A B2B Buyer’s Guide to Rubber On Steel: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for rubber on steel

Navigating the complex landscape of sourcing rubber on steel products can pose significant challenges for international B2B buyers. With varying quality standards, manufacturing processes, and supplier reliability across regions, businesses must ensure they are making informed decisions to mitigate risks. This comprehensive guide delves into the multifaceted world of rubber bonded to metal, addressing key considerations such as the types of rubber available, their applications across diverse industries, and the critical process of supplier vetting.

By exploring essential aspects like cost factors, material specifications, and performance characteristics, this guide equips buyers from Africa, South America, the Middle East, and Europe—particularly in markets like Saudi Arabia and Brazil—with the knowledge they need to navigate this global market effectively. Each section is designed to empower decision-makers, enabling them to select the right products that meet their operational requirements while also ensuring quality and durability.

Ultimately, this resource serves as an authoritative reference point, guiding buyers through the intricacies of sourcing rubber on steel solutions that enhance their business operations and drive competitive advantage in their respective industries.

Understanding rubber on steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Rubber on Steel | Excellent mechanical properties, high tensile strength | Automotive mounts, industrial machinery | Pros: Superior durability, high flexibility; Cons: Limited temperature resistance compared to synthetic options. |

| Neoprene on Steel | Good oil and chemical resistance, moderate temperature range | Oil and gas applications, HVAC systems | Pros: Excellent resistance to oils, versatile; Cons: Slightly lower mechanical strength than natural rubber. |

| EPDM on Steel | Exceptional weather and ozone resistance | Outdoor applications, construction | Pros: Long-lasting in harsh environments; Cons: Limited mechanical properties for dynamic applications. |

| Silicone on Steel | High-temperature tolerance, excellent flexibility | Aerospace, high-performance automotive | Pros: Performs well in extreme temperatures; Cons: Higher cost, may not withstand certain chemicals. |

| SBR on Steel | Cost-effective, decent abrasion resistance | General industrial applications | Pros: Economical choice for bulk applications; Cons: Lower performance in extreme conditions. |

What Are the Key Characteristics of Natural Rubber on Steel?

Natural rubber bonded to steel is known for its exceptional mechanical properties, including high tensile strength and flexibility. It is particularly suitable for applications that require durability, such as automotive mounts and industrial machinery. When purchasing, buyers should consider the rubber’s performance under varying temperatures, as natural rubber has limitations compared to synthetic alternatives. Its cost-effectiveness and high performance make it a preferred choice in many sectors, although it may not be ideal for environments exceeding 190°F.

How Does Neoprene on Steel Compare to Other Options?

Neoprene, a synthetic elastomer, offers good oil and chemical resistance, making it an ideal choice for applications in the oil and gas industries and HVAC systems. Its moderate temperature range allows for versatility in various environments. Buyers should weigh the benefits of neoprene’s resistance to oils against its slightly lower mechanical strength compared to natural rubber. Neoprene is often favored for applications where exposure to chemicals is a concern, providing a balance between performance and cost.

Why Is EPDM on Steel Ideal for Outdoor Applications?

EPDM (Ethylene Propylene Diene Monomer) bonded to steel is particularly known for its exceptional resistance to weather, ozone, and UV exposure. This makes it an excellent choice for outdoor applications and construction. When considering EPDM, buyers should evaluate the long-term performance in harsh environmental conditions. While it excels in durability, its mechanical properties may not suit dynamic applications where movement is involved. Thus, it is crucial to align EPDM’s strengths with specific application requirements.

What Are the Advantages of Using Silicone on Steel?

Silicone bonded to steel is recognized for its high-temperature tolerance and excellent flexibility. It is commonly used in aerospace and high-performance automotive applications, where extreme temperatures are a factor. Buyers should consider the higher cost associated with silicone but can benefit from its outstanding performance in demanding conditions. Its ability to maintain integrity under thermal stress makes it a valuable option, though it may not be suitable for all chemical exposures.

How Does SBR on Steel Fit into General Industrial Applications?

Styrene-Butadiene Rubber (SBR) bonded to steel offers a cost-effective solution with decent abrasion resistance. It is commonly used in general industrial applications due to its economical nature. Buyers looking for bulk applications may find SBR an attractive option, but should be aware of its limitations in extreme conditions. While it serves well in standard environments, its performance may not match that of specialized elastomers in more demanding applications.

Key Industrial Applications of rubber on steel

| Industry/Sector | Specific Application of rubber on steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace and Defense | Vibration isolation mounts for aircraft components | Enhances safety and performance by reducing vibrations | Certifications for aerospace standards, material durability, and weight considerations |

| Automotive | Engine mounts and suspension systems | Improves ride comfort and vehicle stability | Compliance with automotive regulations, temperature resistance, and noise reduction capabilities |

| Oil and Gas | Seals and gaskets for drilling equipment | Prevents leaks and enhances operational efficiency | Resistance to harsh chemicals, temperature extremes, and compatibility with various fluids |

| Industrial Equipment | Vibration dampers for manufacturing machinery | Increases equipment lifespan and reduces maintenance costs | Customization options, load-bearing capacity, and environmental resistance |

| Construction | Shock-absorbing pads for heavy machinery | Enhances safety and equipment stability on job sites | Durability, ease of installation, and compliance with safety standards |

How is Rubber on Steel Used in Aerospace and Defense Industries?

In the aerospace sector, rubber bonded to steel is primarily utilized in vibration isolation mounts for aircraft components. These mounts absorb and dampen vibrations generated during flight, enhancing safety and performance. Buyers in this sector must ensure that the materials meet stringent aerospace standards, focusing on certifications and durability to withstand extreme conditions. Additionally, weight considerations are critical, as any excess can affect fuel efficiency and overall aircraft performance.

What Role Does Rubber on Steel Play in the Automotive Sector?

