The Definitive Guide to Bead Blasted Gold: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for bead blasted gold

In the competitive landscape of international trade, sourcing high-quality bead blasted gold can pose significant challenges for B2B buyers. With its unique aesthetic appeal and versatility, bead blasted gold stainless steel is increasingly sought after for applications ranging from architectural cladding and decorative facades to automotive and marine industries. However, the complexity of the global market necessitates a comprehensive understanding of supplier capabilities, product specifications, and pricing structures to make informed purchasing decisions.

This guide aims to empower international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—by offering a detailed overview of bead blasted gold products. We will explore various types of bead blasted gold finishes, their applications across different industries, and essential factors to consider when vetting suppliers. Additionally, we will provide insights into cost considerations, lead times, and quality assurance practices, enabling businesses to mitigate risks and optimize their sourcing strategies.

By leveraging the information presented in this guide, buyers can confidently navigate the complexities of the global bead blasted gold market, ensuring that they secure products that meet their specific needs while fostering long-term supplier relationships. This resource is designed to facilitate strategic decision-making, ultimately enhancing the quality and aesthetic appeal of projects across multiple sectors.

Understanding bead blasted gold Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bead Blasted Stainless Steel | Matte gold finish with a textured surface | Architectural cladding, elevator panels, street furniture | Pros: Durable, aesthetically pleasing, low maintenance. Cons: Limited reflective quality compared to polished finishes. |

| PVD Coated Bead Blasted | Enhanced durability with a vapor deposition layer | High-end architectural projects, luxury interiors | Pros: Superior scratch resistance, vibrant colors. Cons: Higher cost, potential color variations. |

| Decorative Bead Blasted | Customizable patterns and textures | Interior design, furniture, art installations | Pros: Unique designs, tailored solutions. Cons: Longer lead times for customization. |

| Bead Blasted Aluminum | Lightweight alternative with a similar finish | Automotive components, marine applications | Pros: Lightweight, corrosion-resistant. Cons: Less strength compared to stainless steel. |

| Bead Blasted Gold Plated | Gold plating over stainless steel | Jewelry, luxury items, decorative accents | Pros: Luxurious appearance, affordable alternative to solid gold. Cons: Prone to wear over time, requires care. |

