Graphite Stick: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for graphite stick

In the ever-evolving global market, sourcing graphite sticks presents a unique set of challenges for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. Understanding the diverse types of graphite sticks available—ranging from traditional compressed varieties to innovative water-soluble options—can be daunting. Buyers must navigate not only the technical specifications and applications of these products but also the nuances of supplier vetting, pricing structures, and shipping logistics across different regions.

This comprehensive guide is designed to empower B2B buyers by providing actionable insights into the graphite stick market. From exploring the various types and their specific uses in artistic and industrial applications to offering tips on how to evaluate suppliers effectively, this resource aims to enhance your purchasing decisions. Key considerations such as cost analysis, quality assurance, and market trends will be covered, equipping you with the knowledge necessary to make informed choices.

As a buyer from countries like Nigeria or Vietnam, you will find tailored strategies that address your specific market conditions and procurement needs. By leveraging this guide, you will not only streamline your sourcing process but also gain a competitive edge in your respective industries.

Understanding graphite stick Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Jumbo Compressed Graphite Sticks | Available in soft, medium, and hard degrees; flat edges for broad strokes; can be sanded for fine points. | Fine arts, sketching, shading, and blending. | Pros: Versatile for various techniques; affordable. Cons: Potential for breakage; size may vary slightly. |

| Water-Soluble Graphite Sticks | Hexagonal shape for comfort; can be used dry or wet; creates watercolor effects. | Illustration, mixed media art, and design. | Pros: Versatile application; easily erasable. Cons: Requires additional tools (water, brushes) for full effect. |

| Woodless Graphite Sticks | Solid graphite body; available in various hardness levels; no wood casing. | Drafting, sketching, and detailed drawings. | Pros: Consistent performance; less waste. Cons: Can be less portable than traditional pencils. |

| Graphite Crayons | Soft and smooth, wrapped in paper; ideal for sketching and layout. | Educational settings, art classes, and workshops. | Pros: Easy to handle; clean to use. Cons: Limited precision compared to sticks. |

| Graphite Powder | Finely ground graphite; can be mixed with water or used dry for shading. | Background shading, textures, and mixed media. | Pros: Flexible application; can create various textures. Cons: Messy to handle; requires additional tools for application. |

What are the Characteristics of Jumbo Compressed Graphite Sticks?

Jumbo compressed graphite sticks are designed for artists seeking versatility in their work. They come in various degrees of hardness—soft, medium, and hard—allowing for a range of strokes from broad to fine. The flat edge is particularly useful for creating wide strokes, while the ability to sand the stick to a point enables detailed work. Buyers should consider the handcrafted nature of these sticks, which may lead to slight variations in size and potential breakage during shipping.

How do Water-Soluble Graphite Sticks Enhance Artistic Techniques?

Water-soluble graphite sticks offer artists a unique blend of dry and wet applications. Their hexagonal shape ensures a comfortable grip, making them easy to handle during extended use. Artists can utilize them dry for sketching or wet with a brush for watercolor effects, adding depth and texture to their work. B2B buyers should note that while these sticks are versatile, they require additional materials like water and brushes for optimal use.

What Advantages do Woodless Graphite Sticks Provide?

Woodless graphite sticks are ideal for those who prioritize consistency and minimal waste. Made entirely of solid graphite, they are available in various hardness levels, making them suitable for detailed drawings and sketches. Their lack of wood casing means they can be sharpened to a fine point without losing material. However, buyers may find them less portable than traditional graphite pencils, which could be a consideration for on-the-go artists.

In What Situations are Graphite Crayons Most Effective?

Graphite crayons are particularly effective in educational settings and art classes, where ease of use is paramount. Wrapped in paper, they provide a clean way to sketch and layout designs without the mess associated with traditional graphite sticks. While they are excellent for general sketching, they may not offer the precision required for more detailed work. Buyers should consider the intended use when selecting these products.

How Can Graphite Powder be Utilized in Art?

Graphite powder is a flexible medium that can be used for shading, texturing, and creating backgrounds. It can be applied dry or mixed with water for various effects, making it a valuable tool in mixed media projects. However, it is essential to note that graphite powder can be messy, requiring additional tools for application and cleanup. B2B buyers should ensure they have the necessary equipment to handle this medium effectively.

Key Industrial Applications of graphite stick

| Industry/Sector | Specific Application of graphite stick | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Art and Design | Sketching and shading in fine arts | Enhances creativity with versatile drawing techniques | Quality of graphite, range of softness, and availability |

| Education | Teaching drawing techniques in art classes | Improves student engagement and skill development | Bulk purchasing options, durability, and safety standards |

| Manufacturing | Creating prototypes and models in product design | Facilitates quick iterations and visualizations | Consistency in quality, size specifications, and sourcing reliability |

| Construction and Engineering | Drafting plans and designs for architectural projects | Streamlines the design process and improves accuracy | Availability of various degrees of hardness, and bulk supply |

| Cosmetics and Beauty | Formulating and testing new makeup products | Enables precise application and testing of formulations | Sourcing for specific purity levels and compliance with regulations |

How is Graphite Stick Used in the Art and Design Sector?

In the art and design sector, graphite sticks serve as essential tools for sketching and shading. Artists utilize them for their ability to create both fine and broad strokes, making them ideal for detailed illustrations and expressive pieces. The versatility of graphite allows for smooth blending and layering, which enhances the overall quality of artwork. For international buyers, sourcing high-quality graphite sticks that offer a range of softness is crucial to meet various artistic needs, ensuring that artists can achieve their desired effects without compromising on quality.

