Vertical Conveyor Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for vertical conveyor

In an increasingly competitive global landscape, sourcing efficient vertical conveyor systems can be a daunting challenge for international B2B buyers. These systems are essential for optimizing material handling processes, especially in industries that demand high throughput and space efficiency. This guide delves deep into the realm of vertical conveyors, exploring various types, including hydraulic and mechanical options, alongside their applications across sectors such as manufacturing, warehousing, and distribution.

By providing actionable insights on supplier vetting, cost considerations, and safety standards, this comprehensive resource empowers businesses in regions like Africa, South America, the Middle East, and Europe—such as Vietnam and Nigeria—to make informed purchasing decisions. From understanding the unique requirements of your operational environment to navigating complex international regulations, this guide serves as a strategic partner in enhancing your material handling capabilities.

Whether you are looking to streamline operations, improve safety, or maximize space utilization, this guide equips you with the knowledge to select the right vertical conveyor system tailored to your specific needs. Prepare to navigate the global market with confidence, ensuring that your investment in vertical conveyors yields optimal returns and supports your business’s growth trajectory.

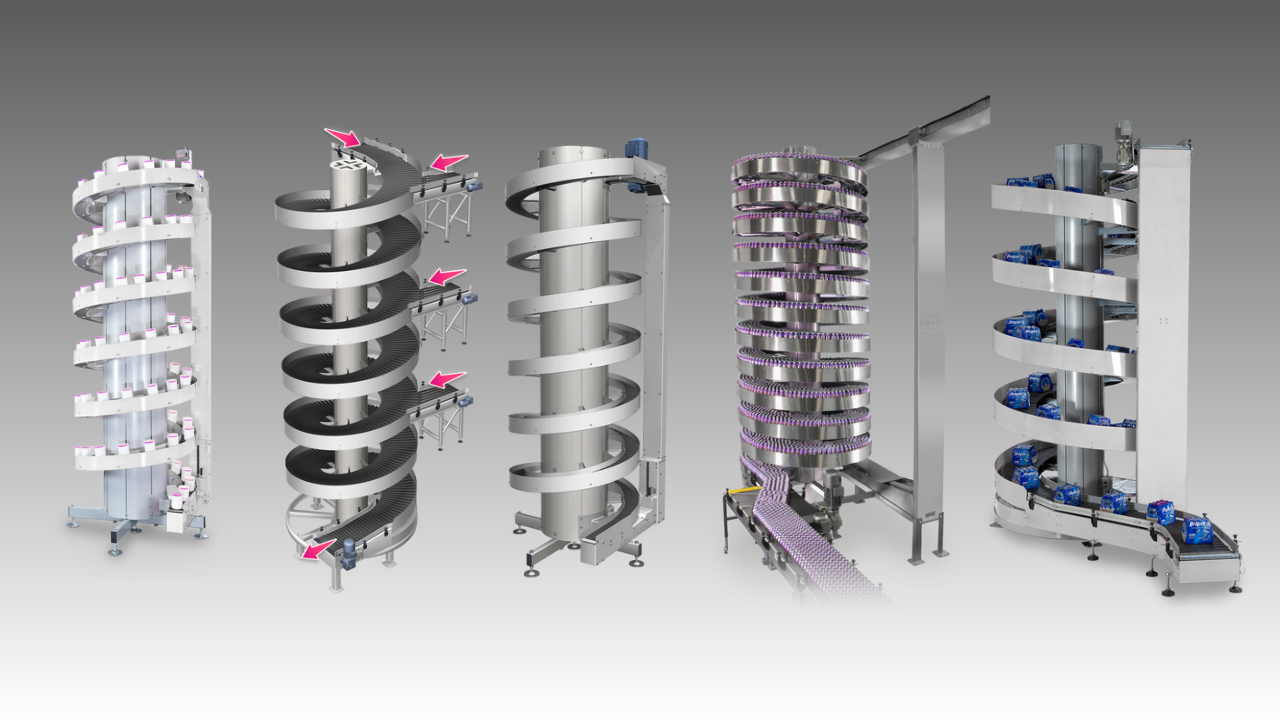

Understanding vertical conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

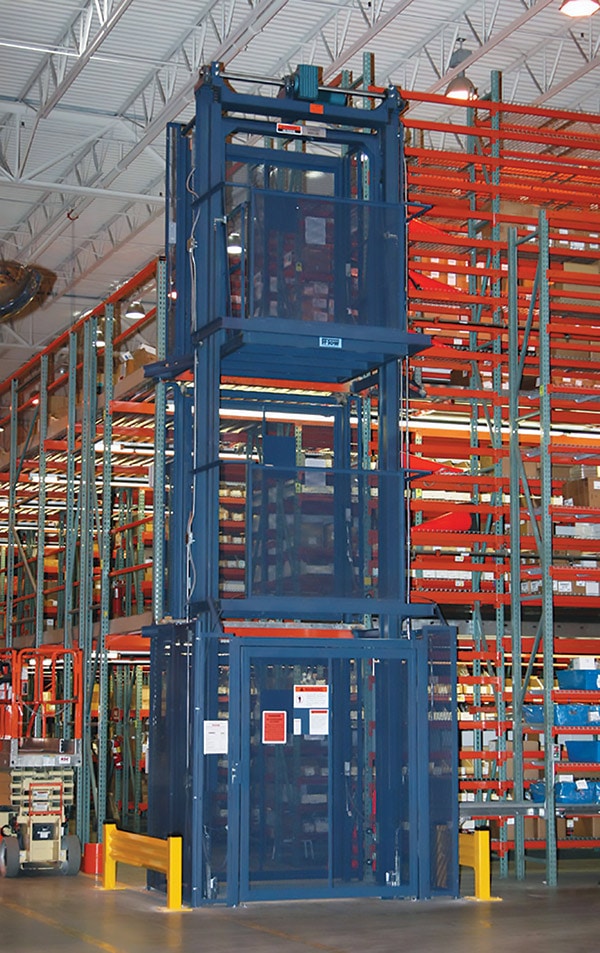

| Vertical Reciprocating Conveyor (VRC) | Can be mechanical or hydraulic; designed for heavy loads; not for passenger use. | Warehouses, factories, distribution centers | Pros: Economical, space-efficient, customizable. Cons: Limited to material handling only. |

| Mechanical VRC | High-speed operation; unlimited load capacity; continuous cycle use. | High-volume manufacturing, automotive, logistics | Pros: Fast, efficient for heavy loads. Cons: Higher initial investment. |

| Hydraulic VRC | Cost-effective for two-level lifting; stable load movement; less space required. | Small to medium-sized facilities, retail environments | Pros: Affordable, compact design. Cons: Limited load capacity compared to mechanical options. |

| Automated Vertical Conveyor | Fully automated systems with integrated controls for seamless operation. | E-commerce fulfillment, automated warehouses | Pros: Reduces labor costs, increases efficiency. Cons: Higher complexity and maintenance. |

| Custom Vertical Conveyors | Tailored solutions based on specific operational needs and space constraints. | Specialized manufacturing, unique material handling needs | Pros: Highly adaptable, meets unique requirements. Cons: Longer lead times and potential for higher costs. |

What Are the Characteristics of Vertical Reciprocating Conveyors (VRCs)?

