Choosing Your Wiring Diagram Pressure Switch: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for wiring diagram pressure switch

In the dynamic landscape of global industrial operations, understanding the intricacies of wiring diagram pressure switches is paramount for B2B buyers seeking reliable solutions. These components serve as critical control centers for various applications, from air compressors to well pumps, ensuring safe and efficient system performance. However, sourcing the right pressure switch and understanding its wiring can pose significant challenges, particularly for international buyers navigating diverse electrical standards and regulations.

This comprehensive guide delves into the multifaceted world of wiring diagram pressure switches, offering insights on various types, their applications across different industries, and essential considerations for supplier vetting. Buyers will find valuable information on cost factors, compatibility issues, and best practices for installation, enabling them to make informed purchasing decisions. Whether you’re operating in Africa, South America, the Middle East, or Europe—countries such as Germany and Brazil—this guide is tailored to address your unique market needs.

By equipping B2B buyers with actionable knowledge and practical advice, this resource empowers organizations to enhance operational efficiency, reduce downtime, and ultimately, achieve greater profitability. As you navigate the complexities of sourcing wiring diagram pressure switches, let this guide serve as your trusted companion in making sound, strategic choices for your business.

Understanding wiring diagram pressure switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Pressure Switch | Uses a diaphragm and mechanical contacts | HVAC systems, water pumps | Pros: Simple design, reliable; Cons: Limited precision, less suitable for modern automation. |

| Electronic Pressure Switch | Incorporates electronic sensors and digital readouts | Industrial automation, robotics | Pros: High accuracy, programmable settings; Cons: Higher cost, requires more technical knowledge. |

| Differential Pressure Switch | Monitors pressure differences between two points | Filtration systems, HVAC applications | Pros: Precise control, essential for safety; Cons: Complex installation, may require calibration. |

| Adjustable Pressure Switch | Allows manual adjustment of pressure settings | Air compressors, irrigation systems | Pros: Customizable for specific needs; Cons: User error can lead to misconfigurations. |

| Low-Pressure Switch | Activates at lower pressure thresholds | Fire suppression systems, fuel systems | Pros: Essential for safety in critical applications; Cons: Limited applications, may be less durable. |

What Are the Characteristics of Mechanical Pressure Switches?

Mechanical pressure switches are characterized by their straightforward design, utilizing a diaphragm to detect pressure changes. This type is widely used in HVAC systems and water pumps due to its reliability and simplicity. B2B buyers seeking cost-effective solutions often prefer mechanical switches for their robustness in less demanding environments. However, they may lack the precision required for more advanced applications, making them less suitable for industries that rely on stringent pressure control.

How Do Electronic Pressure Switches Enhance Efficiency?

Electronic pressure switches utilize advanced sensors and digital displays to provide precise pressure readings and control. These switches are ideal for industrial automation and robotics applications, where accuracy is paramount. B2B buyers should consider the initial investment against the long-term benefits of reduced downtime and improved efficiency. While they offer programmable settings for various operational needs, the complexity may require specialized training for staff.

What Makes Differential Pressure Switches Essential in B2B Applications?

Differential pressure switches are designed to monitor the pressure difference between two points, making them indispensable in filtration systems and HVAC applications. Their ability to provide precise control enhances safety and efficiency. For B2B buyers, understanding the installation requirements and the need for calibration is crucial, as improper setup can lead to system failures. Despite their complexity, the benefits of accurate pressure monitoring justify the investment.

Why Choose Adjustable Pressure Switches for Custom Applications?

Adjustable pressure switches allow users to manually set desired pressure levels, making them suitable for air compressors and irrigation systems. This flexibility is a significant advantage for B2B buyers who require tailored solutions for specific operational needs. However, the potential for user error during adjustments necessitates thorough training and clear operational guidelines to avoid misconfigurations that could impact system performance.

What Are the Key Considerations for Low-Pressure Switches?

Low-pressure switches are designed to activate at lower pressure thresholds, making them critical for safety in applications such as fire suppression and fuel systems. B2B buyers must consider the specific operational context and the switch’s durability, as these components often face demanding conditions. While they are essential for ensuring safety in critical applications, their limited scope may restrict their use in broader industrial settings.

Key Industrial Applications of wiring diagram pressure switch

| Industry/Sector | Specific Application of wiring diagram pressure switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Management | Wiring pressure switches for well pumps | Ensures reliable water supply and pressure regulation | Compatibility with local voltage standards and pump types |

| Manufacturing | Pressure control in pneumatic systems | Enhances operational efficiency and safety | Durability and resistance to industrial environments |

| HVAC | Regulation of air conditioning and refrigeration systems | Improves energy efficiency and system performance | Temperature and pressure range suitability |

| Agriculture | Automation in irrigation systems | Optimizes water usage and crop yield | Resistance to environmental factors and ease of installation |

| Oil & Gas | Monitoring and control of pressure in pipelines | Prevents leaks and ensures safety in operations | Compliance with international safety standards |

How is a Wiring Diagram Pressure Switch Used in Water Management?