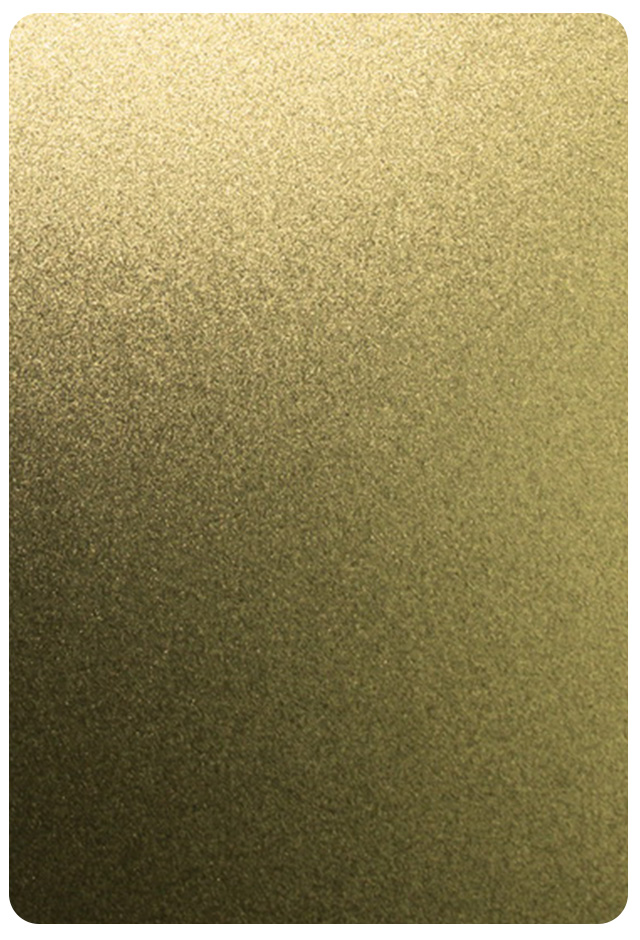

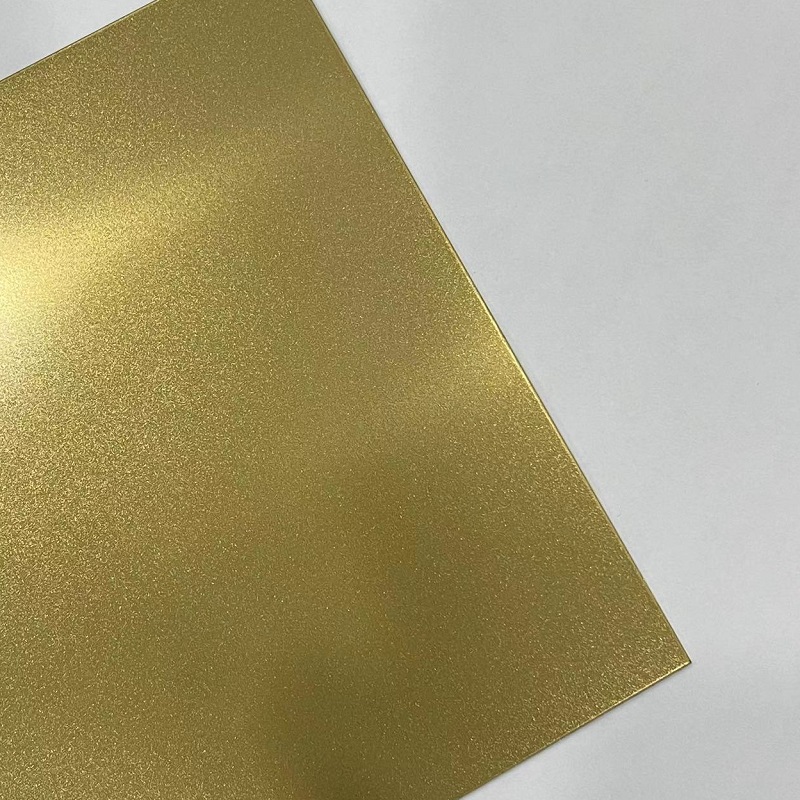

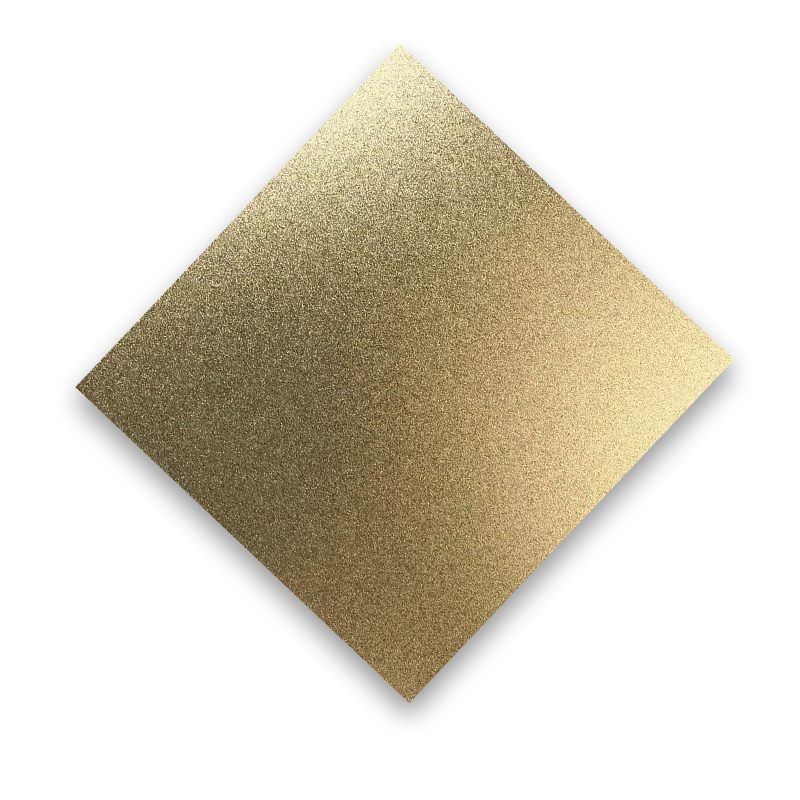

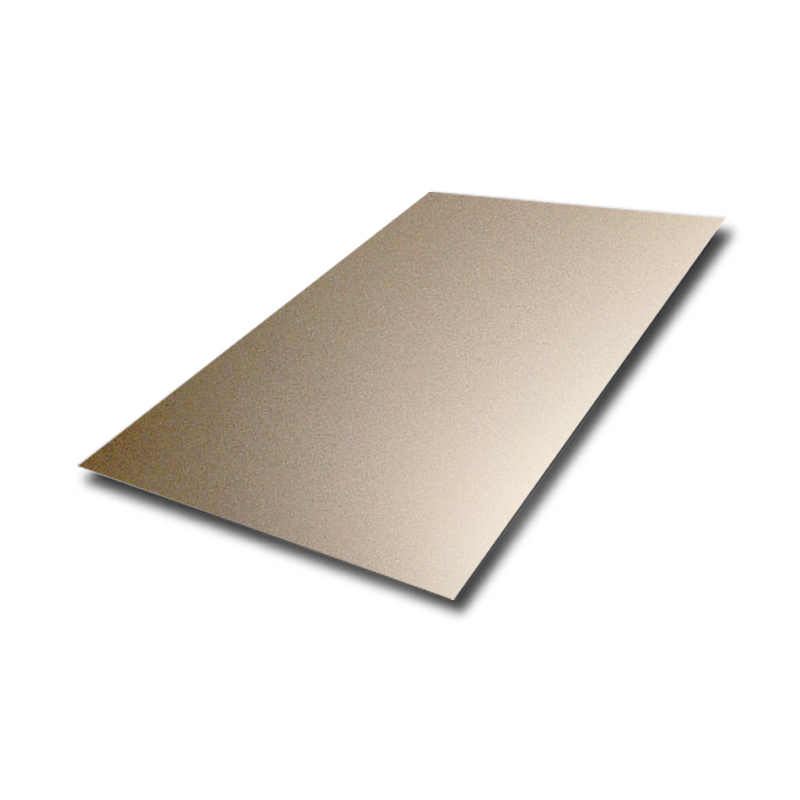

What Are the Key Characteristics of Bead Blasted Stainless Steel?

Bead blasted stainless steel features a matte gold finish achieved through a surface treatment that creates a textured appearance. This type is especially suitable for architectural cladding and elevator panels, where both aesthetics and durability are essential. Buyers should consider the long-term maintenance needs and the potential for scratches compared to polished finishes.

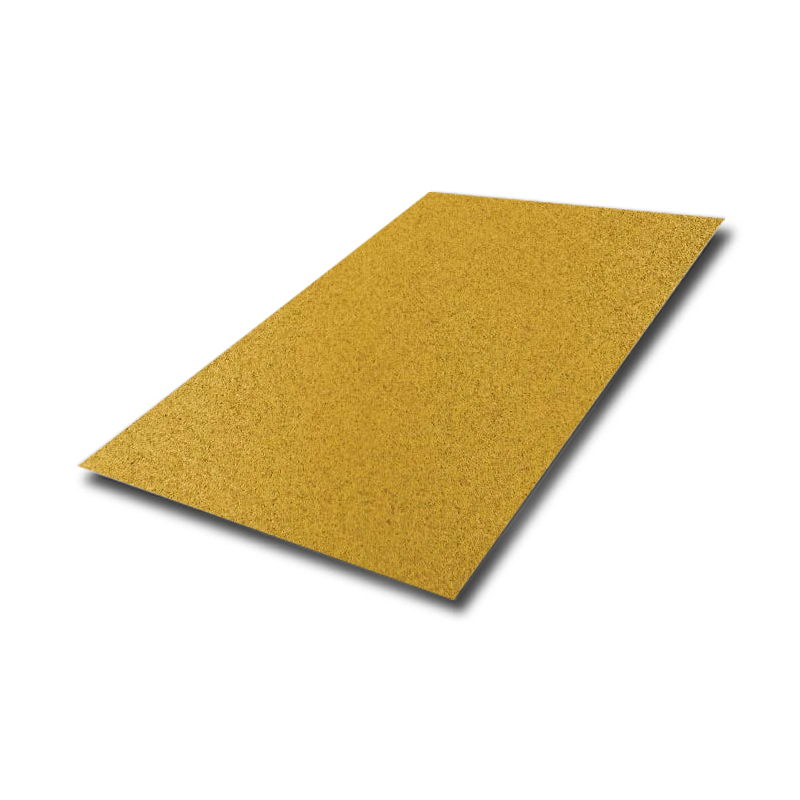

Illustrative image related to bead blasted gold

How Does PVD Coating Enhance Bead Blasted Products?

PVD (Physical Vapor Deposition) coated bead blasted materials provide enhanced durability and vibrant colors, making them ideal for high-end architectural projects and luxury interiors. The PVD layer offers superior scratch resistance, which is a significant advantage for surfaces exposed to frequent use. However, the higher costs and the possibility of color variations should be factored into purchasing decisions.

What Customization Options Are Available for Decorative Bead Blasted Products?

Decorative bead blasted finishes allow for customizable patterns and textures, making them popular in interior design, furniture, and art installations. This flexibility enables businesses to create unique designs that stand out. However, buyers should be aware of the longer lead times associated with custom orders, which may impact project timelines.

What Are the Benefits of Bead Blasted Aluminum?

Bead blasted aluminum offers a lightweight alternative with a similar aesthetic to stainless steel. This type is particularly suited for automotive components and marine applications, where weight reduction is critical. While it provides excellent corrosion resistance, buyers should note that it may lack the strength of stainless steel, making it less suitable for heavy-duty applications.

Why Consider Bead Blasted Gold Plated Options?

Bead blasted gold plated products provide a luxurious appearance at a more affordable price compared to solid gold. These items are commonly used in jewelry and decorative accents. However, buyers should consider the wear and tear associated with gold plating, as it may require more care to maintain its appearance over time.

