Top 8 3 Pinned Plug Suppliers (And How to Choose)

Introduction: Navigating the Global Market for 3 pinned plug

In an increasingly interconnected world, international B2B buyers face the challenge of sourcing reliable 3 pinned plugs that meet both local standards and global quality expectations. The diverse applications of these essential electrical components—from industrial machinery to consumer electronics—underscore the necessity for thorough supplier vetting and a nuanced understanding of regional compliance requirements. This comprehensive guide delves into the various types of 3 pinned plugs available, their specific applications across different industries, and essential factors to consider when evaluating suppliers.

Buyers will gain insights into pricing structures, including bulk purchasing options that can significantly impact overall procurement costs. Additionally, this guide emphasizes the importance of quality certifications and product specifications, ensuring that buyers can confidently navigate their sourcing decisions.

By equipping B2B purchasers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—with actionable insights and strategic guidance, we aim to empower informed purchasing decisions. This resource not only streamlines the sourcing process but also fosters partnerships that enhance operational efficiency and product reliability. Whether you are a seasoned buyer or new to the market, understanding the dynamics of 3 pinned plugs is crucial for optimizing your supply chain and ensuring compliance with international standards.

Understanding 3 pinned plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DT 3-Pin Plug | Solid black or nickel finish, robust industrial design | Automotive, industrial equipment | Pros: Durable, available in bulk, fast shipping. Cons: Limited to specific industrial uses. |

| 3-Pin Round Mains Plug | Standardized design, typically rated for 15A | Household appliances, lighting systems | Pros: Widely compatible, easy to source. Cons: May not suit high-power applications. |

| 3-Pin Screw Terminal Connector | Accommodates various wire sizes, adaptable design | Data logging, sensor connections | Pros: Versatile, easy installation. Cons: Requires knowledge of wire sizes for proper use. |

| 3-Pin Field Installable Plug | High current capacity, field-installable | Outdoor equipment, temporary setups | Pros: Customizable, reliable under harsh conditions. Cons: Higher upfront cost. |

| 3-Pin EFI Connector | Designed for automotive applications, heat-resistant | Fuel injection systems, automotive repairs | Pros: Specialized for vehicles, robust design. Cons: Limited to automotive sector. |

What are the Characteristics of the DT 3-Pin Plug?

The DT 3-Pin Plug is a popular choice in industrial applications due to its solid construction and durability. Available in both black and nickel finishes, these plugs are designed to withstand harsh environments, making them ideal for automotive and industrial equipment. B2B buyers should consider the bulk pricing options, as this can significantly reduce costs for large orders. However, these plugs may not be suitable for general consumer applications.

How Does the 3-Pin Round Mains Plug Serve Various Industries?

The 3-Pin Round Mains Plug is a standardized connector commonly used in household appliances and lighting systems. Rated for 15A, this plug is widely recognized and easily sourced, making it a go-to choice for many businesses. Its compatibility with various devices is a key advantage, although it may not be suitable for high-power applications, which could limit its use in certain industrial settings.

What Makes the 3-Pin Screw Terminal Connector Versatile?

The 3-Pin Screw Terminal Connector is known for its adaptability, accommodating wire sizes from 12 to 24 AWG. This feature makes it particularly useful in data logging and sensor connections, where flexibility is crucial. B2B buyers should consider ease of installation and the need for specific wire sizes, as this can impact the efficiency of their projects. While versatile, proper knowledge of wire specifications is necessary for optimal use.

Why Choose the 3-Pin Field Installable Plug for Outdoor Applications?

Designed for high current capacity, the 3-Pin Field Installable Plug is an excellent choice for outdoor equipment and temporary setups. Its customizable nature allows businesses to adapt it for various applications, providing reliability even in harsh conditions. Although the initial cost may be higher than standard plugs, the long-term benefits of durability and adaptability can justify the investment for many B2B buyers.

What Are the Benefits of the 3-Pin EFI Connector in Automotive Applications?

The 3-Pin EFI Connector is specifically engineered for automotive applications, making it essential for fuel injection systems and automotive repairs. Its heat-resistant design ensures longevity and reliability in demanding environments. B2B buyers in the automotive sector should consider this connector for its specialized features, although its limited application outside the automotive industry may restrict its versatility in broader contexts.

Key Industrial Applications of 3 pinned plug

| Industry/Sector | Specific Application of 3 pinned plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electrical connectors for vehicle wiring | Ensures reliable electrical connections, reducing downtime and maintenance costs | Quality certifications, compatibility with existing systems, and environmental ratings |

| Industrial Machinery | Power supply connections for machinery | Provides efficient power delivery, enhancing productivity and operational safety | Voltage ratings, durability under heavy use, and compliance with international standards |

| Renewable Energy | Connections in solar energy systems | Supports efficient energy transfer, crucial for maximizing system output | Weather resistance, compatibility with various solar technologies, and ease of installation |

| Telecommunications | Signal and power connections in telecom devices | Enhances communication reliability, minimizing signal loss and system failures | Quality of materials, resistance to interference, and ease of integration into existing infrastructure |

| Consumer Electronics | Power connections in home appliances | Ensures safety and efficiency in energy consumption, leading to customer satisfaction | Compliance with local electrical standards, safety certifications, and design flexibility |

How Are 3 Pinned Plugs Utilized in the Automotive Sector?

In the automotive industry, 3 pinned plugs are essential for establishing robust electrical connections within vehicle wiring systems. These connectors facilitate the seamless operation of critical components like sensors, lights, and engine controls. By ensuring reliable connectivity, they help minimize downtime and reduce maintenance costs, which is particularly important for automotive manufacturers and suppliers. When sourcing these plugs, buyers should prioritize quality certifications and compatibility with existing wiring systems, especially in regions like Africa and South America where varying standards may exist.

What Role Do 3 Pinned Plugs Play in Industrial Machinery?

