A B2B Buyer’s Guide to Shot Peener: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for shot peener

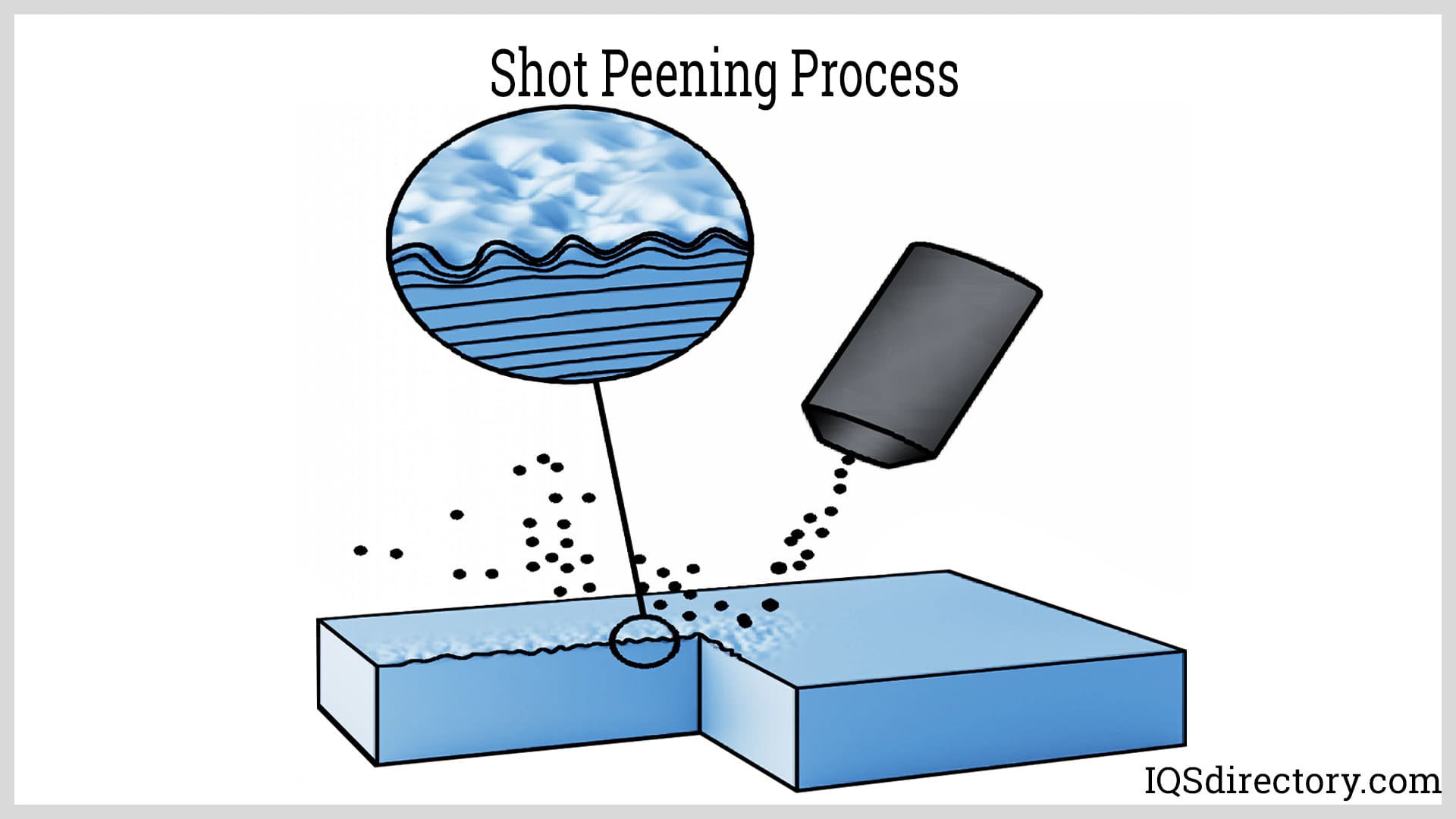

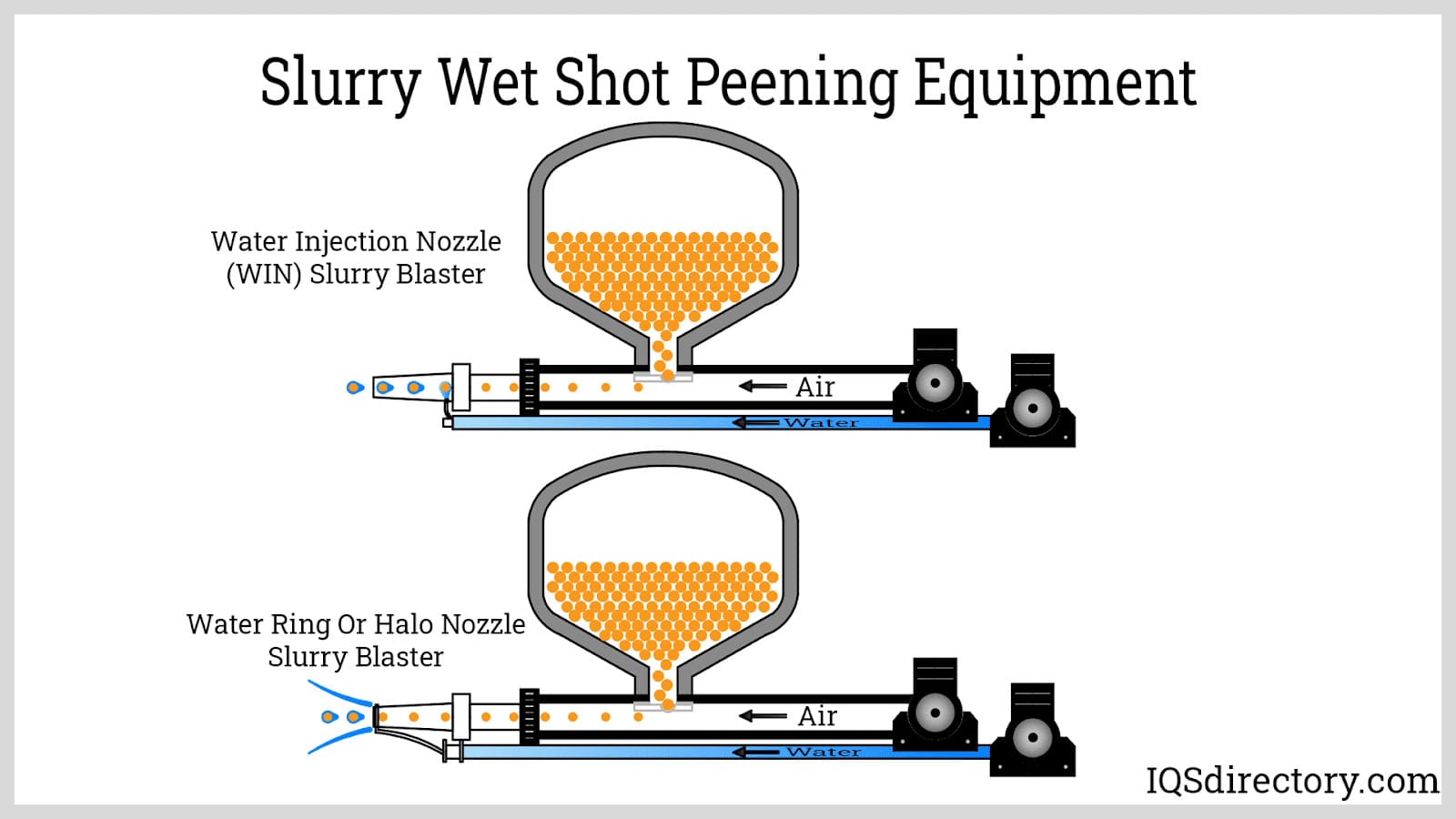

In the competitive landscape of manufacturing and engineering, sourcing the right shot peener can be a daunting challenge for international B2B buyers, especially those hailing from diverse regions such as Africa, South America, the Middle East, and Europe. As industries increasingly rely on shot peening to enhance the durability and performance of their components, understanding the nuances of this process becomes crucial. This guide serves as a comprehensive resource, addressing key aspects such as the various types of shot peening equipment, their applications across multiple sectors, effective supplier vetting strategies, and cost considerations.