In the automotive industry, rubber on steel is essential for applications such as engine mounts and suspension systems. These components significantly improve ride comfort and vehicle stability by isolating engine vibrations and shocks from the chassis. For international buyers, compliance with automotive regulations is paramount, alongside ensuring the materials can resist high temperatures and provide effective noise reduction. Sourcing suppliers with a proven track record in automotive applications can lead to enhanced product reliability.

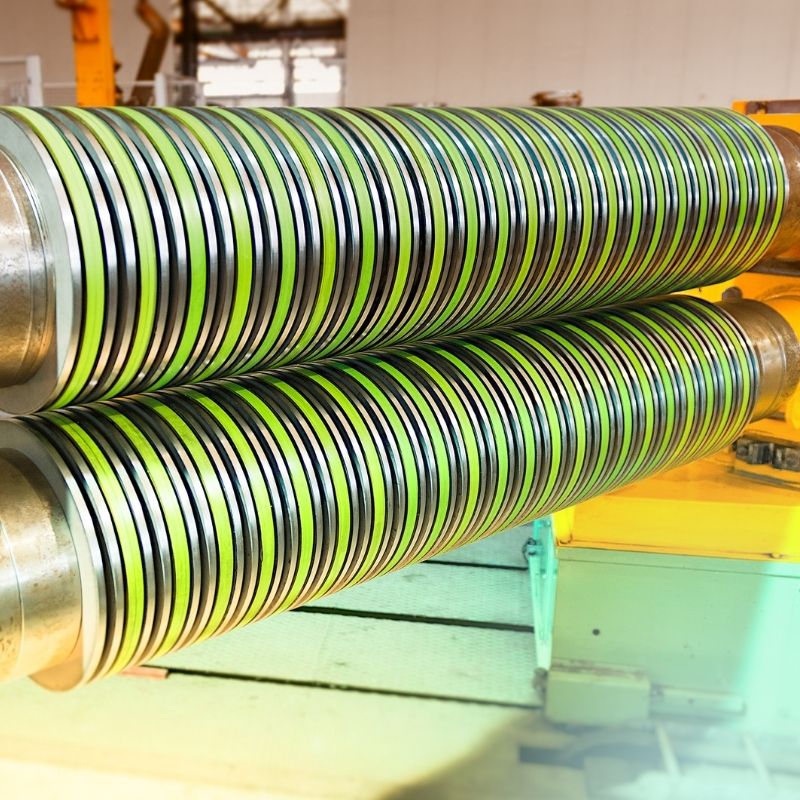

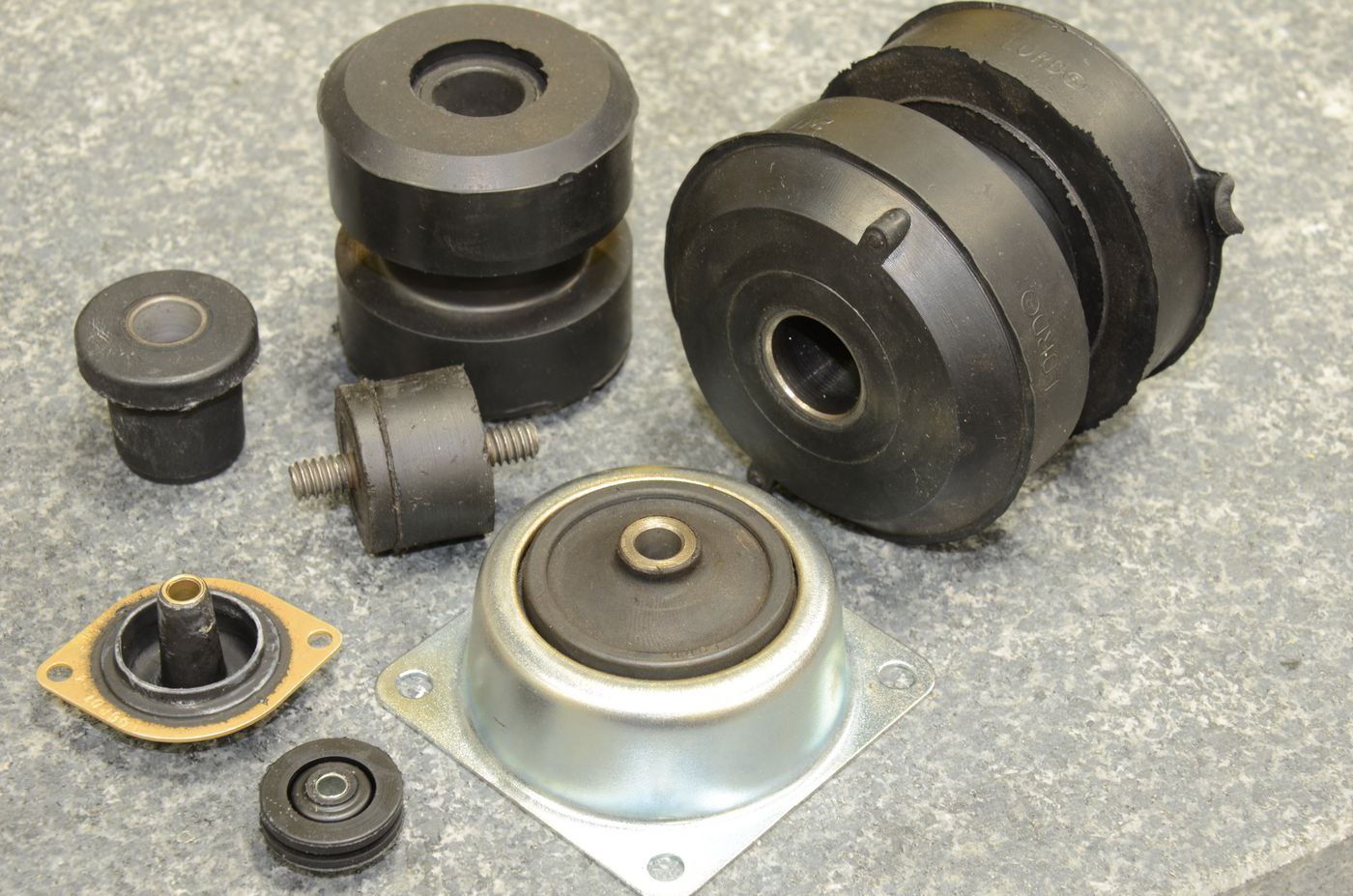

Illustrative image related to rubber on steel

How is Rubber on Steel Essential in Oil and Gas Applications?

