What Is A Rotating Latch Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for what is a rotating latch

In today’s fast-paced global market, sourcing reliable components like rotating latches can pose significant challenges for B2B buyers. These essential mechanical devices not only provide security and convenience in various applications—from automotive to industrial equipment—but also require careful consideration in terms of compatibility and durability. This comprehensive guide delves into the multifaceted world of rotating latches, exploring their diverse types, applications, and operational mechanisms.

By examining key factors such as supplier vetting, cost analysis, and industry standards, this guide empowers international B2B buyers—especially those from regions like Africa, South America, the Middle East, and Europe (including Brazil and Saudi Arabia)—to make informed purchasing decisions. Whether you are seeking heavy-duty latches for construction machinery or lightweight options for self-service kiosks, understanding the nuances of rotary latches is crucial.

With insights into the latest innovations and best practices, this resource aims to streamline your procurement process, ensuring that you select the right products that align with your operational needs and budgetary constraints. Equip yourself with the knowledge to navigate the complexities of the global market and enhance your supply chain efficiency with confidence.

Understanding what is a rotating latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Rotor Rotary Latch | Basic design with one rotor; compact and lightweight | Automotive, kiosks, light equipment | Pros: Simple installation; cost-effective. Cons: Limited tolerance for misalignment. |

| Double Rotor Rotary Latch | Two mirrored rotors for enhanced rigidity; wider catch opening | Heavy machinery, off-road vehicles | Pros: Better misalignment tolerance; more secure. Cons: Higher cost; bulkier design. |

| Magnetic Rotary Latch | Uses magnets for locking; offers push-to-close function | Doors, gates, and panels | Pros: Easy operation; minimal wear and tear. Cons: May not suit high-security needs. |

| Remote Drive Rotary Latch | Allows for operation from a distance; cable-actuated | Automotive, industrial equipment | Pros: Convenient access; versatile installation options. Cons: Requires precise cable routing. |

| Spring-Loaded Rotary Latch | Incorporates a spring mechanism for automatic closing | Storage units, cabinets | Pros: Self-closing feature; reduces manual effort. Cons: Spring fatigue may occur over time. |