In industrial settings, 3 pinned plugs are commonly used for power supply connections to machinery. They ensure efficient power delivery, which is vital for maintaining productivity and operational safety. The durability of these connectors under heavy usage conditions is a critical consideration for buyers. Additionally, compliance with international electrical standards is paramount, particularly for businesses in the Middle East and Europe that may operate across multiple jurisdictions. Buyers should also assess the voltage ratings to ensure compatibility with their specific machinery.

How Are 3 Pinned Plugs Integral to Renewable Energy Systems?

In renewable energy applications, such as solar energy systems, 3 pinned plugs are used for electrical connections that facilitate energy transfer between panels, inverters, and storage systems. These connectors are designed to withstand environmental challenges, ensuring efficient energy delivery crucial for maximizing system output. Buyers in regions with high solar potential, like parts of Africa and the Middle East, should focus on sourcing plugs that offer weather resistance and compatibility with various solar technologies to ensure long-term performance and reliability.

Why Are 3 Pinned Plugs Important in Telecommunications?

The telecommunications sector relies on 3 pinned plugs for both signal and power connections in devices and infrastructure. Their role in enhancing communication reliability is critical, as they minimize signal loss and potential system failures. For international buyers, especially in Europe and South America, sourcing connectors with high-quality materials and resistance to interference is essential. Ensuring ease of integration into existing telecom infrastructure will also facilitate smoother operations and reduce installation costs.

How Do 3 Pinned Plugs Enhance Consumer Electronics?

In consumer electronics, 3 pinned plugs are vital for power connections in various home appliances, ensuring safe and efficient energy consumption. These connectors contribute significantly to customer satisfaction by enhancing the reliability and performance of devices. When sourcing these plugs, businesses must consider compliance with local electrical standards and safety certifications, particularly in diverse markets across Africa and Europe. Additionally, design flexibility can help manufacturers adapt to varying product specifications, enhancing their market competitiveness.

3 Common User Pain Points for ‘3 pinned plug’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: Many B2B buyers sourcing 3 pinned plugs face the challenge of inconsistent quality when ordering from different suppliers. This inconsistency can lead to compatibility issues, increased failure rates, and ultimately, unsatisfied customers. For instance, a company in Nigeria may find that plugs sourced from one supplier work perfectly with their machinery, while those from another supplier fail to perform under similar conditions. This variability can disrupt operations, create safety hazards, and lead to costly downtime.

The Solution: To mitigate quality inconsistencies, B2B buyers should establish long-term relationships with reputable suppliers who adhere to rigorous quality control standards. It is advisable to request detailed product specifications and certifications, such as ISO or AS9120B compliance, that ensure adherence to industry standards. Buyers can also conduct sample testing before committing to large orders, allowing them to assess the plugs’ performance under their specific conditions. Furthermore, joining industry forums or groups can provide insights into reliable suppliers and user experiences, helping buyers make informed decisions.

Scenario 2: Difficulty in Finding Compatible Connectors

The Problem: Another common issue arises when B2B buyers struggle to find 3 pinned plugs that are compatible with existing equipment. For businesses in South America, this might involve integrating new electrical components into older machinery, which may not have standardized connections. This incompatibility can lead to expensive modifications, increased installation times, and potential operational disruptions.

The Solution: To address compatibility issues, it is crucial to have a comprehensive understanding of the existing equipment’s specifications and electrical requirements. Buyers should engage with manufacturers to identify which 3 pinned plugs are designed to work with their equipment. Additionally, leveraging universal connectors or adapters can provide flexible solutions for bridging compatibility gaps. When purchasing, it’s wise to consider modular systems that allow for easy upgrades and replacements, ensuring future adaptability. Regularly consulting with electrical engineers or technicians can also help in selecting the right products that fit seamlessly with existing systems.

Scenario 3: High Shipping Costs and Delays

The Problem: B2B buyers, particularly those in the Middle East and Africa, often encounter high shipping costs and delays when sourcing 3 pinned plugs from international suppliers. These logistical challenges can lead to increased operational costs and missed project deadlines, particularly when urgent replacements or bulk orders are needed for ongoing projects. For instance, a construction firm may require immediate replacements for faulty connectors but faces long lead times and excessive shipping fees from overseas suppliers.

The Solution: To combat high shipping costs and delays, buyers should consider sourcing from local suppliers or manufacturers within their region. This not only reduces shipping expenses but also shortens lead times, allowing for quicker turnaround on essential components. Additionally, buyers can negotiate bulk purchasing agreements to lower overall shipping costs. Establishing a robust inventory management system to track stock levels can help prevent last-minute orders, ensuring that necessary plugs are always available on hand. Exploring partnerships with logistics providers that specialize in B2B shipping can also lead to more favorable shipping rates and improved delivery times.