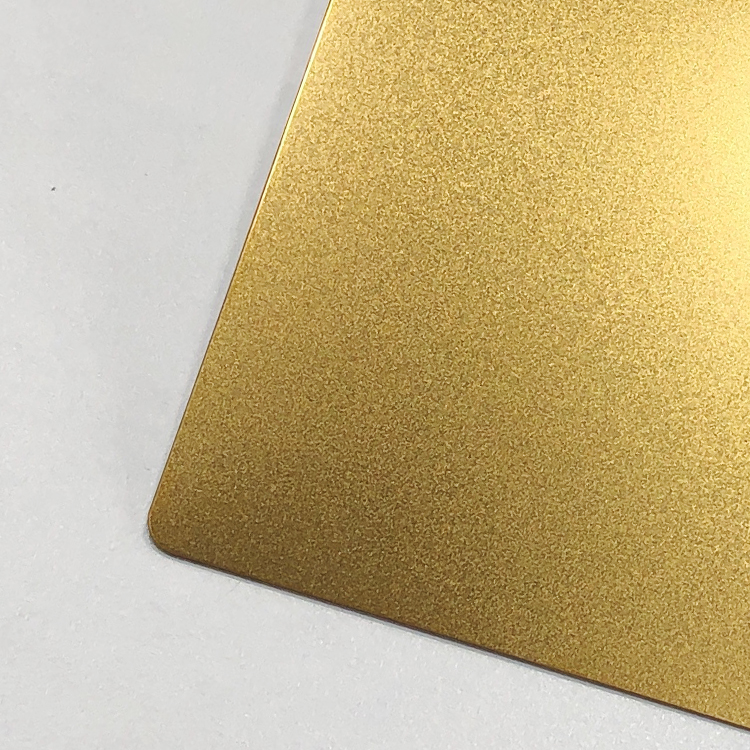

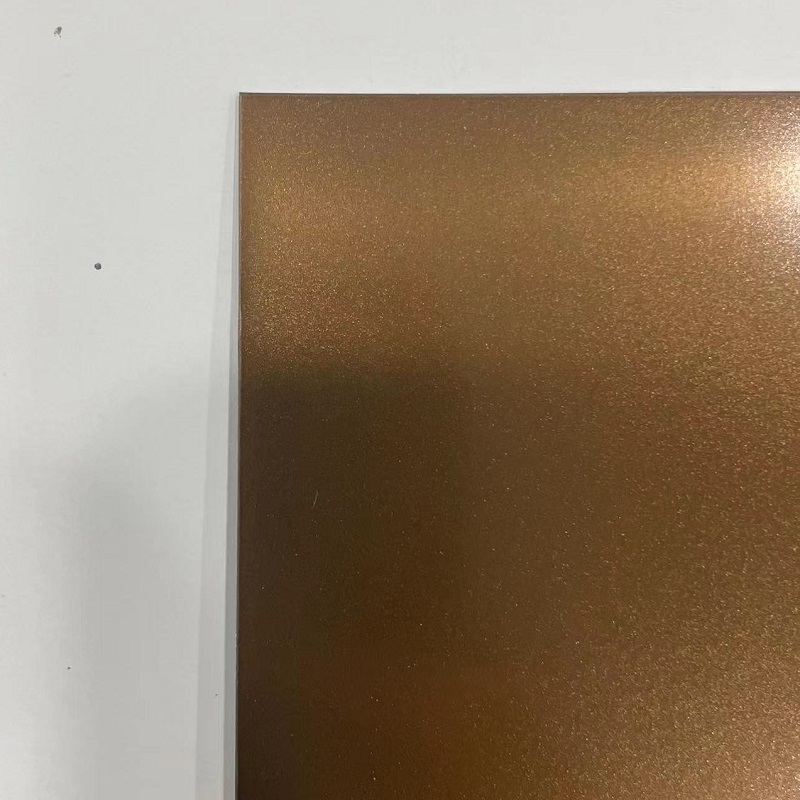

Illustrative image related to bead blasted gold

Key Industrial Applications of bead blasted gold

| Industry/Sector | Specific Application of bead blasted gold | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architectural Design | Decorative Facades | Enhances aesthetic appeal and durability in building exteriors | Ensure compliance with local building codes and standards. |

| Retail & Hospitality | Elevator Panels | Creates a luxurious experience that attracts customers | Consider lead times for custom sizes and finishes. |

| Marine Industry | Boat Interiors | Resilient to harsh marine environments while providing elegance | Check for corrosion resistance and material certifications. |

| Automotive & Aviation | Interior Trim | Offers a high-end finish that adds value to vehicles | Source materials with high durability and aesthetic standards. |

| Public Infrastructure | Street Furniture | Provides a stylish yet functional element in public spaces | Assess local regulations and environmental impact compliance. |

How is bead blasted gold used in architectural design, and what are the benefits?

In architectural design, bead blasted gold is primarily utilized for decorative facades, offering a unique blend of elegance and resilience. This finish not only enhances the aesthetic appeal of buildings but also provides a durable surface that withstands environmental factors. For international buyers, particularly those in Africa and Europe, it is vital to ensure that the materials comply with local building codes and standards to avoid costly delays during construction.

What role does bead blasted gold play in the retail and hospitality sectors?

Within the retail and hospitality sectors, bead blasted gold is frequently applied to elevator panels. This application creates a luxurious experience that can significantly attract customers and enhance brand perception. Buyers should consider lead times for custom sizes and finishes when sourcing these materials, as timely delivery is crucial for maintaining project schedules and ensuring customer satisfaction.

Why is bead blasted gold important in the marine industry?

In the marine industry, bead blasted gold is used for interior applications on boats and yachts, providing an aesthetic upgrade while also ensuring resistance to harsh marine environments. The durability of this material is essential for longevity, making it a preferred choice for luxury vessels. Buyers should verify the corrosion resistance and obtain relevant material certifications to ensure compliance with marine standards.

How does bead blasted gold enhance automotive and aviation interiors?

Bead blasted gold is employed in the automotive and aviation sectors for interior trim, offering a high-end finish that adds significant value to vehicles and aircraft. This application not only improves visual appeal but also contributes to the overall quality perception of the product. When sourcing, it’s crucial for buyers to prioritize materials that meet high durability and aesthetic standards, ensuring they can withstand wear and tear while maintaining their luxurious appearance.

What are the benefits of using bead blasted gold in public infrastructure?

In public infrastructure, bead blasted gold is commonly used in street furniture, such as benches and trash bins, to provide a stylish yet functional element in urban spaces. This application enhances the overall environment while ensuring durability and ease of maintenance. Buyers should assess local regulations and environmental impact compliance to ensure that their sourcing aligns with community standards and sustainability initiatives.

3 Common User Pain Points for ‘bead blasted gold’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Bead Blasted Gold Procurement

The Problem: B2B buyers often face significant difficulties in ensuring the quality of bead blasted gold materials. Variability in surface finish, color consistency, and raw material quality can lead to unsatisfactory products that do not meet project specifications. This is especially concerning when sourcing from international suppliers, where discrepancies in standards and quality assurance protocols may arise. A buyer may receive a shipment of bead blasted gold sheets that do not align with their expectations, leading to project delays and increased costs due to rework.

The Solution: To mitigate these quality control issues, buyers should prioritize sourcing from reputable suppliers who adhere to stringent quality assurance processes. Request detailed datasheets and certifications that outline the material properties and surface finish standards. Engage in regular communication with suppliers to clarify expectations regarding surface finishes and dimensions. Additionally, consider ordering samples before committing to larger quantities. This allows buyers to inspect the quality firsthand and ensure that it meets their project requirements. Implementing a quality checklist during the procurement process can also help identify potential issues before the materials reach the project site.

