cons: Slower access, potential for user error. |

| Smart Locks | Keyless entry, biometric options, remote management | Hotels, corporate offices, residential | Pros: Enhanced security, convenience, customizable. Cons: Higher initial cost, dependency on technology. |

| Linear Positioning Locks | Adjustable locking positions, high axial load capacity | Aircraft, automotive, health equipment | Pros: Versatile applications, robust design. Cons: Complexity in installation, may require maintenance. |

| Hasp Locks | Simple design, often used with padlocks | Storage units, gates, sheds | Pros: Cost-effective, easy installation. Cons: Limited security features, vulnerable to cutting. |

| Biometric Locks | Fingerprint scanning, advanced security features | High-security facilities, data centers | Pros: Superior security, quick access. Cons: Higher cost, potential for technical malfunctions. |

What Are Dial Combination Locks and Their Suitability for Businesses?

Dial combination locks are mechanical locks that utilize a numeric dial for operation. They are widely used in commercial settings such as offices, schools, and gyms due to their reliability and independence from power sources. When considering these locks, businesses should weigh their security needs against the potential for slower access times, especially in high-traffic areas where quick entry is essential. Additionally, user training is necessary to minimize the risk of errors during operation.

How Do Smart Locks Differ from Traditional Locks?

Smart locks represent a modern solution to security, offering keyless entry and features such as biometric scanning and remote management capabilities. These locks are particularly suitable for applications in hotels, corporate offices, and residential properties where convenience and enhanced security are paramount. While they provide significant benefits, such as customizable access and real-time monitoring, buyers must consider the initial investment and the reliance on technology, which may require ongoing updates and support.

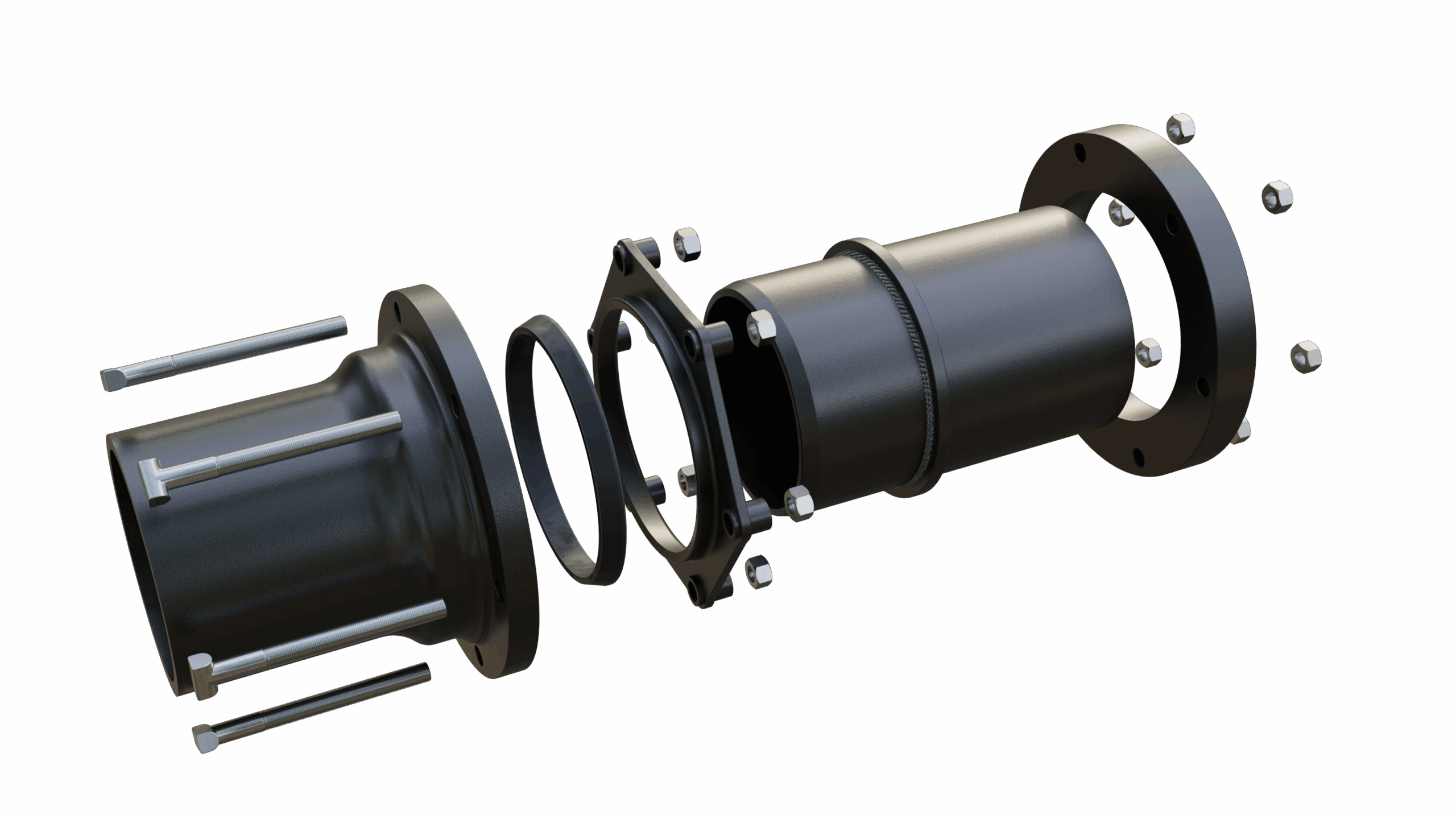

What Are the Benefits of Linear Positioning Locks in Various Industries?