Vertical Reciprocating Conveyors (VRCs) are engineered for safe and efficient material handling between different levels. They can be either mechanical or hydraulic, providing flexibility based on the specific load and application needs. VRCs are commonly used in warehouses, factories, and distribution centers where heavy materials need to be transported vertically. Buyers should consider their operational requirements, as VRCs are not designed for passenger transport, ensuring compliance with safety regulations.

Illustrative image related to vertical conveyor

How Do Mechanical VRCs Operate and What Are Their Benefits?

Mechanical VRCs are known for their high-speed capabilities and can handle unlimited load capacities, making them ideal for high-volume manufacturing environments. They are particularly beneficial in industries like automotive and logistics, where rapid material movement is essential. When considering mechanical VRCs, buyers should evaluate their production cycles and the need for continuous operation, as these systems can require a higher initial investment but yield significant returns in efficiency.

What Makes Hydraulic VRCs a Cost-Effective Solution?

Hydraulic VRCs are an economical choice for applications requiring two-level lifting, typically accommodating loads up to 6,000 lbs. They are designed for stability and efficiency, often taking up less space than mechanical variants. These systems are best suited for small to medium-sized facilities, including retail environments. Buyers should weigh the cost benefits against the limited load capacity, particularly in operations where heavier materials are frequently handled.

Why Choose Automated Vertical Conveyors for Your Operations?

Automated vertical conveyors integrate advanced controls for seamless operation, significantly reducing labor costs and improving efficiency in high-demand environments like e-commerce fulfillment and automated warehouses. While they offer considerable advantages in productivity, buyers should consider the complexity of these systems and the potential for higher maintenance costs. Investing in automation may be justified by the long-term gains in operational efficiency.

What Are the Advantages of Custom Vertical Conveyors?

Custom vertical conveyors are tailored to meet specific operational requirements, accommodating unique material handling challenges and space constraints. They are essential for specialized manufacturing processes where standard solutions may not suffice. Buyers interested in custom solutions should be prepared for longer lead times and potentially higher costs, but these systems can ultimately provide significant value by optimizing workflow and enhancing safety in material handling operations.

Key Industrial Applications of vertical conveyor

| Industry/Sector | Specific Application of Vertical Conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Transporting heavy machinery between levels | Increases efficiency and reduces manual handling risks | Load capacity, speed, and safety features |

| Food Processing | Elevating bulk ingredients to processing areas | Enhances productivity and maintains hygiene standards | Compliance with food safety regulations, easy cleaning |

| Warehousing | Moving pallets between storage and shipping areas | Optimizes space utilization and streamlines operations | Customization for load sizes and vertical heights |

| Automotive Assembly | Lifting components to assembly lines | Reduces labor costs and improves assembly line flow | Durability, maintenance requirements, and cycle speed |

| Retail Distribution | Elevating goods from storage to retail floor | Increases product accessibility and reduces time delays | Integration with existing systems and safety standards |

How is Vertical Conveyor Used in Manufacturing?

In manufacturing, vertical conveyors are crucial for transporting heavy machinery and materials between different levels of a facility. This application addresses the challenges of manual handling, which can lead to injuries and inefficiencies. Buyers in this sector should focus on load capacity and speed, ensuring that the conveyor can handle their specific machinery weights and operational cycles. Additionally, safety features such as emergency stops and guards are essential for protecting workers.

What Role Does Vertical Conveyor Play in Food Processing?

In the food processing industry, vertical conveyors elevate bulk ingredients to various processing stages, ensuring a seamless workflow. This application not only enhances productivity but also adheres to stringent hygiene standards necessary in food handling. Buyers must consider compliance with food safety regulations, as well as the ease of cleaning the conveyor systems to prevent contamination. Custom solutions may be needed to accommodate different ingredient sizes and weights.

How Does Vertical Conveyor Optimize Warehousing Operations?

Vertical conveyors in warehousing facilitate the efficient movement of pallets between storage and shipping areas, significantly optimizing space utilization. This application helps streamline operations by reducing the time taken to move goods, thus enhancing overall productivity. When sourcing for this application, businesses should prioritize customization options to fit specific load sizes and vertical heights, ensuring compatibility with existing warehouse layouts.

In What Ways Does Vertical Conveyor Enhance Automotive Assembly?

In the automotive assembly sector, vertical conveyors are used to lift components to assembly lines, thereby improving workflow and reducing labor costs. This application is vital for maintaining a steady supply of parts to the assembly line, minimizing downtime. Buyers should focus on the durability of the conveyors and their maintenance requirements, as well as the cycle speed to match the pace of the assembly process.

How is Vertical Conveyor Beneficial for Retail Distribution?

Vertical conveyors are instrumental in retail distribution, where they elevate goods from storage areas to the retail floor, improving product accessibility for staff and customers. This application not only speeds up the restocking process but also reduces time delays in product availability. When sourcing vertical conveyors for retail, businesses need to consider the integration capabilities with existing systems and compliance with safety standards to ensure smooth operations.

3 Common User Pain Points for ‘vertical conveyor’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Vertical Conveyor Configuration

The Problem: B2B buyers often face confusion when selecting the appropriate vertical conveyor system for their specific application. With various configurations available—such as hydraulic vs. mechanical, straddle vs. cantilever—buyers may struggle to identify which type will meet their operational needs without compromising safety or efficiency. This indecision can lead to delays in project timelines and increased costs if the wrong system is selected initially.

The Solution: To navigate this complexity, buyers should start with a comprehensive assessment of their material handling requirements. This includes understanding the types of loads to be moved, the frequency of use, and the vertical rise needed. Engage with a manufacturer or distributor who can provide expert guidance on different configurations. Request detailed specifications and case studies that demonstrate how similar businesses have successfully implemented these systems. Additionally, consider a custom-engineered solution that caters specifically to your operational constraints, ensuring a perfect fit for your facility’s layout.

Scenario 2: Safety Concerns and Compliance with Regulations

The Problem: Safety is paramount in any industrial setting, and B2B buyers often worry about the compliance of vertical conveyors with national safety standards. The fear of accidents due to inadequate safety measures can lead to hesitation in investing in vertical conveyors, especially in regions with stringent regulations. Non-compliance can result in hefty fines and increased liability, making it a critical concern for decision-makers.

The Solution: It is essential to prioritize suppliers who demonstrate a commitment to safety and compliance. Buyers should ensure that the vertical conveyors they consider conform to relevant safety codes, such as ASME B20.1. Request documentation that outlines the safety features included in the conveyor design, such as emergency stop buttons, safety gates, and load sensors. Conduct site visits to see existing installations and discuss safety protocols with current users. Additionally, consider opting for conveyors that offer advanced safety features and ongoing support to ensure compliance is maintained throughout the system’s lifecycle.

