Single Direction Valve: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for single direction valve

In today’s competitive landscape, international B2B buyers face the critical challenge of sourcing reliable single direction valves that meet their specific operational needs while ensuring cost-effectiveness and compliance with industry standards. As industries across Africa, South America, the Middle East, and Europe increasingly rely on advanced fluid control solutions, understanding the diverse types of single direction valves and their applications becomes essential for making informed purchasing decisions. This comprehensive guide explores various valve types, including solenoid, hydraulic, and mechanical options, and their specific uses in sectors such as automotive, medical, and manufacturing.

Throughout this guide, we will delve into vital aspects such as supplier vetting strategies, cost considerations, and the latest market trends. By equipping B2B buyers with actionable insights, this resource empowers you to navigate the complexities of the global market effectively. Whether you are seeking to enhance your supply chain or ensure compliance with local regulations, our guide provides the knowledge needed to make strategic decisions that drive efficiency and profitability. With a focus on the unique requirements of buyers from key regions like Germany and Brazil, this guide serves as your authoritative resource for sourcing single direction valves that align with your business objectives.

Understanding single direction valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solenoid Valves | Electrically operated, quick response, low power consumption | Automotive, medical devices, packaging | Pros: Fast operation, energy-efficient. Cons: Sensitive to electrical issues. |

| Monoblock Hydraulic Valves | Compact design, high tensile strength, multiple spool options | Agricultural machinery, construction | Pros: Space-saving, durable. Cons: Limited to specific flow rates. |

| Air Operated Valves | Operated by compressed air, suitable for high flow rates | Industrial automation, pneumatic systems | Pros: Reliable in harsh environments. Cons: Requires air supply. |

| Mechanical Valves | Manual operation, simple construction | General industry, maintenance applications | Pros: Low maintenance, robust. Cons: Slower response than automated options. |

| Check Valves | Prevents backflow, simple design | Water treatment, chemical processing | Pros: Essential for system integrity. Cons: Limited functionality beyond backflow prevention. |

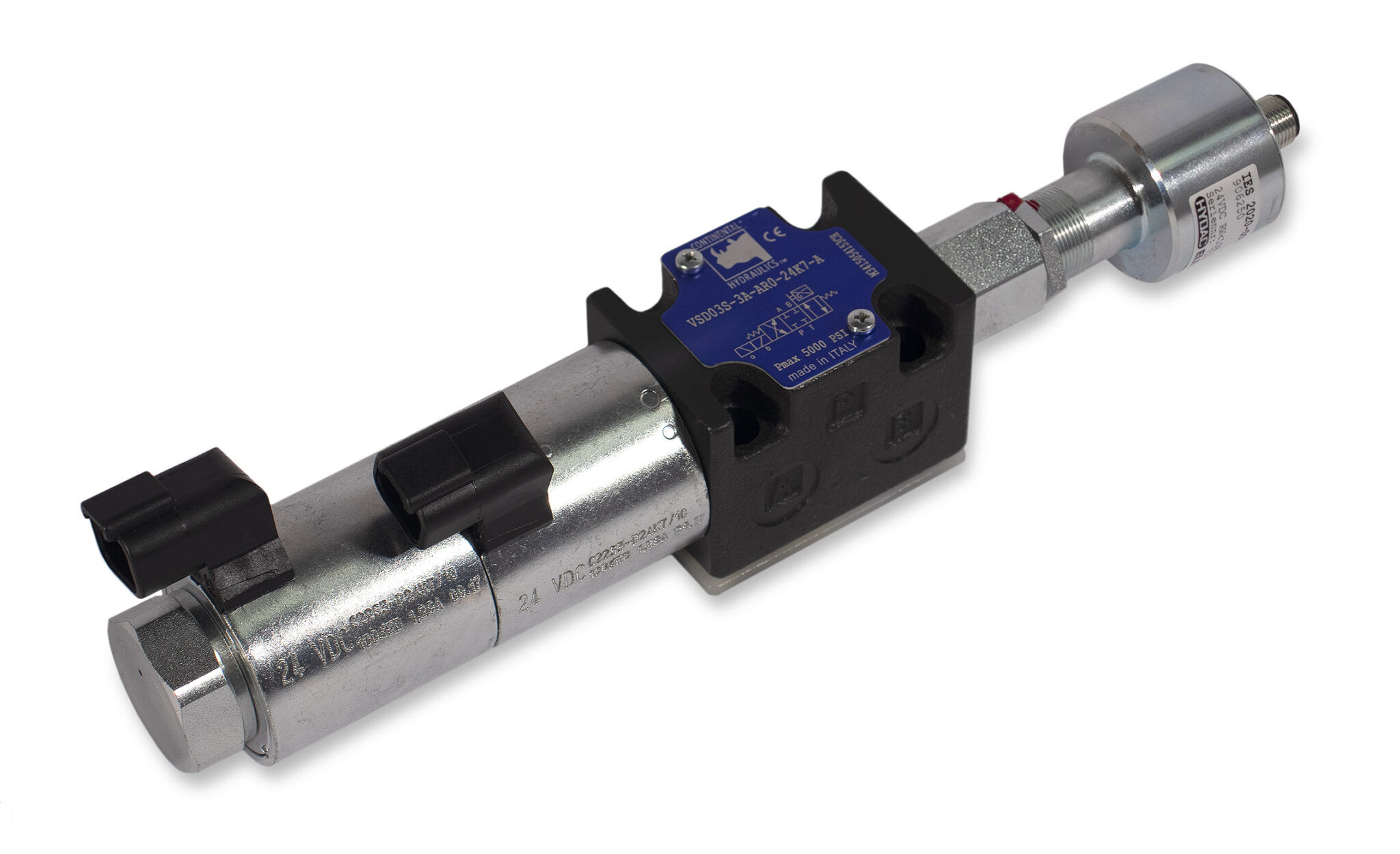

What Are Solenoid Valves and Their Key B2B Considerations?

Solenoid valves are a popular choice for applications requiring rapid operation and precise control. Their ability to operate electrically makes them suitable for industries like automotive and medical devices, where quick responsiveness is critical. B2B buyers should consider the valve’s power consumption, compatibility with existing systems, and potential electrical issues that could affect performance.

