A B2B Buyer’s Guide to Honda Grass Cutter Parts: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for honda grass cutter parts

In the ever-evolving landscape of landscaping equipment, sourcing high-quality Honda grass cutter parts presents a significant challenge for international B2B buyers. With the increasing demand for efficient and reliable machinery in markets across Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these essential components is crucial. This guide aims to equip buyers with the knowledge necessary to navigate the complexities of Honda grass cutter parts, including identifying various types of components, understanding their applications, and evaluating potential suppliers.

Within this comprehensive guide, we will delve into the critical factors influencing purchasing decisions, such as cost considerations, quality assurance, and supplier vetting processes. International buyers will learn how to effectively assess suppliers to ensure they are obtaining genuine Honda parts that meet operational needs. Additionally, we will explore regional market trends and the implications for sourcing strategies, helping businesses adapt to local demands while maximizing efficiency and profitability.

By providing actionable insights and detailed information, this guide empowers B2B buyers to make informed purchasing decisions that enhance their operational capabilities. Whether you are sourcing for a large-scale landscaping operation or a small business, understanding the global market for Honda grass cutter parts will enable you to streamline your procurement processes and drive success in your ventures.

Understanding honda grass cutter parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Blades | Various sizes and designs (e.g., mulching, standard) | Landscaping, lawn maintenance | Pros: Efficient cutting; Cons: Requires regular sharpening. |

| Air Filters | Different types (foam, paper) for engine performance | Equipment maintenance and repair | Pros: Ensures engine longevity; Cons: Needs regular replacement. |

| Drive Belts | Varying lengths and materials for power transmission | Heavy-duty lawn care operations | Pros: Durable; Cons: Can wear out under heavy use. |

| Starter Assemblies | Manual vs. electric starters tailored for different models | Start-up and repair services | Pros: Reliable starting; Cons: May require model-specific parts. |

| Nylon Line Heads | Different spool designs for various brush cutter models | Agricultural and landscaping applications | Pros: Easy line replacement; Cons: Line durability can vary. |

What Are the Key Characteristics of Honda Grass Cutter Blades?

Honda grass cutter blades come in various designs, including mulching and standard blades. They are engineered for durability and efficiency, allowing for clean cuts that promote healthy grass growth. In a B2B context, selecting the right blade type is crucial for ensuring optimal performance in landscaping operations. Buyers should consider the specific grass types and terrain they will be working on, as well as the frequency of blade sharpening needed to maintain cutting efficiency.

How Do Air Filters Impact the Performance of Honda Grass Cutters?

Air filters are essential for maintaining engine performance by preventing dirt and debris from entering the engine. Honda offers different types of air filters, including foam and paper options, tailored to various models. For B2B buyers, investing in high-quality air filters can lead to reduced maintenance costs and extended engine life. Regular replacement is a must, so businesses should establish a maintenance schedule to avoid downtime during peak operational periods.

Why Are Drive Belts Critical for Honda Grass Cutters?

Drive belts are integral to the power transmission system of Honda grass cutters, connecting the engine to the cutting mechanism. They come in various lengths and materials, designed to withstand heavy-duty use. For businesses engaged in lawn care services, understanding the wear characteristics of drive belts is essential for planning maintenance. Buyers should evaluate the expected workload to determine the appropriate belt type, balancing durability with cost-effectiveness.

What Should Buyers Consider When Purchasing Starter Assemblies?

Starter assemblies, whether manual or electric, are crucial for the operation of Honda grass cutters. They vary by model, and selecting the right one can significantly affect start-up reliability. B2B buyers must consider the specific models they operate and the frequency of use when purchasing these components. A reliable starter assembly can minimize downtime and enhance productivity, making it a vital investment for landscaping professionals.

How Do Nylon Line Heads Enhance Efficiency in Grass Cutting?

Nylon line heads are designed for brush cutters, allowing for efficient trimming and edging. Different spool designs cater to various Honda models, providing flexibility for different landscaping tasks. For businesses involved in agricultural or landscaping applications, easy line replacement is a significant advantage. However, the durability of the line can vary, so buyers should consider the expected usage and choose a line head that balances ease of use with performance longevity.

Key Industrial Applications of honda grass cutter parts

| Industry/Sector | Specific Application of Honda Grass Cutter Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Landscaping and Gardening | Replacement parts for commercial lawn maintenance equipment | Ensures optimal performance and longevity of equipment | OEM quality assurance, compatibility with various models |

| Agriculture | Maintenance of grass and crop borders | Supports healthy crop growth and reduces pests | Availability of specific parts for different models |

| Municipal Services | Upkeep of public parks and recreational areas | Enhances aesthetic appeal and safety for communities | Bulk purchasing options, reliable supply chains |

| Construction and Development | Clearing sites and maintaining green spaces | Improves site readiness and worker safety | Timely delivery, robust parts for heavy-duty use |

| Golf Courses and Sports Facilities | Precision mowing and trimming for greens and fairways | Maintains high standards of turf quality | Specialized parts for specific equipment types |

How Are Honda Grass Cutter Parts Used in Landscaping and Gardening?

In the landscaping and gardening sector, Honda grass cutter parts are essential for maintaining commercial lawn maintenance equipment. Landscape professionals rely on high-quality parts to ensure their mowers and trimmers operate efficiently, minimizing downtime during peak seasons. The availability of OEM parts guarantees compatibility and performance, which is crucial for businesses aiming to deliver consistent results. International buyers must consider sourcing from reputable suppliers to ensure parts meet specific standards for durability and reliability.