Scenario 3: High Maintenance and Downtime Issues

The Problem: Many B2B buyers are concerned about the ongoing maintenance and potential downtime associated with vertical conveyors. Frequent breakdowns or high maintenance requirements can disrupt operations, leading to lost productivity and increased operational costs. This is particularly concerning in fast-paced environments where efficiency is crucial.

Illustrative image related to vertical conveyor

The Solution: To mitigate these concerns, buyers should focus on sourcing vertical conveyors designed for durability and low maintenance. Investigate the quality of materials used in the construction of the conveyor and inquire about the manufacturer’s warranty and support services. Implementing a preventive maintenance program can also help reduce unexpected downtime; this involves scheduling regular inspections and servicing to address minor issues before they escalate. Additionally, consider investing in automated monitoring systems that track the performance of the conveyor in real-time, allowing for timely interventions and ensuring consistent operational efficiency. Engaging with manufacturers who provide comprehensive training for your maintenance staff can further enhance the reliability and lifespan of the equipment.

Strategic Material Selection Guide for vertical conveyor

What Are the Key Materials Used in Vertical Conveyors?

When selecting materials for vertical conveyors, it is crucial to consider their properties, advantages, and limitations, especially in the context of specific applications and regional compliance standards. Here, we analyze four common materials used in the construction of vertical conveyors: steel, aluminum, plastic, and composite materials.

How Does Steel Perform in Vertical Conveyor Applications?

Key Properties: Steel is renowned for its high strength and durability, with a temperature rating suitable for a wide range of industrial applications. It exhibits excellent corrosion resistance when treated with coatings or galvanization.

Pros & Cons: The primary advantage of steel is its robustness, allowing it to handle heavy loads and high-stress environments. However, it can be more expensive than alternatives like aluminum and may require additional treatments to prevent rust, especially in humid or corrosive environments.

Impact on Application: Steel’s strength makes it suitable for heavy-duty applications, such as transporting machinery or large pallets. However, the weight of steel can be a limitation in designs requiring lighter materials.

Considerations for International Buyers: Steel specifications often align with ASTM standards in the U.S. and EN standards in Europe. Buyers in Africa and South America should ensure that the steel complies with local regulations regarding material quality and safety.

What Advantages Does Aluminum Offer for Vertical Conveyors?

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it suitable for various environmental conditions. It has a lower temperature rating compared to steel but is often sufficient for many applications.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which facilitates easier installation and reduces energy consumption during operation. However, it has a lower load capacity compared to steel, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum is ideal for applications requiring frequent movement or where weight reduction is critical. It is commonly used in food processing or pharmaceutical industries due to its resistance to corrosion and ease of cleaning.

Considerations for International Buyers: Aluminum standards vary globally, with JIS standards in Japan and EN standards in Europe. Buyers should be aware of local preferences for aluminum grades and their respective certifications.

How Do Plastics Function in Vertical Conveyor Systems?

Key Properties: Plastics, such as polyethylene and polypropylene, offer excellent chemical resistance and can withstand a range of temperatures. They are lightweight and can be molded into various shapes.

Illustrative image related to vertical conveyor

Pros & Cons: The main advantage of plastics is their resistance to corrosion and chemicals, making them suitable for industries like food processing and pharmaceuticals. However, they may not withstand heavy loads and can be less durable than metals.

Impact on Application: Plastics are ideal for applications where chemical exposure is a concern. However, their limited load capacity may restrict their use in heavy-duty environments.

Considerations for International Buyers: Compliance with food safety regulations is critical for plastic materials in food and pharmaceutical applications. Buyers should check for certifications like FDA compliance in the U.S. and similar standards in their respective regions.

What Role Do Composite Materials Play in Vertical Conveyors?

Key Properties: Composite materials combine the benefits of various materials, offering high strength-to-weight ratios and excellent corrosion resistance. They can be engineered to meet specific performance criteria.

Pros & Cons: The advantage of composites is their versatility and durability, making them suitable for a wide range of applications. However, they can be more expensive to manufacture and may require specialized handling during installation.

Impact on Application: Composites are often used in environments where both weight and corrosion resistance are critical, such as in marine or chemical processing industries.

Considerations for International Buyers: Buyers should ensure that composite materials meet international standards such as ASTM or ISO, particularly regarding fire resistance and environmental impact.

Summary of Material Selection for Vertical Conveyors

| Material | Typical Use Case for Vertical Conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High strength and durability | Heavier and may require corrosion treatment | High |

| Aluminum | Light to medium-duty applications | Lightweight and corrosion-resistant | Lower load capacity | Medium |

| Plastic | Food and pharmaceutical industries | Excellent chemical resistance | Limited load capacity | Low |

| Composite | Marine and chemical processing | High strength-to-weight ratio | Higher manufacturing complexity | High |

This guide provides a strategic overview of material selection for vertical conveyors, helping international B2B buyers make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vertical conveyor

What Are the Key Stages in the Manufacturing Process of Vertical Conveyors?

The manufacturing process for vertical conveyors, particularly Vertical Reciprocating Conveyors (VRCs), involves several critical stages that ensure the final product meets the required specifications and quality standards.

Material Preparation: What Materials Are Used in Vertical Conveyor Manufacturing?

The first step in manufacturing vertical conveyors is material preparation. Typically, high-quality steel or aluminum is used due to their strength and durability. The choice of material can depend on the specific application and load requirements. For instance, heavier loads may necessitate thicker steel plates, while lighter applications might utilize aluminum for weight reduction.

Once the materials are selected, they are cut to size using advanced cutting techniques such as laser cutting or plasma cutting. This precision ensures that the components will fit together accurately during assembly, which is crucial for the conveyor’s overall performance.

How Are Vertical Conveyors Formed and Assembled?

Following material preparation, the next stage is forming. This involves shaping the cut materials into the necessary components for the conveyor system, such as frames, carriages, and support structures. Techniques like welding, bending, and machining are commonly employed to create these components.

Illustrative image related to vertical conveyor

Once the individual parts are formed, they move to the assembly phase. Here, skilled technicians or automated systems bring together the various components to create the complete vertical conveyor. This stage is critical, as the alignment and fit of the parts directly influence the system’s performance and safety.

What Finishing Processes Are Applied to Vertical Conveyors?

After assembly, the finishing process begins. This may include painting, powder coating, or galvanizing the conveyor to prevent corrosion and enhance durability. The finishing touches not only improve the aesthetic appeal but also add a layer of protection, especially for conveyors used in harsh environments.

Quality checks are integrated throughout the manufacturing process to ensure that each stage meets predefined standards before progressing to the next.

What Quality Assurance Practices Are Essential for Vertical Conveyor Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of vertical conveyors, as it directly impacts safety, efficiency, and compliance with international standards.

Which International Standards Apply to Vertical Conveyors?

