Top 8 Does A Gear Have Teeth Suppliers (And How to Choose)

Introduction: Navigating the Global Market for does a gear have teeth

In the complex landscape of industrial machinery, understanding whether a gear has teeth is crucial for businesses aiming to optimize their operations. The presence of teeth on gears significantly influences their performance, load capacity, and efficiency. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate the procurement of these essential components, they face challenges in identifying the right gear types and specifications that align with their unique operational demands.

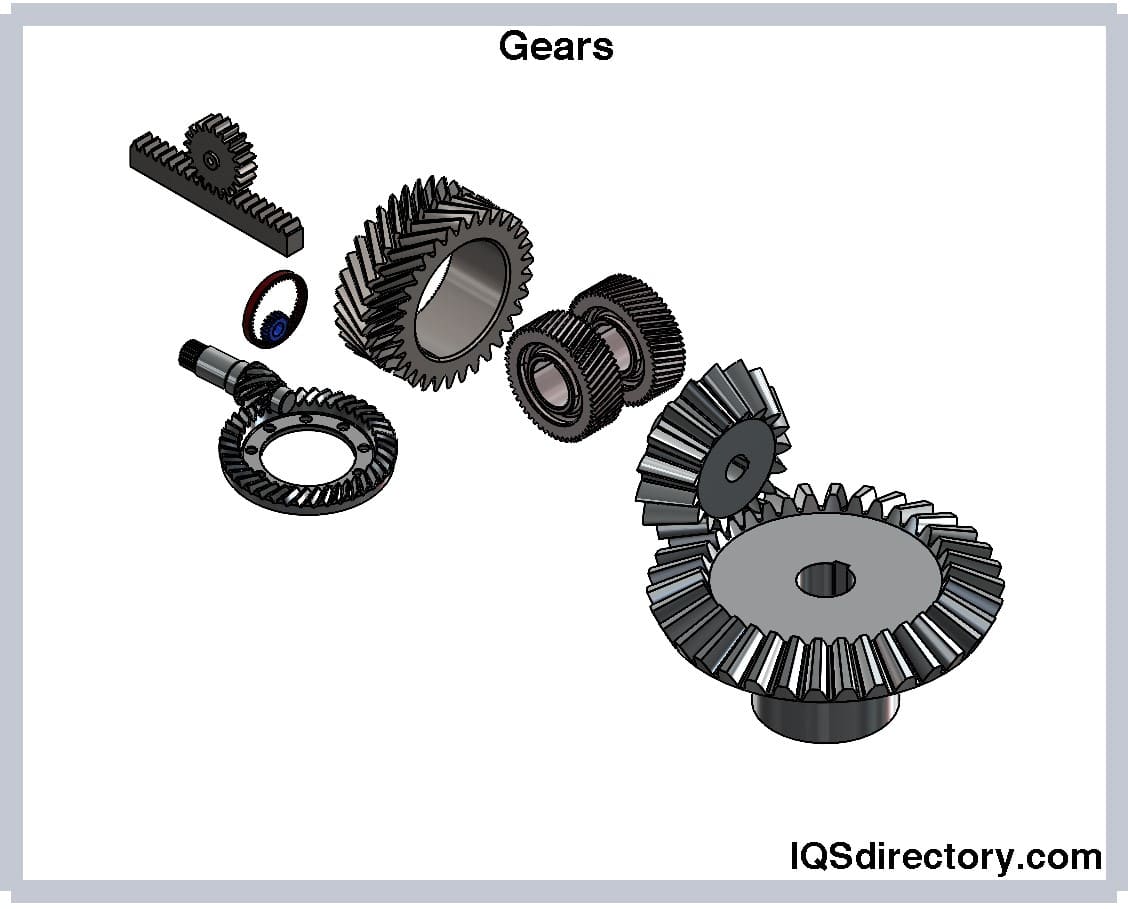

This comprehensive guide delves into the various types of gears, including helical, bevel, and worm gears, along with their specific applications across multiple industries. It also provides insights into the critical aspects of supplier vetting, cost considerations, and best practices for ensuring quality and reliability in gear sourcing. By breaking down the complexities associated with gear selection and procurement, this guide empowers buyers to make informed purchasing decisions that enhance their operational efficiency and reduce downtime.

With a focus on actionable insights tailored to diverse markets, this resource serves as an essential tool for international buyers seeking to streamline their supply chains and enhance their product offerings. Whether you are in Brazil’s agricultural sector or Saudi Arabia’s oil and gas industry, understanding the nuances of gear functionality will enable you to leverage the right solutions for your business needs.

Understanding does a gear have teeth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Helical Gears | Angled teeth for smoother operation, multiple teeth in contact | Mining, marine propulsion, energy generation | Pros: High load capacity, quieter operation. Cons: Requires robust bearings due to axial thrust. |

| Bevel Gears | Cone-shaped, ideal for intersecting shafts, available in various designs | Plant equipment, shipbuilding, turbine applications | Pros: Handles heavy loads efficiently. Cons: Higher machining costs due to precision requirements. |

| Worm Gears | Screw-like design for high reduction ratios, compact space usage | Manufacturing, agriculture, mining | Pros: Quiet operation, good for shock loading. Cons: Less efficient due to friction. |

