The Definitive Guide to 213 Lithium Battery: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for 213 lithium battery

Navigating the complexities of sourcing the right 213 lithium battery can be a significant challenge for international B2B buyers. With the growing demand for high-performance energy solutions across various industries, understanding the nuances of this market is essential for making informed purchasing decisions. This comprehensive guide delves into the diverse types of 213 lithium batteries available, their specific applications—from automotive to medical devices—and the critical factors to consider when evaluating potential suppliers.

As global markets continue to expand, especially in regions like Africa, South America, the Middle East, and Europe, the need for reliable battery solutions has never been more pressing. This guide empowers B2B buyers with actionable insights on supplier vetting processes, cost considerations, and compliance with international standards, ensuring that your procurement strategy is not only efficient but also aligned with best practices.

By exploring the intricacies of the 213 lithium battery market, you will be equipped to make strategic decisions that enhance operational efficiency and meet the evolving demands of your business. Whether you are looking to optimize performance, reduce costs, or ensure sustainability, this guide serves as your essential resource for navigating the global landscape of lithium battery sourcing.

Understanding 213 lithium battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium Iron Phosphate (LiFePO4) | High thermal stability, long lifespan (2000-3000 cycles), lightweight | Electric vehicles, renewable energy storage, UPS | Pros: Long-lasting, safe, eco-friendly. Cons: Higher initial cost. |

| Lithium Polymer | Flexible design, lightweight, high energy density | Consumer electronics, drones, portable devices | Pros: Lightweight, customizable shapes. Cons: Sensitive to puncture. |

| Lithium Ion | Widely used, reliable performance, varied sizes | Laptops, smartphones, power tools | Pros: Good energy density, well-established. Cons: Shorter lifespan compared to LiFePO4. |

| Lithium Cobalt Oxide (LCO) | High energy density, excellent cycle stability | Smartphones, laptops, electric bikes | Pros: High capacity, compact size. Cons: Less stable, thermal issues. |

| Lithium Manganese Oxide (LMO) | Good thermal stability, lower cost, moderate energy density | Power tools, medical devices | Pros: Cost-effective, safe. Cons: Lower energy density than LCO. |

What are the Characteristics of Lithium Iron Phosphate (LiFePO4) Batteries?

Lithium Iron Phosphate (LiFePO4) batteries are renowned for their high thermal stability and safety. With a lifespan of 2000 to 3000 cycles, they are ideal for applications requiring longevity, such as electric vehicles and renewable energy storage systems. Their lightweight nature makes them suitable for various uses, including UPS systems. When considering a purchase, B2B buyers should evaluate the higher initial cost against the long-term savings on replacements and maintenance.

How Do Lithium Polymer Batteries Stand Out in the Market?

Lithium Polymer batteries are distinguished by their flexibility in design, allowing manufacturers to create various shapes and sizes tailored to specific applications. Their high energy density makes them popular in consumer electronics, drones, and portable devices. However, B2B buyers should be aware that while they offer lightweight advantages, they are sensitive to punctures, which may require additional protective measures during transportation and usage.

Why are Lithium Ion Batteries a Reliable Choice for Businesses?

Lithium Ion batteries are the backbone of many modern electronic devices, including laptops and smartphones. They provide reliable performance and come in various sizes to fit different applications. While they are widely recognized for their good energy density, B2B buyers should consider their comparatively shorter lifespan, which may lead to more frequent replacements. This factor can influence total cost of ownership, making it crucial for procurement decisions.

What are the Benefits and Drawbacks of Lithium Cobalt Oxide (LCO) Batteries?

Lithium Cobalt Oxide (LCO) batteries are known for their high energy density and excellent cycle stability, making them a preferred choice for compact devices like smartphones and laptops. However, they are less stable than other lithium battery types and can face thermal issues if not managed properly. Businesses should weigh the high capacity and compactness against the potential risks and consider applications where safety and performance are paramount.

How Does Lithium Manganese Oxide (LMO) Compare to Other Lithium Battery Types?

Lithium Manganese Oxide (LMO) batteries offer a balance of good thermal stability and lower costs, making them suitable for power tools and medical devices. While they are cost-effective and safe, they have a lower energy density compared to Lithium Cobalt Oxide batteries. B2B buyers should assess their specific application needs and consider whether the trade-offs in energy density align with their operational requirements and budget constraints.

Key Industrial Applications of 213 lithium battery

| Industry/Sector | Specific Application of 213 lithium battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Equipment | Backup power for portable medical devices | Ensures reliable operation during power outages, enhancing patient safety. | Compliance with medical regulations, battery lifespan, and weight considerations. |

| Telecommunications | Power supply for communication devices | Provides stable energy for critical communication, minimizing downtime. | Voltage requirements, compatibility with existing systems, and global sourcing options. |

| Automotive | Start-stop systems in vehicles | Increases fuel efficiency and reduces emissions through optimized energy use. | Temperature tolerance, weight, and compatibility with various vehicle models. |

| Security Systems | Backup for alarm and surveillance systems | Maintains functionality during power failures, enhancing security. | Reliability, discharge rates, and certifications for safety standards. |

| Consumer Electronics | Power source for high-performance gadgets | Offers lightweight and compact solutions for portable devices, improving user experience. | Energy density, charge cycles, and compatibility with device specifications. |

How is the 213 Lithium Battery Used in Medical Equipment?

In the medical sector, the 213 lithium battery is crucial for powering portable medical devices like defibrillators and infusion pumps. These devices often require backup power to ensure continuous operation during outages, which can be critical for patient safety. B2B buyers in this sector must consider compliance with stringent medical regulations, battery lifespan, and weight constraints to ensure that the batteries meet the specific needs of healthcare applications.

What Role Does the 213 Lithium Battery Play in Telecommunications?

Telecommunications rely heavily on the 213 lithium battery to provide a stable power supply for communication devices, including base stations and mobile repeaters. The reliability of these batteries minimizes downtime, ensuring that communication remains uninterrupted, which is essential in emergency situations. Buyers should focus on voltage requirements, compatibility with existing systems, and the availability of global sourcing options to meet their operational demands.

How Can the Automotive Industry Benefit from 213 Lithium Batteries?

In the automotive sector, the 213 lithium battery is increasingly utilized in start-stop systems, enhancing fuel efficiency and reducing vehicle emissions. These batteries support the automotive industry’s move towards greener technologies by optimizing energy use during idling. Buyers should prioritize temperature tolerance, weight considerations, and compatibility with various vehicle models to ensure seamless integration and performance.

Why Are 213 Lithium Batteries Essential for Security Systems?

Security systems, including alarms and surveillance cameras, depend on the 213 lithium battery for backup power during outages. This ensures that security measures remain operational, providing peace of mind for businesses and homeowners alike. B2B buyers in this sector must consider the reliability of the batteries, discharge rates, and certifications that guarantee adherence to safety standards to protect their investments.

How Do Consumer Electronics Utilize the 213 Lithium Battery?

The consumer electronics industry leverages the lightweight and compact nature of the 213 lithium battery to power high-performance gadgets such as smartphones and laptops. This battery type provides an excellent energy density, which translates into longer usage times and enhanced user experience. Buyers should evaluate energy density, charge cycles, and compatibility with device specifications to ensure optimal performance in their products.