To ensure quality and safety, manufacturers must comply with various international standards. The ISO 9001 standard is widely recognized as a benchmark for quality management systems. It emphasizes the importance of systematic processes and continuous improvement, which are vital for maintaining high-quality manufacturing practices.

In addition to ISO 9001, industry-specific certifications such as CE marking for European markets and API standards for the oil and gas sector may apply. These certifications indicate compliance with safety and environmental regulations, which are essential for international B2B buyers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

The quality control process typically involves several checkpoints:

-

Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival to ensure they meet specified standards. This may include checking dimensions, material properties, and certification documents.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the assembly process. This includes verifying weld integrity, alignment of components, and adherence to design specifications.

-

Final Quality Control (FQC): After assembly and finishing, the completed vertical conveyor undergoes a comprehensive inspection. This includes functionality tests, load tests, and safety checks to confirm that the conveyor operates as intended.

How Can B2B Buyers Verify the Quality Assurance of Vertical Conveyor Suppliers?

B2B buyers seeking to ensure the quality of vertical conveyor suppliers can employ several strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

One effective method is to conduct supplier audits. This involves visiting the manufacturing facility to review their processes, quality control measures, and compliance with international standards. During the audit, buyers should assess the equipment used, the qualifications of the workforce, and the overall commitment to quality and safety.

How Can Buyers Obtain Quality Control Reports and Certifications?

Buyers should also request quality control reports and certifications from potential suppliers. These documents provide evidence of compliance with relevant standards and the outcomes of quality inspections.

Furthermore, third-party inspections by independent organizations can serve as an additional layer of verification. These inspections can help ensure that the supplier adheres to industry standards and maintains consistent quality throughout the manufacturing process.

What Are the Unique QC Considerations for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, there are specific quality control nuances to consider.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have varying regulations and standards that impact quality assurance practices. Buyers should familiarize themselves with local regulations that apply to vertical conveyors in their respective markets. For example, CE marking is mandatory in Europe, while specific certifications may be required in African or South American countries.

What Role Do Cultural Differences Play in Quality Control Expectations?

Cultural differences can also influence expectations regarding quality and communication. Establishing clear lines of communication and understanding regional practices can help mitigate misunderstandings and ensure that quality standards are met.

Illustrative image related to vertical conveyor

Conclusion: Why Quality Assurance is Essential for Vertical Conveyor Manufacturing

In summary, the manufacturing processes and quality assurance practices for vertical conveyors are intricate and vital for ensuring the safety and efficiency of these systems. By understanding the key stages of manufacturing, the relevant quality standards, and the verification methods available, B2B buyers can make informed decisions when selecting suppliers. This thorough approach not only enhances operational efficiency but also protects investments in critical material handling equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vertical conveyor’

Introduction

This practical sourcing guide is designed to assist B2B buyers in identifying, evaluating, and procuring vertical conveyors, specifically tailored for diverse industrial applications. Whether you’re in manufacturing, warehousing, or logistics, selecting the right vertical conveyor can enhance operational efficiency, reduce labor costs, and ensure safety. Follow this step-by-step checklist to streamline your sourcing process.

1. Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right vertical conveyor for your needs. Consider factors such as load capacity, vertical rise, and carriage size.

– Load Requirements: Determine the maximum weight and size of materials you will be moving.

– Height and Space Constraints: Assess the available vertical space and required rise between levels.

2. Identify Your Application Needs

Different industries have varying requirements for vertical conveyors. Understanding your specific application will guide you in choosing the right type—mechanical or hydraulic.

– Type of Materials: Consider the materials being lifted (e.g., pallets, machinery) and their respective handling needs.

– Frequency of Use: Evaluate whether you need a system for continuous use or occasional lifting.

3. Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough due diligence. Request detailed company profiles, case studies, and references from other clients in your industry.

– Reputation and Experience: Look for suppliers with a solid track record in your specific market.

– Customization Capabilities: Ensure the supplier can tailor solutions to meet your unique needs.

Illustrative image related to vertical conveyor

4. Check for Compliance and Certifications

Ensure that your selected vertical conveyor complies with relevant safety standards and regulations. This is vital for ensuring safe operation and minimizing liability risks.

– Industry Standards: Look for compliance with ASME B20.1 and other local or international standards.

– Supplier Certifications: Verify that the supplier holds necessary certifications and has undergone relevant safety inspections.

5. Request and Compare Quotes

Once you have identified potential suppliers, request detailed quotes that outline pricing, delivery timelines, and warranty information.

– Cost Breakdown: Ensure the quote provides a comprehensive breakdown of costs, including installation and maintenance.

– Value Analysis: Compare not only prices but also the value offered in terms of quality, service, and support.

6. Assess After-Sales Support and Maintenance

After-sales support is crucial for the long-term success of your vertical conveyor system. Evaluate the level of support offered by the supplier.

– Service Agreements: Look for suppliers that provide service agreements for maintenance and repairs.

– Training and Support: Ensure that the supplier offers training for your staff on safe and effective operation.

7. Finalize and Document the Purchase

Once you’ve made your decision, finalize the purchase by documenting all agreements. Clear documentation ensures accountability and helps manage expectations.

– Contract Details: Ensure the contract specifies all terms, including delivery schedules and payment terms.

– Follow-Up Procedures: Establish procedures for follow-up and performance evaluation post-installation.

By following these steps, B2B buyers can effectively navigate the procurement process for vertical conveyors, ensuring they select the best solution for their operational needs.

Comprehensive Cost and Pricing Analysis for vertical conveyor Sourcing

What Are the Key Cost Components in Vertical Conveyor Sourcing?

When sourcing vertical conveyors, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials directly impacts the overall cost. High-quality steel or specialized alloys may be necessary for heavy-duty applications, while more economical materials can be used for lighter loads. Customizations, such as corrosion-resistant coatings for outdoor installations, also add to material costs.

-

Labor: Labor costs encompass both direct and indirect wages associated with manufacturing. Skilled labor is often required for assembly, particularly for customized units, which can increase costs. Additionally, labor rates vary significantly by region, affecting overall pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment. Manufacturers with advanced technologies and processes may have higher overheads, which can be reflected in the pricing.

-

Tooling: Custom designs necessitate specialized tooling, which can be a significant upfront cost. Buyers should consider whether the supplier has the capacity to produce custom tools in-house or if they rely on third-party manufacturers.

-

Quality Control: Rigorous QC processes ensure safety and reliability, particularly for heavy machinery. Enhanced QC measures can increase costs but provide long-term value by reducing the risk of failures.

-

Logistics: Shipping and handling costs vary based on the size and weight of the conveyors, as well as the distance from the manufacturer to the buyer. Incoterms can significantly influence logistics costs, particularly for international shipments.

-

Margin: Supplier margins can fluctuate based on market conditions, demand, and competition. Understanding the typical margin in the industry can help buyers negotiate better pricing.

How Do Price Influencers Affect Vertical Conveyor Costs?