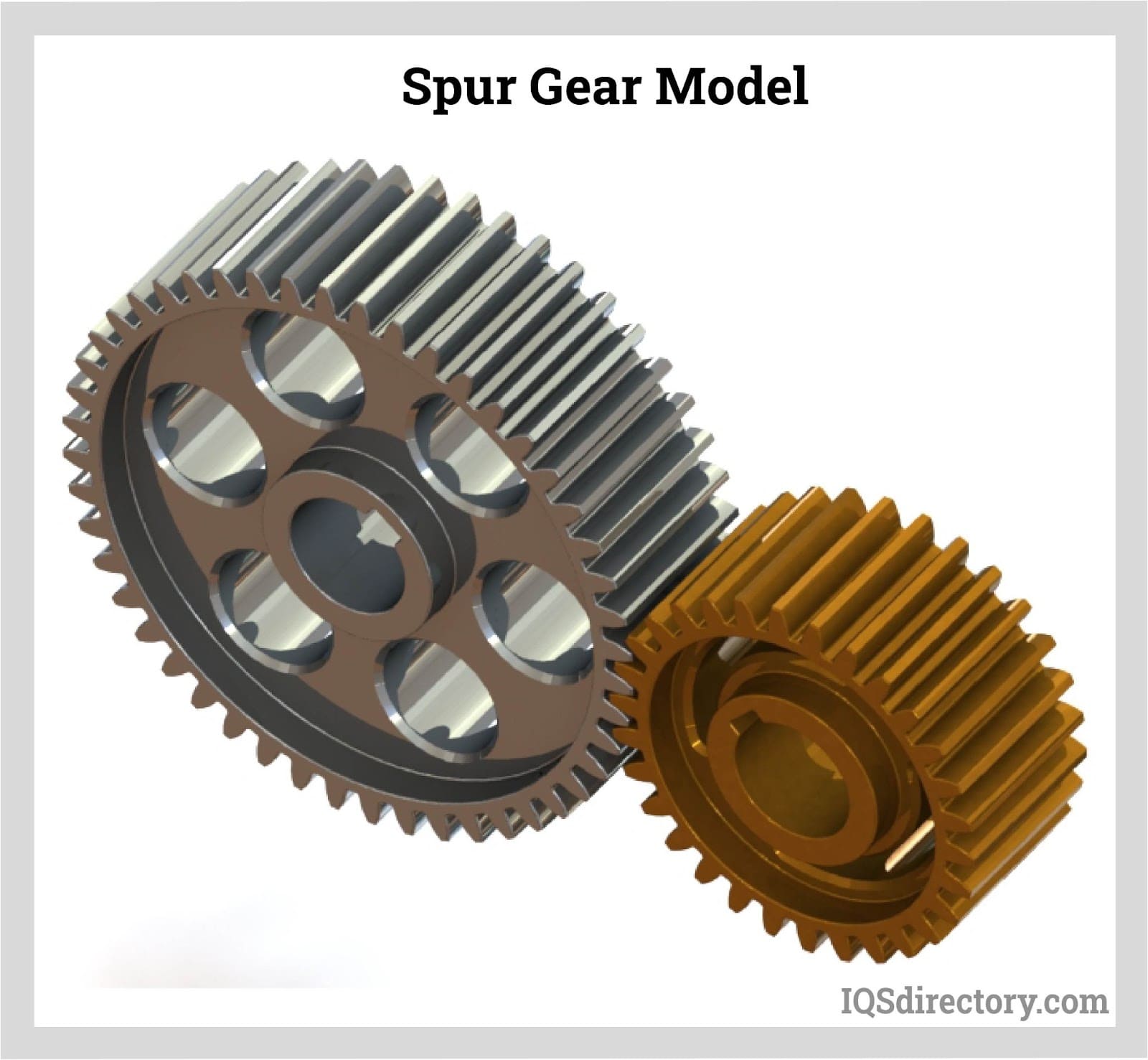

| Spur Gears | Straight, parallel teeth for direct motion transfer | General machinery, automotive applications | Pros: Simple design, cost-effective. Cons: Noisy operation at high speeds. |

| Double Helical Gears | Two sets of angled teeth to balance thrust, V-shaped design | Power generation, oil and gas, heavy machinery | Pros: Smooth operation, high torque handling. Cons: Complex manufacturing and assembly. |

What Are Helical Gears and When Should They Be Used?

Helical gears feature teeth that are cut at an angle, allowing multiple teeth to engage simultaneously. This design minimizes noise and vibration, making them ideal for applications requiring smooth operation and high load capacity, such as in mining and marine propulsion. When purchasing helical gears, buyers should consider the axial thrust generated and ensure that robust bearings are in place to handle the additional forces.

Illustrative image related to does a gear have teeth

How Do Bevel Gears Function in Industrial Applications?

Bevel gears are distinguished by their cone shape and ability to transfer power between intersecting shafts, typically at a 90-degree angle. They are essential in applications like plant equipment and shipbuilding, where space constraints and heavy loads are common. Buyers should note the precision required in bevel gear machining, which can lead to higher costs but results in reliable performance under demanding conditions.

What Advantages Do Worm Gears Offer in Machinery?

Worm gears utilize a screw-like mechanism to achieve high reduction ratios in compact spaces, making them suitable for applications in manufacturing and agriculture. Their ability to provide quiet and vibration-free operation is a significant advantage. However, buyers should be aware of their lower efficiency due to friction and ensure that the design meets the specific torque requirements of their applications.

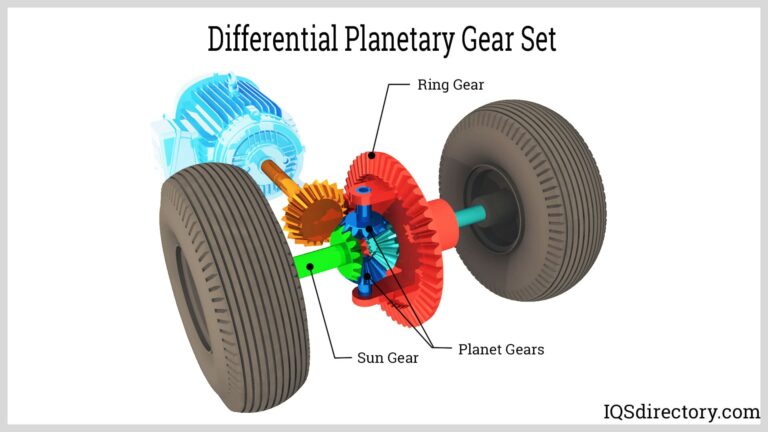

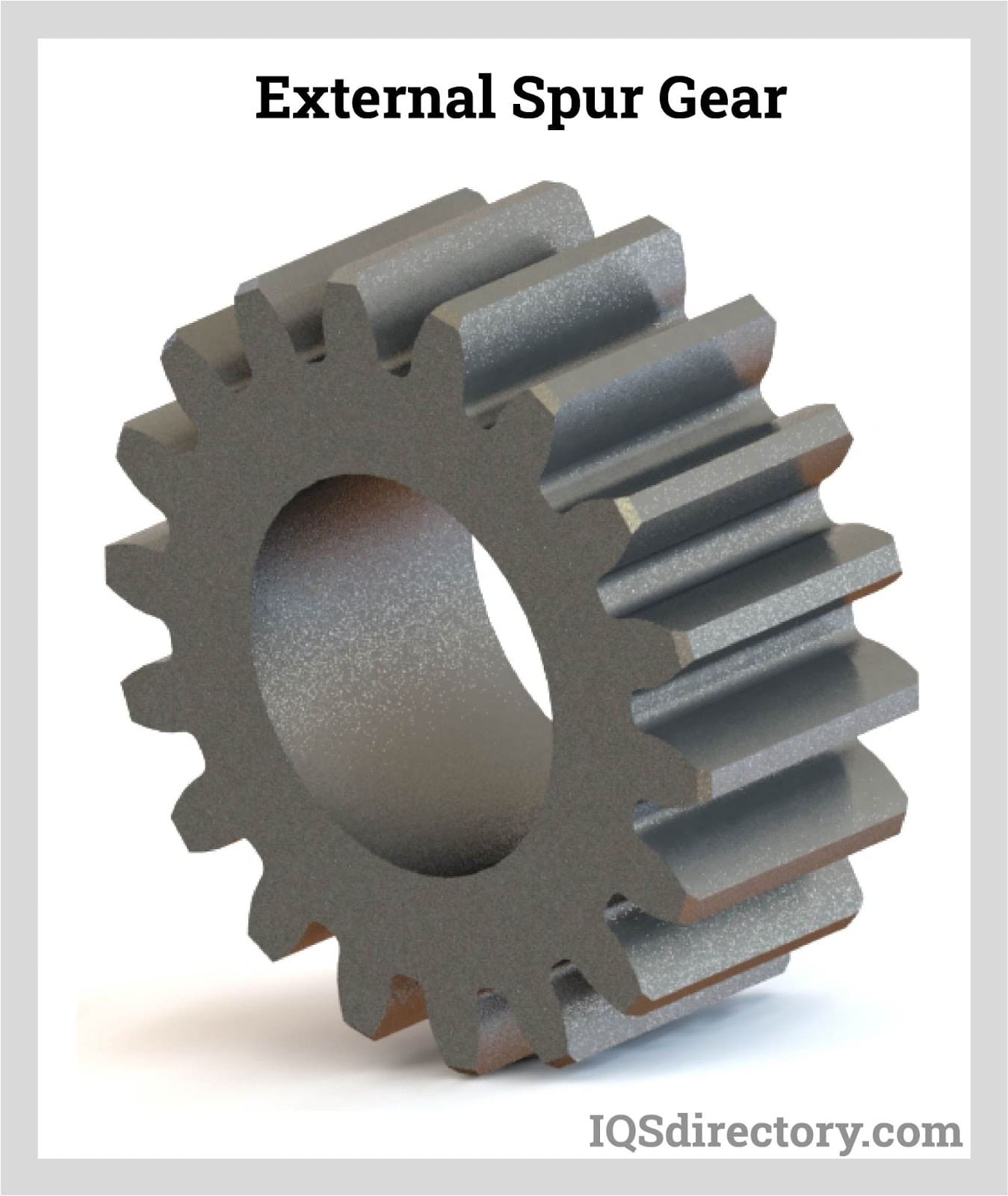

Why Choose Spur Gears for Your Gear Train Needs?