In the water management sector, wiring diagram pressure switches are crucial for well pumps. They regulate the pressure in systems that supply water to residential and commercial properties. By maintaining consistent pressure, these switches prevent pump burnout and ensure efficient operation. Buyers from regions with variable water supply, such as parts of Africa and South America, should consider switches that are compatible with local voltage standards and the specific types of pumps in use.

What Role Does a Wiring Diagram Pressure Switch Play in Manufacturing?

In manufacturing, pressure switches are integral to pneumatic systems that drive machinery. These switches help regulate pressure levels, thereby preventing equipment failures and enhancing operational efficiency. For B2B buyers in this sector, particularly in Europe and the Middle East, sourcing pressure switches that are durable and resistant to harsh industrial environments is essential for maintaining production uptime and safety.

How Do HVAC Systems Benefit from Wiring Diagram Pressure Switches?

In HVAC applications, wiring diagram pressure switches control the operation of air conditioning and refrigeration systems. They help maintain optimal pressure levels, which directly affects energy efficiency and system performance. Buyers in Europe, where energy regulations are stringent, should prioritize switches that can operate effectively within specific temperature and pressure ranges to comply with energy-saving standards.

Why Are Wiring Diagram Pressure Switches Important in Agriculture?

For agricultural applications, wiring diagram pressure switches are vital for automating irrigation systems. These switches ensure that water is delivered efficiently, optimizing usage and enhancing crop yields. Buyers, especially in developing regions, should look for switches that can withstand environmental factors such as humidity and temperature fluctuations while being easy to install and maintain.

How Do Wiring Diagram Pressure Switches Ensure Safety in Oil & Gas?

In the oil and gas industry, wiring diagram pressure switches are used to monitor and control pressure in pipelines. They play a critical role in preventing leaks and ensuring safe operations. International buyers should focus on sourcing switches that comply with safety standards relevant to their region, particularly in the Middle East, where safety regulations are rigorously enforced.

3 Common User Pain Points for ‘wiring diagram pressure switch’ & Their Solutions

Scenario 1: Miswiring Leading to Equipment Failure

The Problem: One of the most significant challenges faced by B2B buyers, particularly those in manufacturing and industrial sectors, is the risk of miswiring pressure switches. This issue often arises from inadequate understanding of wiring diagrams or the specific requirements of different systems. Miswiring can lead to equipment failure, causing costly downtime and potential safety hazards. For instance, a factory that relies on air compressors may experience continuous operation of the compressor due to improper wiring, which can cause overheating and eventual breakdown.

The Solution: To mitigate this risk, it is crucial to invest in thorough training for staff responsible for wiring installations. Providing comprehensive manuals and clear wiring diagrams tailored to the specific equipment can enhance understanding. Additionally, sourcing pressure switches that come with detailed installation guides and visual aids can be beneficial. When selecting a wiring diagram pressure switch, ensure that it includes labeled terminals and a straightforward explanation of each wire’s function. Implement a system of checks, such as peer reviews of wiring setups before power is applied, to catch potential mistakes early.

Scenario 2: Inconsistent Pressure Control and System Performance

The Problem: Another prevalent issue is inconsistent performance from pressure-controlled systems due to improper wiring. B2B buyers often face difficulties when pressure switches do not engage or disengage at the correct pressure levels, leading to inefficient operations. This inconsistency can result from incorrect wiring configurations, such as connecting motor contacts instead of line contacts. Such errors can ultimately lead to overpressurization, posing safety risks and damaging equipment.

The Solution: To address this pain point, businesses should prioritize using pressure switches that come with clear wiring diagrams and installation instructions. When wiring a pressure switch, it’s essential to familiarize staff with the specific functions of each terminal, ensuring that power input wires are connected to the correct terminals. Additionally, conducting regular training sessions focused on troubleshooting common wiring issues can empower teams to identify and rectify errors promptly. Implementing a standardized testing procedure after installation—using tools like multimeters to verify voltage and functionality—will further ensure that systems operate efficiently and safely.

Scenario 3: Limited Access to Technical Support and Resources

The Problem: For many international B2B buyers, especially in regions with less access to technical expertise, sourcing reliable technical support for wiring pressure switches can be a daunting task. This challenge is exacerbated by language barriers and varying electrical standards across countries. Buyers may find themselves struggling to get timely assistance when they encounter problems, leading to extended downtimes and frustration.

The Solution: To overcome this hurdle, businesses should establish partnerships with suppliers who offer robust technical support services. Look for manufacturers that provide multilingual resources and have a responsive customer service team available via various communication channels. Additionally, consider sourcing pressure switches from suppliers that offer online training resources, such as video tutorials or webinars, to help users better understand installation and troubleshooting processes. Building a network of local technicians trained in wiring pressure switches can also create a buffer against potential issues, ensuring that help is available on-site when needed.

Strategic Material Selection Guide for wiring diagram pressure switch

What Are the Key Materials for Wiring Diagram Pressure Switches?