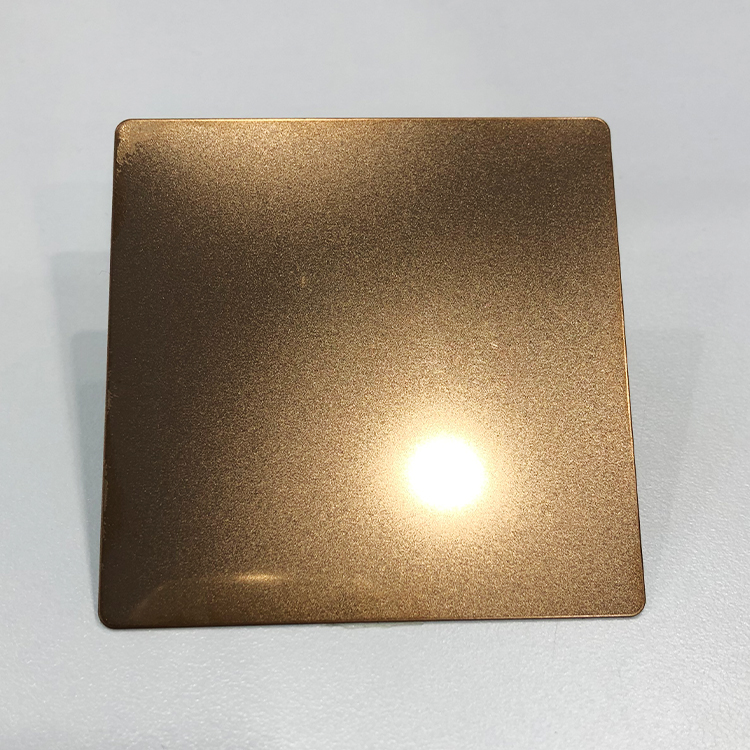

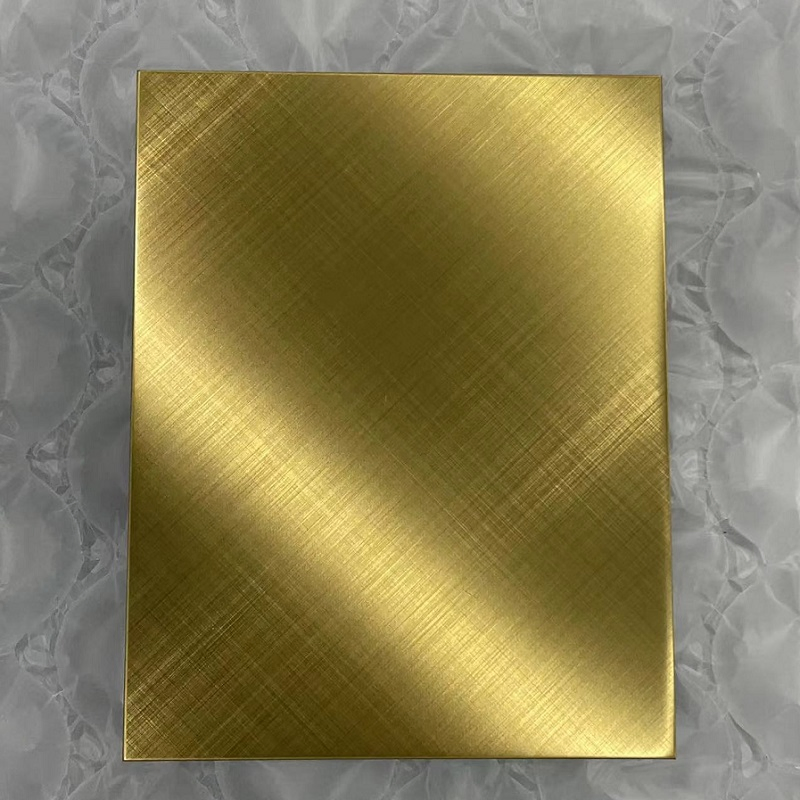

Illustrative image related to bead blasted gold

Scenario 2: Addressing Supply Chain Delays for Bead Blasted Gold Products

The Problem: Supply chain disruptions are a common pain point for B2B buyers, particularly those dealing with bead blasted gold. Factors such as geopolitical tensions, raw material shortages, or logistical challenges can lead to extended lead times and unanticipated project delays. Buyers in regions like Africa or South America may find it particularly challenging to access timely deliveries, affecting their ability to meet client deadlines and maintain competitiveness in the market.

The Solution: To counteract supply chain issues, B2B buyers should develop a diversified sourcing strategy. This involves establishing relationships with multiple suppliers across different regions to ensure a backup supply in case of disruptions. Buyers should also negotiate clear lead times and delivery terms upfront, including penalties for delays, to incentivize timely shipments. Implementing a robust inventory management system can help track stock levels and anticipate when to reorder materials, thereby avoiding last-minute shortages. Additionally, utilizing technology for real-time tracking of shipments can provide visibility into the supply chain, enabling proactive decision-making.

Scenario 3: Customization Limitations with Bead Blasted Gold Finishes

The Problem: Many buyers seek specific finishes and dimensions for their bead blasted gold products to achieve unique design aesthetics. However, suppliers may have limitations in their production capabilities, leading to frustration when buyers cannot obtain the desired specifications. This is particularly problematic for projects in the architectural and automotive sectors, where custom finishes play a crucial role in the overall design and branding.

The Solution: To overcome customization limitations, buyers should clearly communicate their specific requirements during the initial discussions with suppliers. This includes detailing the desired thickness, dimensions, and surface finish variations, such as PVD coatings or artistic processes. Engage suppliers who offer flexibility in their production capabilities and are open to custom orders. It may also be beneficial to collaborate with suppliers on design prototypes, allowing for adjustments before final production. Establishing a partnership with manufacturers who have advanced technology and equipment can also enhance the ability to produce bespoke solutions that align with the buyer’s vision.

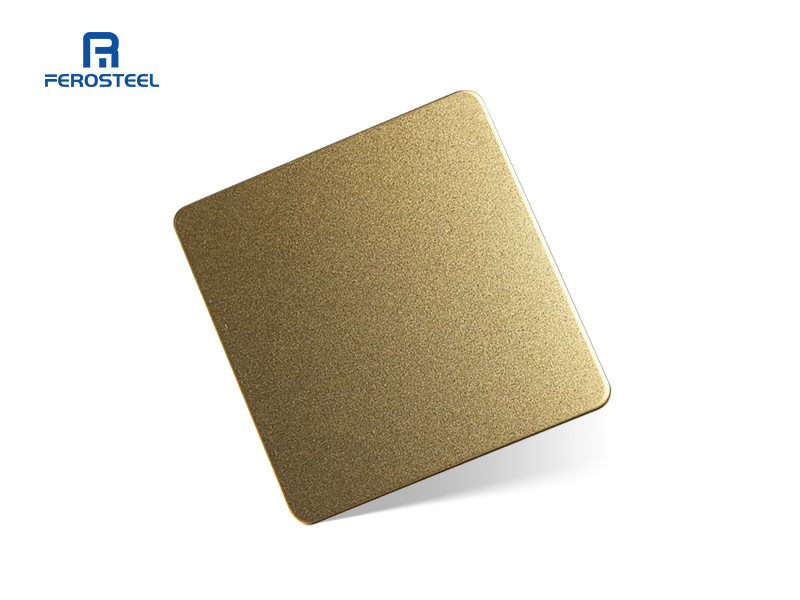

Illustrative image related to bead blasted gold

Strategic Material Selection Guide for bead blasted gold

What Are the Common Materials Used for Bead Blasted Gold?

When selecting materials for bead blasted gold applications, several options are prevalent in the market. Each material offers distinct properties, advantages, and limitations that are crucial for B2B buyers to consider. Below, we analyze four common materials: AISI 304, AISI 316L, AISI 201, and Aluminum.

How Does AISI 304 Stainless Steel Perform in Bead Blasted Gold Applications?

AISI 304 is one of the most widely used stainless steels due to its excellent corrosion resistance and good mechanical properties. It can withstand temperatures up to 870°C (1,600°F) and is suitable for a variety of environments, including those with moderate corrosive elements.

Pros: Its durability and aesthetic appeal make it ideal for architectural applications like decorative facades and elevator panels. Additionally, it is relatively cost-effective compared to higher grades.

Cons: While it offers good corrosion resistance, AISI 304 is not suitable for extremely corrosive environments, such as marine applications, where AISI 316L would be more appropriate.

Illustrative image related to bead blasted gold

Impact on Application: AISI 304 is often used in shopping malls and street furniture, where visual appeal is essential. However, buyers in coastal regions should consider the limitations regarding corrosion.

Why Choose AISI 316L Stainless Steel for Bead Blasted Gold?