3 Common User Pain Points for ‘213 lithium battery’ & Their Solutions

Scenario 1: Difficulty in Sourcing Replacement Batteries for Specific Applications

The Problem: B2B buyers often encounter challenges when searching for replacement batteries, particularly for specific applications like medical devices, security systems, or specialized machinery. The 213 lithium battery may not be widely stocked by local suppliers, leading to delays in procurement and potential operational downtime. This can be especially problematic for businesses that rely on consistent power supply for critical functions, such as in healthcare or emergency services.

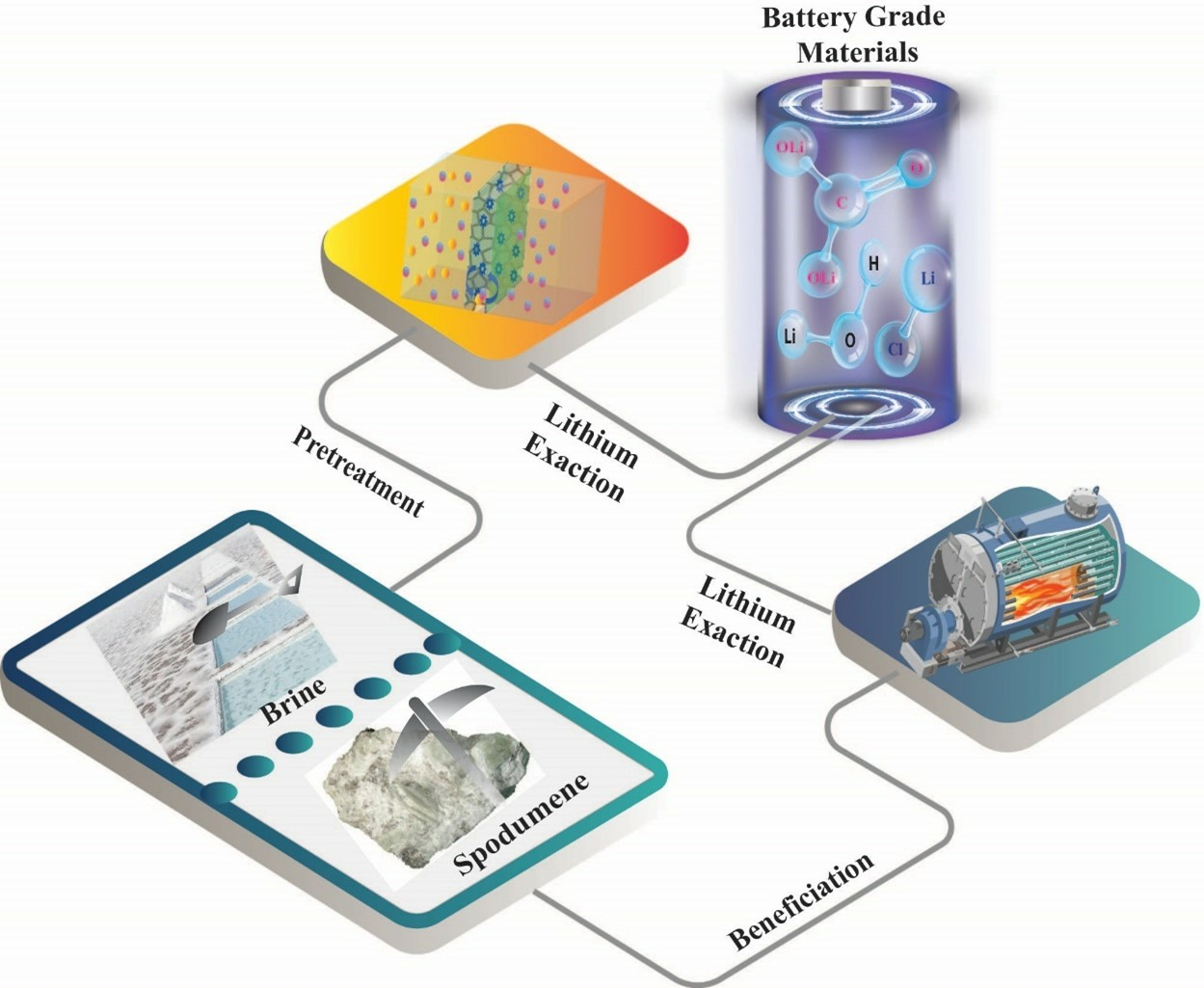

Illustrative image related to 213 lithium battery

The Solution: To mitigate sourcing issues, B2B buyers should establish relationships with multiple suppliers that specialize in batteries or offer comprehensive catalogs. It is also beneficial to look for suppliers that provide online platforms with detailed product specifications and availability. When placing orders, buyers should clearly specify their requirements, including voltage, dimensions, and application needs. Additionally, consider leveraging bulk purchasing agreements to ensure stock availability, which can reduce lead times and costs. Engaging in regular communication with suppliers can also help in anticipating stock levels and understanding upcoming product releases or alternatives.

Scenario 2: Managing Battery Performance in Diverse Climates

The Problem: Buyers operating in regions with extreme temperatures may face performance issues with lithium batteries. The 213 lithium battery, while efficient, can exhibit reduced performance in both high and low-temperature environments. This becomes critical for businesses in industries like agriculture, transportation, and outdoor services, where equipment must function reliably regardless of weather conditions.

The Solution: To address this challenge, buyers should select 213 lithium batteries that are specifically designed for enhanced temperature resilience, such as those with a built-in Battery Management System (BMS) that regulates temperature fluctuations. Prior to purchasing, review the manufacturer’s specifications related to operational temperature ranges and performance metrics in various conditions. It is also advisable to conduct field tests to understand how batteries perform in real-world scenarios. For added reliability, consider implementing environmental controls or insulation for battery storage areas to stabilize conditions. Regular maintenance checks can also help identify performance issues early, allowing for timely replacements.

Scenario 3: Understanding the Cost-Benefit of Lithium Battery Technology

The Problem: Many B2B buyers struggle to justify the higher initial costs of lithium batteries, including the 213 model, compared to traditional lead-acid batteries. This can lead to hesitation in transitioning to lithium technology, despite the long-term benefits of efficiency and longevity. Decision-makers may find it challenging to present a solid case for investment to stakeholders, especially when initial capital outlay is a concern.

The Solution: Buyers can effectively communicate the value of transitioning to lithium batteries by conducting a thorough cost-benefit analysis that includes not only purchase price but also total cost of ownership (TCO). Factors to consider include longer lifespan, reduced maintenance costs, and improved energy efficiency. Create a comparison chart that highlights these metrics against lead-acid options, including data on charge cycles, performance in various applications, and potential savings over time. Additionally, case studies or testimonials from other businesses that have made similar transitions can provide persuasive evidence of the benefits. By presenting a comprehensive analysis, buyers can build a compelling case that demonstrates how the initial investment in 213 lithium batteries will lead to greater operational efficiency and cost savings in the long run.

Strategic Material Selection Guide for 213 lithium battery

What Are the Key Materials Used in 213 Lithium Batteries?