Spur gears are characterized by their straight, parallel teeth, making them one of the most straightforward and cost-effective gear types. They are widely used in general machinery and automotive applications. While spur gears are efficient at transferring motion, they can be noisy at high speeds, so buyers should evaluate the operational environment and consider noise reduction solutions if necessary.

Illustrative image related to does a gear have teeth

What Are the Benefits of Double Helical Gears in High-Torque Applications?

Double helical gears consist of two sets of angled teeth that counterbalance axial thrust, allowing for smoother operation and greater strength. This design is particularly beneficial in high-torque applications such as power generation and oil and gas industries. Buyers should consider the complexity of manufacturing and alignment when selecting double helical gears, as these factors can impact both cost and performance reliability.

Key Industrial Applications of does a gear have teeth

| Industry/Sector | Specific Application of does a gear have teeth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Use in heavy-duty equipment like conveyors and crushers | Increased operational efficiency and reliability in harsh conditions | Material strength, load capacity, and environmental resistance |

| Marine | Powering propulsion systems in ships | Enhanced performance and durability in marine environments | Corrosion resistance, weight considerations, and efficiency |

| Energy | Driving turbines and generators in power plants | Improved energy conversion efficiency and reduced downtime | High torque capacity, thermal management, and reliability |

| Manufacturing | Utilization in robotics and automated systems | Increased precision and speed in production processes | Compatibility with existing systems and precision engineering |

| Agriculture | Operation of irrigation systems and harvesting machinery | Enhanced productivity and reduced labor costs | Durability, resistance to environmental factors, and maintenance requirements |

How Are Gears with Teeth Utilized in the Mining Industry?

In the mining sector, gears with teeth are critical components in heavy-duty machinery such as conveyors and crushers. These gears facilitate the transfer of rotational motion, allowing for the efficient movement of materials and operation of equipment. Buyers in this industry must prioritize material strength and load capacity, as mining environments are often harsh and demanding. Additionally, sourcing gears that offer resistance to wear and fatigue can significantly reduce operational downtime and maintenance costs.

What Role Do Gears Play in Marine Applications?

In marine applications, gears with teeth are essential for powering propulsion systems in ships. The durability and reliability of these gears are paramount, as they operate in challenging environments characterized by moisture and salt exposure. International buyers, particularly in regions like the Middle East and South America, should consider sourcing gears made from corrosion-resistant materials. This ensures longevity and optimal performance, ultimately enhancing the vessel’s operational efficiency.

How Are Gears with Teeth Used in Energy Production?

In the energy sector, gears are vital for driving turbines and generators within power plants. The efficiency of energy conversion heavily relies on the gear’s ability to handle high torque and operate smoothly under varying loads. For B2B buyers, especially in Europe and Africa, it is crucial to source gears that not only meet the required specifications but also provide thermal management to prevent overheating. This can lead to reduced downtime and increased energy output, translating to significant cost savings.

What Are the Applications of Gears in Manufacturing?

Manufacturing industries leverage gears with teeth in robotics and automated systems, where precision and speed are critical. These gears facilitate the accurate transfer of motion, enhancing the overall productivity of manufacturing processes. Buyers should focus on sourcing gears that are compatible with existing systems and engineered for precision. This ensures seamless integration and optimal performance, which is vital for maintaining competitive advantage in global markets.

Illustrative image related to does a gear have teeth

How Are Gears Utilized in Agriculture?

In agriculture, gears are employed in irrigation systems and harvesting machinery, playing a crucial role in enhancing productivity. The efficient operation of these systems can lead to reduced labor costs and improved crop yields. For international buyers, especially in regions like Brazil and Africa, sourcing durable gears that can withstand environmental factors such as moisture and dirt is essential. Additionally, understanding maintenance requirements can help in selecting gears that minimize downtime and enhance operational efficiency.

3 Common User Pain Points for ‘does a gear have teeth’ & Their Solutions

Scenario 1: Understanding Gear Specifications for Optimal Performance

The Problem: B2B buyers often face confusion regarding the specific tooth design of gears when selecting components for their machinery. This uncertainty can stem from the vast array of gear types, such as helical, spur, and bevel gears, each with distinct tooth configurations that affect performance. For instance, a buyer might choose a spur gear expecting it to function efficiently in a high-torque application, only to find it produces excessive noise and wear due to its tooth design. This misalignment can lead to costly downtimes and repairs, impacting production schedules and overall operational efficiency.

The Solution: To avoid such pitfalls, buyers should prioritize thorough research and consultation with gear manufacturers or suppliers who can provide detailed specifications for each gear type. When selecting gears, it’s essential to consider factors such as load capacity, speed requirements, and the specific application environment. A well-structured specification sheet that outlines these parameters can help ensure the right gear type is chosen. Additionally, leveraging online resources and tools that provide comparisons of gear types based on their tooth designs can aid in making informed decisions. Engaging with technical support teams from manufacturers can further clarify how different tooth geometries influence gear performance in specific applications.

Scenario 2: Navigating the Complexities of Gear Sourcing

The Problem: Many B2B buyers encounter challenges when sourcing gears, particularly when dealing with international suppliers. Factors such as varying quality standards, material specifications, and production capabilities can lead to inconsistencies in the gears received. For example, a company in Brazil may order helical gears from a supplier in Europe, only to discover that the material used does not meet their operational standards, resulting in premature wear and operational failures. These issues not only increase operational costs but also create trust issues with suppliers.

The Solution: To navigate these complexities, buyers should establish clear communication channels with suppliers and insist on standardized quality certifications, such as ISO compliance, which ensure that the gears meet specific performance criteria. It’s advisable to request samples or prototypes before placing bulk orders to evaluate the quality and compatibility of the gears with existing machinery. Additionally, utilizing local distributors or manufacturers that understand regional standards can mitigate risks associated with international sourcing. Conducting thorough supplier audits and referencing customer testimonials can further ensure that the chosen supplier has a reliable track record.

Scenario 3: Ensuring Proper Maintenance and Longevity of Gears

The Problem: A prevalent issue among B2B buyers is the lack of understanding regarding the maintenance requirements of gears, particularly concerning their teeth. Many businesses underestimate the importance of regular maintenance, leading to unexpected failures and costly repairs. For instance, a manufacturing facility may overlook the need for lubrication and alignment checks, resulting in accelerated wear on gear teeth, decreased efficiency, and potential breakdowns during critical production cycles.

The Solution: To enhance the longevity and performance of gears, buyers should implement a proactive maintenance program that includes regular inspections, lubrication schedules, and alignment checks. Creating a maintenance checklist that details the frequency of inspections and specific tasks related to gear teeth—such as checking for wear patterns and ensuring proper lubrication—can greatly reduce the risk of failures. Additionally, providing training for maintenance staff on the importance of gear tooth health and its impact on operational efficiency can foster a culture of diligence. Leveraging digital monitoring tools can also facilitate real-time tracking of gear performance, allowing for timely interventions before issues escalate.