AISI 316L is known for its superior corrosion resistance, particularly in chloride environments, making it ideal for marine and chemical applications. It can handle temperatures up to 870°C (1,600°F) and is often used in more demanding environments.

Pros: Its high resistance to pitting and crevice corrosion makes it suitable for applications in harsh conditions. This material is also aesthetically pleasing, enhancing the overall design.

Cons: AISI 316L is generally more expensive than AISI 304, which could impact budget considerations for large projects.

Impact on Application: AISI 316L is preferred in marine and automotive industries, where durability and resistance to corrosion are paramount. Buyers should ensure compliance with international standards like ASTM and DIN for quality assurance.

What Are the Benefits and Limitations of AISI 201 Stainless Steel?

AISI 201 is a lower-cost alternative to AISI 304 and 316L, offering decent corrosion resistance and strength. It can withstand temperatures up to 870°C (1,600°F) but is less resistant to corrosion than its higher-grade counterparts.

Pros: The cost-effectiveness of AISI 201 makes it attractive for budget-sensitive projects. It is suitable for applications where high corrosion resistance is not a primary concern.

Cons: Its lower corrosion resistance limits its use in applications exposed to harsh environments, which could lead to increased maintenance costs over time.

Illustrative image related to bead blasted gold

Impact on Application: AISI 201 is often used in decorative applications where cost is a significant factor, but international buyers should be cautious about its limitations in corrosive environments.

How Does Aluminum Compare in Bead Blasted Gold Applications?

Aluminum is another material used in bead blasted gold applications, particularly for lightweight structures. It offers excellent corrosion resistance and can be anodized for additional protection.

Pros: Aluminum is lightweight and easy to work with, making it suitable for various applications, including display equipment and interior decorations. Its natural resistance to corrosion enhances its longevity.

Illustrative image related to bead blasted gold

Cons: While it is generally less expensive than stainless steel, aluminum may not offer the same level of strength and durability, particularly in structural applications.

Impact on Application: Aluminum is ideal for applications where weight is a concern, but buyers should consider the mechanical strength required for their specific use cases.

Summary Table of Material Selection for Bead Blasted Gold

| Material | Typical Use Case for bead blasted gold | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| AISI 304 | Architectural cladding, elevator panels | Good corrosion resistance, cost-effective | Not suitable for extreme environments | Medium |

| AISI 316L | Marine applications, chemical industries | Superior corrosion resistance | Higher cost | High |

| AISI 201 | Decorative applications | Cost-effective | Lower corrosion resistance | Low |

| Aluminum | Display equipment, interior decor | Lightweight, excellent corrosion resistance | Less strength in structural applications | Medium |

This guide provides a comprehensive overview of strategic material selection for bead blasted gold, enabling B2B buyers to make informed decisions based on their specific application needs and market conditions.

Illustrative image related to bead blasted gold

In-depth Look: Manufacturing Processes and Quality Assurance for bead blasted gold

What Are the Key Stages in the Manufacturing Process of Bead Blasted Gold?

The manufacturing process of bead blasted gold involves several critical stages, each crucial for ensuring the final product meets the aesthetic and functional requirements of international B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: Selecting High-Quality Raw Materials

The foundation of any quality bead blasted gold product lies in the selection of raw materials. Manufacturers typically use stainless steel grades such as AISI 304, 316, or even specialized alloys like 201 and 430, depending on the intended application. These materials are chosen for their corrosion resistance, durability, and aesthetic appeal. The raw materials undergo thorough inspections upon arrival at the manufacturing facility to verify their specifications and quality.

Forming: Precision Cutting and Shaping

Once the materials are prepared, they are cut to the desired dimensions. Advanced cutting techniques, such as laser cutting or water jet cutting, ensure high precision and minimal waste. The standard sizes for bead blasted gold sheets often range from 1219mm x 2438mm to larger formats of 1500mm x 3048mm. Manufacturers can also accommodate special dimensions as per client requests. This flexibility is essential for B2B buyers looking for tailored solutions.

Assembly: Ensuring Structural Integrity

During the assembly phase, manufacturers may perform welding or other joining techniques if the bead blasted gold is part of a more complex structure, such as architectural cladding or display equipment. Each assembly method is selected based on the intended use of the final product, ensuring that it meets industry standards for strength and durability.

Finishing: Achieving the Desired Aesthetic

Finishing is where the bead blasting technique comes into play. The surface of the stainless steel is treated using abrasive media to create a uniform, matte finish that enhances the gold color. This bead blasting process not only improves the aesthetic appeal but also increases the surface’s resistance to scratches and tarnishing. After bead blasting, additional treatments such as PVD (Physical Vapor Deposition) coating can be applied for enhanced color and protection.

What Quality Assurance Measures Are Implemented in Bead Blasted Gold Production?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final products meet both customer specifications and international standards. Manufacturers often adhere to recognized quality management systems such as ISO 9001, which outlines requirements for a quality management system that helps organizations improve their processes and provide consistent products.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the production process:

-

Incoming Quality Control (IQC): Raw materials undergo rigorous testing upon receipt. This includes checking material grades, dimensions, and surface conditions to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspectors monitor each stage, from cutting to assembly, to ensure adherence to quality standards. This may involve visual inspections and measurements to verify dimensional accuracy.

-

Final Quality Control (FQC): Before packaging, finished products undergo a comprehensive inspection. This includes checking for surface defects, dimensional tolerances, and overall quality. Products that pass inspection are often protected with a PVC film to prevent damage during transport.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe, must take proactive steps to verify the quality control practices of potential suppliers. Here are several strategies:

Conducting Audits and Visits

One of the most effective ways to assess a supplier’s quality control is through on-site audits. Buyers can evaluate the manufacturing processes, quality management systems, and overall facility conditions. This provides firsthand insight into the supplier’s commitment to quality.

Requesting Documentation and Reports

Suppliers should be willing to provide documentation that outlines their quality control processes, including inspection reports, certificates of compliance (such as CE or API), and any relevant ISO certifications. This documentation serves as proof of adherence to international standards.

Engaging Third-Party Inspection Services

For added assurance, buyers can engage third-party inspection services. These independent entities can conduct inspections at various stages of production, ensuring that products meet specified quality and safety standards before shipment.

What Are the Quality Certification Nuances for International B2B Buyers?

Understanding the nuances of quality certifications is vital for international B2B transactions. Different regions may have varying certification requirements, which can affect the importation and acceptance of products. For instance, while ISO 9001 is a globally recognized standard, certifications like CE mark in Europe or API standards in the oil and gas industry may be necessary for specific applications.

Illustrative image related to bead blasted gold

Importance of Compliance with Local Regulations

B2B buyers must ensure that suppliers comply with local regulations and standards in their target markets. This is particularly important in industries such as construction, automotive, and marine, where non-compliance can lead to legal issues and product recalls.

Conclusion: Ensuring Quality Through Rigorous Processes

The manufacturing processes and quality assurance measures for bead blasted gold are designed to meet the high standards expected by international B2B buyers. By understanding the stages of production, implementing robust quality control checkpoints, and verifying supplier practices, buyers can ensure they receive products that not only meet their specifications but also enhance their own market reputation.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bead blasted gold’

In the competitive landscape of B2B procurement, sourcing high-quality bead blasted gold products requires careful consideration and strategic planning. This checklist serves as a guide to streamline your sourcing process, ensuring that you make informed decisions that align with your business needs and quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful procurement. Identify the material grades (e.g., AISI 304, 316) and thicknesses (typically ranging from 0.6 mm to 5.0 mm) required for your projects. Additionally, specify the dimensions you need, as suppliers often provide standard sizes but can accommodate custom requests.