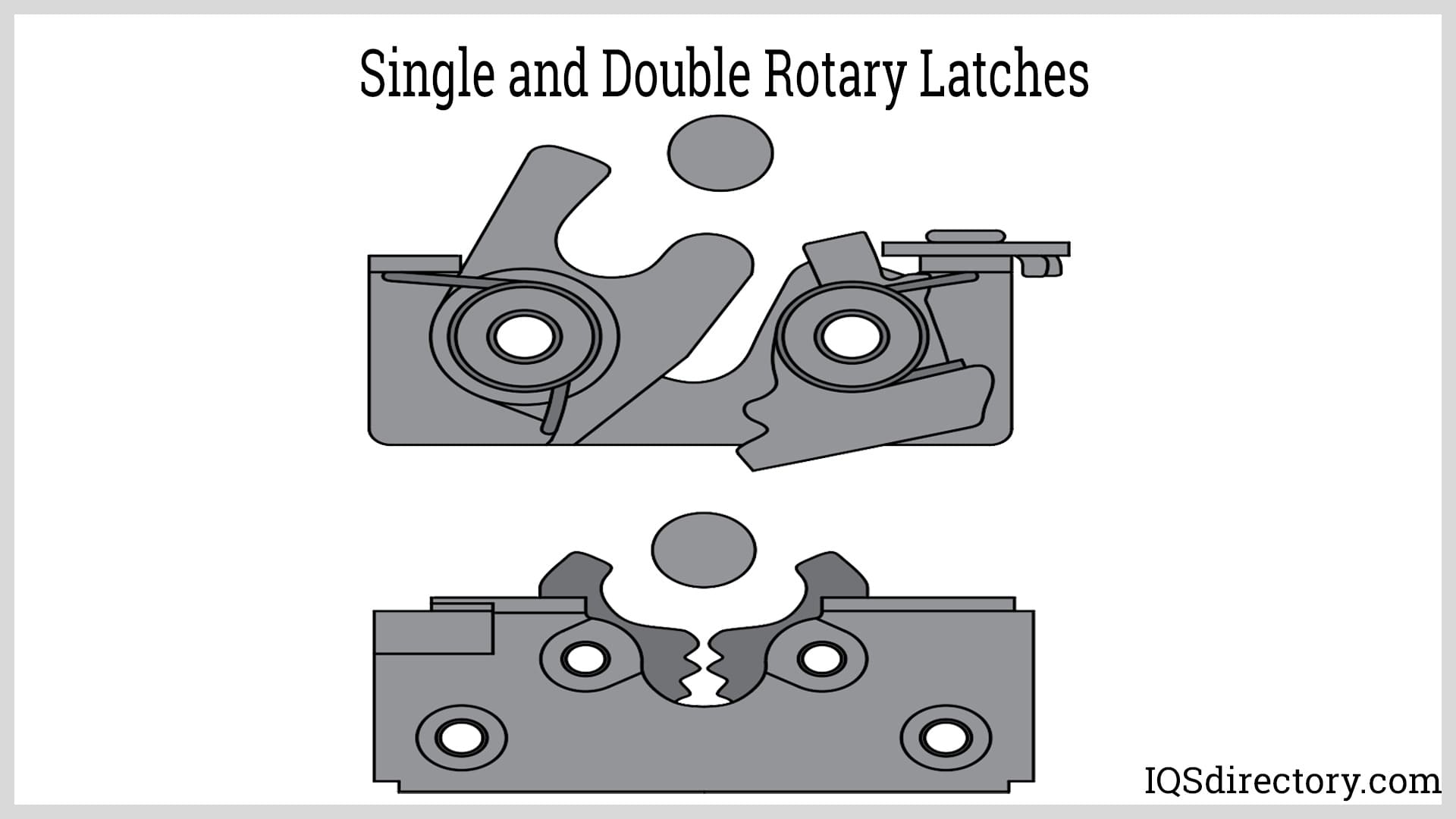

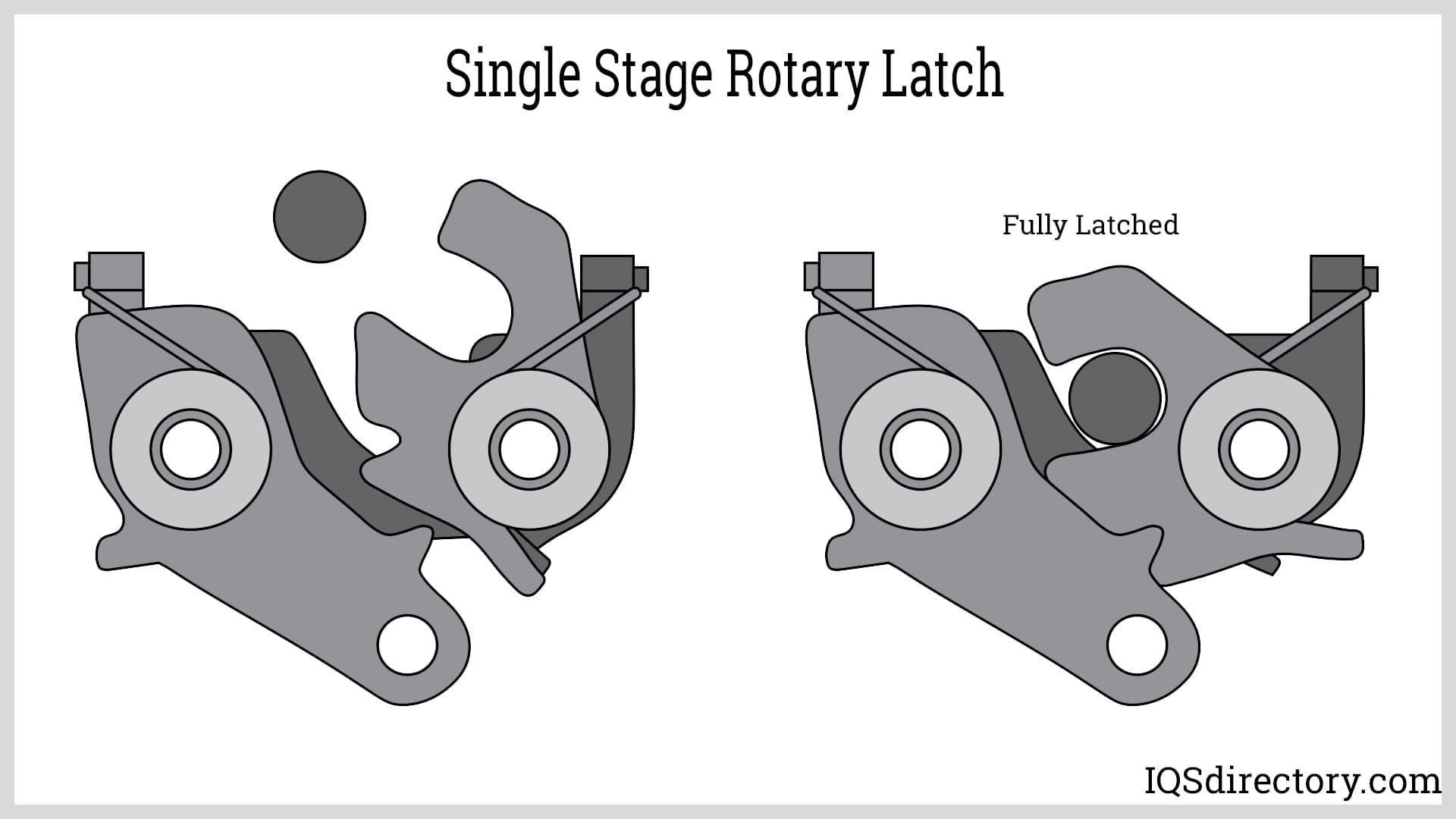

What are the Characteristics of a Single Rotor Rotary Latch?

The single rotor rotary latch is characterized by its straightforward mechanism, consisting of a single rotating component that secures doors and panels. This type is particularly suited for lightweight applications such as kiosks and automotive interiors. When purchasing, consider the latch’s size and weight capacity to ensure it meets the specific requirements of your project. Its affordability makes it a popular choice, but be aware that it offers limited tolerance for misalignment, which could be a concern in certain installations.

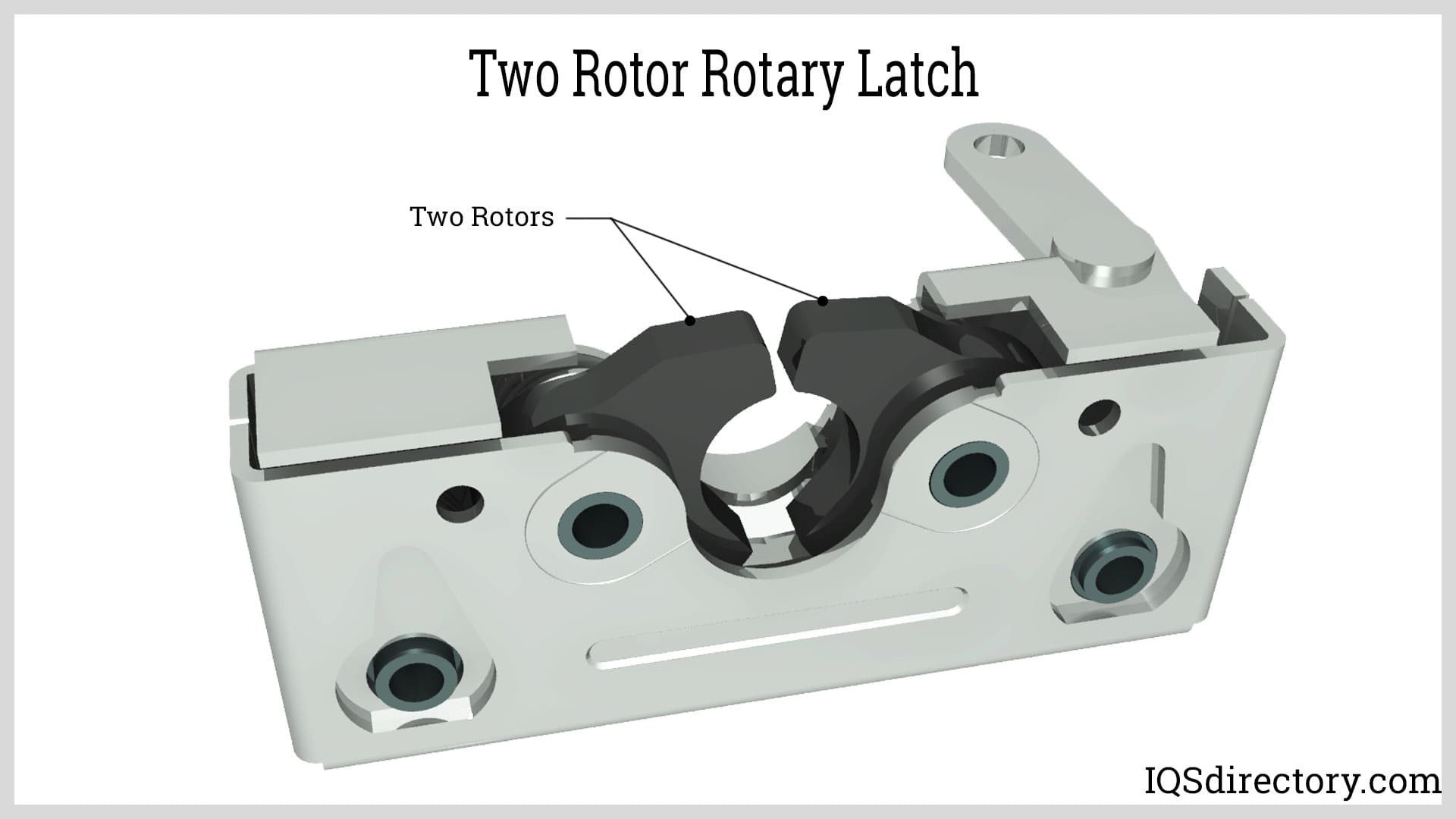

How Does a Double Rotor Rotary Latch Enhance Security?