When selecting materials for the 213 lithium battery, it is crucial to consider their properties, advantages, and limitations. Here, we analyze four common materials used in lithium batteries, focusing on their performance characteristics and implications for international B2B buyers.

Lithium Iron Phosphate (LiFePO4)

Key Properties:

LiFePO4 is known for its thermal stability and safety. It operates effectively within a temperature range of -20°C to 60°C and has a low self-discharge rate.

Pros & Cons:

The advantages of LiFePO4 include a long lifespan (up to 3,000 cycles), excellent safety features, and a lower environmental impact compared to other lithium chemistries. However, it has a lower energy density than alternatives like lithium cobalt oxide, which may limit its application in compact devices.

Impact on Application:

LiFePO4 is particularly suitable for applications requiring high discharge rates and safety, such as electric vehicles and energy storage systems. Its stability makes it a preferred choice in regions with extreme temperatures.

Considerations for International Buyers:

Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with local safety standards and regulations, such as RoHS and REACH. Understanding the specific requirements of markets like Germany, which emphasizes environmental sustainability, is also essential.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, making it suitable for battery casings. It can withstand moderate temperatures and pressures.

Pros & Cons:

Aluminum’s lightweight nature contributes to overall battery efficiency, reducing the weight of the final product. However, it can be more expensive than other metals like steel and may require additional treatments to enhance its corrosion resistance.

Impact on Application:

Aluminum is often used in battery enclosures and connectors, where weight reduction is critical. Its corrosion resistance is beneficial in humid or coastal environments.

Considerations for International Buyers:

When sourcing aluminum components, buyers should consider the material’s compliance with international standards such as ASTM and DIN. Additionally, understanding the local supply chain dynamics can help mitigate costs.

Copper

Key Properties:

Copper is an excellent conductor of electricity and offers good thermal conductivity. It can operate effectively in a wide range of temperatures.

Pros & Cons:

The primary advantage of copper is its superior electrical conductivity, which enhances battery performance. However, its susceptibility to corrosion can be a drawback, necessitating protective coatings or treatments.

Impact on Application:

Copper is commonly used in battery terminals and connectors, where efficient electrical flow is crucial. Its conductivity ensures minimal energy loss during operation.

Considerations for International Buyers:

Buyers should be aware of the fluctuating prices of copper in global markets. Additionally, compliance with international standards for electrical components is vital to ensure reliability and safety.

Graphite

Key Properties:

Graphite serves as the anode material in lithium batteries, offering good conductivity and stability. It can handle high charge and discharge rates.

Pros & Cons:

Graphite is relatively inexpensive and widely available, making it a popular choice. However, its performance can degrade over time due to structural changes during cycling, which may limit its lifespan.

Impact on Application:

Graphite’s stability makes it suitable for various applications, including consumer electronics and electric vehicles. Its ability to handle rapid charging is particularly beneficial in high-demand scenarios.

Illustrative image related to 213 lithium battery

Considerations for International Buyers:

Buyers should consider sourcing natural or synthetic graphite based on application needs and local availability. Understanding the environmental impact of graphite mining is also increasingly important, especially in markets focused on sustainability.

Summary Table

| Material | Typical Use Case for 213 lithium battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium Iron Phosphate | Electric vehicles, energy storage | Long lifespan and safety | Lower energy density compared to others | Medium |

| Aluminum | Battery casings and connectors | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Copper | Battery terminals and connectors | Superior electrical conductivity | Susceptible to corrosion | Medium |

| Graphite | Anode material in lithium batteries | Inexpensive and widely available | Performance degradation over time | Low |

This strategic material selection guide provides insights for international B2B buyers, ensuring informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 213 lithium battery

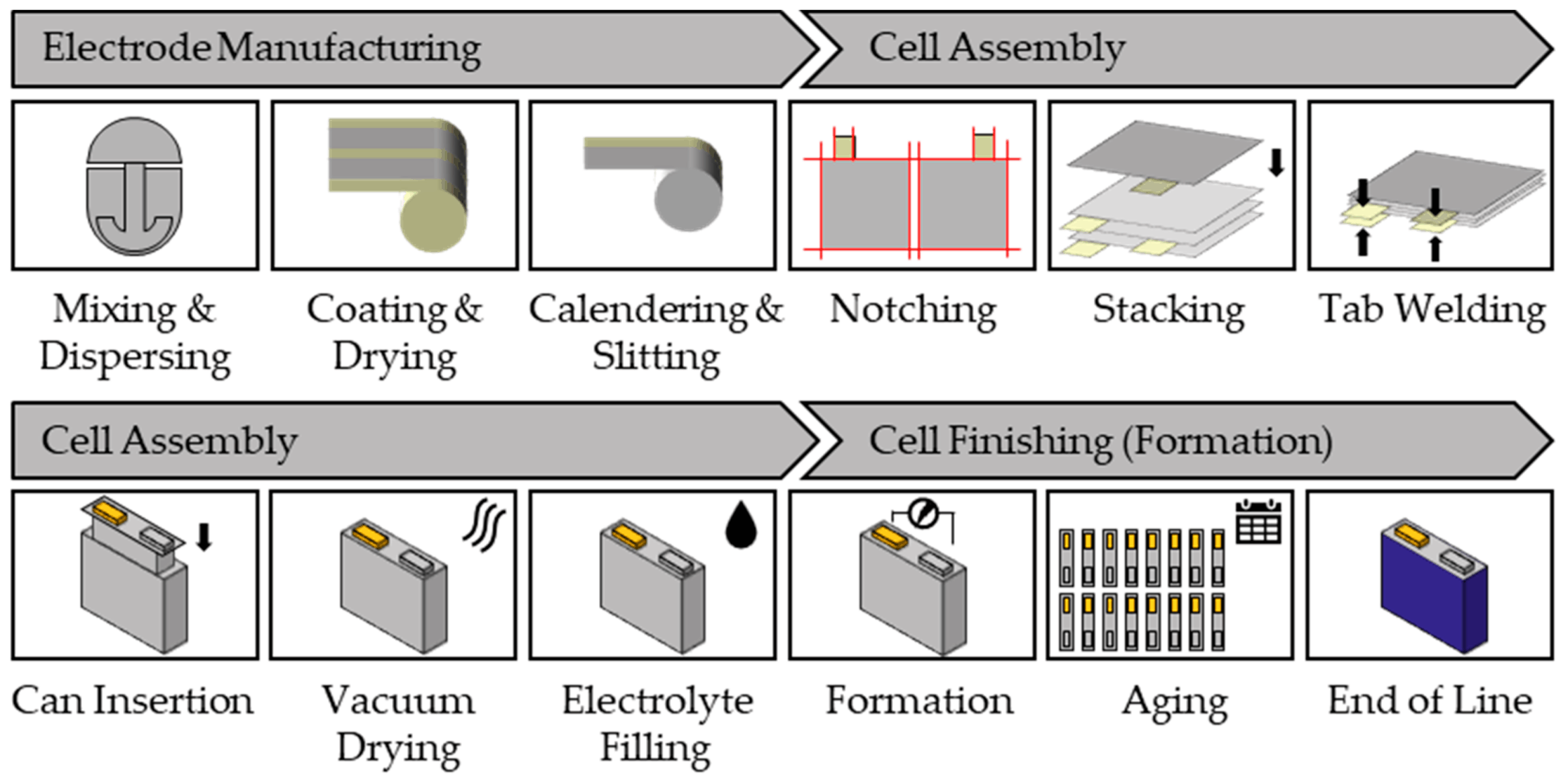

What Are the Key Stages in the Manufacturing Process of a 213 Lithium Battery?