Several factors can influence the pricing of vertical conveyors, making it essential for buyers to be aware of them:

-

Volume/MOQ: Purchasing in larger volumes often leads to discounts. Buyers should assess their needs to determine if committing to a higher minimum order quantity (MOQ) can yield significant savings.

-

Specifications and Customization: Custom solutions tailored to specific applications typically come at a premium. Buyers should balance the need for customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASME) usually increase costs but provide assurance of durability and compliance with safety standards.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their experience and proven track record.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

What Are the Best Buyer Tips for Sourcing Vertical Conveyors?

When sourcing vertical conveyors, especially in international markets, consider the following tips to optimize costs:

-

Negotiate Wisely: Building relationships with suppliers can lead to better negotiation outcomes. Be clear about your needs and explore options for bulk purchasing or long-term contracts.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership, including installation, maintenance, and operational costs, rather than just the initial purchase price. A lower upfront cost may lead to higher long-term expenses.

-

Understand Pricing Nuances: Pricing structures can differ across regions. For instance, suppliers in Africa may have varying overhead costs compared to those in Europe or South America. Research local market conditions to better gauge pricing.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of all costs, including materials, labor, and logistics. This transparency helps in making informed comparisons between suppliers.

-

Consider Local Suppliers: Local sourcing can reduce logistics costs and lead times. Additionally, local suppliers may offer better understanding and compliance with regional regulations and standards.

Disclaimer on Indicative Prices

Please note that prices for vertical conveyors can vary widely based on the factors discussed above. It is advisable to obtain detailed quotes from multiple suppliers to ensure competitive pricing tailored to your specific requirements.

Alternatives Analysis: Comparing vertical conveyor With Other Solutions

Introduction: Exploring Alternatives to Vertical Conveyors

When considering material handling solutions, vertical conveyors present a unique approach to elevating and transporting goods between multiple levels. However, businesses often evaluate various alternatives to determine the most suitable option for their specific needs. This analysis will compare vertical conveyors against two viable alternatives: inclined conveyors and automated guided vehicles (AGVs). Each option has distinct advantages and disadvantages that can impact operational efficiency, cost-effectiveness, and overall utility.

Comparison Table

| Comparison Aspect | Vertical Conveyor | Inclined Conveyor | Automated Guided Vehicle (AGV) |

|---|---|---|---|

| Performance | High load capacity; continuous use | Limited load capacity; slower speeds | Flexible routing; high adaptability |

| Cost | Moderate initial cost; low maintenance | Lower initial cost; moderate upkeep | High initial investment; higher maintenance |

| Ease of Implementation | Customizable; requires structural support | Easier installation; less structural need | Requires navigation systems and setup |

| Maintenance | Low maintenance with proper use | Moderate maintenance; susceptible to wear | Requires regular software and hardware updates |

| Best Use Case | Heavy loads in multi-level facilities | Light to moderate loads in small spaces | Dynamic environments with variable loads |

Detailed Breakdown of Alternatives

Inclined Conveyors: What Are Their Benefits and Drawbacks?

Inclined conveyors serve as a straightforward alternative, designed to transport materials from one elevation to another along a sloped path. The primary advantage of inclined conveyors is their lower initial cost and simpler installation process, making them suitable for businesses with limited budgets or space constraints. However, their performance is typically limited to lighter loads, and they can be slower than vertical conveyors, especially when handling larger items. Additionally, the wear and tear on belts can lead to increased maintenance needs over time, which may offset initial savings.

Automated Guided Vehicles (AGVs): Are They Worth the Investment?

Automated guided vehicles (AGVs) offer a highly flexible and automated solution for material handling. They are capable of transporting goods across varying distances and can adapt to dynamic environments, making them ideal for facilities with shifting layouts or fluctuating inventory levels. The primary drawback of AGVs is their high upfront investment and ongoing maintenance costs, as they require sophisticated navigation systems and regular software updates. While they excel in automation and efficiency, the initial setup and operational costs can be prohibitive for some businesses.

Conclusion: Choosing the Right Material Handling Solution

Selecting the appropriate material handling solution involves a careful assessment of specific operational requirements, budget constraints, and long-term goals. Vertical conveyors are ideal for businesses needing to move heavy loads efficiently between multiple levels, particularly in industrial settings. In contrast, inclined conveyors may be more suitable for lighter materials in compact spaces, while AGVs provide unmatched flexibility for dynamic operations but come with a higher cost. B2B buyers must weigh these factors against their unique circumstances to identify the most effective solution for their material handling challenges.

Essential Technical Properties and Trade Terminology for vertical conveyor

What Are the Key Technical Properties of Vertical Conveyors?

Understanding the essential technical properties of vertical conveyors is vital for making informed purchasing decisions. Here are some critical specifications to consider:

Illustrative image related to vertical conveyor

1. Load Capacity

Load capacity refers to the maximum weight a vertical conveyor can safely transport. This specification is crucial for B2B buyers as it determines whether the conveyor can handle the specific materials or products needed for their operations. Load capacities can vary significantly, with some conveyors designed for light loads (up to 500 lbs) and others capable of moving heavy machinery (over 100,000 lbs). Ensuring that the chosen conveyor meets or exceeds the necessary load capacity can prevent operational inefficiencies and safety hazards.

2. Travel Speed

Travel speed indicates how quickly the conveyor can move materials from one level to another, typically measured in feet per minute (FPM). This property is essential for optimizing workflow efficiency. For instance, mechanical vertical conveyors may operate at speeds ranging from 18 to 25 FPM, while hydraulic models might vary between 17 to 24 FPM. Understanding the required speed for your operations can help in selecting a conveyor that aligns with your production timelines.

3. Vertical Rise

Vertical rise describes the maximum height a conveyor can lift materials. This specification is vital for applications in multi-level facilities, warehouses, or production plants. Depending on the design, vertical conveyors can accommodate rises from a few feet to over 200 feet. Buyers must assess their facility’s layout and height requirements to choose a conveyor that fits seamlessly within their operational framework.

4. Material Composition

The material grade used in the construction of vertical conveyors affects durability, maintenance, and safety. Common materials include steel, aluminum, and specialized alloys. Choosing the right material can enhance the conveyor’s lifespan, ensure it meets industry standards, and reduce the risk of breakdowns. Buyers should consider the environment in which the conveyor will operate (e.g., exposure to moisture, chemicals) to select the appropriate material grade.

5. Safety Features

Safety features are integral to the design of vertical conveyors. These can include emergency stop buttons, safety gates, and overload protection systems. Understanding these features is essential for compliance with industry regulations and for ensuring worker safety. Buyers should inquire about the specific safety certifications, such as ASME B20.1, that the conveyor meets to ensure they are investing in a safe solution.

What Are Common Trade Terms Associated with Vertical Conveyors?