Rubber bonded to steel finds critical use in seals and gaskets for drilling equipment in the oil and gas industry. These components are vital for preventing leaks and maintaining operational efficiency, especially in high-pressure environments. Buyers must prioritize sourcing materials that exhibit resistance to harsh chemicals and extreme temperatures, ensuring compatibility with various fluids used in drilling operations. Long-term reliability and durability are key factors in vendor selection.

What Benefits Does Rubber on Steel Offer in Industrial Equipment?

In the realm of industrial equipment, rubber on steel is commonly employed in vibration dampers for manufacturing machinery. These dampers help increase the lifespan of equipment by reducing wear and tear caused by vibrations, ultimately leading to lower maintenance costs. Buyers should look for customization options that cater to specific load-bearing capacities and environmental conditions, as well as suppliers who can demonstrate a commitment to quality and performance.

How is Rubber on Steel Applied in the Construction Industry?

In construction, rubber bonded to steel is utilized in shock-absorbing pads for heavy machinery. These pads enhance safety and stability on job sites by minimizing the impact of vibrations from operating equipment. Buyers should consider the durability and ease of installation of these pads, as well as compliance with safety standards, to ensure they meet the rigorous demands of construction environments. Reliable sourcing partnerships can significantly impact project efficiency and safety.

3 Common User Pain Points for ‘rubber on steel’ & Their Solutions

Scenario 1: Concerns Over Bonding Durability in Harsh Environments

The Problem: Many B2B buyers in sectors like construction or automotive express concerns about the durability of rubber bonded to steel, especially when exposed to harsh environmental conditions. Factors such as extreme temperatures, moisture, and chemical exposure can significantly impact the bond’s integrity. For instance, a manufacturer in the oil and gas sector may find that standard rubber-to-metal bonds fail prematurely, leading to costly downtime and safety risks. This creates hesitation in selecting the right materials and technologies, as buyers fear they will not meet performance expectations.

The Solution: To ensure reliability, it is crucial to select high-performance elastomers specifically designed for demanding environments. Natural rubber and neoprene are excellent choices due to their superior mechanical properties. However, the selection of the adhesive is equally important. Utilizing advanced structural adhesives like LORD’s Chemlok® can enhance bond durability significantly. B2B buyers should prioritize suppliers that provide comprehensive testing data on their products, ensuring they can withstand specific environmental stresses. Additionally, working closely with an experienced technical representative during the design and bonding process can help mitigate risks, ensuring that all materials are properly prepared and applied according to the manufacturer’s specifications.

Scenario 2: Inconsistent Bonding Quality Leading to High Scrap Rates

The Problem: Buyers often face challenges with inconsistent bonding quality, which can lead to high scrap rates and increased production costs. For example, a manufacturer of vibration isolators may discover that some batches of rubber-to-steel components exhibit weak bonds, resulting in failures during testing. This inconsistency can stem from improper surface preparation, contamination, or incorrect adhesive application techniques. The financial implications are substantial, as rework and scrap not only waste materials but also labor and time.

The Solution: To address this pain point, buyers should implement a rigorous quality control process throughout the rubber-to-metal bonding stages. Proper surface preparation is critical; ensure that all metal surfaces are thoroughly cleaned and free from contaminants. Using methods like solvent degreasing or grit blasting can enhance bond quality. Furthermore, adopting a two-coat adhesive application—using both a primer and an adhesive topcoat—can significantly improve adhesion. Suppliers should provide detailed guidelines on the recommended application techniques and environmental conditions for bonding. Regular training sessions for production staff on best practices in handling and bonding can also help maintain consistent quality.

Scenario 3: Challenges in Material Specification for Diverse Applications

The Problem: B2B buyers often struggle with specifying the right rubber-to-metal materials for diverse applications. For instance, a buyer in the automotive sector might need components that can withstand both high temperatures and exposure to oils. Without a clear understanding of the material properties and performance metrics, buyers risk choosing unsuitable products, which can lead to performance failures and increased lifecycle costs. This lack of clarity can make it difficult for businesses to meet specific regulatory standards or customer expectations.

The Solution: To overcome this challenge, it is essential to engage with suppliers who offer a wide range of elastomer options and provide detailed technical data sheets. Buyers should work closely with their suppliers to identify the specific requirements of their applications, such as temperature ranges, chemical exposures, and mechanical loads. Investing in simulation tools or prototypes can also help assess how different rubber types perform under varying conditions. Additionally, utilizing suppliers that offer customization services can ensure that the selected materials are tailored to meet unique application needs, thereby enhancing overall performance and reliability. Regular communication with engineering teams will facilitate better decision-making, ensuring that all specifications align with operational goals.

Strategic Material Selection Guide for rubber on steel

What Are the Key Properties of Natural Rubber for Rubber on Steel Applications?

Natural rubber, derived from the latex of the Hevea brasiliensis tree, is renowned for its exceptional mechanical properties. It exhibits high tensile strength, excellent abrasion resistance, and superior elasticity, making it ideal for dynamic applications such as vibration isolation mounts. With a temperature range of -40°F to 190°F, natural rubber is suitable for various environments, including automotive and industrial applications. However, its susceptibility to degradation from oils and solvents can limit its use in certain applications.