Illustrative image related to graphite stick

What Role Does Graphite Stick Play in Education?

In educational settings, graphite sticks are commonly used to teach drawing techniques in art classes. They help students develop essential skills, such as shading and perspective, while engaging them in creative expression. The tactile experience of using graphite sticks can enhance learning outcomes, making art more accessible and enjoyable. For B2B buyers in the education sector, considerations such as bulk purchasing options and the durability of the sticks are vital to ensure that they can withstand frequent use in classroom environments.

How is Graphite Stick Beneficial in Manufacturing?

In manufacturing, graphite sticks are employed for creating prototypes and models, particularly in product design. Their ease of use allows designers to quickly sketch ideas and iterate on concepts, facilitating a faster design process. This capability is essential for businesses that require visual representations of their products before finalizing designs. Buyers in this sector should focus on sourcing graphite sticks that offer consistent quality and specific size specifications to meet their design requirements efficiently.

Why is Graphite Stick Important in Construction and Engineering?

In the construction and engineering industries, graphite sticks are utilized for drafting plans and designs, particularly in architectural projects. Their ability to produce precise lines and shading enhances the clarity of technical drawings, which is crucial for communication among stakeholders. For international buyers in these sectors, it is important to ensure that the graphite sticks sourced provide a range of hardness levels suitable for different drafting needs and that they can be procured in bulk to support ongoing projects.

Illustrative image related to graphite stick

How Does Graphite Stick Support the Cosmetics and Beauty Industry?

The cosmetics and beauty industry employs graphite sticks for formulating and testing new makeup products. They enable precise application during the testing phase, helping formulators assess the texture and performance of various products. For buyers in this sector, sourcing graphite sticks that meet specific purity levels and comply with industry regulations is essential to ensure product safety and quality. This attention to detail can significantly impact product success in a highly competitive market.

3 Common User Pain Points for ‘graphite stick’ & Their Solutions

Scenario 1: Ensuring Consistent Quality in Graphite Sticks

The Problem: Many B2B buyers, especially those in art supplies and educational sectors, struggle with inconsistent quality and performance in graphite sticks. Variability in hardness, texture, and even size can lead to frustration among users, resulting in dissatisfaction with the final product. For businesses relying on graphite sticks for production or teaching, this inconsistency can disrupt workflows, waste resources, and tarnish their reputation if they cannot deliver reliable products to their customers.

The Solution: To mitigate these issues, it is essential for buyers to establish strong relationships with reputable suppliers who prioritize quality control. When sourcing graphite sticks, request samples to evaluate their hardness and texture before committing to bulk purchases. Additionally, ensure that the supplier provides specifications regarding the manufacturing process and materials used. Look for suppliers that offer a range of degrees (soft, medium, hard) to cater to different artistic needs, and consider those that allow for customization based on your specific requirements. This proactive approach not only ensures consistent quality but also strengthens supplier relationships, leading to better service and support.