What Role Do Honda Grass Cutter Parts Play in Agriculture?

In agriculture, Honda grass cutter parts are utilized to maintain grass and crop borders, helping to create a clean and healthy environment for crops. By regularly replacing worn parts, farmers can ensure their equipment runs efficiently, which is vital for pest control and maintaining soil health. Buyers in regions like Africa and South America should focus on sourcing parts that are not only compatible with their existing equipment but also designed to withstand local environmental conditions, such as humidity and temperature fluctuations.

How Do Municipal Services Benefit from Honda Grass Cutter Parts?

Municipal services utilize Honda grass cutter parts for the upkeep of public parks and recreational areas. The reliability of these parts ensures that equipment can handle the rigors of frequent use, providing well-maintained green spaces for communities. B2B buyers in this sector should prioritize sourcing from suppliers that offer bulk purchasing options and a reliable supply chain to ensure timely maintenance and repairs, especially in high-demand seasons.

Why Are Honda Grass Cutter Parts Important for Construction and Development?

In the construction and development industry, Honda grass cutter parts are vital for clearing sites and maintaining green spaces. Efficient equipment allows construction teams to prepare sites quickly and safely, which is crucial for project timelines. Buyers need to ensure that they source robust parts suitable for heavy-duty applications, with an emphasis on timely delivery to keep projects on schedule.

How Do Golf Courses and Sports Facilities Use Honda Grass Cutter Parts?

Golf courses and sports facilities require precision mowing and trimming to maintain the quality of their greens and fairways. Honda grass cutter parts ensure that the equipment performs at optimal levels, meeting the high standards expected in these sectors. B2B buyers should look for specialized parts that cater to specific equipment types used in these environments, ensuring they maintain the aesthetics and playability of their facilities.

3 Common User Pain Points for ‘honda grass cutter parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Genuine Honda Grass Cutter Parts

The Problem: Many B2B buyers encounter challenges when trying to source genuine Honda grass cutter parts. The market is flooded with counterfeit or substandard components, which can lead to equipment failure, reduced performance, and ultimately higher maintenance costs. Buyers in regions like Africa and South America may also face logistical issues in accessing reliable suppliers, making it hard to ensure they are getting OEM (Original Equipment Manufacturer) parts that meet Honda’s quality standards. This situation not only affects operational efficiency but can also harm the reputation of landscaping businesses that rely on quality equipment.

The Solution: To effectively source genuine Honda grass cutter parts, buyers should establish relationships with authorized dealers or reputable distributors known for their integrity and commitment to quality. It is crucial to verify the authenticity of the supplier by checking their certifications and customer reviews. Additionally, utilizing Honda’s official website can provide access to a list of authorized parts dealers based on geographical location. When placing orders, ensure to request OEM parts and confirm their compatibility with specific Honda grass cutter models. Implementing a robust inventory management system will also help track parts usage and reordering needs, ensuring that businesses are always equipped with the right parts at the right time.

Scenario 2: Incompatibility of Replacement Parts

The Problem: Another common pain point for B2B buyers is the incompatibility of replacement parts with existing Honda grass cutter models. This issue often arises when buyers purchase parts without confirming the model specifications, leading to wasted time, increased costs, and disruption of services. For landscaping businesses that operate on tight schedules, any delays caused by incorrect parts can result in lost revenue and dissatisfied customers.

The Solution: To prevent issues of incompatibility, buyers should take the time to verify the model numbers and specifications of their Honda grass cutters before placing an order for parts. Using Honda’s online parts lookup tool allows buyers to identify the correct part numbers based on their specific model. Additionally, maintaining a detailed record of the equipment fleet, including model numbers and parts used, can streamline the ordering process. When in doubt, reaching out to customer service representatives from authorized dealers can provide clarity and ensure that the right parts are selected. This proactive approach minimizes downtime and enhances operational efficiency.

Scenario 3: Lack of Knowledge on Maintenance and Parts Usage

The Problem: Many B2B buyers lack comprehensive knowledge about the maintenance and optimal usage of Honda grass cutter parts. This gap can lead to improper installation, poor maintenance practices, and ultimately, equipment failures. For buyers from regions with varying climates and grass types, understanding how to adapt their equipment accordingly can be a significant hurdle, affecting productivity and equipment lifespan.

The Solution: To address this knowledge gap, B2B buyers should invest in training and resources that focus on the proper maintenance of Honda grass cutters. Manufacturers like Honda often provide manuals, online tutorials, and maintenance guides that detail how to care for and use their equipment effectively. Additionally, participating in workshops or webinars conducted by industry experts can enhance understanding of best practices in equipment maintenance tailored to specific regional needs. Establishing a routine maintenance schedule based on the manufacturer’s recommendations will also help prolong the lifespan of the equipment and ensure optimal performance. By prioritizing education on equipment care, businesses can reduce repair costs and improve service delivery.

Strategic Material Selection Guide for honda grass cutter parts

What Are the Key Materials Used in Honda Grass Cutter Parts?

When selecting materials for Honda grass cutter parts, it is essential to understand the properties, advantages, and limitations of each material. This knowledge helps international B2B buyers make informed decisions that align with their operational needs and local conditions.

How Does Aluminum Benefit Honda Grass Cutter Parts?