Illustrative image related to rubber on steel

Pros & Cons: Natural rubber is highly durable and cost-effective, making it a preferred choice for many manufacturers. However, its performance can diminish when exposed to certain chemicals, necessitating careful application consideration. Additionally, the manufacturing complexity can increase if specific formulations are required to enhance oil resistance.

How Does Neoprene Compare as a Material for Rubber on Steel?

Neoprene, a synthetic rubber, offers properties similar to natural rubber but with enhanced chemical resistance, particularly to oils and solvents. It operates effectively in temperatures ranging from -30°F to 212°F, making it versatile for various industrial applications. Neoprene’s ability to maintain its properties under stress and exposure to various media makes it a reliable choice for vibration dampening and sealing applications.

Pros & Cons: The key advantage of neoprene is its resistance to oil and ozone, which extends its lifespan in harsh environments. However, it is generally more expensive than natural rubber and may require more complex manufacturing processes, potentially increasing production costs.

What Role Does EPDM Play in Rubber on Steel Applications?

Ethylene Propylene Diene Monomer (EPDM) rubber is another synthetic option favored for its excellent weather resistance and durability against UV exposure and ozone. It performs well in temperatures from -50°F to 150°F, making it suitable for outdoor applications. EPDM is particularly effective in environments where exposure to steam, water, and various chemicals is common.

Pros & Cons: EPDM’s resistance to environmental factors is a significant advantage, making it a long-lasting option for outdoor applications. However, its lower tensile strength compared to natural rubber may limit its use in high-stress applications. Additionally, EPDM can be more costly than both natural rubber and neoprene.

What Are the Considerations for International Buyers When Selecting Materials for Rubber on Steel?

When sourcing rubber materials for steel applications, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider local compliance standards such as ASTM, DIN, or JIS. These standards ensure that materials meet specific performance criteria, which is crucial for safety and reliability. Additionally, regional preferences for certain materials based on environmental conditions and availability can influence purchasing decisions. Understanding the local market dynamics and regulatory requirements is essential for optimizing procurement strategies.

Summary Table of Material Selection for Rubber on Steel

| Material | Typical Use Case for rubber on steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Vibration isolation mounts in automotive and industrial applications | High tensile strength and abrasion resistance | Susceptible to oil and solvent degradation | Medium |

| Neoprene | Seals and vibration dampening in automotive and industrial sectors | Excellent oil and ozone resistance | Higher cost and manufacturing complexity | High |

| EPDM | Outdoor applications and environments with exposure to steam and water | Superior weather and UV resistance | Lower tensile strength than natural rubber | Medium to High |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their rubber on steel applications. By understanding the properties, advantages, and limitations of each material, companies can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to rubber on steel

In-depth Look: Manufacturing Processes and Quality Assurance for rubber on steel

What Are the Main Stages of the Manufacturing Process for Rubber on Steel?

The manufacturing of rubber on steel products involves several critical stages, each ensuring the final product meets industry standards and customer specifications. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Rubber on Steel Bonding?

The first step in the manufacturing process is material preparation. This involves selecting the appropriate elastomer, typically natural rubber or neoprene, and preparing the metal substrate, often low carbon steel. The rubber undergoes a mixing process where various additives are incorporated to enhance its properties. This stage is akin to preparing a recipe, where precise measurements and conditions are essential to achieve desired material characteristics.

Simultaneously, the steel components must be prepared to ensure optimal adhesion. This includes thorough cleaning to remove oils and contaminants, often achieved through solvent degreasing or alkaline cleaning. If necessary, rust removal techniques such as grit blasting are employed. Proper handling in a controlled environment is crucial to prevent recontamination, as any residue could compromise the bond integrity.

What Techniques Are Used in the Forming Process?

Once the materials are prepared, the forming process begins. This typically involves applying a structural adhesive, such as LORD’s Chemlok®, which is designed for rubber-to-metal bonding. The adhesive application can take place via several methods, including spraying, dipping, or brushing, depending on the production requirements. The application is followed by a drying phase, either at room temperature or using heated air, to set the adhesive.

The actual molding of the rubber onto the steel occurs during this stage. Manufacturers may employ transfer or injection molding techniques, with temperature control critical to ensure proper vulcanization of the rubber. The components are placed in heated molds, where the uncured rubber is introduced and subjected to high temperatures to facilitate the curing process, resulting in a strong and durable bond.

How Is Assembly and Finishing Conducted in Rubber on Steel Products?

Following the forming stage, assembly involves integrating various components into the final product. This may include adding additional features or integrating multiple bonded parts. Once assembled, the products undergo finishing processes that may include trimming, surface smoothing, or applying protective coatings.

Finishing is crucial for aesthetic purposes and to enhance durability and resistance to environmental factors. The final inspection ensures that the product meets all design specifications and quality standards before packaging and distribution.

What International Standards Govern Quality Assurance in Rubber on Steel Manufacturing?

Quality assurance is paramount in the manufacturing of rubber on steel products. International standards such as ISO 9001 outline a framework for establishing effective quality management systems. This certification ensures that a manufacturer consistently meets customer and regulatory requirements.

Illustrative image related to rubber on steel

In addition to ISO 9001, industry-specific standards such as CE marking for products sold in the European market and API specifications for the oil and gas sector provide further guidance on quality expectations. These standards emphasize the importance of robust quality control measures throughout the manufacturing process.

What Are the Key Quality Control Checkpoints in Rubber on Steel Production?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure product integrity. The three primary QC stages include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified standards. For rubber, this may involve checking for consistency in elasticity and tensile strength, while for steel, it may involve verifying the grade and thickness.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is conducted to ensure adherence to established protocols. This may include regular checks on adhesive application thickness, curing temperatures, and bonding integrity.