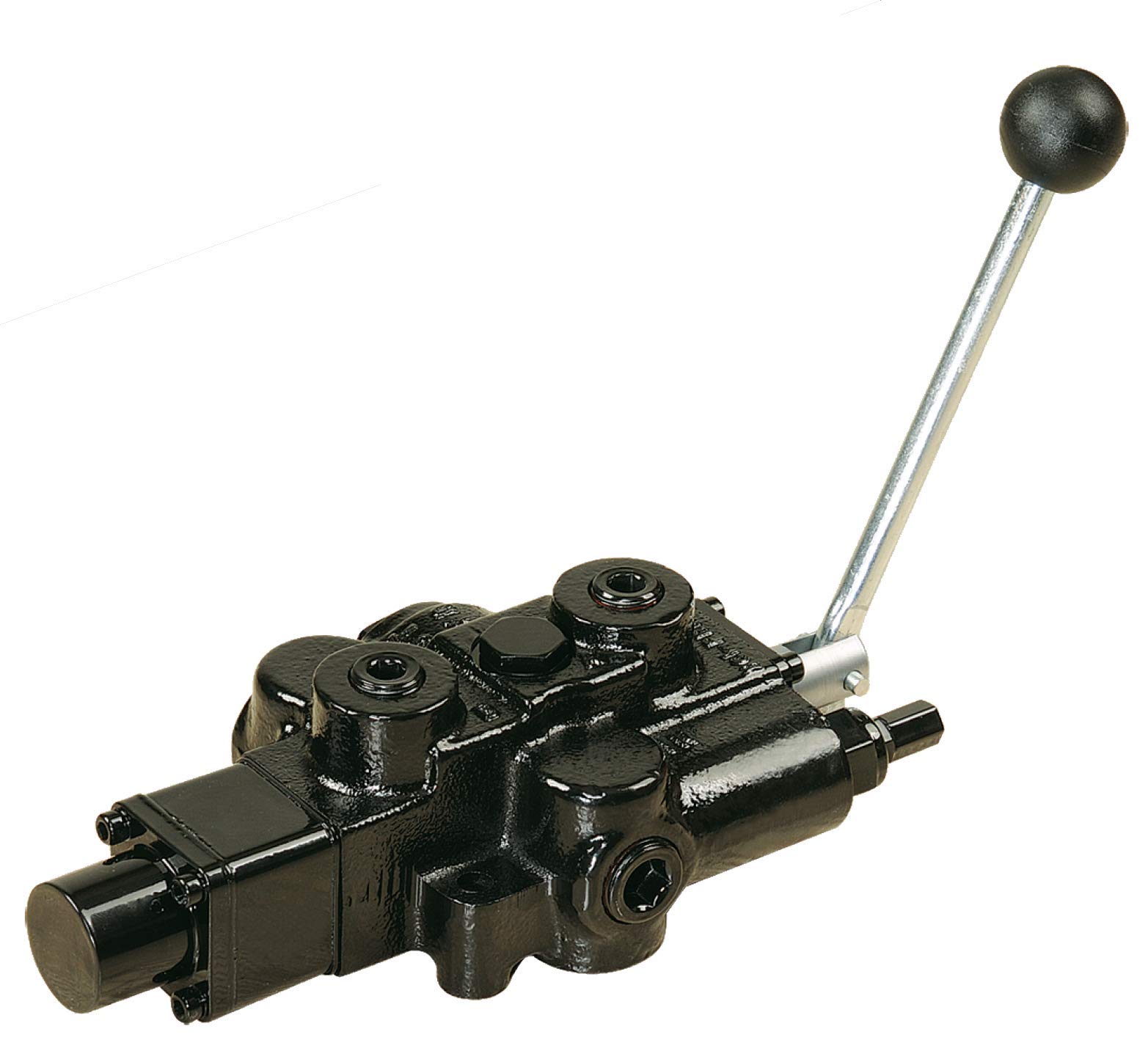

How Do Monoblock Hydraulic Valves Benefit Agricultural and Construction Industries?

Monoblock hydraulic valves feature a compact design and are made from high-tensile strength materials, making them ideal for agricultural and construction machinery. Their multiple spool options allow for versatile applications, including the operation of hydraulic cylinders and motors. When purchasing, buyers should evaluate the flow rate and pressure specifications to ensure compatibility with their systems.

Why Choose Air Operated Valves for Industrial Automation?

Air operated valves leverage compressed air to control fluid flow, making them suitable for high-flow applications in industrial automation. These valves are reliable and efficient, especially in harsh environments. Buyers must consider the availability of compressed air and the specific operational requirements of their applications to select the right valve type.

What Are the Advantages of Mechanical Valves in General Industry?

Mechanical valves are characterized by their manual operation and robust construction, making them ideal for general industry applications and maintenance tasks. While they require more manual effort and have a slower response time compared to automated options, their simplicity and low maintenance needs make them a reliable choice for many businesses. Buyers should assess the operational environment and ease of use when selecting these valves.

How Do Check Valves Ensure System Integrity in Various Applications?

Check valves are essential for preventing backflow in fluid systems, making them critical in applications like water treatment and chemical processing. Their simple design and functionality ensure system integrity, protecting against potential damage. B2B buyers should focus on the valve’s material compatibility with the fluids being handled and the pressure ratings to ensure optimal performance in their specific applications.

Key Industrial Applications of single direction valve

| Industry/Sector | Specific Application of single direction valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation Systems | Ensures controlled flow of water, preventing backflow and wastage | Compatibility with existing systems, durability in harsh conditions, and ease of maintenance. |

| Manufacturing | Hydraulic Machinery | Manages fluid direction for precision in machinery operations | Flow rate specifications, pressure ratings, and material compatibility with hydraulic fluids. |

| Oil and Gas | Pipeline Flow Control | Prevents reverse flow, ensuring safety and operational efficiency | High-pressure ratings, corrosion resistance, and compliance with industry standards. |

| Automotive | Fuel Delivery Systems | Controls fuel flow direction, enhancing engine performance | Temperature resistance, size specifications, and reliability under high-stress conditions. |

| Water Treatment | Wastewater Management | Facilitates directional flow in treatment processes, reducing contamination risk | Compliance with environmental regulations, material durability, and maintenance ease. |

How is a Single Direction Valve Used in Agriculture Irrigation Systems?