When selecting materials for wiring diagram pressure switches, it’s essential to consider their specific properties, advantages, and limitations. The right choice can significantly influence performance, reliability, and compliance with international standards. Here, we analyze four common materials used in wiring diagram pressure switches.

What Are the Properties and Suitability of Copper for Wiring?

Key Properties:

Copper is highly conductive, offering excellent electrical performance with a temperature rating of up to 200°C. It also has good corrosion resistance, especially when coated.

Pros & Cons:

Copper’s durability and conductivity make it a preferred choice for wiring applications. However, its higher cost compared to alternatives like aluminum can be a drawback. Additionally, copper is susceptible to oxidation, which may affect its conductivity over time.

Impact on Application:

Copper is compatible with various media, including air and water, making it versatile for different pressure switch applications. However, its cost might deter budget-conscious buyers.

International Considerations:

In regions like Europe, compliance with standards such as DIN and ASTM is critical. Buyers should ensure that copper wiring meets these standards to avoid issues in installation and operation.

How Does Aluminum Compare as a Wiring Material?

Key Properties:

Aluminum is lightweight and has a lower conductivity than copper, but it is still suitable for wiring applications. Its temperature rating can reach up to 150°C.

Pros & Cons:

Aluminum is more cost-effective than copper, making it an attractive option for large-scale projects. However, its lower conductivity can lead to increased energy loss. Additionally, aluminum is prone to corrosion if not properly treated.

Impact on Application:

Aluminum is suitable for applications where weight is a concern, such as in mobile or portable pressure switches. However, its lower performance in high-temperature environments may limit its use.

International Considerations:

Buyers in regions like Africa and South America should verify that aluminum wiring complies with local standards, as regulations can vary significantly.