-

Final Quality Control (FQC): Once the products are completed, they undergo final inspections that may involve visual inspections, dimensional checks, and functional testing. Common testing methods include tensile testing, shear testing, and fatigue testing to ensure the product can withstand operational stresses.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Buyers can undertake several actions to ensure supplier reliability:

-

Conduct Audits: Regular on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This firsthand assessment can reveal the supplier’s commitment to quality.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance with international standards. Buyers should seek detailed reports that outline the quality assurance methodologies employed.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can add an extra layer of assurance. These inspectors can evaluate the manufacturing process and verify that the supplier meets specified quality standards.

What Are the Nuances of Quality Control for International Buyers?

International buyers must navigate specific challenges regarding quality control. Different countries may have varying standards and regulations that affect product quality and compliance. For instance, while CE marking is crucial for products in Europe, similar certifications may not be recognized in other regions.

Buyers should be aware of the implications of these standards on product usability and market entry. Additionally, cultural differences in business practices can impact quality expectations, making it essential for buyers to clearly communicate their requirements and ensure that suppliers understand and adhere to these standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for rubber on steel products is crucial for B2B buyers. By focusing on material preparation, forming techniques, assembly, and stringent quality control protocols, buyers can ensure they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber on steel’

Introduction

This practical sourcing guide is designed for B2B buyers interested in procuring rubber on steel components. By following this step-by-step checklist, you can ensure that you select the right materials and suppliers, ultimately leading to high-quality products that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for rubber on steel products. This includes specifying the type of elastomer (e.g., natural rubber or neoprene), the dimensions of the metal substrate, and performance characteristics such as temperature resistance and tensile strength. Precise specifications help suppliers deliver products that meet your exact needs, reducing the risk of costly errors later in the process.

Illustrative image related to rubber on steel

Step 2: Identify Potential Suppliers

Research and compile a list of suppliers specializing in rubber on steel bonding. Look for companies with proven track records in your industry, particularly those that demonstrate expertise in advanced adhesive technologies like Chemlok®. A well-established supplier is more likely to provide reliable products and services, ensuring your project runs smoothly.

Step 3: Evaluate Supplier Certifications

It is crucial to verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management systems. These certifications indicate adherence to industry standards and best practices, which can enhance product reliability. Additionally, inquire about any specific certifications related to rubber bonding processes that may apply in your region.

Step 4: Request Samples for Testing

Ask suppliers for samples of their rubber on steel products to evaluate their performance in real-world conditions. Testing samples will allow you to assess factors such as adhesion strength, durability, and overall compatibility with your applications. This step is essential to ensure the products meet your technical specifications and quality expectations.

Step 5: Review Manufacturing Processes

Gain insight into the manufacturing processes used by your shortlisted suppliers. Understanding whether they employ advanced bonding techniques and high-quality materials will help you gauge their ability to deliver consistent results. Look for suppliers who utilize automated systems for adhesive application and have robust quality control measures in place.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a preferred supplier, engage in discussions to negotiate pricing, lead times, and payment terms. Clear communication about your expectations can help establish a mutually beneficial partnership. Ensure that the contract includes provisions for quality assurance and potential recourse in case of product failures.

Step 7: Establish a Long-Term Relationship

After procurement, maintain an open line of communication with your supplier. Regular feedback and updates on product performance can foster a strong partnership, leading to better service and potential future collaborations. Building a long-term relationship is beneficial for both parties, ensuring consistent quality and innovation in your rubber on steel applications.

By following this checklist, B2B buyers can streamline their sourcing process and achieve optimal results in their rubber on steel procurement efforts.

Comprehensive Cost and Pricing Analysis for rubber on steel Sourcing

What Are the Key Cost Components in Rubber on Steel Sourcing?

When sourcing rubber on steel products, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of rubber, whether natural or synthetic (like neoprene), greatly influences the material cost. Steel quality, typically low carbon steel, is preferred for its machinability and cost-effectiveness. The total cost of materials can vary significantly based on market fluctuations, availability, and the specific requirements of the application.

-

Labor: Skilled labor is required for both the manufacturing process and quality assurance. Labor costs can vary by region, with higher costs typically found in developed markets. For international buyers, it’s crucial to consider local labor rates when evaluating suppliers.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling may be necessary for specific applications, contributing to the initial setup costs. The complexity and size of the tooling will impact the overall pricing structure.

-

Quality Control: Ensuring that products meet required specifications necessitates investment in quality assurance processes. The costs associated with testing and certifications can add to the overall price but are vital for maintaining product reliability.

-

Logistics: Transportation and warehousing costs can significantly affect the final price, especially for international shipments. Incoterms play a crucial role in defining responsibilities and costs associated with shipping.

-

Margin: Suppliers will typically apply a margin to cover their costs and generate profit. This margin can vary based on market competition and the supplier’s position in the supply chain.

How Do Price Influencers Affect Rubber on Steel Sourcing?

Several factors can influence pricing in the rubber on steel market, which international buyers must consider.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can impact pricing. Larger orders often lead to discounts, while smaller orders may incur higher per-unit costs. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Custom specifications, such as unique dimensions or enhanced performance characteristics, can lead to increased costs. It’s essential to clearly communicate requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., ISO) can raise costs. Buyers should evaluate whether these certifications are necessary for their applications to balance quality and cost.

-

Supplier Factors: Supplier reputation, experience, and geographic location can influence pricing. Established suppliers may command higher prices due to perceived reliability and quality assurance.

-

Incoterms: The chosen Incoterms affect pricing by determining who is responsible for shipping costs and risk during transit. Understanding these terms can help buyers calculate total costs more accurately.

What Are Some Effective Buyer Tips for Cost-Efficiency?

-

Negotiate Terms: Effective negotiation can yield better pricing and payment terms. Buyers should come prepared with market knowledge and be willing to explore multiple suppliers.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, TCO includes shipping, maintenance, and operational costs. Evaluating TCO can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local economic conditions, tariffs, and regulations. Buyers in Africa, South America, the Middle East, and Europe should be aware of these nuances and factor them into their sourcing strategies.