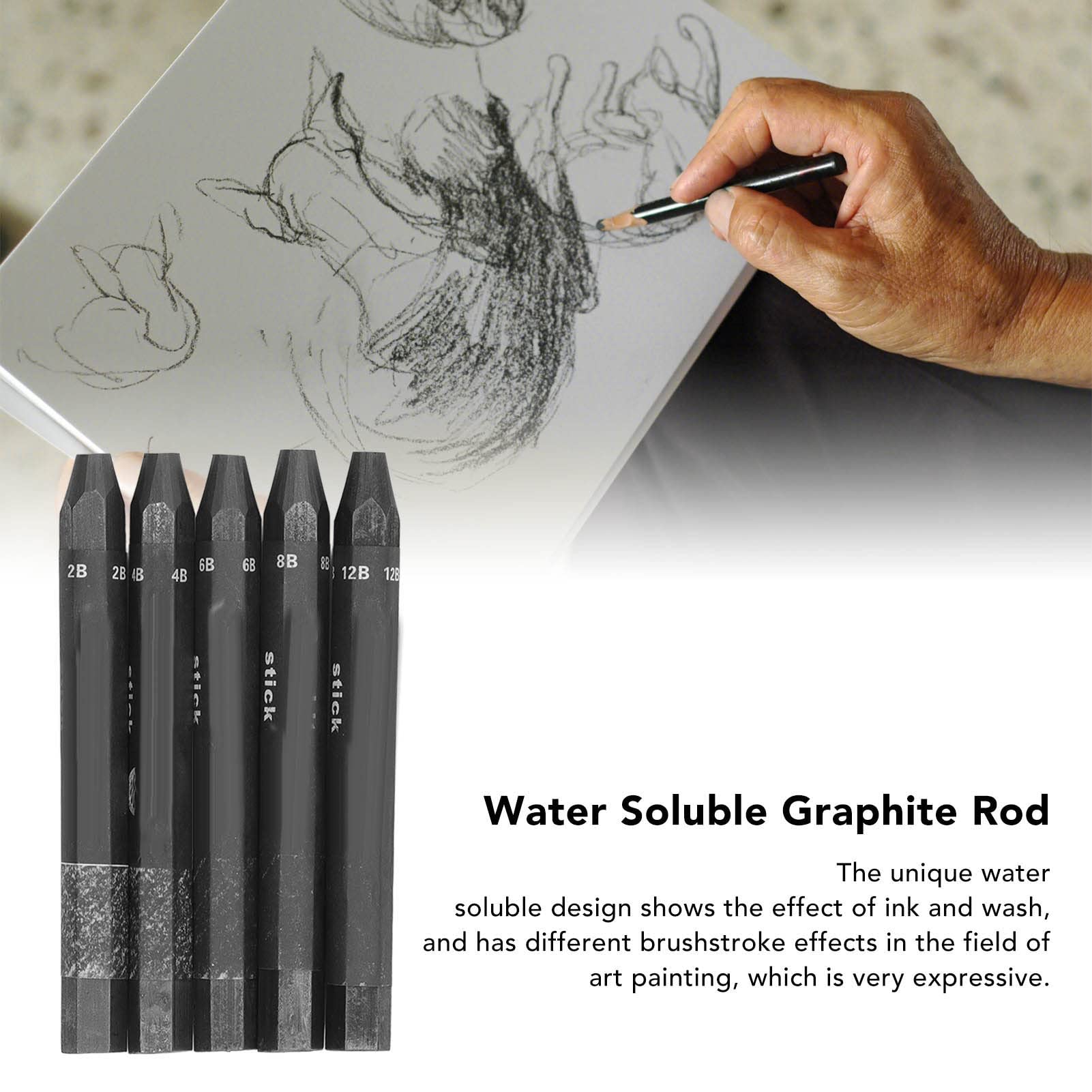

Illustrative image related to graphite stick

Scenario 2: Addressing Supply Chain Disruptions

The Problem: B2B buyers often face challenges related to supply chain disruptions, particularly in regions like Africa and South America, where logistics can be unpredictable. Natural disasters, political instability, or transportation issues can lead to delays or shortages of graphite sticks, hindering production schedules and project timelines. This unpredictability can create significant financial burdens and impact customer satisfaction.

The Solution: To combat supply chain issues, buyers should diversify their sources of graphite sticks. Instead of relying on a single supplier or region, consider establishing relationships with multiple suppliers across different geographic locations. This strategy not only reduces the risk of disruptions but also offers flexibility in pricing and product availability. Additionally, maintaining a buffer stock of essential supplies can help mitigate the impact of unexpected delays. Implementing inventory management systems that track stock levels and reorder points can also ensure that you are prepared for fluctuations in demand or supply disruptions.

Scenario 3: Navigating the Variety of Graphite Stick Options

The Problem: With a plethora of graphite stick options available, B2B buyers can find it overwhelming to choose the right products for their specific applications. Differences in formulation, shape, and water solubility can make it challenging to determine which graphite sticks will meet their needs—whether for fine art, drafting, or educational purposes. Poor choices can lead to subpar results, affecting the quality of work produced and potentially leading to higher costs due to returns or rework.

Illustrative image related to graphite stick

The Solution: To make informed decisions, buyers should invest time in understanding the applications and characteristics of various graphite sticks. Create a comprehensive comparison chart that outlines the features of different products, including their hardness, solubility, and intended use. Conducting product testing in-house with small batches can provide valuable insights into performance and user satisfaction. Furthermore, collaborating with artists or educators can yield feedback on their experiences and preferences, guiding purchasing decisions. Engaging with suppliers who offer expert advice and educational resources can also help buyers better navigate their options, ensuring they select the most suitable graphite sticks for their specific needs.

Strategic Material Selection Guide for graphite stick

What Are the Common Materials Used in Graphite Sticks?

When selecting graphite sticks for various applications, understanding the materials involved is crucial for B2B buyers. The primary materials used in graphite sticks include compressed graphite, water-soluble graphite, and woodless graphite. Each material has unique properties that affect performance, cost, and suitability for different applications.

How Does Compressed Graphite Perform in Graphite Sticks?

Compressed graphite is a popular choice for graphite sticks, known for its solid structure and versatility. This material typically exhibits high durability and can withstand a range of temperatures, making it suitable for various artistic and technical applications. The key advantage of compressed graphite is its ability to create both broad strokes and fine details, which is essential for artists and designers.

However, compressed graphite can be relatively brittle, leading to breakage during shipping or handling. Additionally, while it is cost-effective, the manufacturing process can be complex, requiring specialized equipment to ensure uniformity. For international buyers, especially in regions like Africa and South America, compliance with local standards such as ASTM or DIN is essential to ensure product quality and safety.

What Advantages Do Water-Soluble Graphite Sticks Offer?

Water-soluble graphite sticks provide a unique advantage by allowing users to create watercolor effects. When mixed with water, these sticks produce rich, smooth lines that are ideal for artists seeking versatility in their media. The hexagonal shape of these sticks also offers a comfortable grip, enhancing usability.

On the downside, water-soluble graphite can be less durable than its compressed counterpart, as it may dissolve or smudge when exposed to excessive moisture. This characteristic limits its use in environments with high humidity, which is a consideration for buyers in tropical regions. Moreover, international shipping regulations may affect the availability of these products, particularly in areas with stringent import controls.

Why Choose Woodless Graphite for Certain Applications?

Woodless graphite sticks are made entirely of graphite, eliminating the wood casing found in traditional pencils. This design allows for a more substantial application of graphite, making them ideal for shading and large-scale drawings. The absence of wood means that users can utilize the entire stick without waste, offering a cost-effective solution for artists.

However, woodless graphite sticks can be more expensive due to their manufacturing process. They also require careful handling, as they can be prone to breakage. For international buyers, understanding the local market’s preferences and price sensitivity is crucial, as it can influence purchasing decisions.