In agriculture, single direction valves play a crucial role in irrigation systems. They ensure that water flows in one direction, preventing backflow that can lead to contamination of the water supply. This is particularly important in regions where water quality is a concern. For international buyers, especially in Africa and South America, sourcing valves that can withstand varying soil conditions and climates is critical. Buyers should consider the valve’s durability, compatibility with existing irrigation setups, and ease of maintenance to ensure long-term functionality.

What Are the Benefits of Single Direction Valves in Manufacturing Hydraulic Machinery?

In the manufacturing sector, single direction valves are essential for hydraulic machinery operations. They control the flow of hydraulic fluid, allowing for precise movements of machinery components. This capability enhances productivity and minimizes downtime. Buyers in Europe, especially Germany, should focus on the flow rate specifications and pressure ratings of the valves to match their machinery needs. Additionally, material compatibility with hydraulic fluids is vital to prevent wear and tear, ensuring reliability in high-demand environments.

How Do Single Direction Valves Enhance Safety in Oil and Gas Pipeline Flow Control?

In the oil and gas industry, single direction valves are pivotal in pipeline flow control. They prevent reverse flow, which can pose significant safety risks and operational inefficiencies. For businesses in the Middle East, where pipeline integrity is paramount, sourcing valves that meet high-pressure ratings and are resistant to corrosion is essential. Compliance with industry standards is also a critical consideration to ensure safety and reliability in operations.

Why Are Single Direction Valves Important for Automotive Fuel Delivery Systems?

In automotive applications, single direction valves control the flow of fuel to engines, enhancing performance and efficiency. They ensure that fuel flows correctly, preventing backflow that could damage the engine. For manufacturers in Brazil, sourcing valves that can withstand high temperatures and pressures is crucial. Additionally, size specifications must align with engine designs to ensure compatibility, making reliability under high-stress conditions a top priority.

Illustrative image related to single direction valve

How Do Single Direction Valves Support Water Treatment Processes?

Single direction valves are vital in wastewater management and water treatment facilities. They facilitate directional flow, minimizing the risk of contamination and ensuring efficient treatment processes. Buyers in the water treatment sector should prioritize valves that comply with environmental regulations and are made from durable materials to withstand corrosive substances. Ease of maintenance is also a key consideration, as it affects the overall efficiency and longevity of the treatment systems.

3 Common User Pain Points for ‘single direction valve’ & Their Solutions

Scenario 1: Inconsistent Flow Control in Hydraulic Applications

The Problem: Many B2B buyers using single direction valves in hydraulic systems often encounter issues with inconsistent flow control. This inconsistency can lead to unpredictable operation of machinery, resulting in inefficient processes and potential downtime. For instance, a manufacturer in Brazil might find that their hydraulic cylinders are not extending or retracting smoothly, causing delays in production. This not only hampers productivity but also increases operational costs due to wasted time and resources.

The Solution: To overcome this challenge, buyers should ensure they select single direction valves that are specifically designed for their application’s flow requirements. It is crucial to verify the specifications of the valve, including flow rates, pressure ratings, and compatibility with the hydraulic fluid being used. Investing in high-quality valves with precision-engineered components can significantly improve flow consistency. Additionally, regular maintenance checks should be implemented to ensure that the valves are functioning optimally. Buyers can also consult with manufacturers or suppliers who specialize in hydraulic systems to obtain tailored recommendations based on their operational needs.

Scenario 2: Compatibility Issues with Existing Systems

The Problem: Another common pain point arises when B2B buyers experience compatibility issues between single direction valves and their existing hydraulic systems. For example, a company in South Africa may have older machinery that requires specific valve dimensions and thread types, but they may inadvertently purchase a valve that does not fit. This mismatch can lead to costly modifications or even necessitate the replacement of entire systems, disrupting production schedules and increasing expenses.

The Solution: To avoid compatibility problems, buyers should conduct a thorough assessment of their existing systems before purchasing single direction valves. This includes checking the specifications such as port sizes, thread types, and flow configurations. It is advisable to consult technical drawings and documentation to ensure the chosen valve matches the required parameters. Furthermore, working with suppliers who offer a range of valve options, including custom solutions, can help buyers find the right fit without compromising their existing infrastructure. Buyers should also consider leveraging online configurators or contacting technical support for assistance in selecting the appropriate valve.

Scenario 3: Difficulty in Achieving Optimal Pressure Settings

The Problem: Many international B2B buyers, particularly in industries requiring precise pressure control (like automotive or manufacturing), struggle with achieving the desired pressure settings in their applications. For instance, a company in Germany may find that the pressure relief settings on their single direction valves are not adjustable enough to meet the dynamic needs of their hydraulic systems. This can lead to either excessive pressure, risking equipment damage, or insufficient pressure, which can compromise performance.

The Solution: To address this issue, buyers should prioritize single direction valves that feature adjustable pressure settings or have built-in pressure relief capabilities. When sourcing these valves, it is essential to examine the product specifications closely to confirm that they can handle the desired pressure range. Additionally, incorporating pressure gauges and control systems into the hydraulic setup can provide real-time monitoring and adjustments, ensuring optimal performance. Buyers should also engage with manufacturers who offer technical support to help calibrate the valves for their specific applications, ensuring that they operate within safe and efficient parameters.

Strategic Material Selection Guide for single direction valve

When selecting materials for single direction valves, it is crucial to consider various factors that directly impact performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of single direction valves, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Brass for Single Direction Valves?

Brass is a popular choice for single direction valves due to its excellent corrosion resistance and good mechanical properties. It typically operates effectively at temperatures up to 200°C and pressures around 20 bar. The alloy’s inherent resistance to corrosion makes it suitable for applications involving water and various chemicals.

Pros and Cons of Brass

The primary advantage of brass is its durability and resistance to rust, making it ideal for outdoor applications or environments with moisture. However, brass can be more expensive than other materials, and its performance can degrade when exposed to certain aggressive chemicals, limiting its use in some industrial applications.

Impact on Application

Brass valves are commonly used in plumbing, HVAC systems, and some chemical processing applications. However, buyers should ensure compatibility with the specific media being handled to avoid premature failure.

Considerations for International Buyers

Brass valves must comply with standards such as ASTM B16 for fittings and JIS H3250 for Japanese markets. In regions like Europe, buyers should also consider the DVGW certification for gas and water applications.