The manufacturing of a 213 lithium battery involves several critical stages that ensure the final product meets performance and safety standards. Understanding these processes can help B2B buyers assess the capabilities of potential suppliers.

Material Preparation: What Materials Are Used in Lithium Battery Manufacturing?

The first stage of manufacturing begins with sourcing high-quality raw materials. Lithium batteries primarily use lithium iron phosphate (LiFePO4) or lithium cobalt oxide as cathode materials, and graphite for anodes. Other components include electrolyte solutions, separators, and casing materials. Suppliers typically need to verify the quality and purity of these materials, as they significantly influence the battery’s performance and longevity.

How Is the Forming Process Conducted for 213 Lithium Batteries?

Once the materials are prepared, the forming process begins. This involves several sub-steps:

-

Electrode Coating: The anode and cathode materials are mixed with binders and solvents to create a slurry, which is then coated onto thin metal foils. This step is crucial for ensuring uniformity and optimal performance.

-

Drying: The coated electrodes are passed through drying ovens to remove any residual solvents, ensuring that the electrodes are ready for assembly.

-

Cutting and Stacking: After drying, the electrodes are cut into specific sizes and stacked or rolled together with separators to create cell structures. This is a delicate process that must ensure minimal defects.

What Assembly Techniques Are Employed in Lithium Battery Manufacturing?

The assembly phase is where the cell components come together. Key steps include:

-

Cell Assembly: The stacked electrodes are placed into battery casings, and electrolyte is added. This process must be conducted in a controlled environment to prevent contamination.

-

Sealing: The cells are sealed to ensure they are airtight, which is vital for safety and performance. This step may involve welding or using adhesive seals.

-

Formation: Newly assembled cells undergo an initial charge and discharge cycle, a process known as formation. This step is critical for activating the battery chemistry and ensuring the cells reach optimal performance.

How Does the Finishing Stage Impact Battery Quality?

The finishing stage involves several final touches that contribute to the battery’s performance. These include:

-

Testing: Each battery undergoes rigorous testing to assess capacity, voltage, and internal resistance. This ensures that only batteries meeting specified performance criteria are packaged for shipment.

-

Labeling and Packaging: Proper labeling is essential for safety and regulatory compliance. Batteries are then packaged to minimize damage during transportation.

What Quality Assurance Standards Are Relevant for 213 Lithium Batteries?

Quality assurance is paramount in lithium battery manufacturing to ensure safety and reliability. International and industry-specific standards play a significant role in this.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most important international standards is ISO 9001, which outlines criteria for a quality management system (QMS). Companies certified to ISO 9001 demonstrate a commitment to quality management and continual improvement. Additionally, CE marking is crucial for products sold in Europe, indicating compliance with health, safety, and environmental protection standards.

What Are the Industry-Specific Standards for Lithium Batteries?

In addition to ISO and CE, there are industry-specific standards such as IEC 62133, which covers the safety requirements for portable lithium batteries. For buyers from Africa, South America, the Middle East, and Europe, understanding these standards can help in selecting reliable suppliers.

Illustrative image related to 213 lithium battery

What Are the Key Quality Control Checkpoints in Lithium Battery Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process with specific checkpoints to ensure product integrity.

How Are Incoming Quality Checks (IQC) Conducted?

Incoming Quality Control (IQC) is the first line of defense. Raw materials are thoroughly inspected upon arrival to ensure they meet quality standards. This may include visual inspections and laboratory testing for purity and composition.

What Is the Role of In-Process Quality Control (IPQC)?

In-Process Quality Control (IPQC) involves monitoring the manufacturing process at various stages. Key metrics such as temperature, humidity, and material consistency are tracked to prevent defects. This real-time monitoring helps in making immediate corrections if deviations are observed.

How Does Final Quality Control (FQC) Ensure Product Reliability?

Final Quality Control (FQC) occurs after assembly and includes comprehensive testing of the finished batteries. Parameters such as charge capacity, discharge rate, and overall functionality are evaluated. Batteries that fail to meet established benchmarks are removed from the production line.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international buyers, especially those in regions like Africa and South America, verifying a supplier’s quality control measures is critical.

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. Buyers should request access to quality management certifications, production records, and audit reports.

How Important Are Third-Party Inspections?

Engaging third-party inspection agencies can add an extra layer of assurance. These organizations can conduct independent evaluations of the supplier’s processes and products, providing unbiased reports that buyers can trust.

What Are the Specific Quality Control Nuances for Different Regions?

B2B buyers from different regions must be aware of local regulations that may impact battery safety and quality. For instance, the EU has stringent regulations for battery recycling and disposal, while countries in Africa may have less stringent standards. Understanding these nuances helps in making informed purchasing decisions.

Conclusion: Why Quality Assurance Is Critical for B2B Buyers of 213 Lithium Batteries

In conclusion, the manufacturing processes and quality assurance measures for 213 lithium batteries are intricate and vital to ensuring product reliability and safety. By understanding these processes and standards, B2B buyers can make informed decisions, ensuring that their selected suppliers adhere to the highest quality standards. This knowledge not only helps in mitigating risks but also enhances the overall value of their procurement strategy in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘213 lithium battery’

Introduction

Sourcing a reliable and high-quality ‘213 lithium battery’ is crucial for businesses that depend on these power solutions for various applications. This guide offers a structured checklist to help international B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right battery for your needs while minimizing risks associated with sourcing from unfamiliar suppliers.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the ‘213 lithium battery.’ Consider factors such as voltage, capacity, weight, and compatibility with existing systems.

– Voltage and Capacity: Ensure that the battery meets the voltage requirements of your application and offers sufficient capacity for operational efficiency.

– Dimensions and Weight: Evaluate space constraints and weight limitations, especially for portable or mobile applications.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify potential suppliers specializing in lithium batteries. Look for companies with a strong market presence and positive reviews.

– Industry Experience: Prioritize suppliers who have a proven track record in supplying lithium batteries to your specific industry.

– Certifications and Compliance: Verify that the suppliers meet international standards, such as ISO certifications, to ensure quality and safety.

Illustrative image related to 213 lithium battery

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, check their certifications and compliance with industry regulations. This step is essential to mitigate risks associated with product quality and safety.

– Quality Assurance: Look for certifications such as ISO 9001, which indicate a commitment to quality management.

– Environmental Compliance: Ensure the supplier adheres to environmental regulations, such as RoHS, to confirm that the batteries are eco-friendly.

Step 4: Request Samples for Testing

Once you have narrowed down potential suppliers, request samples of the ‘213 lithium batteries’ for testing. This allows you to evaluate performance and compatibility with your systems before making a bulk purchase.

– Performance Testing: Assess the samples under real-world conditions to gauge reliability and efficiency.