Linear positioning locks are designed for applications requiring adjustable locking positions, making them ideal for industries like aerospace, automotive, and healthcare. These locks can withstand high axial loads and provide positive locking capabilities in both directions. When purchasing, businesses should evaluate their specific application needs, as the complexity of installation and potential maintenance requirements can vary. Their robust construction ensures durability, which can lead to long-term cost savings.

Why Choose Hasp Locks for Basic Security Needs?

Hasp locks are a straightforward locking solution often used in conjunction with padlocks. They are commonly found in storage units, gates, and sheds, where basic security is needed. The advantages of hasp locks lie in their cost-effectiveness and ease of installation. However, businesses should be aware that these locks offer limited security features and can be vulnerable to cutting, making them less suitable for high-security environments.

What Makes Biometric Locks a Preferred Choice for High-Security Applications?

Biometric locks utilize fingerprint scanning technology to provide advanced security features, making them ideal for high-security facilities and data centers. They allow for quick access while maintaining a high level of security. When evaluating biometric locks, businesses should consider their budget and the potential for technical malfunctions. Despite the higher initial costs, the investment can be justified by the enhanced security and efficiency they offer.

Key Industrial Applications of mech lock

| Industry/Sector | Specific Application of mech lock | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Cabin seating and storage bin locking | Ensures safety and reliability in high-stress environments | Compliance with aviation standards, weight considerations |

| Automotive | Seat recline and steering column locking | Enhances passenger comfort and vehicle safety | Durability under extreme conditions, design compatibility |

| Healthcare | Locking mechanisms for therapy and dental chairs | Provides safety and stability for patients during treatment | Hygiene standards, ease of operation, and maintenance needs |

| Commercial Security | Access control for hotels and offices | Improves security and access management | Customization options, integration with existing systems |

| Transportation | Locking systems for passenger rail and buses | Increases passenger safety and operational efficiency | Robustness against wear and tear, ease of installation |

How is Mech Lock Used in Aerospace Applications?

In the aerospace industry, mech locks are crucial for securing cabin seating and storage bins. These mechanical locks must withstand rigorous safety standards and high-stress conditions, ensuring that seats remain securely locked during flight. For international buyers, especially in regions like Africa and Europe, compliance with aviation regulations is paramount. Selecting mech locks that meet these standards not only enhances safety but also reduces liability for airlines and manufacturers.

What Role Does Mech Lock Play in the Automotive Sector?

In automotive applications, mech locks are employed for seat recline mechanisms and steering column locking systems. These locks contribute to overall vehicle safety and passenger comfort, providing a reliable way to secure seating positions. For businesses in South America and the Middle East, sourcing locks that can endure extreme temperatures and vibrations is essential. Buyers should prioritize suppliers who offer durability and compatibility with modern vehicle designs.

How are Mech Locks Beneficial in Healthcare Settings?

In healthcare, mech locks are used in therapy tables and dental chairs, ensuring that these devices remain stable during use. This stability is critical for patient safety and comfort. Buyers in the healthcare sector, particularly from Africa and Europe, should consider hygiene standards and ease of operation when sourcing mech locks. Locks that can be easily sanitized and operated with minimal effort are highly desirable in clinical environments.

What is the Importance of Mech Lock in Commercial Security?

For commercial applications, mech locks serve as access control solutions in hotels and office buildings. They enhance security by providing reliable locking mechanisms that can be integrated with keyless entry systems. International buyers should look for customization options that cater to specific security needs and the ability to integrate with existing security infrastructures. This adaptability is crucial for businesses aiming to enhance their security protocols.

How Do Mech Locks Enhance Transportation Safety?

In the transportation sector, mech locks are vital for ensuring the safety of passengers in trains and buses. These locks help secure seating and storage areas, contributing to the overall operational efficiency of transport services. Buyers, particularly from regions with fluctuating climates, should focus on sourcing robust locking systems that can withstand wear and tear. Ease of installation and maintenance should also be key considerations to ensure long-term reliability.

3 Common User Pain Points for ‘mech lock’ & Their Solutions

Scenario 1: Difficulty in Ensuring Lock Compatibility Across Diverse Applications

The Problem: Many B2B buyers face the challenge of selecting mechanical locks that are compatible with various applications, such as commercial facilities, hotels, and residential buildings. The difficulty in ensuring that a single lock solution can meet the diverse needs of different environments often leads to confusion and inefficiencies in procurement. For example, a buyer might purchase a mech lock that performs well in a hotel setting but fails to provide adequate security or usability in an industrial facility. This mismatch can result in increased costs due to returns, replacements, and additional installation efforts.