The double rotor rotary latch features two adjacent mirrored rotors, providing a more robust locking mechanism compared to its single rotor counterpart. This design allows for a wider catch opening, making it more tolerant of misalignment. It is ideal for heavy machinery and off-road vehicles where durability and security are paramount. Buyers should assess the latch’s installation requirements and overall weight, as the added complexity and cost may not be justified for lighter applications.

In What Scenarios are Magnetic Rotary Latches Most Effective?

Magnetic rotary latches utilize a magnetic locking system, allowing for a push-to-close function that is both user-friendly and efficient. These latches are commonly used in doors, gates, and panels where ease of access is essential. While they require minimal maintenance and exhibit low wear, businesses should consider their security needs, as magnetic latches may not provide the same level of protection as mechanical alternatives.

Illustrative image related to what is a rotating latch

What Advantages Do Remote Drive Rotary Latches Offer?

Remote drive rotary latches are designed for operation from a distance, often utilizing a cable system connected to the locking mechanism. This feature is particularly advantageous in automotive and industrial settings where convenient access is required. When choosing this type, ensure that the cable routing is feasible within your application to avoid complications. While they offer versatility and ease of use, the need for precise installation can be a drawback.

How Do Spring-Loaded Rotary Latches Improve Efficiency?

Spring-loaded rotary latches incorporate a spring mechanism that allows for automatic closing, making them ideal for applications like storage units and cabinets. This feature reduces the manual effort required to secure a door, enhancing operational efficiency. However, buyers should consider the longevity of the spring mechanism, as fatigue can occur over time, potentially leading to failure. Overall, these latches are a practical choice for environments where ease of use is a priority.

Key Industrial Applications of what is a rotating latch

| Industry/Sector | Specific Application of what is a rotating latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine compartment access in vehicles | Enhances user convenience with remote access | Durability, compatibility with vehicle models, and corrosion resistance |

| Heavy Equipment | Secure panel access on construction machinery | Ensures safety and easy maintenance access | Load capacity, environmental resistance, and installation flexibility |

| Aerospace | Cabin door locking mechanisms in aircraft | Improves safety and reliability in high-stress environments | Lightweight materials, compliance with aviation standards, and ease of operation |

| Medical Equipment | Access to compartments in medical devices | Facilitates quick access for maintenance and safety | Sterilization compatibility, reliability, and ease of integration |

| Commercial Refrigeration | Door latching for refrigerated units | Maintains temperature control, enhancing product safety | Energy efficiency, durability, and resistance to extreme temperatures |

How Is a Rotating Latch Used in the Automotive Industry?

In the automotive sector, rotating latches are commonly utilized for engine compartment access. They provide a secure yet convenient method for drivers to open the hood remotely, enhancing user experience. These latches must withstand vibrations and harsh environmental conditions, making durability and resistance to corrosion critical factors for buyers. For international buyers, particularly in regions like Brazil and Saudi Arabia, sourcing latches that comply with local automotive standards while ensuring compatibility with various vehicle models is essential.

What Role Do Rotating Latches Play in Heavy Equipment?

Heavy machinery, such as construction vehicles, relies on rotating latches for securing access panels. These latches are crucial for ensuring that maintenance personnel can easily access critical components while maintaining safety standards. Buyers need to consider the load capacity and environmental resistance of these latches, as they often operate in extreme conditions. In markets across Africa and South America, where heavy equipment faces rugged terrains, sourcing robust and reliable latches is vital for operational efficiency.

How Are Rotating Latches Integrated into Aerospace Applications?

In the aerospace industry, rotating latches are integral to the locking mechanisms of cabin doors. Their design ensures that doors remain securely closed during flight while allowing for easy access when needed. The latches must meet stringent aviation safety standards, which require lightweight materials and reliable performance in high-stress environments. Buyers in the Middle East and Europe should prioritize suppliers that offer latches with proven reliability and compliance with international aviation regulations.

Why Are Rotating Latches Important in Medical Equipment?

Rotating latches are essential in medical devices for securing access to compartments that house sensitive equipment. They facilitate quick access for maintenance and ensure safety during operation. Buyers in the medical sector must consider the sterilization compatibility of these latches, as hygiene is paramount. Additionally, sourcing latches that offer high reliability and ease of integration can significantly impact the efficiency of medical operations, especially in regions with developing healthcare infrastructures.

What Benefits Do Rotating Latches Provide in Commercial Refrigeration?

In commercial refrigeration, rotating latches are used to secure doors on refrigerated units, maintaining product safety and temperature control. These latches must be durable and capable of withstanding extreme temperatures. When sourcing for this application, businesses should focus on energy-efficient designs that contribute to lower operational costs. For international buyers, understanding local regulations regarding refrigeration equipment can guide the selection of compliant and effective latching solutions.

Illustrative image related to what is a rotating latch

3 Common User Pain Points for ‘what is a rotating latch’ & Their Solutions

Scenario 1: Misalignment Issues in Heavy-Duty Applications

The Problem: B2B buyers often face challenges when using rotary latches in heavy-duty applications, such as construction or agricultural machinery. The inherent design of rotary latches, especially those with single rotors, can lead to misalignment due to vibrations and movement during operation. This misalignment can prevent the latch from securing properly, leading to safety risks and operational inefficiencies. For instance, a latch that fails to engage can result in machinery doors swinging open unexpectedly, posing dangers to operators and damaging equipment.

The Solution: To mitigate misalignment issues, buyers should consider utilizing double rotor rotary latches, which are designed to provide enhanced rigidity and a wider catch opening. This design feature allows for greater tolerance of misalignment, ensuring that the latch can still function effectively even under adverse conditions. When sourcing rotary latches, it is vital to specify the application environment and potential movement scenarios to manufacturers. Additionally, integrating a robust installation guide that includes recommendations for alignment checks during installation can significantly enhance the latch’s performance. Regular maintenance checks should also be scheduled to ensure that the latch remains properly aligned and functional throughout its operational life.

Scenario 2: Difficulty in Remote Operation

The Problem: Many B2B applications require remote operation of rotary latches, particularly in automotive and industrial settings. However, buyers may encounter issues with the responsiveness and reliability of the actuators that connect to the latches. Problems such as cable stretch, improper routing, or inadequate actuator strength can hinder the effective operation of the latch, leading to frustrations for end-users who expect smooth, effortless access to compartments or doors.