– Compatibility Check: Verify that the battery integrates seamlessly with your existing equipment or systems.

Step 5: Inquire About Warranty and Support

A comprehensive warranty and support policy can significantly affect your purchasing decision. Ensure that the supplier offers adequate protection and assistance post-purchase.

– Warranty Terms: Look for suppliers that provide a minimum warranty period, indicating their confidence in product quality.

– Customer Support: Assess the availability of customer service and technical support to address any issues that may arise during the battery’s lifecycle.

Step 6: Negotiate Pricing and Payment Terms

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. This step is vital for optimizing your procurement costs.

– Bulk Discounts: Inquire about discounts for larger orders or long-term contracts to reduce unit costs.

– Payment Flexibility: Explore payment options that align with your cash flow needs while ensuring security for both parties.

Illustrative image related to 213 lithium battery

Step 7: Finalize Your Order and Logistics

After agreeing on terms, finalize your order and plan the logistics for delivery. Ensure that all details are documented to avoid misunderstandings.

– Order Confirmation: Obtain a detailed order confirmation that outlines the agreed-upon specifications, pricing, and delivery dates.

– Logistics Coordination: Coordinate with the supplier for shipping arrangements, ensuring that the delivery schedule aligns with your operational needs.

By following this checklist, you can streamline the sourcing process for ‘213 lithium batteries’ and secure a partnership with a reliable supplier that meets your business needs.

Comprehensive Cost and Pricing Analysis for 213 lithium battery Sourcing

What Are the Key Cost Components in Sourcing 213 Lithium Batteries?

When evaluating the cost structure for sourcing 213 lithium batteries, several components must be considered. These include:

-

Materials: The primary materials used in lithium batteries—such as lithium iron phosphate (LiFePO4), cobalt, nickel, and aluminum—are significant cost drivers. The fluctuations in the prices of these raw materials can heavily influence overall battery costs.

-

Labor: Manufacturing labor costs vary by region. Countries with lower labor costs may offer competitive pricing, but factors such as workforce skill level and labor regulations can also impact the total cost.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead and enhance profitability.

-

Tooling: The cost of molds and tools required for battery production can be substantial, especially for customized or high-spec models. Initial tooling investments may be amortized over high-volume orders, reducing per-unit costs.

-

Quality Control (QC): Ensuring product quality is essential, particularly for international markets where certifications are crucial. QC processes, including testing and compliance with international standards, contribute to overall costs.

-

Logistics: Shipping and handling costs, including warehousing and transportation, can vary significantly based on the destination and shipping terms. Incoterms play a critical role in determining who bears these costs.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding typical margins within the battery market can help buyers negotiate better prices.

What Influences Pricing for 213 Lithium Batteries?

Several factors can influence the pricing of 213 lithium batteries:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Establishing a long-term relationship with suppliers can help negotiate better terms.

-

Specifications and Customization: Custom features, such as enhanced energy density or specific dimensions, can increase costs. Buyers should clearly define their specifications to avoid unexpected pricing changes.

-

Materials and Quality Certifications: Higher-quality materials or batteries with advanced features (like integrated battery management systems) typically command higher prices. Certifications (e.g., ISO, RoHS) may also add costs but are necessary for compliance.

-

Supplier Factors: The reputation and location of the supplier can affect pricing. Established suppliers with a track record of reliability may charge a premium but often provide better service and quality assurance.

-

Incoterms: The choice of Incoterms can influence total costs. Buyers should understand whether they are responsible for shipping, insurance, and tariffs, which can significantly affect the overall budget.

How Can International Buyers Optimize Costs When Sourcing 213 Lithium Batteries?

To ensure cost-efficiency when sourcing 213 lithium batteries, especially in regions like Africa, South America, the Middle East, and Europe, buyers can consider the following tips:

-

Negotiation Strategies: Engage in transparent negotiations with suppliers. Understanding the cost structure can provide leverage in discussions, allowing buyers to request discounts for larger orders or long-term contracts.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term operational costs, including maintenance, lifespan, and efficiency. Batteries with higher upfront costs may offer lower TCO due to longer life cycles and reduced maintenance.

-

Understand Pricing Nuances: Familiarize yourself with regional market conditions, including demand fluctuations and regulatory impacts that may affect pricing. This knowledge can aid in making informed purchasing decisions.

-

Leverage Local Market Insights: Buyers should tap into local distributors who understand the market dynamics and can provide insights into pricing, availability, and potential savings.

-

Consider Alternative Suppliers: Don’t limit sourcing to a single supplier. Exploring multiple options can reveal competitive pricing and lead to better negotiation leverage.

Disclaimer on Pricing

The prices for 213 lithium batteries can vary widely based on the factors discussed above. Buyers are encouraged to obtain multiple quotes and assess the total cost implications specific to their needs and circumstances.

Alternatives Analysis: Comparing 213 lithium battery With Other Solutions

Exploring Alternatives to the 213 Lithium Battery

When considering battery solutions, the 213 lithium battery is a popular choice due to its advanced technology and performance. However, various alternatives may suit specific applications or budget constraints. This analysis compares the 213 lithium battery with two viable alternatives: lead-acid batteries and nickel-metal hydride (NiMH) batteries. By examining aspects such as performance, cost, ease of implementation, maintenance, and best use cases, businesses can make informed decisions tailored to their operational needs.

| Comparison Aspect | 213 Lithium Battery | Lead-Acid Battery | Nickel-Metal Hydride (NiMH) Battery |

|---|---|---|---|

| Performance | High energy density, longer lifespan (up to 3,000 cycles), faster charging | Lower energy density, shorter lifespan (500-1,000 cycles) | Moderate energy density, decent lifespan (1,000 cycles) |

| Cost | Higher initial cost but lower total cost of ownership | Lower upfront cost, higher replacement frequency increases long-term costs | Moderate initial cost, competitive lifespan |

| Ease of Implementation | Requires specific charging systems; lighter and more compact | Widely available and easy to install; heavier | Generally compatible with existing systems; moderate weight |

| Maintenance | Minimal; no topping off required | Requires regular maintenance and checks | Limited maintenance needed, but may have self-discharge issues |

| Best Use Case | High-performance applications (e.g., electric vehicles, drones) | General-purpose use, backup power | Hybrid vehicles, consumer electronics |

In-Depth Look at Each Alternative

Lead-Acid Batteries

Lead-acid batteries have been the go-to option for many applications due to their lower initial costs and widespread availability. They are relatively easy to install and are compatible with a variety of systems. However, their performance lags behind lithium batteries; they have a shorter lifespan and require regular maintenance to ensure optimal performance. Lead-acid batteries are best suited for applications where cost is a primary concern and where weight is less critical, such as in stationary energy storage or backup power systems.

Illustrative image related to 213 lithium battery

Nickel-Metal Hydride (NiMH) Batteries

NiMH batteries present a middle ground between lead-acid and lithium batteries. They offer better energy density than lead-acid batteries and can be more cost-effective over time compared to lead-acid options. They are commonly used in hybrid vehicles and consumer electronics. However, NiMH batteries typically have a higher self-discharge rate, which can lead to decreased performance if not regularly used. They are a viable alternative in applications where weight and efficiency are important but where the higher costs of lithium batteries may not be justified.