Illustrative image related to single direction valve

How Does Stainless Steel Perform in Single Direction Valves?

Stainless steel is renowned for its strength and resistance to corrosion, making it an excellent choice for high-pressure applications. It can handle temperatures exceeding 300°C and pressures above 30 bar, depending on the grade.

Pros and Cons of Stainless Steel

One of the key advantages of stainless steel is its exceptional durability and resistance to a wide range of chemicals, which makes it suitable for harsh environments. However, the manufacturing process can be more complex and costly, which may impact the overall pricing for buyers.

Impact on Application

Stainless steel valves are ideal for food and beverage, pharmaceutical, and chemical processing industries due to their sanitary properties and compliance with health standards.

Considerations for International Buyers

Buyers should ensure compliance with international standards such as ISO 9001 for quality management and ASTM A312 for stainless steel pipes. In Europe, adherence to EN standards is also crucial.

What Role Does PVC Play in Single Direction Valve Applications?

Polyvinyl chloride (PVC) is a lightweight and cost-effective material often used in low-pressure applications. PVC valves typically operate effectively at temperatures up to 60°C and pressures around 10 bar.

Pros and Cons of PVC

PVC’s primary advantage is its low cost and ease of installation, making it suitable for residential and light industrial applications. However, its temperature and pressure limitations can restrict its use in more demanding environments.

Impact on Application

PVC valves are commonly used in irrigation, drainage, and swimming pool systems. They are not suitable for high-temperature applications or aggressive chemicals, which could lead to deformation.

Considerations for International Buyers

Buyers should verify compliance with ASTM D1784 for PVC materials and consider local regulations regarding the use of plastics in plumbing applications.

How Does Aluminum Compare for Single Direction Valves?

Aluminum offers a balance of lightweight construction and good corrosion resistance, making it suitable for various applications. It typically operates at temperatures up to 150°C and pressures around 15 bar.

Pros and Cons of Aluminum

The lightweight nature of aluminum makes it easy to handle and install, which is a significant advantage in mobile or portable applications. However, it may not be as durable as stainless steel or brass under extreme conditions, potentially limiting its lifespan.

Impact on Application

Aluminum valves are often used in pneumatic and hydraulic systems, particularly in automotive and aerospace applications where weight is a critical factor.

Considerations for International Buyers

Buyers should check compliance with standards such as ASTM B221 for aluminum extrusions and consider any regional regulations regarding the use of aluminum in specific applications.

Summary of Material Selection for Single Direction Valves

| Material | Typical Use Case for Single Direction Valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Plumbing, HVAC systems | Excellent corrosion resistance | Limited chemical compatibility | Medium |

| Stainless Steel | Food and beverage, chemical processing | Exceptional durability and chemical resistance | Higher manufacturing costs | High |

| PVC | Irrigation, drainage | Low cost and easy installation | Limited temperature and pressure tolerance | Low |

| Aluminum | Pneumatic and hydraulic systems | Lightweight and easy to handle | Less durable under extreme conditions | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing single direction valves, ensuring compatibility and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for single direction valve

What Are the Key Stages in the Manufacturing Process of Single Direction Valves?

The manufacturing process of single direction valves involves several key stages, each critical to ensuring the product meets industry standards and performs reliably. Here’s a breakdown of the main stages:

Material Preparation

The first step in the manufacturing process is material preparation. Common materials used for single direction valves include brass, stainless steel, and various plastics, selected based on the application requirements. During this phase, raw materials are sourced from certified suppliers to ensure quality. The materials undergo inspection to verify their chemical composition and mechanical properties, ensuring they meet the specified standards before proceeding.

Forming Techniques: How Are Single Direction Valves Shaped?

Once the materials are prepared, the next step is forming. This can involve various techniques such as machining, forging, or molding, depending on the complexity of the valve design.

-

Machining: For precision components, CNC (Computer Numerical Control) machining is often employed. This method allows for high precision in shaping the valve body and other components.

-

Forging: For high-strength applications, forging processes create a more robust structure. This technique is often used for metal components that require enhanced durability.

-

Molding: For plastic valves, injection molding is a common technique. This method allows for the rapid production of complex shapes and is cost-effective for large volumes.

Assembly: How Are Components Brought Together?

The assembly stage involves the integration of all components, including the valve body, seals, and actuators. This process typically includes:

-

Component Inspection: Each component is inspected for defects before assembly to ensure only quality parts are used.

-

Manual or Automated Assembly: Depending on the scale of production, assembly can be performed manually or through automated systems that enhance efficiency and consistency.

-

Sealing and Testing: After assembly, valves are often pressure tested to ensure they can withstand operational pressures without leaking.

Finishing: What Does the Final Touch Involve?

The finishing stage enhances the valve’s appearance and protects it from environmental factors. Common finishing processes include:

-

Surface Treatment: Techniques like anodizing, plating, or powder coating are applied to improve corrosion resistance and aesthetics.

-

Quality Inspection: The finished product undergoes a final inspection to confirm that it meets all specifications and standards before packaging and shipment.

What Quality Assurance Measures Are Essential for Single Direction Valves?

Quality assurance is paramount in the manufacturing of single direction valves, ensuring that they perform reliably under various conditions. Here are some key elements of a robust quality assurance program:

What International Standards Should Buyers Be Aware Of?

For global B2B transactions, compliance with international standards is crucial. The most relevant standards include:

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to all organizations. Certification indicates that the manufacturer adheres to consistent quality processes.

-

CE Marking: For products sold in the European Economic Area, CE marking confirms that the product meets EU safety, health, and environmental protection standards.

-

API Standards: In industries like oil and gas, adherence to American Petroleum Institute (API) standards ensures that valves can operate safely and efficiently in demanding environments.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. It ensures that only materials meeting specified standards are used.

-

In-Process Quality Control (IPQC): During production, IPQC monitors critical processes and tolerances, ensuring that any deviations from standards are corrected immediately.

-

Final Quality Control (FQC): After production, FQC involves comprehensive testing and inspection of finished valves. This may include pressure testing, functional testing, and dimensional checks to ensure compliance with specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s QC processes is vital to ensuring product reliability. Here are some methods to consider:

-

Supplier Audits: Conducting audits allows buyers to assess the manufacturing processes and quality management systems in place. This can be done directly or through third-party auditors.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality assurance processes, including inspection reports and certifications.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product compliance.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances when it comes to QC and certifications:

-

Regional Compliance: Different regions may have unique certification requirements. For instance, Middle Eastern countries often require compliance with local standards, while European buyers may prioritize CE marking.