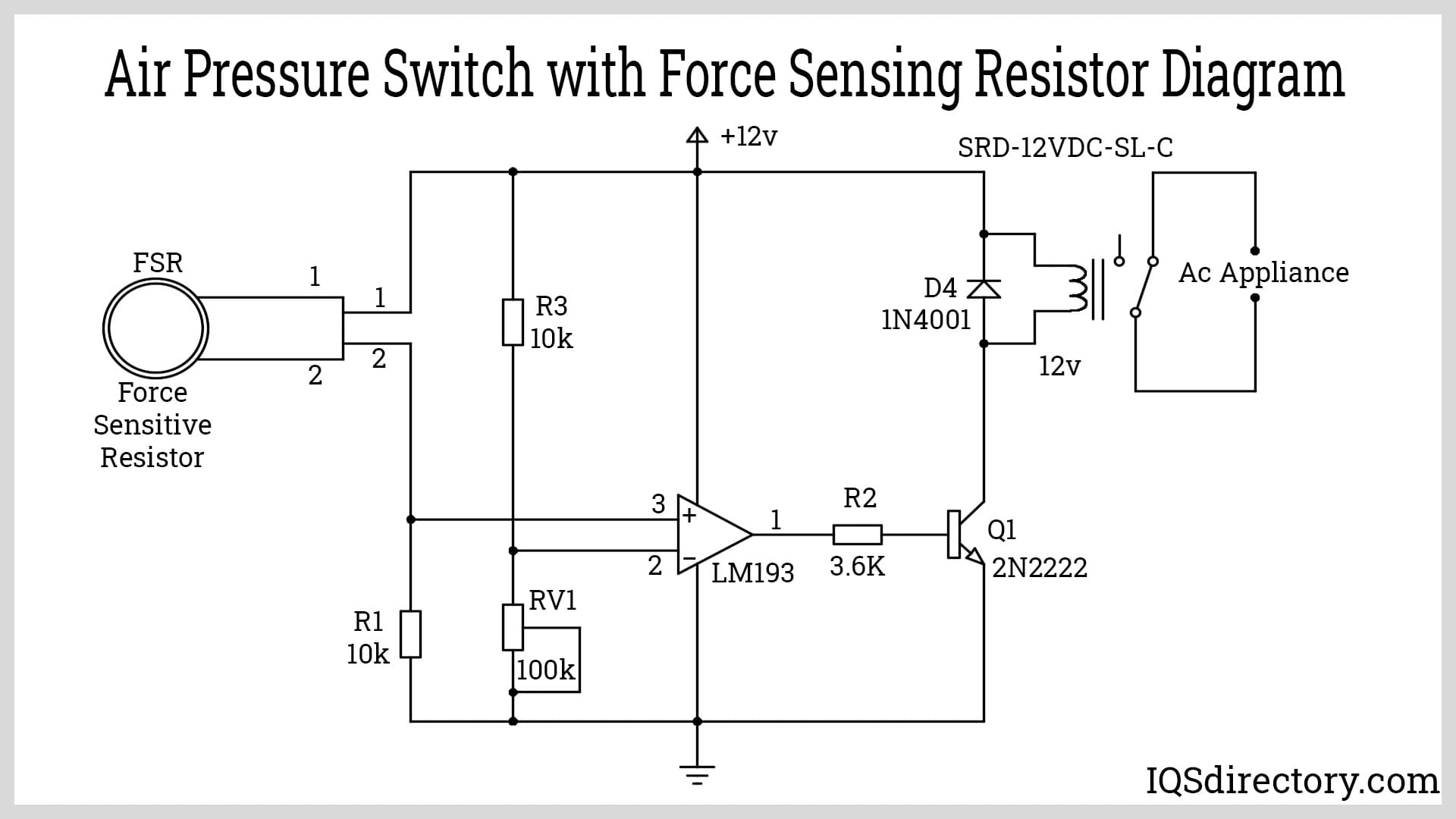

Illustrative image related to wiring diagram pressure switch

What Advantages Does Stainless Steel Offer for Pressure Switch Components?

Key Properties:

Stainless steel is known for its exceptional corrosion resistance and high strength. It can withstand high pressures and temperatures, often rated up to 300°C.

Pros & Cons:

The durability of stainless steel makes it ideal for harsh environments. However, its higher manufacturing complexity and cost can be prohibitive for some applications.

Impact on Application:

Stainless steel is particularly suitable for pressure switches used in corrosive environments, such as chemical processing. Its robustness ensures long-term reliability.

International Considerations:

In the Middle East, where corrosive conditions are common, stainless steel components must meet specific standards to ensure safety and compliance.

Why is Thermoplastic a Viable Option for Wiring Insulation?

Key Properties:

Thermoplastic materials offer good electrical insulation properties and can operate within a temperature range of -40°C to 85°C.

Pros & Cons:

Thermoplastics are lightweight and cost-effective, making them suitable for various applications. However, they may lack the durability of metals and can be susceptible to environmental degradation.

Impact on Application:

Thermoplastics are ideal for low-pressure applications where insulation is critical. However, they may not be suitable for high-pressure or high-temperature environments.

International Considerations:

B2B buyers should ensure that thermoplastic materials comply with international standards such as JIS, particularly in regions with stringent safety regulations.

Summary Table of Material Selection for Wiring Diagram Pressure Switches

| Material | Typical Use Case for wiring diagram pressure switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | General wiring in pressure switches | Excellent conductivity | Higher cost, oxidation risk | High |

| Aluminum | Lightweight applications, budget-sensitive projects | Cost-effective | Lower conductivity, corrosion risk | Medium |

| Stainless Steel | Harsh environments, chemical processing | Exceptional corrosion resistance | Higher cost, manufacturing complexity | High |

| Thermoplastic | Insulation for low-pressure applications | Lightweight, cost-effective | Less durable, environmental degradation | Low |

This comprehensive analysis of materials for wiring diagram pressure switches provides valuable insights for international B2B buyers, ensuring they make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for wiring diagram pressure switch

What Are the Main Stages of Manufacturing a Wiring Diagram Pressure Switch?

The manufacturing process for a wiring diagram pressure switch involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets stringent quality and performance standards.

Material Preparation

The first step in manufacturing involves sourcing high-quality materials, including metals, plastics, and electronic components. This stage often includes inspecting raw materials for compliance with specifications and standards. Suppliers must provide documentation to verify the quality of their materials, such as certificates of analysis and material safety data sheets.

Forming

In this stage, the prepared materials are transformed into the necessary components. Techniques like stamping, molding, or machining are commonly used to create the switch housing, terminals, and other parts. For instance, metal components may be stamped from sheets using precision dies, while plastic parts might be created through injection molding. This stage requires careful control of dimensions and tolerances to ensure compatibility among components.

Assembly

Once all individual parts are produced, they are assembled into the final product. This process often involves automated machinery, particularly for high-volume production, but can also include manual assembly for more complex components. Quality control measures during assembly might include visual inspections and automated testing to ensure that each component fits correctly and functions as intended.

Finishing

The final stage involves applying protective coatings, printing labels, and performing final inspections. This stage is crucial for ensuring the product is durable and meets aesthetic requirements. Finishing processes may include plating, painting, or applying insulation, depending on the intended application of the pressure switch.

How is Quality Assurance Implemented in Manufacturing Wiring Diagram Pressure Switches?

Quality assurance (QA) is an essential aspect of the manufacturing process, ensuring that each wiring diagram pressure switch meets international and industry-specific standards.

What Are the Relevant International Standards?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that a company consistently provides products that meet customer and regulatory requirements. Additionally, certifications such as CE mark or API standards may be relevant for specific applications, especially in regions like Europe and the Middle East.

What Quality Control Checkpoints Are Commonly Used?

Quality control is implemented at various stages of production through several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify they meet specified requirements. Suppliers should provide quality documentation for review.

- In-Process Quality Control (IPQC): Ongoing inspections are performed during the manufacturing process to identify any defects early. This could involve monitoring the forming processes or assembly stages.

- Final Quality Control (FQC): Once the pressure switches are assembled, they undergo a final inspection to ensure they function correctly and meet all specifications. This may include electrical testing and performance checks.