How to Choose the Right Battery Solution for Your Needs

Selecting the right battery solution involves assessing various factors, including performance requirements, budget constraints, and specific application needs. For businesses focused on high efficiency and long-term savings, the 213 lithium battery offers superior performance despite its higher upfront cost. Conversely, if initial investment is a primary concern and the application allows for it, lead-acid batteries may be suitable. For those seeking a balance between cost and performance, NiMH batteries can serve well in hybrid applications. Ultimately, understanding the unique demands of your operations will guide you in making the most effective choice.

Essential Technical Properties and Trade Terminology for 213 lithium battery

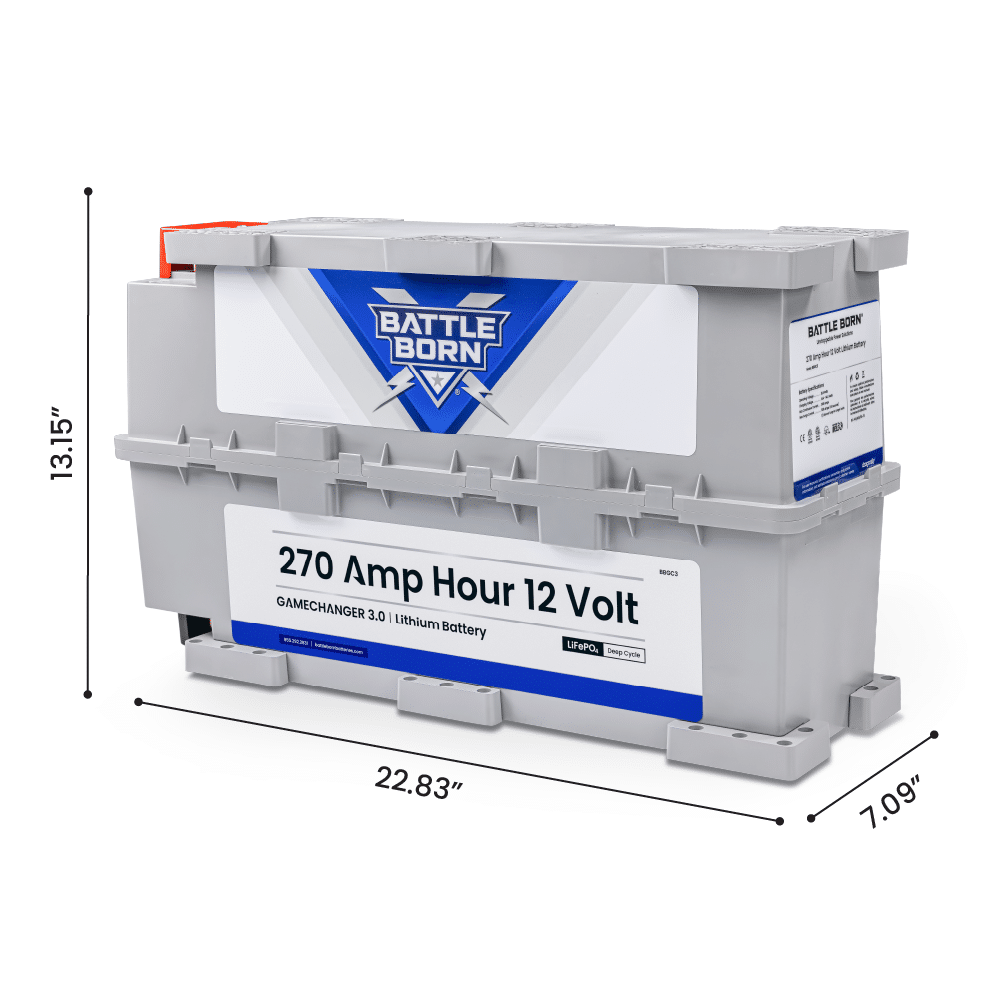

What Are the Key Technical Properties of the 213 Lithium Battery?

When considering the purchase of 213 lithium batteries, understanding their technical specifications is crucial for making informed decisions. Here are several critical specifications and their B2B significance:

-

Nominal Voltage (12.8V)

– The nominal voltage indicates the standard voltage output of the battery under typical operating conditions. A nominal voltage of 12.8V is common in lithium batteries, providing adequate power for various applications. For B2B buyers, ensuring compatibility with existing systems is essential to avoid operational issues. -

Capacity (Ah)

– Measured in ampere-hours (Ah), capacity refers to the amount of energy a battery can store and deliver over time. For example, a 7 Ah capacity means the battery can provide 7 amps for one hour. This specification is vital for businesses to assess how long the battery can power their devices or vehicles, ensuring operational efficiency. -

Cranking Amps (CA)

– Cranking Amps represent the maximum current a battery can deliver for 30 seconds at 0°F while maintaining a voltage of at least 7.2V. A higher cranking amp rating is beneficial for applications requiring high starting power, such as in vehicles. This property is particularly important for industries where reliability in starting engines is critical, such as automotive or marine. -

Weight (1.7 lb)

– The weight of the battery affects both installation and application. A lightweight battery, like the 213 lithium battery at 1.7 lbs, is advantageous for applications where weight reduction is essential, such as in motorcycles or drones. B2B buyers should consider weight in relation to transport and installation logistics. -

Battery Management System (BMS)

– A Battery Management System is integral for ensuring safety and longevity. It monitors the battery’s voltage, current, and temperature, protecting against overcharging and overheating. For businesses, a reliable BMS translates to reduced risks of failure and maintenance costs, making it a critical feature to evaluate. -

Cycle Life (2000-3000 Cycles)

– Cycle life indicates how many charge-discharge cycles a battery can undergo before its capacity significantly diminishes. A cycle life of 2000-3000 cycles means lower replacement costs and less downtime for businesses. This property is particularly important for organizations seeking sustainable and cost-effective energy solutions.

Which Trade Terms Are Essential for B2B Buyers of 213 Lithium Batteries?

Familiarity with industry terminology is equally important for navigating the procurement process. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications helps B2B buyers ensure compatibility with existing equipment and maintain standards. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, as purchasing below this threshold may lead to higher costs or unavailability. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, submitting an RFQ can facilitate competitive pricing and ensure they receive the best possible terms. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms helps businesses manage logistics and potential costs effectively. -

LiFePO4 (Lithium Iron Phosphate)

– LiFePO4 is a type of lithium battery chemistry known for its safety, thermal stability, and longevity. B2B buyers should consider this when evaluating battery options, as it influences performance and safety standards. -

B2B (Business-to-Business)

– B2B refers to transactions between businesses, as opposed to transactions between a business and individual consumers (B2C). Understanding this distinction helps companies tailor their strategies for procurement and sales effectively.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right 213 lithium battery solutions for their needs.

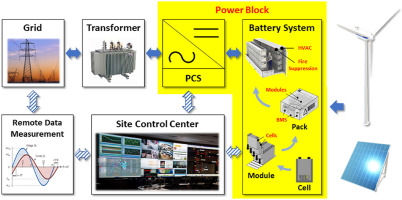

Navigating Market Dynamics and Sourcing Trends in the 213 lithium battery Sector

What Are the Key Market Dynamics and Trends Influencing the 213 Lithium Battery Sector?