-

Documentation Requirements: Ensure that all required documentation, such as compliance certificates and test reports, are available in the relevant languages and formats to facilitate customs clearance and regulatory compliance.

-

Cultural Considerations: Understanding cultural differences in business practices can enhance communication and negotiation with suppliers, ensuring smoother transactions and adherence to quality expectations.

Conclusion

Manufacturing single direction valves involves a meticulous process that encompasses material preparation, forming, assembly, and finishing, all underpinned by rigorous quality assurance practices. For B2B buyers, understanding these processes and the relevant standards, quality control checkpoints, and verification methods is essential for making informed purchasing decisions. By prioritizing quality and compliance, buyers can ensure they receive reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘single direction valve’

The following guide provides a structured approach for B2B buyers looking to procure single direction valves. This checklist will help you navigate the complexities of sourcing, ensuring that you make informed decisions that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly define the technical specifications required for your single direction valves. Consider factors such as flow rate, pressure requirements, and compatibility with existing systems. This clarity will help you communicate your needs effectively to potential suppliers.

- Flow Rate: Determine the maximum flow rate (in GPM or LPM) that your application requires.

- Pressure Ratings: Identify the pressure limits the valve must withstand to ensure safe and efficient operation.

Step 2: Research Market Options

Conduct thorough market research to identify the various types of single direction valves available. This includes assessing different manufacturers and their product offerings. Understanding the market landscape will enable you to compare features, prices, and supplier reputations.

- Types of Valves: Familiarize yourself with options such as hydraulic, pneumatic, and solenoid valves.

- Industry Applications: Look for suppliers that specialize in your industry to ensure they understand your specific needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, product catalogs, and case studies to assess their experience and reliability. Additionally, seek references from other buyers in similar industries or regions.

- Certification and Compliance: Ensure the supplier meets relevant industry standards and certifications, such as ISO or CE markings.

- Reputation: Investigate customer reviews and testimonials to gauge satisfaction levels with the supplier’s products and services.

Step 4: Request Samples or Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of the single direction valves you are considering. Testing these samples in your operational environment will provide critical insights into their performance and compatibility.

Illustrative image related to single direction valve

- Functionality Testing: Assess the valves for ease of installation, operation, and maintenance.

- Durability Assessment: Evaluate the materials used in the construction for longevity and reliability under your specific conditions.

Step 5: Negotiate Terms and Pricing

Engage in negotiations to discuss pricing, payment terms, and delivery schedules. It’s important to ensure that the terms align with your budget and operational timelines.

- Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

- After-Sales Support: Clarify warranty terms and the availability of technical support or replacement parts.

Step 6: Finalize the Purchase Agreement

Once you have agreed on terms, draft a purchase agreement that outlines all critical elements, including pricing, delivery dates, and specifications. This contract should protect both parties and serve as a reference point for any future disputes.

- Clear Specifications: Ensure that all technical specifications are documented to avoid misunderstandings.

- Delivery and Payment Terms: Clearly outline logistics and payment milestones.

Step 7: Monitor Performance Post-Purchase

After the valves have been delivered and installed, monitor their performance closely to ensure they meet the defined specifications. Gather feedback from your operational team to identify any issues early.

- Performance Reviews: Schedule regular evaluations to determine if the valves are functioning as intended.

- Supplier Feedback: Maintain open communication with the supplier for any necessary adjustments or support.

By following these steps, you can streamline the procurement process for single direction valves, ensuring that you select the best products for your operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for single direction valve Sourcing

What Are the Key Cost Components in Single Direction Valve Sourcing?

When sourcing single direction valves, understanding the cost structure is crucial for international B2B buyers. The primary components of cost include:

-

Materials: The choice of materials significantly impacts pricing. Common materials include brass, stainless steel, and plastic, each varying in cost based on quality and availability. For instance, stainless steel valves are typically more expensive due to their durability and resistance to corrosion.

-

Labor: Labor costs are influenced by geographic location and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing, but this should be balanced with quality assurance practices.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and equipment maintenance. Manufacturers with advanced technology may have lower overhead costs, which can translate into better pricing for buyers.

-

Tooling: Custom tooling may be necessary for specific valve designs, adding to upfront costs. However, once the tooling is established, the cost per unit can decrease significantly with higher volumes.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but can add to manufacturing costs. Certifications (e.g., ISO standards) may also increase costs, but they provide assurance of quality that is crucial for many industries.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and volume. Incoterms (International Commercial Terms) also play a role, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

-

Margin: Suppliers typically include a profit margin that varies based on market competition and the uniqueness of the product. Understanding the typical margins in your target market can aid in negotiations.

How Do Price Influencers Affect the Cost of Single Direction Valves?

Several factors influence the pricing of single direction valves, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Higher volumes typically lead to lower per-unit costs, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom valves designed for specific applications can incur additional costs. Understanding your exact requirements can help in evaluating whether customization is necessary or if standard options will suffice.

-

Materials and Quality Certifications: Higher-quality materials and certifications may increase initial costs but can lead to lower maintenance and replacement costs over time. International buyers should consider the Total Cost of Ownership (TCO) rather than just the upfront price.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Selecting the right Incoterms can affect overall costs. For example, choosing FOB (Free On Board) can help buyers manage shipping costs better, while DDP (Delivered Duty Paid) may result in higher upfront costs but less hassle.

What Are the Best Practices for Negotiating Single Direction Valve Prices?

When negotiating prices for single direction valves, B2B buyers should consider the following tips:

-

Research Market Prices: Understanding the average prices for similar products in your region can provide leverage in negotiations.

-

Focus on Total Cost of Ownership: Emphasize the long-term value of higher-quality products over the initial purchase price. This can justify a higher upfront cost.

-

Evaluate Multiple Suppliers: Obtain quotes from various suppliers to create competitive tension, which can lead to better pricing and terms.

-

Leverage Volume Discounts: If possible, consolidate purchases to meet MOQ thresholds and negotiate volume discounts.

-

Build Long-Term Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms over time, as they may prioritize loyal customers.