By delving into the intricacies of shot peening, this guide empowers decision-makers to make informed purchasing choices that align with their operational needs and budget constraints. Whether you are a manufacturer in Nigeria seeking to improve the fatigue life of your products or a procurement officer in Vietnam aiming to enhance surface integrity, the insights provided will help navigate the complexities of the global market.

As you explore this guide, expect to gain actionable knowledge that not only simplifies the sourcing process but also enhances your understanding of how shot peening can significantly impact product performance and longevity. With the right information at your fingertips, you can confidently select the best shot peening solutions tailored to your business’s unique requirements.

Understanding shot peener Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air-Operated Peener | Utilizes compressed air to propel shot; portable design | Aerospace, automotive, and medical | Pros: Flexible, easy to use; Cons: Requires compressed air, which can limit mobility. |

| Wheelabrator Peener | Employs a wheel to launch shot; efficient for large volumes | Heavy industries, steel fabrication | Pros: High throughput; Cons: Higher initial investment and maintenance. |

| Cabinet Peener | Enclosed system for controlled peening; ideal for small parts | Precision engineering, electronics | Pros: Dust-free operation; Cons: Limited to smaller components. |

| Robot-Assisted Peener | Integrates robotic technology for automation; versatile | High-volume production, automotive | Pros: Consistent results; Cons: Significant upfront costs for setup. |

| Portable Peener | Compact, mobile units for on-site applications | Construction, maintenance, repair | Pros: Easy transport; Cons: Lower capacity compared to stationary units. |

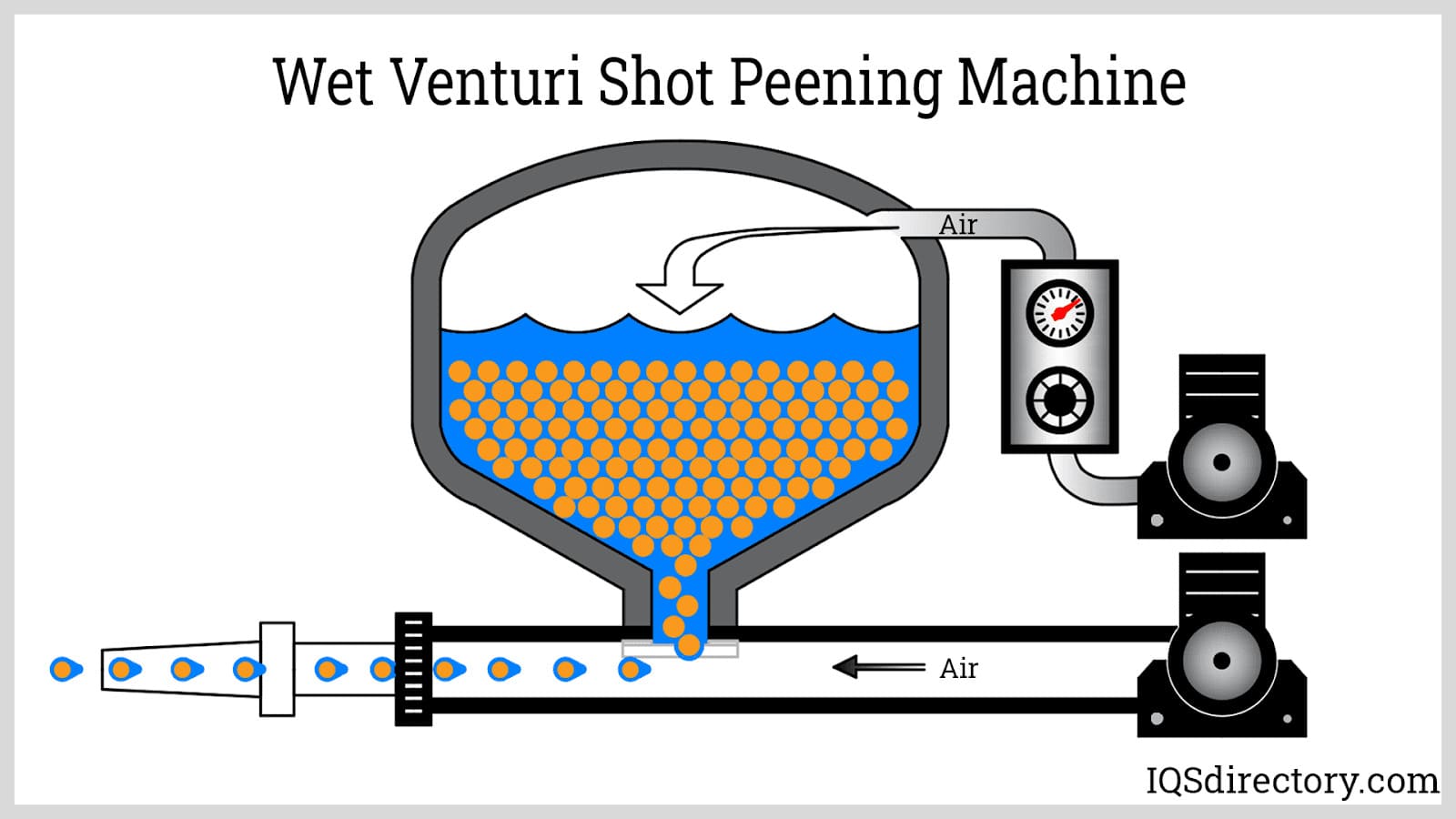

What Are the Characteristics of Air-Operated Peeners?

Air-operated peeners are favored for their portability and ease of use, making them suitable for various applications, including aerospace and medical sectors. These machines utilize compressed air to propel shot, allowing for flexible operation in diverse environments. When purchasing, buyers should consider the availability of compressed air sources and the potential limitations on mobility, especially in larger workspaces.