The Solution: To enhance the reliability of remote operations, buyers should prioritize the selection of high-quality actuators that are specifically designed for the intended application. When sourcing rotary latches, it is critical to ensure compatibility between the actuator and the latch mechanism. For instance, opting for actuators with robust materials and higher tensile strength can prevent issues associated with cable stretch. Additionally, proper cable routing should be a key consideration; avoiding sharp bends and ensuring that cables are secured and free from obstructions will help maintain their integrity. Buyers should also consider installing actuators with feedback mechanisms that alert users when the latch is engaged or disengaged, providing an added layer of reliability and user confidence.

Scenario 3: Limited Understanding of Latch Specifications

The Problem: B2B buyers often struggle with selecting the right specifications for rotary latches, particularly when dealing with varied applications across different industries. The complexity of rotary latch designs, including variations in size, strength, and locking mechanisms, can lead to confusion. Inadequate understanding can result in the procurement of latches that do not meet the operational requirements, leading to increased costs and project delays due to the need for replacements or modifications.

The Solution: To address this knowledge gap, it is essential for buyers to engage with manufacturers and suppliers who offer comprehensive technical support and resources. Buyers should request detailed product specifications, including load ratings, material compositions, and installation requirements. Participating in training sessions or workshops offered by suppliers can also enhance understanding of latch functionality and application suitability. Additionally, creating a checklist that outlines specific project requirements—such as environmental conditions, load-bearing needs, and frequency of use—will help streamline the selection process. This proactive approach not only aids in sourcing the right latch but also fosters stronger relationships with suppliers, ensuring ongoing support for future projects.

Strategic Material Selection Guide for what is a rotating latch

What Materials Are Commonly Used for Rotating Latches?

When selecting materials for rotating latches, it is crucial to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of rotating latches: stainless steel, zinc-plated steel, aluminum, and plastic composites.

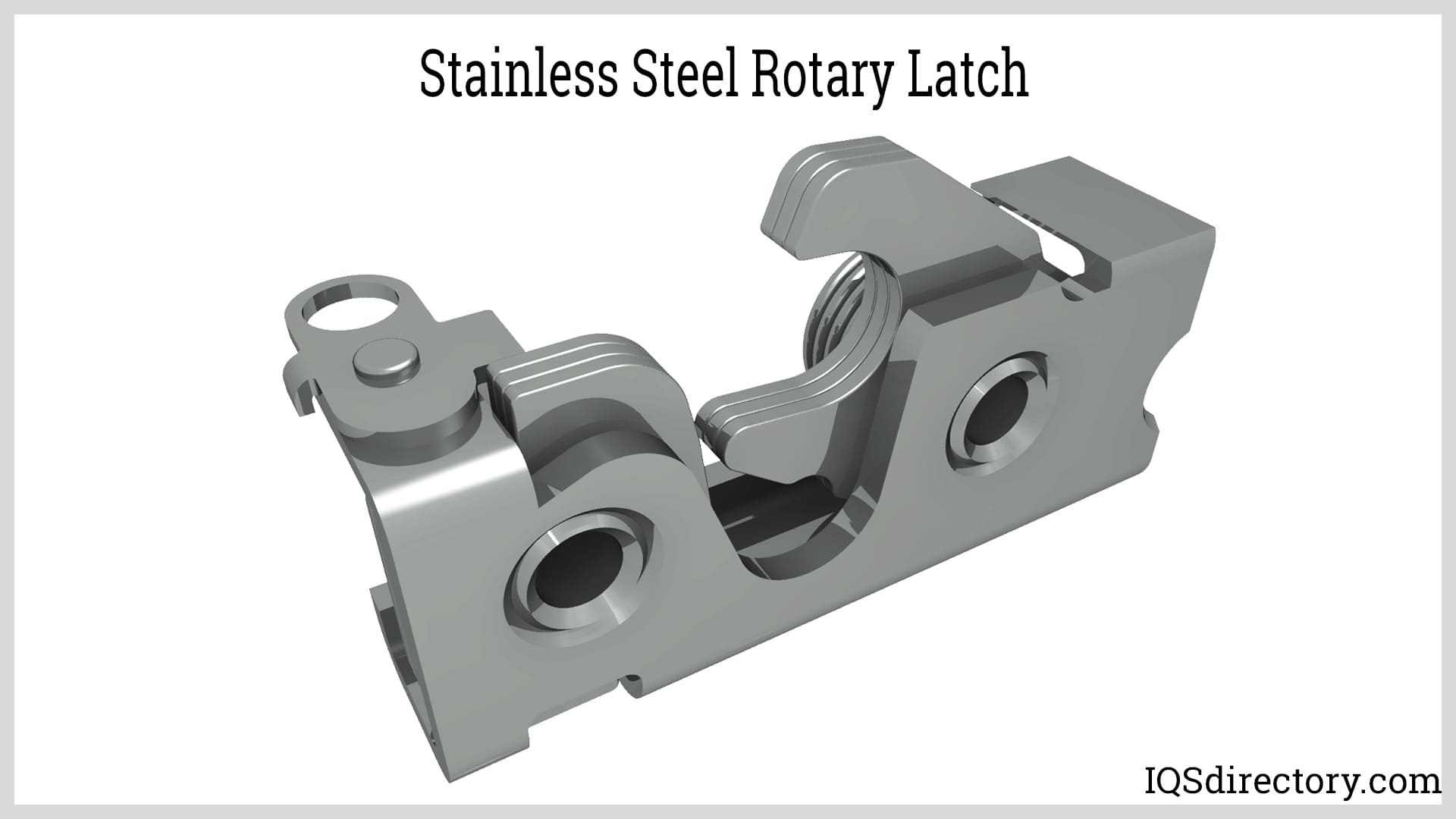

How Does Stainless Steel Perform in Rotating Latch Applications?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it a popular choice for rotating latches used in harsh environments. Its ability to withstand high temperatures and pressures ensures reliable performance in demanding applications, such as automotive and industrial machinery.

Illustrative image related to what is a rotating latch

Pros: Stainless steel offers high durability, making it suitable for long-term use in various environments. It is also easy to clean and maintain, which is advantageous in industries requiring hygiene.

Cons: The primary drawback is its cost, which tends to be higher than other materials. Additionally, manufacturing processes for stainless steel can be more complex, potentially leading to longer lead times.

Impact on Application: Stainless steel latches are ideal for applications exposed to moisture, chemicals, or extreme temperatures, such as marine or agricultural equipment.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel grades. In regions like Europe and the Middle East, certifications for corrosion resistance may also be necessary.

What Are the Benefits of Zinc-Plated Steel for Rotating Latches?

Zinc-plated steel is commonly used for rotating latches due to its cost-effectiveness and decent corrosion resistance. The zinc coating provides a protective layer that helps prevent rust, making it suitable for moderate exposure to moisture.