Aluminum is a lightweight and corrosion-resistant metal commonly used in various components of Honda grass cutters, such as frames and casings. Its key properties include a temperature rating up to 200°C and excellent resistance to rust, making it suitable for outdoor applications.

Pros: Aluminum’s lightweight nature enhances maneuverability, while its corrosion resistance extends the lifespan of parts exposed to moisture. It is also relatively easy to manufacture and can be extruded or cast into complex shapes.

Cons: The primary drawback of aluminum is its lower tensile strength compared to steel, which may limit its use in high-stress applications. Additionally, while generally cost-effective, the price can vary based on global market conditions.

Impact on Application: Aluminum is compatible with various media, including fuels and oils, but may not perform well under extreme mechanical stress.

International Considerations: Buyers from regions like Africa and the Middle East should ensure compliance with local regulations regarding aluminum use, particularly regarding environmental impacts and recycling.

What Role Does Steel Play in Honda Grass Cutter Parts?

Steel is another prevalent material in the manufacturing of Honda grass cutter parts, especially for components that require high strength and durability, such as blades and drive systems. The material can withstand high pressure and has a temperature rating of up to 300°C.

Pros: Steel’s high tensile strength makes it ideal for parts that experience significant wear and tear. It is also widely available and cost-effective, making it a popular choice for manufacturers.

Cons: The main disadvantage of steel is its susceptibility to corrosion if not properly coated or treated. Additionally, steel components can be heavier, which may affect the overall weight of the grass cutter.

Impact on Application: Steel is suitable for various media, including fuels and lubricants, but requires protective coatings to enhance corrosion resistance.

International Considerations: Compliance with international standards such as ASTM and DIN is crucial for steel parts, especially in regions with stringent quality controls.

How Does Plastic Enhance the Functionality of Honda Grass Cutter Parts?

Plastics, such as polypropylene and nylon, are increasingly used in Honda grass cutter parts, particularly for components like handles and guards. These materials offer temperature ratings up to 80°C and are resistant to many chemicals.

Pros: The lightweight nature of plastics contributes to reduced overall weight, enhancing user comfort. They are also resistant to corrosion and can be molded into complex shapes, making them versatile for various applications.

Cons: Plastics generally have lower mechanical strength compared to metals, which may limit their use in high-stress components. They can also degrade under UV exposure unless treated.

Impact on Application: Plastics are compatible with various media, including fuels, but their performance can be affected by extreme temperatures.

International Considerations: Buyers should consider local regulations regarding plastic use, particularly concerning environmental impacts and recyclability in regions like Europe and South America.

What Advantages Do Composite Materials Offer for Honda Grass Cutter Parts?

Composite materials, such as fiberglass and carbon fiber, are used in high-performance applications within Honda grass cutters. These materials can withstand high temperatures and pressures, making them suitable for demanding environments.

Pros: Composites are lightweight yet strong, offering excellent durability and resistance to corrosion. They can also be engineered for specific performance characteristics, making them ideal for specialized applications.

Cons: The primary limitation of composites is their higher cost and manufacturing complexity. They often require specialized processing techniques, which can lead to longer lead times.

Impact on Application: Composites are compatible with a wide range of media, but their performance can vary significantly based on the specific formulation used.

International Considerations: Compliance with international standards is critical, especially in regions with rigorous quality and safety regulations, such as Europe.

Summary Table of Material Selection for Honda Grass Cutter Parts

| Material | Typical Use Case for Honda Grass Cutter Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames, casings | Lightweight, corrosion-resistant | Lower tensile strength | Medium |

| Steel | Blades, drive systems | High strength, cost-effective | Susceptible to corrosion | Low |

| Plastic | Handles, guards | Lightweight, versatile | Lower mechanical strength | Low |

| Composite | High-performance components | Lightweight, customizable | Higher cost, manufacturing complexity | High |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to choose the right materials for Honda grass cutter parts, ensuring performance, compliance, and cost-effectiveness in their operations.

In-depth Look: Manufacturing Processes and Quality Assurance for honda grass cutter parts

What Are the Key Stages in the Manufacturing Process of Honda Grass Cutter Parts?

The manufacturing process for Honda grass cutter parts involves several critical stages, each designed to ensure the high quality and performance expected from Honda products. Understanding these stages helps B2B buyers appreciate the complexity and commitment to excellence that goes into each component.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in manufacturing Honda grass cutter parts begins with the careful selection of raw materials. Typically, high-grade metals such as steel and aluminum are chosen for their durability and resistance to wear. In addition to metals, composites and plastics may be used for specific components like handles and casings.

Once selected, raw materials undergo preparation processes, which can include cutting, shaping, and treating to enhance their properties. For instance, metal parts may be treated with coatings to prevent corrosion. This stage is crucial, as the quality of materials directly affects the overall performance and longevity of the grass cutter.

What Techniques Are Used in Forming Honda Grass Cutter Parts?

After material preparation, the next phase is forming, where raw materials are transformed into specific shapes. This can involve various techniques, including:

- Casting: Molten metal is poured into molds to create complex shapes.

- Machining: Precision tools are used to cut, drill, or mill materials into desired dimensions.

- Stamping: Sheets of metal are punched or pressed into specific forms.

These techniques ensure that each part meets the stringent specifications required for optimal performance. The choice of forming technique depends on the part’s complexity, volume of production, and material type.