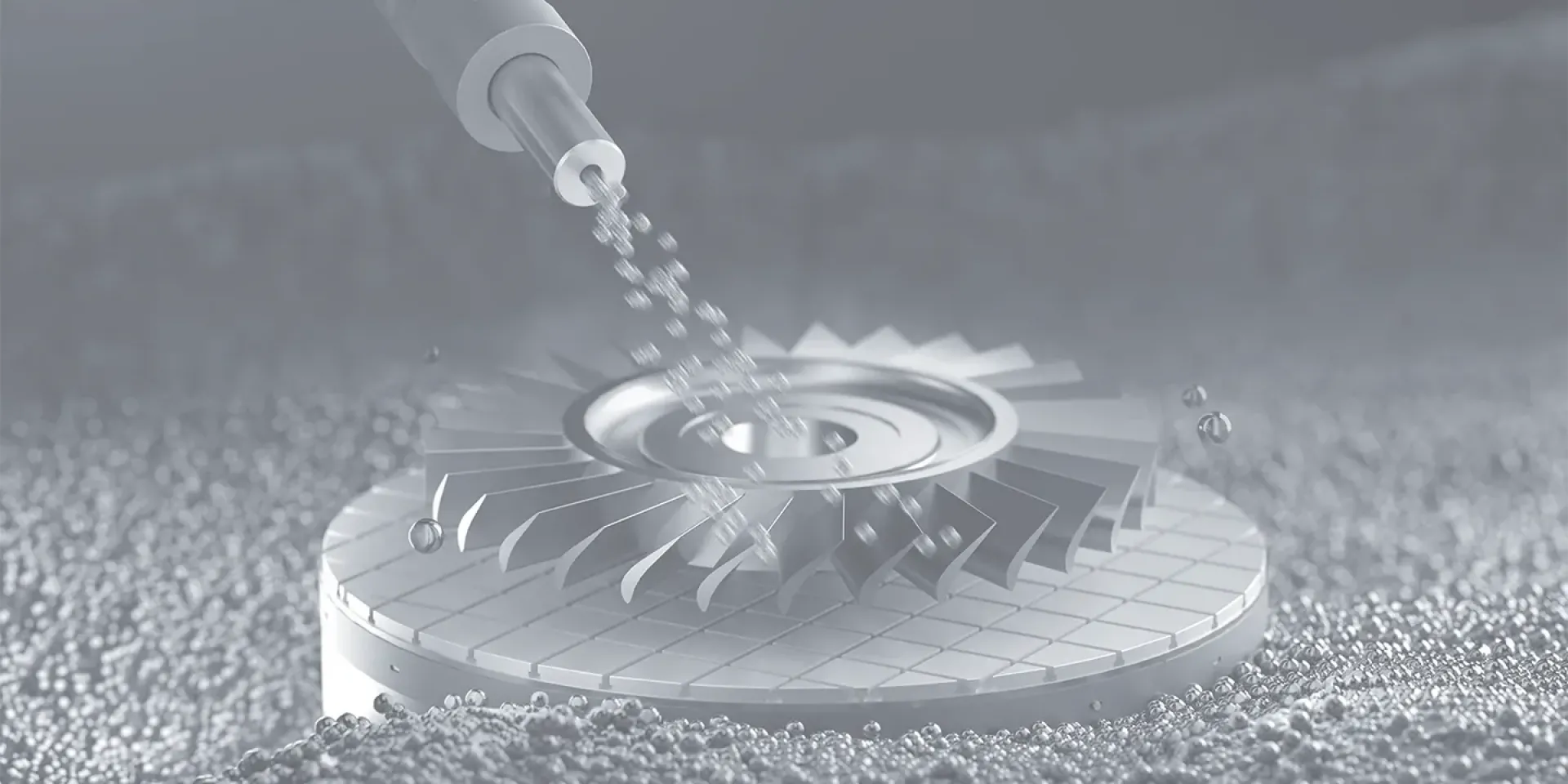

Illustrative image related to shot peener

How Do Wheelabrator Peeners Stand Out?

Wheelabrator peeners use a rotating wheel to launch shot at high speeds, making them particularly effective for processing large volumes of materials. Commonly found in heavy industries like steel fabrication, these machines offer high throughput and efficiency. Buyers should evaluate their production needs against the higher initial investment and ongoing maintenance costs associated with these systems.

What Benefits Do Cabinet Peeners Offer for Precision Engineering?

Cabinet peeners are enclosed systems designed for controlled shot peening, making them ideal for precision engineering and electronic components. They provide a dust-free environment, ensuring that small parts are treated without contamination. However, their limited capacity for larger components may be a downside for some businesses. B2B buyers should assess their specific size requirements before opting for this type.

Why Choose Robot-Assisted Peeners for High-Volume Production?

Robot-assisted peeners incorporate automation to deliver consistent and high-quality results, making them suitable for high-volume production environments, particularly in the automotive sector. While they significantly enhance efficiency and reduce labor costs, the initial setup costs can be substantial. Buyers need to consider their production scale and budget when exploring this option.

What Are the Advantages of Portable Peeners in Construction and Maintenance?

Portable peeners are compact and designed for on-site applications, making them ideal for construction and maintenance tasks. Their mobility allows for easy transport to various job sites, enhancing operational flexibility. However, they generally have a lower capacity than stationary models, which may limit their effectiveness for larger projects. Buyers should weigh their need for mobility against potential productivity constraints.

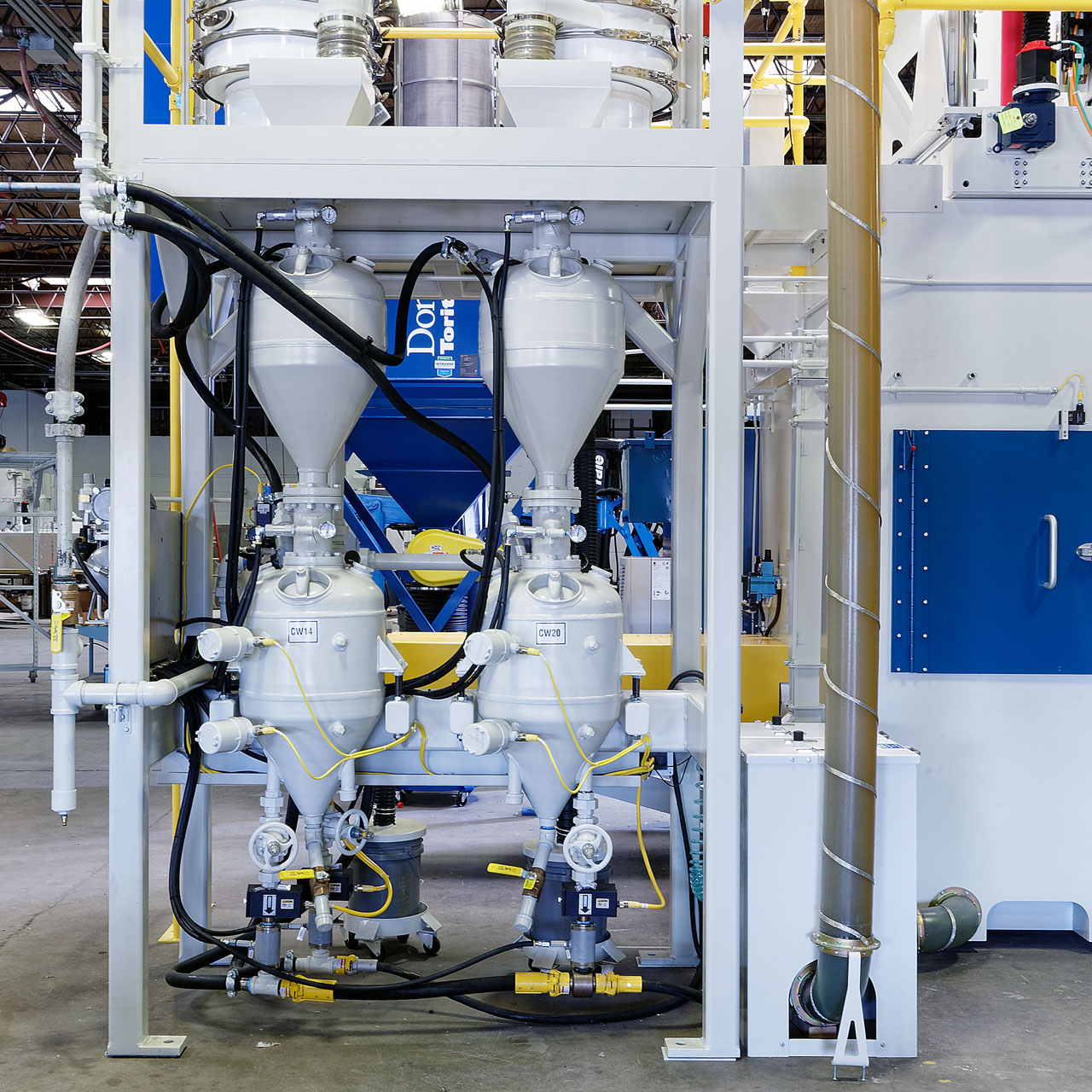

Illustrative image related to shot peener

Key Industrial Applications of shot peener

| Industry/Sector | Specific Application of shot peener | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Surface treatment of turbine blades | Enhances fatigue resistance and extends component life | Need for precision in shot size and process control, compliance with aerospace standards |

| Automotive | Shot peening of suspension components | Reduces stress concentrations, improving durability | Considerations for material compatibility and process scalability |

| Energy | Treatment of pressure vessels and pipelines | Increases resistance to fatigue and corrosion | Sourcing of high-quality media and equipment for large-scale operations |

| Medical Devices | Surface hardening of surgical instruments | Increases lifespan and performance of critical tools | Regulatory compliance and biocompatibility standards are essential |

| Heavy Machinery | Surface preparation and stress relief of gears | Improves performance and reduces maintenance costs | Requirement for robust equipment to handle large components and high volumes of production |

How is Shot Peening Applied in the Aerospace Sector and What Are the Benefits?