Pros: This material is relatively inexpensive and easy to manufacture, allowing for quick production times. It is also strong enough for many applications.

Cons: While zinc plating offers some corrosion protection, it is not as robust as stainless steel. Over time, the coating can wear off, exposing the steel to corrosion.

Impact on Application: Zinc-plated steel latches are suitable for indoor applications or environments with low humidity, such as office furniture or light-duty machinery.

Considerations for International Buyers: Buyers should check compliance with standards like ASTM A153 for zinc coatings. In regions like South America, where humidity may be higher, additional protective measures may be needed.

How Does Aluminum Compare for Rotating Latch Use?

Aluminum is a lightweight material that offers good corrosion resistance and is often used in applications where weight is a critical factor, such as aerospace and automotive industries.

Pros: The lightweight nature of aluminum makes it easy to handle and install. It also has a good strength-to-weight ratio, making it suitable for applications requiring lightweight components.

Cons: While aluminum is resistant to corrosion, it may not withstand high temperatures as effectively as stainless steel. Additionally, its softer nature can lead to wear and deformation over time.

Impact on Application: Aluminum latches are ideal for applications where weight savings are essential, such as in aircraft or portable equipment.

Illustrative image related to what is a rotating latch

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum extrusions is crucial. Buyers in regions like Africa should consider local environmental conditions that may affect aluminum’s performance.

What Role Do Plastic Composites Play in Rotating Latch Design?

Plastic composites are increasingly used in rotating latches due to their lightweight nature and resistance to corrosion. They are particularly advantageous in applications where electrical insulation is necessary.

Pros: Plastic composites are cost-effective and can be molded into complex shapes, allowing for versatile designs. They are also resistant to chemicals and moisture.

Cons: The primary limitation is their lower strength compared to metals, which may not be suitable for heavy-duty applications. They can also be affected by UV exposure, leading to degradation over time.

Impact on Application: Plastic composite latches are suitable for lightweight applications, such as electronic enclosures or indoor furniture.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards for plastics, such as ISO 9001 for quality management. In regions like the Middle East, UV resistance may be a critical factor.

Summary Table of Material Selection for Rotating Latches

| Material | Typical Use Case for what is a rotating latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty industrial machinery | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Zinc-Plated Steel | Indoor office furniture | Cost-effective and easy to manufacture | Limited corrosion resistance | Low |

| Aluminum | Aerospace and automotive applications | Lightweight and good corrosion resistance | Lower temperature tolerance | Medium |

| Plastic Composites | Electronic enclosures and indoor furniture | Versatile design and chemical resistance | Lower strength and UV sensitivity | Low |

This guide provides insights into selecting the appropriate materials for rotating latches, ensuring that international buyers can make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a rotating latch

What Are the Key Stages in the Manufacturing Process of a Rotary Latch?

The manufacturing process of a rotary latch involves several critical stages that ensure the final product meets the durability and functionality requirements of various applications. Understanding these stages is crucial for B2B buyers, especially those sourcing components for heavy machinery, automotive applications, or security systems.

How Are Materials Prepared for Rotary Latch Production?

The first stage in manufacturing a rotary latch is material preparation. Typically, the primary materials used include high-strength metals like galvanized iron, stainless steel, or even specialized alloys depending on the application. The choice of material affects the latch’s durability, resistance to corrosion, and overall performance in extreme environments.

Before processing, materials are inspected for quality, ensuring they meet the required specifications. This involves checking for defects, dimensions, and compliance with international standards. Suppliers may employ techniques such as spectrometry for alloy verification and ultrasonic testing for internal flaws.

What Forming Techniques Are Used in Rotary Latch Manufacturing?

Once the materials are prepared, the next stage is forming. This can involve various techniques, including:

- Stamping: This is commonly used for creating the latch’s body and components. High-precision stamping machines are employed to ensure consistent dimensions and shapes.

- Machining: For more complex components, machining processes such as milling and turning are utilized. This allows for precise adjustments and the creation of intricate designs needed for the latch’s locking mechanism.

- Forging: In some cases, forging may be used to enhance the material’s strength. This involves shaping the metal using compressive forces, which aligns the internal grain structure and increases durability.

These forming processes must be closely monitored to maintain consistency and quality throughout production.

How Is Assembly Conducted for Rotary Latches?

The assembly stage involves combining the formed components into a complete rotary latch. This may include integrating the actuator, locking mechanism, and cable system. During assembly, manufacturers often utilize automated systems to ensure precision and efficiency, minimizing human error.

Quality checkpoints are critical at this stage. Each component must be tested for fit and function before proceeding to the next assembly step. This can involve visual inspections and functional testing to ensure that the latch operates smoothly and meets design specifications.

What Finishing Techniques Are Applied to Rotary Latches?

After assembly, finishing processes are applied to enhance the latch’s appearance and protect it from environmental factors. Common finishing techniques include:

- Coating: Applying a protective coating, such as powder coating or galvanization, helps prevent corrosion and wear, especially in outdoor applications.

- Polishing: For aesthetic purposes and to reduce friction during operation, components may be polished to a smooth finish.

- Quality Control: The final product undergoes rigorous inspections to ensure that the finishing meets the required standards, including visual checks for defects and testing for adherence of coatings.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance in rotary latch manufacturing is paramount, particularly for international buyers from diverse regions. Adhering to recognized standards ensures that products meet safety and performance criteria.

Which International Standards Are Relevant for Rotary Latches?

One of the most recognized standards is ISO 9001, which specifies requirements for a quality management system. It emphasizes customer satisfaction, process efficiency, and continuous improvement. Compliance with ISO 9001 can assure buyers of a manufacturer’s commitment to quality.

For specific industries, other certifications may apply, such as:

- CE Marking: Essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, API standards ensure that products can withstand extreme conditions and operate reliably.

What Are the Key Quality Control Checkpoints in Rotary Latch Manufacturing?

Quality control (QC) checkpoints throughout the manufacturing process are essential for ensuring that rotary latches meet specifications. Key QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify defects early, reducing waste and rework.

- Final Quality Control (FQC): Before shipping, finished products undergo comprehensive testing, including functional tests, dimensional checks, and compliance with applicable standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are actionable strategies:

- Conduct Supplier Audits: Regular audits can provide insights into the supplier’s quality management systems and adherence to standards.

- Request Quality Reports: Suppliers should be able to provide documentation of their QC processes, including inspection reports and certifications.

- Engage Third-party Inspectors: Hiring independent inspectors can add an extra layer of assurance, ensuring that products meet quality standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Understanding local regulations, compliance requirements, and cultural differences in business practices can facilitate smoother transactions.

It’s advisable for buyers to familiarize themselves with both local and international standards applicable to their industry, as well as any potential trade barriers that could affect quality compliance. Additionally, establishing clear communication channels with suppliers can help address any quality concerns promptly.