Familiarity with industry jargon can facilitate more effective communication and negotiation in B2B transactions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of vertical conveyors, an OEM may provide custom designs or components tailored to specific operational needs. Understanding OEM relationships can help buyers identify reliable suppliers and ensure they receive high-quality products.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers, as it can impact inventory management and procurement strategies. Knowing the MOQ can help businesses plan their purchases and avoid overstocking or understocking situations.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products or services. In the context of vertical conveyors, submitting an RFQ can help buyers compare offers from multiple suppliers and make informed decisions based on cost, specifications, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms is crucial for B2B transactions, especially when sourcing from international suppliers. These terms dictate aspects such as shipping responsibilities, risk transfer, and customs clearance, influencing the overall cost and logistics of procurement.

By grasping these technical properties and trade terminology, B2B buyers can navigate the complexities of purchasing vertical conveyors more effectively, ensuring they select the right solutions for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the vertical conveyor Sector

What Are the Key Market Dynamics and Trends in the Vertical Conveyor Sector?

The vertical conveyor market is experiencing significant growth, driven by the increasing need for efficient material handling solutions across various industries. Factors such as urbanization, a rise in e-commerce, and the demand for automation in manufacturing and warehousing are propelling this trend. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking advanced vertical conveyor systems to optimize their operations.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are reshaping the vertical conveyor landscape. These technologies enhance operational efficiency by allowing real-time monitoring and predictive maintenance, thereby reducing downtime and operational costs. Additionally, the trend towards customization is gaining traction, as businesses look for solutions tailored to their specific needs, whether it’s handling oversized materials or integrating with automated systems.

Another noteworthy trend is the growing focus on safety and compliance. With stricter regulations surrounding material handling equipment, suppliers are investing in advanced safety features and certifications to meet international standards. Buyers are advised to evaluate vendors based on their adherence to safety codes and the robustness of their engineering practices to ensure compliance and mitigate risks in their operations.

How Is Sustainability Influencing Sourcing Decisions in the Vertical Conveyor Sector?

Sustainability is becoming a critical factor in B2B purchasing decisions within the vertical conveyor sector. As global awareness of environmental issues rises, companies are increasingly prioritizing eco-friendly practices in their supply chains. The impact of vertical conveyors on the environment, including energy consumption and waste generation, is under scrutiny. Buyers are encouraged to seek out suppliers who utilize sustainable materials and energy-efficient technologies in their conveyor systems.

The importance of ethical sourcing cannot be overstated. Businesses are moving towards transparent supply chains that prioritize ethical labor practices and the responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. By partnering with vendors who hold these certifications, B2B buyers can enhance their corporate social responsibility (CSR) initiatives, which are increasingly important in today’s market.

Moreover, incorporating ‘green’ materials into vertical conveyor systems not only reduces environmental impact but also attracts eco-conscious consumers. Suppliers offering recyclable components or those that minimize the carbon footprint during production can provide a competitive edge in the market.

Illustrative image related to vertical conveyor

How Has the Vertical Conveyor Sector Evolved Over Time?

The vertical conveyor sector has undergone substantial evolution since its inception. Initially designed for simple material lifting tasks, vertical conveyors have transformed into sophisticated systems capable of integrating with automated workflows. The introduction of hydraulic and mechanical lifts has expanded their applications across various industries, from manufacturing to distribution centers.

In the past, vertical conveyors were often limited by safety concerns and regulatory restrictions. However, advancements in engineering and safety standards have led to the development of more robust and reliable systems that comply with international safety codes. This evolution has enabled vertical conveyors to become a preferred choice for businesses looking to streamline their operations and enhance productivity.

Today, the focus is not only on efficiency but also on customization and sustainability, reflecting broader market trends. As businesses continue to adapt to changing demands, the vertical conveyor sector is poised for further innovation, driven by technological advancements and an increasing emphasis on sustainable practices.

Frequently Asked Questions (FAQs) for B2B Buyers of vertical conveyor

-

How do I solve the challenge of selecting the right vertical conveyor for my facility?

Selecting the appropriate vertical conveyor involves assessing your specific material handling needs, including the weight, size, and type of materials you need to transport. Consider whether a hydraulic or mechanical lift is more suitable based on your operational requirements. Engage with suppliers to discuss potential configurations, such as straddle or cantilever designs, and ensure they can customize the lift to fit your space and operational flow. Additionally, review safety standards and installation requirements relevant to your location. -

What is the best type of vertical conveyor for high-capacity material handling?

For high-capacity material handling, mechanical vertical reciprocating conveyors (VRCs) are often the best choice due to their ability to handle larger loads and faster cycle times. Mechanical lifts typically offer unlimited load capacity and can accommodate larger carriage sizes, making them ideal for heavy machinery or bulk material transport. However, if your application requires a more cost-effective solution for two-level lifting, hydraulic VRCs can also be efficient, particularly for loads up to 6,000 lbs. -

What customization options are available for vertical conveyors?

Most manufacturers provide extensive customization options for vertical conveyors to meet specific operational needs. This can include adjustments in carriage size, weight capacity, speed, and configuration (e.g., cantilever or straddle). Additionally, safety features such as DeckLock systems, maintenance pins, and explosion-proof components can be tailored to enhance operational safety. Discuss your requirements with suppliers to explore how they can adapt their products to suit your unique application and facility layout. -

What are the minimum order quantities (MOQ) for vertical conveyors?

Minimum order quantities for vertical conveyors can vary significantly by manufacturer and the complexity of the customizations required. Many suppliers may have a standard MOQ for their products, while others may be flexible depending on your specific needs and the size of your project. It’s advisable to directly inquire with potential suppliers about their MOQ policies and whether they can accommodate smaller orders, especially if you are testing a new application or system. -

What payment terms should I expect when sourcing vertical conveyors internationally?

Payment terms for international purchases of vertical conveyors can vary widely among suppliers. Common arrangements may include upfront deposits, progress payments during production, or net payment terms upon delivery. Always clarify payment methods accepted, such as wire transfers, letters of credit, or payment through platforms like PayPal. Make sure to also discuss any potential tariffs, duties, or additional costs associated with international shipping to avoid unexpected expenses. -

How can I ensure quality assurance when purchasing vertical conveyors?

To ensure quality assurance, request detailed documentation from suppliers, including certifications that comply with international safety standards (e.g., ASME B20.1) and quality management systems (e.g., ISO 9001). Conduct thorough due diligence by reviewing customer testimonials, case studies, and references. If possible, arrange for factory visits or audits to observe manufacturing processes firsthand. Establishing a clear agreement regarding warranty terms and after-sales support can also enhance your confidence in the product’s quality. -

What logistics considerations should I keep in mind for importing vertical conveyors?

When importing vertical conveyors, consider logistics factors such as shipping methods, lead times, and customs clearance procedures. Work with experienced freight forwarders who understand the regulations in your region, especially if you’re sourcing from different continents. Ensure that the supplier provides all necessary documentation, including packing lists, commercial invoices, and certificates of origin, to facilitate a smooth customs process. Additionally, confirm that the conveyor’s specifications align with local regulations to avoid delays. -

What are the safety regulations I need to be aware of when installing vertical conveyors?