The Solution: To address this issue, buyers should conduct a thorough needs assessment before sourcing mech locks. This involves identifying the specific requirements of each application, such as load capacity, environmental conditions, and desired security features. For instance, a lock for an industrial setting may require higher durability and weather resistance compared to one used in an office building. Engaging with manufacturers who offer a variety of mech lock designs can provide tailored solutions. Additionally, buyers should request samples to evaluate functionality and compatibility across different environments before making bulk purchases. Leveraging a comprehensive lock management system can also help streamline the selection process, ensuring that the right lock is deployed in the right application.

Scenario 2: Challenges in Maintenance and Longevity of Mechanical Locks

The Problem: Maintenance is a critical concern for B2B buyers, particularly in sectors where mech locks are subjected to heavy use. Over time, mechanical locks can suffer from wear and tear, leading to malfunction and potential security breaches. This scenario is especially prevalent in high-traffic areas such as schools, hospitals, and commercial buildings, where the frequency of use can significantly reduce the lifespan of locks. Buyers may find themselves facing unexpected costs related to repairs or replacements, impacting budget planning and operational efficiency.

The Solution: To mitigate these issues, buyers should prioritize the selection of high-quality mech locks designed for durability and minimal maintenance. Engaging with suppliers that offer robust testing and quality assurance can help ensure that the locks can withstand rigorous use. Additionally, implementing a routine maintenance schedule can extend the life of mechanical locks. This could include regular inspections, lubrication, and minor repairs to catch issues before they escalate. Training staff on proper usage and maintenance procedures can also significantly reduce wear and tear. By investing in reliable locks and a proactive maintenance strategy, buyers can save costs and enhance the overall security posture of their facilities.

Scenario 3: Complexity in Customizing Lock Solutions for Unique Needs

The Problem: Customization is often a significant pain point for B2B buyers, particularly when their projects require unique locking solutions. Many standard mech locks may not meet specific design or functional requirements, leading to frustration during the procurement process. For example, a buyer in the aerospace industry might require mech locks that can endure extreme conditions while providing specific locking mechanisms for aircraft seating. The inability to find a suitable lock can result in project delays and increased costs due to the need for additional modifications or alternative sourcing.

The Solution: To overcome customization challenges, buyers should seek out manufacturers that offer OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. This allows for the development of bespoke solutions tailored to the unique specifications of a project. Buyers should communicate their requirements in detail, including environmental conditions, desired features, and operational functionality. Collaborating closely with the manufacturer during the design and testing phases can lead to innovative solutions that align perfectly with project needs. Additionally, considering suppliers with a robust research and development capability can enhance the likelihood of finding a viable customized mech lock solution that meets both security and design requirements.

Strategic Material Selection Guide for mech lock

What Are the Key Properties of Common Materials Used in Mech Locks?

Selecting the right materials for mechanical locks is crucial for ensuring optimal performance, durability, and security. Below, we analyze four common materials used in mech locks, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Stainless Steel Perform as a Material for Mech Locks?

Stainless steel is renowned for its excellent corrosion resistance, making it an ideal choice for mech locks exposed to various environmental conditions. It typically has a temperature rating of up to 870°C (1,600°F) and can withstand significant pressure, ensuring reliable performance in demanding applications.

Pros: Stainless steel offers high durability and resistance to rust and corrosion, which is crucial for longevity. It also provides a modern aesthetic that appeals to many buyers.

Cons: The primary drawback is its cost, which is generally higher than other materials. Additionally, manufacturing complexity can increase due to its hardness, requiring specialized tooling.

Impact on Application: Stainless steel is particularly suitable for outdoor and industrial applications where exposure to moisture and harsh conditions is common.

Considerations for International Buyers: Compliance with standards such as ASTM A240 is essential. Buyers from regions like Europe may prefer grades such as AISI 304 or AISI 316 for enhanced corrosion resistance.

What Role Does Brass Play in Mechanical Lock Construction?

Brass is a traditional material in lock manufacturing, known for its good machinability and resistance to corrosion. It typically operates well in temperatures ranging from -20°C to 70°C (-4°F to 158°F).

Pros: Brass is relatively inexpensive and easy to manufacture, making it a cost-effective choice for many lock applications. It also has a pleasing appearance, often used in decorative locks.

Cons: While brass is durable, it is softer than stainless steel, making it more susceptible to wear and tear over time. It may also tarnish, requiring regular maintenance to retain its appearance.

Impact on Application: Brass is commonly used in residential and commercial locks where aesthetic appeal and moderate durability are sufficient.

Considerations for International Buyers: Buyers should be aware of standards like ASTM B453 for brass materials. In regions like Africa and South America, the availability of brass may vary, influencing supply chain decisions.

How Does Aluminum Compare as a Material for Mech Locks?

Aluminum is lightweight and resistant to corrosion, making it a popular choice for applications requiring reduced weight without sacrificing strength. It typically has a temperature rating of up to 150°C (302°F).

Illustrative image related to mech lock

Pros: The lightweight nature of aluminum allows for easy installation and handling. It is also cost-effective compared to stainless steel while still providing adequate durability for many applications.

Cons: Aluminum is not as strong as stainless steel or brass, which may limit its use in high-security applications. It is also more prone to scratching and denting.

Impact on Application: Aluminum is often used in applications where weight is a critical factor, such as portable locks or locks used in lightweight structures.

Illustrative image related to mech lock

Considerations for International Buyers: Compliance with standards like ASTM B221 is important. In regions like the Middle East, where temperatures can be extreme, ensuring the right alloy is critical for performance.