In summary, the manufacturing and quality assurance processes for rotary latches are intricate and demand attention to detail. By understanding these processes, B2B buyers can make informed decisions, ensuring they source reliable and high-quality products for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a rotating latch’

Introduction

This practical sourcing guide provides B2B buyers with a systematic checklist to effectively procure rotating latches. These mechanical components are critical for ensuring secure and reliable closures in various applications, from automotive to heavy equipment. By following this checklist, buyers can make informed decisions that meet their operational needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the rotating latch you need. Consider factors such as size, load capacity, and environmental conditions (e.g., exposure to moisture or temperature extremes).

– Load Capacity: Ensure the latch can handle the weight and stress of the application.

– Material Requirements: Choose materials that withstand your specific conditions, such as galvanized iron for corrosion resistance.

Illustrative image related to what is a rotating latch

Step 2: Determine the Type of Rotary Latch Needed

Identify which type of rotary latch best suits your application. Options include single rotor and double rotor latches, each offering different levels of security and alignment tolerance.

– Single Rotor: Ideal for basic applications where standard security suffices.

– Double Rotor: Offers enhanced rigidity and is better for misaligned applications, providing greater reliability.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specific needs. Request company profiles, product catalogs, and references from similar industries or regions.

– Quality Assurance: Inquire about their quality control measures and certifications to ensure product reliability.

– Industry Experience: Suppliers with experience in your industry will better understand your requirements and constraints.

Step 4: Request Samples for Testing

Before making a large order, request samples of the rotary latches. Testing the samples in real-world conditions can help you evaluate their performance and compatibility with your systems.

– Functionality Testing: Assess the ease of operation and durability under expected conditions.

– Compatibility Checks: Ensure the latch integrates well with your existing systems and components.

Step 5: Confirm Compliance with Industry Standards

Verify that the rotary latches comply with relevant industry standards and regulations. This is especially important in sectors like automotive and aerospace, where safety and reliability are paramount.

– Certification Verification: Check for certifications such as ISO or ANSI that validate the quality and safety of the product.

– Regulatory Compliance: Ensure adherence to local and international regulations, especially if operating in multiple regions.

Step 6: Assess Delivery and Support Services

Evaluate the supplier’s delivery capabilities and customer support services. Timely delivery and responsive support are crucial for maintaining production schedules and addressing any issues that may arise.

– Lead Times: Confirm lead times for orders and ensure they align with your project timelines.

– Post-Purchase Support: Investigate the availability of technical support and warranty services for ongoing assistance.

Step 7: Negotiate Terms and Finalize Purchase

Once you’ve selected a supplier, negotiate terms of purchase, including price, payment options, and delivery schedules. Make sure all agreements are documented to avoid misunderstandings.

– Volume Discounts: Inquire about pricing tiers based on order size for potential savings.

– Contract Clarity: Ensure that all terms are clear and mutually agreed upon to facilitate a smooth transaction process.

By following this checklist, B2B buyers can effectively source high-quality rotating latches that meet their specific needs, ensuring operational efficiency and reliability in their applications.

Comprehensive Cost and Pricing Analysis for what is a rotating latch Sourcing

What are the Cost Components of Sourcing a Rotating Latch?

When considering the procurement of rotating latches, understanding the cost structure is crucial for B2B buyers. The primary components of cost include:

-

Materials: The choice of materials significantly impacts the overall cost. Rotating latches are commonly made from iron or galvanized steel for durability, especially in extreme environments. Alternative materials such as stainless steel or specialized plastics may be more expensive but can offer enhanced performance or corrosion resistance.

-

Labor: Labor costs encompass both direct and indirect labor involved in manufacturing the latches. This includes wages for skilled workers who assemble the components and quality assurance teams that ensure the latches meet industry standards.

-

Manufacturing Overhead: This involves costs related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, ultimately affecting pricing.

-

Tooling: The initial investment in tooling can be significant, especially for custom or specialized latches. This cost is often amortized over large production runs, making it essential to discuss minimum order quantities (MOQs) with suppliers.

-

Quality Control (QC): Rigorous quality control processes are vital for ensuring product reliability, especially in applications where safety is a concern. The costs associated with QC can vary depending on the complexity of the latch design and the certification requirements.

-

Logistics: Transportation and warehousing costs must be factored into the total cost. These can vary significantly based on the supplier’s location, shipping methods, and Incoterms.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market position and the competitive landscape.

What Factors Influence the Pricing of Rotating Latches?

Several factors can influence the pricing of rotating latches, particularly in international markets:

-

Volume and Minimum Order Quantities (MOQs): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their operational needs while taking advantage of cost savings.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. It’s essential to balance the need for customization with budget constraints.

-

Material Quality and Certifications: Latches that meet specific industry standards or certifications (e.g., ISO, ASTM) may come at a premium. Buyers should consider the long-term benefits of investing in higher-quality products.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Suppliers with a proven track record may charge more but can provide better service and product quality.

-

Incoterms: Understanding the shipping terms and responsibilities outlined in Incoterms can affect total costs. Buyers should evaluate their ability to handle logistics, including import duties and taxes.

What Tips Can Help Buyers Negotiate Better Prices for Rotating Latches?

To maximize cost-efficiency when sourcing rotating latches, consider the following buyer tips:

-

Negotiate Terms: Leverage your purchasing power by negotiating pricing, payment terms, and delivery schedules. Building a long-term relationship with suppliers can lead to better pricing and service.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the total cost of ownership, which includes maintenance, replacement, and operational costs over the product’s lifecycle.

-

Understand Pricing Nuances for International Buyers: B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, trade tariffs, and local regulations that can affect pricing.

-

Conduct Market Research: Familiarize yourself with market trends and competitor pricing to ensure you are receiving a fair offer. This knowledge can empower you during negotiations.

Disclaimer on Indicative Prices

It’s important to note that prices for rotating latches can vary widely based on the factors discussed above. This analysis aims to provide a framework for understanding costs and pricing in the context of sourcing, but actual prices may differ based on specific circumstances and supplier negotiations.

Alternatives Analysis: Comparing what is a rotating latch With Other Solutions

Exploring Alternatives to Rotating Latches: Key Comparisons

When evaluating fastening and locking solutions, it’s essential to consider various options available in the market. While rotating latches offer unique benefits, other mechanisms may better suit specific applications or environments. This comparison will highlight how rotating latches stack up against alternative solutions such as magnetic door latches and spring latches.

| Comparison Aspect | What Is A Rotating Latch | Magnetic Door Latch | Spring Latch |

|---|---|---|---|

| Performance | High security with remote actuation; suitable for heavy-duty applications. | Good for lightweight doors; relies on magnetic force, less secure against forceful entry. | Effective for quick, manual operation but less secure; can be affected by wear over time. |

| Cost | Moderate; pricing varies based on material and design. | Generally lower cost, making it budget-friendly for many applications. | Low cost; widely available and simple design. |

| Ease of Implementation | Requires careful installation of actuator and cable; may need specific mounting points. | Easy to install; often comes with adhesive backing or simple mounting hardware. | Straightforward to install; typically requires minimal tools. |

| Maintenance | Minimal; robust design reduces wear and tear; occasional lubrication needed. | Requires periodic checks for magnet strength; can lose effectiveness over time. | Regular inspection needed; may need replacement due to mechanical wear. |

| Best Use Case | Ideal for heavy machinery, automotive applications, and situations requiring remote access. | Best for light-duty doors, cabinets, or applications where aesthetics matter. | Suitable for doors and gates that need quick access without high-security demands. |

In-Depth Analysis of Alternatives

What are Magnetic Door Latches?