Illustrative image related to graphite stick

Summary of Material Considerations for Graphite Sticks

When selecting graphite sticks, B2B buyers should consider the specific properties, advantages, and limitations of each material. Understanding these factors can significantly impact the choice of product based on application needs, budget constraints, and compliance with international standards.

| Material | Typical Use Case for graphite stick | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Compressed Graphite | Sketching, shading, detailed work | Versatile for broad and fine strokes | Brittle, prone to breakage | Medium |

| Water-Soluble Graphite | Watercolor effects, sketching | Creates rich, smooth lines with water | Less durable, sensitive to moisture | Medium |

| Woodless Graphite | Large-scale drawings, shading | No waste, full utilization of graphite | More expensive, prone to breakage | High |

In-depth Look: Manufacturing Processes and Quality Assurance for graphite stick

What Are the Key Stages in the Manufacturing Process of Graphite Sticks?

The manufacturing of graphite sticks involves several critical stages that ensure the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality graphite. Natural graphite is often mined and then processed to create a fine powder. This powder may be mixed with binding agents to enhance the stick’s integrity and usability. For premium products, suppliers may use a blend of different grades of graphite to achieve desired hardness and softness levels.

-

Forming: In this stage, the prepared graphite mixture is subjected to a forming technique, usually extrusion or molding. For extruded sticks, the mixture is pushed through a die to create long shapes, which are then cut to size. Molding involves compressing the mixture into specific shapes using high-pressure machinery. This stage is crucial as it defines the dimensions and density of the graphite sticks.

-

Assembly: While graphite sticks are typically single-component products, some specialized variants may require additional components such as coatings or packaging. This stage involves ensuring that any additional elements are securely attached and that the sticks are organized for further processing.

-

Finishing: The finishing process involves drying and curing the graphite sticks. This step is essential to remove moisture and achieve the desired hardness. After curing, the sticks may be sanded or polished to provide a smooth surface. This enhances the usability for artists or engineers who require precise control over their drawing or drafting tools.

How Is Quality Assurance Implemented in Graphite Stick Production?

Quality assurance (QA) is paramount in ensuring that graphite sticks meet both industry standards and customer expectations. The implementation of QA typically follows several international and industry-specific standards.

-

International Standards: Many manufacturers adhere to ISO 9001, which sets out criteria for a quality management system. This standard emphasizes a process approach to ensure consistent quality and continuous improvement. Compliance with ISO 9001 can be a significant factor for B2B buyers, particularly in international markets.

-

Industry-Specific Standards: Depending on the application, additional certifications such as CE marking (for safety in Europe) or API (American Petroleum Institute) specifications may be required. These certifications ensure that the graphite sticks are safe for use in specific applications, such as industrial or artistic purposes.

-

Quality Control Checkpoints: Manufacturers typically implement several quality control checkpoints throughout the production process:

– Incoming Quality Control (IQC): This initial phase involves inspecting raw materials for compliance with specifications. Graphite quality is assessed for purity and granularity.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples are taken to monitor the quality of the formed and finished products. This helps identify issues early in the production cycle.

– Final Quality Control (FQC): After production, the finished graphite sticks undergo a rigorous inspection process. This includes testing for dimensions, surface quality, and performance characteristics.

What Common Testing Methods Are Used for Graphite Sticks?

To ensure that graphite sticks meet quality standards, several testing methods are commonly employed:

-

Dimensional Testing: This involves measuring the length, width, and diameter of the graphite sticks to ensure they meet specified tolerances. Precision is crucial for applications requiring fine detail.

-

Hardness Testing: Hardness is often measured using a durometer or similar device to ensure that the graphite sticks have the appropriate firmness for their intended use.

-

Performance Testing: This testing evaluates the usability of the graphite sticks, including their ability to produce consistent lines, ease of blending, and resistance to breakage. Performance tests often simulate real-world conditions.

-

Chemical Analysis: Some manufacturers conduct chemical analyses to ensure that the graphite is free from harmful substances and meets safety standards. This is particularly important for products intended for use in sensitive environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is critical to ensuring product reliability and compliance with local standards.

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their quality management systems. This includes reviewing compliance with ISO standards and examining their QA processes in detail.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the quality control measures in place. These reports should include information on testing methods, results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can include audits, product sampling, and performance evaluations.

-

Certifications and Compliance Documents: Buyers should verify that suppliers hold relevant certifications and comply with international standards. This may include requesting copies of ISO certifications, CE markings, or other industry-specific compliance documents.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing graphite sticks from international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several nuances to consider:

-

Cultural Differences: Understanding the cultural context of suppliers can influence communication and expectations around quality. Buyers should be aware of regional norms regarding manufacturing practices and customer service.

-

Regulatory Compliance: Different regions may have varying regulations concerning product safety and quality. It is crucial for buyers to ensure that suppliers are compliant with local regulations, which may differ significantly from their home markets.

-

Shipping and Logistics: Quality can be compromised during shipping if not properly managed. Buyers should ensure that suppliers have robust logistics practices in place to protect products during transit, especially for delicate items like graphite sticks.

-

Local Market Knowledge: Engaging local representatives or consultants can help buyers navigate the complexities of sourcing from different regions. These professionals can provide insights into reliable suppliers and help assess quality control practices effectively.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing graphite sticks, ensuring they receive high-quality products that meet their specific needs.