Strategic Material Selection Guide for does a gear have teeth

What Materials Are Commonly Used for Gears with Teeth?

When selecting materials for gears, particularly those designed with teeth, it’s essential to consider their properties and how they align with the specific requirements of various applications. Below, we explore some of the most common materials used in gear manufacturing, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform as a Gear Material?

Steel is one of the most widely used materials for gears due to its excellent mechanical properties. It typically offers high strength, durability, and wear resistance, making it suitable for high-load applications. Steel gears can withstand significant temperature and pressure variations, which is crucial in industries such as automotive and aerospace. However, they can be prone to corrosion unless properly treated or alloyed.

Pros: Steel gears are known for their high load capacity and durability, making them ideal for heavy-duty applications. They can be heat-treated to enhance hardness and wear resistance.

Cons: The manufacturing process for steel gears can be complex and costly, particularly for precision gears. Additionally, untreated steel may require protective coatings to prevent corrosion, adding to overall costs.

Impact on Application: Steel gears are compatible with a wide range of media, including oils and lubricants, making them versatile for various industrial applications. However, in corrosive environments, such as in coastal or chemical processing industries, additional protective measures are necessary.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial when sourcing steel gears. Buyers from regions like Brazil or Saudi Arabia should ensure that suppliers can meet local regulations regarding material specifications and certifications.

What Role Does Plastic Play in Gear Manufacturing?

Plastic gears are increasingly popular due to their lightweight nature and resistance to corrosion. Made from engineering plastics like nylon or acetal, these gears perform well in low-load applications and environments where noise reduction is essential. They are particularly useful in consumer products and machinery where weight reduction is a priority.

Pros: Plastic gears are generally less expensive to manufacture and can be produced in various shapes and sizes. They are also resistant to corrosion and can operate quietly, making them suitable for applications like household appliances and toys.

Cons: While plastic gears are lightweight, they typically have lower strength and load capacity compared to metal gears. They may also be less suitable for high-temperature applications, as many plastics can deform under heat.

Impact on Application: Plastic gears are often used in environments where moisture is present, as they do not rust. However, their compatibility with certain chemicals should be evaluated to avoid degradation.

Considerations for International Buyers: Buyers should look for compliance with international standards for plastics, such as ISO certifications. Understanding the specific properties of the plastic used is vital for applications in diverse climates, particularly in humid regions like parts of Africa and South America.

Why Choose Bronze for Gear Applications?

Bronze is another material option for gears, particularly in applications requiring excellent wear resistance and low friction. Its natural corrosion resistance makes it suitable for marine and high-humidity environments, which is beneficial for industries like shipbuilding and offshore drilling.

Pros: Bronze gears exhibit good machinability and can withstand harsh conditions without significant degradation. They also provide good thermal conductivity and are less prone to galling compared to steel.

Cons: Bronze can be more expensive than steel and plastic, potentially impacting budget considerations. Additionally, its mechanical properties may not match those of high-strength steels for heavy-duty applications.

Impact on Application: Bronze gears are ideal for applications involving water or corrosive environments, such as pumps and valves in marine settings. However, they may not be suitable for extremely high-load applications without careful consideration.

Considerations for International Buyers: Buyers should ensure that bronze gears meet relevant standards for marine applications, particularly in Europe and the Middle East, where compliance with environmental regulations is critical.

Summary Table of Gear Materials

| Material | Typical Use Case for does a gear have teeth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery, automotive applications | High load capacity and durability | Complex manufacturing and corrosion risk | High |

| Plastic | Consumer products, low-load applications | Lightweight and corrosion-resistant | Lower strength and heat sensitivity | Medium |

| Bronze | Marine applications, pumps, and valves | Excellent wear resistance and low friction | Higher cost and limited load capacity | High |

In conclusion, selecting the right material for gears with teeth is critical for ensuring optimal performance in various applications. International B2B buyers must consider not only the material properties but also compliance with local standards and environmental conditions to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for does a gear have teeth

What Are the Main Stages of Gear Manufacturing Processes?

The manufacturing of gears involves several critical stages that ensure the final product meets the required specifications for performance and durability. Understanding these stages can help B2B buyers make informed decisions when sourcing gears for their applications.

How is Material Prepared for Gear Manufacturing?

The first step in gear manufacturing is material preparation, where raw materials are selected based on the specific requirements of the gear type. Common materials include various grades of steel, aluminum, and engineering plastics. The choice of material directly affects the gear’s strength, weight, and resistance to wear.

Illustrative image related to does a gear have teeth

Once the material is chosen, it undergoes processes such as cutting and shaping to create blanks, which are essentially the rough forms of the gears. This stage may also include heat treatment processes to enhance the material properties, such as hardness and tensile strength, ensuring the gears can withstand operational stresses.

What Forming Techniques Are Used in Gear Production?

The next stage is forming, where the gear blanks are shaped into their final configurations. Common techniques include:

-

Hobbing: This is a widely used method for producing spur and helical gears. A rotating hob cuts the gear teeth into the blank, allowing for high precision and efficiency.

-

Shaping: This technique is used for internal gears and involves a cutting tool that moves across the blank to create teeth profiles.

-

Broaching: Ideal for producing gears with complex tooth shapes, broaching employs a multi-tooth cutting tool that removes material in a single pass.

-

Casting and Forging: For larger gears, casting or forging techniques may be used to create robust components. These methods are particularly beneficial for high-load applications.

Each of these techniques plays a vital role in achieving the desired tooth profile, accuracy, and surface finish, which are crucial for the gear’s performance.

How Are Gears Assembled and Finished?

After forming, the gears undergo assembly, which may involve fitting multiple gears together in gear trains or other mechanical systems. Precision during assembly is paramount to ensure proper meshing and functionality.

Finishing processes follow assembly and may include:

-

Grinding: This enhances the surface finish and dimensional accuracy of gear teeth, reducing friction and wear during operation.

-

Polishing: While not always necessary, polishing can improve aesthetic qualities and reduce surface roughness.

-

Coating: Applying protective coatings can enhance corrosion resistance and overall durability, especially for gears used in harsh environments.

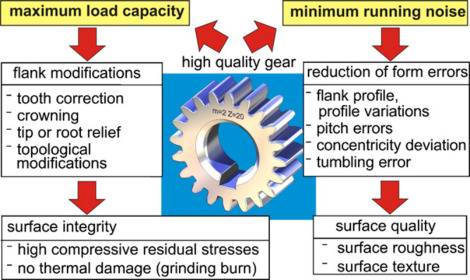

What Are the Quality Assurance Practices in Gear Manufacturing?

Quality assurance (QA) is critical in gear manufacturing, ensuring that the final products meet international standards and specific customer requirements. For B2B buyers, understanding these practices can facilitate better supplier relationships and product reliability.

What International Standards Govern Gear Quality?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring manufacturers consistently deliver products that meet customer expectations. Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector further validate a manufacturer’s commitment to quality.

Buyers should inquire about a supplier’s compliance with these standards to ensure they adhere to best practices in manufacturing and quality control.

What Are the Key Quality Control Checkpoints in Gear Production?

Quality control in gear manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specified requirements before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the process and ensure that the gears are being produced according to specifications. This can include dimensional checks and visual inspections.