Magnetic door latches utilize magnets to keep doors closed, providing a simple and effective solution for lightweight applications. Their ease of installation makes them a popular choice for residential and light commercial environments. However, their security features are limited, as they can be easily forced open. Additionally, the strength of the magnets can degrade over time, which might necessitate replacements or adjustments.

Understanding Spring Latches

Spring latches are mechanical devices that provide a basic level of security and quick access. They operate using a spring mechanism that allows the latch to engage when the door is closed. Spring latches are relatively low-cost and easy to install, making them suitable for various applications. However, they may not be the best choice for environments requiring high security, as they can wear down and become less effective over time. Regular maintenance is necessary to ensure optimal performance.

Conclusion: Making the Right Choice for Your Needs

Choosing the right fastening mechanism depends on specific application requirements, including security needs, installation complexity, and budget constraints. Rotating latches offer robust performance and remote actuation capabilities, making them ideal for demanding environments. On the other hand, magnetic and spring latches may be more suitable for lighter applications where ease of installation and lower costs are priorities. B2B buyers should carefully evaluate their unique requirements and consider factors such as operational environment and desired security level before making a decision. By aligning the right latch solution with their operational needs, businesses can enhance efficiency and ensure reliable performance in their applications.

Essential Technical Properties and Trade Terminology for what is a rotating latch

When considering the procurement of rotary latches, understanding their essential technical properties and common trade terminology is critical for making informed purchasing decisions. This section outlines the key specifications and terminology relevant to rotary latches that B2B buyers should be familiar with.

What Are the Critical Technical Properties of a Rotary Latch?

-

Material Grade

Rotary latches are typically constructed from high-grade materials such as galvanized iron or stainless steel. The choice of material is vital as it impacts the latch’s durability, corrosion resistance, and performance in extreme environments. For international buyers, selecting the right material ensures compliance with local safety and quality standards. -

Load Capacity

The load capacity of a rotary latch refers to the maximum weight it can securely hold when engaged. This specification is crucial for applications in heavy machinery, automotive, and industrial settings where latches must endure significant stress. Understanding the load capacity helps in selecting a latch that meets operational requirements without risking failure. -

Operating Temperature Range

Many rotary latches are designed to function effectively within specific temperature ranges. Knowing the operating temperature range is essential for buyers in regions with extreme climates, as it determines the latch’s reliability in various conditions. This specification ensures that the latch will perform consistently, whether in hot or cold environments. -

Tolerances and Clearances

Tolerances refer to the permissible limits of variation in a latch’s dimensions, while clearances indicate the space required for proper installation. These technical properties are crucial for ensuring that the latch fits seamlessly with the corresponding hardware. Precise tolerances and clearances prevent mechanical failures and enhance the overall performance of the system. -

Actuation Mechanism

Rotary latches can have various actuation mechanisms, including manual and remote options. Understanding the type of actuation required for a specific application is vital for ease of use and functionality. Buyers should assess whether the latch will be operated by a cable, lever, or electronic system to ensure compatibility with existing systems.

What Are the Common Trade Terms Associated with Rotary Latches?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of rotary latches, an OEM might supply components that are integrated into larger machinery. Understanding OEM relationships can help buyers ensure they are sourcing high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers, as it affects inventory management and procurement strategies. Knowing the MOQ helps businesses plan their purchases according to demand without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. For rotary latches, submitting an RFQ can help buyers compare prices and specifications from multiple suppliers, ensuring they secure the best deal while meeting their technical requirements. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping, insurance, and risk management aspects related to the procurement of rotary latches. -

Lead Time

Lead time refers to the amount of time taken from placing an order to the product being delivered. This is particularly important in B2B transactions where timely delivery can impact project timelines. Buyers should inquire about lead times to align their procurement schedules with operational needs.

By grasping these technical properties and trade terms, B2B buyers can make strategic decisions when sourcing rotary latches, ensuring that they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the what is a rotating latch Sector

What Are the Current Market Dynamics for Rotary Latches?

The global market for rotary latches is experiencing significant growth, driven by the increasing demand for robust locking mechanisms in various industries such as automotive, aerospace, and heavy machinery. Key trends influencing this market include the rising emphasis on automation and remote access solutions, which enhance user convenience and operational efficiency. International buyers from regions like Africa, South America, the Middle East, and Europe are particularly interested in rotary latches for their adaptability in diverse applications—from securing vehicle compartments to ensuring safety in industrial equipment.

Emerging technologies, such as smart locking systems and integrated IoT capabilities, are reshaping sourcing strategies. Buyers are increasingly seeking suppliers who can provide advanced rotary latches that integrate seamlessly with electronic systems. This shift towards tech-enabled solutions is further fueled by the need for enhanced security features and remote operability, allowing users to control access from a distance. In regions like Brazil and Saudi Arabia, where infrastructure development is booming, the demand for high-quality rotary latches is likely to surge, presenting ample sourcing opportunities for manufacturers and suppliers.

How Does Sustainability Impact the Sourcing of Rotary Latches?

Sustainability is becoming a critical consideration in the sourcing of rotary latches. As environmental regulations tighten globally, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes using eco-friendly materials and implementing efficient manufacturing processes that minimize waste and energy consumption.

Buyers should look for suppliers that offer green certifications and utilize sustainable materials, such as recycled metals and non-toxic coatings. These practices not only reduce the environmental footprint but also enhance the overall brand reputation in the eyes of consumers who are increasingly conscious of sustainability issues. Furthermore, ethical sourcing is essential for maintaining a positive supply chain image, particularly in markets where corporate social responsibility is a significant factor in purchasing decisions. By aligning with suppliers that uphold these values, businesses can ensure that their sourcing strategies contribute to a sustainable future while meeting market demands.

What Is the Evolution of Rotary Latches in the B2B Sector?

The evolution of rotary latches can be traced back to their initial use in mechanical applications, where they provided a simple yet effective means of securing doors and panels. Over the years, advancements in materials and design have led to the development of more sophisticated rotary latches that are capable of withstanding extreme conditions. Today, rotary latches are not only functional but also designed with aesthetics in mind, catering to a broad range of applications from automotive to industrial uses.