Illustrative image related to graphite stick

Practical Sourcing Guide: A Step-by-Step Checklist for ‘graphite stick’

In today’s competitive market, sourcing high-quality graphite sticks is crucial for businesses involved in art supplies, manufacturing, or any field requiring precise drawing tools. This guide will help international B2B buyers navigate the procurement process, ensuring they find the right products to meet their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline your technical requirements for graphite sticks. Consider factors such as the degree of hardness (soft, medium, hard), dimensions (length and diameter), and specific features (e.g., water-soluble properties or ease of blending). Clearly defined specifications will streamline your search and help you communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in graphite sticks. Utilize online directories, trade platforms, and industry forums to gather a list of manufacturers and distributors. Pay attention to their product range, pricing, and customer reviews to gauge their reputation in the market.

Illustrative image related to graphite stick

Step 3: Evaluate Supplier Certifications and Standards

It’s vital to ensure that your chosen suppliers adhere to quality standards and certifications. Look for ISO certifications or industry-specific qualifications that demonstrate a commitment to quality control. This step not only mitigates risks but also assures you that the products you receive will meet international quality benchmarks.

Step 4: Request Samples for Evaluation

Once you have shortlisted potential suppliers, request samples of their graphite sticks. Testing samples allows you to assess the quality, performance, and suitability of the products for your intended use. This hands-on evaluation can reveal important information about the material properties and usability of the graphite sticks.

Step 5: Inquire About Pricing and Payment Terms

Discuss pricing structures with your selected suppliers, including bulk order discounts and any additional costs such as shipping or handling fees. Understanding the total cost upfront will help you budget effectively. Additionally, clarify payment terms to ensure they align with your financial practices, as this can affect cash flow.

Step 6: Review Shipping and Delivery Options

Confirm the shipping methods and delivery timelines offered by your suppliers. Consider factors such as international shipping capabilities, lead times, and any potential customs issues that may arise. Reliable shipping options are crucial for maintaining your supply chain and ensuring timely project completion.

Step 7: Establish a Communication Plan

Effective communication with your suppliers is key to a successful partnership. Establish a clear communication plan that outlines how often you will check in, preferred communication channels, and points of contact. Consistent communication helps address any issues promptly and fosters a positive working relationship.

By following these steps, B2B buyers can confidently navigate the procurement of graphite sticks, ensuring that they source high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for graphite stick Sourcing

What Are the Key Cost Components in Graphite Stick Sourcing?

When sourcing graphite sticks, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality and type of graphite significantly influence costs. Higher-grade graphite is generally more expensive but can enhance the product’s performance. Sourcing materials locally versus internationally can also affect pricing due to transportation and import duties.

-

Labor: The labor cost varies depending on the manufacturing region. Countries with lower labor costs may offer a competitive advantage, but it’s crucial to consider the skill level of the workforce, which can impact product quality.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can lower overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial tooling costs can be significant, especially for customized graphite sticks. If a supplier needs to create specialized molds or tools, this cost will be reflected in the pricing.

-

Quality Control (QC): Effective QC processes ensure product consistency and reliability. Suppliers who invest in robust QC measures may have higher costs, which can affect pricing but can also lead to reduced returns and customer dissatisfaction.

-

Logistics: Shipping and handling costs can vary greatly based on the distance from the supplier, mode of transport, and any tariffs or customs duties involved. Understanding Incoterms is crucial, as they define the responsibilities of buyers and sellers in shipping.

-

Margin: Finally, suppliers will add a profit margin to cover their business costs and ensure sustainability. This margin can vary based on market competition and demand.

How Do Price Influencers Affect Graphite Stick Costs?

Several factors can influence the final pricing of graphite sticks:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often come with discounts due to economies of scale. Negotiating MOQs can lead to better pricing, especially for B2B buyers planning long-term projects.

-

Specifications and Customization: Custom specifications—such as dimensions, hardness, and packaging—can lead to increased costs. Clear communication about requirements can help in obtaining accurate quotes.

-

Materials and Quality Certifications: Suppliers offering certified products (e.g., ISO certifications) may charge more due to the assurance of quality and compliance with international standards.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can impact pricing. Established suppliers with a track record may command higher prices but often provide better service and quality assurance.

-

Incoterms: Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can help buyers make informed decisions about total landed costs, which can significantly affect budgeting.

What Buyer Tips Can Enhance Cost Efficiency in Graphite Stick Sourcing?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, the following strategies can enhance cost efficiency:

-

Negotiation: Always negotiate pricing, especially when dealing with larger orders. Suppliers may be willing to offer discounts based on volume or long-term contracts.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but also logistics, storage, and disposal costs. A lower upfront price may lead to higher TCO if quality is subpar.

-

Research and Comparison: Conduct thorough market research to compare prices and quality among different suppliers. This can provide leverage during negotiations and help identify the best value.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions, currency fluctuations, and economic factors that may influence pricing. This knowledge can help in making informed purchasing decisions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and service. Suppliers are often more flexible with loyal customers.

Conclusion

Sourcing graphite sticks involves a complex interplay of costs and pricing factors. By understanding these components and leveraging negotiation strategies, B2B buyers can optimize their purchasing decisions and enhance their overall cost efficiency. Always remember that indicative prices can fluctuate due to market conditions, so maintaining open communication with suppliers is vital for securing the best deals.