Conclusion

The sourcing of single direction valves involves a multifaceted cost structure influenced by various components and market factors. By understanding these elements, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. It is essential to approach negotiations with a comprehensive understanding of pricing dynamics, focusing on TCO to ensure optimal value in procurement.

Alternatives Analysis: Comparing single direction valve With Other Solutions

Exploring Alternative Solutions to Single Direction Valves

In the realm of fluid control systems, single direction valves play a crucial role in ensuring unidirectional flow. However, there are alternative solutions that can achieve similar objectives, each with its own set of advantages and limitations. This analysis will compare single direction valves with two notable alternatives: solenoid valves and hydraulic directional control valves. By examining performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions suited to their operational needs.

Comparison Table

| Comparison Aspect | Single Direction Valve | Solenoid Valve | Hydraulic Directional Control Valve |

|---|---|---|---|

| Performance | High efficiency in controlling flow direction | Fast operation with low power consumption | Capable of handling high flow rates and pressures |

| Cost | Generally low cost | Moderate cost | Higher initial investment |

| Ease of Implementation | Simple installation | Requires electrical connections | More complex, may need additional hydraulic components |

| Maintenance | Low maintenance needs | Regular checks on electrical components | Moderate; requires periodic checks for fluid leaks |

| Best Use Case | Basic flow control in low-pressure applications | Automated systems in packaging, automotive | Heavy-duty applications requiring robust flow control |

Detailed Breakdown of Alternatives

Solenoid Valves

Solenoid valves are electromechanical devices that control fluid flow through the use of an electromagnetic solenoid. These valves are known for their rapid actuation and low power requirements, making them ideal for applications in industries such as automotive, packaging, and pharmaceuticals. However, they can be more complex to install due to the necessity for electrical connections, and their performance may be impacted by the ambient temperature or humidity levels. Regular maintenance is required to ensure the electrical components are functioning correctly, which can lead to higher operational costs over time.

Illustrative image related to single direction valve

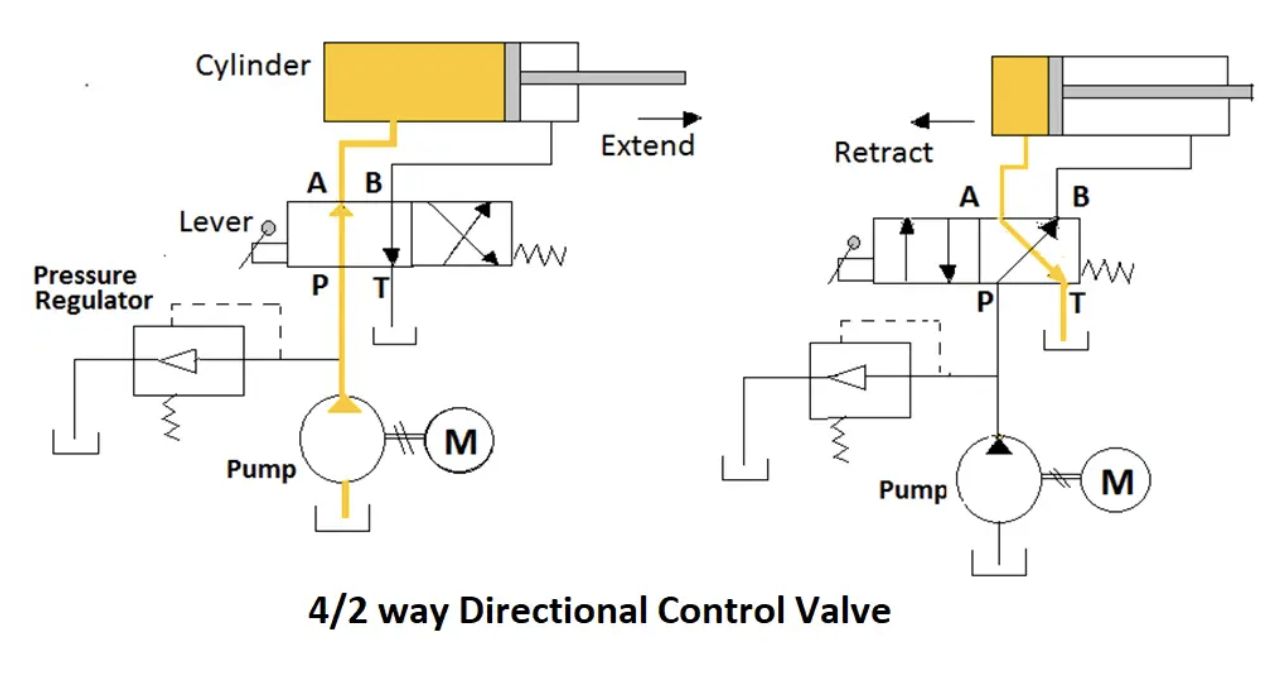

Hydraulic Directional Control Valves

Hydraulic directional control valves are used to manage the flow of hydraulic fluid in heavy machinery and equipment. These valves can handle higher flow rates and pressures, making them suitable for demanding applications, such as in construction and agricultural machinery. While they offer superior performance and versatility, they come with a higher initial investment and require more complex installation. Maintenance can also be more intensive, as it often involves monitoring hydraulic fluid levels and checking for leaks. Nevertheless, their ability to operate under extreme conditions makes them a preferred choice in high-stakes environments.

Making the Right Choice: How Can B2B Buyers Select the Best Solution?

When selecting the right valve solution, B2B buyers should consider their specific operational requirements and the environment in which the valves will be used. For applications requiring basic flow control with a low initial investment, single direction valves may be the best choice. Conversely, for automated systems where speed and efficiency are paramount, solenoid valves could be more suitable. If the application involves heavy machinery or requires robust flow control under high pressure, hydraulic directional control valves are likely the most effective option. By carefully evaluating the pros and cons of each alternative, buyers can ensure they choose a solution that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for single direction valve

What Are the Key Technical Properties of a Single Direction Valve?