In the aerospace industry, shot peening is crucial for the surface treatment of turbine blades. This process enhances the fatigue resistance of components that operate under extreme conditions, significantly extending their operational life. International buyers in this sector must ensure that the shot peening process adheres to stringent aerospace standards, which necessitates precise control over shot size and peening intensity. Additionally, suppliers must provide documentation to validate compliance with industry regulations.

What Role Does Shot Peening Play in the Automotive Industry?

Within the automotive sector, shot peening is commonly employed to treat suspension components. By reducing stress concentrations, this method improves the overall durability and performance of these critical parts. For B2B buyers in this industry, it is vital to consider the compatibility of the peening process with various materials and the scalability of the operations to meet production demands. The ability to customize shot peening parameters can also enhance the effectiveness of the treatment.

How is Shot Peening Beneficial for Energy Sector Applications?

In the energy sector, shot peening is utilized for the treatment of pressure vessels and pipelines, where it plays a key role in increasing resistance to fatigue and corrosion. This application is particularly important for international buyers looking to enhance the longevity and reliability of their infrastructure. When sourcing shot peening services, businesses should focus on the quality of the media used and the capabilities of the equipment, especially for large-scale operations that demand consistent results.

What is the Importance of Shot Peening for Medical Devices?

Shot peening also finds significant application in the medical device industry, particularly for the surface hardening of surgical instruments. This process not only increases the lifespan of these critical tools but also enhances their performance, which is vital in medical settings. Buyers in this sector must prioritize suppliers who comply with regulatory standards and can ensure the biocompatibility of the materials used. This requirement is essential to maintain the safety and efficacy of medical devices.

How Does Shot Peening Improve Heavy Machinery Performance?

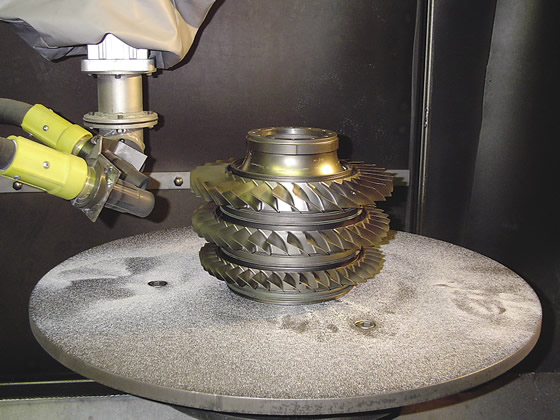

For heavy machinery, shot peening is applied to prepare surfaces and relieve stress in gears and other components. This treatment not only improves performance but also reduces maintenance costs over time. When sourcing shot peening solutions, companies should seek robust equipment capable of handling large components and high production volumes. Additionally, understanding the specific requirements of different materials can help optimize the peening process for maximum effectiveness.

Illustrative image related to shot peener

3 Common User Pain Points for ‘shot peener’ & Their Solutions

Scenario 1: The Challenge of Inconsistent Surface Finishing in Shot Peening

The Problem: Many B2B buyers encounter issues with inconsistent surface finishing after shot peening processes. This inconsistency can lead to varying levels of compressive stress and fatigue life across a batch of parts, which ultimately affects product quality and performance. Such discrepancies may arise from improper machine settings, variations in shot material, or differences in part geometry. For manufacturers in sectors like aerospace and automotive, where precision is critical, these inconsistencies can lead to costly reworks or even product failures.

The Solution: To address this challenge, buyers should invest in advanced shot peening equipment that allows for precise control over parameters such as shot velocity, coverage, and intensity. Implementing a systematic approach to machine calibration is essential. Regularly scheduled maintenance and calibration checks should be part of the operational protocol to ensure consistency. Additionally, using advanced monitoring systems that track shot peening parameters in real-time can help identify and correct deviations immediately. Collaborating with a reputable supplier who offers robust training on machine operation and process optimization can also enhance the skill set of personnel, ensuring that they are capable of achieving uniform results across all parts.

Scenario 2: Difficulty in Complying with Industry Standards and Specifications

The Problem: Compliance with industry standards such as SAE J442 or AMS 2430 is a common pain point for B2B buyers involved in shot peening. These standards dictate specific requirements for the peening process, including shot size, intensity, and coverage, which can be complex and challenging to implement. Buyers may find it difficult to interpret these specifications, leading to the risk of non-compliance and potential liability issues, particularly in high-stakes industries like aviation or medical device manufacturing.

Illustrative image related to shot peener

The Solution: To navigate these compliance challenges, buyers should engage with experts in shot peening who can provide guidance on the applicable standards for their industry. Investing in training sessions focused on regulatory requirements can empower teams to understand and implement necessary protocols. Furthermore, utilizing shot peening machines equipped with programmable settings that adhere to industry specifications can streamline compliance. Buyers should also consider conducting regular audits of their processes and products against these standards to proactively identify any areas of concern. Establishing a partnership with suppliers who are well-versed in compliance issues can provide valuable insights and resources, ensuring that all processes meet the necessary regulations.

Scenario 3: Managing Costs and Efficiency in Shot Peening Operations

The Problem: Cost management is a significant concern for B2B buyers utilizing shot peening services. Inefficient processes can lead to excessive material costs, energy consumption, and labor expenses. Buyers often struggle to balance the need for quality surface treatment with budget constraints, which can result in either overspending or settling for lower-quality processes that compromise product integrity.

The Solution: To optimize costs while maintaining high-quality shot peening, buyers should conduct a thorough analysis of their current processes to identify inefficiencies. Investing in automated shot peening systems can significantly reduce labor costs and improve throughput. Buyers should also explore bulk purchasing agreements for shot media to lower material costs. Implementing a lean manufacturing approach can help streamline operations, minimize waste, and enhance overall efficiency. Additionally, establishing key performance indicators (KPIs) related to cost and quality can help monitor progress and make informed decisions about resource allocation. Collaborating with industry peers or consultants to share best practices can also yield insights that drive both efficiency and cost-effectiveness in shot peening operations.

Illustrative image related to shot peener

Strategic Material Selection Guide for shot peener

What Are the Key Materials Used in Shot Peening Applications?

When selecting materials for shot peening equipment, it’s essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: steel, ceramic, glass, and plastic. Each material has unique characteristics that impact performance and suitability for various applications, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe.

How Does Steel Perform as a Material for Shot Peening?

Steel is one of the most widely used materials in shot peening applications due to its durability and effectiveness. Steel shot offers excellent hardness and is capable of producing significant compressive residual stress in treated parts. It is particularly effective for applications requiring high impact resistance and fatigue life enhancement.

Pros: Steel is cost-effective and readily available, making it a popular choice among manufacturers. Its high density allows for efficient energy transfer during the peening process, resulting in superior surface treatment.

Cons: However, steel is susceptible to corrosion, which may require additional protective measures in humid or corrosive environments. Moreover, its weight can lead to higher shipping costs for international buyers.

Impact on Application: Steel shot is compatible with a wide range of materials and is effective in industries such as aerospace and automotive.

Illustrative image related to shot peener

What Advantages Do Ceramic Materials Offer in Shot Peening?

Ceramic media is another option for shot peening, particularly valued for its hardness and low density. Ceramic shot is ideal for applications that require a finer finish and less weight, making it suitable for delicate components.

Pros: The primary advantage of ceramic is its resistance to wear and its ability to maintain shape over time. This makes it particularly effective for precision applications.