How Are Honda Grass Cutter Parts Assembled?

The assembly stage involves bringing together all the manufactured components into a complete product. This process may be done manually or through automated assembly lines, depending on the scale of production.

During assembly, each part is carefully fitted together, and critical functions are tested to ensure they operate as intended. For instance, drive belts, engines, and blades must be aligned perfectly to ensure efficiency and safety. Attention to detail in this stage is vital, as even minor misalignments can lead to performance issues.

What Finishing Processes Are Applied to Enhance Product Quality?

Finishing processes are the final steps in manufacturing Honda grass cutter parts. These processes can include:

- Painting and Coating: Protective and aesthetic coatings are applied to prevent rust and enhance appearance.

- Polishing: Surfaces are smoothed to improve functionality and aesthetic appeal.

- Quality Inspections: Each finished part undergoes rigorous inspections to ensure it meets Honda’s quality standards.

These finishing touches not only improve the visual appeal of the parts but also enhance their durability and resistance to the elements.

What Quality Assurance Practices Are Essential for Honda Grass Cutter Parts?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that each part meets international standards and customer expectations. For B2B buyers, understanding these practices is crucial for making informed purchasing decisions.

Which International Standards Govern Honda Grass Cutter Parts?

Honda adheres to various international quality standards, including ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards indicates that Honda maintains consistent quality in its manufacturing processes.

Additionally, products may also meet industry-specific standards such as CE marking for compliance with European safety regulations or API standards for components related to engine performance. These certifications provide assurance to buyers that the products are safe and reliable.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integral to the manufacturing process, with several checkpoints established to maintain high standards:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any defects early on.

- Final Quality Control (FQC): The finished products undergo rigorous testing before they are shipped to ensure they meet all specifications.

These checkpoints help to catch any potential issues early, reducing the risk of defective products reaching the market.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some effective strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality control reports from suppliers, including results from IQC, IPQC, and FQC processes. Additionally, suppliers should be willing to provide documentation of their compliance with international standards like ISO 9001 and any relevant industry certifications.

How Can Third-Party Inspections Enhance Confidence in Supplier Quality?

Engaging third-party inspection services can further assure buyers of a supplier’s quality control processes. These independent audits can evaluate manufacturing facilities, review quality control documentation, and perform product testing to ensure compliance with established standards.

What Are the Unique QC Considerations for International B2B Buyers?

When sourcing Honda grass cutter parts internationally, buyers should be aware of specific quality control nuances. Factors such as local regulations, shipping constraints, and potential variations in manufacturing standards can impact product quality.

Buyers should ensure that suppliers are familiar with the regulations in their respective countries, particularly if importing products into regions with strict compliance requirements. Understanding these nuances will help mitigate risks and ensure a smooth procurement process.

In conclusion, the manufacturing processes and quality assurance practices for Honda grass cutter parts are designed to ensure durability, performance, and safety. By understanding these processes, B2B buyers can make informed decisions, ensuring they source high-quality parts that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘honda grass cutter parts’

Introduction

In the competitive landscape of landscaping and agricultural equipment, sourcing Honda grass cutter parts effectively is crucial for maintaining operational efficiency and delivering quality service. This guide provides a step-by-step checklist to help international B2B buyers streamline their procurement process, ensuring they acquire the right parts from reliable sources.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the Honda grass cutter parts you need. This includes model numbers, part numbers, and any specific features required for your operation. Having precise specifications helps in narrowing down your search and ensures that you receive compatible and high-quality parts.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in Honda parts. Utilize online platforms, trade directories, and industry forums to gather a list of reputable vendors. Look for suppliers with a strong market presence and positive reviews, particularly from businesses in your region.

- Check for online marketplaces that focus on OEM parts to ensure quality.

- Investigate suppliers’ websites for product availability and customer service options.

Step 3: Evaluate Supplier Certifications

It’s essential to verify the certifications and qualifications of your potential suppliers. Look for ISO certifications or other industry-specific credentials that demonstrate compliance with international standards. This step is vital for ensuring that the parts you source meet safety and performance requirements.

- Request documentation that verifies their status as an authorized dealer for Honda parts.

- Ensure that suppliers provide warranties or guarantees on their products.

Step 4: Assess Pricing and Terms

Gather quotes from multiple suppliers to compare pricing and procurement terms. Pay attention to unit costs, shipping fees, and payment terms. Understanding the total cost of ownership, including potential import duties and taxes, will help you budget effectively.

- Look for bulk purchase discounts or loyalty programs that may benefit your business.

- Negotiate terms to secure the best deal while maintaining quality standards.

Step 5: Review Delivery and Logistics Options

Evaluate the delivery options and logistics capabilities of your chosen suppliers. Reliable shipping methods and timelines are critical, especially for businesses that rely on timely maintenance and repair services. Confirm whether the supplier can meet your delivery expectations.

- Inquire about tracking systems for shipments to monitor progress.

- Check if they offer expedited shipping or local distribution centers for faster delivery.

Step 6: Conduct a Trial Order

Before making a significant investment, place a trial order to assess the quality and compatibility of the parts. This initial order will allow you to evaluate not only the product but also the supplier’s efficiency and customer service.

- Monitor the entire order process, from placement to delivery.

- Provide feedback to the supplier based on your experience to foster better communication.