-

Final Quality Control (FQC): Once manufacturing is complete, a comprehensive inspection is performed on the finished gears. This may include testing for hardness, tooth profile accuracy, and overall dimensional specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial to ensuring reliability and performance. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. This can be done directly or through third-party inspection agencies.

-

Request Quality Reports: Suppliers should be able to provide detailed reports on their quality control processes, including inspection results and compliance certifications. Reviewing these documents can help assess a supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s capabilities and adherence to quality standards. This is particularly important when sourcing from regions with varying manufacturing practices.

What Nuances Should International Buyers Consider in Gear Quality Control?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control:

-

Cultural and Regulatory Differences: Understanding the local manufacturing culture and regulatory environment can help buyers navigate quality assurance practices effectively. For instance, certain regions may have different tolerances for quality control failures.

-

Logistics and Supply Chain Considerations: The geographical location of suppliers can affect delivery times and the ability to perform on-site inspections. Buyers should factor this into their sourcing strategies.

-

Language Barriers: Clear communication is essential in ensuring quality expectations are understood. Engaging bilingual representatives or translators may be necessary to facilitate discussions with suppliers in different regions.

By considering these factors, B2B buyers can enhance their procurement processes and establish successful partnerships with gear manufacturers, ensuring the reliability and performance of their mechanical systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘does a gear have teeth’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure gears with teeth, a critical component in various industrial applications. Understanding the specifications, supplier capabilities, and operational requirements is essential to ensure you select the right gear for your needs. By following this step-by-step process, buyers can make informed decisions that enhance operational efficiency and reliability.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications of the gear you require. Consider factors such as gear type (e.g., helical, bevel, spur), material composition, size, and load capacity. Precise specifications will help streamline the sourcing process and enable suppliers to provide accurate quotes.

- Load Capacity: Determine the maximum load the gear will need to handle.

- Material Requirements: Decide if you need metal, plastic, or composite materials based on the application.

Step 2: Identify Your Application Needs

Understanding the specific application for which the gear will be used is crucial. Different gears serve distinct functions, such as torque transmission, speed reduction, or direction change. Knowing the operational context will guide your selection process.

- Operational Environment: Consider factors like temperature, humidity, and exposure to chemicals.

- Performance Requirements: Assess whether you need high-speed performance or high torque.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from buyers in similar industries. This step is vital to ensure you partner with a reputable manufacturer who can deliver quality products.

- Supplier Experience: Look for suppliers with a proven track record in your industry.

- Customer Testimonials: Seek feedback from previous clients regarding product performance and service quality.

Step 4: Check for Certifications and Compliance

Verify that your selected suppliers hold relevant certifications and comply with industry standards. This step ensures that the gears meet safety, quality, and performance benchmarks.

- ISO Certification: A supplier with ISO certification indicates a commitment to quality management.

- Industry Standards: Check for compliance with specific standards relevant to your application, such as ANSI or AGMA.

Step 5: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the gears. Testing these samples will help you verify their suitability for your application, ensuring they meet your technical specifications.

- Functional Testing: Assess how the gear operates under real-world conditions.

- Fit and Compatibility: Ensure that the gear fits seamlessly with existing machinery.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and warranty terms. Clear communication during this phase can lead to favorable terms that benefit both parties.

- Volume Discounts: Inquire about pricing breaks for larger orders.

- Warranty and Support: Discuss warranty conditions and after-sales support options.

Step 7: Finalize the Purchase Agreement

After successfully negotiating terms, finalize the purchase agreement. Ensure that all agreed-upon terms are documented to protect both parties and facilitate a smooth transaction.

Illustrative image related to does a gear have teeth

- Clear Deliverables: Specify delivery dates and quantities.

- Payment Terms: Establish clear payment schedules and methods.

By following this checklist, B2B buyers can confidently navigate the procurement process for gears with teeth, ensuring they select the most suitable options for their operational needs.

Comprehensive Cost and Pricing Analysis for does a gear have teeth Sourcing

What Are the Key Cost Components in Sourcing Gears?

When sourcing gears, the total cost structure typically comprises several critical components. Materials represent a substantial portion of the cost, with common options including steel, aluminum, and engineering plastics. The choice of material directly affects performance, durability, and, ultimately, the price. Labor costs also play a significant role, particularly in regions with higher wage standards or when skilled labor is required for precision manufacturing.

Manufacturing overhead encompasses expenses related to utilities, facility maintenance, and equipment depreciation, which can significantly impact the final price of gears. Tooling costs are particularly relevant for custom gears, as specialized molds and dies can be expensive to produce. Quality Control (QC) measures are essential for ensuring that gears meet industry standards, and the associated costs should be factored into the pricing. Lastly, logistics expenses, including shipping and handling, are crucial, especially for international transactions where tariffs and duties may apply.

How Do Price Influencers Affect Gear Sourcing?

Several factors influence the pricing of gears in the B2B marketplace. Volume and Minimum Order Quantity (MOQ) are significant; suppliers often offer discounts for larger orders, which can lead to substantial cost savings. Specifications and customization can also affect price. Gears designed for specific applications or with unique features typically come at a premium.

The choice of materials and their quality certifications can further impact pricing. High-grade materials with certifications like ISO or ANSI may be more expensive but provide better performance and longevity. Supplier factors such as reputation, reliability, and location also play a crucial role. Suppliers in regions with robust manufacturing capabilities may offer competitive prices, while those in emerging markets may provide cost advantages due to lower labor costs.

Additionally, understanding Incoterms is vital for international buyers. These terms dictate who is responsible for shipping costs, insurance, and risk during transport, which can significantly affect the total cost of ownership.

What Are Effective Buyer Tips for Negotiating Gear Prices?

B2B buyers should adopt strategic approaches when negotiating gear prices to ensure they receive the best value. One effective strategy is to conduct a Total Cost of Ownership (TCO) analysis, which goes beyond the initial purchase price to include maintenance, operational costs, and potential downtime. This comprehensive view helps buyers understand the long-term implications of their purchasing decisions.

Negotiation is key, and buyers should be prepared to discuss pricing openly. Building a relationship with suppliers can lead to better terms and discounts, especially for repeat business. Additionally, buyers should leverage market research to understand prevailing prices and supplier capabilities, enabling them to negotiate from an informed position.

Illustrative image related to does a gear have teeth

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s important to be aware of pricing nuances related to currency fluctuations, import/export regulations, and local market conditions. Engaging with local representatives or consultants can provide valuable insights and help navigate these complexities.

What Should Buyers Keep in Mind About Indicative Prices?

It’s essential to approach pricing with a clear understanding that indicative prices can vary widely based on numerous factors. Fluctuations in raw material costs, changes in labor rates, and evolving market dynamics can all affect the prices of gears. Buyers should request detailed quotes from multiple suppliers to compare offers comprehensively.

Ultimately, a thorough understanding of the cost structure and pricing influencers, coupled with strategic negotiation tactics, can empower B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing does a gear have teeth With Other Solutions

Exploring Alternatives to Gears with Teeth

In the realm of mechanical engineering and industrial applications, gears with teeth are foundational components used to transfer motion and force between different parts of machinery. However, there are alternative solutions that can also achieve similar objectives, each with unique benefits and drawbacks. This analysis will explore how gears with teeth compare to two viable alternatives: belt drives and chain drives.