What Are Common Testing Methods for Wiring Diagram Pressure Switches?

Testing methods are integral to ensuring the reliability and safety of wiring diagram pressure switches. Common testing methods include:

- Electrical Testing: This checks for continuity, resistance, and insulation integrity. A multimeter is often used to verify that the switch operates correctly under various conditions.

- Pressure Testing: This method assesses the switch’s response to different pressure levels, ensuring it activates and deactivates as designed.

- Environmental Testing: To ensure durability, switches may be subjected to temperature extremes, humidity, and vibration tests that simulate real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are several strategies to consider:

Supplier Audits

Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control measures, and compliance with international standards. This firsthand observation can provide insight into the supplier’s commitment to quality.

Requesting Quality Reports

Buyers should request detailed quality reports that outline the supplier’s testing procedures and results. This documentation can include IQC, IPQC, and FQC data, showcasing the supplier’s adherence to quality standards.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These inspectors can verify compliance with industry standards and provide certification that can be crucial for international transactions.

What Quality Control Nuances Should International B2B Buyers Consider?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural and Regulatory Differences: Understanding local regulations and cultural attitudes towards quality can aid in establishing effective communication with suppliers. For example, European buyers may place a higher emphasis on CE certification compared to buyers in other regions.

- Supply Chain Reliability: Ensure that suppliers have robust supply chains that can provide consistent quality materials. This is particularly important for components that must meet specific regulatory standards.

- Traceability: Buyers should inquire about the traceability of materials used in manufacturing. This is vital for ensuring that all components can be tracked back to their source, which is particularly important in industries like aerospace and automotive.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for wiring diagram pressure switches is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, while also implementing stringent quality control measures, manufacturers can produce reliable products that meet international standards. B2B buyers can enhance their procurement strategies by verifying supplier quality through audits, reports, and third-party inspections, ultimately ensuring they acquire high-quality pressure switches for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wiring diagram pressure switch’

In the intricate world of industrial equipment, selecting the right wiring diagram pressure switch is crucial for ensuring operational efficiency and safety. This guide offers a step-by-step checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Understanding your specific technical requirements is the first step in sourcing a wiring diagram pressure switch. This includes voltage ratings, current specifications, and application type (e.g., well pumps or air compressors). Clearly defining these specifications helps in narrowing down potential suppliers that can meet your needs.

Step 2: Research Industry Standards and Compliance

Familiarize yourself with relevant industry standards and compliance requirements applicable to pressure switches in your region. Different regions may have distinct regulations regarding electrical components, and compliance is essential for safety and legal operations. Look for certifications such as CE, UL, or ISO that demonstrate adherence to these standards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct thorough evaluations. Request company profiles, product catalogs, and case studies to assess their capabilities. Additionally, seek references from buyers in similar industries or regions to gauge their reliability and performance history. This step minimizes risks associated with supplier selection.

Step 4: Request Technical Documentation

Obtain detailed technical documentation from potential suppliers, including wiring diagrams, installation guides, and user manuals. This information is crucial for understanding how to integrate the pressure switch into your existing systems effectively. Ensure that the documentation is clear, comprehensive, and suited to your specific applications.

Step 5: Inquire About After-Sales Support and Warranty

Assess the after-sales support offered by suppliers, as this can significantly impact your operational continuity. Reliable support includes installation assistance, troubleshooting guidance, and easy access to spare parts. Additionally, clarify warranty terms to ensure that you are protected against potential defects or failures.

Step 6: Compare Pricing and Payment Terms

Gather quotes from various suppliers to compare pricing structures and payment terms. While cost is a critical factor, also consider the value offered, including product quality, support, and warranty. Ensure that payment terms align with your financial planning to avoid cash flow issues.

Step 7: Test Samples Before Bulk Ordering

If possible, request samples of the wiring diagram pressure switches for testing before placing a bulk order. This allows you to evaluate the product’s performance and compatibility with your systems. Testing ensures that you make an informed decision and reduces the likelihood of costly returns or replacements.

By following this structured checklist, B2B buyers can streamline the procurement process for wiring diagram pressure switches, ensuring they select the right products for their operational needs.

Comprehensive Cost and Pricing Analysis for wiring diagram pressure switch Sourcing

In the global market for wiring diagram pressure switches, understanding the cost structure and pricing dynamics is crucial for B2B buyers. This section delves into the various components of cost, price influencers, and strategic tips for negotiation, particularly relevant to international buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Wiring Diagram Pressure Switch Sourcing?

-

Materials: The primary cost driver in manufacturing wiring diagram pressure switches is the quality of materials used. This includes the pressure switch housing, electrical components, and wiring, which can vary significantly based on specifications and desired performance. High-quality materials often lead to increased durability and efficiency, influencing the overall pricing.

-

Labor: Labor costs encompass the wages of skilled technicians and engineers involved in the assembly and testing of pressure switches. Regions with lower labor costs may offer competitive pricing, but it’s essential to consider the skill level and experience of the workforce, which can affect product reliability.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, potentially lowering the final price for buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized pressure switches. These costs are typically amortized over the production run, impacting pricing based on order volume.