Step 7: Establish a Long-Term Relationship

Once you find a reliable supplier, work towards establishing a long-term partnership. Strong relationships can lead to better pricing, priority service, and exclusive access to new products. Regular communication and feedback will help ensure that your needs are consistently met.

- Schedule regular check-ins to discuss any upcoming needs or changes in your requirements.

- Consider signing a service-level agreement to formalize your partnership and expectations.

By following these steps, B2B buyers can effectively source Honda grass cutter parts, ensuring operational continuity and enhancing service delivery in their respective markets.

Comprehensive Cost and Pricing Analysis for honda grass cutter parts Sourcing

What Are the Key Cost Components in Sourcing Honda Grass Cutter Parts?

When analyzing the cost structure for sourcing Honda grass cutter parts, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the margin applied by suppliers.

-

Materials: The quality and type of materials used directly impact the cost. Genuine OEM parts, such as air filters and blades, often command higher prices due to their durability and performance guarantees. Non-OEM parts might be cheaper but can lead to higher failure rates.

-

Labor: The cost of labor varies significantly across regions. For instance, labor costs in Europe may be higher compared to South America or Africa. Understanding local labor rates can help buyers gauge the overall pricing structure of parts.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative costs. Suppliers with efficient operations tend to offer more competitive prices.

-

Tooling: The initial investment in tooling for custom parts can be significant. If a buyer requires customized components, they should anticipate higher costs due to the setup involved.

-

Quality Control (QC): Ensuring parts meet specific standards adds to the cost. Suppliers with robust QC processes may charge more but offer better reliability and performance, which can reduce long-term costs for buyers.

-

Logistics: Shipping costs, tariffs, and handling fees are critical in international sourcing. Understanding Incoterms (International Commercial Terms) helps buyers anticipate these costs and negotiate better shipping terms.

-

Margin: The profit margin varies between suppliers based on their market positioning and brand value. Established suppliers often have higher margins due to brand loyalty and perceived quality.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of Honda grass cutter parts, especially for international buyers.

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities can lead to significant discounts. Buyers should evaluate their needs to optimize order sizes, balancing inventory costs with price benefits.

-

Specifications and Customization: Customized parts or those with specific requirements often incur higher costs. Buyers should assess whether standard parts can meet their needs to avoid additional expenses.

-

Materials and Quality Certifications: Parts that comply with international quality standards or certifications can be more expensive. However, investing in certified parts may reduce the risk of failure and associated costs over time.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Suppliers with a proven track record may charge more but offer greater assurance of quality and service.

-

Incoterms: Understanding the implications of Incoterms on shipping and delivery responsibilities can help buyers avoid unexpected costs. Choosing the right terms can lead to cost savings in logistics.

What Are the Best Buyer Tips for Negotiating Prices on Honda Grass Cutter Parts?

B2B buyers looking to optimize their sourcing strategy for Honda grass cutter parts should consider the following tips:

-

Negotiation: Don’t hesitate to negotiate prices, especially for bulk orders. Establishing a good relationship with suppliers can lead to better terms and discounts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and potential replacement costs. Sometimes, a higher upfront cost can lead to lower long-term expenses.

-

Pricing Nuances for International Buyers: Understand local market conditions, currency fluctuations, and regional economic factors that may impact pricing. This knowledge can provide leverage in negotiations and help avoid unfavorable pricing.

-

Due Diligence: Always research potential suppliers thoroughly. Compare prices, quality, and service levels across multiple vendors to ensure you are making an informed decision.

-

Stay Informed on Market Trends: Keep abreast of trends in the lawn care equipment market, as changes in demand can affect pricing. This insight can help in timing your purchases for optimal savings.

In conclusion, a comprehensive understanding of the cost components and price influencers can significantly enhance the sourcing strategy for Honda grass cutter parts. By leveraging these insights, international buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing honda grass cutter parts With Other Solutions

Understanding Alternative Solutions for Grass Cutting Needs

In the competitive landscape of landscaping and maintenance, businesses often seek effective solutions for grass cutting. While Honda grass cutter parts are a recognized choice due to their reliability and performance, several alternatives exist that might better suit specific operational needs or budgets. This analysis will compare Honda grass cutter parts against two viable alternatives: Electric Lawn Mowers and Robotic Lawn Mowers.

Comparison Table

| Comparison Aspect | Honda Grass Cutter Parts | Electric Lawn Mowers | Robotic Lawn Mowers |

|---|---|---|---|

| Performance | High efficiency with durable parts | Good for small to medium lawns | Automated mowing with sensors |

| Cost | Moderate initial investment | Varies widely; generally lower | Higher upfront cost, but lower maintenance |

| Ease of Implementation | Requires manual assembly and knowledge of parts | Simple setup with minimal effort | Self-operating; minimal intervention needed |

| Maintenance | Regular maintenance needed for parts | Requires battery care and blade replacement | Low maintenance; occasional cleaning |

| Best Use Case | Professional landscaping services | Residential lawns, eco-friendly options | Large lawns, commercial use with minimal human oversight |

Detailed Breakdown of Alternatives

Electric Lawn Mowers

Electric lawn mowers are an increasingly popular alternative, especially in residential settings. They offer a quieter operation and are environmentally friendly, making them suitable for urban areas where noise restrictions may apply. The cost of electric mowers can vary significantly based on features and brand, often leading to a lower initial investment compared to Honda parts. However, their performance may be limited to smaller lawns, and they require regular maintenance, such as battery care and blade sharpening.