Step 2: Research Supplier Capabilities

Conduct thorough research on potential suppliers to gauge their production capabilities. Look for suppliers that have automated bead blasting production lines and use high-quality raw materials sourced from reputable manufacturers like TISCO or BAOSTEEL. Understanding their manufacturing process will help ensure that you receive consistent quality and timely delivery.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Check for certifications and quality assurance processes to confirm that they adhere to international standards.

- Tip: Utilize platforms like LinkedIn or industry forums to connect with other buyers and gather insights about suppliers’ reputations.

Step 4: Request Samples

Always request samples before making a bulk purchase. This step allows you to evaluate the quality of the bead blasted finish, color consistency, and material durability. Pay attention to the surface characteristics and finish options, as variations can occur due to the manufacturing process.

Step 5: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers, engage in negotiations to secure favorable terms. Discuss pricing, lead times, and payment options to ensure transparency and mutual benefit. Be clear about minimum order quantities, especially since some suppliers may have specific requirements based on material thickness.

- Consider: Inquire about bulk discounts or long-term partnership benefits, which can lead to cost savings.

Step 6: Assess Logistics and Shipping Options

Evaluate the logistics involved in transporting the bead blasted gold products. Confirm that the supplier has reliable shipping methods and packaging solutions to prevent damage during transit. Ensure they can accommodate your preferred shipping timelines and methods, especially if you operate in diverse international markets.

Step 7: Establish Quality Control Measures

Implement quality control measures to monitor the products upon arrival. Create a checklist based on your initial specifications to verify that the delivered goods meet your requirements. Consider setting up a process for addressing any discrepancies, ensuring a seamless resolution with the supplier.

By following these steps, you can enhance your sourcing strategy for bead blasted gold, minimizing risks and maximizing quality in your procurement process.

Illustrative image related to bead blasted gold

Comprehensive Cost and Pricing Analysis for bead blasted gold Sourcing

What Are the Key Cost Components in Bead Blasted Gold Sourcing?

Understanding the cost structure of bead blasted gold is essential for B2B buyers, particularly those in international markets. The primary cost components include:

-

Materials: The base material for bead blasted gold typically includes various grades of stainless steel, such as AISI 304, 316, and other alloys. Prices fluctuate based on market demand for raw materials and quality specifications. Additional costs may arise from surface treatments and coatings, such as PVD, which enhance aesthetic appeal and durability.

-

Labor: Labor costs encompass the skilled workforce required for bead blasting, finishing, and quality control. Depending on the region, labor costs can vary significantly, influencing overall pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, machinery, utilities, and administrative costs. Efficient production processes and advanced technology can help reduce overhead costs, which may be passed on to the buyer.

-

Tooling: Custom tooling may be necessary for specialized shapes or sizes, adding to the initial investment. Buyers should evaluate whether the tooling costs are justified by the production volume and customization needs.

-

Quality Control (QC): Rigorous quality control measures ensure that products meet international standards. This involves inspection processes, testing, and certification, which can add to the overall cost but are vital for maintaining quality assurance.

-

Logistics: Transportation costs are a significant factor, especially for international shipments. Factors such as shipping method, distance, and Incoterms can all affect the final price.

-

Margin: Suppliers typically apply a profit margin based on their cost structure, competition, and market conditions. Understanding the supplier’s margin can provide insights into pricing flexibility.

What Influences the Pricing of Bead Blasted Gold Products?

Several factors influence the pricing of bead blasted gold products, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their needs while maximizing cost-efficiency.

-

Specifications and Customization: Custom dimensions, thicknesses, and finishes can significantly impact pricing. Buyers must clearly communicate their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher-grade materials and recognized certifications can lead to increased prices. Buyers should weigh the benefits of premium materials against their project requirements.

-

Supplier Factors: The reputation, location, and operational efficiency of suppliers can affect pricing. Established suppliers may command higher prices due to their reliability and quality assurance processes.

-

Incoterms: Understanding the agreed-upon Incoterms is crucial, as they dictate responsibility for shipping costs, insurance, and customs duties. This knowledge can help buyers avoid unforeseen expenses.

What Tips Can Help Buyers Negotiate Better Prices for Bead Blasted Gold?

When sourcing bead blasted gold, international B2B buyers can employ several strategies to optimize costs:

-

Negotiate Terms: Engaging in open dialogue with suppliers can yield better pricing and terms. Highlighting long-term partnership potential may encourage suppliers to offer favorable conditions.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also shipping, handling, and potential maintenance costs. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Understand Pricing Nuances: Familiarize yourself with regional market conditions and pricing trends in your target markets (Africa, South America, the Middle East, and Europe). This knowledge can empower you during negotiations.

-

Leverage Samples: Requesting samples allows buyers to assess quality before making bulk purchases. This step can prevent costly mistakes and ensure the final product meets expectations.

What Should Buyers Keep in Mind Regarding Pricing?

It is important to note that prices for bead blasted gold can vary significantly based on the above factors and market conditions. Buyers should approach pricing discussions with a clear understanding of their requirements and the potential for negotiation. Always request indicative prices and be prepared for fluctuations based on market dynamics and supplier capabilities.

Alternatives Analysis: Comparing bead blasted gold With Other Solutions

Introduction to Alternatives for Bead Blasted Gold

In the competitive landscape of architectural and decorative materials, bead blasted gold offers a distinctive aesthetic and functional appeal. However, buyers often seek alternatives that can fulfill similar roles in design and construction. This section will explore various options, allowing B2B buyers to make informed decisions based on their specific project requirements.

Illustrative image related to bead blasted gold

Comparison Table

| Comparison Aspect | Bead Blasted Gold | PVD Coated Stainless Steel | Mirror Finish Stainless Steel |

|---|---|---|---|

| Performance | Excellent corrosion resistance, aesthetic appeal | Superior scratch resistance, vibrant colors | High reflectivity, elegant finish |

| Cost | Moderate to high | Moderate to high | Lower than bead blasted gold |

| Ease of Implementation | Requires specialized equipment for installation | Relatively easy to handle and install | Easy to install, readily available |

| Maintenance | Low maintenance, regular cleaning | Low maintenance, resistant to tarnishing | Moderate maintenance, prone to scratches |

| Best Use Case | High-end architectural projects, luxury interiors | Commercial applications, modern designs | Retail displays, decorative elements |

Detailed Breakdown of Alternatives

PVD Coated Stainless Steel

Physical Vapor Deposition (PVD) coated stainless steel is a robust alternative to bead blasted gold. This method involves depositing a thin film of metal onto a substrate, resulting in a durable, scratch-resistant surface. PVD coatings can achieve a variety of colors and finishes, allowing for customization to fit specific design aesthetics. The primary advantage of PVD is its enhanced resistance to wear and tarnishing, making it ideal for high-traffic environments. However, the initial setup and specialized equipment required for PVD processes can lead to higher upfront costs.

Mirror Finish Stainless Steel

Mirror finish stainless steel is another appealing alternative that offers a bright, reflective surface. This finish is achieved through polishing, which results in a highly reflective surface that can elevate the visual appeal of any space. It is often used in retail settings and decorative applications. The ease of installation and lower cost compared to bead blasted gold makes it a practical choice for many projects. However, mirror finishes are more susceptible to scratches and may require more frequent maintenance to keep them looking pristine.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between bead blasted gold and its alternatives, B2B buyers should carefully consider the specific requirements of their projects. Factors such as performance, cost, and maintenance play critical roles in this decision-making process. Bead blasted gold is ideal for high-end applications where aesthetics and corrosion resistance are paramount. In contrast, PVD coated stainless steel offers exceptional durability, while mirror finish stainless steel provides a cost-effective solution with a distinct look. Understanding these differences will enable buyers to choose the most suitable option for their unique applications, ensuring both functionality and design excellence.