-

Seek Long-Term Partnerships: Building relationships with suppliers can lead to better terms and pricing over time. Long-term partnerships can facilitate smoother transactions and provide leverage during negotiations.

-

Stay Informed About Market Trends: Keeping abreast of trends in rubber and steel markets can help buyers anticipate price changes and make timely purchasing decisions.

Conclusion

In summary, effective sourcing of rubber on steel involves a comprehensive understanding of cost components and pricing influencers. By leveraging negotiation strategies and considering the total cost of ownership, international buyers can make informed decisions that align with their business objectives. It is advisable to consult multiple suppliers, compare quotes, and consider both quality and price to achieve the best outcomes.

Alternatives Analysis: Comparing rubber on steel With Other Solutions

Understanding Alternatives to Rubber on Steel

In the quest for optimal solutions in vibration isolation and structural support, various materials and bonding methods are available in the marketplace. While rubber bonded to steel has proven to be a reliable choice, it’s essential to explore alternatives that may offer different advantages depending on specific application requirements. The following analysis compares rubber on steel with two viable alternatives: polyurethane on steel and metal springs.

Comparison Table

| Comparison Aspect | Rubber On Steel | Polyurethane On Steel | Metal Springs |

|---|---|---|---|

| Performance | Excellent vibration damping and durability; ideal for extreme temperatures | High resilience and good wear resistance; versatile in applications | High load-bearing capacity; effective for dynamic loads |

| Cost | Moderate initial cost; potential for higher long-term savings due to durability | Generally lower cost than rubber; may require more frequent replacements | Higher initial cost; longevity can justify investment |

| Ease of Implementation | Requires specialized adhesive processes; skilled labor needed | Easier to implement; straightforward application methods | Simple installation; minimal training required |

| Maintenance | Low maintenance; periodic inspections recommended | Moderate maintenance; may degrade faster under certain conditions | Minimal maintenance; regular checks needed for wear |

| Best Use Case | Heavy machinery, automotive, and aerospace applications | Automotive parts, industrial equipment, and consumer products | High-impact machinery, suspension systems, and load-bearing structures |

Detailed Breakdown of Alternatives

Polyurethane on Steel

Polyurethane offers a versatile alternative to rubber on steel, particularly favored for its excellent abrasion resistance and the ability to withstand various environmental conditions. Its lower cost can be appealing for many applications, making it a practical choice for manufacturers looking to optimize their budgets. However, polyurethane may not provide the same level of vibration isolation as rubber, potentially leading to increased noise and wear in some settings. Additionally, while it is easier to apply, it may require more frequent replacements in high-stress scenarios, which could affect long-term cost efficiency.

Metal Springs

Metal springs are a traditional solution for load-bearing applications and dynamic load management. They excel in environments where high resilience and responsiveness are critical. The ease of installation and minimal maintenance required make them an attractive option for many industries. However, metal springs may not offer the same level of vibration damping as rubber or polyurethane, which can lead to increased noise and mechanical stress on connected components. Their higher initial investment may also deter some buyers, though their longevity often justifies the cost.

Illustrative image related to rubber on steel

Making the Right Choice for Your Application

When selecting between rubber on steel and its alternatives, B2B buyers must consider several factors, including performance requirements, budget constraints, and long-term maintenance needs. Each alternative presents unique benefits and drawbacks tailored to specific applications. For instance, if vibration isolation is a top priority, rubber on steel may remain the preferred choice. Conversely, if cost and ease of implementation are more pressing, polyurethane on steel could be more suitable. Ultimately, understanding the specific demands of the application and weighing these alternatives will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for rubber on steel

What Are the Critical Technical Properties of Rubber on Steel?

When considering rubber bonded to steel, several technical properties are essential for ensuring optimal performance and longevity of the product. Understanding these properties is crucial for B2B buyers who need to ensure that their applications meet specific operational demands.

-

Material Grade

The material grade refers to the specific classification of the rubber and steel used in the bonding process. Common grades for rubber include natural rubber and neoprene, each offering distinct mechanical properties. For steel, low carbon steel is frequently used due to its machinability and cost-effectiveness. Selecting the appropriate grade ensures that the final product can withstand the intended environmental conditions, such as temperature extremes and mechanical stress. -

Tensile Strength

This property measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. For rubber, high tensile strength is essential for applications involving dynamic loads, such as vibration isolation mounts. In B2B contexts, knowing the tensile strength helps buyers assess how well a product can perform under operational stresses, reducing the risk of premature failure. -

Elongation at Break

Elongation at break is a measure of how much a material can stretch before it breaks, expressed as a percentage of its original length. This property is particularly important for rubber applications, as it indicates the material’s ability to absorb shocks and vibrations. A higher elongation value typically translates to greater flexibility and durability, which is vital for industries requiring resilience in harsh conditions. -

Hardness (Shore A)

Hardness indicates the resistance of rubber to indentation and is measured on the Shore A scale. Different applications require different hardness levels; softer rubber provides better shock absorption, while harder rubber offers greater load-bearing capabilities. B2B buyers must understand the hardness requirements for their specific applications to ensure compatibility and performance. -

Compression Set

Compression set measures the rubber’s ability to return to its original thickness after being compressed. A low compression set indicates that the rubber maintains its shape over time, making it more effective for sealing and vibration isolation applications. Understanding this property helps buyers anticipate the longevity and reliability of rubber components in their products.

What Are the Common Trade Terms Used in Rubber on Steel Industry?