The 213 lithium battery sector is witnessing a surge driven by multiple global factors, particularly in the realms of electric mobility, renewable energy storage, and portable electronics. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing advanced battery technologies that align with their operational needs and sustainability goals. The demand for high-performance batteries, such as lithium iron phosphate (LiFePO4), is on the rise due to their superior longevity, safety, and efficiency compared to traditional lead-acid batteries.

Emerging trends include the integration of smart technology in battery management systems (BMS), which enhance operational efficiency and safety by preventing issues like overcharging and overheating. Additionally, the shift toward circular economies is prompting companies to seek suppliers that prioritize recyclability and the use of secondary raw materials. As a result, partnerships with manufacturers who can demonstrate innovation in battery design and production processes are becoming increasingly valuable for international buyers.

Furthermore, geopolitical factors and supply chain disruptions are influencing sourcing strategies. Buyers are diversifying their supplier base to mitigate risks associated with dependence on specific regions for raw materials such as lithium, cobalt, and nickel. This diversification not only enhances supply chain resilience but also opens up opportunities for strategic collaborations with local manufacturers who understand regional market dynamics.

How Are Sustainability and Ethical Sourcing Shaping the 213 Lithium Battery Industry?

Sustainability is now a cornerstone of the lithium battery industry, particularly as global attention shifts toward reducing carbon footprints and promoting ethical sourcing. The environmental impact of lithium extraction and battery production is under scrutiny, prompting buyers to prioritize suppliers that adhere to sustainable practices. This includes utilizing eco-friendly extraction methods, minimizing waste during production, and ensuring responsible sourcing of raw materials.

Illustrative image related to 213 lithium battery

For B2B buyers, understanding the importance of ethical supply chains is critical. Many companies are seeking ‘green’ certifications that validate their commitment to sustainability, such as ISO 14001 for environmental management and certifications from the Responsible Minerals Initiative. These certifications not only enhance brand reputation but also cater to the growing consumer demand for ethically sourced products.

Moreover, the adoption of recyclable materials in battery production is gaining traction. Companies that innovate in this area are more likely to attract B2B partnerships, as buyers increasingly prefer suppliers who can demonstrate a commitment to reducing environmental impact. The integration of sustainable practices in manufacturing processes not only aligns with global sustainability goals but also offers a competitive edge in the marketplace.

What Is the Historical Context of the 213 Lithium Battery Market?

The evolution of the lithium battery market can be traced back to the late 20th century when lithium-ion technology emerged as a game changer in energy storage solutions. Initially, these batteries were primarily used in consumer electronics, but advancements in technology have since propelled their use into various sectors, including electric vehicles and renewable energy storage systems.

Over the past two decades, the demand for lithium batteries has escalated, driven by the need for efficient energy solutions and the transition to electric mobility. The introduction of lithium iron phosphate (LiFePO4) batteries in the early 2000s marked a significant milestone, offering enhanced safety, longer lifespans, and better thermal stability compared to their predecessors. As battery technology continues to evolve, the focus on sustainability and ethical sourcing is reshaping the industry, creating new opportunities for B2B buyers to engage with innovative suppliers who prioritize both performance and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of 213 lithium battery

-

How do I ensure the quality of 213 lithium batteries from suppliers?

To ensure the quality of 213 lithium batteries, verify that your suppliers adhere to international quality standards such as ISO 9001. Request certification documents and conduct audits if possible. Additionally, ask for samples and conduct performance tests under varied conditions to assess durability and efficiency. Establish clear quality assurance protocols and communicate your specifications thoroughly to prevent discrepancies in product quality. -

What is the best voltage and capacity for 213 lithium batteries?

The optimal voltage and capacity for 213 lithium batteries depend on your specific application. Typically, a nominal voltage of 12.8V is standard for many applications, while the capacity can range from 7Ah to higher values based on usage demands. Ensure that the specifications align with the requirements of your devices or systems to achieve optimal performance. -

What customization options are available for 213 lithium batteries?

Many manufacturers offer customization options for 213 lithium batteries, including variations in size, capacity, and terminal configuration. You can also request specific features such as built-in Battery Management Systems (BMS) or enhanced safety features. Discuss your needs with potential suppliers, and inquire about their ability to produce batteries that meet your exact specifications. -

What are the minimum order quantities (MOQ) for 213 lithium batteries?

Minimum order quantities (MOQ) for 213 lithium batteries can vary significantly between suppliers. Some may require a MOQ of 100 units, while others may offer smaller quantities for testing or trial purposes. It is advisable to discuss your purchasing needs upfront and negotiate terms that suit your business requirements, especially if you are entering a new market. -

What payment terms should I expect when sourcing 213 lithium batteries?

Payment terms can vary widely among suppliers. Common arrangements include advance payment, payment upon shipment, or net terms (e.g., net 30 or net 60 days). It’s essential to clarify payment terms during negotiations to ensure both parties have aligned expectations. Consider using secure payment methods and escrow services for larger transactions to mitigate financial risks. -

How do I vet suppliers for 213 lithium batteries internationally?

To vet suppliers for 213 lithium batteries, start by researching their market reputation and customer reviews. Request references from previous clients and check their compliance with international standards. Conduct background checks and assess their manufacturing capabilities through factory visits or virtual tours. Utilize platforms like Alibaba or ThomasNet, which often provide supplier ratings and feedback. -

What logistics considerations should I keep in mind for shipping 213 lithium batteries?

Shipping 213 lithium batteries involves specific logistics considerations due to their classification as hazardous materials. Ensure compliance with international shipping regulations, including proper labeling and documentation. Work with experienced logistics partners familiar with handling lithium batteries. Additionally, factor in lead times, customs clearance processes, and potential tariffs based on the destination country. -

What warranties and return policies should I expect for 213 lithium batteries?

Warranties for 213 lithium batteries typically range from one to three years, covering defects in materials and workmanship. Be sure to inquire about the specifics of the warranty, including what it covers and the process for claiming it. Additionally, understand the return policy—many suppliers allow returns within a specified period, provided the products are unused and in original condition. This information is crucial for mitigating risk in your purchase decisions.

Top 7 213 Lithium Battery Manufacturers & Suppliers List

1. Batteries Plus – 213 Battery Replacement

Domain: batteriesplus.com

Registered: 1997 (28 years)

Introduction: 213 Battery Replacement at Batteries Plus

Store Location: Elmwood Park, IL

Store Address: 1700 North Harlem Avenue

Today’s Hours: 8:00 AM – 7:00 PM

Store Phone: 708-948-7885

Compatible Brands: AC Delco, Duracell, Energizer, Sony, and many more.