Essential Technical Properties and Trade Terminology for bead blasted gold

What Are the Key Technical Properties of Bead Blasted Gold?

Understanding the essential technical properties of bead blasted gold is crucial for international B2B buyers, especially when sourcing materials for architectural and decorative applications. Here are some critical specifications:

-

Material Grade

The quality of stainless steel used in bead blasted gold products significantly impacts durability and aesthetics. Common grades include AISI 304, 316, and 201. AISI 304 is the most frequently used due to its excellent corrosion resistance, while 316 offers superior protection in marine environments. Selecting the right material grade ensures the longevity and performance of the final product. -

Thickness

The thickness of bead blasted gold sheets typically ranges from 0.60 mm to 5.00 mm, depending on the application. Thicker sheets are preferred for structural applications, while thinner options may suffice for decorative purposes. Understanding thickness specifications is vital for ensuring that the material meets specific design and structural requirements. -

Finish Type

The bead blasted finish provides a distinctive textured surface, enhancing the visual appeal of products. This finish can also be complemented by other surface treatments like PVD (Physical Vapor Deposition) or etching. Buyers should consider how the finish aligns with their design objectives and maintenance capabilities. -

Dimensions and Customization

Standard dimensions for bead blasted gold sheets often include sizes such as 1219 mm x 2438 mm or 1500 mm x 3000 mm. Custom sizes may be available upon request, allowing buyers to tailor products to specific project needs. Knowing the available dimensions helps in planning material usage effectively. -

Lead Time and Availability

Understanding lead times—typically one business day for in-stock items—is crucial for project planning. Buyers should inquire about production lead times for custom orders to avoid delays in project timelines. Availability of stock can influence purchasing decisions and project scheduling. -

Surface Color Variations

Bead blasted gold can come in various shades, including gold, black, and bronze. Color consistency is essential for ensuring that the final product meets design specifications. Buyers should request samples to verify color before committing to larger orders.

What Are Common Trade Terms Used in Bead Blasted Gold Transactions?

Navigating B2B transactions involves familiarizing oneself with industry jargon. Here are several key terms:

Illustrative image related to bead blasted gold

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bead blasted gold, buyers might work with OEMs for custom designs or unique applications. -

MOQ (Minimum Order Quantity)

MOQ specifies the least number of units a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, as it can affect the overall cost of procurement. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for specific quantities of materials. This process helps buyers compare prices and terms, ensuring they get the best deal for their bead blasted gold supplies. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps in understanding shipping costs and liabilities, which can impact the total cost of goods. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the goods. Knowing the lead time is vital for project management, ensuring materials arrive when needed to avoid delays. -

Surface Finish

This term encompasses the various treatments applied to the material’s surface, such as bead blasting, polishing, or coating. Different finishes affect both aesthetics and functionality, making it essential for buyers to specify their preferences clearly.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing bead blasted gold, ensuring that their projects meet both aesthetic and functional requirements.

Navigating Market Dynamics and Sourcing Trends in the bead blasted gold Sector

What Are the Current Market Dynamics and Key Trends in the Bead Blasted Gold Sector?

The bead blasted gold market is experiencing significant growth driven by various global factors. The architectural and construction sectors are leading the demand for bead blasted gold finishes, primarily due to their aesthetic appeal and durability. Regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in construction projects, particularly in urban development and luxury building designs. This trend is further supported by advancements in manufacturing technologies that enhance the quality and customization of bead blasted finishes, making them more accessible to international buyers.

Emerging technologies in sourcing and production, such as automated bead blasting and PVD coating, are reshaping the landscape. These innovations not only streamline production but also allow for a wider range of finishes and colors, catering to diverse client needs. Additionally, the growth of e-commerce platforms is facilitating easier access for B2B buyers to source materials globally, thereby increasing competition and driving prices down. Sustainability is also becoming a pivotal factor, with many suppliers emphasizing eco-friendly practices in their production processes, appealing to environmentally conscious buyers.

As the market evolves, international B2B buyers must stay informed about these trends, leveraging technology to optimize their sourcing strategies and ensuring they partner with suppliers that align with their quality and sustainability standards.

How Does Sustainability and Ethical Sourcing Impact the Bead Blasted Gold Market?

Sustainability and ethical sourcing are becoming increasingly crucial in the bead blasted gold sector. The environmental impact of production processes, including energy consumption and waste generation, is under scrutiny. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing emissions during production. This shift is not merely a trend but a necessity as regulations tighten globally, especially in Europe and North America.

Moreover, ethical supply chains are gaining importance as businesses seek to ensure that their materials are sourced responsibly. Suppliers who can provide certifications for their materials, indicating adherence to environmental and social governance standards, are likely to have a competitive edge. ‘Green’ certifications, such as ISO 14001 for environmental management, are becoming essential for suppliers aiming to attract conscious buyers.

By prioritizing sustainability, international B2B buyers can not only enhance their brand reputation but also mitigate risks associated with supply chain disruptions caused by environmental factors. Implementing sustainable sourcing practices can lead to long-term cost savings and improved customer loyalty, making it a strategic imperative in today’s market.

Illustrative image related to bead blasted gold

What Is the Evolution of Bead Blasted Gold and Its Relevance to Today’s B2B Buyers?

The evolution of bead blasted gold can be traced back to the growing demand for decorative and functional finishes in various industries, including architecture, automotive, and marine. Initially, bead blasting was primarily used for surface preparation and cleaning; however, its aesthetic applications have expanded significantly over the years. The introduction of gold finishes in bead blasting coincided with the rising trend of luxury materials in construction and design, offering an elegant alternative to traditional stainless steel finishes.

As technology advanced, the quality and variety of bead blasted gold products improved, allowing for more intricate designs and applications. Today, B2B buyers are increasingly drawn to bead blasted gold for its versatility and ability to enhance the visual appeal of both interior and exterior spaces. This evolution reflects a broader trend towards customization and innovation in material finishes, where buyers are seeking unique solutions that align with modern design aesthetics.

Understanding this historical context is essential for B2B buyers as it not only informs their purchasing decisions but also helps them anticipate future trends in the market. By recognizing the evolution of bead blasted gold, buyers can better appreciate the value of investing in high-quality, aesthetically pleasing materials that meet contemporary demands.

Frequently Asked Questions (FAQs) for B2B Buyers of bead blasted gold

-

How do I ensure the quality of bead blasted gold products from suppliers?

To ensure the quality of bead blasted gold products, it’s essential to request certifications and quality assurance documentation from your suppliers. Look for ISO certifications and specific product datasheets detailing material grades, thickness, and finish. Additionally, ask for samples to assess the quality firsthand. Engage in thorough communication regarding their production processes and quality control measures. Visiting the supplier’s facility, if feasible, can also provide insights into their operations and standards. -

What are the common applications of bead blasted gold in various industries?

Bead blasted gold is widely used across multiple industries due to its aesthetic appeal and durability. Common applications include architectural cladding, decorative facades, elevator panels, and street furniture. In the marine and automotive industries, it is utilized for components requiring both beauty and resilience. Additionally, it serves in interior design, enhancing items like kitchen equipment and display racks, making it a versatile choice for various projects. -

What customization options are available for bead blasted gold products?

Many suppliers offer extensive customization options for bead blasted gold products. Customizations can include variations in thickness, dimensions, and surface finishes, such as additional etching or PVD coatings. You can also request specific colors beyond standard gold, like rose gold or bronze. To ensure your exact requirements are met, it’s advisable to discuss your needs directly with the supplier during the initial inquiry. -

What is the minimum order quantity (MOQ) for bead blasted gold products?