Cons: On the downside, ceramic materials are more brittle than steel and can break under high impact, which may lead to higher replacement costs.

Illustrative image related to shot peener

Impact on Application: Ceramic shot is often used in industries such as medical device manufacturing, where surface finish is critical.

How Do Glass Materials Compare for Shot Peening Applications?

Glass beads are frequently used in shot peening due to their ability to provide a smooth surface finish without significantly altering the dimensions of the part. Glass media is particularly effective for cleaning and surface preparation applications.

Pros: Glass beads are non-metallic and do not cause contamination, making them ideal for sensitive applications. They also offer excellent visibility during the peening process.

Cons: However, glass beads are less effective than steel or ceramic in producing compressive residual stress, which may limit their use in high-stress applications.

Impact on Application: Glass media is commonly used in the automotive and aerospace sectors for surface cleaning and finishing.

What Role Do Plastic Materials Play in Shot Peening?

Plastic media is often utilized in applications where a softer touch is required, such as in the treatment of softer metals or delicate components. Plastic shot is lightweight and can be used in various peening applications.

Pros: The primary advantage of plastic is its ability to reduce the risk of damage to the substrate material. It is also less abrasive, making it suitable for applications requiring a gentle touch.

Cons: However, plastic media may not provide the same level of compressive stress as steel or ceramic, which can limit its effectiveness in certain applications.

Illustrative image related to shot peener

Impact on Application: Plastic shot is often used in industries such as electronics and automotive for surface preparation and cleaning.

Summary Table of Material Selection for Shot Peening

| Material | Typical Use Case for shot peener | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Aerospace and automotive | High density for effective energy transfer | Susceptible to corrosion | Medium |

| Ceramic | Precision applications in medical devices | Excellent wear resistance | Brittle and can break under impact | High |

| Glass | Surface cleaning in automotive and aerospace | Non-contaminating and good visibility | Less effective in producing compressive stress | Medium |

| Plastic | Treatment of softer metals and delicate components | Gentle on substrates | Limited compressive stress capability | Low |

This strategic material selection guide provides essential insights for B2B buyers, enabling them to make informed decisions based on the unique requirements of their applications and the specific characteristics of each material.

In-depth Look: Manufacturing Processes and Quality Assurance for shot peener

What Are the Main Stages of the Manufacturing Process for Shot Peeners?

The manufacturing process for shot peeners involves several critical stages that ensure the final product meets the necessary performance and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing shot peening equipment.

Illustrative image related to shot peener

Material Preparation: How Are Components Selected and Treated?

The first step in the manufacturing process is material preparation. Typically, high-grade steel or aluminum alloys are selected for their durability and resistance to wear. The chosen materials undergo surface treatment processes such as cleaning and degreasing to remove any contaminants that could affect the integrity of the final product. This step is crucial for ensuring that the shot peener operates effectively and that the media used in shot peening does not degrade.

What Forming Techniques Are Used in Shot Peener Manufacturing?

Following material preparation, the forming stage involves shaping the components through various techniques. Common methods include machining, welding, and casting, depending on the design requirements of the shot peener. Precision machining is often employed to ensure that parts fit together seamlessly, while welding is used to create sturdy joints that can withstand the operational stresses encountered during shot peening.

How Is the Assembly of Shot Peeners Conducted?

The assembly process integrates all the individual components into a cohesive unit. This stage typically involves the installation of the blast cabinet, media delivery systems, and control mechanisms. Skilled technicians pay close attention to the alignment and fit of each part, as any misalignment can affect the performance and longevity of the shot peener. Assembly often includes the installation of safety features such as interlocks and pressure regulators, which are critical for safe operation.

What Finishing Processes Are Applied to Enhance Shot Peener Quality?

Finishing processes, such as painting and coating, are applied to enhance both the aesthetic appeal and corrosion resistance of the shot peener. A durable enamel finish is commonly used to protect the metal surfaces from environmental factors. Additionally, some manufacturers apply non-stick coatings to internal components to facilitate easier cleaning and maintenance. These finishing techniques are essential for ensuring that the equipment remains functional and visually appealing over its lifespan.

What International Standards and Certifications Are Relevant for Shot Peener Quality Assurance?

Quality assurance is a vital aspect of shot peener manufacturing. To ensure that products meet global standards, manufacturers often comply with various international certifications.

Illustrative image related to shot peener

How Does ISO 9001 Certification Impact Manufacturing Quality?

ISO 9001 is a widely recognized quality management standard that emphasizes a process-oriented approach to manufacturing. Companies that hold this certification demonstrate their commitment to consistent quality and customer satisfaction. Adherence to ISO 9001 involves regular audits and continuous improvement processes, which can give B2B buyers confidence in the reliability of their suppliers.

What Industry-Specific Certifications Should Buyers Look For?

In addition to ISO 9001, certain industry-specific certifications may also be relevant. For instance, CE marking is crucial for products sold within the European market, ensuring compliance with health and safety regulations. Similarly, the American Petroleum Institute (API) certification may be necessary for manufacturers supplying the oil and gas industry. Buyers should inquire about these certifications to verify that suppliers meet the necessary industry standards.

How Are Quality Control Checkpoints Structured in Shot Peener Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process to ensure that every shot peener meets the required specifications.

What Are the Key QC Checkpoints in the Manufacturing Process?

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers are often required to provide certificates of conformity to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, various inspections are conducted to monitor the production process. This includes verifying dimensions, checking weld integrity, and ensuring that components are assembled correctly.

-

Final Quality Control (FQC): Before shipment, a comprehensive inspection is performed to assess the overall functionality and safety of the shot peener. This may include performance testing under operational conditions to ensure it meets operational benchmarks.

What Common Testing Methods Are Used to Ensure Shot Peener Quality?

Testing methods vary depending on the intended application of the shot peener. Common testing techniques include:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to detect internal defects without damaging the components.

- Performance Testing: This involves operating the shot peener under simulated conditions to evaluate its effectiveness and durability. Performance metrics such as media flow rate, pressure consistency, and operational noise levels are monitored.

- Dimensional Inspection: Using precision measuring tools, manufacturers check that all dimensions comply with engineering specifications, ensuring that the shot peener will operate correctly.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability.

Illustrative image related to shot peener

What Are Effective Strategies for Conducting Supplier Audits?

- On-Site Audits: Visiting the manufacturing facility allows buyers to observe the production processes firsthand. During these visits, buyers can assess the adherence to quality standards, review documentation, and engage with quality assurance personnel.

- Requesting Documentation: Suppliers should provide documentation detailing their quality control processes, including inspection records, testing results, and compliance certifications. This information can be vital for assessing the reliability of the supplier.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and the quality of the products. These agencies often have the expertise to conduct thorough evaluations and offer insights into potential risks.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing shot peeners from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of certain nuances:

- Cultural Differences: Understanding the cultural context of suppliers can improve communication and collaboration, which are essential for quality assurance.

- Regulatory Compliance: Different countries have varying regulatory requirements. Buyers should familiarize themselves with local regulations that may impact quality standards and certifications.

- Language Barriers: Language differences can complicate the understanding of quality documentation. Utilizing translators or bilingual staff can help bridge these gaps and ensure that all parties have a clear understanding of quality expectations.

By comprehensively understanding the manufacturing processes and quality assurance measures for shot peeners, B2B buyers can make more informed sourcing decisions, ensuring that they procure equipment that meets their operational needs and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shot peener’

The following is a practical checklist designed to assist international B2B buyers in sourcing shot peening equipment effectively. This guide aims to streamline your procurement process, ensuring you make informed decisions that align with your business needs.