-

Quality Control (QC): Implementing rigorous quality control measures is vital to ensure product reliability. The costs associated with QC processes can vary, with higher investment in quality often translating to higher prices but improved performance and safety.

-

Logistics: Shipping and handling costs can greatly affect the final price, especially for international shipments. Factors such as distance, shipping method, and customs duties must be considered. Understanding Incoterms is essential for buyers to navigate these logistics effectively.

-

Margin: Suppliers build a margin into their pricing to ensure profitability. This margin can vary widely based on market competition and perceived product value.

What Influences Prices in the Wiring Diagram Pressure Switch Market?

-

Volume/MOQ: Minimum order quantities (MOQ) and order volume play a significant role in pricing. Larger orders often yield bulk discounts, making it economically advantageous for buyers to negotiate higher quantities.

-

Specifications and Customization: Custom specifications can lead to increased costs due to unique materials or design requirements. Buyers should balance customization with cost-effectiveness by clearly defining their needs.

-

Quality and Certifications: Products that meet international quality standards or possess specific certifications (e.g., ISO, CE) may command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind regarding product performance.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they define the responsibilities of buyers and sellers in shipping arrangements. Different terms can lead to varying total costs, impacting overall pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms, especially for larger orders. Suppliers may be willing to offer discounts or better payment terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate long-term costs, including maintenance, potential failures, and energy efficiency, to determine the true value of the switch.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, tariffs, and regional market conditions that can affect pricing. It’s beneficial to establish relationships with multiple suppliers to compare quotes and terms.

-

Evaluate Supplier Relationships: Building long-term relationships with reliable suppliers can lead to better pricing, improved service, and priority access to products.

Conclusion

Sourcing wiring diagram pressure switches involves navigating a complex landscape of costs and pricing dynamics. By understanding the key cost components, price influencers, and applying strategic buying tips, international B2B buyers can optimize their sourcing processes and achieve better value for their investments. Always remember to check for indicative prices, as they can fluctuate based on the factors discussed.

Alternatives Analysis: Comparing wiring diagram pressure switch With Other Solutions

Exploring Alternatives to Wiring Diagram Pressure Switches in Industrial Applications

When evaluating solutions for pressure regulation and control in industrial systems, it’s crucial to consider alternatives to the traditional wiring diagram pressure switch. While these switches are widely used for their reliability and straightforward operation, other technologies may offer distinct advantages depending on the application. Below, we provide a comparison of wiring diagram pressure switches against two viable alternatives: digital pressure sensors and pneumatic pressure regulators.

| Comparison Aspect | Wiring Diagram Pressure Switch | Digital Pressure Sensor | Pneumatic Pressure Regulator |

|---|---|---|---|

| Performance | Reliable for on/off control | High precision, continuous monitoring | Adjustable pressure control |

| Cost | Generally low-cost | Higher initial investment | Moderate cost |

| Ease of Implementation | Requires basic wiring skills | Needs calibration and programming | Simple installation |

| Maintenance | Low maintenance | Requires periodic calibration | Regular filter replacement |

| Best Use Case | Simple systems, on/off control | Automated systems, data logging | Variable pressure applications |

Understanding Digital Pressure Sensors: Advantages and Disadvantages

Digital pressure sensors offer a modern alternative to traditional wiring diagram pressure switches. These sensors provide high precision and can continuously monitor pressure levels, making them ideal for automated systems requiring data logging. The initial investment is generally higher than that of a wiring diagram pressure switch, but the enhanced performance and ability to integrate with smart systems can justify the cost. However, they do require periodic calibration to maintain accuracy, which can add to maintenance efforts.

Evaluating Pneumatic Pressure Regulators: Pros and Cons

Pneumatic pressure regulators are another alternative that serves a specific function in pressure management. These devices allow for adjustable pressure control, making them suitable for applications where the required pressure may fluctuate. While their installation is relatively simple, they do require regular maintenance, particularly in replacing filters to ensure clean operation. The cost is moderate, making them a reasonable option for businesses looking to optimize their pneumatic systems without extensive investment.

Making the Right Choice for Your Industrial Needs

When choosing between a wiring diagram pressure switch and its alternatives, consider the specific requirements of your application. If you need a straightforward solution for basic on/off control, a wiring diagram pressure switch may be the most effective option. However, for more complex systems that require precise monitoring and data integration, a digital pressure sensor would be beneficial despite the higher cost and maintenance. Alternatively, if your application demands variable pressure control, a pneumatic pressure regulator could provide the necessary flexibility. Ultimately, evaluating performance, cost, ease of implementation, and maintenance will guide B2B buyers in selecting the most suitable pressure management solution for their operational needs.

Essential Technical Properties and Trade Terminology for wiring diagram pressure switch

What Are the Key Technical Properties of Wiring Diagram Pressure Switches?