What Are the Advantages of Using Zinc Alloy in Mech Locks?

Zinc alloy is increasingly used in the production of mech locks due to its good corrosion resistance and strength. It typically operates well in temperatures up to 120°C (248°F).

Pros: Zinc alloy is relatively inexpensive and can be easily cast into complex shapes, allowing for innovative designs. It also provides a good balance between strength and weight.

Cons: While it offers decent durability, zinc alloy is more susceptible to corrosion than stainless steel and brass, especially in harsh environments.

Impact on Application: Zinc alloy is suitable for applications where cost is a significant factor, such as budget-friendly locks for residential use.

Considerations for International Buyers: Compliance with standards such as ASTM B240 is essential. Buyers should also consider the environmental conditions in their region, as zinc alloy may not perform well in highly corrosive environments.

Summary Table of Material Selection for Mech Locks

| Material | Typical Use Case for mech lock | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor/Industrial Applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Residential/Commercial Locks | Cost-effective and aesthetically pleasing | Softer, prone to wear and tarnishing | Med |

| Aluminum | Lightweight Applications | Lightweight and easy to handle | Less strength, prone to scratching | Low |

| Zinc Alloy | Budget-Friendly Residential Locks | Cost-effective and versatile | Susceptible to corrosion in harsh environments | Low |

This guide provides a comprehensive overview of material selection for mech locks, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for mech lock

What Are the Main Stages in the Manufacturing Process of Mech Locks?

Manufacturing mech locks involves a series of precise stages, each critical to ensuring product quality and functionality.

Material Preparation

The foundation of any durable mech lock lies in the selection of high-quality materials. Commonly used materials include brass, hardened steel, stainless steel, and nickel. These materials are chosen for their strength, corrosion resistance, and aesthetic appeal. The process begins with sourcing raw materials, which are then inspected for quality to ensure they meet the required specifications. This initial quality check is essential as it sets the stage for all subsequent manufacturing processes.

Forming

Once the materials are prepared, they undergo various forming techniques. Depending on the design specifications, this may include processes such as stamping, forging, and machining. For example, CNC (Computer Numerical Control) machining is frequently employed to achieve high precision in cutting and shaping components. Advanced techniques like laser cutting may also be utilized for intricate designs, allowing for complex shapes that enhance both functionality and aesthetics.

Assembly

The assembly stage is where the individual components come together to form the complete mech lock. This stage often employs both manual and automated assembly techniques to ensure efficiency and precision. Each lock may consist of multiple parts, including dials, cams, and housings, which must fit together seamlessly. The integration of technology, such as automated assembly lines, ensures that high volume orders can be met without compromising quality.

Finishing

Finishing processes are crucial for both functionality and visual appeal. This may involve surface treatments like brushing, anodizing, or plating to enhance durability and resistance to wear. The standard finish for many mech locks is brushed nickel, which not only looks appealing but also provides a protective layer against corrosion. During this phase, locks are also tested for operational smoothness and durability.

How Is Quality Assurance Implemented in Mech Lock Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for mech locks. It ensures that products meet both international standards and customer expectations.

What International Standards Are Relevant for Mech Lock Production?

B2B buyers should be aware of several international standards that govern the quality of mech locks. One of the most recognized is ISO 9001, which focuses on quality management systems. This certification ensures that manufacturers adhere to best practices in their processes, resulting in consistent product quality.

In addition to ISO 9001, other certifications such as CE marking (which indicates conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards may apply, especially for locks used in specialized industries.

What Are the Key Quality Control Checkpoints in Mech Lock Manufacturing?

Quality control (QC) is typically implemented at several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before they enter the production line. It ensures that only materials meeting quality standards are used.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor the quality of components and processes. This helps identify any deviations from specifications in real time, allowing for immediate corrective actions.

-

Final Quality Control (FQC): Once the mech locks are fully assembled, a final inspection is performed to ensure they meet all functional and aesthetic criteria. This may include testing for locking mechanisms, durability, and resistance to tampering.

What Testing Methods Are Commonly Used for Mech Locks?

Testing is a critical aspect of quality assurance in mech lock manufacturing. Various methods are employed to ensure that the locks are secure and reliable.

-

Functional Testing: This involves checking the locking and unlocking mechanisms to ensure they operate smoothly and reliably under various conditions.

-

Durability Testing: Mech locks are subjected to stress tests that simulate real-world conditions, including extreme temperatures and environmental factors. This helps to evaluate the lock’s longevity and performance over time.

-

Security Testing: Locks are tested against various attack methods, including physical break-in attempts and electronic hacking techniques, to ensure they provide the necessary level of security.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing mech locks, particularly from international suppliers, B2B buyers must take steps to verify quality control processes to mitigate risks.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include reviewing their certifications, quality management systems, and past performance records.

-

Requesting Quality Reports: Buyers should request detailed quality reports from suppliers, which outline testing results, QC processes, and any certifications obtained. This documentation can help verify that the supplier adheres to international standards.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of a supplier’s quality assurance processes. This can be particularly useful when dealing with suppliers from regions where standards may vary.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Control?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in mech lock manufacturing is crucial.