Familiarity with industry-specific terminology can significantly streamline the procurement process for B2B buyers. Here are some key terms to understand:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the rubber on steel industry, understanding OEM specifications ensures that components meet the necessary standards for integration into larger systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand, as it affects inventory management and cost efficiency. Knowing the MOQ helps buyers plan their purchases according to their production needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. In the rubber on steel sector, submitting an RFQ can help buyers compare options and negotiate better deals based on their requirements. -

Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers in global transactions. Understanding these terms is vital for B2B buyers to clarify shipping, insurance, and delivery obligations, ensuring smooth and compliant transactions. -

Vibration Isolation

This term refers to the process of minimizing the transmission of vibrations from one surface to another. It is a critical application of rubber on steel products, especially in automotive and industrial machinery. Buyers must understand the principles of vibration isolation to select appropriate materials that enhance performance and longevity.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and enhance product performance.

Navigating Market Dynamics and Sourcing Trends in the rubber on steel Sector

What Are the Current Market Dynamics and Key Trends in the Rubber on Steel Sector?

The rubber on steel sector is undergoing significant transformation, driven by a combination of technological advancements and evolving market demands. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for high-performance rubber-to-metal bonded products. Key drivers include the growing emphasis on automation and the increasing complexity of machinery that requires effective vibration isolation solutions.

Emerging trends in B2B technology are influencing sourcing strategies, with innovations in adhesive formulations and bonding processes enhancing product durability and performance. For instance, advanced adhesives like Chemlok® are enabling stronger and more reliable bonds between rubber and metal, minimizing failure risks in critical applications. Additionally, the rise of Industry 4.0 is promoting the adoption of smart manufacturing techniques, allowing for greater precision in production and quality control.

Market dynamics are also shaped by fluctuating raw material costs and supply chain disruptions. Buyers should be vigilant about sourcing strategies that emphasize flexibility and resilience, particularly in light of geopolitical tensions and environmental regulations. The trend toward localized supply chains is gaining traction, as companies aim to mitigate risks associated with long-distance logistics and ensure timely delivery of high-quality components.

How Is Sustainability and Ethical Sourcing Shaping the Rubber on Steel Market?

Sustainability is increasingly central to sourcing decisions within the rubber on steel sector. The environmental impact of production processes, particularly in terms of waste generation and emissions, is under scrutiny from both consumers and regulatory bodies. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, including responsible sourcing of raw materials and efficient manufacturing processes.

Ethical supply chains are essential in mitigating risks associated with labor practices and environmental degradation. Buyers should seek partnerships with manufacturers who adhere to recognized sustainability certifications, such as ISO 14001 or specific certifications for natural rubber sourcing. Utilizing “green” materials—such as recycled rubber or bio-based elastomers—can significantly reduce the carbon footprint of rubber on steel products.

Moreover, transparency in the supply chain is becoming a critical factor for buyers. Companies that can provide detailed documentation of their sourcing practices and environmental impact assessments are likely to gain a competitive edge. Engaging in sustainable practices not only enhances brand reputation but can also lead to cost savings through improved efficiency and waste reduction.

How Has the Rubber on Steel Sector Evolved Over Time?

The evolution of the rubber on steel sector is marked by significant advancements in bonding technologies and materials science. Historically, rubber-to-metal bonding faced challenges related to adhesive reliability and the performance of elastomers. Early methods relied on basic adhesives, often leading to high failure rates and limited application versatility.

With the introduction of specialized adhesives like Chemlok® and the development of advanced rubber formulations, the sector has seen a dramatic improvement in product performance. These innovations have enabled the production of vibration isolation mounts and other components that are not only more durable but also better suited to a variety of demanding environments, from automotive to industrial applications.

As the industry continues to adapt to changing technological landscapes and market demands, international B2B buyers are encouraged to stay informed about these developments to make strategic sourcing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber on steel

-

1. How do I solve bonding failures in rubber on steel applications?

To address bonding failures, ensure proper surface preparation of the steel components by removing oils, rust, and contaminants through degreasing or grit blasting. Utilize high-quality structural adhesives specifically designed for rubber-to-metal bonding, such as Chemlok® adhesives, which offer superior adhesion properties. Conduct thorough testing after the bonding process to identify any weaknesses. If issues persist, consult with a technical expert who can provide guidance tailored to your specific application and materials. -

2. What is the best adhesive for rubber on steel applications?

The best adhesive for rubber on steel bonding is a structural adhesive like Chemlok®, which has proven effective in industrial applications. This type of adhesive provides exceptional bond strength and resistance to environmental factors such as temperature fluctuations and moisture. Depending on your specific application, consult with suppliers to select the right adhesive variant that suits your rubber type (natural rubber or neoprene) and the conditions it will face. -

3. How can I ensure the quality of rubber on steel products?

To ensure quality, work with reputable suppliers who adhere to stringent manufacturing standards. Request detailed information about their production processes, materials used, and quality assurance practices. Additionally, consider obtaining samples for testing before placing large orders. Implementing a robust quality control process on your end, such as inspections and testing, can further safeguard against defects and ensure that the products meet your specifications. -

4. What customization options are available for rubber on steel products?

Customization options for rubber on steel products include variations in rubber hardness, thickness, and bonding techniques. Many manufacturers offer tailored solutions based on specific application requirements, such as temperature resistance or load-bearing capabilities. When discussing your needs with suppliers, be clear about your application’s requirements to receive the most suitable recommendations and ensure that the final product aligns with your expectations. -

5. What are the minimum order quantities (MOQs) for rubber on steel products?

Minimum order quantities (MOQs) can vary significantly among suppliers and depend on factors such as production capabilities and material availability. Typically, MOQs can range from a few hundred to several thousand units. When sourcing, inquire directly with potential suppliers about their MOQs, as some may offer flexibility for smaller businesses or first-time orders. This can help you manage inventory and reduce upfront costs. -

6. What payment terms should I expect when sourcing internationally?

Payment terms in international B2B transactions often include options such as advance payment, letters of credit, or net 30/60/90 days after delivery. Terms can vary based on the supplier’s policies, your purchasing history, and the perceived risk involved. Always negotiate favorable terms that align with your cash flow needs, and consider using escrow services for high-value transactions to ensure security for both parties. -