Understanding the essential technical properties of wiring diagram pressure switches is crucial for B2B buyers aiming to ensure compatibility and reliability in their applications. Here are some critical specifications:

-

Voltage Rating

Voltage rating refers to the maximum voltage the pressure switch can handle without risking damage or failure. Common ratings include 110V and 220V for different applications. Selecting a switch with the correct voltage rating is vital to prevent electrical hazards and ensure operational efficiency. -

Current Rating

This specification indicates the maximum current (measured in amperes) that the switch can safely carry. It is essential for ensuring that the switch can handle the load of the connected device, be it an air compressor or water pump. Using a switch with an inadequate current rating can lead to overheating and potential system failures. -

Temperature Tolerance

The temperature tolerance defines the range of ambient temperatures in which the pressure switch can operate effectively. This is especially important in regions with extreme climates, as a switch that cannot tolerate high or low temperatures may fail prematurely, leading to costly downtime. -

Material Grade

The construction materials of the pressure switch impact its durability and resistance to environmental factors. Common materials include brass, plastic, and stainless steel. A higher-grade material often means better resistance to corrosion and longer service life, which is a key consideration for B2B buyers in industrial applications. -

Differential Pressure Settings

This property indicates the range of pressure that the switch can detect and respond to. Properly configured differential settings are crucial for ensuring that the system maintains optimal pressure levels, preventing over-pressurization or inadequate pressure. -

Ingress Protection (IP) Rating

The IP rating denotes the degree of protection provided against dust and water ingress. For applications in harsh environments, a higher IP rating (e.g., IP65) is essential to ensure the longevity and reliability of the pressure switch.

What Are Common Trade Terms Related to Wiring Diagram Pressure Switches?

Familiarity with industry jargon can facilitate smoother transactions and communication between buyers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end product. Understanding OEM specifications is important for ensuring compatibility and performance in applications that require specific components. -

MOQ (Minimum Order Quantity)

This term refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory effectively and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. It is a critical step in the procurement process, enabling buyers to compare pricing and terms from different suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers and sellers clarify who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It is crucial for B2B buyers to understand lead times to plan their projects and avoid delays in production. -

Certification Standards

Many pressure switches must meet specific certification standards (e.g., CE, UL) to ensure safety and reliability. Familiarity with these standards helps buyers choose products that comply with regulatory requirements in their respective markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing wiring diagram pressure switches, ultimately leading to improved operational efficiency and reduced risks.

Navigating Market Dynamics and Sourcing Trends in the wiring diagram pressure switch Sector

What Are the Current Market Dynamics and Key Trends in the Wiring Diagram Pressure Switch Sector?

The wiring diagram pressure switch market is experiencing significant growth, driven by the increasing demand for automation in various industries, including agriculture, water management, and HVAC systems. The rise of smart technologies and IoT applications has led to the development of advanced pressure switches that offer enhanced functionality, such as remote monitoring and predictive maintenance. This trend is particularly relevant for B2B buyers in regions like Africa and South America, where infrastructure development is gaining momentum and the need for reliable pressure management solutions is paramount.

Emerging technologies, such as wireless communication and data analytics, are reshaping the sourcing landscape. International B2B buyers are increasingly seeking suppliers that offer integrated solutions, combining hardware with software capabilities. This shift towards system-level thinking is encouraging manufacturers to innovate, resulting in products that not only meet traditional pressure management requirements but also contribute to overall system efficiency. Additionally, the emphasis on regulatory compliance and safety standards is influencing purchasing decisions, with buyers prioritizing suppliers that adhere to international certifications.

How Is Sustainability and Ethical Sourcing Impacting the Wiring Diagram Pressure Switch Market?

Sustainability is becoming a cornerstone of the wiring diagram pressure switch sector, with environmental impact considerations influencing procurement strategies. B2B buyers are increasingly aware of the ecological footprint of their supply chains, prompting a shift towards products that utilize sustainable materials and manufacturing processes. This trend is particularly pronounced in Europe, where stringent environmental regulations drive the demand for greener solutions.

The importance of ethical supply chains cannot be overstated. Buyers are looking for suppliers that demonstrate a commitment to ethical practices, including fair labor standards and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management systems and RoHS compliance for hazardous substances are becoming critical benchmarks in supplier selection. As companies strive to enhance their corporate social responsibility (CSR) profiles, those offering environmentally friendly wiring diagram pressure switches will likely gain a competitive edge.

How Has the Wiring Diagram Pressure Switch Sector Evolved Over Time?

The evolution of the wiring diagram pressure switch sector can be traced back to the increasing complexity of industrial systems. Initially, pressure switches were simple mechanical devices, but advancements in technology have transformed them into sophisticated electronic components capable of precise control and monitoring. Over the past few decades, the integration of microcontrollers and digital interfaces has allowed for greater customization and functionality, enabling manufacturers to meet the diverse needs of B2B buyers across various industries.