-

Regional Compliance Standards: Different regions may have specific compliance standards that must be adhered to. Buyers should familiarize themselves with these regulations, which can affect product certifications and quality expectations.

-

Cultural Differences in Quality Assurance: The approach to quality assurance can vary significantly between regions. It’s essential for buyers to understand these differences and communicate their quality expectations clearly to suppliers.

-

Logistical Considerations: International shipping can introduce additional risks to product quality. Buyers should work closely with suppliers to ensure proper handling and storage during transit to maintain product integrity.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing mech locks, ultimately ensuring they receive high-quality, reliable products suited to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mech lock’

Introduction

When sourcing mechanical locks, also known as mech locks, it’s essential for B2B buyers to follow a structured approach. This guide provides a step-by-step checklist to help you navigate the procurement process effectively, ensuring that you select the right products for your needs while mitigating risks associated with quality and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. Consider the specific application of the mech locks you require—whether for commercial, industrial, or residential use. Detail the necessary features such as locking mechanisms, load capacities, and finish options to ensure the locks meet your operational requirements.

- Key considerations:

- Required load-bearing capacities (e.g., axial load).

- Compatibility with existing systems or structures.

- Desired design and aesthetics.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in mech locks. Look for companies with a strong reputation in the industry, emphasizing their experience and product range. This step is crucial for ensuring you partner with reliable manufacturers who can meet your quality standards.

- What to look for:

- Supplier certifications and compliance with international standards.

- Testimonials or case studies from previous clients.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Assess their production capabilities, including technology used in manufacturing and quality control processes. Understanding their capacity to handle your specific order size and customization requests will help prevent delays and issues down the line.

- Important factors:

- Availability of advanced testing facilities for product durability.

- Flexibility in production to accommodate custom designs.

Step 4: Request Samples for Evaluation

Once you have narrowed down your options, request samples of the mech locks you are considering. Testing samples allows you to assess their functionality, durability, and overall quality in real-world applications. This step is vital to ensure that the locks will perform as expected under your specific conditions.

- Testing criteria:

- Ease of installation and operation.

- Resistance to wear and tear in expected usage scenarios.

Step 5: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications that validate their commitment to quality and safety standards. Certifications like ISO 9001 can indicate a reliable quality management system, which is crucial for minimizing risks associated with product defects or failures.

- Certification importance:

- Provides assurance of product reliability and safety.

- Enhances your company’s credibility when using certified products.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms and conditions for your purchase. Discuss pricing, lead times, payment terms, and warranty provisions. A well-negotiated contract can protect your interests and ensure you receive the best possible value for your investment.

Illustrative image related to mech lock

- Key negotiation points:

- Bulk order discounts or payment flexibility.

- Warranty and post-purchase support options.

Step 7: Plan for Logistics and Delivery

Lastly, consider the logistics involved in delivering the mech locks to your location. Collaborate with your supplier to determine the most efficient shipping methods and timelines. Planning ahead can prevent delays and ensure that your products arrive in a timely manner.

- Logistical considerations:

- Customs clearance and import regulations in your region.

- Tracking and communication channels for shipping updates.

By following this checklist, B2B buyers can streamline their sourcing process for mech locks, ensuring they make informed decisions that align with their operational needs and quality expectations.

Comprehensive Cost and Pricing Analysis for mech lock Sourcing

What Are the Key Cost Components for Mech Lock Sourcing?

When considering the sourcing of mechanical locks, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials such as brass, hardened steel, and stainless steel are often used for their durability and security features. The quality of these materials can vary, affecting the price and longevity of the lock.

-

Labor: Labor costs vary based on the manufacturing location. In regions with lower labor costs, such as parts of Africa and South America, sourcing may yield significant savings. However, the expertise of the labor force in producing high-quality locks is crucial.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can minimize these overheads, contributing to a more competitive pricing strategy.

-

Tooling: Customization often requires specialized tooling, which can lead to increased upfront costs. However, investing in the right tooling can enhance production efficiency and quality, ultimately benefiting the buyer.

-

Quality Control (QC): Rigorous QC processes are essential to ensure product reliability. While implementing stringent QC measures may increase costs, it also reduces the likelihood of defects, leading to lower returns and higher customer satisfaction.

-

Logistics: Shipping costs can vary significantly based on the origin of the product and the destination. Buyers should account for potential tariffs, duties, and shipping fees when calculating total costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the supplier’s margin can provide insights into pricing flexibility during negotiations.

How Do Price Influencers Affect Mech Lock Sourcing?

Several factors influence pricing in the mech lock market:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Establishing a minimum order quantity (MOQ) can help negotiate better pricing and terms.

-

Specifications and Customization: Custom designs or specific features (like biometric access or unique finishes) can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of high-grade materials can enhance security and durability but may also elevate costs. Buyers should weigh the long-term benefits against initial investments.

-

Quality and Certifications: Locks that meet international security standards or certifications (like ISO) may command higher prices. Buyers should assess whether these certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge a premium but often provide superior quality and support.

-

Incoterms: Understanding shipping terms is critical for international transactions. Incoterms define who bears costs and risks during transportation, affecting overall pricing.

What Tips Can Help Buyers Navigate Mech Lock Pricing?