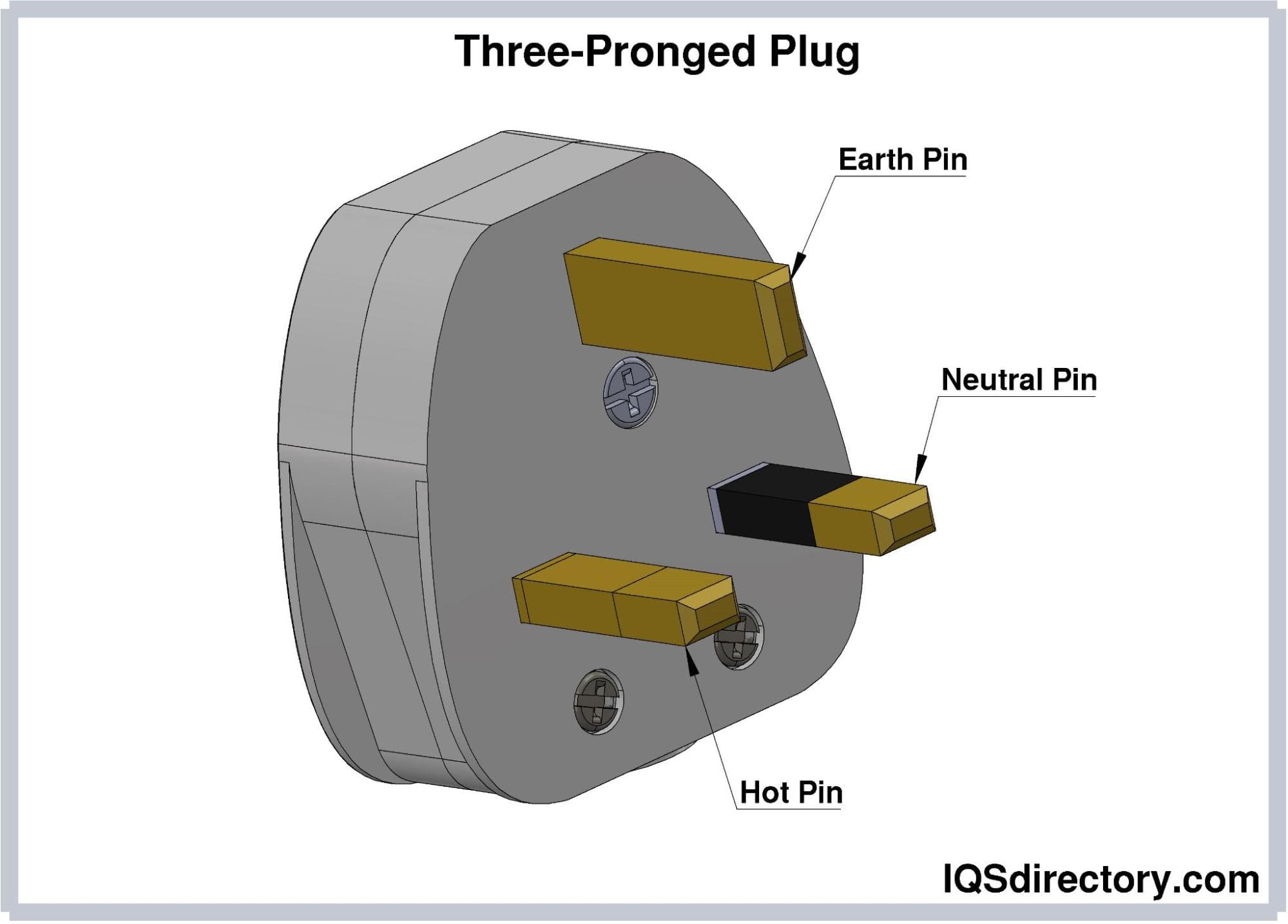

Illustrative image related to 3 pinned plug

By proactively addressing these pain points, B2B buyers can enhance their procurement processes, improve operational efficiency, and ultimately drive greater satisfaction among their customers.

Strategic Material Selection Guide for 3 pinned plug

What Materials Are Commonly Used for 3-Pinned Plugs and Their Properties?

When selecting materials for 3-pinned plugs, it is crucial to consider their performance characteristics, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of 3-pinned plugs: thermoplastic, thermoset, metal, and rubber.

How Do Thermoplastics Perform in 3-Pinned Plug Applications?

Thermoplastics, such as polyvinyl chloride (PVC) and nylon, are widely used in 3-pinned plugs due to their excellent electrical insulation properties and versatility. They can withstand moderate temperatures, typically up to 85°C, and are resistant to moisture and chemicals, making them suitable for various environments.

Illustrative image related to 3 pinned plug

Pros: Thermoplastics are lightweight, cost-effective, and easy to mold, allowing for complex designs. They also provide good impact resistance and can be produced in various colors for easy identification.

Cons: However, thermoplastics may not perform well under extreme temperatures or heavy mechanical stress, which could lead to deformation or failure. Their long-term exposure to UV light can also degrade their properties.

Impact on Application: Thermoplastics are ideal for general-purpose applications, especially where electrical insulation is critical. Buyers in regions like Africa and South America should ensure compliance with local electrical standards to avoid safety hazards.

What Are the Advantages of Thermoset Materials for 3-Pinned Plugs?

Thermoset materials, such as epoxy and phenolic resins, are known for their high thermal stability and mechanical strength. They can withstand higher temperatures (up to 150°C) and are less prone to deformation under stress compared to thermoplastics.

Pros: These materials offer superior durability and resistance to chemical exposure, making them suitable for harsh environments. They also have excellent electrical insulating properties.

Cons: The manufacturing process for thermosets is more complex and costly, which can increase the overall price of the plugs. Additionally, once set, thermosets cannot be reshaped or remolded.

Impact on Application: Thermoset plugs are ideal for industrial applications where high performance and reliability are paramount. Buyers from the Middle East and Europe should consider compliance with ASTM and DIN standards for thermoset materials.

How Do Metals Enhance the Performance of 3-Pinned Plugs?

Metal materials, such as brass or stainless steel, are often used in the pins of 3-pinned plugs due to their excellent conductivity and strength. Metal connectors can handle high electrical loads and are highly resistant to wear and corrosion.

Pros: Metals provide superior durability and are less likely to fail under mechanical stress. They are also resistant to environmental factors, such as moisture and temperature fluctuations.

Cons: The primary drawback is their higher cost and weight compared to plastic materials. Additionally, metals can be susceptible to corrosion if not properly treated or coated.

Impact on Application: Metal pins are essential in high-power applications, particularly in industrial settings. Buyers should ensure that metal components comply with international standards to avoid compatibility issues.

What Role Does Rubber Play in 3-Pinned Plug Design?

Rubber is often used for the insulation and sealing of 3-pinned plugs, providing flexibility and excellent moisture resistance. It can withstand a wide range of temperatures and is often used in outdoor applications.