Safety regulations for vertical conveyors vary by region but generally include compliance with national and local codes. For instance, in the U.S., vertical reciprocating conveyors must adhere to the ASME B20.1 safety standard. Familiarize yourself with local regulations applicable to your industry and location, including any specific requirements for installation and maintenance. Engaging with suppliers who prioritize safety in their design and offer additional safety features can help mitigate risks in your facility.

Top 7 Vertical Conveyor Manufacturers & Suppliers List

1. NERAK – Vertical Conveyors and Lifts

Domain: nerak-systems.com

Registered: 1998 (27 years)

Introduction: NERAK vertical conveyors and lifts are space-saving, quiet, durable, high-performance, cost-effective solutions for vertical transport. They utilize a unique Rubber Block Chain, capable of transporting loads up to 120 ft in temperatures from -50 to 280 degrees F. The product range includes: Continuous Vertical Conveyors (CVC) for high-capacity transport with horizontal product orientation; Vertica…

2. Nercon Conveyors – Conveyor Elevators

Domain: nerconconveyors.com

Registered: 2013 (12 years)

Introduction: Conveyor elevators are designed to transport products between multiple levels efficiently, accommodating both packaged and unpackaged loads. Key product details include: 1. **Types of Elevators**: – Draper Z Incline Conveyor: Moves products of various shapes without changeovers. – Gripper Elevators: Provides gentle handling with adjustable openings. – Neroco™ Lift: Compact design with a small foot…