When considering a single direction valve, understanding its technical properties is crucial for ensuring compatibility with specific applications and operational efficiency. Here are some essential specifications:

-

Material Grade

The material used for the valve body, such as stainless steel, brass, or plastic, significantly affects durability and corrosion resistance. For B2B buyers, selecting the right material ensures the valve can withstand the operational environment, especially in industries like automotive or chemical processing. -

Pressure Rating

This specification indicates the maximum pressure the valve can handle, typically measured in PSI (pounds per square inch). It’s vital for buyers to match the valve’s pressure rating with their system requirements to prevent failures that could lead to costly downtime or safety hazards. -

Flow Rate

Measured in gallons per minute (GPM) or liters per minute (L/min), the flow rate determines how much fluid can pass through the valve in a given timeframe. Understanding flow rate is essential for ensuring that the valve meets the demands of the application without causing bottlenecks in the system. -

Temperature Range

This property defines the operational temperature limits within which the valve can function effectively. Buyers should consider the temperature range to ensure the valve’s materials and seals can withstand the conditions of their specific application, preventing premature wear or failure. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. High tolerance levels are critical for ensuring proper fit and function, especially in automated systems where precision is paramount. Buyers should seek valves with tight tolerances to enhance reliability and performance. -

Actuation Type

This specifies how the valve is operated, such as manual, pneumatic, or electric. The choice of actuation affects the valve’s responsiveness and integration into existing systems. Understanding the actuation type helps buyers select valves that align with their operational workflows.

What Are Common Trade Terms Related to Single Direction Valves?

Navigating the procurement process for single direction valves often involves familiarizing oneself with industry-specific terminology. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of valves, buyers may deal with OEMs to source components that meet specific quality and performance standards. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory levels and cash flow, especially when sourcing valves in bulk for large projects. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically includes detailed specifications and requirements for the valves needed. This process helps buyers compare offers and negotiate better pricing. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding Incoterms is critical for B2B transactions involving international shipping, as they dictate who is responsible for shipping costs, insurance, and risk during transit. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to delivery. For buyers, knowing the lead time is crucial for project planning and ensuring that valves arrive when needed to avoid project delays. -

Certification Standards

This term encompasses the various industry standards and regulations that valves must meet, such as ISO or ANSI. Buyers should prioritize valves that comply with relevant certification standards to ensure safety, reliability, and performance in their applications.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing single direction valves, ensuring they select products that meet their operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the single direction valve Sector

What Are the Key Market Trends Influencing the Single Direction Valve Sector?

The single direction valve market is experiencing significant growth, driven by several global factors. The rise of automation and the increasing demand for efficient fluid control systems in various industries—such as automotive, manufacturing, and energy—are leading to a surge in the adoption of single direction valves. Technological advancements, particularly in smart valve technology and IoT integration, are shaping the market dynamics. These innovations enable remote monitoring and control, enhancing operational efficiency for international B2B buyers.

Emerging markets in Africa and South America are witnessing rapid industrialization, leading to an increased need for reliable fluid control solutions. In Europe, particularly in Germany, there is a strong focus on manufacturing high-quality, precision-engineered valves, which aligns with the region’s reputation for engineering excellence. Additionally, the Middle East’s expanding oil and gas sector is fostering demand for durable and efficient valve solutions.

B2B buyers should be aware of sourcing trends favoring customization and modular designs that cater to specific applications. The growing emphasis on reducing lead times and improving supply chain efficiency is prompting manufacturers to adopt just-in-time production methods. This shift not only optimizes inventory management but also enhances responsiveness to market demands.

Illustrative image related to single direction valve

How Is Sustainability and Ethical Sourcing Shaping the Single Direction Valve Market?

Sustainability has become a critical consideration for B2B buyers in the single direction valve sector. The environmental impact of manufacturing processes and materials used in valve production is under scrutiny. Buyers are increasingly seeking suppliers who prioritize eco-friendly practices, such as reducing waste and utilizing energy-efficient production methods.

Ethical sourcing is equally important, as companies strive to ensure that their supply chains adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming prerequisites for supplier selection. These certifications provide assurance that manufacturers are committed to minimizing their environmental footprint and maintaining high-quality standards.

Moreover, the use of ‘green’ materials, such as recyclable metals and environmentally friendly coatings, is gaining traction. B2B buyers are encouraged to engage with suppliers who can demonstrate their commitment to sustainability through transparent reporting and certifications. This not only enhances brand reputation but also aligns with increasing consumer demand for environmentally responsible products.

How Has the Single Direction Valve Sector Evolved Over Time?

The evolution of the single direction valve sector can be traced back to the industrial revolution, where the need for efficient fluid control systems first emerged. Initially, valves were simple mechanical devices, but advancements in materials and manufacturing techniques have transformed them into sophisticated components essential for modern machinery.

The introduction of automation and electronic controls in the late 20th century marked a significant turning point. This shift enabled the development of advanced solenoid and pneumatic valves, which offered enhanced performance, reliability, and control. As industries increasingly adopted automation, the demand for versatile and efficient single direction valves surged.

Today, the sector is characterized by ongoing innovation, with a strong focus on integrating smart technologies and sustainable practices. Manufacturers are continuously adapting to meet the diverse needs of global markets, ensuring that single direction valves remain a vital component in various applications across multiple industries.

Frequently Asked Questions (FAQs) for B2B Buyers of single direction valve

-

How do I select the right single direction valve for my application?

Selecting the right single direction valve involves understanding your specific application requirements, including flow rate, pressure range, and fluid type. Consider the valve’s construction material, as it must be compatible with the media it will control. Evaluate the operational environment, such as temperature and exposure to chemicals, to ensure durability. Additionally, check if you need features like manual override or specific port sizes. Consulting with suppliers about your needs can help you make an informed decision. -

What are the key specifications to look for in a single direction valve?

When sourcing a single direction valve, key specifications include flow rate (measured in GPM or L/min), pressure ratings (maximum operating pressure), and connection type (threaded, flanged, etc.). Additionally, assess the valve’s material and design, such as whether it’s a monoblock or modular type. It’s also crucial to confirm the valve’s response time and any additional features, like built-in check functions, which can enhance performance in your specific application. -

What customization options are available for single direction valves?

Many manufacturers offer customization options for single direction valves, including size, material, and port configuration. You can often request specific sealing materials for compatibility with different fluids and environments. Additionally, customization might extend to operational features, such as flow control settings or integrated sensors. Discussing your unique requirements with suppliers will ensure you receive a valve tailored to your operational needs. -

What are the minimum order quantities (MOQ) for single direction valves?