Alternatives Analysis: Comparing graphite stick With Other Solutions

Exploring Alternatives to Graphite Sticks: A Comparative Analysis

In the realm of artistic and technical drawing, graphite sticks are a popular choice due to their versatility and ease of use. However, various alternatives can cater to different needs and preferences. This section delves into a comparison of graphite sticks against two viable alternatives: water-soluble graphite sticks and woodless graphite pencils. Each solution offers unique features that may align better with specific project requirements or user preferences.

| Comparison Aspect | Graphite Stick | Water-Soluble Graphite Sticks | Woodless Graphite Pencils |

|---|---|---|---|

| Performance | Offers broad and fine strokes for sketching and shading. | Provides versatile use; can be used dry or with water for watercolor effects. | Delivers precise control and fine lines, ideal for detailed work. |

| Cost | Generally affordable, around $5 for a set. | Slightly higher at approximately $10 for a set. | Varies widely, typically $2-$20 depending on brand and quality. |

| Ease of Implementation | Simple to use; requires no special tools. | Requires water for optimal effects; may need brushes for application. | Straightforward use; can be sharpened for precision. |

| Maintenance | Minimal; should be stored properly to prevent breakage. | Needs care to avoid water damage; brushes need cleaning. | Low maintenance; periodic sharpening required. |

| Best Use Case | Ideal for sketching, shading, and creating backgrounds. | Excellent for artists looking for mixed media effects and watercolor techniques. | Best suited for detailed drawings and technical illustrations. |

What are the Benefits and Drawbacks of Water-Soluble Graphite Sticks?

Water-soluble graphite sticks are an innovative alternative that allows artists to explore both dry and wet mediums. When used dry, they can create rich, bold lines similar to traditional graphite. However, the unique feature of these sticks is their ability to dissolve in water, transforming sketches into watercolor-like images. This versatility can be particularly appealing for artists looking to combine drawing with painting techniques. On the downside, they may require additional tools such as brushes and water containers, potentially complicating the setup.

How Do Woodless Graphite Pencils Compare?

Woodless graphite pencils present a different approach by offering a solid, thick core of graphite without the encasing wood. This design allows for a greater range of marks, from thin lines to broader strokes, without the need to sharpen frequently. They are ideal for detailed work and can be easily transported, making them a favorite among artists who value precision. However, their cost can vary significantly based on brand and quality, which may not be as economical as traditional graphite sticks for bulk purchases.

Choosing the Right Solution for Your Needs

In selecting the right drawing solution, B2B buyers should consider their specific project requirements, budget constraints, and desired outcomes. Graphite sticks are a solid choice for general use, offering versatility at an affordable price. On the other hand, water-soluble graphite sticks are ideal for those looking to blend drawing with painting, while woodless graphite pencils cater to artists focused on precision and detail. Evaluating these aspects will enable buyers to make informed decisions that align with their artistic or technical needs, ensuring they invest in the most suitable tools for their projects.

Essential Technical Properties and Trade Terminology for graphite stick

What Are the Key Technical Properties of Graphite Sticks for B2B Buyers?

When sourcing graphite sticks, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Composition

Graphite sticks are primarily composed of natural or synthetic graphite. The material grade can affect the stick’s performance in terms of hardness and texture. High-quality graphite provides better smoothness and consistency in drawing. B2B buyers should assess the composition to ensure it aligns with their intended applications, such as fine art or industrial design.

2. Hardness Grades

Graphite sticks typically come in various hardness levels, including soft, medium, and hard. The hardness influences the darkness of the marks produced; softer sticks yield darker lines while harder sticks create lighter marks. Understanding these grades is essential for artists and manufacturers who require specific characteristics for their projects, ensuring the correct product is sourced for different applications.

Illustrative image related to graphite stick

3. Dimensions and Weight

The size and weight of graphite sticks can vary significantly, often measured in inches or millimeters. Common dimensions include lengths of 4 to 5 inches and diameters ranging from ¼ to ½ inch. A thorough understanding of these measurements helps buyers select the right size for their needs, whether for detailed work or broader strokes.

4. Erasability

Graphite sticks differ in their erasability, which can be a critical factor for artists and designers. Products designed for easy erasure will facilitate corrections and adjustments, enhancing workflow efficiency. B2B buyers should inquire about the specific erasing properties of the sticks they intend to purchase to ensure they meet their project requirements.

5. Water Solubility

Some graphite sticks are formulated to be water-soluble, allowing for versatile applications such as watercolor effects. This property is particularly valuable for artists looking to create a range of textures and effects. Understanding whether a product is water-soluble can influence purchasing decisions, especially for mixed media projects.

What Common Trade Terms Should B2B Buyers Know When Purchasing Graphite Sticks?

Navigating the procurement of graphite sticks involves familiarizing oneself with key industry terminology. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

In the context of graphite sticks, OEM refers to companies that produce products that can be sold under another brand’s name. Buyers looking for custom or branded graphite sticks should consider working with OEMs that can meet their specifications.

Illustrative image related to graphite stick

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can significantly impact inventory management and cost-effectiveness. Buyers should always inquire about MOQs to ensure they can meet supplier requirements while staying within budget.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products. For B2B buyers, sending an RFQ can help gather competitive pricing and terms from multiple suppliers, aiding in cost-effective decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is essential for B2B buyers to understand shipping costs, risk transfer, and delivery obligations, especially in international transactions.

Illustrative image related to graphite stick

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is critical for buyers to manage project timelines effectively. Knowing the expected lead time for graphite sticks can help ensure that projects remain on schedule and that any necessary adjustments can be made in advance.

By grasping both the technical properties and essential trade terminology associated with graphite sticks, B2B buyers can make well-informed decisions that align with their operational needs and artistic objectives.

Navigating Market Dynamics and Sourcing Trends in the graphite stick Sector

What Are the Key Trends Shaping the Global Graphite Stick Market?

The graphite stick market is witnessing a surge in demand driven by the growing popularity of drawing, sketching, and crafting among artists and hobbyists worldwide. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where there is a burgeoning interest in art education and creative expression. Notably, the rise of digital art has spurred a renewed appreciation for traditional art materials, including graphite sticks.