3. IQS Directory – Vertical Conveyors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

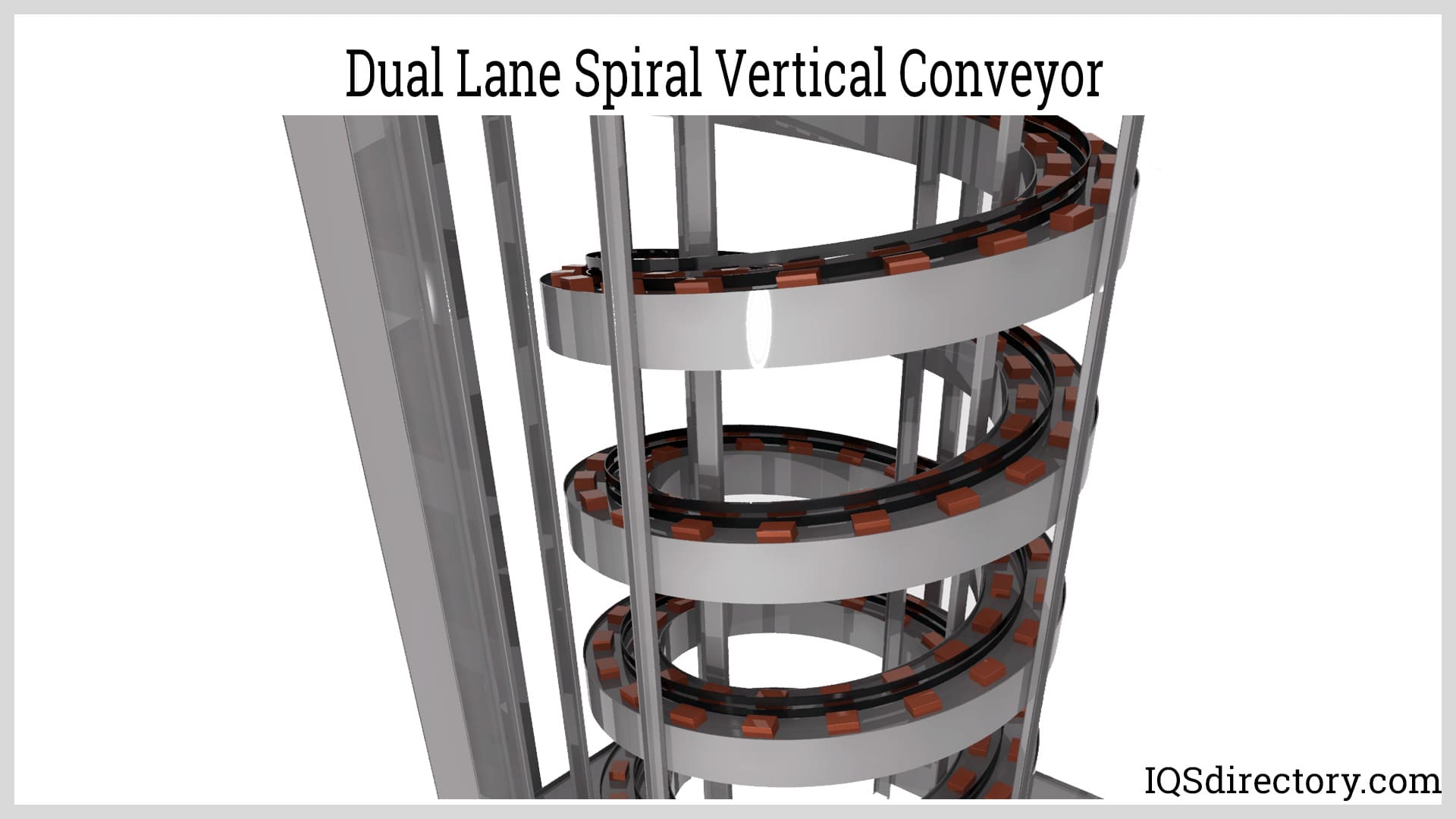

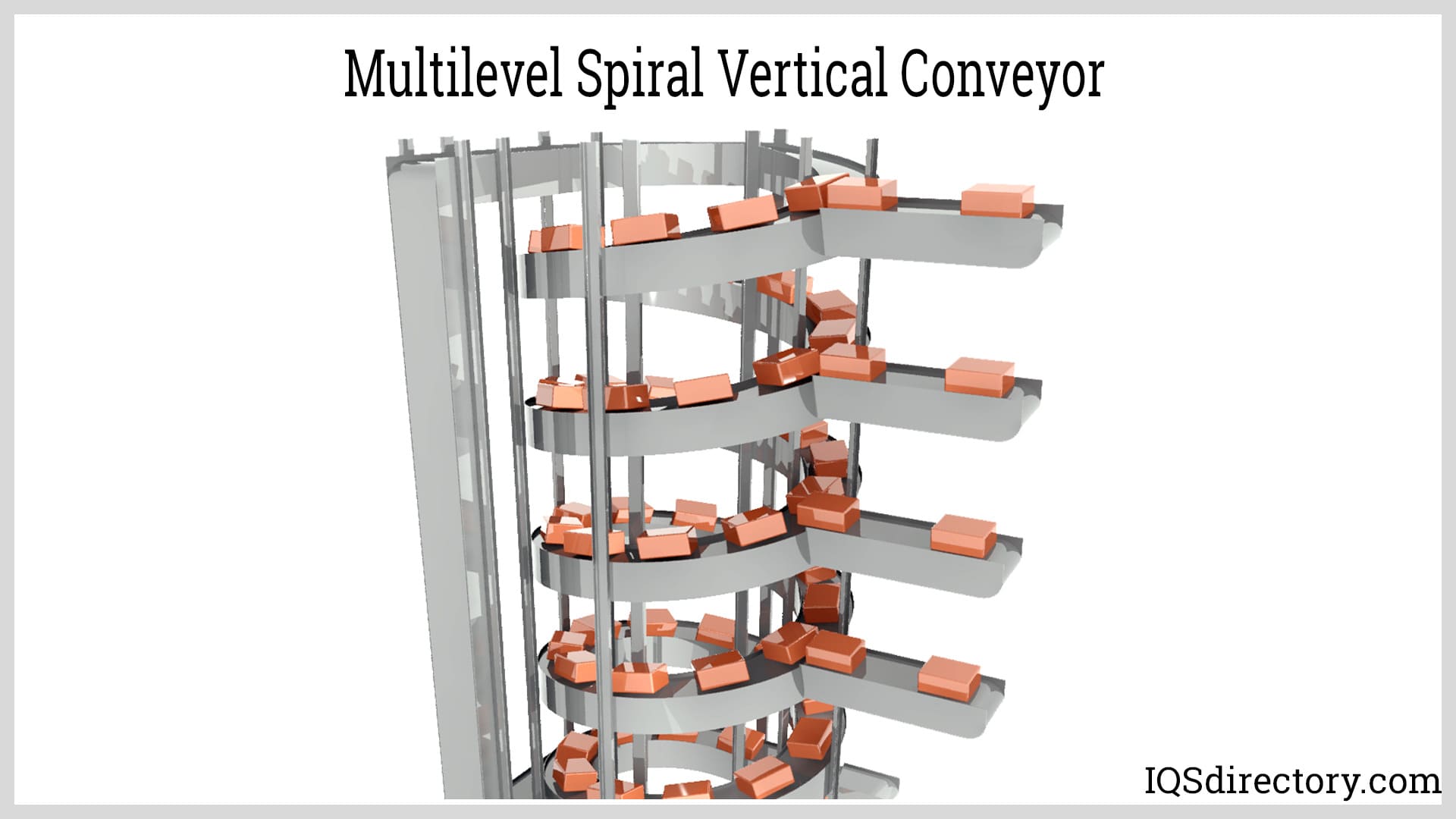

Introduction: Vertical conveyors, also known as vertical reciprocating conveyors (VRCs), are mechanical systems designed for elevating items between various height levels, enhancing efficiency by saving time and minimizing physical effort. They are classified under material handling equipment and governed by ASME safety standards. Types include: 1. Spiral Vertical Conveyors – Continuous motion systems for trans…

4. Hy-Tek – Vertical Conveyors

Domain: hy-tek.com

Registered: 2004 (21 years)

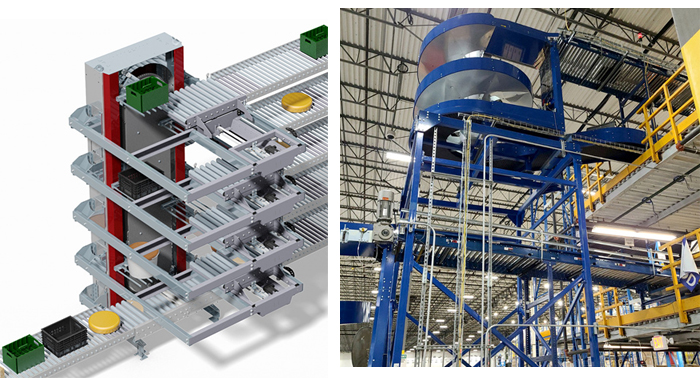

Introduction: Vertical Conveyors are designed to optimize vertical space in warehouses and distribution centers. They include three main types: Spiral Lifts, Continuous Vertical Lifts, and Reciprocal Vertical Lifts.

1. **Spiral Lifts**:

– Transport products vertically to merge with conveying lines at different levels.

– Suitable for accumulating products and customizable for various applications.

2….

5. Frontier Kemper – Corrugated Sidewall Conveyor

Domain: frontierkemper.com

Registered: 2000 (25 years)

Introduction: {“Type”:”Corrugated Sidewall”,”Max Lift”:”2,600 ft. (800m)”,”Max Tonnage”:”Up to 6,000 TPH (varies by depth & density)”,”Belt Construction”:”Fabric & Steel Cord Base Belts”,”Braking”:”External Backstops & Spring-Applied Caliper Brakes/Hydraulic Release”,”Controls”:”Soft-Start or VFD”}

6. SMB International – Vertical Conveyors

Domain: smb-international.com

Registered: 2023 (2 years)

Introduction: Vertical Conveyors: Pallet Elevator Systems for Efficient Transport Across Multiple Levels. Key features include: Weight: 1.5 – 12 tons, Power requirement: from approx. 3KW, Maximum load capacity: 2,000kg, Pallet cycles per hour: 30 – 120. Types include Pallet Conveyor Elevators, S- and C-shaped conveyors, Paternoster conveyors, and custom designs. Designed for transporting pallets, drums, and can…

7. PFI Conveyors – PURlift Positive Drive Vertical Lift Conveyor

Domain: pficonveyors.com

Registered: 2022 (3 years)

Introduction: PURlift Positive Drive Vertical Lift Conveyor features a dual “sandwich” lift design for vertical product elevation with minimal waste. Key features include:

– Self-tracking positive drive belt and belt scrapers for optimal product integrity, suitable for sticky products like dough and peanut butter.

– Automatic infeed for continuous operation.

– Pneumatic belt tensioning for quick adjustments and…

Strategic Sourcing Conclusion and Outlook for vertical conveyor

What Are the Key Takeaways for B2B Buyers of Vertical Conveyors?

In summary, vertical conveyors, specifically Vertical Reciprocating Conveyors (VRCs), present a strategic advantage for businesses looking to optimize material handling. Their ability to efficiently move loads between multiple levels not only enhances space utilization but also significantly reduces labor costs and improves safety. Customization options ensure that these systems can be tailored to meet specific operational needs, making them suitable for various industries from manufacturing to distribution.

How Can Strategic Sourcing Enhance Your Investment in Vertical Conveyors?

Engaging in strategic sourcing is crucial for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By thoroughly vetting suppliers and understanding the nuances of different VRC types—mechanical versus hydraulic—you can secure better pricing, ensure compliance with safety regulations, and optimize your supply chain. This proactive approach not only mitigates risks but also fosters long-term partnerships with manufacturers known for innovation and reliability.

What’s Next for Your Business in Vertical Conveyor Solutions?

As you consider integrating vertical conveyor systems into your operations, seize the opportunity to leverage the expertise of manufacturers who can provide comprehensive support and customized solutions. The demand for efficient material handling solutions is expected to grow, driven by advancements in automation and sustainability. Now is the time to invest in vertical conveyors that align with your operational goals and future-proof your business. Reach out to suppliers today to explore tailored solutions that can elevate your material handling processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to vertical conveyor

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.