Minimum order quantities (MOQ) can vary significantly between manufacturers and regions. Some suppliers may have an MOQ of just one unit for standard valves, while others might require larger orders, especially for customized products. It’s essential to confirm the MOQ with potential suppliers during your sourcing process to ensure it aligns with your purchasing capabilities and project requirements. -

How can I vet suppliers of single direction valves for quality assurance?

To vet suppliers effectively, start by reviewing their certifications, such as ISO standards, which indicate adherence to quality management systems. Request references or case studies from previous clients to assess their reliability and product performance. Additionally, consider visiting their facilities or requesting samples to evaluate the manufacturing processes and quality control measures in place. Engaging with suppliers who have a strong reputation and positive customer feedback is crucial for ensuring product quality. -

What payment terms are typically offered for international B2B transactions?

Payment terms in international B2B transactions often include options such as advance payment, letter of credit, or open account terms. Suppliers may require a deposit before manufacturing, especially for custom orders. It’s essential to clarify these terms upfront and ensure they are documented in the contract. Additionally, consider using secure payment methods to protect your investment and reduce the risk of fraud. -

How do I handle logistics and shipping for single direction valves?

Handling logistics for single direction valves involves coordinating with suppliers on shipping methods, delivery times, and costs. Ensure you understand the incoterms (like FOB or CIF) that dictate shipping responsibilities. It’s also important to plan for customs clearance and any import duties applicable in your region. Engaging a reliable freight forwarder can streamline the process, ensuring timely delivery and compliance with all regulations. -

What are the common applications for single direction valves in industrial settings?

Single direction valves are widely used in various industrial applications, including hydraulic systems, pneumatic systems, and fluid control in manufacturing processes. Common uses include controlling the flow of hydraulic fluids in machinery, ensuring proper operation of actuators, and preventing backflow in piping systems. Understanding the specific requirements of your industry will help you identify the most suitable valve options for your operations.

Top 7 Single Direction Valve Manufacturers & Suppliers List

1. SMC – Directional Control Valves

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: Directional Control Valves include various types such as Solenoid Valves (4 & 5 Port, 3 Port, Direct Operated), Air Operated Valves, Mechanical & Hand Operated Valves, and ISO Solenoid Valves. They are used in automation and control processes across multiple industries including automotive, semiconductor, food and beverage, and life sciences. The product range also includes actuator accessories an…

2. Summit Hydraulics – Monoblock Hydraulic Directional Control Valve

Domain: summit-hydraulics.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Monoblock Hydraulic Directional Control Valve, 1 Spool, 11 GPM”, “Price Range”: “$94.95 – $119.95”, “SKU”: “P40G-1A1”, “Flow Rating”: “11 GPM (40 l/min)”, “Max Operating Pressure”: {“Pressure Port”: “3625 PSI”, “Tank Port”: “725 PSI”, “A & B Work Ports”: “4350 PSI”}, “Spool Type”: “A Spool (Double Acting Cylinders)”, “Inlet Port Size”: “#10 SAE O-Ring (7/8′-14)”, “Outlet Port Siz…

3. Magister Hyd – Directional Control Valves

Domain: magisterhyd.com

Registered: 2014 (11 years)

Introduction: Directional control valves are used to control the direction of fluids in hydraulic or pneumatic systems. They manage fluid flow by changing the position of internal components, allowing or restricting flow to actuators. Key classifications include: 1. Type of Construction: Spool, ball, or poppet configurations. 2. Number of Ports: Two-way, three-way, four-way valves. 3. Number of Switching Positi…

4. Ibex Equipment – Single Direction Flow Restrictor Valve

Domain: tractortoolsdirect.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Single Direction Flow Restrictor Valve (RC1/4)”, “Brand”: “Ibex Equipment”, “SKU”: “PSRSGBT81001987”, “UPC”: “”, “MPN”: “GBT81001987”, “Condition”: “New”, “Price”: “$52.00”, “Description”: “Hydraulic flow speed control valve”, “Shipping”: “Calculated at Checkout”}

5. SMC – Directional Control Valves

Domain: smcworld.com

Registered: 1998 (27 years)

Introduction: Directional Control Valves include various models such as Pilot Operated 4/5 Port Solenoid Valves (JSY1000/3000/5000, SJ1000/2000/3000/4000, SY3000/5000/7000), Pilot Operated 3 Port Solenoid Valves (SYJ300/500/700), Direct Operated 3/4/5 Port Solenoid Valves (VV061, VV100, V100), Air Operated Valves (SYA3000/5000/7000), Mechanical Valves/Transmitters (VM100F), and more. The product range includes …

6. Buyers Products – High-Pressure Hydraulic Pump

Domain: buyersproducts.com

Registered: 1997 (28 years)

Introduction: This company, Buyers Products – High-Pressure Hydraulic Pump, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Clippard – Electronic Directional Control Valves

Domain: clippard.com

Registered: 1995 (30 years)

Introduction: Electronic Directional Control Valves are essential for controlling the direction of flow, flow rate, and valve functionality in various applications. Key types include: 2/2 Valves (two ports, two positions), 3/2 Valves (three ports, two positions), 4/2 Valves (four ports, two positions), 5/2 Valves (five ports, similar to 4/2 but with independent exhaust paths), and 6/2 Valves (six ports, two 3-w…

Strategic Sourcing Conclusion and Outlook for single direction valve

In the dynamic landscape of industrial applications, the strategic sourcing of single direction valves is pivotal for optimizing operational efficiency and cost-effectiveness. As highlighted, these valves play a crucial role in controlling fluid flow, making them indispensable across sectors such as automotive, packaging, and medical equipment manufacturing. By investing in high-quality valves that align with specific operational needs, buyers can enhance system performance and reliability.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer robust product lines and innovative solutions tailored to diverse applications. This strategic approach not only mitigates risks associated with supply chain disruptions but also fosters long-term partnerships with manufacturers who understand regional market demands.

Looking ahead, the evolution of single direction valve technology promises exciting advancements in efficiency and performance. Buyers are encouraged to stay informed about emerging trends and innovations to leverage these developments for their operational advantage. As you navigate your sourcing strategy, consider the long-term benefits of aligning with suppliers committed to quality and innovation. Embrace the future of fluid control solutions today to ensure your business remains competitive and responsive to market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to single direction valve

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.