Comparison Table

| Comparison Aspect | Does A Gear Have Teeth | Belt Drive | Chain Drive |

|---|---|---|---|

| Performance | High efficiency and torque transfer; suitable for high-load applications | Moderate efficiency; best for lower torque applications | High efficiency; excels in high-load scenarios |

| Cost | Higher initial cost due to manufacturing precision | Lower initial cost; inexpensive materials | Moderate cost; requires durable materials |

| Ease of Implementation | Requires precise alignment and installation | Simple installation; less precision needed | Requires careful alignment; more complex than belts |

| Maintenance | Regular lubrication needed; can wear over time | Minimal maintenance; occasional tension adjustments | Regular lubrication and tension adjustments needed |

| Best Use Case | Heavy-duty machinery, high-torque applications | Light to moderate power transmission, such as in fans and conveyors | High-load applications, such as bicycles and motorcycles |

In-Depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Belt Drives?

Belt drives utilize flexible belts to transmit power between pulleys. They are often favored for their simplicity and cost-effectiveness. The advantages include lower initial costs and minimal maintenance requirements. However, belt drives generally offer moderate efficiency and are not ideal for high-torque applications. They can slip under heavy loads, which may lead to performance issues in demanding environments.

How Do Chain Drives Compare in Performance?

Chain drives are similar to gears in that they use links to transfer motion and power. They are highly efficient and excel in high-load applications, making them suitable for machinery like motorcycles and industrial conveyors. The main benefits of chain drives include their strength and durability under heavy loads. However, they require regular maintenance, including lubrication and tension adjustments, which can increase operational costs over time.

Conclusion: Choosing the Right Mechanical Solution for Your Needs

When selecting between gears with teeth, belt drives, and chain drives, B2B buyers must consider several factors including the specific application, budget constraints, and maintenance capabilities. Gears are best suited for high-torque and heavy-duty applications, while belt drives may be more appropriate for lighter loads and cost-sensitive projects. Chain drives serve as a robust alternative for high-load scenarios but require diligent upkeep. Ultimately, understanding the unique characteristics of each option will empower buyers to make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for does a gear have teeth

What Are the Key Technical Properties of Gears with Teeth?

Understanding the essential technical properties of gears is crucial for B2B buyers involved in manufacturing, engineering, and other industrial sectors. Here are six critical specifications that influence gear performance and selection:

-

Material Grade

Gears are typically made from various materials, including steel, brass, aluminum, and engineering plastics. The material choice affects strength, weight, corrosion resistance, and wear characteristics. For instance, steel gears offer high tensile strength and durability, making them suitable for heavy-duty applications. Buyers should consider the operational environment and load requirements when selecting materials to ensure longevity and reliability. -

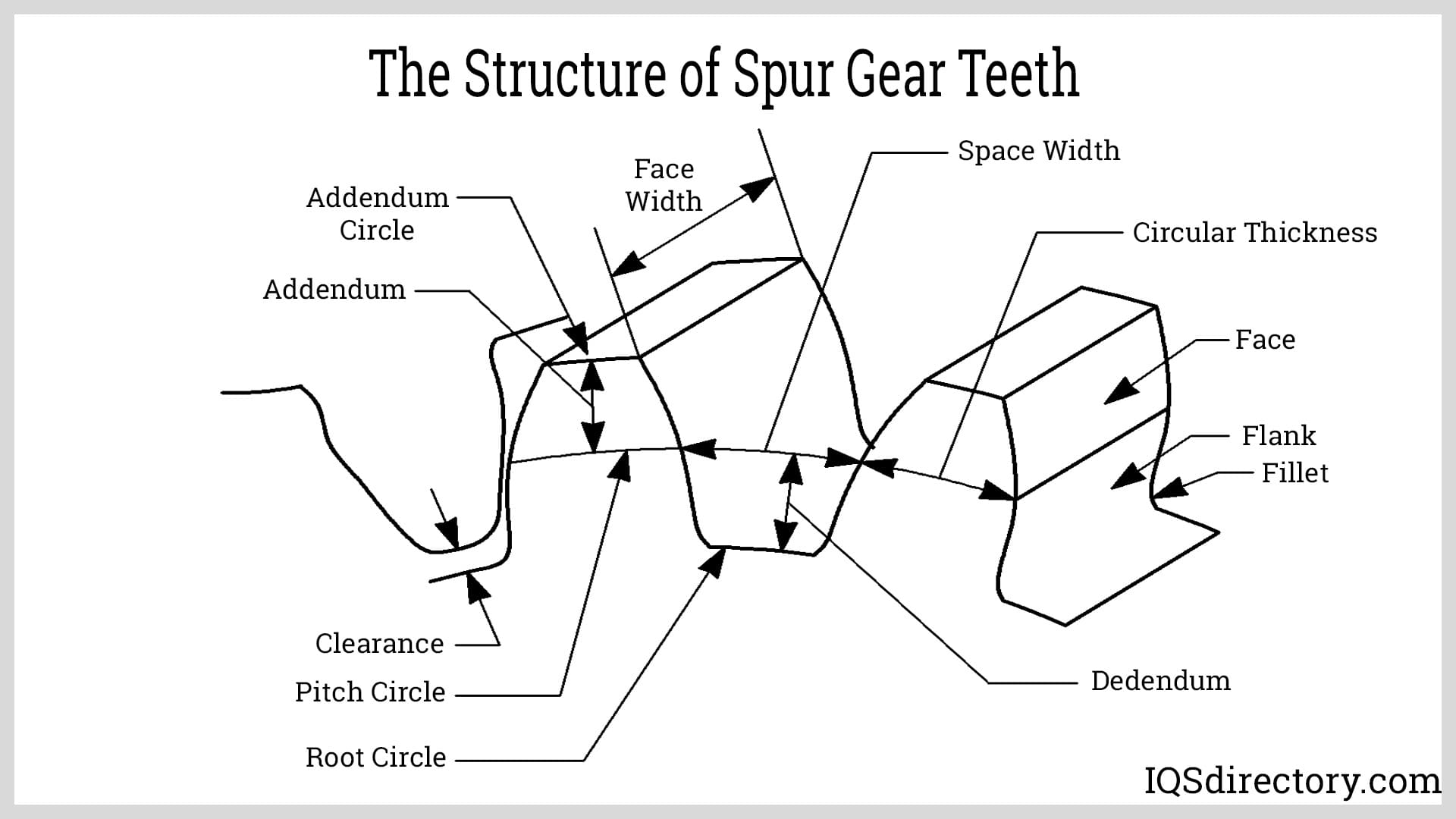

Tooth Profile and Design

The shape and design of gear teeth significantly impact performance. Common tooth profiles include spur, helical, and bevel. Helical gears, for example, feature angled teeth that provide smoother engagement and higher load capacities. A proper understanding of tooth profiles helps in selecting gears that minimize noise and vibration while maximizing efficiency in specific applications. -