To maximize cost-efficiency in mech lock sourcing, consider the following strategies:

-

Negotiate Effectively: Leverage your purchasing power by negotiating price breaks for larger orders. Building a long-term relationship with suppliers can also lead to better pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, replacement costs, and potential risks associated with lower-quality locks. A higher upfront cost for a durable product may save money in the long run.

-

Understand Pricing Nuances for International Buyers: Buyers from diverse regions should be aware of currency fluctuations, local market conditions, and additional costs like shipping and tariffs. This understanding can help in making informed purchasing decisions.

-

Stay Informed About Market Trends: Keeping abreast of industry developments can help anticipate price changes and identify potential suppliers who offer innovative solutions.

-

Request Samples: Before committing to large orders, request samples to assess quality and compatibility with your needs. This can help avoid costly mistakes down the line.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other factors. Always conduct thorough research and due diligence before finalizing sourcing decisions.

Alternatives Analysis: Comparing mech lock With Other Solutions

Understanding Alternatives in Locking Solutions

In the competitive landscape of security solutions, businesses must evaluate various locking mechanisms to determine which best meets their operational needs. Mechanical locks, such as mech locks, are traditional options that offer reliability and durability. However, several alternative locking technologies can also provide effective security solutions. This section compares mech locks against two viable alternatives: smart locks and electronic locks.

| Comparison Aspect | Mech Lock | Smart Lock | Electronic Lock |

|---|---|---|---|

| Performance | Reliable with minimal maintenance | Offers advanced features like remote access | High-security options with programmable access |

| Cost | Generally lower upfront cost | Higher initial investment | Mid-range cost with varied features |

| Ease of Implementation | Simple installation process | Requires Wi-Fi or Bluetooth setup | Moderate complexity, wiring may be needed |

| Maintenance | Low, with occasional lubrication | Software updates needed | Regular battery replacement required |

| Best Use Case | High-traffic areas needing durability | Residential and commercial settings needing convenience | Secure areas requiring controlled access |

Analyzing Smart Locks as an Alternative

Smart locks represent a significant advancement in locking technology, integrating features such as remote access, keyless entry, and user management via mobile apps. They are ideal for modern residential and commercial environments where convenience and flexibility are paramount. However, smart locks typically come with a higher initial investment and require a stable internet connection for optimal functionality. While they offer advanced security features, they may also be vulnerable to cyber threats if not properly secured.

Exploring Electronic Locks as an Alternative

Electronic locks provide a middle ground between traditional mechanical locks and cutting-edge smart locks. These locks often feature programmable keypads or card access systems that allow for controlled entry. They are suitable for environments where security and access control are crucial, such as in corporate offices or secure facilities. While they may require more complex installation compared to mech locks, electronic locks offer a balance of security and user convenience. However, they do require regular maintenance, including battery replacements and occasional software updates.

Choosing the Right Locking Solution for Your Business Needs

When selecting a locking solution, B2B buyers should consider their specific requirements, including the environment in which the lock will be used, budget constraints, and the desired level of security. Mech locks excel in durability and cost-effectiveness, making them ideal for high-traffic areas. In contrast, smart locks and electronic locks provide enhanced convenience and advanced security features, catering to modern security needs. Ultimately, the choice between these options will depend on the unique operational requirements and security strategies of the business.

Essential Technical Properties and Trade Terminology for mech lock

What Are the Key Technical Properties of Mech Locks?

Understanding the technical specifications of mech locks is crucial for B2B buyers, particularly when evaluating products for security and durability in various applications. Here are some essential properties:

-

Material Grade

– Definition: The material grade indicates the quality and type of metals used in the lock’s construction, such as brass, stainless steel, or hardened steel.

– Importance: High-grade materials enhance durability and resistance to wear and corrosion, ensuring the lock can withstand various environmental conditions. This is particularly important for international buyers in regions with diverse climates. -

Locking Mechanism Type

– Definition: Mech locks can employ different locking mechanisms, such as dial combinations, keyless entry, or biometric systems.

– Importance: The type of mechanism affects ease of use and security level. For instance, biometric locks offer higher security but may require additional investment in technology. -

Axial Load Capacity

– Definition: This specification indicates the maximum load that the lock can handle, measured in pounds (lbs).

– Importance: Knowing the axial load capacity is vital for applications in heavy-duty environments, such as industrial settings or commercial buildings, where locks must endure significant stress. -

Stroke Adjustment

– Definition: Stroke adjustment refers to the lock’s ability to adjust its locking position within a specified range.

– Importance: Locks with infinite stroke adjustment can accommodate various applications, making them versatile for different installation needs, such as in aircraft seating or automotive systems. -

Finish Options

– Definition: The finish denotes the surface treatment applied to the lock, such as brushed nickel or powder coating.

– Importance: The finish not only impacts the aesthetic appeal but also contributes to corrosion resistance. This is particularly relevant for buyers looking for locks that match design specifications while offering longevity. -

Compliance Standards

– Definition: Compliance standards refer to the certifications the lock meets, such as ANSI/BHMA ratings or ISO certifications.

– Importance: Adherence to recognized standards ensures that the lock meets specific security and performance benchmarks, providing confidence to buyers about the product’s reliability.

What Are Common Trade Terms Related to Mech Locks?