In addition to this cultural shift, technological advancements are reshaping sourcing strategies. International B2B buyers are increasingly leveraging e-commerce platforms to streamline procurement, making it easier to compare products and prices from various suppliers. Moreover, the rise of artificial intelligence in supply chain management is enabling more efficient inventory management and demand forecasting, which can significantly reduce lead times and costs.

Emerging trends also indicate a shift towards customization and personalization in product offerings. Suppliers are beginning to offer graphite sticks in various degrees of hardness and sizes, catering to diverse artistic needs. This flexibility is essential for international buyers who must navigate different market preferences and standards across regions.

How Is Sustainability Influencing the Sourcing of Graphite Sticks in B2B Transactions?

Sustainability has become a pivotal concern for B2B buyers in the graphite stick sector. The environmental impact of graphite mining, particularly in regions like Africa and South America, has raised alarms about the ecological footprint associated with sourcing raw materials. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as responsible mining, waste reduction, and eco-friendly packaging.

Ethical sourcing is also gaining traction, with businesses emphasizing transparency in their supply chains. Many suppliers are now obtaining certifications that validate their commitment to ethical practices, such as Fair Trade and ISO certifications for environmental management. These credentials not only enhance brand reputation but also align with the values of consumers who are increasingly inclined to support companies that demonstrate social responsibility.

Furthermore, the use of ‘green’ materials is becoming a differentiator in the market. Suppliers are exploring alternatives to traditional graphite sources, including recycled materials and innovative manufacturing processes that minimize environmental impact. For international buyers, partnering with suppliers who prioritize sustainability can lead to enhanced customer loyalty and a competitive edge in their respective markets.

How Has the Graphite Stick Market Evolved Over Time?

The evolution of the graphite stick market can be traced back to the early 16th century when graphite was first discovered in Borrowdale, England. Initially used for marking sheep, the material quickly found its way into the hands of artists and draftsmen, leading to the production of the first graphite pencils. Over the centuries, the manufacturing process has advanced significantly, with modern techniques allowing for the creation of high-quality compressed graphite sticks that cater to a variety of artistic needs.

Today, the market is characterized by a diverse range of products, from traditional compressed graphite sticks to innovative water-soluble variants. This evolution reflects a broader trend in the art supply industry, where the demand for versatility and quality continues to drive product development. For B2B buyers, understanding this historical context is crucial as it highlights the importance of sourcing from reputable manufacturers who uphold quality standards and innovation in their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of graphite stick

-

1. How do I choose the right type of graphite stick for my needs?

Selecting the right graphite stick depends on the intended application. For fine details and intricate work, opt for softer graphite sticks that can be sharpened to a fine point. Medium and hard sticks are ideal for broader strokes and shading. Consider the specific requirements of your projects, such as whether you need water-soluble options for watercolor effects or traditional sticks for sketching. Additionally, assess the quality and brand reputation to ensure consistency and reliability in your supplies. -

2. What are the key factors to consider when sourcing graphite sticks from international suppliers?

When sourcing graphite sticks internationally, prioritize supplier reliability and quality assurance. Verify certifications and compliance with industry standards. Assess shipping capabilities, including delivery times and costs, to ensure they align with your operational needs. Investigate the supplier’s track record through reviews and references. Consider their ability to customize products to meet your specifications, including size, hardness, and packaging requirements, which can be essential for your business. -

3. What is the minimum order quantity (MOQ) for graphite sticks from suppliers?

Minimum order quantities (MOQs) for graphite sticks can vary significantly between suppliers. Typically, MOQs can range from as low as 100 units to several thousand, depending on the manufacturer and product type. It is advisable to communicate directly with potential suppliers to negotiate terms that suit your business needs. Keep in mind that higher MOQs may provide cost benefits, while lower quantities can help minimize upfront investment and inventory risk. -

4. How can I ensure the quality of graphite sticks before making a bulk purchase?

To ensure quality, request samples from suppliers before committing to a bulk order. Evaluate the samples for consistency in texture, hardness, and performance. Additionally, inquire about the supplier’s quality assurance processes, including material sourcing and production methods. Certifications from recognized quality standards can also provide assurance. Establish clear communication regarding your quality expectations and consider conducting audits or inspections if feasible. -

5. What payment terms are typically offered by suppliers of graphite sticks?

Payment terms can vary among suppliers and often depend on the relationship established. Common options include full payment in advance, partial payments with a balance upon delivery, or net payment terms (e.g., 30, 60, or 90 days). It’s crucial to clarify payment methods accepted, such as bank transfers or letters of credit, to avoid delays. Negotiate favorable terms that align with your cash flow management while ensuring the supplier is comfortable with the arrangement. -

6. How do I handle logistics and shipping when ordering graphite sticks internationally?

When ordering graphite sticks internationally, consider logistics factors such as shipping methods, costs, and delivery timelines. Engage with suppliers who have experience in international shipping to streamline the process. Review Incoterms to understand who is responsible for shipping risks and costs. Choose reliable freight forwarders and ensure proper customs documentation is prepared to avoid delays. Assess the total landed cost, including tariffs and taxes, to accurately budget your order. -

7. Can I customize graphite sticks to meet specific requirements?

Many suppliers offer customization options for graphite sticks, allowing you to specify dimensions, hardness levels, and packaging. Custom branding and labeling are also common requests. To initiate customization, communicate your requirements clearly and assess the supplier’s capabilities. Be prepared to discuss minimum order quantities and any associated costs with customizations, as these factors can impact your overall pricing. -

8. What are the best practices for vetting suppliers of graphite sticks?

Effective supplier vetting involves researching potential partners thoroughly. Start by checking their business credentials and certifications to confirm legitimacy. Review customer testimonials and case studies to gauge reliability and product quality. Request references from other clients, especially those in your industry. Conduct due diligence by visiting facilities if possible, and ensure open lines of communication. Establishing a strong relationship with your supplier can lead to better service and flexibility in future transactions.