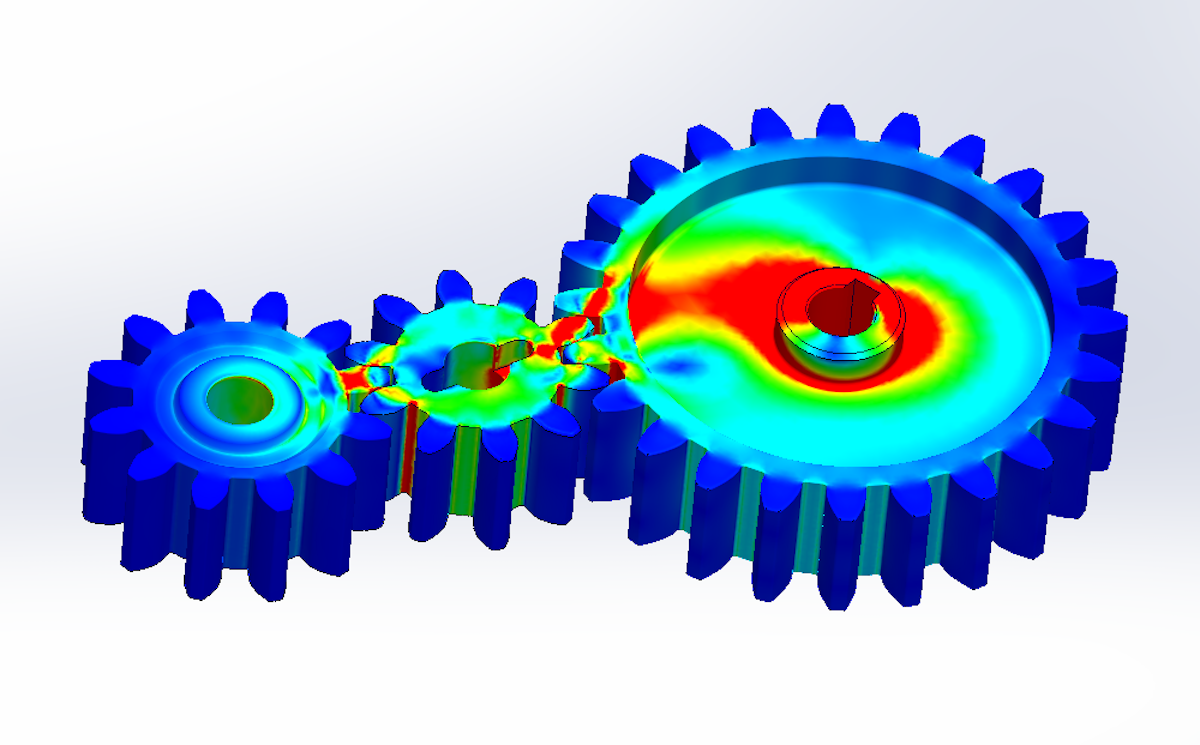

Tolerance and Precision

Tolerance levels indicate the allowable deviation from specified dimensions. High precision is vital in applications requiring accurate motion transfer. For instance, automotive and aerospace industries demand tight tolerances to ensure performance and safety. B2B buyers should specify tolerance requirements in their procurement processes to avoid operational failures. -

Load Capacity

Load capacity refers to the maximum load a gear can handle without failure. This property is influenced by gear size, material, and design. Understanding load capacity is critical for buyers to ensure that the selected gears can withstand operational demands without premature wear or damage, especially in heavy machinery and industrial applications. -

Gear Ratio

Gear ratio is the relationship between the number of teeth on two meshing gears. This ratio determines speed reduction and torque multiplication. For example, a higher gear ratio means slower output speed but increased torque. Buyers should assess the required gear ratio for their applications to achieve optimal performance. -

Surface Finish

The surface finish of gears can influence friction, wear, and noise levels. A smoother surface finish generally reduces friction and enhances the gear’s lifespan. Buyers should evaluate surface finish requirements based on the operational context, especially in high-speed applications where heat generation is a concern.

What Are Common Trade Terms Related to Gears?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to gear procurement:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of gears, OEMs are crucial for ensuring compatibility and quality in replacement parts. Buyers often rely on OEM specifications to maintain equipment performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory costs and ensure sufficient supply without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. It helps streamline the procurement process by gathering competitive pricing and terms. Buyers should prepare comprehensive RFQs to facilitate accurate and timely responses. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and risk management. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics when procuring gears globally. -

Lead Time

Lead time is the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management and production scheduling. Buyers should factor in lead times when planning their operations to prevent delays in project timelines. -

Customization

Customization refers to the process of altering standard gear designs to meet specific requirements. Many manufacturers offer customization options to address unique operational needs. Buyers should explore customization opportunities to enhance the performance of gears in their applications.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing gears, ensuring optimal performance and reliability in their operations.

Navigating Market Dynamics and Sourcing Trends in the does a gear have teeth Sector

What Are the Current Market Dynamics and Key Trends in the Gear Sector?

The global gear market is experiencing significant growth, driven by advancements in technology and increasing industrial applications. As industries evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is a notable shift towards the adoption of innovative gear solutions. The demand for high-performance gears, such as helical and bevel gears, is on the rise due to their ability to enhance operational efficiency and reduce noise levels. Additionally, the expansion of renewable energy projects is creating new opportunities for gear suppliers, especially in wind and hydroelectric power generation.

Emerging technologies, including automation and smart manufacturing, are reshaping sourcing trends. B2B buyers are increasingly seeking suppliers who can provide integrated gear systems that include advanced monitoring and predictive maintenance capabilities. This trend is particularly relevant for industries such as mining and manufacturing, where downtime can lead to significant losses. Moreover, digital platforms and e-commerce solutions are streamlining the procurement process, allowing international buyers to connect with manufacturers more efficiently.

In the context of sourcing, buyers are looking for suppliers with robust logistics capabilities to ensure timely delivery, particularly in regions with complex supply chains. The ability to offer customized gear solutions tailored to specific applications is becoming a critical differentiator among suppliers, making partnerships with manufacturers who can provide tailored designs increasingly important.

How is Sustainability and Ethical Sourcing Impacting the Gear Industry?

Sustainability is becoming a cornerstone of purchasing decisions in the gear sector. B2B buyers are increasingly aware of the environmental impact of their supply chains, pushing manufacturers to adopt greener practices. This includes utilizing eco-friendly materials, such as recycled metals and bioplastics, in gear production. Manufacturers are also implementing energy-efficient processes to minimize their carbon footprint.

Ethical sourcing is equally crucial. Buyers are demanding transparency regarding the sourcing of raw materials, ensuring that they come from responsible suppliers. Certifications like ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for manufacturers aiming to prove their commitment to sustainability. By prioritizing suppliers with these certifications, international buyers can align their procurement strategies with global sustainability goals.

Furthermore, the adoption of circular economy principles is gaining traction. Manufacturers are exploring take-back programs for worn-out gears, promoting recycling and re-manufacturing. This shift not only supports environmental initiatives but also offers cost-saving opportunities for buyers looking to reduce waste and enhance operational efficiency.

What is the Historical Context of Gear Development and Its Relevance Today?

The history of gears dates back to the fourth century BC, when they were first utilized in simple machines. Over the centuries, gear design has evolved significantly, transitioning from rudimentary wooden gears to highly engineered metal components. The Industrial Revolution marked a pivotal moment, as gears became integral to machinery, driving advancements in manufacturing and transportation.

Today, the evolution of gears continues to influence various sectors. The introduction of computer-aided design (CAD) and manufacturing (CAM) technologies has revolutionized gear production, allowing for precise customization and rapid prototyping. As industries increasingly rely on automation and robotics, the demand for specialized gears, such as planetary and worm gears, is expected to grow. Understanding the historical context of gear development not only highlights the importance of innovation but also underscores the necessity for B2B buyers to partner with manufacturers who can offer both legacy knowledge and cutting-edge solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of does a gear have teeth

-

How do I choose the right gear type for my application?