Pros: Rubber is highly durable, flexible, and resistant to environmental factors, making it suitable for outdoor and industrial applications. It also provides good electrical insulation.

Cons: However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures. Its manufacturing process can also be more complex, leading to higher costs.

Impact on Application: Rubber-sealed plugs are ideal for applications requiring waterproofing and flexibility. Buyers in humid regions, like parts of Africa, should prioritize rubber materials to ensure longevity and reliability.

Summary Table of Material Selection for 3-Pinned Plugs

| Material | Typical Use Case for 3 Pinned Plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | General-purpose electrical applications | Lightweight and cost-effective | Limited temperature and mechanical strength | Low |

| Thermoset | Industrial applications requiring high performance | High thermal stability and durability | Higher manufacturing complexity | Medium |

| Metal | High-power industrial applications | Superior conductivity and durability | Higher cost and weight | High |

| Rubber | Outdoor and moisture-sensitive applications | Excellent flexibility and moisture resistance | Degradation over time | Medium |

This guide provides essential insights for B2B buyers in diverse regions, aiding in the selection of the most suitable materials for their specific applications and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 pinned plug

What Are the Key Stages in the Manufacturing Process of 3-Pinned Plugs?

Manufacturing 3-pinned plugs involves several critical stages, each integral to ensuring a high-quality final product. The process typically includes material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, such as thermoplastics for housings and copper alloys for contacts. Suppliers must ensure that materials meet international standards, such as RoHS compliance, to avoid hazardous substances. Quality control begins at this stage, where incoming materials are inspected for defects.

-

Forming: This stage includes the molding of plastic housings and stamping or machining of metal contacts. Injection molding is commonly used for plastic components, ensuring precision and uniformity. For metal contacts, techniques such as die-casting or extrusion are employed. Each method requires strict adherence to specifications to maintain consistency and functionality.

-

Assembly: After forming, components are assembled. Automated assembly lines are often utilized for efficiency, where connectors are fitted with their respective pins, and wiring is attached. Skilled operators perform manual checks during this stage to ensure proper alignment and connection integrity.

-

Finishing: The final stage involves surface treatment processes, such as plating for corrosion resistance and aesthetic enhancement. Products may undergo additional treatments like insulation and labeling. This stage ensures that the plugs are not only functional but also visually appealing and compliant with safety regulations.

How Is Quality Assurance Integrated into the Manufacturing of 3-Pinned Plugs?

Quality assurance (QA) is a vital part of the manufacturing process for 3-pinned plugs, ensuring that products meet both industry standards and customer expectations. Various international and industry-specific standards guide these QA processes.

-

International Standards: Compliance with ISO 9001 is essential, as it outlines criteria for a quality management system. Adhering to this standard helps manufacturers maintain a consistent quality level and improve customer satisfaction. Additionally, certifications such as CE mark and UL listing may be required for products to ensure safety and compliance in specific markets.

-

Key Quality Control Checkpoints:

– Incoming Quality Control (IQC): At this stage, materials are inspected upon arrival. This includes checking certifications and conducting random sampling tests to verify quality.

– In-Process Quality Control (IPQC): During manufacturing, operators conduct ongoing checks to ensure that the assembly process adheres to specifications. This may include visual inspections and functional testing of components.

– Final Quality Control (FQC): Before shipping, each batch undergoes a final inspection where products are tested for electrical conductivity, insulation resistance, and mechanical durability. -

Common Testing Methods: Various testing methods are employed to verify the quality of 3-pinned plugs. These can include:

– Electrical Testing: Ensures that the connectors meet electrical specifications and safety standards.

– Mechanical Testing: Assesses durability through stress tests and environmental simulations.

– Visual Inspections: Conducted throughout the manufacturing process to identify defects early.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures directly. This provides insights into the supplier’s commitment to quality and adherence to standards.

-

Quality Assurance Reports: Requesting detailed reports on quality control processes, including IQC, IPQC, and FQC results, can help buyers understand how the supplier maintains product quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections can be scheduled at various stages of production, ensuring that any issues are addressed promptly.

-

Certifications and Compliance Documents: Buyers should request copies of relevant certifications (ISO, CE, UL) and compliance documents. This not only verifies the supplier’s adherence to quality standards but also assures that the products meet international safety regulations.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control when sourcing 3-pinned plugs internationally is essential for B2B buyers. Here are key considerations:

Illustrative image related to 3 pinned plug

-

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality and compliance. Buyers should be aware of local standards and how they align with international practices.

-

Communication Barriers: Clear communication with suppliers is vital. Buyers should ensure that there is a mutual understanding of quality expectations and specifications. Language barriers can lead to misunderstandings, so using clear, concise documentation is advisable.

-

Regulatory Requirements: Buyers must familiarize themselves with the regulatory requirements in their target markets. For instance, products sold in the European Union may require CE marking, while those in the United States may need UL certification.

-

Supply Chain Transparency: A transparent supply chain helps buyers track the quality of materials and components used in manufacturing. Suppliers should provide visibility into their sourcing and production processes.

By understanding the manufacturing processes and quality assurance practices for 3-pinned plugs, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality standards and regulatory requirements. This proactive approach not only mitigates risks but also enhances the overall supply chain efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 pinned plug’

When sourcing 3 pinned plugs, it is essential to approach the process systematically to ensure that you find products that meet your technical needs while also aligning with your budget and supplier reliability. This checklist serves as a comprehensive guide to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating your search, clarify the technical specifications required for the 3 pinned plugs. Consider factors such as voltage ratings, amperage capacity, and environmental conditions (e.g., temperature ranges, humidity). This step is crucial because mismatched specifications can lead to failures in applications and increased costs due to returns or replacements.