Today, the market is witnessing a convergence of traditional pressure management solutions with cutting-edge technologies, such as IoT and smart automation. This evolution is shaping the future of the wiring diagram pressure switch sector, as businesses seek products that not only enhance operational efficiency but also align with sustainability and ethical sourcing initiatives. As these trends continue to unfold, the sector is poised for further innovation and growth, offering exciting opportunities for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of wiring diagram pressure switch

-

How do I solve wiring issues with pressure switches?

Wiring issues often stem from incorrect connections, loose terminals, or using improper gauge wires. To troubleshoot, first ensure that all power is disconnected. Inspect the wiring against the manufacturer’s diagram to confirm correct terminal connections (L1, L2 for power and T1, T2 for the motor). Use a multimeter to test voltage and continuity. If problems persist, consider consulting with a qualified technician to avoid safety hazards and ensure compliance with local electrical codes. -

What is the best wiring diagram for a pressure switch?

The best wiring diagram for a pressure switch will depend on the specific application—be it for a well pump or an air compressor. Always refer to the manufacturer’s documentation for precise diagrams tailored to your model. A good diagram will clearly label terminals (like L1, L2, T1, T2) and provide safety warnings. For complex systems, consider working with an electrical engineer to ensure optimal performance and safety. -

What are the common mistakes when wiring a pressure switch?

Common mistakes include bypassing the pressure switch by wiring directly to the motor, incorrect terminal connections, and misunderstanding the function of various contacts. These errors can lead to operational inefficiencies or even safety hazards, such as overpressurization. Always double-check connections and adhere to the wiring diagram provided by the manufacturer. Additionally, ensure proper grounding to mitigate electrical shock risks. -

How can I vet suppliers for pressure switch wiring diagrams?

To effectively vet suppliers, check their industry reputation, client testimonials, and certifications. Request samples of their wiring diagrams and pressure switches to assess quality and compatibility with your applications. Engage in conversations about their manufacturing processes and quality assurance measures. Consider suppliers with experience in international trade, especially those familiar with regulations in your target market. -

What is the typical minimum order quantity (MOQ) for pressure switches?

Minimum order quantities can vary significantly by supplier, often ranging from 50 to 500 units for pressure switches. Factors influencing MOQ include the supplier’s production capacity, the complexity of the product, and customization options. It’s advisable to communicate your requirements upfront and negotiate based on your projected demand. Some suppliers may offer lower MOQs for new customers or trial orders. -

What payment terms should I expect when purchasing pressure switches internationally?

Payment terms can vary by supplier and region, but common practices include upfront payments, partial payments upon order confirmation, and the balance upon shipment. For larger orders, letters of credit or escrow services may be used to ensure security for both parties. Always clarify payment terms during negotiations to avoid misunderstandings and ensure timely processing of your order. -

What quality assurance practices should I look for in pressure switch suppliers?

Look for suppliers that implement rigorous quality assurance (QA) practices, including ISO certifications and regular third-party audits. Verify if they conduct pre-shipment inspections and have in-house testing facilities to ensure product reliability. Ask about their warranty policies and how they handle defects or returns. A solid QA program indicates a commitment to delivering high-quality products. -

How do logistics impact the sourcing of pressure switches?

Logistics play a critical role in the sourcing of pressure switches, affecting delivery times, costs, and overall supply chain efficiency. Consider factors like shipping methods, customs regulations, and the supplier’s location. Establish clear logistics plans that account for potential delays and ensure compliance with international shipping standards. Engage with freight forwarders experienced in your target markets for optimized logistics solutions.

Top 2 Wiring Diagram Pressure Switch Manufacturers & Suppliers List

1. RPS – 220V Well Pump Pressure Switch

Domain: rpswaterpumps.com

Registered: 2022 (3 years)

Introduction: 220V pressure switch for well pumps, designed for use with pressure tanks or pressurized irrigation systems. Requires tools such as a screwdriver, wire stripper, wire cutter, voltage tester, and adjustable wrench. Materials needed include 220V regular action well pump pressure switch, wiring for connecting pump starter box to pressure switch, wiring for connecting pressure switch to breaker or out…

2. Facebook – Pressure Switch Wiring Diagram

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Pressure Switch Wiring Diagram, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for wiring diagram pressure switch

As the global demand for pressure switches continues to rise, particularly in industries such as agriculture, water management, and manufacturing, strategic sourcing becomes essential for B2B buyers. Understanding the wiring diagrams and installation processes not only enhances operational efficiency but also mitigates risks associated with improper installations. By investing in high-quality pressure switches and ensuring proper wiring, businesses can improve their system reliability and safety.

International buyers, especially from Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer comprehensive support, including detailed wiring diagrams and expert guidance. This approach ensures that installations are executed flawlessly, maximizing both productivity and safety.

Looking ahead, the landscape of pressure switch technology is evolving, with innovations poised to enhance functionality and energy efficiency. Buyers are encouraged to stay informed about these advancements and consider partnerships with suppliers that prioritize sustainable practices and cutting-edge technology. Engage with your suppliers, ask for best practices, and leverage their expertise to ensure your operations remain at the forefront of efficiency and reliability. Together, we can drive success in an increasingly interconnected market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.