Choosing the right gear type involves evaluating several critical factors. First, consider the load capacity required for your application; helical and bevel gears excel in high-torque environments, while worm gears are ideal for high-reduction ratios. Next, assess the speed and noise tolerance needed, as some gear types, like spiral bevel gears, offer smoother operations. Additionally, environmental conditions and space constraints should influence your decision. Consulting with experienced manufacturers can help you navigate these considerations effectively to ensure optimal performance. -

What types of gears have teeth, and how do they differ?

Most gears have teeth, which are essential for transferring motion and power. Common types include spur gears, which have straight, parallel teeth; helical gears, with angled teeth for smoother operation; and bevel gears, which connect non-parallel shafts. Worm gears feature a screw-like design for speed reduction, while planetary gears consist of a sun gear and orbiting planet gears. Each type’s tooth design impacts efficiency, noise, and load capacity, making it crucial to select the appropriate gear for your specific application. -

What are the benefits of using helical gears over spur gears?

Helical gears offer several advantages compared to spur gears. The angled teeth of helical gears allow for multiple points of contact, resulting in smoother operation and reduced noise levels. They also distribute forces more evenly, enhancing load capacity and minimizing wear. While helical gears may require more robust bearings due to axial thrust, their ability to handle higher torque makes them suitable for demanding applications in sectors like mining, marine, and energy. -

How can I vet a supplier for industrial gears?

When vetting a supplier for industrial gears, start by assessing their experience and expertise in your specific industry. Request references and case studies to evaluate their performance history. It’s also crucial to review their manufacturing capabilities, quality assurance processes, and certifications (e.g., ISO). Additionally, consider their ability to customize gears based on your specifications and their responsiveness to inquiries. Visiting their facility or arranging a virtual meeting can provide further insight into their operations and reliability. -

What customization options are available for industrial gears?

Customization options for industrial gears are extensive and can include modifications in size, tooth design, material, and surface treatment. Many manufacturers offer tailored solutions to meet specific operational requirements, such as load capacity and environmental conditions. Discussing your unique needs with suppliers can lead to innovative solutions, such as specialized coatings for enhanced durability or custom gear ratios for optimized performance. Ensure your supplier has a robust design and engineering team to facilitate these customizations effectively. -

What are the typical minimum order quantities (MOQs) for gears?

Minimum order quantities (MOQs) for gears vary widely based on the manufacturer, gear type, and customization requirements. Standard gears may have lower MOQs, while specialized or custom gears often require larger orders to justify production costs. When sourcing gears, inquire about MOQs early in the negotiation process to align your purchasing strategy with your project needs. Some suppliers may offer flexibility for trial orders or smaller quantities, especially for new clients or initial projects. -

What payment terms should I expect when sourcing gears internationally?

Payment terms for international gear sourcing can vary significantly by supplier and region. Common practices include advance payment, letters of credit, or payment upon delivery. It’s essential to clarify payment terms upfront to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and international transaction fees. Establishing a solid relationship with your supplier can also lead to more favorable payment terms over time, particularly as you demonstrate reliability in your purchasing history. -

How can I ensure quality assurance (QA) in gear manufacturing?

To ensure quality assurance in gear manufacturing, start by selecting suppliers with robust QA processes and certifications (e.g., ISO 9001). Request detailed information on their testing and inspection procedures, including materials, dimensional accuracy, and performance testing. Regular audits and on-site visits can help verify compliance with quality standards. Additionally, consider establishing clear specifications and performance criteria in your contracts, allowing for accountability and recourse if quality issues arise during production.

Top 8 Does A Gear Have Teeth Manufacturers & Suppliers List

1. KHK Gears – Types of Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Types of Gears: Spur Gears, Helical Gears, Gear Rack, Worm Gears, Bevel Gears, Miter Gears, Internal Gears, Screw Gears. Key Characteristics: Spur Gears – cylindrical with straight teeth, no axial load; Helical Gears – winding teeth, better meshing, thrust force; Gear Rack – converts rotational to linear motion; Bevel Gears – cone-shaped for intersecting shafts; Spiral Bevel Gears – curved teeth f…

2. Philagear – Industrial Gear Solutions

Domain: philagear.com

Introduction: Common industrial gear types include: 1. Helical Gears: Cylinder-shaped with angled teeth for smoother operation, higher load capacity, and applications in mining, marine, energy, and infrastructure. 2. Double Helical Gears: Two helical gears counterbalancing thrust, ideal for power generation, marine, oil and gas, mining, and cement applications. 3. Crossed Helical Gears: Designed for non-paralle…

3. Reddit – Spur Gear Considerations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Factors to consider for spur gear teeth include the relative number of teeth between two gears to avoid accelerated damage, the need for gears to have the same Module or Diametral Pitch for compatibility, and a minimum teeth count of 19 for smooth operation, ideally not going below 13. The goal is to maintain a close drive ratio while ensuring that the teeth interact in a way that minimizes wear a…

4. IQS Directory – Gears and Torque Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Gears are rotating circular devices with teeth designed to convey torque and adjust speed between shafts. They operate on the lever principle, altering power direction, speed, and torque. Gears come in various shapes (involute, cycloidal, trochoidal) and shaft positions (parallel, intersecting, non-parallel/non-intersecting). Key measurements include root radius, addendum radius, pitch circle diam…

5. The Naked Scientists – Gear Teeth Explained

Domain: thenakedscientists.com

Registered: 2001 (24 years)

Introduction: This company, The Naked Scientists – Gear Teeth Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Nakamura-Tome – Multitasking Gear Machining Solutions

Domain: nakamura-tome.com

Introduction: Nakamura-Tome multitasking machines excel in gear machining by offering integrated solutions for various gear production methods. They provide easy gear machining programming support software and streamlined setup, making gear production efficient and user-friendly.

7. ScienceDirect – Gear Teeth Essentials

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Gear teeth are essential elements of gears that include the tooth surface and profile, flank, top and bottom land, crown, root, and pitch circle. They are critical for the functionality of gears, which are vital for power transmission between shafts. Key aspects include: 1. **Common Elements**: Tooth surface and profile, flank, top and bottom land, crown, root, pitch circle, gear center, line of c…

8. Ondrives – Helical and Spur Gears

Domain: ondrivesus.com

Registered: 2007 (18 years)

Introduction: Helical and spur gears are used for mechanical drives to transmit motion, power, and torque. Key differences include:

– Helical gears have teeth inclined at an angle, while spur gears have straight teeth parallel to the gear axis.

– Helical gears impose both radial and axial loads on bearings, whereas spur gears impose only radial loads.

– Helical gears can be used for both parallel and crossed…

Strategic Sourcing Conclusion and Outlook for does a gear have teeth

Why is Strategic Sourcing Essential for Gear Procurement?

In the ever-evolving landscape of industrial applications, understanding the types and functionalities of gears is crucial for optimizing operational efficiency. Gears, with their varying tooth designs and configurations, play a pivotal role in the performance of machinery across sectors such as mining, energy, and manufacturing. By strategically sourcing the right gear type—be it helical, bevel, or worm gears—businesses can enhance productivity, reduce maintenance costs, and improve overall system reliability.

Moreover, engaging with trusted manufacturers ensures access to high-quality products tailored to specific industry needs. This approach not only mitigates risks associated with equipment failure but also supports sustainable practices by optimizing resource utilization.

As we look ahead, international B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to leverage strategic sourcing as a means to stay competitive in the global market. By prioritizing quality and reliability in gear procurement, businesses can position themselves for future growth. Now is the time to connect with experienced suppliers who can provide the insights and products necessary to drive your operations forward.

Illustrative image related to does a gear have teeth

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.