Step 2: Research Market Options

Conduct thorough research on the different types of 3 pinned plugs available in the market. Look for various styles, such as waterproof connectors or connectors designed for specific industries (automotive, industrial, etc.). Understanding the range of options will help you identify which products best fit your requirements and budget.

Illustrative image related to 3 pinned plug

Step 3: Evaluate Potential Suppliers

Before committing, vet potential suppliers to ensure they meet industry standards. Request company profiles, certifications, and references from previous clients, especially those in similar regions or industries. This evaluation is vital to guarantee that the supplier can deliver high-quality products consistently.

- Check Certifications: Look for ISO, RoHS, and other relevant certifications that demonstrate compliance with international standards.

- Assess Experience: Suppliers with a proven track record in your industry are more likely to understand your specific needs.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the 3 pinned plugs. Testing samples allows you to assess the quality, durability, and compatibility of the products with your existing systems. This step helps to prevent costly mistakes and ensures that the plugs meet your operational standards.

Step 5: Negotiate Pricing and Terms

Engage with suppliers to negotiate pricing based on your order volume. Be sure to inquire about bulk purchase discounts, payment terms, and shipping costs. A clear understanding of the financial aspects will help you manage your budget effectively and ensure a smooth procurement process.

- Consider Total Cost of Ownership: Include shipping, duties, and potential return costs in your calculations to avoid unexpected expenses.

Step 6: Verify After-Sales Support and Warranty

Before finalizing your order, confirm the level of after-sales support and warranty offered by the supplier. Good after-sales support can significantly reduce downtime in your operations, while a solid warranty provides peace of mind in case of defects or failures.

Step 7: Finalize the Purchase Agreement

Once all aspects are satisfactory, finalize the purchase agreement with clear terms regarding delivery timelines, quality standards, and payment conditions. Ensure both parties understand their obligations to avoid disputes later.

By following this step-by-step checklist, B2B buyers can effectively source 3 pinned plugs that meet their needs while ensuring reliability and value in their procurement processes.

Comprehensive Cost and Pricing Analysis for 3 pinned plug Sourcing

What Are the Key Cost Components in Sourcing 3 Pinned Plugs?

When sourcing 3 pinned plugs, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The raw materials used in manufacturing 3 pinned plugs, such as plastics and metals, significantly influence the price. The choice of material impacts durability, electrical conductivity, and overall performance.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. Skilled labor may be required for assembly and quality control, which can raise costs.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient operations can help mitigate these costs.

-

Tooling: Initial investments in molds and specialized equipment for producing specific plug designs can be substantial. These costs are often spread across production runs, impacting per-unit pricing.

-

Quality Control (QC): Ensuring that products meet industry standards requires rigorous quality testing. This involves costs associated with inspections, testing equipment, and compliance certifications.

-

Logistics: Shipping and handling costs, including packaging and transportation, play a vital role in the total expenditure. Factors such as distance, shipping method, and volume can alter logistics costs significantly.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the margin expectations can aid in negotiation discussions.

How Do Price Influencers Affect the Cost of 3 Pinned Plugs?

Several factors can influence the pricing of 3 pinned plugs, making it essential for buyers to consider these elements:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often results in better pricing due to economies of scale. Suppliers may offer tiered pricing structures that incentivize bulk orders.

-

Specifications and Customization: Custom designs or specific technical requirements can increase manufacturing complexity, thus raising costs. Buyers should be clear about their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: The choice of materials affects not only the price but also the quality. Higher-quality materials and certifications (e.g., RoHS compliance) often come at a premium.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding delivery terms (e.g., FOB, CIF) can affect the total landed cost. Buyers should clarify these terms to prevent unexpected charges during shipping.

What Are Essential Buyer Tips for Sourcing 3 Pinned Plugs Internationally?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should adopt specific strategies when sourcing 3 pinned plugs:

-

Negotiation: Engage in transparent discussions with suppliers about pricing and terms. Leverage volume purchases to negotiate better rates and payment terms.

-

Cost-Efficiency: Focus on the total cost of ownership rather than just the initial purchase price. Consider factors like durability, maintenance, and replacement frequency to assess long-term value.

-

Pricing Nuances: Be aware of currency fluctuations, import duties, and taxes that can affect overall costs. Obtain quotes in your local currency to avoid surprises.

-

Supplier Evaluation: Assess suppliers based on their ability to meet quality standards and delivery timelines. Request samples to evaluate product quality before committing to larger orders.

-

Cultural Considerations: Understanding cultural differences can enhance communication and foster stronger relationships with suppliers. This can lead to better service and pricing flexibility.

Conclusion

Sourcing 3 pinned plugs involves navigating a complex landscape of costs and pricing influences. By understanding these factors and employing strategic purchasing practices, international B2B buyers can optimize their sourcing decisions, ensuring they achieve the best value for their investments. Always remember to consult with multiple suppliers to benchmark prices and terms, allowing for informed choices that align with your operational needs.

Alternatives Analysis: Comparing 3 pinned plug With Other Solutions

Introduction to Alternative Solutions for 3 Pinned Plugs

When selecting electrical connectors, businesses often evaluate various options based on performance, cost, and ease of implementation. While the 3 pinned plug is a popular choice for its reliability and versatility in connecting electrical circuits, alternative solutions exist that may better suit specific applications or environments. This analysis will compare the 3 pinned plug against two viable alternatives: the 4 pinned connector and the wireless connection method.