Top 7 Graphite Stick Manufacturers & Suppliers List

1. General’s® – Jumbo Compressed Graphite Sticks

Domain: generalpencil.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Jumbo Compressed Graphite Sticks”, “brand”: “General’s® / Kimberly®”, “price”: “$5.07”, “sku”: “980ABP”, “quantity”: “In stock (can be backordered)”, “description”: “Flat edge creates broad strokes. Sticks can also be sanded to a fine point for detailed work. Drawing may be blended with a tortillion or a General’s® Kneaded Eraser. Erase with General’s® Factis® Extra Soft ES-20 Er…

2. Pacific Arc – Jumbo Water Soluble Graphite Sticks

Domain: shop.pacificarc.us

Registered: 2007 (18 years)

Introduction: {“product_name”: “Jumbo Water Soluble Graphite Sticks”, “price”: “$9.97”, “sku”: “WSG-3A”, “available_sets”: [{“set_type”: “Soft Set”, “degrees”: [“12B”, “10B”, “8B”]}, {“set_type”: “Medium Set”, “degrees”: [“6B”, “4B”, “2B”]}], “dimensions”: {“length”: “4.75 inches”, “diameter”: “7/16 inches”}, “features”: [“Hexagon-shaped body for a secure grip”, “Versatile for dry and wet use”, “Easily erasable…

3. Jerry’s Artarama – Graphite Sticks

Domain: jerrysartarama.com

Registered: 1999 (26 years)

Introduction: This company, Jerry’s Artarama – Graphite Sticks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – Graphite and Charcoal Drawing Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Graphite and compressed charcoal are used for general drawing, similar to pencils or pens. They can be used on various paper sizes, including larger sheets and smaller drawing notebooks. Artists typically alternate between the flat side and sharp edge of the charcoal for different effects, such as edges or shading. Charcoal provides darker tones compared to graphite but is messier and harder to er…

5. FlaxArt – General’s Compressed Graphite Sticks Set/4

Domain: flaxart.com

Registered: 1996 (29 years)

Introduction: General’s Compressed Graphite Sticks Set/4 includes 4 sticks: 2 soft, 1 medium, and 1 hard. The sticks are extra smooth and consistent, ideal for layout work and sketching. They are less prone to smudging than charcoal sticks, allowing for greater coverage and depth. The graphite sticks can be held at different angles and sharpened to achieve a wide range of effects. Made in the U.S.A. Current pri…

6. General’s – Jumbo Graphite Sticks Set

Domain: artistcraftsman.com

Registered: 1999 (26 years)

Introduction: General’s Jumbo Graphite Sticks Set includes 3 pieces of General’s 980ABP Jumbo Graphite Sticks. High quality graphite sticks for drawing. Available in three rectangular sticks with soft, medium, and hard densities. Jumbo size allows for easy coverage of large areas. MSRP: $4.60.

7. General Pencil – PRIMO COMPRESSED CHARCOAL STICKS SET/4

Domain: shophulls.com

Registered: 2019 (6 years)

Introduction: {“products”:[{“name”:”PRIMO COMPRESSED CHARCOAL STICKS SET/4″,”brand”:”GENERAL PENCIL”,”price”:”$5.00″,”availability”:”In Stock”},{“name”:”GENERAL’S COMPRESSED CHARCOAL STICKS ASSORTED SET/4″,”brand”:”GENERAL PENCIL”,”price”:”$4.58″,”availability”:”In Stock”},{“name”:”WIDE COMPRESSED CHARCOAL STICKS NO.6B”,”brand”:”GENERAL PENCIL”,”price”:”$4.58″,”availability”:”Sold out”},{“name”:”CARANDACHE CHAR…

Strategic Sourcing Conclusion and Outlook for graphite stick

What Are the Key Takeaways for B2B Buyers in the Graphite Stick Market?

In today’s competitive landscape, strategic sourcing of graphite sticks is essential for B2B buyers seeking high-quality, versatile products. Understanding the various applications—ranging from fine arts to industrial uses—can help buyers make informed decisions. The availability of different types, such as compressed and water-soluble graphite sticks, allows for flexibility in artistic expression and technical applications. Moreover, sourcing from reputable suppliers ensures product quality and consistency, which are critical for maintaining brand integrity.

How Can International Buyers Leverage Strategic Sourcing?

For buyers in Africa, South America, the Middle East, and Europe, engaging with suppliers that prioritize sustainability and ethical sourcing practices can enhance their market reputation. As demand for high-quality graphite products continues to rise, establishing strong relationships with manufacturers will not only secure competitive pricing but also ensure timely deliveries. This is particularly important in regions where supply chain disruptions can impact production schedules.

What’s Next for B2B Buyers in the Graphite Stick Sector?

As the market evolves, staying ahead of trends and emerging technologies will be pivotal. Buyers are encouraged to explore partnerships that facilitate innovation and product development. By investing in strategic sourcing initiatives now, businesses can position themselves for growth and success in the dynamic graphite stick market. Embrace this opportunity to enhance your procurement strategy and elevate your offerings in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.