Compatible Models: 1123M, 1124A, 1124MP, 1130SO, 1131SO, 1166A, 1406LC, 1406SOP, 1414A, 1811A, 213, 215, 220, 221, 5008LC, 5018LC, 5024LC, 5046LC, 722, 908…

2. BatteryGuy – 4.8 Volt Replacement Battery

Domain: batteryguy.com

Registered: 2003 (22 years)

Introduction: This company, BatteryGuy – 4.8 Volt Replacement Battery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

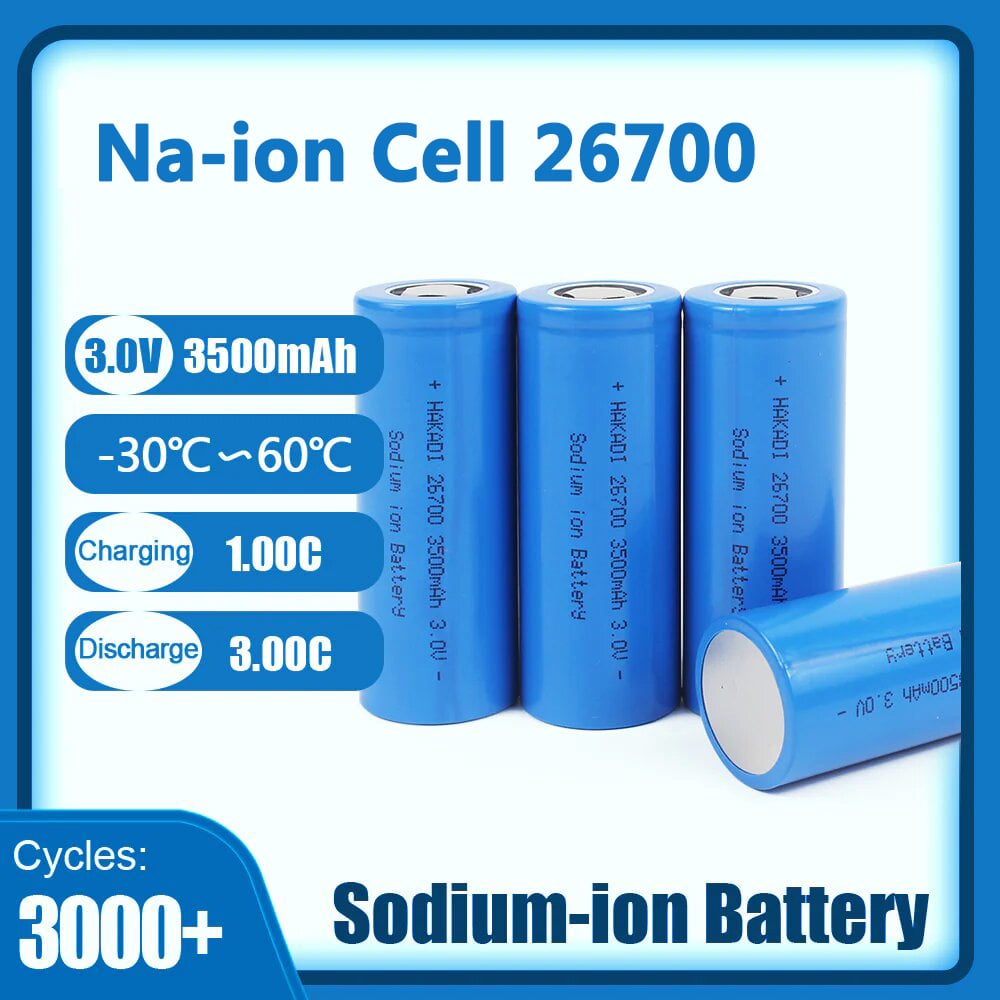

3. Powertex – 2016 Honda RC213V-S Lithium Iron Phosphate Battery Replacement

Domain: powertexbatteries.com

Registered: 2020 (5 years)

Introduction: Product Name: 2016 Honda RC213V-S Lithium Iron Phosphate Battery Replacement YTX5L-BS LiFePO4 For Motorcycle

Price: $109.99

Voltage: 12.8 V

Weight: 1.7 lb

Capacity: 7 Ah

Cranking Amps: 210 CA

Dimensions: 4.5″ x 2.75″ x 4.1″

Battery Management System: Fully integrated BMS

Features: Built-in jump-starting feature, shake-to-restart functionality

Replaces: YTX4L-BS, YTX5L-BS, YTX7L-BS, YTZ5S, YTZ7S, Y…

4. EJ12 – Battery Box Jump Starter

Domain: appbattery.com

Registered: 2017 (8 years)

Introduction: EJ12-213 Battery box jump box battery for 213/86-61086-650/85610. Body and cover molded in ABS for protection against dust and moisture. Pre-installed with glue. Outside dimensions (mm): 230*175*162/183. Inside dimensions (mm): 221*162*144.

5. Bromure – Pile CR213A 3V Lithium

Domain: bromurefilm.com

Introduction: {“Product Name”: “Pile CR213A 3V Lithium”, “Price”: “$8.00”, “Shipping”: “Expédié depuis la France sous 72h”, “Battery Type”: “Lithium”, “Voltage”: “3V”, “Format”: “CR213A”, “Compatibility”: “Cela dépend du modèle, nous contacter si besoin.”, “Note”: “La marque de la pile peut varier en fonction des stocks disponibles. Cependant, nous garantissons que toutes les piles fournies seront techniquement…

6. Rick’s Motorsport Electric – Hot Shot Regulator/Rectifier

Domain: spazcycle.com

Registered: 2015 (10 years)

Introduction: {“product_name”:”RICK’S MOTORSPORT ELECTRIC 2112-1805 14-213H Lithium-Ion Compatible Rectifier Regulator Hot Shot Regulator/Rectifier”,”price”:”$169.95″,”availability”:”Out of stock”,”output_voltage”:”14 V +/- .2″,”type”:”Lithium-Ion Battery Compatible”,”riding_style”:”Street”,”fitment”:”2001-2005 Suzuki GSX-R 600, 1998-2005 Suzuki GSX-R 750, 1999-2007 Suzuki GSX 1300 R Hayabusa, 2001-2004 Suzuki …

7. Zoro – i-Mobile 213 Replacement Battery

Domain: zoro.com

Registered: 1995 (30 years)

Introduction: Replacement battery for i-Mobile 213, compatible with i-Mobile devices, provides reliable power, designed for easy installation, ensures long-lasting performance.

Strategic Sourcing Conclusion and Outlook for 213 lithium battery

As the demand for high-performance energy solutions continues to rise, strategic sourcing of the 213 lithium battery presents a compelling opportunity for international B2B buyers. Key takeaways emphasize the importance of selecting suppliers that offer not only quality products but also comprehensive support and flexibility in meeting diverse application needs. The lithium battery market is characterized by rapid technological advancements, particularly in lithium iron phosphate (LiFePO4) batteries, which deliver enhanced performance, longevity, and eco-friendliness compared to traditional lead-acid options.

Illustrative image related to 213 lithium battery

Investing in strategic sourcing allows businesses to optimize their supply chains, reduce costs, and ensure access to the latest innovations. For buyers in regions such as Africa, South America, the Middle East, and Europe, this is a pivotal moment to align with reliable manufacturers and suppliers who understand the regional nuances and regulatory landscapes.

Looking ahead, the focus should remain on building partnerships that can adapt to evolving market demands and technological shifts. As you explore sourcing opportunities, prioritize collaboration with manufacturers committed to sustainability and cutting-edge technology. By doing so, you can position your business for long-term success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to 213 lithium battery