Robotic Lawn Mowers

Robotic lawn mowers represent a cutting-edge solution for grass cutting needs. These devices operate autonomously, utilizing advanced sensors to navigate and mow the lawn efficiently. While they come with a higher upfront cost, they significantly reduce labor requirements and ongoing maintenance efforts. Robotic mowers are ideal for large commercial spaces or residential properties where consistent lawn care is needed without human intervention. However, they may struggle in complex landscapes or during extreme weather conditions, which can limit their effectiveness.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right solution for grass cutting, B2B buyers should evaluate their specific needs, including lawn size, maintenance capabilities, and budget constraints. Honda grass cutter parts offer robust performance and reliability, particularly for professional landscapers who prioritize quality and durability. In contrast, electric and robotic mowers may provide cost-effective and labor-saving alternatives for smaller, more manageable lawns or automated solutions. Ultimately, the decision should align with operational goals, ensuring that the chosen equipment maximizes efficiency and meets the unique demands of the market.

Essential Technical Properties and Trade Terminology for honda grass cutter parts

What Are the Essential Technical Properties of Honda Grass Cutter Parts?

When sourcing Honda grass cutter parts, understanding the technical specifications is crucial for ensuring compatibility, performance, and durability. Here are some key properties that international B2B buyers should consider:

-

Material Grade

The material grade of parts like blades, casings, and frames significantly affects their performance and lifespan. Common materials include high-carbon steel for blades, which offers superior hardness and wear resistance, and aluminum for lightweight components. Selecting the right material is essential to meet specific operational demands, such as resistance to rust or impact. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in a physical dimension. For example, a blade must fit precisely to the mower’s assembly to ensure safety and efficiency. Tighter tolerances often translate to higher manufacturing costs but can lead to better performance and less maintenance in the long run, making it a critical consideration for B2B buyers focused on quality. -

Compatibility Specifications

Each Honda grass cutter part is designed to fit specific models, which is vital for maintaining operational efficiency. Compatibility specifications include model numbers and part numbers that ensure the right fit. Buyers should verify these specifications to avoid costly errors and ensure that replacement parts function optimally with existing equipment. -

Weight Capacity

For components like frames and wheels, understanding weight capacity is crucial, especially in commercial applications. Parts must be able to support the weight of the mower and any additional loads without compromising performance. This is particularly important in regions where heavy-duty usage is common. -

Performance Ratings

Performance ratings indicate how well a part performs under various conditions. For example, mower blades may have ratings for cutting efficiency and longevity. Evaluating these ratings helps buyers select parts that will deliver the expected results, especially in challenging environments typical in Africa or South America.

What Are Common Trade Terminology and Jargon Related to Honda Grass Cutter Parts?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM parts are made by the original manufacturer of the equipment. They are designed to meet specific quality and performance standards, ensuring compatibility and reliability. B2B buyers often prefer OEM parts for their assurance of quality. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding the MOQ is critical for managing inventory and cash flow, particularly for businesses in regions with varying demand levels. -

RFQ (Request for Quotation)

An RFQ is a document that businesses use to request pricing and terms from suppliers. It is essential for comparing offers from different vendors and ensuring that the best value is obtained for bulk purchases. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, risk, and insurance. Knowing the applicable Incoterms helps B2B buyers understand their obligations and costs, facilitating smoother logistics. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For businesses operating in competitive markets, understanding lead times is crucial for planning and ensuring that they can meet customer demands promptly. -

Aftermarket Parts

These are parts made by third-party manufacturers, not the original manufacturer. While they may offer cost savings, their quality and compatibility can vary. B2B buyers should assess the risks and benefits of using aftermarket parts versus OEM options.

Understanding these technical properties and trade terminologies will empower international B2B buyers to make informed purchasing decisions, ensuring that they acquire the right Honda grass cutter parts for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the honda grass cutter parts Sector

What Are the Key Market Dynamics and Trends in the Honda Grass Cutter Parts Sector?

The global market for Honda grass cutter parts is driven by a combination of technological advancements, increasing demand for landscaping services, and a growing focus on efficient agricultural practices. In regions like Africa, South America, the Middle East, and Europe, the need for reliable and durable lawn maintenance equipment has surged. B2B buyers are increasingly leveraging digital platforms for sourcing parts, utilizing advanced search tools and databases that simplify the procurement process. This trend is particularly prominent in regions with rapidly urbanizing populations, where landscaping and maintenance services are becoming essential.

Emerging technologies such as predictive analytics and AI are reshaping how businesses forecast demand and manage inventory. B2B buyers can now utilize data-driven insights to optimize their supply chains, ensuring that they have the right parts available at the right time. Furthermore, partnerships with manufacturers and suppliers that offer comprehensive catalogs, including OEM parts, are becoming critical for maintaining operational efficiency. As international buyers seek to enhance their competitive edge, they are increasingly prioritizing suppliers who can provide not only quality parts but also robust customer support and logistics solutions.

How Can Sustainability and Ethical Sourcing Impact the Sourcing of Honda Grass Cutter Parts?

Sustainability is becoming a core consideration for B2B buyers in the Honda grass cutter parts sector. The environmental impact of manufacturing processes and the lifecycle of parts are under scrutiny, pushing companies to adopt more eco-friendly practices. Buyers are encouraged to seek suppliers that prioritize ethical sourcing, utilizing sustainable materials and reducing waste throughout their operations.