Familiarity with industry jargon can streamline communication and decision-making for B2B buyers. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Context: Understanding OEM relationships is crucial for buyers seeking custom solutions or components that integrate seamlessly into existing systems. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Context: Buyers should be aware of MOQs to budget effectively and avoid excess inventory, especially when sourcing mech locks for large projects. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to request pricing and other details from suppliers for specific products or services.

– Context: Submitting an RFQ can help buyers compare offers from different suppliers, ensuring they obtain the best value for their investment. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping contracts.

– Context: Knowledge of Incoterms is essential for international transactions, as they clarify who is responsible for shipping, insurance, and tariffs, thereby minimizing potential disputes. -

Lead Time

– Definition: Lead time is the period from placing an order to receiving the goods.

– Context: Understanding lead times is vital for project planning, particularly for international buyers who need to align product availability with timelines. -

BOM (Bill of Materials)

– Definition: A BOM is a comprehensive list of materials, components, and assemblies required to manufacture a product.

– Context: For buyers, a detailed BOM can help in understanding the components involved in mech locks, aiding in maintenance and replacement planning.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the best mech locks for their needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the mech lock Sector

What Are the Key Market Trends Influencing the Mech Lock Sector?

The mech lock market is experiencing significant transformation driven by technological advancements, changing consumer preferences, and regional economic dynamics. Key trends include the increasing adoption of smart and keyless entry systems, which are gaining traction in both residential and commercial applications. Buyers from regions such as Africa and the Middle East are particularly interested in innovative security solutions that offer convenience and enhanced safety features. Additionally, the demand for customizable lock solutions is rising, as businesses seek to differentiate their offerings and cater to specific security needs.

Moreover, the global push for enhanced security measures is influencing sourcing strategies. International buyers are prioritizing suppliers who can provide robust, high-quality products that comply with international safety standards. This is particularly relevant for markets in Europe, like Germany, where regulatory compliance is stringent. The emergence of advanced manufacturing technologies, such as automation and precision engineering, is also shaping the sector, enabling suppliers to deliver products with greater accuracy and efficiency.

How Is Sustainability Shaping the Sourcing Decisions in the Mech Lock Market?

Sustainability is becoming a critical factor in the sourcing decisions of B2B buyers in the mech lock sector. The environmental impact of manufacturing processes and materials used in lock production is under scrutiny, prompting companies to seek out suppliers who prioritize eco-friendly practices. This includes the use of recyclable materials, energy-efficient production methods, and sustainable packaging solutions.

Ethical sourcing is equally important, as buyers are increasingly demanding transparency in the supply chain. This shift is driving manufacturers to adopt ‘green’ certifications and adhere to ethical labor practices. For instance, suppliers that use sustainably sourced metals or recycled materials can appeal to conscientious buyers looking to minimize their ecological footprint. These considerations are not just about compliance; they represent a strategic advantage in a competitive market, particularly for companies operating in regions with strong environmental regulations.

What Is the Historical Context of the Mech Lock Industry for B2B Buyers?

The mech lock industry has evolved significantly from its origins in traditional lock and key systems to the modern landscape of high-tech security solutions. Initially, mechanical locks relied on simple mechanical components and manual key systems. Over the decades, innovations in metallurgy and engineering have led to the development of more sophisticated locking mechanisms, including combination locks and electronic systems.

As security concerns escalated globally, particularly in urban areas, the demand for reliable locking solutions surged, paving the way for advanced technologies like biometrics and smart locks. This evolution reflects broader trends in security and technology, where the integration of electronic components has transformed how locks function, offering enhanced security features and user convenience. Understanding this historical context can help B2B buyers appreciate the innovations available today and make informed sourcing decisions that align with their security needs.

Frequently Asked Questions (FAQs) for B2B Buyers of mech lock

-

1. How do I choose the right mechanical lock for my business needs?

Selecting the right mechanical lock involves assessing your specific security requirements, the environment in which the lock will be used, and the level of access control needed. Consider factors such as durability, ease of use, and whether you need features like keyless entry or biometric access. Evaluate the lock’s material, construction, and performance specifications to ensure it meets your operational demands. Consulting with manufacturers or suppliers can also provide insights into which products best fit your application. -

2. What are the advantages of using mechanical locks over electronic locks?

Mechanical locks offer several benefits, including reliability and lower maintenance costs since they do not require batteries or electronic components. They are often more resistant to hacking and electronic failures, making them ideal for high-security applications. Additionally, mechanical locks can be simpler to install and operate in environments where electricity may be unreliable. For businesses in remote areas, these advantages can be crucial for ensuring continuous security. -

3. What customization options are available for mechanical locks?

Many manufacturers provide customization options such as unique key designs, finishes, and sizes to fit specific applications. You may also request additional features like engraved logos or specific locking mechanisms tailored to your security needs. It’s essential to communicate your requirements clearly during the design phase to ensure the final product meets your expectations. Discussing your needs with the supplier can lead to innovative solutions that align with your branding and operational goals. -

4. What is the minimum order quantity (MOQ) for mechanical locks?

Minimum order quantities can vary significantly among manufacturers and depend on the type of lock and customization requirements. Typically, MOQs range from 50 to several hundred units. It’s crucial to discuss your needs with potential suppliers to understand their MOQ policies and whether they can accommodate smaller orders for trial or pilot projects. Some manufacturers may offer flexibility for first-time buyers or bulk orders. -