Illustrative image related to shot peener

Step 1: Define Your Technical Specifications

Before exploring suppliers, clearly outline your technical requirements. This includes the type of materials you will be processing, the desired surface finish, and any specific industry standards that must be met. Understanding these parameters will help you communicate effectively with suppliers and ensure that the equipment meets your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of shot peening equipment. Look for companies with a strong reputation in the industry, and pay attention to their experience and specialization. Utilize online resources, industry publications, and trade shows to gather information and create a list of potential vendors.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold relevant certifications, such as ISO 9001 or specific industry certifications. These credentials demonstrate a commitment to quality and compliance with international standards. Certifications can also provide assurance regarding the supplier’s manufacturing processes and product reliability.

Step 4: Request Detailed Quotations

Once you have identified suitable suppliers, request detailed quotations that outline the costs associated with the equipment, including shipping and installation. Ensure that the quote includes information on warranty terms, after-sales support, and potential maintenance services. This transparency will help you assess the overall value of each supplier’s offering.

Step 5: Assess Equipment Specifications and Features

Examine the technical specifications and features of the shot peening machines offered. Look for equipment that aligns with your operational requirements, such as adjustable pressure settings, media flow controls, and ease of maintenance. Consider how these features can improve efficiency and reduce downtime in your production process.

Step 6: Check Customer References and Case Studies

Request customer references and case studies from potential suppliers. Speak to previous clients to gain insights into their experiences, focusing on equipment performance, reliability, and customer service. This feedback can be invaluable in determining which supplier aligns best with your operational needs and expectations.

Step 7: Negotiate Terms and Finalize the Purchase

Once you’ve selected a supplier, engage in negotiations to finalize terms of purchase. Discuss payment options, delivery timelines, and any additional support services. Clear communication during this phase is essential to ensure that both parties have aligned expectations, minimizing the risk of misunderstandings later on.

By following this structured approach, B2B buyers can navigate the complexities of sourcing shot peening equipment effectively, ensuring they choose a solution that enhances their operational capabilities and delivers long-term value.

Illustrative image related to shot peener

Comprehensive Cost and Pricing Analysis for shot peener Sourcing

What Are the Key Cost Components in Shot Peener Sourcing?

Understanding the cost structure of shot peeners is critical for international B2B buyers, especially when sourcing from diverse regions like Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The type of shot used, such as steel shot or ceramic media, significantly impacts costs. Higher-quality materials may offer better performance but come at a premium price.

-

Labor: Skilled labor is essential for operating shot peening equipment. Labor costs can vary widely by region, influenced by local wage rates and the availability of skilled technicians.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead and lower overall prices.

-

Tooling: The initial investment in tooling can be substantial, especially for customized shot peening solutions. Buyers should consider how tooling costs will affect the total investment.

-

Quality Control (QC): Rigorous quality control processes are vital in ensuring that shot peening meets industry standards. This adds to the cost but is essential for maintaining product reliability and safety.

-

Logistics: Shipping and handling costs must be factored in, especially for international buyers. Incoterms can influence logistics expenses, impacting overall pricing.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics can help buyers gauge whether the margin is reasonable.

How Do Price Influencers Affect Shot Peener Costs?

Several factors can influence the pricing of shot peeners, making it crucial for buyers to be aware of these elements:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often offer better pricing for larger orders, making it beneficial for buyers to assess their needs carefully.

-

Specifications and Customization: Customized solutions that meet specific performance criteria may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials: The choice of materials affects both the performance and price of shot peeners. Buyers should balance cost with the desired quality and durability.

-

Quality and Certifications: Higher-quality products often come with certifications that ensure compliance with industry standards. This can justify higher pricing but also adds value in terms of reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better customer service and product guarantees.

-

Incoterms: These international shipping terms can affect the total cost of ownership, as they define the responsibilities of buyers and sellers in shipping arrangements. Understanding Incoterms can help buyers negotiate better terms.

What Tips Can Help Buyers Navigate Shot Peener Pricing?

Navigating the complexities of shot peener pricing can be challenging, especially for international buyers. Here are some actionable tips:

-

Negotiation: Don’t hesitate to negotiate terms and pricing with suppliers. Demonstrating knowledge of market rates can strengthen your position.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, operational efficiency, and potential downtime costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local regulations that can affect pricing. Engage with local experts or consultants to better understand the market landscape.

-

Research and Benchmarking: Utilize available resources, such as industry publications and forums, to benchmark prices and understand market trends. This information can empower buyers during negotiations.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing in shot peener sourcing, prices can vary significantly based on numerous factors. It is recommended that buyers conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing shot peener With Other Solutions

Exploring Alternatives to Shot Peening: Key Comparisons for B2B Buyers

In the pursuit of enhancing the fatigue life and performance of metal components, shot peening is a widely adopted method. However, various alternative solutions exist that can also achieve similar outcomes. Understanding these alternatives can empower B2B buyers to make informed decisions tailored to their specific needs.

| Comparison Aspect | Shot Peener | Alternative 1: Surface Hardening | Alternative 2: Shot Blasting |

|---|---|---|---|

| Performance | Excellent fatigue resistance and surface stress improvement | Good wear resistance; may not improve fatigue life as effectively | Effective for surface cleaning and preparing but less focused on stress induction |

| Cost | Moderate initial investment; cost-effective over time due to reduced failures | Higher operational costs due to energy and material requirements | Generally lower initial costs but ongoing media replacement can add up |

| Ease of Implementation | Requires skilled operators; setup can be complex | Typically requires specialized equipment and skilled labor | Easier setup; can be automated, but may require training for optimal use |

| Maintenance | Regular maintenance needed; parts wear over time | Equipment maintenance is crucial but may have longer intervals | Lower maintenance needs, but media recycling systems may require upkeep |

| Best Use Case | Aerospace, automotive, and industries needing high fatigue resistance | Applications requiring improved surface hardness, such as gears | Cleaning and preparing surfaces for coating or painting |

What Are the Benefits and Drawbacks of Surface Hardening?

Surface hardening, often achieved through processes such as induction hardening or flame hardening, enhances the surface hardness of a material without affecting the core properties. One of the main advantages is its ability to increase wear resistance, making it suitable for applications like gears and bearings. However, it may not significantly improve fatigue life compared to shot peening, which specifically addresses compressive stresses. Additionally, the initial investment in specialized equipment can be high, and the process requires skilled labor for optimal results.