The demand for ‘green’ certifications is rising, with many buyers looking for suppliers that comply with environmental standards. This includes the use of recyclable materials in parts production and the implementation of energy-efficient manufacturing processes. Additionally, understanding the supply chain’s ethical implications—such as labor practices and sourcing of raw materials—is crucial. B2B buyers can enhance their brand reputation and customer loyalty by ensuring that their suppliers adhere to ethical sourcing guidelines, thereby contributing positively to the environment and society.

What Is the Historical Context of the Honda Grass Cutter Parts Market?

The Honda grass cutter parts market has evolved significantly over the past few decades. Initially, the focus was primarily on the production of basic components for lawn maintenance equipment. However, as the landscaping and agricultural sectors expanded, so did the complexity and diversity of parts required. Honda’s commitment to innovation and quality has positioned it as a leader in this space, with continuous improvements in engine technology and equipment efficiency.

Over time, the rise of digital platforms has transformed how B2B buyers interact with suppliers. The ability to easily search for parts by model number or description has streamlined the purchasing process, enabling international buyers to access a wider range of products and services. This evolution reflects broader trends in manufacturing and supply chain management, where efficiency, reliability, and sustainability have become paramount. As the market continues to evolve, staying informed about these historical shifts will be essential for B2B buyers looking to navigate the complexities of sourcing Honda grass cutter parts effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of honda grass cutter parts

-

1. How do I solve issues with my Honda grass cutter not starting?

To troubleshoot a Honda grass cutter that won’t start, check the battery charge and connections if it’s electric. For gas models, inspect the fuel level and ensure that the fuel is fresh. Additionally, examine the spark plug for wear or damage, and replace it if necessary. Ensure that the air filter is clean, as a clogged filter can hinder performance. If these steps do not resolve the issue, consult the owner’s manual for specific diagnostic procedures or consider contacting a certified technician. -

2. What is the best way to source genuine Honda grass cutter parts?

To source genuine Honda grass cutter parts, start by identifying reputable suppliers who specialize in OEM (Original Equipment Manufacturer) parts. Look for authorized Honda dealers or distributors with a solid track record and positive reviews. Utilize online platforms that allow you to search by model or part number, ensuring you receive the correct components. Establishing relationships with suppliers who offer warranties and customer support can also enhance your purchasing experience and ensure part authenticity. -

3. What customization options are available for Honda grass cutter parts?

Many suppliers offer customization options for Honda grass cutter parts, including different sizes, materials, and configurations based on your specific needs. It’s essential to communicate your requirements clearly to the supplier. Some may provide tailored solutions for commercial applications, such as enhanced durability for rugged environments. Always inquire about lead times and any additional costs associated with custom parts to ensure they align with your project timelines and budget. -

4. What is the minimum order quantity (MOQ) for Honda grass cutter parts?

Minimum order quantities (MOQ) for Honda grass cutter parts can vary widely among suppliers. Typically, MOQs are established based on the type of part and the supplier’s inventory policies. While some suppliers may allow orders as low as one unit, others might require larger quantities to optimize their production or shipping processes. It’s advisable to discuss your needs directly with the supplier to negotiate MOQs that work for both parties, especially for bulk purchasing. -

5. What payment terms should I expect when buying Honda grass cutter parts internationally?

Payment terms for international purchases of Honda grass cutter parts often include options like wire transfers, letters of credit, or payment through secure online platforms. Common terms may range from upfront payment to net 30 or net 60 days, depending on the supplier’s policy and your negotiation. Always ensure that payment methods are secure and verify the supplier’s credibility before proceeding. Discussing payment terms early in the negotiation can help avoid misunderstandings later. -

6. How can I ensure quality assurance for Honda grass cutter parts?

To ensure quality assurance when sourcing Honda grass cutter parts, request certifications and quality control documentation from your suppliers. Many reputable suppliers will have established quality management systems, such as ISO certifications, that validate their commitment to quality. Conducting pre-shipment inspections can also be beneficial, allowing you to verify the quality of parts before they arrive. Building a long-term relationship with reliable suppliers can further enhance your confidence in the quality of the products you receive. -

7. What logistics considerations should I keep in mind when importing Honda grass cutter parts?

When importing Honda grass cutter parts, consider factors such as shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder familiar with international shipping regulations to ensure smooth transportation. It’s also crucial to factor in potential delays at customs, particularly in regions with stringent import regulations. Understanding the total landed cost, which includes shipping and duties, will help you manage your budget effectively. -

8. How can I effectively vet suppliers of Honda grass cutter parts?

To effectively vet suppliers of Honda grass cutter parts, conduct thorough research on their background, including years in business, customer testimonials, and industry reputation. Request references from other clients and check their online presence for reviews. Additionally, verify their certifications and compliance with industry standards. Engaging in direct communication, such as video calls or factory visits, can also provide insights into their operations and reliability as a business partner.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Honda Grass Cutter Parts Manufacturers & Suppliers List

1. Honda – High-Demand Lawn Parts

Domain: hondalawnparts.com

Registered: 2011 (14 years)

Introduction: This company, Honda – High-Demand Lawn Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

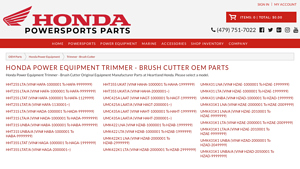

2. Honda – Power Equipment Trimmer Parts

Domain: hondapowersportsparts.com

Registered: 2007 (18 years)