Comparison Table

| Comparison Aspect | 3 Pinned Plug | 4 Pinned Connector | Wireless Connection Method |

|---|---|---|---|

| Performance | Reliable, suitable for low power | Higher power handling, versatile | High-speed data transfer, flexible |

| Cost | Generally low ($1.50 – $3.00) | Moderate ($2.00 – $5.00) | Higher initial setup cost ($50+) |

| Ease of Implementation | Simple installation, widely available | Slightly more complex, requires proper wiring | Requires technical knowledge for setup |

| Maintenance | Low maintenance, durable materials | Moderate, may require checking connections | Low, but software updates needed |

| Best Use Case | General electrical applications | Industrial applications requiring higher power | Data-heavy applications, remote installations |

Detailed Breakdown of Alternatives

4 Pinned Connector

The 4 pinned connector offers enhanced performance capabilities, allowing for higher power transfer than the standard 3 pinned plug. This makes it ideal for industrial applications where equipment demands exceed the capacity of a 3 pinned configuration. While the cost is slightly higher, the trade-off for increased power handling can justify the expense. However, installation is more complex and requires careful attention to wiring, which could lead to higher labor costs.

Wireless Connection Method

Wireless connection methods, such as Bluetooth or Wi-Fi-enabled connectors, provide a modern solution for connecting devices without physical cables. This approach excels in flexibility and ease of use, particularly in environments where mobility is essential. However, the initial setup cost is significantly higher, and ongoing maintenance may include software updates and troubleshooting connectivity issues. This method is best suited for applications where high-speed data transfer is critical, such as in smart devices or IoT solutions.

Conclusion: Choosing the Right Solution for Your Business Needs

In selecting the appropriate electrical connector, B2B buyers must consider their specific operational requirements, budget constraints, and the technical expertise of their teams. The 3 pinned plug is a reliable and cost-effective choice for standard electrical applications. However, for businesses needing higher power handling or modern wireless capabilities, exploring alternatives like the 4 pinned connector or wireless connections may prove beneficial. By weighing the pros and cons of each option, buyers can make informed decisions that align with their operational needs and long-term objectives.

Essential Technical Properties and Trade Terminology for 3 pinned plug

What Are the Key Technical Properties of a 3 Pinned Plug?

Understanding the technical specifications of a 3 pinned plug is crucial for B2B buyers, especially when sourcing products for electrical applications. Here are some essential properties to consider:

-

Material Grade

The material used in the construction of a 3 pinned plug significantly affects its durability and conductivity. Common materials include thermoplastic for housings and copper for pins. High-grade materials enhance resistance to corrosion and thermal degradation, ensuring longevity and reliability in various environments. This is particularly important for businesses operating in harsh conditions, as it minimizes maintenance costs and downtime. -

Current Rating

The current rating, typically expressed in amperes (A), indicates the maximum electrical current the plug can safely handle. For instance, a 3 pinned plug rated at 15A is suitable for standard household appliances, while those rated at 50A or more are used in industrial applications. Understanding current ratings helps businesses select the right plugs for their specific applications, ensuring safety and compliance with electrical standards. -

Voltage Rating

Voltage rating indicates the maximum voltage that a plug can withstand without breaking down. For example, a 3 pinned plug designed for 120V applications is common in North America, while 220-240V ratings are standard in many European and Asian countries. Selecting the appropriate voltage rating is crucial for preventing electrical failures and ensuring compatibility with electrical systems. -

Environmental Ratings (IP Rating)

The Ingress Protection (IP) rating specifies the degree of protection a plug offers against dust and moisture. An IP67 rating, for instance, means the plug is dust-tight and can withstand immersion in water up to 1 meter for 30 minutes. This specification is vital for industries where equipment is exposed to the elements, as it ensures operational reliability and reduces the risk of electrical hazards. -

Pin Configuration and Size

The configuration and size of the pins influence compatibility with sockets and the ease of installation. Standard pin sizes can vary by region, with some configurations specifically designed for certain applications (e.g., automotive vs. industrial). Understanding pin specifications helps in selecting the right connectors for seamless integration into existing systems. -

Temperature Rating

The temperature rating defines the operational temperature range for the plug. A higher temperature rating indicates that the plug can function effectively in extreme heat or cold. This property is essential for businesses operating in diverse climates, ensuring that the plugs perform reliably under varying environmental conditions.

What Are Common Trade Terms Related to 3 Pinned Plugs?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of 3 pinned plugs, an OEM might supply plugs designed for specific equipment brands. Buyers often seek OEM products for guaranteed compatibility and quality assurance. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. This term is crucial for businesses to understand as it affects inventory management and cost efficiency. Buyers should negotiate MOQs to align with their purchasing capabilities and market demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. It is an essential step in the procurement process, allowing buyers to compare offers and select the best supplier based on cost, quality, and delivery terms. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. They clarify shipping responsibilities, risk transfer, and cost implications. Familiarity with Incoterms is vital for B2B buyers engaged in global trade, particularly when sourcing 3 pinned plugs from different regions. -

Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead times helps businesses plan their inventory and production schedules effectively, ensuring they meet customer demands without incurring excess costs. -

Certification Standards

Certification standards refer to the regulatory requirements that products must meet to ensure safety and quality. For electrical products like 3 pinned plugs, certifications such as UL (Underwriters Laboratories) or CE (Conformité Européenne) are important indicators of compliance with safety standards. Buyers should prioritize certified products to mitigate risks associated with electrical failures.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 3 pinned plugs, ensuring compatibility, safety, and efficiency in their electrical applications.

Illustrative image related to 3 pinned plug

Navigating Market Dynamics and Sourcing Trends in the 3 pinned plug Sector

What Are the Current Market Dynamics and Key Trends in the 3-Pinned Plug Sector?

The global market for 3-pinned plugs is experiencing significant growth, driven by the increasing demand for reliable electrical connections across various sectors including automotive, industrial, and consumer electronics. As industries in Africa, South America, the Middle East, and Europe expand, the need for robust and efficient electrical components becomes paramount. This demand is particularly pronounced in regions such as Saudi Arabia and Nigeria, where infrastructure development is accelerating, leading to an uptick in the usage of electrical connectors.