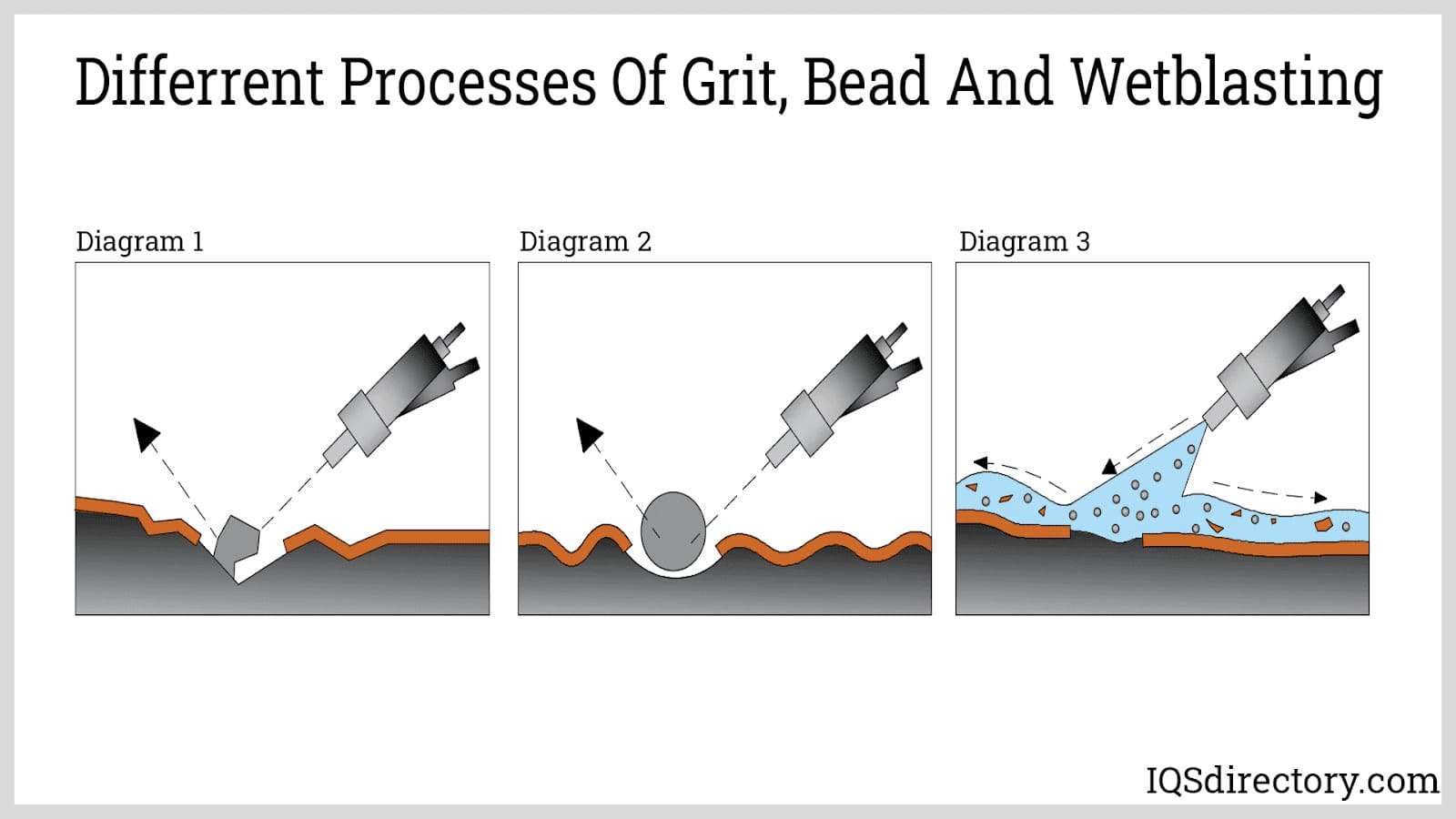

How Does Shot Blasting Compare to Shot Peening?

Shot blasting is primarily a cleaning and surface preparation method. It utilizes abrasive materials to remove contaminants, rust, or old coatings, making it suitable for applications in construction and manufacturing. While it is effective for surface treatment, shot blasting does not impart the same level of compressive stress as shot peening, which is critical for preventing fatigue failures. Furthermore, shot blasting typically has lower initial costs but may incur ongoing expenses for media replacement and equipment wear. Its ease of implementation makes it an attractive option for businesses seeking straightforward surface cleaning solutions.

How Should B2B Buyers Choose the Right Solution?

When selecting the right solution for enhancing metal component performance, B2B buyers should consider several factors, including the specific application, budget constraints, and the desired outcomes. For industries where fatigue life is paramount, shot peening remains the superior choice due to its ability to induce beneficial compressive stresses. Conversely, for applications focused on wear resistance or surface cleaning, surface hardening and shot blasting may be more appropriate. By analyzing these aspects in relation to their operational goals, buyers can make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for shot peener

What are the Key Technical Properties of Shot Peeners?

When selecting shot peeners for manufacturing processes, understanding their technical properties is crucial. Here are several critical specifications that influence the performance and suitability of shot peeners in various applications:

-

Material Grade

– Shot peeners are typically constructed from high-grade steel or aluminum alloys. The material grade affects durability and resistance to wear and corrosion. For B2B buyers, opting for higher-grade materials can lead to longer equipment life and reduced maintenance costs. -

Tolerance Levels

– Tolerance refers to the permissible limit of variation in dimensions. In shot peening, maintaining precise tolerances is essential for achieving consistent surface compressive stresses. Buyers need to ensure that the shot peener can meet the specific tolerances required for their components to avoid compromising structural integrity. -

Shot Size and Shape

– The diameter and shape of the shot media play a vital role in the peening process. Different sizes can generate varying levels of compressive stress and surface finish. Understanding the specific requirements for shot size is important for optimizing performance and ensuring the desired outcomes in metal fatigue resistance. -

Blast Pressure

– This specification indicates the force at which the shot is propelled towards the workpiece. Higher blast pressures can improve the effectiveness of peening but may also risk damaging delicate components. B2B buyers must balance the need for effective treatment with the potential for part damage, especially in sensitive applications. -

Production Capacity

– Refers to the volume of components that can be processed in a given time frame. Understanding the production capacity helps businesses plan their manufacturing schedules and ensure they meet delivery timelines. A shot peener with higher throughput can be a critical asset for companies with large-scale production demands. -

Energy Consumption

– The efficiency of a shot peener can be measured by its energy consumption relative to output. Energy-efficient models can significantly reduce operational costs, making them more attractive for businesses focused on sustainability and cost-effectiveness.

What are Common Trade Terms Related to Shot Peening?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to shot peening that buyers should know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify trustworthy suppliers and the quality of shot peeners suited for their specific applications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to gauge their purchasing power and avoid overcommitting to quantities that exceed their immediate needs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For shot peening services, submitting an RFQ can help buyers compare multiple options and negotiate better terms based on volume and specifications. -

Incoterms (International Commercial Terms)

– These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and logistics. Understanding Incoterms is vital for B2B buyers engaging in international transactions, as they dictate who pays for shipping, insurance, and tariffs. -

CNC (Computer Numerical Control)

– CNC refers to the automated control of machining tools and 3D printers by a computer. In the context of shot peening, CNC technology can enhance precision and repeatability in the peening process, making it a valuable consideration for buyers looking for advanced equipment. -

Residual Stress

– This term refers to the internal forces locked within a material after processing, which can significantly affect its performance. Shot peening induces beneficial residual stresses that improve fatigue resistance. B2B buyers should understand how these stresses impact their components to ensure optimal performance in their applications.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when procuring shot peening equipment and services, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the shot peener Sector

What are the Key Trends Shaping the Shot Peener Market?

The shot peening market is experiencing dynamic shifts driven by globalization and technological advancements. One of the most significant global drivers is the increasing demand for enhanced fatigue life and performance of components across industries such as aerospace, automotive, and energy. This demand is pushing manufacturers to adopt more sophisticated shot peening technologies that optimize efficiency and precision. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Emerging technologies, such as automated shot peening systems and real-time monitoring solutions, are reshaping procurement strategies. These innovations not only improve operational efficiency but also reduce costs associated with manual processes. Buyers are increasingly looking for suppliers who can provide advanced machinery capable of integrating with Industry 4.0 initiatives, ensuring a seamless flow of data and better quality control.

Illustrative image related to shot peener

Additionally, the rise of digital marketplaces is transforming how buyers source shot peening services and equipment. Platforms that connect manufacturers with service providers are becoming popular, enabling easier comparison of prices and services. Buyers can leverage these platforms to find competitive offers while ensuring compliance with international standards.

How is Sustainability Influencing Sourcing in the Shot Peener Sector?

Sustainability is becoming a core concern in the shot peening industry, as B2B buyers increasingly prioritize environmentally responsible practices. The environmental impact of shot peening processes—particularly in terms of waste generation and energy consumption—has led to a demand for sustainable solutions. Suppliers that adopt eco-friendly practices, such as using recyclable shot materials and energy-efficient machinery, are gaining favor among conscientious buyers.

Ethical sourcing has also become a focal point, with buyers seeking suppliers who uphold fair labor practices and responsible sourcing of materials. Certifications like ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are gaining traction as indicators of a supplier’s commitment to sustainability. Buyers should look for these certifications when evaluating potential suppliers.

Furthermore, there is a growing interest in “green” shot peening materials that minimize harmful emissions and waste. For instance, suppliers offering biodegradable or non-toxic alternatives to traditional shot materials are not only meeting regulatory requirements but also appealing to environmentally conscious buyers.

Illustrative image related to shot peener

What is the Historical Context of Shot Peening and Its Relevance Today?