Introduction: Honda Power Equipment Trimmer – Brush Cutter OEM Parts. Models available: HHT25S LTA, HHT25S LTA/A, HHT25S LTAT, HHT25S LTAT/A, HHT31S LTA, HHT31S LTA/A, HHT31S UNBA, HHT31S UNBA/A, HHT35S LTAT, HHT35S LTAT/A, HHT35S UKAT, HHT35S UKAT/A, UMC425A LAAT, UMC425A LAAT/A, UMC435A LAAT, UMC435A LAAT/A, UMK422 LNA, UMK422 LTA, UMK422K1 LNA, UMK422K1 LTA, UMK431 LNA, UMK431 LTA, UMK431 UNBA, UMK431K1 LNA,…

3. Honda – Essential Parts for Lawn Mowers

Domain: themowershop.com

Registered: 1998 (27 years)

Introduction: Honda Parts available include: 1. Honda Air Filter (17211-Z8B-901) – HRN216 / HRR216 / HRX217 – $13.39 2. Honda Oil (08213-10w30) – $4.47 3. Honda HRN216 Drive Belt (22431-VR8-N03) – $12.57 4. Honda Battery (31500-VH7-801) – HRN216 / HRR216 (K9-K11) / HRX217 (K5-K6) – $54.99 5. Honda Recoil Starter (28400-Z9V-014) – HRN216 & HRX217 K6 – Sale Price: $11.99 (Regular Price: $13.43) 6. Honda HRR216 / …

4. Honda – Small Engine Models

Domain: engines.honda.com

Registered: 1989 (36 years)

Introduction: Honda Engines offers a variety of small engine models including the GX Series, V-Twin Series, iGX Series, GC Series, GCV Pressure Washer, GS Series, Mini 4-stroke, and eGX Series. Key specifications include:

– GX Series: 100 cc – 389 cc, OHV design, lower noise levels, better fuel economy, available in horizontal or vertical crankshaft.

– V-Twin Series: 688 cc, pressurized and filtered lubricati…

5. Honda – Trimmer/Brush Cutter Parts

Domain: jackssmallengines.com

Registered: 1997 (28 years)

Introduction: Honda Trimmer/Brush Cutter Parts Lookup by Model. Models include HHT25S LTA, HHT25S LTA/A, HHT25S LTAT, HHT31S LTA, HHT31S UNBA, HHT35S LTAT, UMC425A LAAT, UMK422 LNA, UMK431 LNA, and more. VIN ranges provided for specific models.

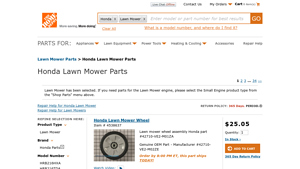

6. Honda – Lawn Mower Parts

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: This company, Honda – Lawn Mower Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Honda – Power Equipment Products

Domain: powerequipment.honda.com

Registered: 1989 (36 years)

Introduction: Honda Power Equipment offers a range of products including Generators, Lawn Mowers, Snow Blowers, Tillers, Trimmers, and Pumps. Key product lines include:

– Generators: Home Backup, Industrial, Recreational, Super Quiet models.

– Lawn Mowers: Battery Powered, HRX Series, HRN Series, HRC Series.

– Tillers: Mini Tiller, Mid-Tine Tillers, Rear-Tine Tiller.

– Trimmers: Versattach System with 4-Str…

8. Honda – Nylon Line Head for Brushcutters

Domain: ripongroundcare.com

Registered: 2023 (2 years)

Introduction: Honda Brushcutter Parts include: 1. Honda Nylon Line Head – 06725-VJ5-305, compatible with models UMK425E1, UMK425ELE, UMK425EL3E, UMK425EUE, UMK425EU3E, UMK431ELE, UMK431EL3E, UMK431EUE, UMK431EU3E, UMK435E1, UMK435ELE, UMK435EL3E, UMK435EUE, and UMK435EU3E. Price: £43.01, In Stock. 2. Honda Brushcutter Blade Adaptor Kit – 06812-VJ5-000HE, compatible with models UMK425ELE, UMK425EUE, UMK431ELE, a…

Strategic Sourcing Conclusion and Outlook for honda grass cutter parts

In the rapidly evolving landscape of lawn care equipment, the strategic sourcing of Honda grass cutter parts presents significant opportunities for B2B buyers across various global markets, including Africa, South America, the Middle East, and Europe. By prioritizing high-quality OEM parts, businesses can ensure superior performance and longevity for their equipment, ultimately leading to enhanced customer satisfaction and reduced operational costs.

Additionally, leveraging advanced search tools and reliable suppliers can streamline the procurement process, making it easier to find the specific parts needed for various Honda models. This approach not only minimizes downtime but also supports efficient inventory management, allowing businesses to focus on growth and profitability.

As we look to the future, the demand for reliable lawn care solutions is set to increase, driven by urbanization and a growing emphasis on landscape aesthetics. International buyers are encouraged to engage with trusted suppliers and explore diverse sourcing strategies to capitalize on this trend. Embrace the potential of strategic sourcing today to secure your competitive edge in the marketplace. Your proactive approach can lead to substantial gains in efficiency and customer loyalty, positioning your business for success in the coming years.