Emerging trends in the B2B sourcing landscape include the adoption of smart technologies and automation in manufacturing processes. Suppliers are increasingly leveraging advanced manufacturing techniques such as 3D printing and IoT integration to enhance the efficiency and reliability of 3-pinned plugs. Additionally, the rise of e-commerce platforms is transforming how international buyers source these products, enabling easier access to a wider range of suppliers and competitive pricing. Furthermore, customization is becoming a key factor, as businesses seek plugs tailored to their specific operational needs, such as varying voltage requirements and environmental conditions.

Another important dynamic is the shift towards higher quality standards and certifications. Buyers are now more focused on sourcing products that meet international safety and performance standards, which not only ensures compatibility but also enhances the longevity and safety of installations. This trend is reflected in the growing emphasis on quality assurance in the supply chain, compelling manufacturers to adopt stringent testing protocols and certifications.

How Is Sustainability and Ethical Sourcing Influencing the 3-Pinned Plug Market?

Sustainability is increasingly becoming a crucial factor for B2B buyers in the 3-pinned plug sector. The environmental impact of electrical components, including waste generated during manufacturing and disposal, is prompting companies to seek eco-friendly alternatives. Many manufacturers are now utilizing recyclable materials and adopting greener production processes to minimize their carbon footprint. This shift is particularly relevant for buyers in regions with stringent environmental regulations, such as Europe, where compliance is not just a legal obligation but also a market differentiator.

Ethical sourcing has gained prominence as buyers become more conscious of the social implications of their supply chains. Companies are expected to ensure that their suppliers adhere to fair labor practices and sustainable sourcing of raw materials. This includes seeking certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices. Buyers are increasingly demanding transparency in their supply chains, which is driving suppliers to enhance their reporting and disclosure practices.

Green certifications are particularly relevant for the 3-pinned plug market, as they signify compliance with environmental standards. Buyers are encouraged to look for products that carry certifications such as RoHS (Restriction of Hazardous Substances) and CE marking, which indicate compliance with EU directives on hazardous substances and safety requirements, respectively. By prioritizing sustainability and ethical sourcing, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation in a market that values corporate responsibility.

How Has the 3-Pinned Plug Evolved Over Time?

The evolution of the 3-pinned plug dates back to the early 20th century, when standardized electrical connections became essential for safety and compatibility. Initially designed for basic electrical applications, these plugs have undergone significant transformations to accommodate the growing complexity of electrical systems.

Advancements in materials technology have allowed for the development of more durable and heat-resistant plugs, enhancing safety and performance. The introduction of weatherproof designs has further expanded their application, making them suitable for outdoor and industrial environments. As digital technologies emerged, the integration of smart features into 3-pinned plugs has begun to gain traction, aligning with the broader trend of automation and connectivity in the electrical industry.

In conclusion, the 3-pinned plug sector is marked by evolving market dynamics, a strong emphasis on sustainability, and a rich history of innovation. B2B buyers must navigate these factors to make informed sourcing decisions that align with their operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 pinned plug

-

How do I solve compatibility issues with 3 pinned plugs in different regions?

To resolve compatibility issues with 3 pinned plugs across various regions, it’s essential to understand the specific standards and voltage requirements in your target market. For instance, Europe typically uses 230V, while North America operates on 120V. Ensure that the plugs you source are rated for the appropriate voltage and comply with local electrical standards. Consulting with local electrical authorities or hiring a local compliance expert can help in verifying compatibility and ensuring that your products meet safety regulations in different countries. -

What is the best material for 3 pinned plugs in industrial applications?

For industrial applications, the best material for 3 pinned plugs is often thermoplastic or thermosetting plastic, as these materials provide excellent durability and resistance to high temperatures and harsh environments. Additionally, connectors made from materials like nickel-plated brass can enhance conductivity and corrosion resistance, which is crucial for outdoor or high-moisture settings. When selecting a plug, consider the specific environmental conditions it will face to ensure long-term reliability and performance. -

What customization options are available for 3 pinned plugs?

Customization options for 3 pinned plugs can vary by supplier but typically include modifications in pin configuration, housing color, and material. Some manufacturers offer the ability to customize the length and gauge of wire leads, as well as the inclusion of heat-shrink or rubber boots for added protection. To ensure you receive a product tailored to your needs, communicate your specific requirements to your supplier and request samples or prototypes for evaluation before placing a bulk order. -

What are the minimum order quantities (MOQs) for 3 pinned plugs?

Minimum order quantities (MOQs) for 3 pinned plugs can vary significantly based on the manufacturer and the specific product. Generally, MOQs can range from as low as 100 units to several thousand. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms. Some suppliers may offer lower MOQs for first-time orders or to establish a business relationship, so it’s beneficial to inquire about flexibility in order sizes. -

How can I vet suppliers for 3 pinned plugs effectively?

To vet suppliers for 3 pinned plugs, start by checking their certifications and compliance with industry standards, such as ISO 9001 or AS9120B. Request references from previous clients and review their track record in delivering quality products on time. It’s also prudent to conduct site visits if possible or utilize third-party inspection services to evaluate manufacturing processes. Additionally, assess their customer service responsiveness and willingness to accommodate your specific needs, which can be indicative of their reliability as a partner. -

What payment terms are typically offered by suppliers of 3 pinned plugs?

Payment terms for suppliers of 3 pinned plugs can vary widely, but common options include net 30, net 60, or cash in advance for first-time orders. Some suppliers may offer discounts for early payments or bulk orders. It’s important to negotiate terms that align with your cash flow needs while also considering the supplier’s policies. Establishing a good relationship with your supplier can lead to more favorable terms over time. -

What quality assurance processes should I expect from a 3 pinned plug supplier?

A reputable supplier of 3 pinned plugs should have robust quality assurance processes in place, including material inspections, in-process quality checks, and final product testing. Look for suppliers that provide certifications for their products, such as CE or UL marks, which indicate compliance with safety and performance standards. Additionally, inquire about their return and warranty policies, as these can provide insight into their commitment to quality and customer satisfaction. -

How can I manage logistics and shipping for international orders of 3 pinned plugs?