The shot peening process has evolved significantly since its inception in the 1920s, initially developed to enhance the fatigue resistance of aircraft components. Over the decades, advancements in technology and materials have expanded its applications across various sectors, including automotive, medical, and energy industries. Today, shot peening is recognized as a critical process for improving product longevity and performance, making it essential for B2B buyers to understand its historical context.

As industries continue to seek innovative methods to enhance product quality and performance, the relevance of shot peening remains robust. Understanding the evolution of this process provides valuable insights into its current applications and future potential, guiding B2B buyers in making strategic sourcing decisions that align with their operational goals.

In conclusion, the shot peening sector is marked by a blend of technological innovation, sustainability concerns, and a rich historical legacy. For international B2B buyers, these elements are crucial in navigating market dynamics and sourcing trends effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of shot peener

-

How do I solve issues with oversized holes after shot peening?

When encountering oversized holes post-shot peening, it’s crucial to identify the root cause of the size alteration. This can stem from either the peening process or subsequent cleaning operations. To mitigate this, you may need to adjust the peening parameters such as intensity and coverage. Collaborating with your shot peening supplier for guidance on specific tolerances and adjustments can ensure you achieve the desired dimensions without compromising the integrity of the component. -

What is the best shot media for achieving optimal peening results?

The choice of shot media significantly impacts the effectiveness of the shot peening process. Common options include steel shot, glass beads, and ceramic media. Steel shot is typically favored for its durability and effectiveness in inducing compressive stresses, while glass beads are ideal for applications requiring a gentler approach. Your selection should align with the material properties of the parts being treated and the desired outcome, such as improved fatigue resistance or surface finish. -

How can I vet suppliers for shot peening equipment and services?

To effectively vet suppliers, consider their industry reputation, certifications, and experience. Request references from previous clients and inquire about their quality assurance processes. Additionally, assess their compliance with international standards, especially if you are sourcing from different regions. A site visit can also provide insights into their operational capabilities. Engaging in discussions about their technical expertise and after-sales support is crucial for ensuring a long-term partnership. -

What customization options are available for shot peening machines?

Many manufacturers offer customization options tailored to your specific requirements. These may include adjustments in size, media type, and automated controls. You can also request modifications for specific applications, such as aerospace or automotive components. Discussing your needs with potential suppliers will help you understand the extent of customization they can provide, ensuring the equipment aligns with your operational goals. -

What are the typical minimum order quantities (MOQs) for shot peening services?

Minimum order quantities can vary significantly between suppliers and are often influenced by the complexity of the service or the type of equipment. Some suppliers may have flexible MOQs for new clients or small-scale projects, while others may require larger commitments for specialized services. It is advisable to discuss your specific needs with suppliers to negotiate favorable terms that align with your production capacity and budget. -

What payment terms should I expect when sourcing shot peening equipment?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common arrangements include upfront payments, net 30-60 days after delivery, or payment upon receipt of the equipment. For international transactions, consider the implications of currency exchange and potential tariffs. It is essential to clarify these terms upfront to avoid misunderstandings and ensure a smooth purchasing process. -

How do I ensure quality assurance in shot peening processes?

To ensure quality assurance, it is essential to engage suppliers who adhere to recognized industry standards, such as ISO 9001. Request detailed documentation of their quality control processes, including the parameters used for shot peening and the methods for measuring residual stress. Regular audits and feedback loops can help maintain quality, and it may be beneficial to implement in-house checks for critical components before and after the peening process. -

What logistics considerations should I keep in mind when sourcing shot peening equipment internationally?

When sourcing internationally, consider shipping costs, customs duties, and delivery timelines. It’s important to work with suppliers who provide clear shipping options and can assist with the necessary documentation for customs clearance. Establishing a reliable logistics partner can also help manage the complexities of international shipping, ensuring timely delivery and reducing the risk of damage during transit. Be proactive in discussing these logistics details during the procurement phase.

Top 7 Shot Peener Manufacturers & Suppliers List

1. Shot Peener – Almen Strips & MagnaValve®

Domain: shotpeener.com

Registered: 1996 (29 years)

Introduction: Almen strips and gages, MagnaValve ® media control valves, shot peening training.

2. The Shot Peener Magazine – Industry Insights

Domain: theshotpeenermagazine.com

Registered: 2012 (13 years)

Introduction: The Shot Peener Magazine is a free publication focused on the shot peening and blast cleaning industries. It covers important topics for a diverse audience including OEMs, engineers, academics, and machine operators. The magazine is distributed by mail and email quarterly in April, July, October, and January, and is also available online and at trade shows and training programs globally. It has be…

3. Electronics Inc. – Shot Peening Solutions

Domain: electronics-inc.com

Registered: 2000 (25 years)

Introduction: Electronics Inc. offers a range of products related to shot peening, including MagnaValves, air blast machines, wheel blast machines, Almen strips (types A, N, and C), mini-strips, aluminum strips, Almen gages (including #2 Almen Gage, Almen Gage Jr, Aero-Almen Gage), calibration tools, rotary flap peening kits, aircraft paint stripping tools, and sensors. The MagnaValves product line includes var…

4. Blast-It-All® – ABC Shot Peeners

Domain: blast-it-all.com

Registered: 1997 (28 years)

Introduction: ABC Shot Peeners – Blast-It-All®

Key Features:

– Designed for precise and effective blast peening of metal components using steel shot or steel grit.

– Gravity fed system for spent shot or grit reuse.

– Adjustable media valve for controlling media flow.

– Regulator for pressure adjustment.

– Foot pedal operation for ease during long projects.

– Simple design for easy maintenance.

– Compatible wit…

5. Little-Blaster™ – Shot Peener Blast Cabinet

Domain: idsblast.com

Registered: 1996 (29 years)

Introduction: {“model”:”4024 LITTLE-BLASTER™ SERIES SHOT PEENER BLAST CABINET”,”dimensions”:”40″ x 24″”,”dust_collector”:”100 CFM cartridge type collector”,”construction”:”heavy gauge metal, continuously welded”,”light_box”:”Two 24″ fluorescent tubes with On-Off control switch”,”viewing_window”:”12″ x 20″ tempered glass”,”door_latch”:”heavy-duty cam type, adjustable for positive door seal”,”glove_arm_hole”:”hea…

6. Dull Men’s Club® – The Shot Peener Magazine

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Dull Men’s Club®, Jack Champaigne, 2024 Shot Peener of the Year, founded The Shot Peener magazine in 1987.

7. Guyson – Automated Shot Peening Equipment

Domain: guyson.co.uk

Introduction: Automated Shot Peening Equipment by Guyson International Limited includes various systems designed to eliminate variations in manual blast processes. Types of automated shot peening machines available are tumble peen, conveyor peen, rotary table peen, and spindle peen. Typical applications include shot peening turbine blades, airframe components, aerostructure ribs, drill rod threads (oil & gas se…

Strategic Sourcing Conclusion and Outlook for shot peener

In conclusion, the strategic sourcing of shot peening solutions presents a significant opportunity for B2B buyers across Africa, South America, the Middle East, and Europe. By focusing on quality and efficiency, organizations can enhance the durability and performance of their metal components, ultimately leading to reduced operational costs and extended product life.

Understanding the intricacies of shot peening—its ability to induce compressive residual stresses and improve surface hardness—enables buyers to make informed decisions that align with their specific industry needs, whether in aerospace, automotive, or energy sectors. Emphasizing partnerships with reputable suppliers who offer advanced technology and expertise in shot peening processes can further strengthen supply chain resilience and innovation.

As the market evolves, international buyers should remain proactive in exploring new technologies and methodologies in shot peening to stay competitive. Now is the time to leverage these insights and invest in strategic sourcing that prioritizes quality and performance. Engage with industry experts and resources to navigate this landscape effectively, ensuring your business is well-positioned to capitalize on the benefits of shot peening technology.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to shot peener

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.