5. What payment terms should I expect when sourcing mechanical locks internationally?

Payment terms in international trade can vary widely based on the supplier’s policies and the buyer’s negotiation power. Common payment methods include letters of credit, wire transfers, and PayPal. It’s advisable to establish clear terms before placing an order, including payment schedules, deposits, and any penalties for late payments. Always ensure that the terms are documented in the contract to avoid misunderstandings. -

6. How can I ensure the quality of mechanical locks before making a purchase?

To ensure quality, request samples of the mechanical locks for testing before committing to a larger order. Ask for certifications that demonstrate compliance with international standards and inquire about the manufacturer’s quality control processes. Additionally, consider visiting the production facility if feasible or rely on third-party quality assurance services to inspect the products. Customer reviews and testimonials can also provide insights into the manufacturer’s reliability and product performance. -

7. What logistics considerations should I keep in mind when importing mechanical locks?

When importing mechanical locks, consider shipping methods, delivery times, and customs regulations specific to your country. Engage with logistics partners who understand international shipping and can assist with paperwork, duties, and taxes. Additionally, factor in lead times for production and shipping to align with your inventory needs. It’s also beneficial to have a contingency plan in case of delays or issues during transit. -

8. How do I vet suppliers of mechanical locks to ensure reliability?

Vetting suppliers involves researching their reputation, production capabilities, and customer service history. Look for reviews, case studies, or references from other businesses in your industry. It’s also advisable to verify certifications and compliance with international standards. Engaging in direct communication, requesting samples, and discussing their quality assurance processes can provide further assurance of their reliability. Establishing a solid relationship with your supplier is vital for long-term collaboration.

Top 6 Mech Lock Manufacturers & Suppliers List

1. DigiLock – Mech Mechanical Locks

Domain: digilock.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Mech – Mechanical Locks”, “Interface”: {“Type”: “Dial operated numeric interface”, “Components”: [“Front Unit”, “Dial”, “Hasp”, “Laser Cam”]}, “Body Style”: {“Type”: “Vertical body style”, “Features”: [“Flat cam that rotates with the knob”, “ADA compliant lever”]}, “Lock Management”: “Select mechanical solutions can be managed with laser cut keys and a reset tool.”, “Finish”: “Br…

2. P.L. PORTER – Mechlok Mechanical Seat Recline Devices

Domain: craneae.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Mechlok Mechanical Seat Recline Devices”, “brand_expertise”: “P.L. PORTER”, “description”: “The rugged, durable Mechlok is an ideal mechanical lock for applications that require high reliability. The system stands up to the toughest usage conditions with minimal maintenance to deliver significant cost savings over the product life cycle.”, “features”: [“Infinite stroke adjustment…

3. Total Clinic Solutions – Mechanical Lock MechLoc

4. GoKeyless – NextLock Mech Dial Combination Lock

Domain: gokeyless.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “NextLock Mech Dial Combination Lock”, “sku”: “02-RCBL-P1-A”, “price”: “$115.00”, “discounted_price”: “$67.69”, “discount_percentage”: “41%”, “features”: {“operation”: “Dial numeric combination operation”, “user_code_length”: “4 digits”, “housing_material”: “All metal housing”, “body_style”: “Vertical body style”, “cam_mechanism”: “Cam locking mechanism”, “mounting”: “Recess mount…

5. U.S. Pipe – MECH-LOK™ Restrained Joint Pipe

Domain: uspipe.com

Registered: 1995 (30 years)

Introduction: MECH-LOK™ Restrained Joint Pipe is a product offered by U.S. Pipe. It is part of their ductile iron pipe range and is designed for applications requiring restrained joints. The product features a unique design that provides enhanced stability and resistance to joint separation under pressure. It is suitable for various installation projects, including those that may experience seismic activity. Th…

6. Super Arbor – Mech Door Lock

Strategic Sourcing Conclusion and Outlook for mech lock

What Are the Key Takeaways for International Buyers of Mech Locks?

In the competitive landscape of mechanical locks, strategic sourcing offers significant advantages for international B2B buyers. Understanding the diverse offerings—from traditional dial locks to innovative smart and biometric solutions—enables businesses to select products that meet their unique security needs. High-quality materials, rigorous testing, and advanced manufacturing processes are critical factors that enhance product durability and reliability. Furthermore, establishing partnerships with reputable manufacturers facilitates customized solutions, ensuring that specific operational requirements are met effectively.

How Can Strategic Sourcing Impact Your Business Growth?

As markets in Africa, South America, the Middle East, and Europe evolve, the demand for secure, efficient locking mechanisms is on the rise. By prioritizing strategic sourcing, businesses can not only reduce costs but also enhance their product offerings, ultimately driving customer satisfaction and loyalty. Engaging with manufacturers who prioritize innovation and quality assurance can position your company as a leader in the security sector.

What’s Next for International Buyers in the Mechanical Lock Market?

As we look to the future, the integration of smart technology into mech locks will continue to transform the industry. Now is the time for international buyers to leverage these advancements by aligning with forward-thinking suppliers. Take action today to explore new opportunities in sourcing mechanical locks that will elevate your business’s security solutions and meet the demands of a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to mech lock

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.