The integration of technology into rotary latch designs marks a significant milestone in their evolution. Modern rotary latches often feature remote actuation capabilities, enhancing user convenience and operational efficiency. As industries continue to innovate, the demand for more versatile and reliable rotary latches is expected to grow, making them an essential component in various mechanical systems worldwide. This ongoing evolution presents valuable opportunities for B2B buyers to invest in cutting-edge solutions that can meet the demands of an increasingly competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a rotating latch

-

How do I select the right rotating latch for my application?

Choosing the appropriate rotating latch involves assessing the specific requirements of your application. Consider factors such as the weight and size of the door or panel, the environment (e.g., exposure to moisture or extreme temperatures), and the level of security needed. Additionally, evaluate the latch’s material—galvanized iron is often preferred for heavy-duty applications. It’s also essential to ensure compatibility with the actuator and cable setup to ensure smooth operation. -

What types of rotating latches are available for different industries?

Rotating latches come in various designs tailored for specific applications. For automotive use, compact and lightweight latches are ideal, while heavy-duty latches suit construction machinery or agricultural equipment. Industries like aerospace and medical may require rubber latches for their non-abrasive properties. Understanding the operational environment and load requirements will help you choose the best type for your needs. -

What customization options are available for rotating latches?

Many manufacturers offer customization options for rotating latches, including size, material, and finish. You can specify features like remote actuation, dual rotor configurations for added strength, or specific cable lengths to fit your installation needs. Discussing your requirements with suppliers can lead to tailored solutions that meet your operational demands. -

What are the typical minimum order quantities (MOQ) for rotating latches?

Minimum order quantities can vary significantly among suppliers. Generally, MOQs for rotating latches range from 100 to 1,000 units, depending on the manufacturer and the complexity of the product. When sourcing, inquire about MOQs to ensure they align with your project requirements. Some suppliers may offer flexibility for first-time buyers or custom orders. -

How can I vet suppliers for rotating latches in international markets?

To vet suppliers effectively, conduct thorough research, including checking their certifications, industry experience, and customer reviews. Consider requesting samples to assess product quality and verify that they meet your specifications. Additionally, look for suppliers with a proven track record in your target market regions, as they will be familiar with local regulations and standards. -

What payment terms should I expect when sourcing rotating latches internationally?

Payment terms can vary widely based on the supplier’s policies and your relationship with them. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing agreements. -

What quality assurance measures should I look for in rotating latches?

When sourcing rotating latches, ensure that the manufacturer adheres to recognized quality standards, such as ISO certifications. Request information on their quality control processes, including inspections and testing protocols. Additionally, inquire about warranty policies and after-sales support to address any potential issues post-purchase. -

How do logistics and shipping impact the sourcing of rotating latches?

Logistics and shipping play a crucial role in international sourcing. Consider factors like shipping costs, lead times, and customs regulations in your target markets. Work with suppliers who have experience in international shipping to ensure smooth delivery. It’s also advisable to discuss packaging requirements to prevent damage during transit, ensuring that your rotating latches arrive in optimal condition.

Top 8 What Is A Rotating Latch Manufacturers & Suppliers List

1. IQS Directory – Rotary Latches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Rotary latches are locking mechanisms designed to secure openings such as doors, enclosures, cabinets, and panels. They are also known as slam latches and engage with a striker to lock when pushed into place. Key components include a housing, jaw, lever, and spring. Types of rotary latches include single-stage, double-stage, and specialized variants. Single-stage rotary latches feature a single ro…

2. Hartwell Corp – Rotary Latches

Domain: hartwellcorp.com

Introduction: Rotary latches are designed to carry loads in tension only and are used with adjacent shear pins or interlocking faces to react to shear loads. They are operated with a standard mechanic’s tool and are aerodynamically friendly with minimum penetration of the aircraft’s skin, allowing for easy sealing and accommodation of aircraft contours. Features include internal ‘O-rings’ for effective sealing,…

3. TCH – Electronic Rotary Latch

Domain: us.tchweb.com

Registered: 1998 (27 years)

Introduction: Electronic Rotary Latch is an electromechanical fastening device that combines a traditional rotary latch’s robust and compact design with electronic control. It uses an electric actuator or solenoid to control the rotating cam or pawl, engaging and disengaging with a mating striker or catch. Features include enhanced security through integration with access control systems, remote operation for c…

4. Latch Manufacturers – Rotary Latches

Domain: latchmanufacturers.com

Registered: 2015 (10 years)

Introduction: Rotary latches, also known as slam latches, are secure and easy methods for closing doors, cabinets, and cupboards. They lock in place by being forced against a striker, which can be a rod, round solid cylindrical shaft, or U-shaped bracket secured to the frame of an opening. Key components include jaws, a lever, and spring, all enclosed in a housing. Rotary latches can be categorized as double, s…

5. Reddit – Cam Locks

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The rotatable latch on access panels is commonly referred to as a “cam lock” or “slotted head cam latch.” Other variants mentioned include “turn button,” “compression latch,” and “offset cam latch or lock.” A related fastener is the “dzus fastener.”

6. McMaster-Carr – Remote-Release Rotary Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster-Carr – Remote-Release Rotary Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Industrilas – Rotary Latching Systems

Domain: industrilas.com

Registered: 1999 (26 years)

Introduction: Rotary latching systems are part of the latching systems product line offered by Industrilas. They are designed for various industries including commercial vehicles, door and window manufacturers, EV charging, food and pharmaceutical, HVAC, IT and telecom, marine, off-highway, power generation and distribution, power sports, railway, recreational vehicles, specialty vehicles, armoured vehicles, an…

8. Metrol – Rotary Latches

Domain: motioncontrol.metrol.com

Registered: 1998 (27 years)

Introduction: Rotary Latches from Metrol are heavy-duty components designed for enhanced durability and security in door or access panel applications. Key features include a self-locking system, slotted recess, and construction from highly durable mild steel with a zinc plated finish. The model 1803 is specifically highlighted, with a price range of £6.46 – £10.23. These latches improve aesthetics and security,…

Strategic Sourcing Conclusion and Outlook for what is a rotating latch

In summary, understanding the intricacies of rotary latches is crucial for international B2B buyers seeking reliable mechanical solutions. These devices, characterized by their durable construction and flexible operating mechanisms, are well-suited for a variety of applications, from automotive to heavy machinery. Their ability to offer secure, remote access enhances both convenience and safety, making them invaluable in industries that require robust security measures.

Strategic sourcing plays a pivotal role in ensuring that companies select high-quality rotary latches that meet specific operational demands. By partnering with reputable suppliers, buyers can gain access to a range of products tailored to diverse environments, from extreme conditions in the Middle East to varying climates in Africa and South America.

As we look ahead, the demand for innovative fastening solutions will continue to rise, driven by advancements in technology and increasing safety standards. Now is the time for international buyers to explore partnerships that can deliver both quality and reliability in rotary latches. Leverage this knowledge to make informed purchasing decisions that will enhance operational efficiency and security in your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to what is a rotating latch

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.