7. How can I vet suppliers for rubber on steel products?

To vet suppliers effectively, start by researching their reputation through industry reviews, customer testimonials, and case studies. Request certifications and compliance documentation to ensure they meet international standards. Conduct site visits if possible, or utilize third-party audits to assess their manufacturing capabilities. Engaging in preliminary discussions about their processes and response times can also provide insights into their reliability and customer service. -

8. What logistics considerations should I keep in mind when importing rubber on steel products?

When importing rubber on steel products, consider factors such as shipping methods, customs regulations, and delivery timelines. Ensure that your supplier provides all necessary documentation, including bills of lading and customs declarations, to facilitate smooth clearance. Additionally, evaluate the total landed cost, which includes shipping, duties, and taxes, to avoid unexpected expenses. Collaborating with experienced logistics partners can streamline the import process and mitigate potential delays.

Top 8 Rubber On Steel Manufacturers & Suppliers List

1. GMT Rubber – Key Products in Bonding Rubber to Metal

Domain: gmtrubber.com

Registered: 2000 (25 years)

Introduction: Key products related to bonding rubber to metal include: Anti Vibration Mounts, Machine Feet, Rubber Bobbins, Cone Mounts, Compactor Mounts, Rubber Mounts, Sandwich Mounts, Device Mounts, Isolation Mounts, Elastomeric Mounts, Buffer Rails, Wire Rope Mounts, Adjustable Machine Feet/Levelling Feet, Rubber Buffers, Stop Buffers, Rubber Pads, Resilient Wheels, Rubber Wheels, Resilient Railway Wheels, …

2. Custom Rubber Corp – Rubber to Metal Bonding Solutions

Domain: customrubbercorp.com

Registered: 1998 (27 years)

Introduction: Custom Rubber Corp. specializes in rubber to metal bonded components, offering expertise to bond various rubber materials to substrates such as steel, plastic, brass, or aluminum. They provide three main bonding methods: 1. Encapsulation (mechanical lock), which is cost-effective and eliminates the need for adhesives; 2. Chemical bonding with adhesive, suitable for complex geometries; and 3. Gluin…

3. Selleys – Kwik Grip Gel

Domain: selleys.com.au

Introduction: Selleys Kwik Grip Gel is suitable for gluing rubber to metal. It is recommended to rough up the rubber surface and clean it with Mineral Turps before applying the adhesive for better bonding.

4. Reddit – Liquid Rubber vs. Powder Coating

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Liquid rubber is being considered for coating rusty metal van shelving to prevent further rust accumulation. However, an alternative method suggested is powder coating, which involves spraying powdered urethane onto metal and baking it for durability. Powder coating is noted to be effective, cheaper, and less labor-intensive than using liquid rubber, which requires extensive cleaning of rust befor…

5. Pliobond – Effective Rubber to Steel Bonding

Domain: practicalmachinist.com

Introduction: 1. JB Weld Epoxy – Initial attempt for bonding rubber to steel, but not very effective. 2. 3M 5200 – A caulk product considered but uncertain for rubber and metal bonding. 3. Pliobond – Recommended for good bond to clean steel and rubber, requires careful cleaning with alcohol. 4. Goop – Successfully used for bonding rubber on a belt sander, durable but not effective with gasoline. 5. RTV – Sugges…

6. The Rubber Company – Rubber to Metal Bonding Solutions

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: Key Features: Tailored to meet specific requirements, bond strength superior to any adhesive, ideal for complex parts, reduced assembly time, wide variety of material options available. Product Description: Rubber to metal bonding is ideal for fabricating components like valve assemblies, shafts, and rollers, fusing rubber with steel, aluminium, and brass, widely used in Rail and Transport sectors…

7. Smooth-On – Urethane Rubber Bonding Solutions

Domain: smooth-on.com

Registered: 1996 (29 years)

Introduction: Urethane rubber will not stick to some metals (e.g., brass or stainless steel) under any circumstances. Urethane rubbers that exude oil (e.g., PMC-121® WET, PMC®-780 WET) will not bond permanently to any metal. Recommended alternatives for bonding urethane rubber to metals include Vytaflex®, Reoflex®, or Brush-On® urethanes. To improve bonding, it is advised to etch or sand the metal surface, clea…

8. Pierce Roberts – Rubber to Metal Bonding Specialists

Domain: pierceroberts.com

Registered: 2005 (20 years)

Introduction: Rubber to Metal Bonding Specialists – Pierce Roberts Rubber Co. offers custom rubber molding services, specializing in rubber to metal bonding. Key services include research and development of molded rubber parts, custom rubber mixing and formulating, rapid prototyping of molded rubber parts, and CNC machining for custom rubber molded parts. The company serves various markets such as electronics, …

Strategic Sourcing Conclusion and Outlook for rubber on steel

In the dynamic landscape of rubber on steel applications, strategic sourcing emerges as a cornerstone for international B2B buyers. Understanding the intricacies of rubber-to-metal bonding processes, including the selection of high-performance adhesives like LORD’s Chemlok®, is essential for ensuring product durability and performance. By prioritizing quality in material selection and manufacturing techniques, businesses can mitigate risks associated with bond failures and optimize their supply chains.

For buyers in Africa, South America, the Middle East, and Europe, the potential for innovation and cost savings in rubber on steel applications is significant. Collaborating with experienced suppliers who offer comprehensive technical support can enhance product development and application outcomes. This partnership approach not only fosters reliability but also positions businesses to stay ahead of market trends.

As we look to the future, the demand for advanced rubber on steel solutions is expected to grow, driven by the need for enhanced performance in various industries, including automotive and industrial equipment. Now is the time to evaluate your sourcing strategies and engage with suppliers that can deliver cutting-edge solutions tailored to your specific needs. Embrace this opportunity to strengthen your supply chain and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.