Minimum order quantities (MOQ) for bead blasted gold products can vary significantly between suppliers. Typically, for standard thicknesses, MOQs may range from 50 to 100 pieces. However, for custom sizes or specialized finishes, the MOQ might increase. Always confirm the MOQ with your supplier before placing an order, as this can affect your purchasing strategy and budget. -

What payment terms should I expect when sourcing bead blasted gold internationally?

Payment terms for international orders of bead blasted gold products often vary by supplier and region. Common practices include upfront payment, partial payment upon order confirmation, and balance upon delivery. Some suppliers may accept letters of credit or payment through secure platforms. It’s essential to discuss and agree on payment terms before finalizing the order to avoid misunderstandings and ensure smooth transactions. -

How can I verify the reliability of a bead blasted gold supplier?

To verify a bead blasted gold supplier’s reliability, conduct thorough due diligence. Start by checking their business credentials, including registration and certifications. Look for customer reviews and testimonials that reflect their service quality. Engaging in discussions about their manufacturing processes and quality controls can provide insight into their operational standards. Additionally, consider requesting references from other clients to gauge their experiences and satisfaction levels. -

What logistics considerations should I take into account when importing bead blasted gold?

When importing bead blasted gold products, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your destination country’s import laws to streamline the process. Discuss packaging requirements with your supplier to prevent damage during transit. Additionally, factor in delivery timelines to ensure your project schedules align with product arrival. -

Are there specific certifications I should look for in bead blasted gold suppliers?

Yes, when sourcing bead blasted gold, look for suppliers with relevant industry certifications, such as ISO 9001 for quality management systems. Certifications related to material standards, like ASTM or EN standards for stainless steel, can also be significant. Additionally, suppliers may hold environmental certifications, which indicate responsible sourcing and production practices. These certifications can assure you of the supplier’s commitment to quality and sustainability.

Top 8 Bead Blasted Gold Manufacturers & Suppliers List

1. Royal Decor Steel – RDS-BDG

Domain: royaldecorsteel.com

Registered: 2013 (12 years)

Introduction: {“Product Code”: “RDS-BDG”, “Applications”: [“Architectural Cladding”, “Shopping Malls”, “Elevator Panels”, “Decorative Facades”, “Door Panels”, “Column Casings”, “Display equipment”, “Street Furniture”, “Kitchen equipment”, “Marine Industry”, “Automotive & Aviation Industries”], “Material”: “AISI 304”, “Finish”: “Bead Blasted”, “Color”: “Gold”, “Thickness”: “20GA”, “Dimensions”: “48” x 96″ Inches…

2. Minox Metal – Bead Blast Gold

Domain: minoxmetal.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “Bead Blast – Gold”, “Product Code”: “MX : BB Gold”, “Material Grades”: [“202”, “304”, “304L”, “316”, “316L”], “Finish”: “Bead Blast”, “Color”: “Gold”, “Thickness”: “0.60 mm to 5.00 mm”, “Dimensions”: [“1260 mm x 2500 mm”, “1500 mm x 3000 mm”], “Special Dimensions”: “On demand”, “Availability”: “In stock / to produce”, “Applications”: [“Architectural Cladding”, “Shopping Malls”, “…

3. Sunsong – Bead Blasted Gold Stainless Steel Sheet

Domain: sunsongss.com

Registered: 2018 (7 years)

Introduction: Bead Blasted Gold Stainless Steel Sheet; Surface Finish: Bead Blasted; Surface Color: Can be customized (Silver, Gold, Black, Gold Rose, Bronze, Brown, Nickle Silver, etc.); Raw Materials: 201, 304, 316L, 430, 441, 443; Material Thickness: 0.8mm to 3.0mm; Material Width: ≤ 1500mm; Material Length: ≤ 4000mm; Standard Sizes: 1219x2438mm (4ftx8ft), 1219x3048mm (4ftx10ft), 1500/1524x2438mm (5ftx8ft), …

4. Fire and Brilliance – Classic 18k Yellow Gold Bead Blast Wedding Band

Domain: fireandbrilliance.com

Registered: 2014 (11 years)

Introduction: {“name”:”Classic 18k Yellow Gold Bead Blast Wedding Band”,”metal_type”:”18k Yellow Gold”,”finish”:”Bead Blast”,”size”:”US Finger Size 5″,”regular_price”:”$860.00 USD”,”sale_price”:”$583.10 USD”,”shipping”:”Free USA Shipping”,”warranty”:”1 Year Warranty”}

5. Hermes Steel – Champagne Gold Stainless Steel Bead Blast Sheets

Domain: hermessteel.net

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Champagne Gold Decorative Color Stainless Steel Bead Blast Sheets”, “Brand Name”: “Hermes Steel”, “Place Of Origin”: “Guangdong, China (Mainland)”, “Thickness”: “0.3 mm – 3.0 mm”, “Size”: [“1000*2000mm”, “1219*2438mm”, “1219*3048mm”, “customized”], “Max Width”: “1500mm”, “SS Grade”: [“304”, “316”, “201”, “430”], “Finish”: “Bead Blasted”, “Available Finishes”: [“No.4”, “Hairline”,…

6. Topson Metal – Bead Blasted Stainless Steel

Domain: topsonmetal.com

Registered: 2021 (4 years)

Introduction: Bead blasted stainless steel, also known as sandblasted stainless steel, features a matte, non-reflective finish achieved through bead blasting. This process removes surface imperfections and creates a texture that diffuses light, resulting in a satin-like appearance. The finish enhances aesthetics and functionality, providing high adhesion for painting. Suitable for various metals including stain…

7. King of Jewelry – 14K Solid Gold Grooved Band

Domain: kingofjewelry.com

Introduction: {“name”: “14K Solid Gold 7 mm Grooved Band with Bead Blast Finish”, “sku”: “19088-A”, “regular_price”: “$2,295.00”, “available_metal_options”: [“14K White & Yellow Gold”, “14K White & Rose Gold”, “14K Yellow & White Gold”], “thickness”: “1.9 mm”, “ring_fit”: “Comfort-Fit”, “gender”: “Unisex”, “plating_type”: “Rhodium”, “surface_finish”: “Polished”, “approx_top_dimensions”: “7 mm”, “customization_o…

8. SDS – Stainless Steel PVD Ti Bead Blast Sheet

Domain: sdsprofile.com

Registered: 2019 (6 years)

Introduction: Stainless Steel PVD Ti Bead Blast Sheet by SDS

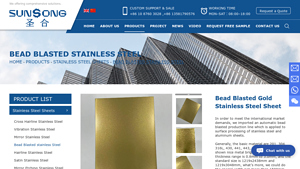

Strategic Sourcing Conclusion and Outlook for bead blasted gold

In conclusion, bead blasted gold presents a unique blend of aesthetic appeal and practical application, making it an attractive choice for various industries, including architecture, automotive, and marine sectors. Its versatility is evident in its use for decorative facades, elevator panels, and street furniture, among others. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the specifications, availability, and potential applications of bead blasted gold is crucial for informed purchasing decisions.

Strategic sourcing in this area can lead to significant cost savings and enhanced product quality. By collaborating with reputable suppliers who prioritize high-grade materials and rigorous quality control, businesses can ensure they receive superior products that meet their specific requirements. Moreover, the option for customization in terms of dimensions and finishes further enhances the value proposition for buyers looking to differentiate their offerings.

Illustrative image related to bead blasted gold

Looking ahead, the demand for bead blasted gold is poised to grow as design trends evolve and industries seek innovative solutions. We encourage B2B buyers to explore partnerships with trusted manufacturers and leverage their capabilities to enhance their projects. Engaging with suppliers who can provide tailored solutions will not only elevate your product offerings but also foster long-term business success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to bead blasted gold