To manage logistics and shipping for international orders of 3 pinned plugs effectively, partner with a reliable freight forwarder who understands the complexities of cross-border shipping. Ensure that you are aware of the import regulations and customs duties in your destination country to avoid delays. Utilizing a just-in-time inventory strategy can also help minimize storage costs and improve cash flow. Regular communication with your supplier regarding shipment tracking and expected delivery dates is crucial to maintaining an efficient supply chain.

Top 8 3 Pinned Plug Manufacturers & Suppliers List

1. Cobo International – 3 PIN Plug

Domain: cobointernational.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “3 PIN Plug”, “part_number”: “1028168, 25.036.200.01”, “price”: “$15”, “supply_voltage”: “12 ÷ 24V”, “type”: “Power & Signal”, “number_of_contacts”: “3 PIN”, “housing_color”: “Black”, “housing_material”: “Plastic”}

2. Koike – 3 Pin Electrical Plug (120V)

Domain: koike.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “3 Pin Electrical Plug (120V)”, “SKU”: “ZS60781”, “UPC”: “”, “Current Stock”: 34, “MSRP”: “$22.06”, “Related Products”: [{“Name”: “3 Pin Electrical Socket (120V)”, “SKU”: “ZS30273”, “Price”: “$16.95”}, {“Name”: “3 Pin Power Cord Assembly (120V)”, “SKU”: “61004264”, “Price”: “$97.29”}, {“Name”: “5 Pin plug (To Welder)”, “SKU”: “ZS37689”, “Price”: “$94.31”}, {“Name”: “4 Pin Electric…

3. Mossled – High Current DC Connectors

Domain: mossled.com

Registered: 2009 (16 years)

Introduction: This company, Mossled – High Current DC Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Adafruit – JST PH 2mm 3-pin Plug-Plug Cable

Domain: adafruit.com

Registered: 2005 (20 years)

Introduction: {“name”: “JST PH 2mm 3-pin Plug-Plug Cable – 100mm long”, “product_id”: “4336”, “price”: “$0.75”, “length”: “100mm (4 inches)”, “connectors”: “JST-PH 3-pin connectors on either end”, “wire_gauge”: “22AWG stranded”, “pitch”: “2mm”, “color_coding”: {“red”: “power”, “black”: “ground”, “white”: “signal”}, “discounts”: {“1-9”: “$0.75”, “10-99”: “$0.68”, “100+”: “$0.60”}, “availability”: “In stock”}

5. Grand General – Male Round 3 Pin Light Plug

Domain: grandgeneral.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Male Round 3 Pin Light Plug”, “manufacturer”: “Grand General”, “category”: “Auto Parts Accessories”, “size”: “8” lead wire”, “features”: “Converts round male 3 pin plug without needing to cut harness”, “wire_gauge”: “18 GA”, “certification”: “UL Listed”, “sold_by”: “each”, “packaging”: “color display bag”, “part_number”: “88078”, “description”: “Converts round male 3 pin plug to …

6. Delta – 3-Pin Low-Profile Connector

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 3-pin connector for a DC blower fan, specifically for the Delta AUB0712HH-C model. The connector is identified as a low-profile wire-to-board connector with a 1 mm pitch, crimp type. Possible manufacturers and series include Adam Tech 1SH + 1CH, Amphenol Minitek 1.00mm, Harwin M40-301, JST SH, Molex Pico-Clasp, TE HPI-1, and Wurth WR-WTB.

7. Super Star – Super Star 3 Pin Flat Plug

Domain: ssgeshop.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “Super Star 3 Pin Flat Plug”, “brand”: “Super Star”, “price”: “৳ 130”, “stock_status”: “In Stock”, “product_code”: “0 09610-001-666”}

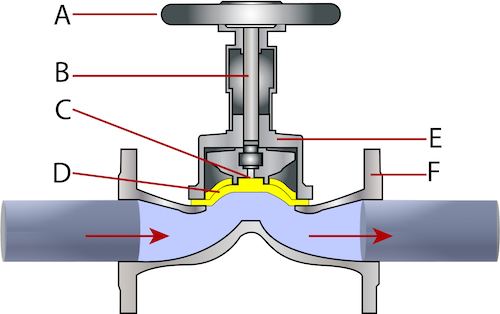

8. Excel at Physics – Three-Pin Plug

Domain: excelatphysics.com

Introduction: Three-pin Plug, also known as a safety plug. Safety features include a cartridge fuse that protects the appliance during electrical faults and an earth wire that protects users from electric shocks. Common mistakes include: no fuse (appliance won’t work), earth wire not connected (metal casing could be live), neutral wire not connected (circuit incomplete), bare earth and live wires (risk of short…

Strategic Sourcing Conclusion and Outlook for 3 pinned plug

In the dynamic landscape of international sourcing, the strategic procurement of 3 pinned plugs presents significant opportunities for B2B buyers across Africa, South America, the Middle East, and Europe. Emphasizing quality, compatibility, and cost-efficiency, sourcing decisions must align with both immediate project requirements and long-term operational goals. The diverse range of available options—from solid black to nickel finishes—provides flexibility to meet various industry standards and applications.

Strategic sourcing not only enhances supply chain efficiency but also fosters strong supplier relationships, which are essential for navigating the complexities of international trade. By leveraging bulk pricing and ensuring timely deliveries, companies can optimize their procurement processes, leading to substantial cost savings and improved project timelines.

Looking ahead, international buyers are encouraged to adopt a proactive approach to sourcing 3 pinned plugs. Engage with trusted suppliers who offer customization and support services to ensure that your electrical connections meet specific operational demands. By prioritizing strategic sourcing practices, businesses can position themselves for sustained growth and innovation in an increasingly competitive marketplace.

Illustrative image related to 3 pinned plug

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.